Biodegradable polyester alloy and preparation method thereof

A technology for degrading polyester and biology, applied in the field of new materials, can solve the problems affecting the properties of alloys, high reactivity, and thermodynamic incompatibility of polyester substrates, and achieve the effect of overcoming thermodynamic incompatibility and improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

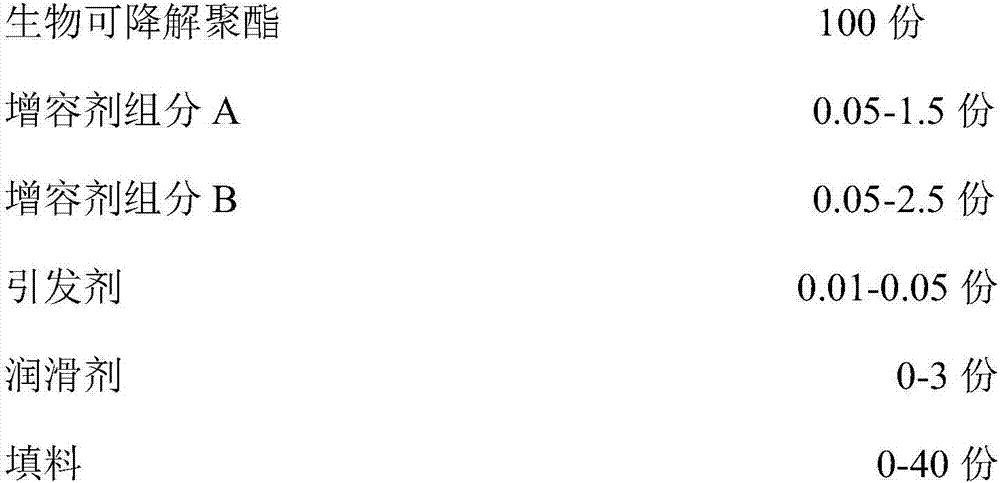

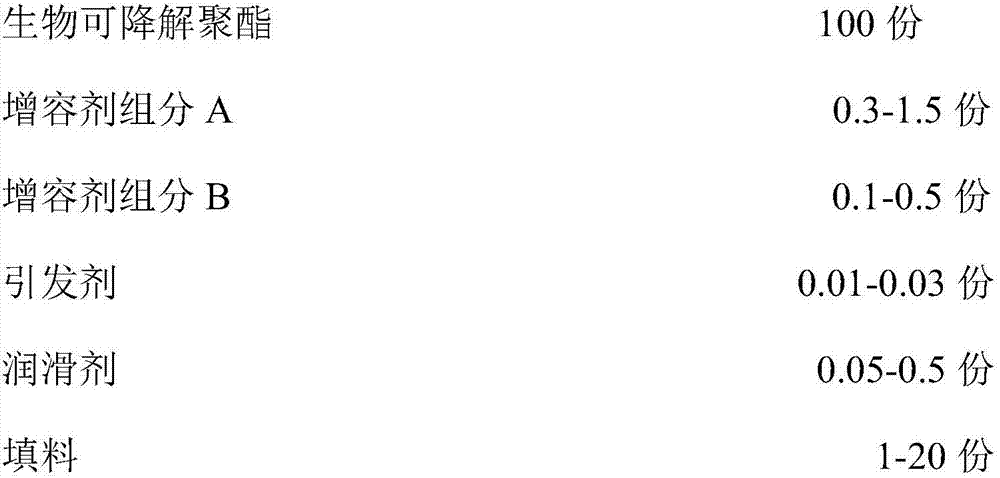

Method used

Image

Examples

Embodiment 1

[0052] (1) PLA (4032D) and PBAT were vacuum-dried at a drying temperature of 60°C and a drying time of 12 hours; calcium carbonate was dried in a blast oven at 120°C for 6 hours;

[0053] (2) Styrene and glycidyl methacrylate are washed with sodium hydroxide dilute solution respectively, and then dried;

[0054] (3) Take 90 parts of PLA, 10 parts of PBAT, 0.5 part of styrene, 0.25 part of glycidyl methacrylate, 0.02 part of dicumyl peroxide, 0.1 part of calcium stearate, and 10 parts of calcium carbonate in high-mixing Mix in the machine at room temperature for 5 minutes;

[0055] (4) Add the obtained mixture to a twin-screw extruder for melting and mixing, and react to extrude and granulate. The temperature of each zone of the twin-screw machine is: 160°C in the first zone, 180°C in the second zone, 180°C in the third zone, and 190°C in the fourth zone , the fifth zone is 190°C, the head is 180°C; the screw speed is 200rpm, the length-to-diameter ratio L / D=44 / 1, and the cool...

Embodiment 2

[0058] (1) PLA (4032D) and PBS were vacuum-dried at a drying temperature of 60°C and a drying time of 12 hours; the fumed silica was dried in a blast oven at 120°C for 12 hours;

[0059] (2) Styrene and glycidyl methacrylate are washed with sodium hydroxide dilute solution respectively, and then dried;

[0060] (3) Get 88 parts of PLA, 12 parts of PBS, 0.4 part of styrene, 0.25 part of glycidyl methacrylate, 0.02 part of dicumyl peroxide, 0.1 part of calcium stearate, 5 parts of fumed silica, Mix in a high mixer at room temperature for 5 minutes;

[0061] (4) Add the obtained mixture to a twin-screw extruder for melting and mixing, and react to extrude and granulate. The temperature of each zone of the twin-screw machine is: 160°C in the first zone, 170°C in the second zone, 180°C in the third zone, and 190°C in the fourth zone , the fifth zone is 190°C, the head is 180°C; the screw speed is 200rpm, the length-to-diameter ratio L / D=40 / 1, and the cooling method of the strands:...

Embodiment 3

[0064] (1) PLA (4032D), PBAT and PBS were vacuum-dried at a drying temperature of 60°C for 12 hours; carbon fiber T500 was dried in a blast oven at 120°C for 6 hours;

[0065] (2) Styrene and glycidyl methacrylate are washed with sodium hydroxide dilute solution respectively, and then dried;

[0066] (3) Take 85 parts of PLA, 10 parts of PBAT, 5 parts of PBS, 0.5 parts of styrene, 0.5 parts of glycidyl methacrylate, 0.02 parts of dicumyl peroxide, 0.1 parts of calcium stearate, and 5 parts of carbon fiber T500 , mixed in a high mixer at room temperature for 5 minutes;

[0067] (4) Put the obtained mixture into a twin-screw extruder for melting and mixing, and react to extrude and granulate. The temperature of each zone of the twin-screw machine is: 160°C in the first zone, 175°C in the second zone, 190°C in the third zone, and 200°C in the fourth zone , the fifth zone is 190°C, the head is 180°C; the screw speed is 200rpm, the length-to-diameter ratio L / D=44 / 1, and the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com