Patents

Literature

153 results about "Polylactic acid polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polylactic Acid (PLA) is an eco-friendly polymer derived from lactic acid which can be produced by fermentation of renewable resources.

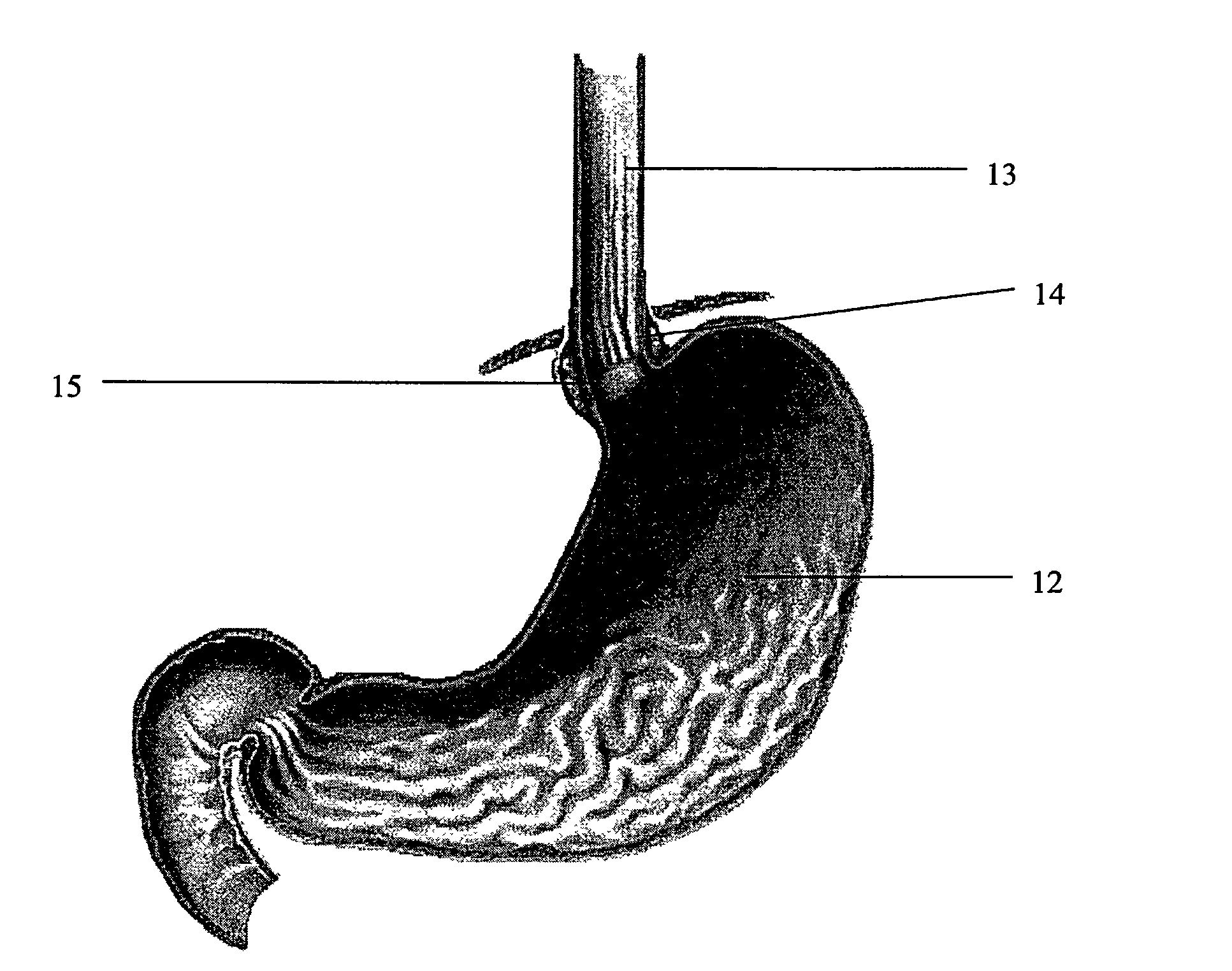

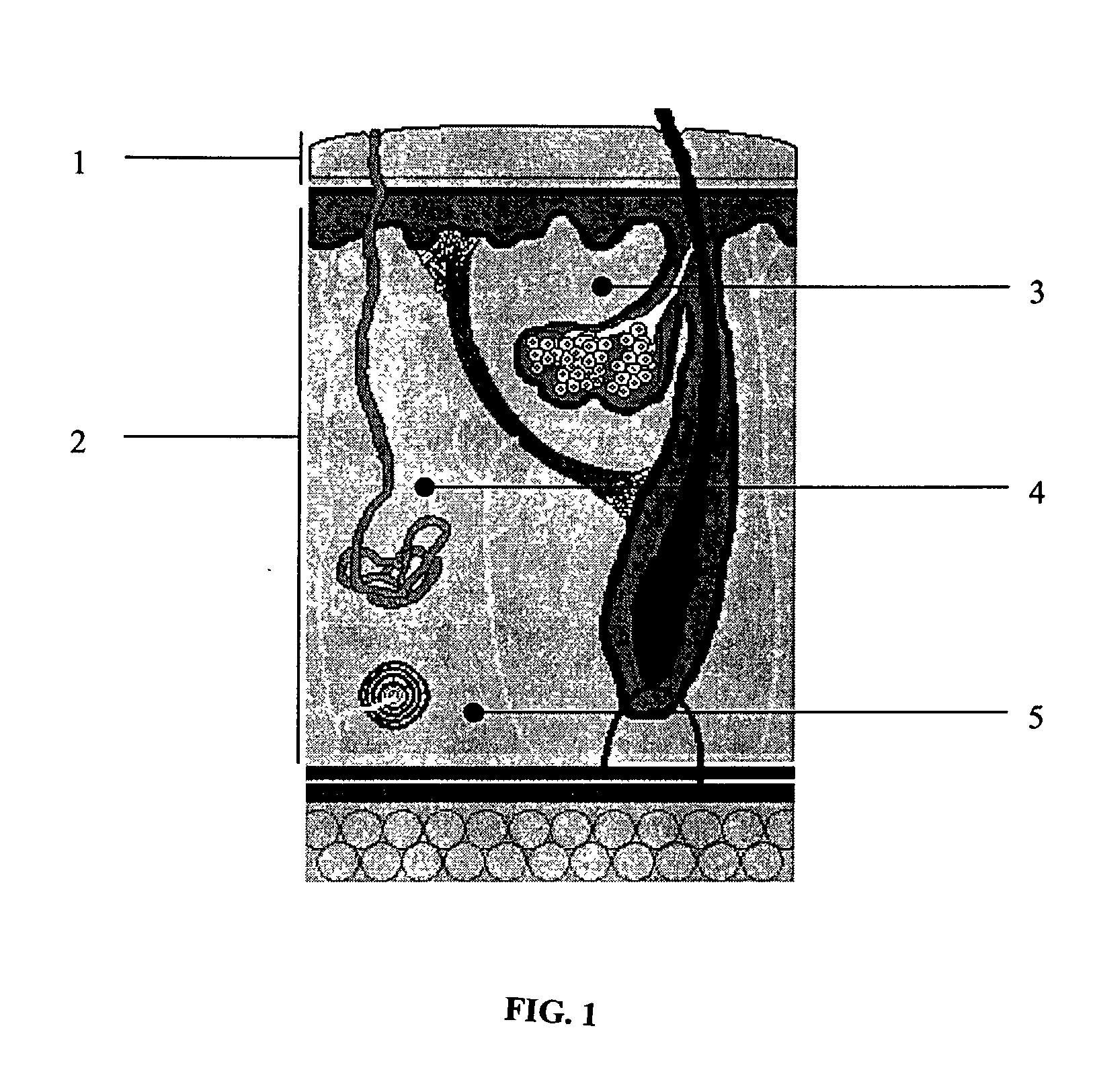

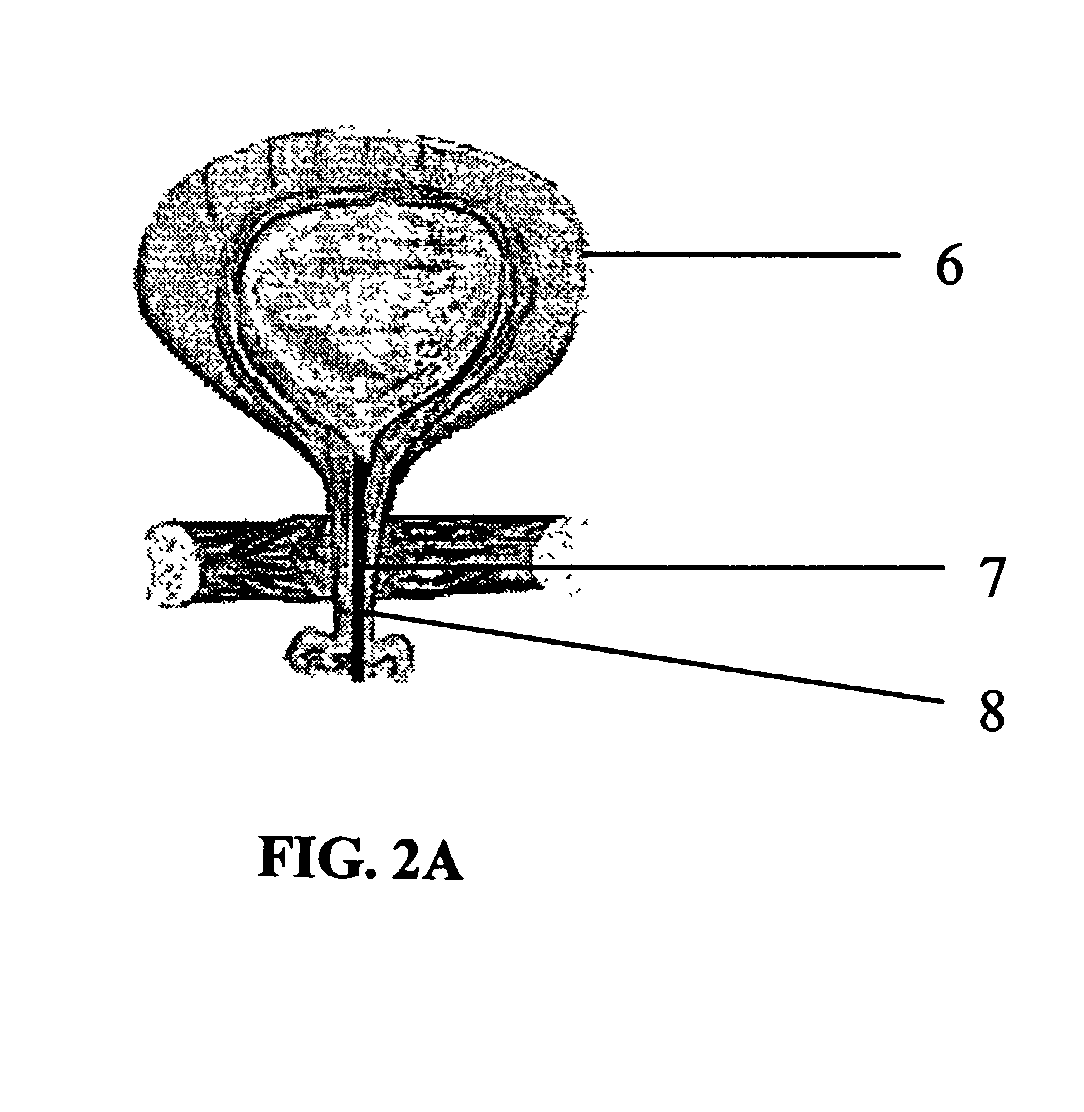

Biodegradable injectable implants and related methods of manufacture and use

InactiveUS20030093157A1Broaden applicationSolution deliveryPharmaceutical non-active ingredientsGlycolic acidImplant

This invention is directed to the field of medical implants, and more specifically to biodegradable injectable implants and their methods of manufacture and use. The injectable implants disclosed herein comprise glycolic acid and bio-compatible / bio-absorbable polymeric particles containing a polymer of lactic acid. The particles are small enough to be injected through a needle but large enough to avoid engulfment by macrophages. The injectables of this invention may be in a pre-activated solid form or an activated form (e.g., injectable suspension or emulsion).

Owner:MEDGRAFT MICROTECH

Biodegradable resin compositions

InactiveUS6669771B2Increase resistanceHigh strengthCosmetic preparationsAntifouling/underwater paintsBiodegradable productDigestion

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

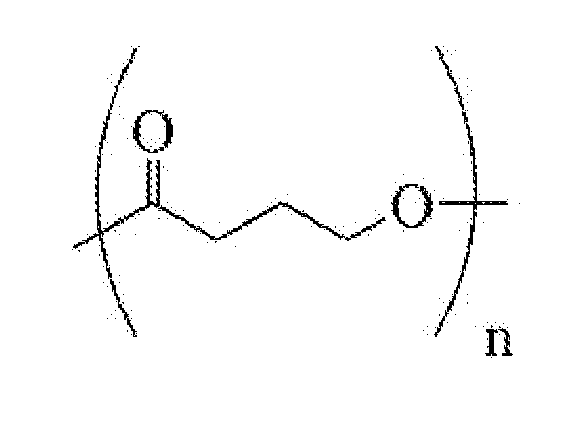

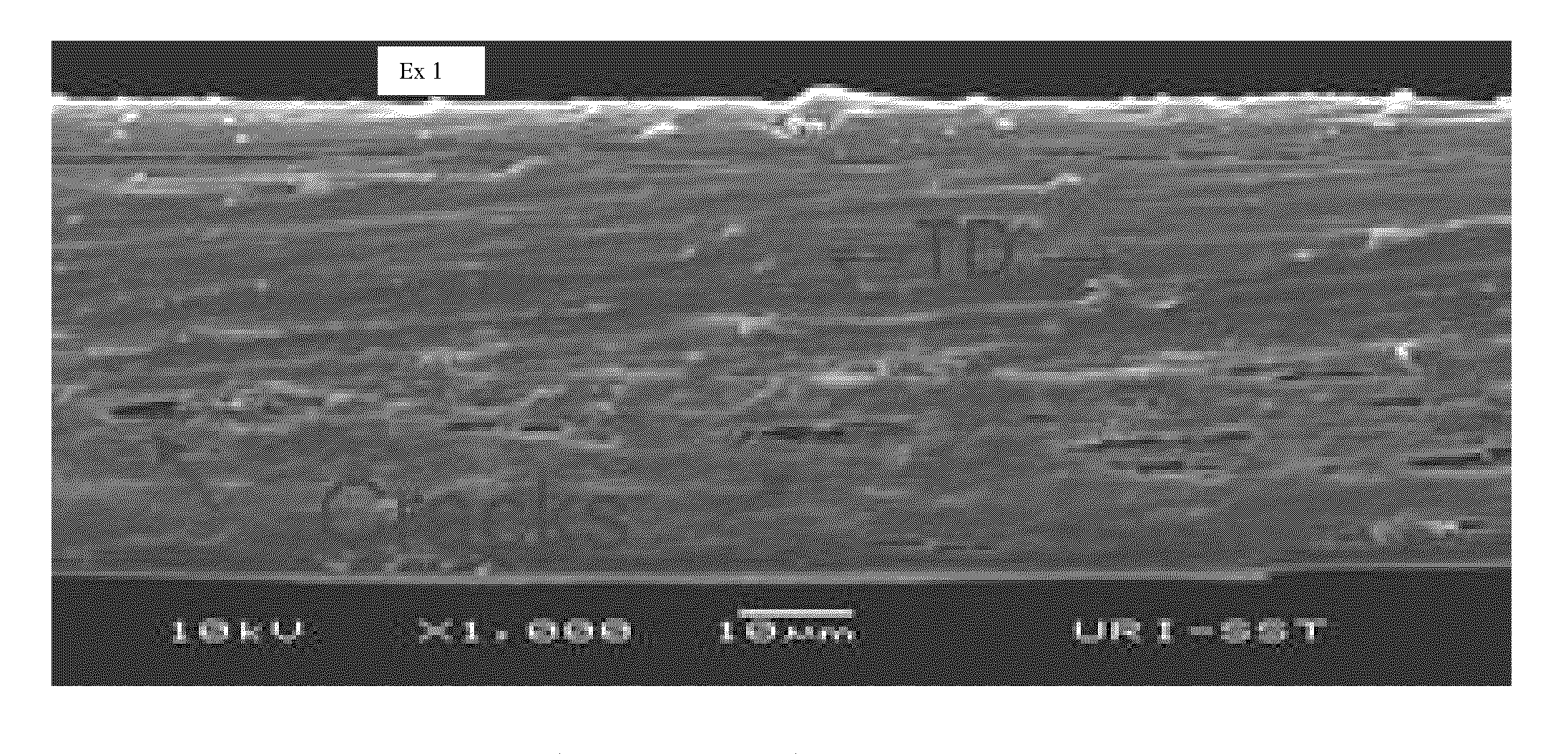

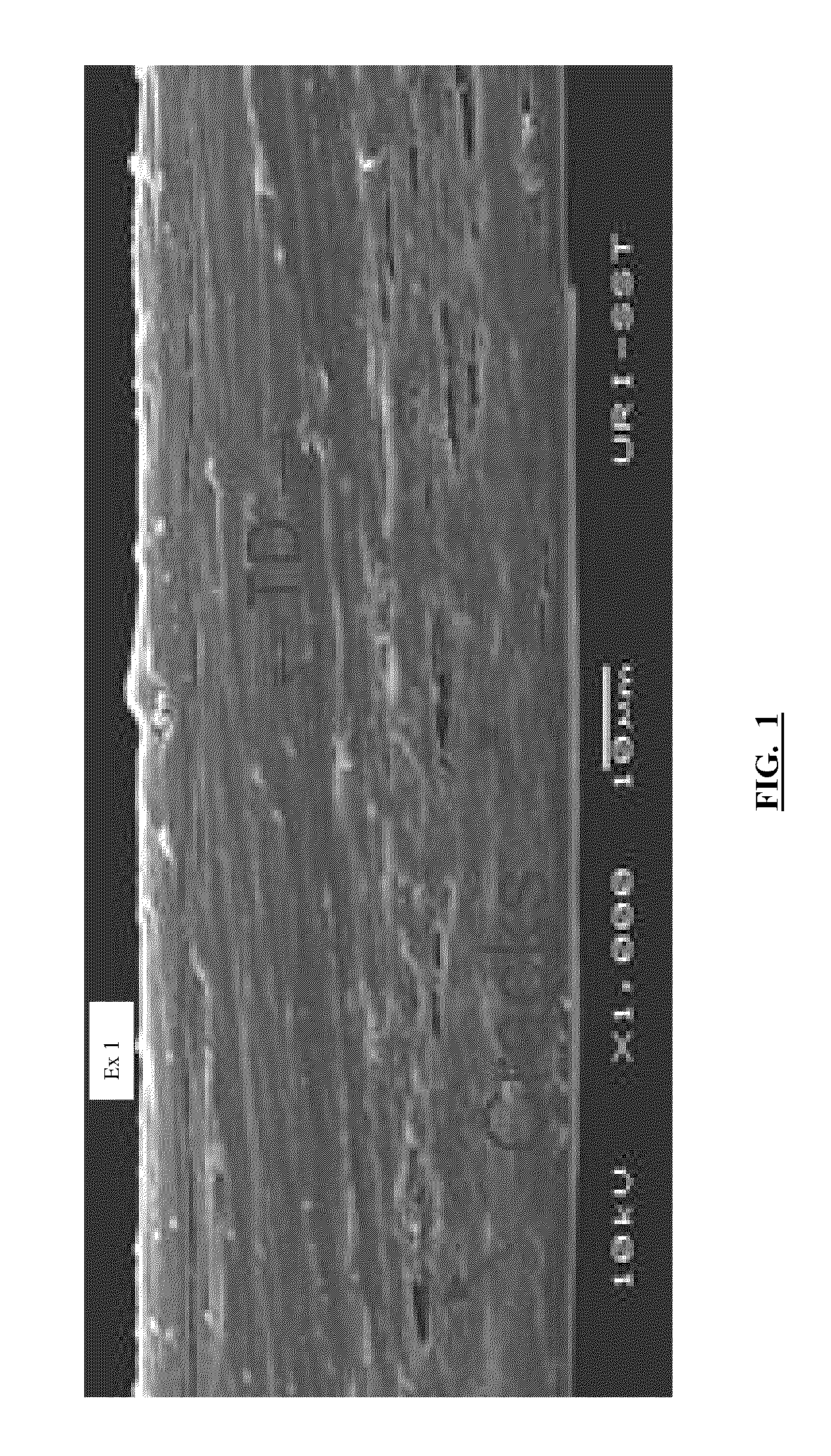

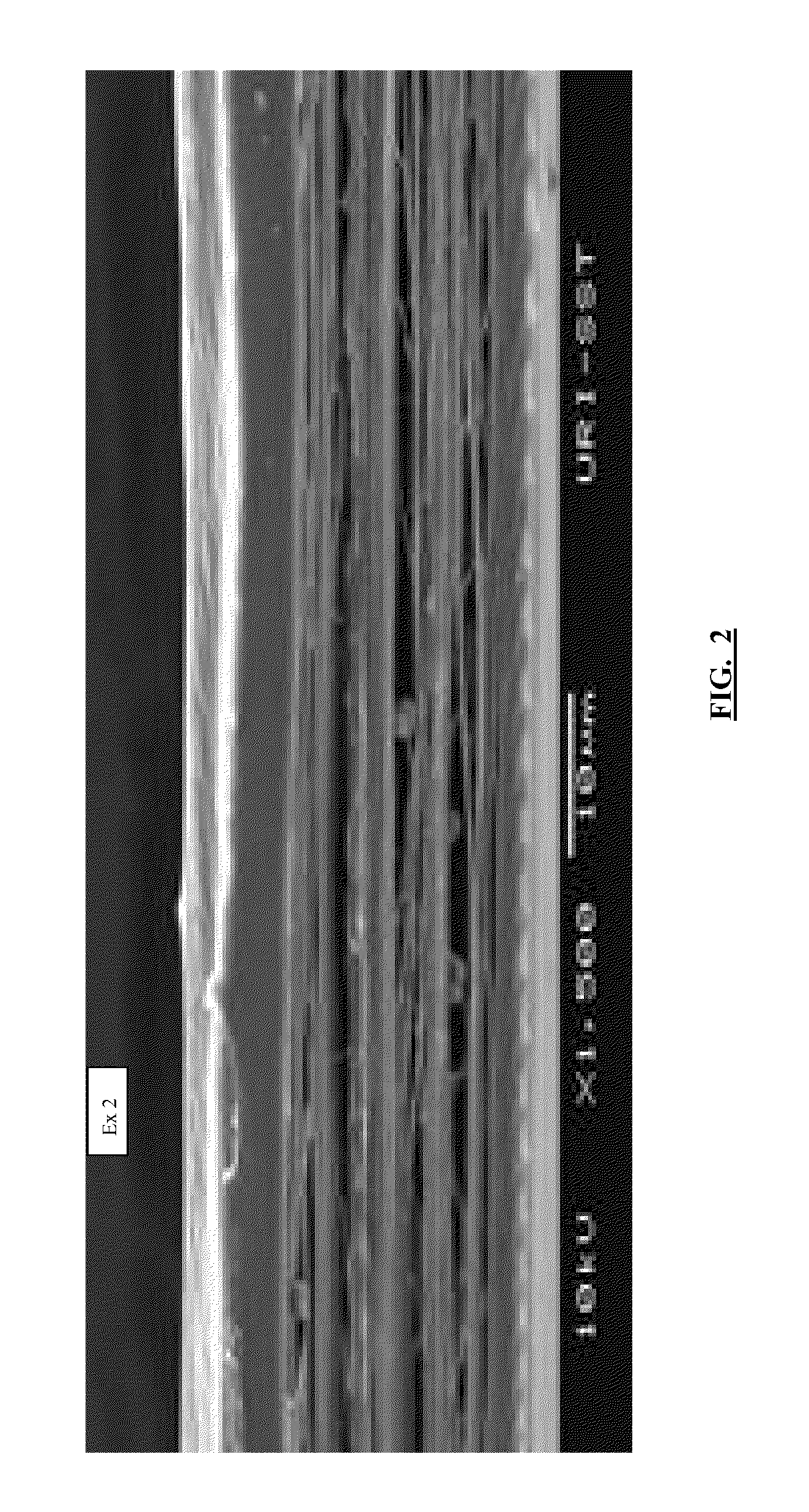

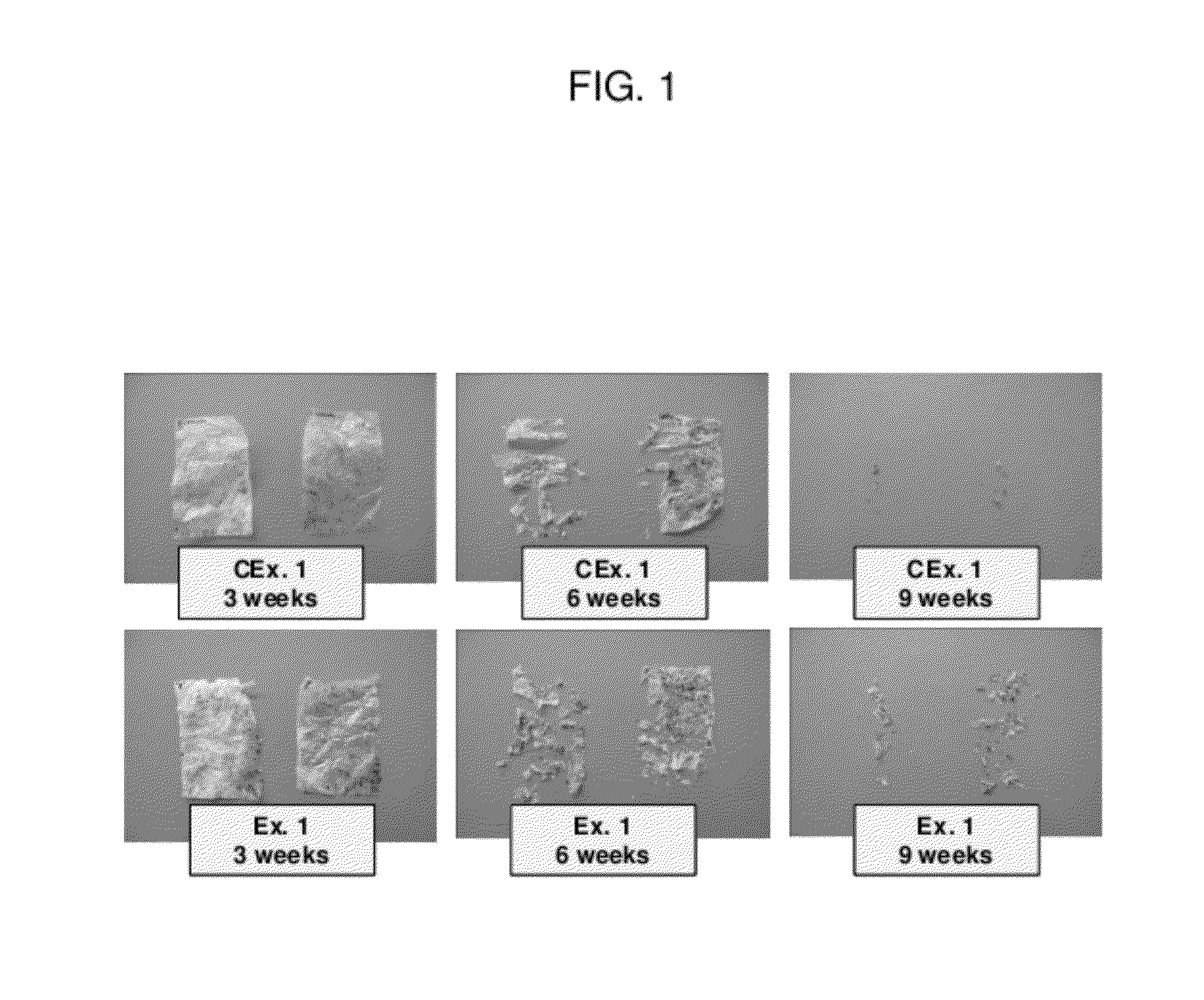

Fibers comprising polyhydroxyalkanoate copolymer/polylactic acid polymer or copolymer blends

InactiveUS6905987B2Improve material performancePersonal careSynthetic resin layered productsFiberPolymer chemistry

Environmentally degradable melt spun fibers comprising a polyhydroxyalkanoate copolymer and a polylactic acid polymer or copolymer are disclosed. A preferred configuration of the present invention is directed to environmentally degradable fibers comprising a sheath / core structure where the core comprises a biodegradable polyhydroxyalkanoate copolymer and the sheath comprises a polymer or copolymer of polylactic acid. Nonwoven webs and disposable articles comprising the environmentally degradable fibers are also disclosed.

Owner:DANIMER IPCO LLC

Thermoplastic polycarbonate/polyester blend compositions with improved mechanical properties

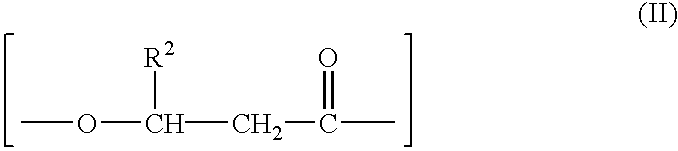

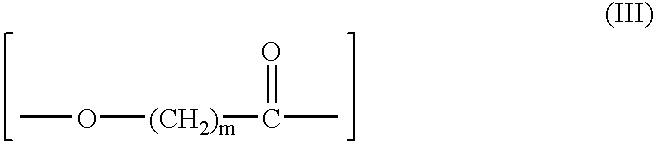

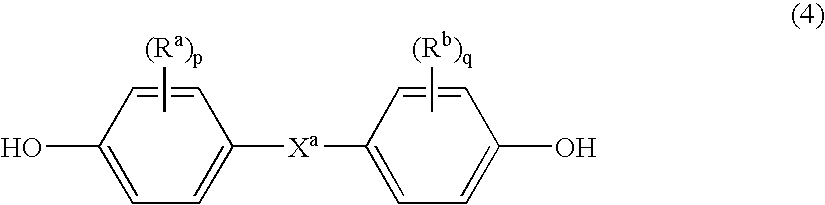

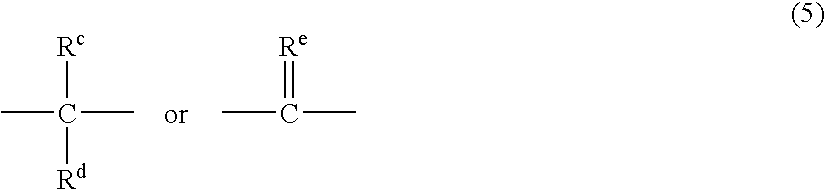

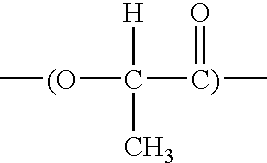

Disclosed is a thermoplastic composition comprising a mixture of from 10 to 98 weight % of a polycarbonate polymer, from 2 to 90 weight % of a polyester polymer comprising structures derived from a diol compound having the structure (A) HO-Z-OH, wherein Z is a C1 to C36 linear aliphatic radical, a C3 to C36 branched aliphatic or cycloaliphatic radical, a C6 to C36 aryl radical, or a C7 to C36 alkylaryl radical, and a diacid compound having the structure (B) HOOC—CH2CH2—COOH, from 0 to 5 weight % of a polylactic acid polymer, wherein the sum of the polycarbonate polymer, the polyester polymer, and the polylactic acid polymer is equal to 100 weight %. The thermoplastic composition has improved mechanical properties.

Owner:SABIC GLOBAL TECH BV

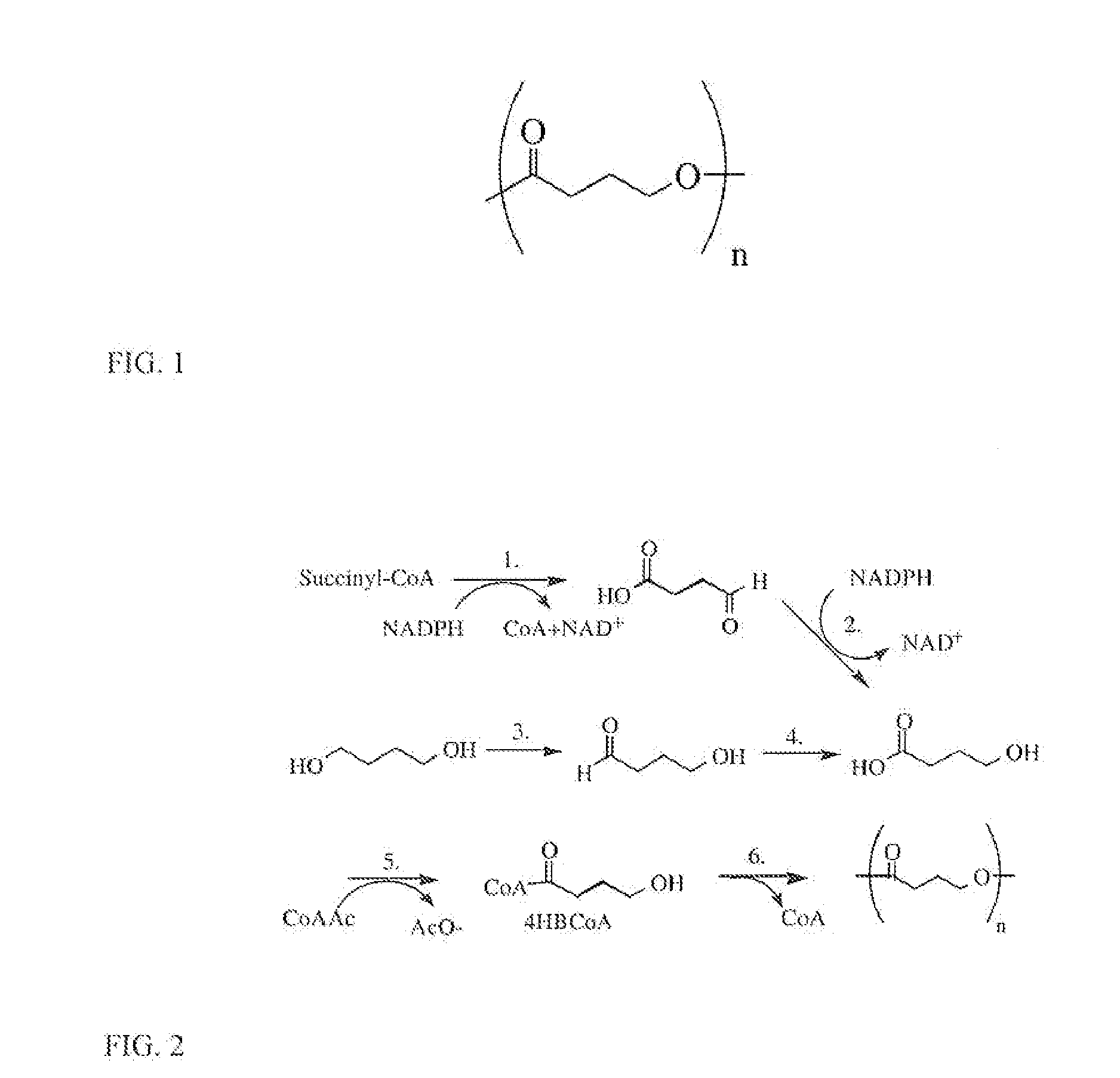

Toughened Polylactic Acid Polymers and Copolymers

InactiveUS20070182041A1Low tensile modulus valueMaintain good propertiesSuture equipmentsCatheterToughnessPolymer chemistry

Toughened compositions of PLA and PLA copolymers are disclosed, which also have low tensile modulus values and greater elongation to break. These toughened compositions are prepared by blending PLA and PLA copolymers with poly-4-hydroxybutyrate, and copolymers thereof. Blending of poly-4-hydroxybutyrate with PLA and its copolymers has been found to impart advantageous properties to the resulting blend. These compositions, and objects formed from these compositions, have improved toughness and lower stiffness than polylactic acid polymers or copolymers alone.

Owner:TEPHA INC

Packaging film

A film of biodegradable polylactic acid polymers and copolymers is produced by coextrusion which displays improved winding and manufacturability and end use performance. The film is coextruded from polylactic acid (PLA) polymers and copolymers and biaxially oriented. The surface layer(s) of the film is modified with a particle and displays improved COF, blocking resistance, reduced static generation, improved winding and improved package formation on packaging machines.

Owner:BIAX INT

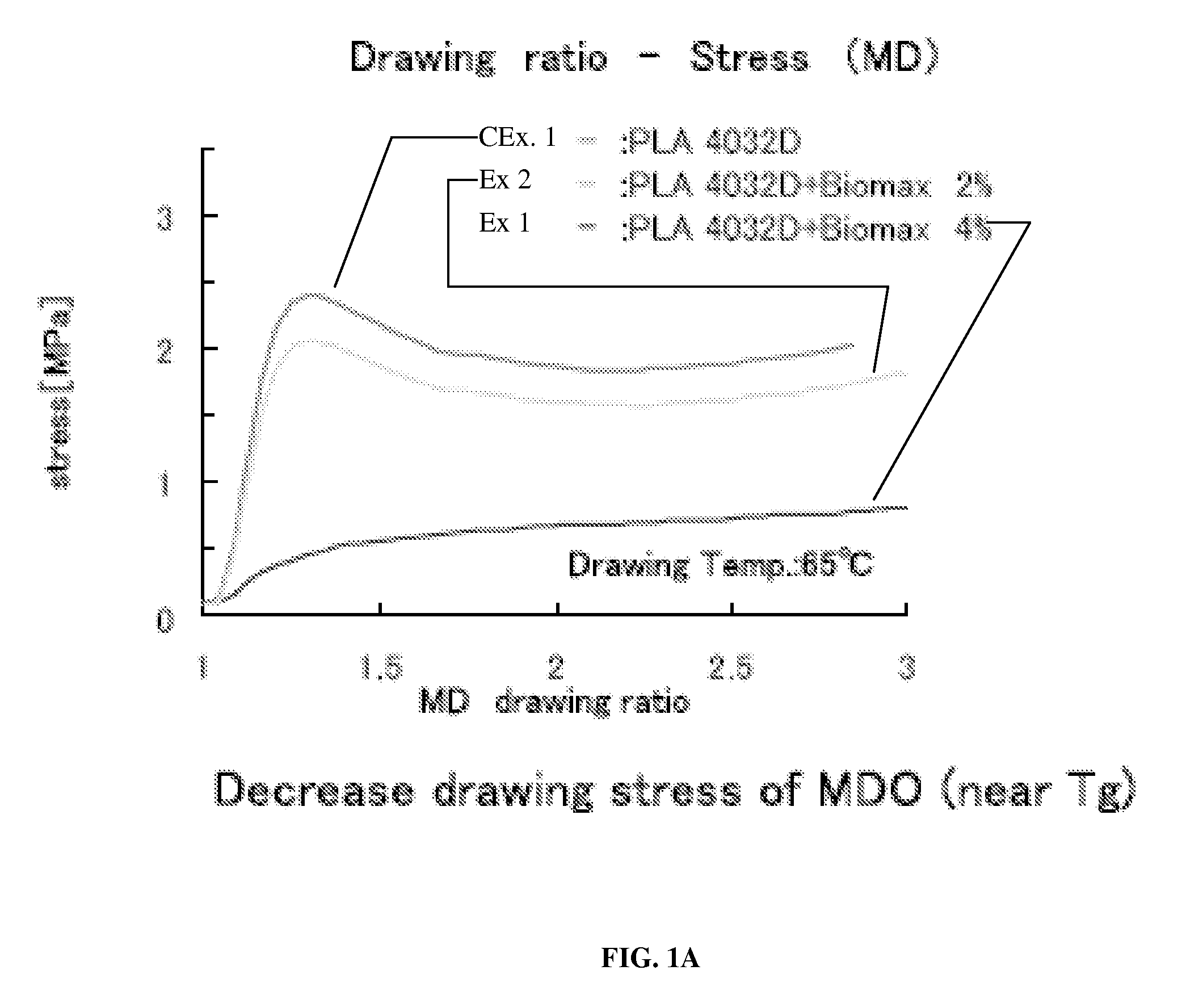

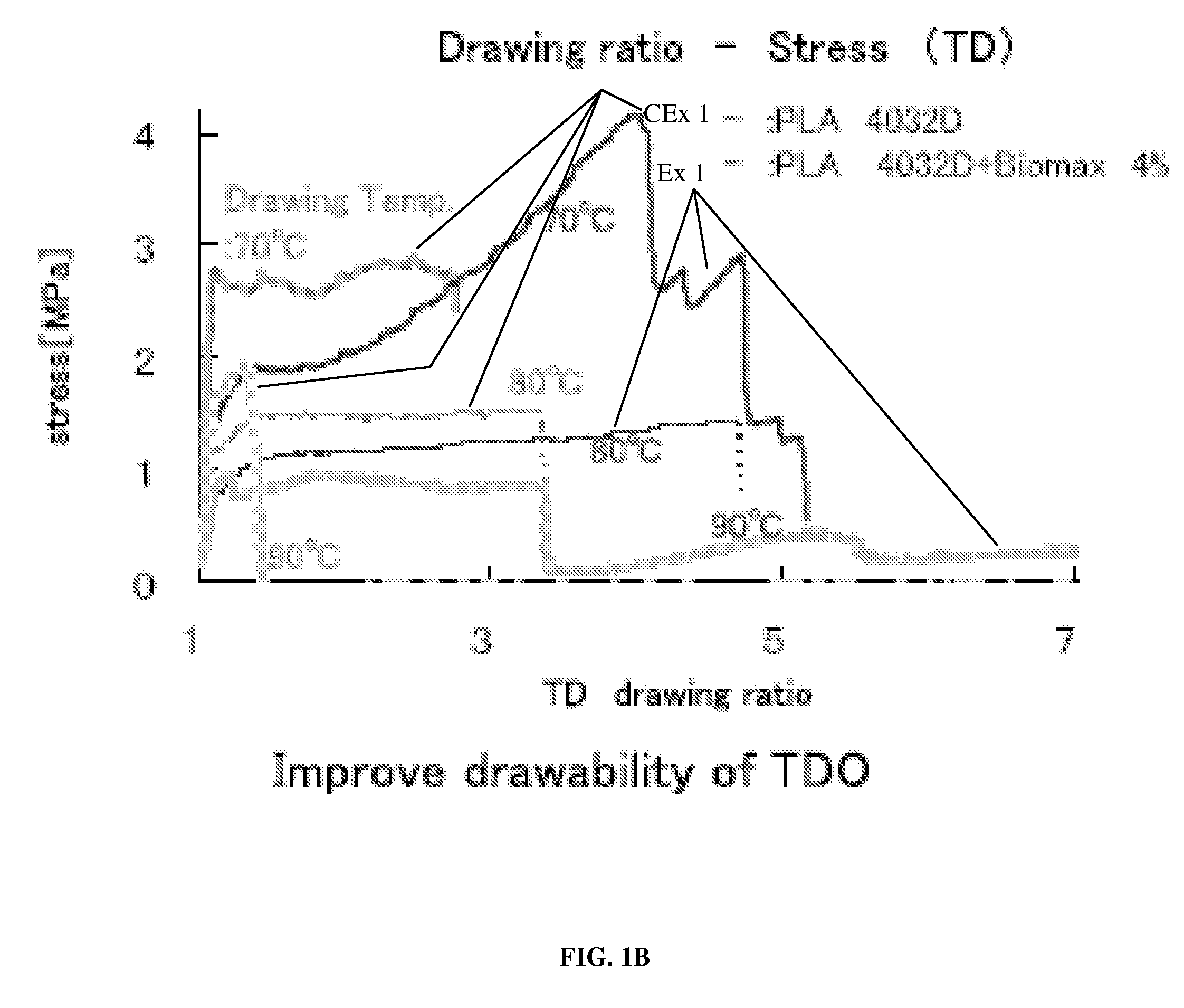

Process to produce biaxially oriented polylactic acid film at high transverse orientation rates

InactiveUS20090148715A1High rate of orientationEasy to stretchSynthetic resin layered productsDomestic articlesTransverse orientationEthylene

A biaxially oriented laminate film including a first amorphous polylactic acid polymer heat sealable resin layer and a second core layer including a blend of crystalline polylactic acid polymer and 2-10 wt % of the core layer of an ethylene-acrylate copolymer. The laminate film, exhibiting the property to be transverse oriented in excess of 6 times its original width, typically 8 to 10 times its original width with excellent operability and relatively low haze, is disclosed. The laminate film may further have additional layers such as a third polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Matte biaxially oriented polylactic acid film

ActiveUS20100009208A1Minimize thermal shrinkage effectReduce internal stressBio-packagingSynthetic resin layered productsPolyolefinPolymer chemistry

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and a minority amount of polyolefin with a compatibilizing resin which is biaxially oriented such that a matte or opaque appearance is obtained. The laminate film may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Biaxially oriented polylactic acid film with improved moisture barrier

InactiveUS20100330382A1Improved barrier resistanceImprove moisture resistanceSynthetic resin layered productsLabelsSealantMetallizing

Owner:TORAY PLASTICS AMERICA

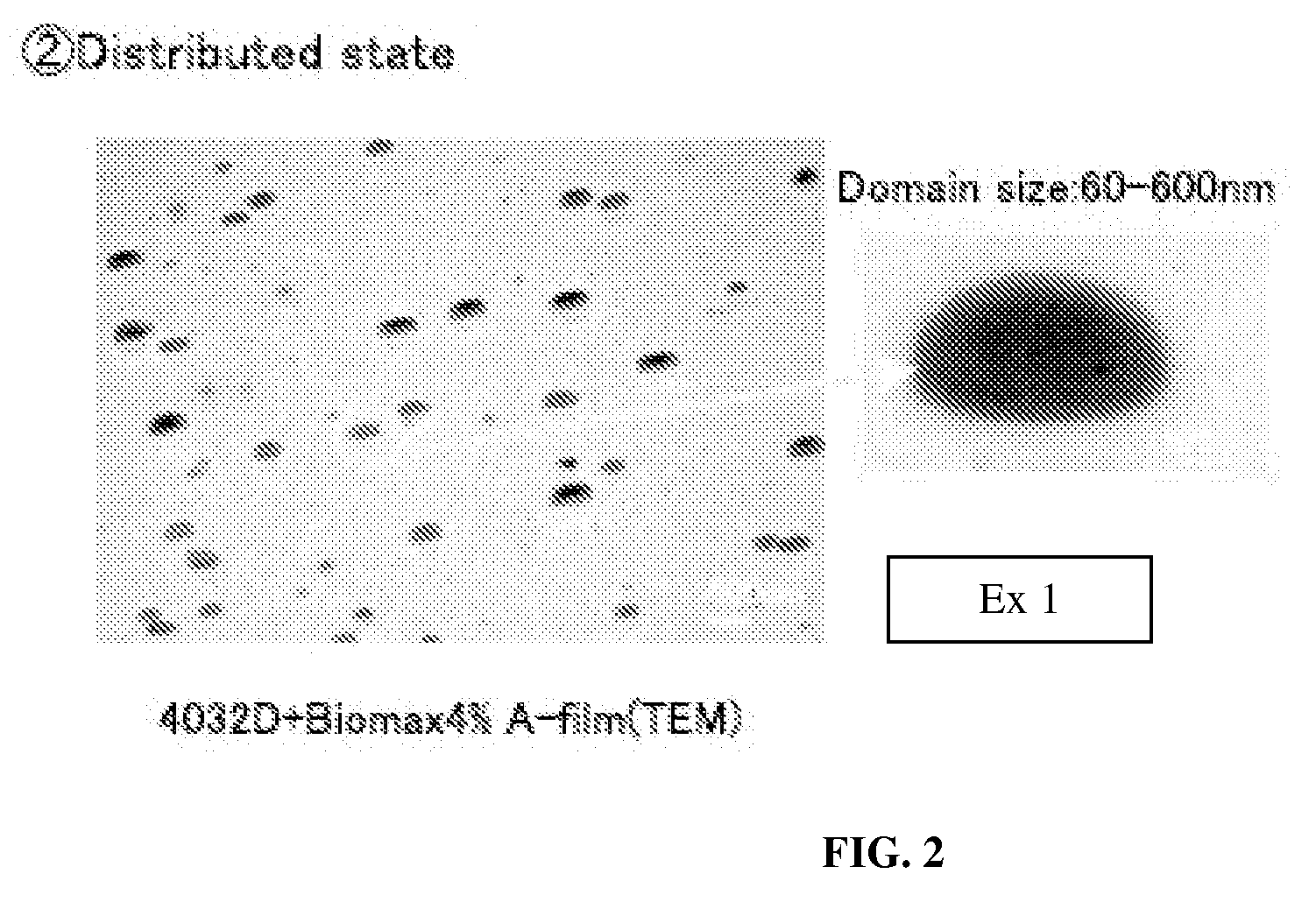

Thermoplastic Resin Composition And Molded Article Comprising The Same

ActiveUS20070276090A1Increase resistanceHigh transparencyDyeing processRefractive indexAcrylic polymer

A thermoplastic resin composition comprising a polylactic acid polymer (A), an acrylic polymer (B) containing units of methyl methacrylate monomer, and a graft copolymer (C) obtained by graft-polymerizing a vinyl monomer onto a rubbery polymer, wherein the refractive index, Rc, of the graft copolymer (C) and the total refractive index, Rab, of the polylactic acid polymer (A) and the acrylic polymer (B) satisfy the following formula (1). −0.004≦−Rc−Rab≦+0.008 (1)

Owner:MITSUBISHI CHEM CORP

Biaxially oriented polylactic acid film with high barrier

ActiveUS20100040904A1Good metal adhesionImproves the gas barrier of the metallized PLA filmSynthetic resin layered productsVacuum evaporation coatingMoisture barrierFood packaging

A multilayer film including a first layer including a polylactic acid polymer, a second layer of a metal primer, deposited upon one surface of the first polylactic acid polymer layer, and a third metal layer deposited on the second metal primer layer. This metal-primed and metallized polylactic acid film exhibits improved moisture barrier properties versus a non-metal-primed and metallized polylactic acid film and can be used as part of a lamination structure for food packaging applications.

Owner:TORAY PLASTICS AMERICA

Biaxially oriented polylactic acid film with high barrier

ActiveUS20090148713A1Improve barrier propertiesRemain biodegradableSynthetic resin layered productsDomestic articlesPolymer sciencePolyolefin

A metallized laminate film exhibiting improved moisture barrier property as well as maintaining a high bio-polymer content and degradability property is disclosed. The laminate film includes a first core layer of polylactic acid polymer and a second skin layer comprising a polyolefin metal receiving layer. The metal receiving layer or the core layer, or both, may be blended with an amount of polar-modified tie-resin to improve bonding. Alternatively, a discrete tie-resin layer may be interposed between the polyolefin metal receiving layer and the crystalline polylactic acid polymer core layer. The polyolefin metal receiving layer may be discharge-treated on the side opposite the core layer and metallized.

Owner:TORAY PLASTICS AMERICA

Method to produce matte and opaque biaxially oriented polylactic acid film

ActiveUS20090311544A1Minimize shrinkage effectReduce internal stressOther chemical processesSynthetic resin layered productsMaterials scienceMetal

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and an inorganic antiblock particle which is biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the particles such that a matte or opaque appearance is obtained. The laminate film may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Biaxially oriented polylactic acid film with high barrier

ActiveUS7951438B2Improve barrier propertiesImprove metallized moisture and oxygen barrierSynthetic resin layered productsLaminationPolymer sciencePolyolefin

A metallized laminate film exhibiting improved moisture barrier property as well as maintaining a high bio-polymer content and degradability property is disclosed. The laminate film includes a first core layer of polylactic acid polymer and a second skin layer comprising a polyolefin metal receiving layer. The metal receiving layer or the core layer, or both, may be blended with an amount of polar-modified tie-resin to improve bonding. Alternatively, a discrete tie-resin layer may be interposed between the polyolefin metal receiving layer and the crystalline polylactic acid polymer core layer. The polyolefin metal receiving layer may be discharge-treated on the side opposite the core layer and metallized.

Owner:TORAY PLASTICS (AMERICA) INC

High barrier metallized film with mirror-like appearance

InactiveUS6844077B2Improved gas propertyImproved moisture barrier propertyFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

A metallized, multi-layer film is disclosed that comprises at least a polyolefin layer, a tie layer, and a metallized lactic acid polymer layer to yield a final film having improved moisture and gas barrier, optical, and mechanical properties.

Owner:EXXONMOBIL CORP (US)

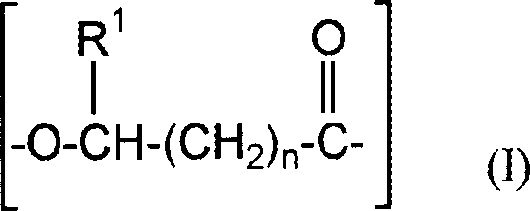

Lactic acid polymer composition, molded article comprising the composition and process for producing the molded article

InactiveUS20090311511A1Improve heat resistanceIncrease productivitySynthetic resin layered productsWood working apparatusPolymer scienceThermoforming

To provide a lactic acid polymer composition excellent in transparency, heat resistance and productivity, a molded article, a sheet and a multilayer sheet each of which comprises the composition, a thermoformed article obtained by secondary-forming the sheet or the multilayer sheet, and a process for producing the thermoformed article with excellent productivity. The lactic acid polymer composition of the invention comprises 100 parts by weight of a lactic acid polymer (A), 0.1 to 3 parts by weight of an organic crystal nucleating agent (B) comprising an aliphatic carboxylic acid amide having an amide bond, and 0.1 to 7 parts by weight of a crystallization accelerator (C). The thermoformed article of the invention is obtained with excellent production efficiency by thermoforming the sheet comprising the composition of the invention at a temperature of 60 to 130° C.

Owner:MITSUI CHEM INC

Thermoplastic resin composition and molded article comprising the same

ActiveUS7589151B2Increase resistanceHigh transparencyDyeing processPolymer scienceMethacrylate methyl

A thermoplastic resin composition comprising a polylactic acid polymer (A), an acrylic polymer (B) containing units of methyl methacrylate monomer, and a graft copolymer (C) obtained by graft-polymerizing a vinyl monomer onto a rubbery polymer, wherein the refractive index, Rc, of the graft copolymer (C) and the total refractive index, Rab, of the polylactic acid polymer (A) and the acrylic polymer (B) satisfy the following formula (1)−0.004≦Rc−Rab≦+0.008 (1).

Owner:MITSUBISHI CHEM CORP

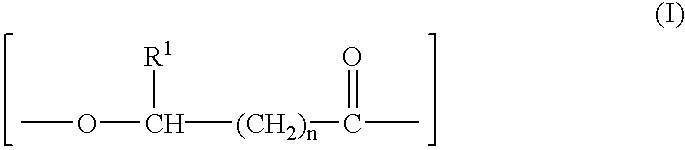

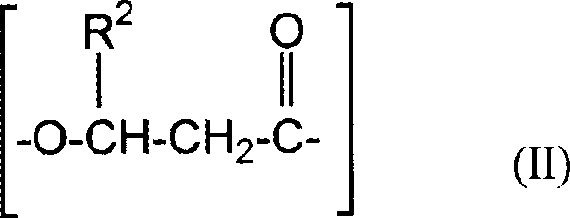

Lactic acid polymer composition and molded object thereof

InactiveUS20050001349A1Crystallinity impairedHeat resistance impairedArtifical filament manufacturePolymer sciencePlasticizer

Disclosed herein are a lactic acid-based polymer composition comprising: (i) an amide compound represented by General Formula (1): R1—(CONHR2)a (1) wherein R1 represents a C2-30 saturated or unsaturated aliphatic polycarboxylic acid residue, a C4-28 saturated or unsaturated alicyclic polycarboxylic acid residue, or a C6-28 aromatic polycarboxylic acid residue, and R2 represents C1-18 alkyl, C2-18 alkenyl, C3-12 cycloalkyl or cycloalkenyl or the like, (ii) an ester plasticizer, and (iii) a lactic acid-based polymer; a transparent, crystalline (heat resistant) molded article molded from such a lactic acid-based polymer composition; and a method for producing such a molded article.

Owner:NEW JAPAN CHEM CO

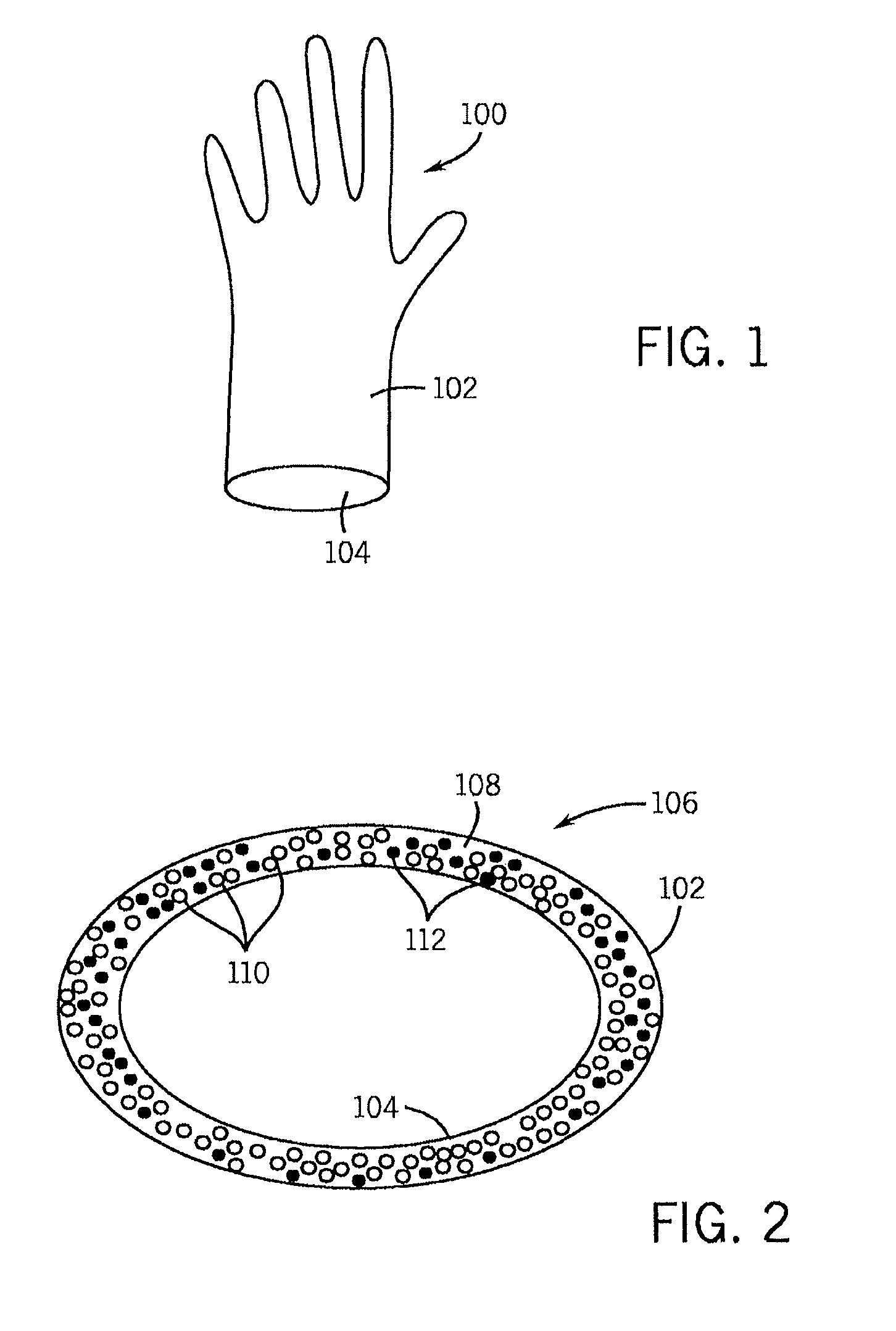

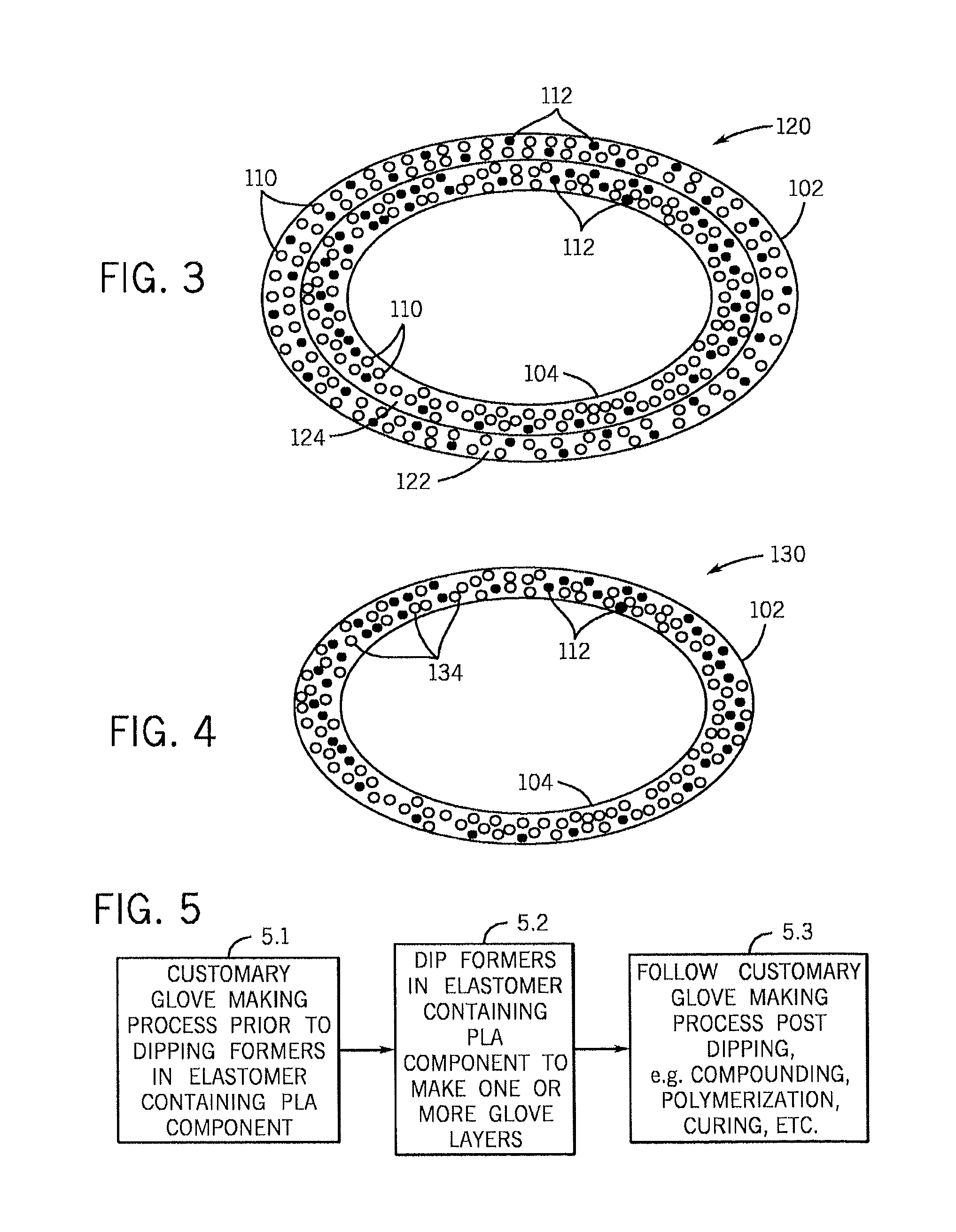

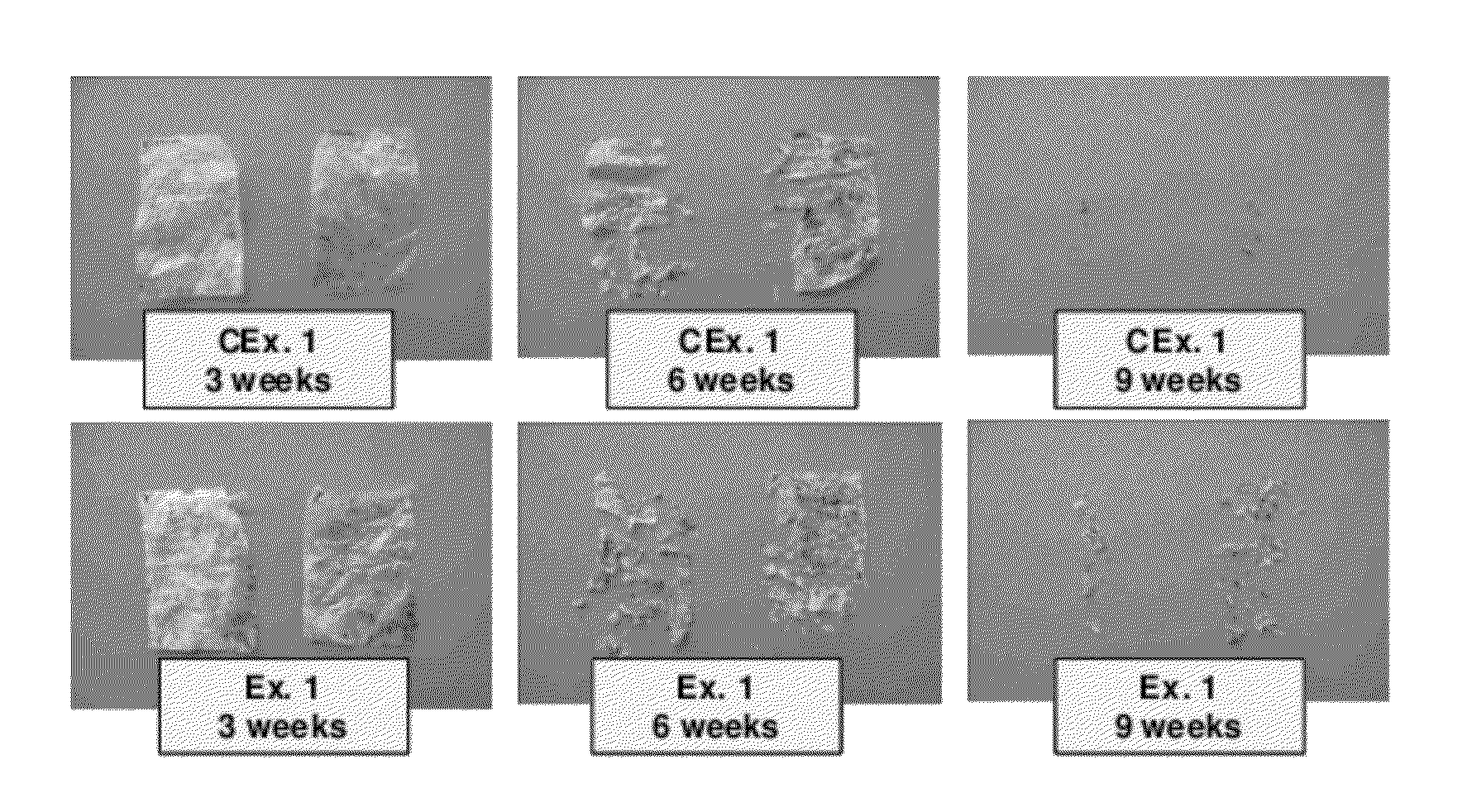

Polylactic acid gloves and methods of manufacturing same

InactiveUS20100257657A1Enhance their market appealBroad possible marketGarment special featuresSurgeryElastomerPolymer science

Biodegradable disposable gloves and methods of manufacturing the same are disclosed in which the elastomeric material used to manufacture the gloves includes a polylactic acid polymer component in combination with a biodegradable plasticizer.

Owner:SMARTHEALTH

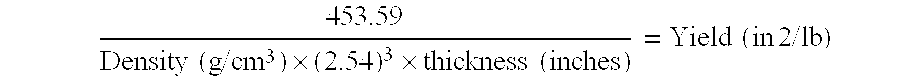

Biaxially oriented cavitated polylactic acid film

InactiveUS20120141766A1Low costRemain biodegradableSynthetic resin layered productsVacuum evaporation coatingPolystyreneMaterials science

Disclosed are biaxially oriented laminate films including a core layer including a blend of crystalline polylactic acid polymer and crystalline polystyrene. The films are biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the crystalline polystyrene such that a white opaque cavitated appearance and lower film densities are obtained. The laminate films may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Film and sheet for folding packaging containers

InactiveUS20060269710A1Improve creasesGood optical claritySynthetic resin layered productsBoxesWood veneerPolymer science

A film of biodegradable polylactic acid polymers (PLA) and copolymers are produced by biaxially orienting single and multilayer extrusions. The film and sheets are stiff, have excellent optical properties and show excellent retained folding and creasing properties making them especially desirable for the production of folded box like containers. The surface layer(s) of the film and sheet may be heat sealable or modified with a particle to give improved coefficient of friction (COF), blocking resistance, reduced static generation, improved winding and improved package formation on packaging machines.

Owner:INGLIS THOMAS L

Fibers comprising polyhydroxyalkanoate copolymer/polylactic acid polymer or copolymer blends

Environmentally degradable melt spun fibers comprising a polyhydroxyalkanoate copolymer and a polylactic acid polymer or copolymer are disclosed. A preferred configuration of the present invention is directed to environmentally degradable fibers comprising a sheath / core structure where the core comprises a biodegradable polyhydroxyalkanoate copolymer and the sheath comprises a polymer or copolymer of polylactic acid. Nonwoven webs and disposable articles comprising the environmentally degradable fibers are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

Ternary mixtures of biodegradable polyesters and products manufactured from them

The invention relates to a mixture of biodegradable polyesters which includes an aromatic-aliphatic polyester (A), an aliphatic polyester (B) and a polylactic acid polymer (C) in which the concentration of A varies, with respect to (A+B) in the range between 40 and 70% by weight, and the concentration of C with respect of (A+B+C) is of between 6 and 30% by weight.

Owner:NOVAMONT SPA

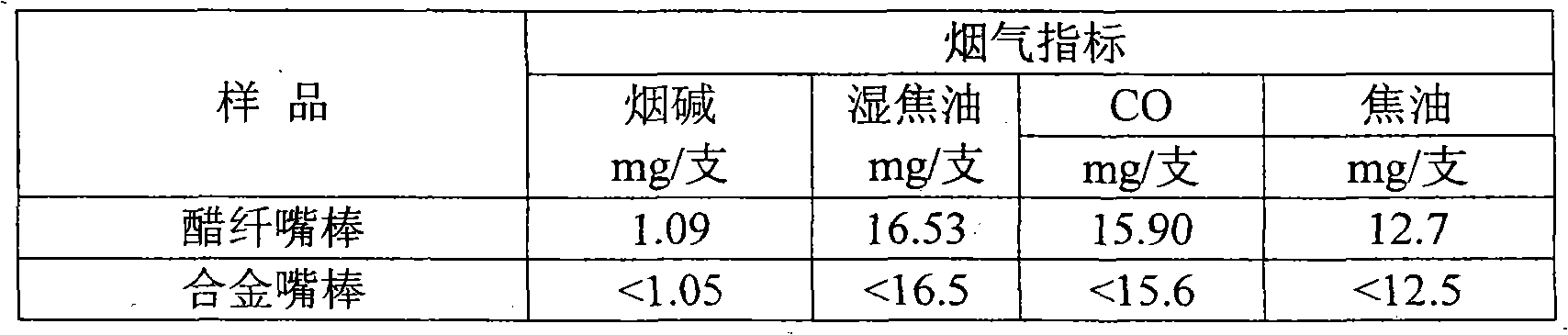

Biodegradable cigarette fiber material and cigarette filter

ActiveCN102080278ABiodegradableImprove adsorption capacityTobacco smoke filtersMelt spinning methodsFiberPolymer science

The invention provides a biodegradable cigarette fiber material and a cigarette filter. The biodegradable cigarette fiber material comprises the following raw materials of 1-99wt percent of poly(butylene succinate) polymer, 1-99wt percent of polylactic acid polymer and 0-3wt percent of stabilizing agent, and the cigarette fiber material is prepared by processing the raw materials with a melting spinning process. The poly(butylene succinate) polymer and the polylactic acid polymer can be respective homopolymers of the two polymers per se and can also be copolymers containing other monomer materials, which do not exceed 30 percent of the total quantity of respective molecular chain segments of the two polymers. The invention also provides a biodegradable cigarette filter rod prepared from the cigarette fibre material through sizing processing, and a cigarette product. The provided cigarette filter has a property equivalent to the property of the traditional general cigarette filter, a cigarette end discarded by a smoker can be decomposed within shorter time in the natural environment, and the pollution of the cigarette waste to the environment is avoided at present while the requirement of cigarette production is met.

Owner:海南海福新材料有限公司

Biaxially oriented cavitated polylactic acid film

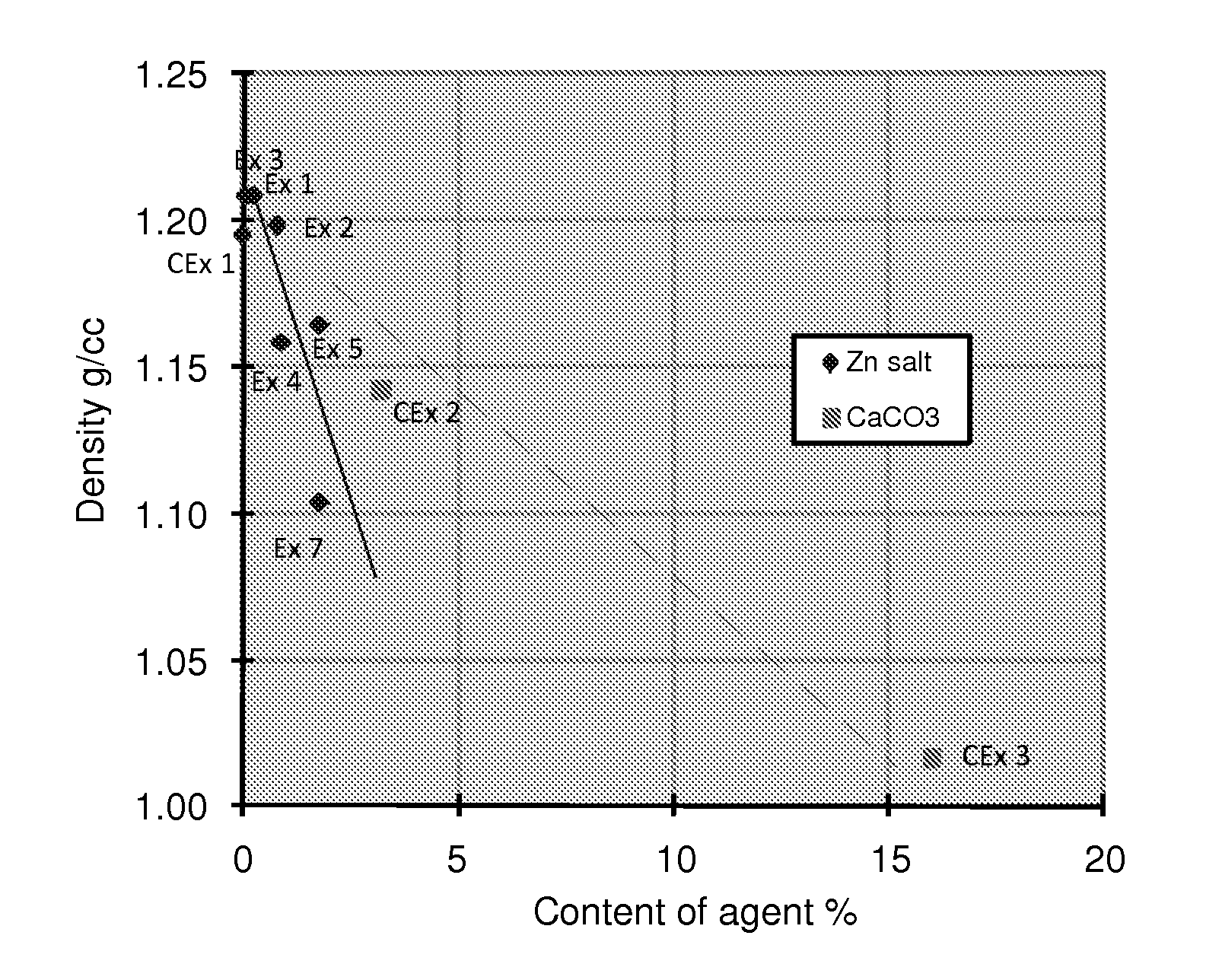

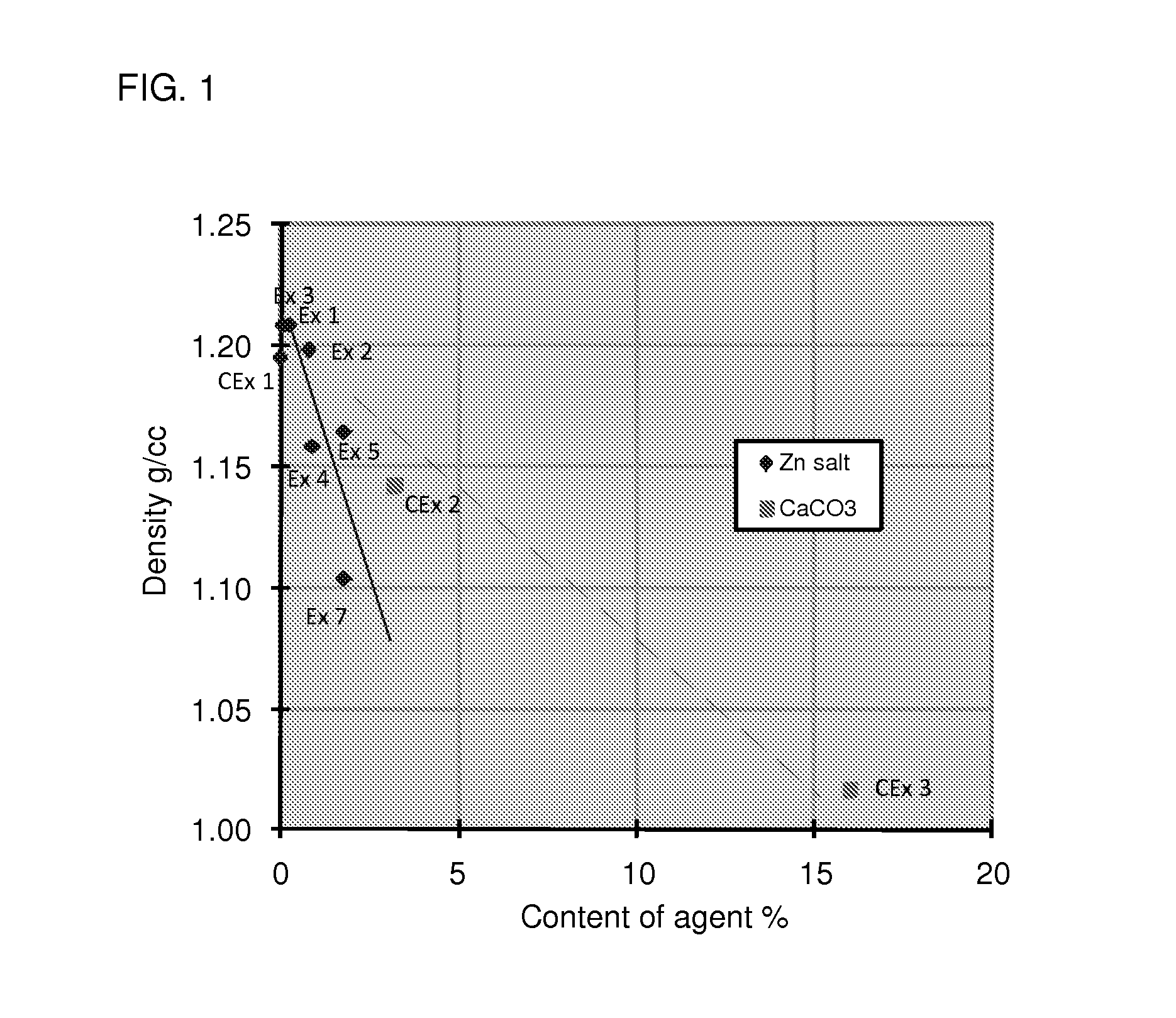

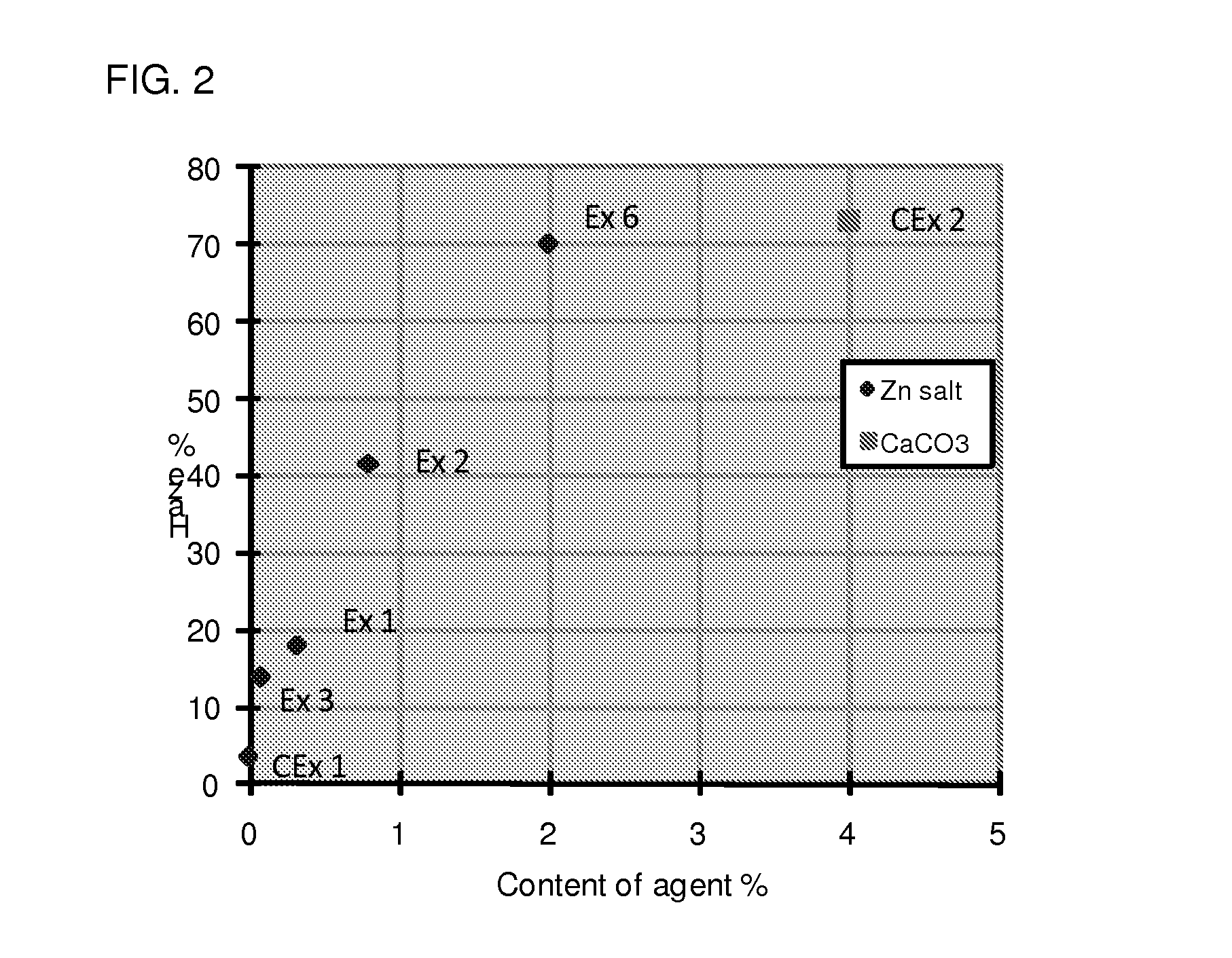

ActiveUS20130122280A1High opacityImprove film yieldLamination ancillary operationsSynthetic resin layered productsMechanical propertyCrystallization

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and a metal salt phosphorus-containing compound nucleating agent which is biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the metal salt phosphorus-containing metal such that a white opaque cavitated appearance and a lower film density and improved mechanical properties are obtained. The laminate film could further have additional layers such as a heat sealable layer disposed on one side of said core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

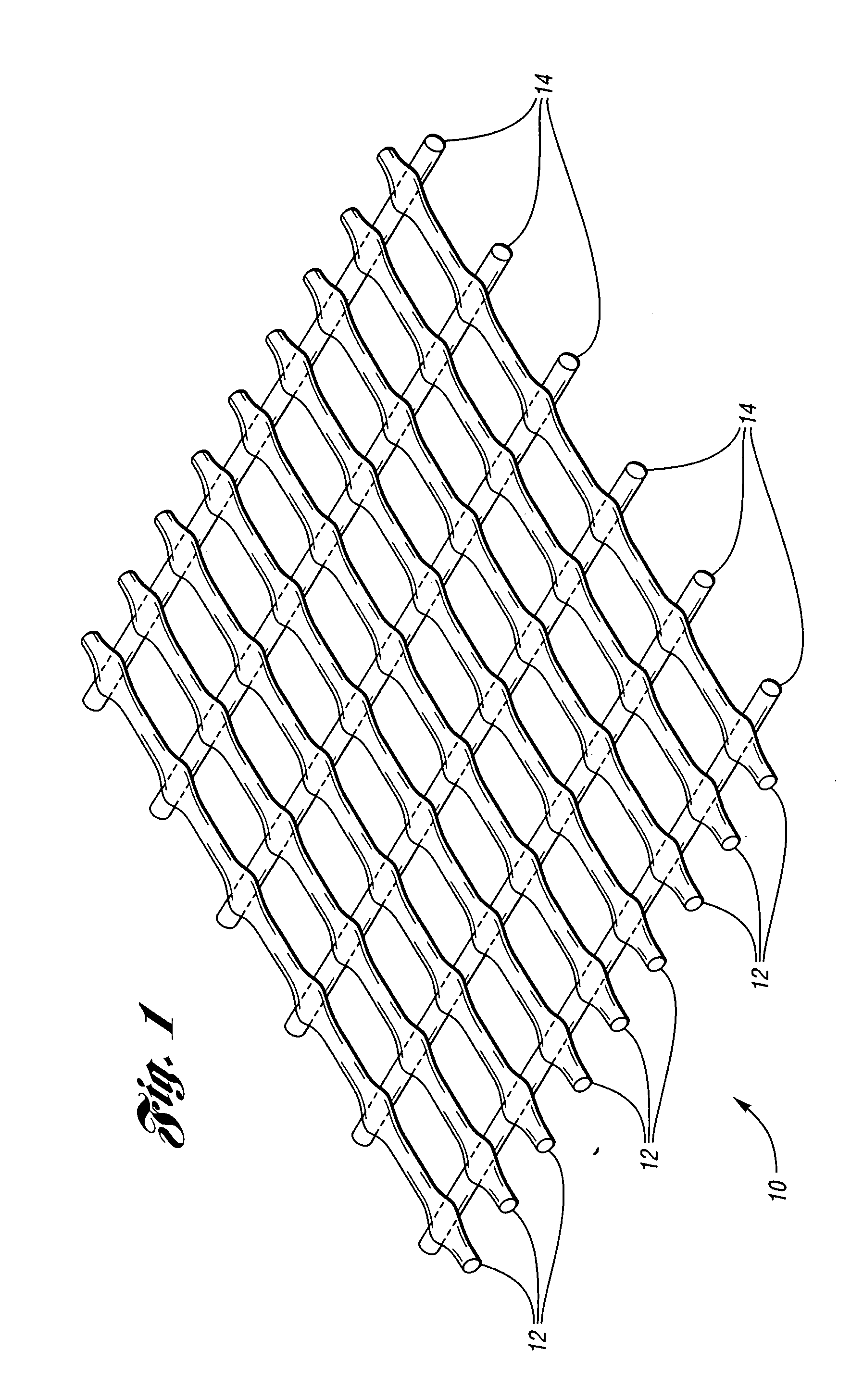

Biodegradable netting

The present invention provides a biodegradable extruded netting. The netting comprises a plurality of interconnected strands with at least some of the strands comprising a biodegradable composition comprising polylactic acid polymer and biodegradable plasticizer. In at least one embodiment, at least 10% of the strands are made of the biodegradable composition. The present invention also relates to a method for making biodegradable extruded netting. The method comprises extruding strands of polymeric material to form a netting wherein at least some of the strands are formed of the biodegradable composition.

Owner:CONWED PLASTICS

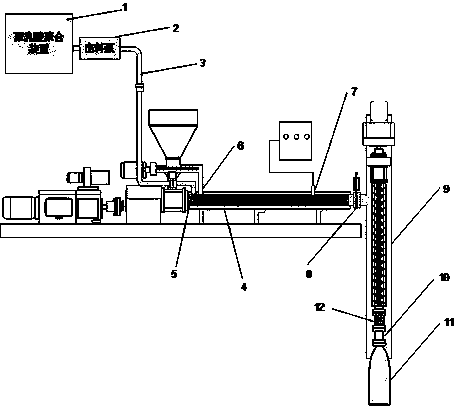

Method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt

InactiveCN101597814AEnsure color consistencyAvoid chromatic aberrationNon-woven fabricsPigment addition to spinning solutionFiberPolymer science

The invention relates to a method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt, belonging to the technical field of high polymer material application. The method comprises the following steps: conveying raw white polylactic acid polymer melt obtained from polymerization reaction in a polylactic acid polymerization reaction device to a melt mixing device through a termination device of the polylactic acid polymerization reaction device; mixing the raw white and colored polylactic acid melt in the melt mixing device to obtain colored polylactic acid mixed melt; leading the colored polylactic acid mixed melt into a spinning tank to be spun to obtain colored polylactic acid fiber. The method of the invention has the following advantages: avoiding causing chromatic aberration in the process of dying fiber or fabrics; saving energy, and preventing waste water generated by printing from polluting the environment; saving resources, and avoiding causing damage to the soil and water source after abandonment of the coloured polylactic acid fiber; providing technical guarantees for promotion and application of the polylactic acid fiber and products produced therewith.

Owner:恒天长江生物材料有限公司

Controlled release composition and method of producing the same

InactiveUS20030134800A1Suppressing initial excess releaseStable releasing speed for a long period of timeNervous disorderTetrapeptide ingredientsControlled release3-hydroxy-2-naphthoic acid

A controlled release composition containing a physiologically active substance in high content, suppressing the initial excess release, and achieving a stable release speed over a long period of time is provided. A controlled release composition comprising (1) a physiologically active substance or salt thereof in an amount of about 14% (w / w) to about 24% (w / w) based on the total composition weight, (2) hydroxynaphthoic acid selected from the group consisting of 3-hydroxy-2-naphthoic acid and 1-hydroxy-2-naphthoic acid or salt thereof, and (3) a lactic acid polymer or salt thereof having a weight-average molecular weight of 15000 to 50000 in which the content of polymers having molecular weights of 5000 or less is about 5% by weight or less, wherein the molar ratio of said hydroxynaphthoic acid or salt thereof to said physiologically active substance or salt thereof is from 3:4 to 4:3.

Owner:TAKEDA PHARMA CO LTD

High-strength absorbable wire composited internal fixation implantable device and preparation method thereof

InactiveCN102871715AHigh strength requirementsMeet mechanical safety requirementsInternal osteosythesisCoatingsHydrogenHigh intensity

The invention relates to a high-strength absorbable wire composited internal fixation implantable device and a preparation method of the device, in particular to an internal fixation implantable device taking high-strength magnesium alloy wires in high content as a basal body, wherein the high-strength magnesium alloy wires are bonded and cured at a high temperature by low-content binder polylactic acid polymers and are arranged in a directional dispersion way or in a two-dimension weaving structure or three-dimension weaving structure, and the binder polylactic acid polymers account for 5%-49.9% of the total amount and the magnesium alloy wires account for 50.1%-95% of the total amount according to the weight percentage. The high-strength absorbable wire composited internal fixation implantable device is closer to the magnesium alloy on the aspect of strength, can meet the mechanism safety requirements for large-load fracture fixation with higher strength requirement, and has the advantages of both controllable uniform internal absorption, slow and less hydrogen degradation and separation, etc., thereby being particularly applicable to clinics like departments of bone traumatology, department of bone defect repair, plastic and beauty operations and the like with high strength requirement and large size.

Owner:SOUTHEAST UNIV

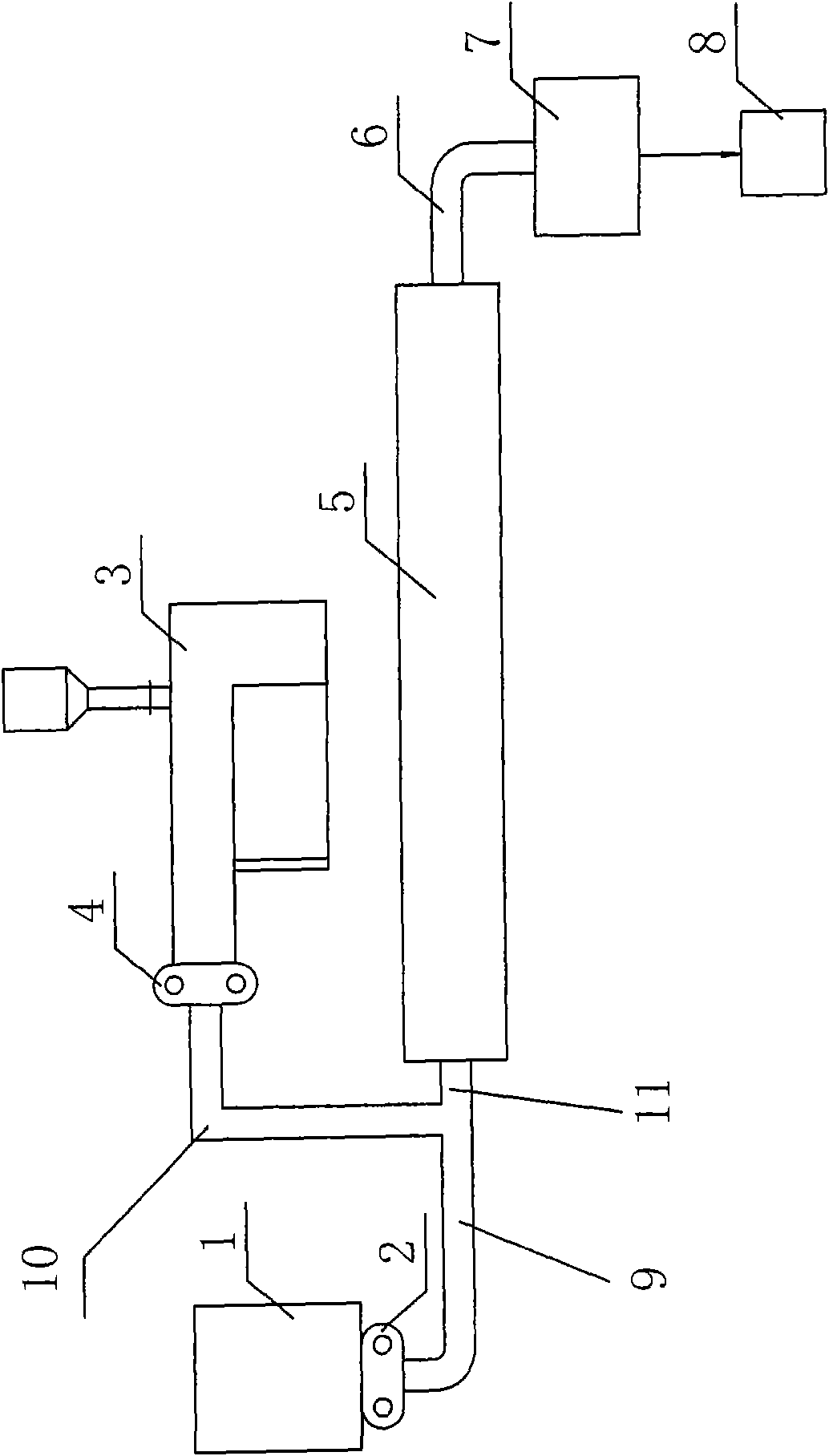

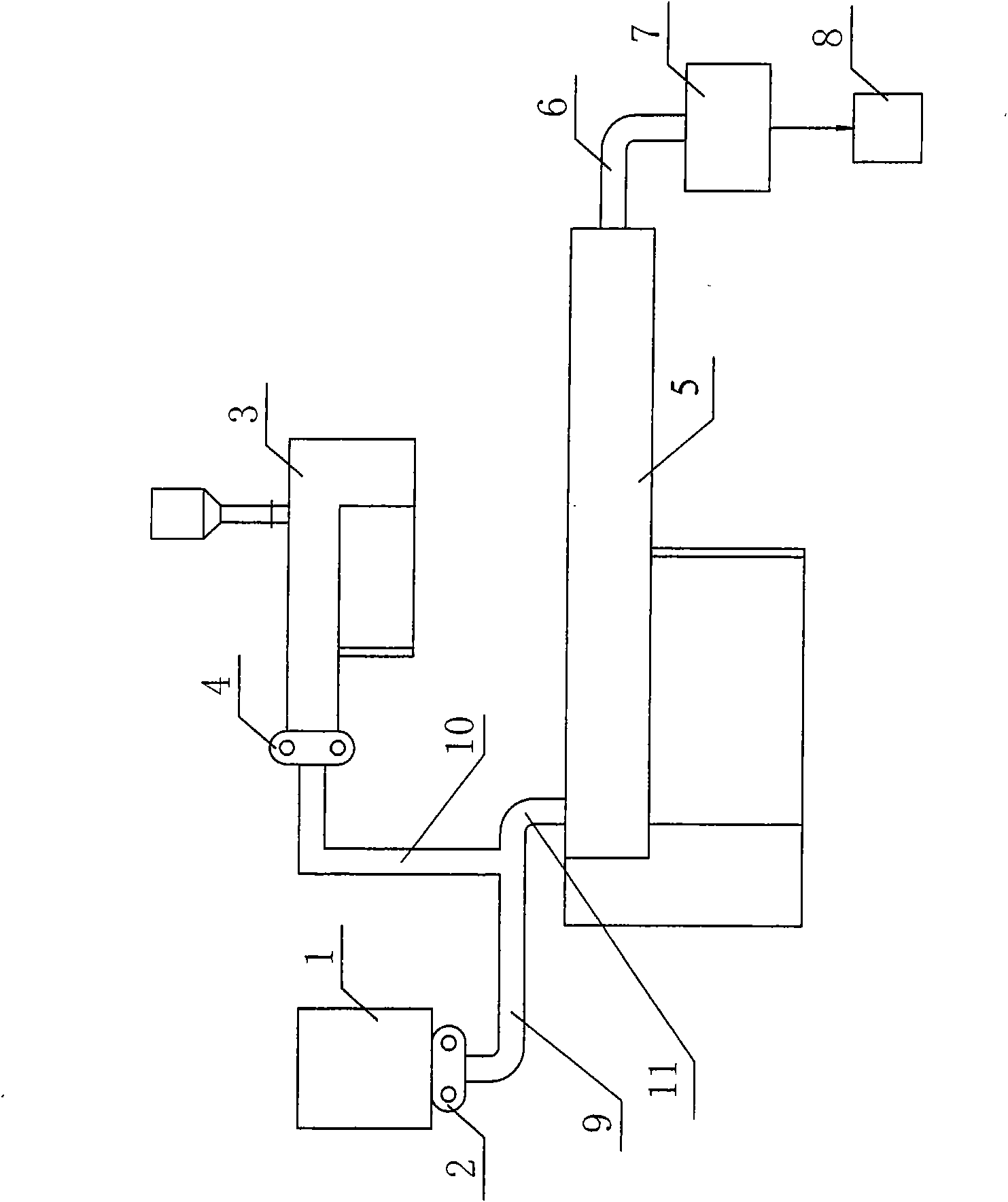

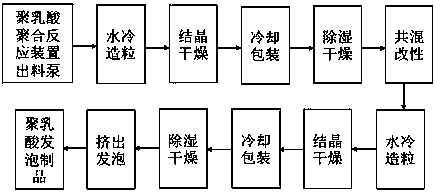

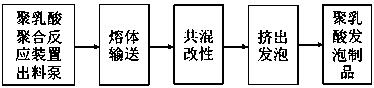

Method and device for directly preparing polylactic acid foam product from polylactic acid polymer melt

The invention provides a method and a device for directly preparing a polylactic acid foam product from a polylactic acid polymerization melt. The method and the device for directly preparing the polylactic acid foam product from the polylactic acid polymerization melt comprises the steps of polylactic acid melt preparation, material feeding and secondary extruding treatment. In the secondary extruding treatment, the outlet pressure of a first-stage double-screw extruder is 15-17 MPa, the material feeding speed of the polylactic acid polymerization melt is 250 kg / h, the foam auxiliary feedingspeed is 7.5-10 kg / h, and the foaming gas feeding speed is 2.8-7.5 L / h. The method and the device for directly preparing the polylactic acid foam product from the polylactic acid polymerization melt,provided by the invention, have the advantages that an influence on the foaming performance is avoided due to no need of processes such as water cooled pelletizing, repeated drying cooling and heating, melting and mixing; the foaming performance can be guaranteed; the quality can also be guaranteed; the energy consumption is saved by about 1 / 3 or above; the foaming multiplying power of an obtainedproduct is adjusted by 3-25 times; the degree of crystallinity is 40.3-48.5%; the tensile strength is 8.7-19.6 MPa; and the apparent density is 0.05-0.4 g / cm<3>.

Owner:CHTC BIO BASED MATERIAL ENG & TECH NINGBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com