Patents

Literature

51results about How to "Ensure color consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

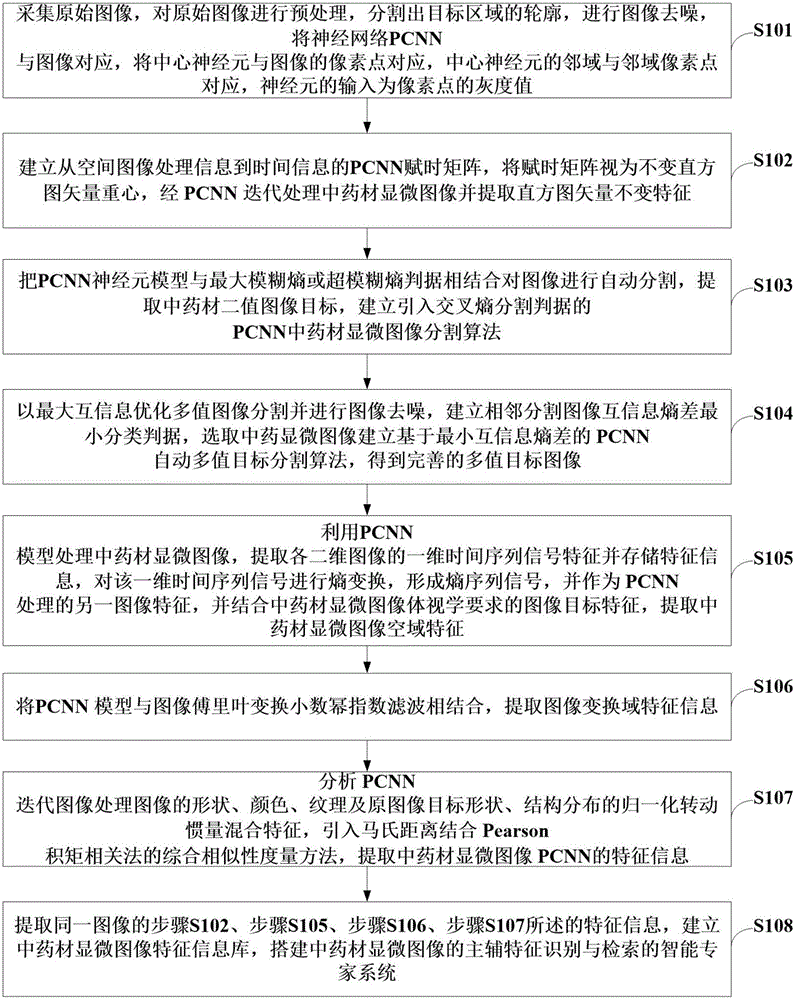

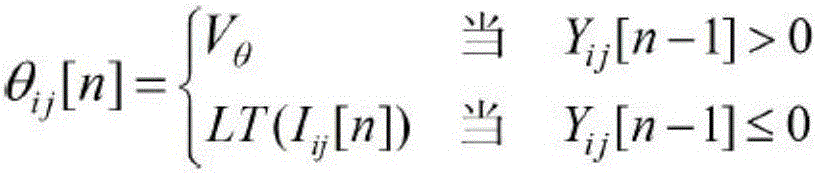

Chinese medicinal material microscopic image feature extraction and recognition retrieval method

InactiveCN106067026AEnsure color consistencyRecover high-frequency detail informationCharacter and pattern recognitionPhysical realisationInformation processingMicroscopic image

The invention discloses a Chinese medicinal material microscopic image feature extraction and recognition retrieval method. A PCNN time matrix information processing method is introduced, image feature information in a transform domain is extracted through combination of PCNN and image Fourier transform and decimal power exponent filtering phase, and a Chinese medicinal material microscopic image information rapid storage and recognition retrieval method is put forward on the basis of mahalanobis distance with combination of comprehensive similarity measure of a Pearson product moment correlation method so that a holographic Chinese medicinal material microstructure image and pollen image feature extraction and recognition retrieval system is constructed, objectivity, accuracy, repeatability and intelligent degree of Chinese medicinal material quality evaluation can be further enhanced, and a new approach is provided for modernization of Chinese medicinal material detection and analysis.

Owner:TIANSHUI NORMAL UNIV

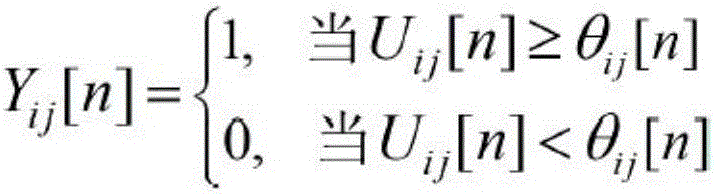

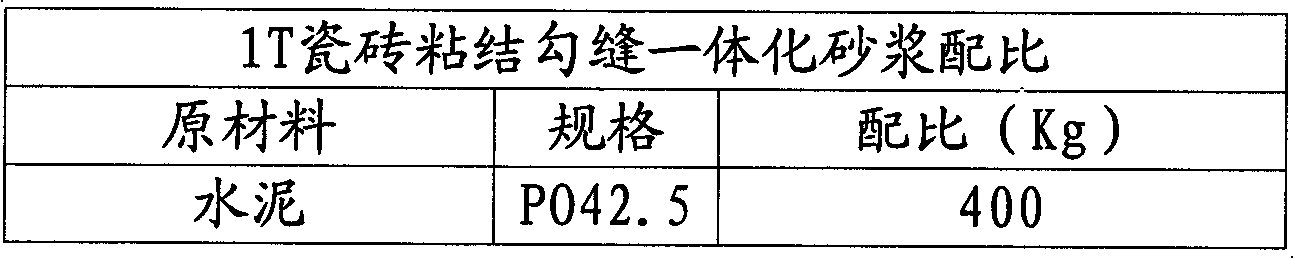

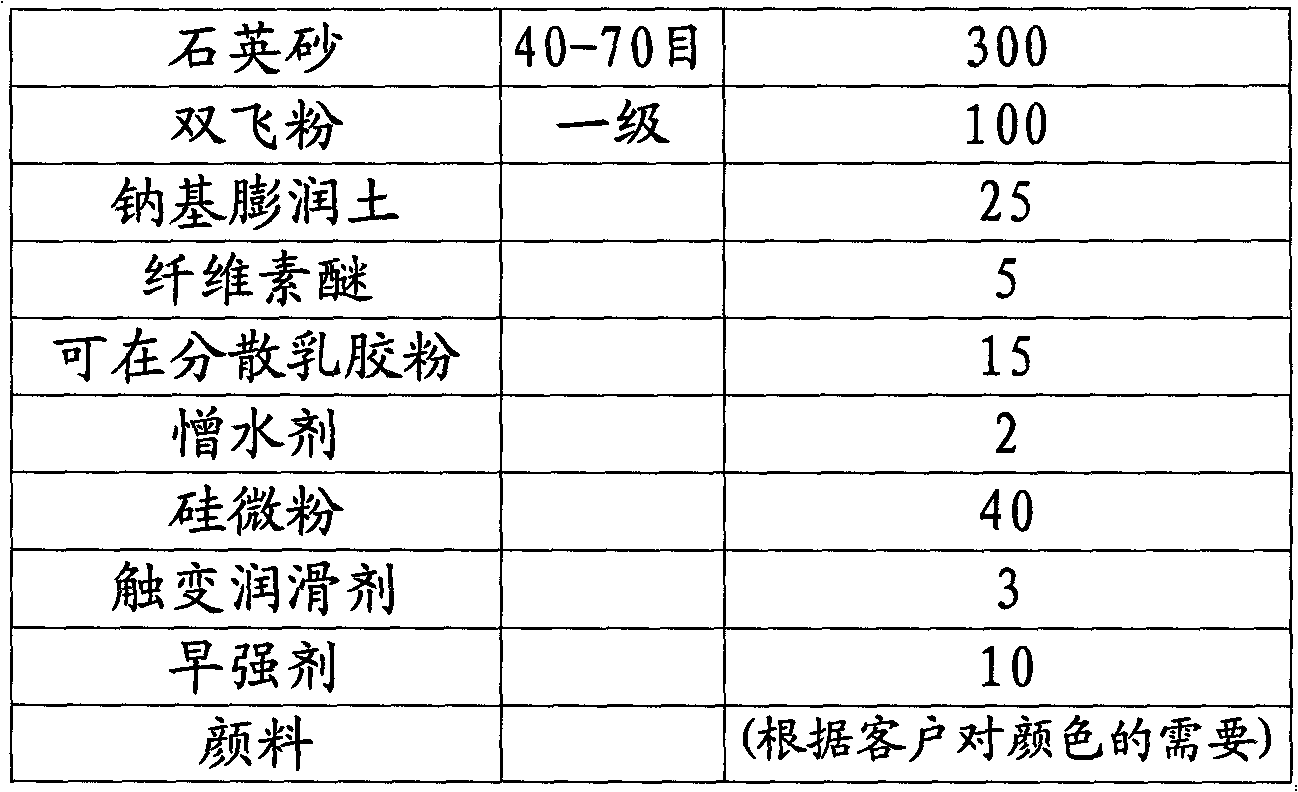

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

Method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt

InactiveCN101597814AEnsure color consistencyAvoid chromatic aberrationNon-woven fabricsPigment addition to spinning solutionFiberPolymer science

The invention relates to a method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt, belonging to the technical field of high polymer material application. The method comprises the following steps: conveying raw white polylactic acid polymer melt obtained from polymerization reaction in a polylactic acid polymerization reaction device to a melt mixing device through a termination device of the polylactic acid polymerization reaction device; mixing the raw white and colored polylactic acid melt in the melt mixing device to obtain colored polylactic acid mixed melt; leading the colored polylactic acid mixed melt into a spinning tank to be spun to obtain colored polylactic acid fiber. The method of the invention has the following advantages: avoiding causing chromatic aberration in the process of dying fiber or fabrics; saving energy, and preventing waste water generated by printing from polluting the environment; saving resources, and avoiding causing damage to the soil and water source after abandonment of the coloured polylactic acid fiber; providing technical guarantees for promotion and application of the polylactic acid fiber and products produced therewith.

Owner:恒天长江生物材料有限公司

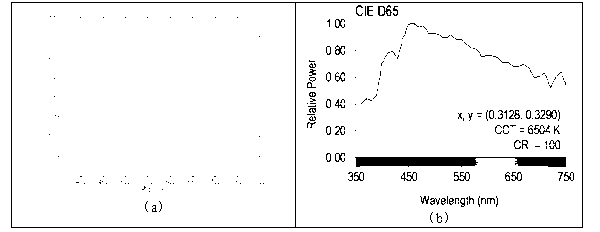

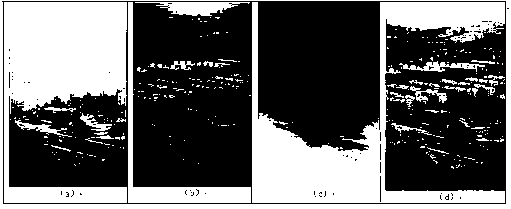

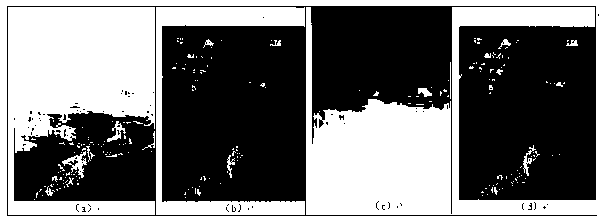

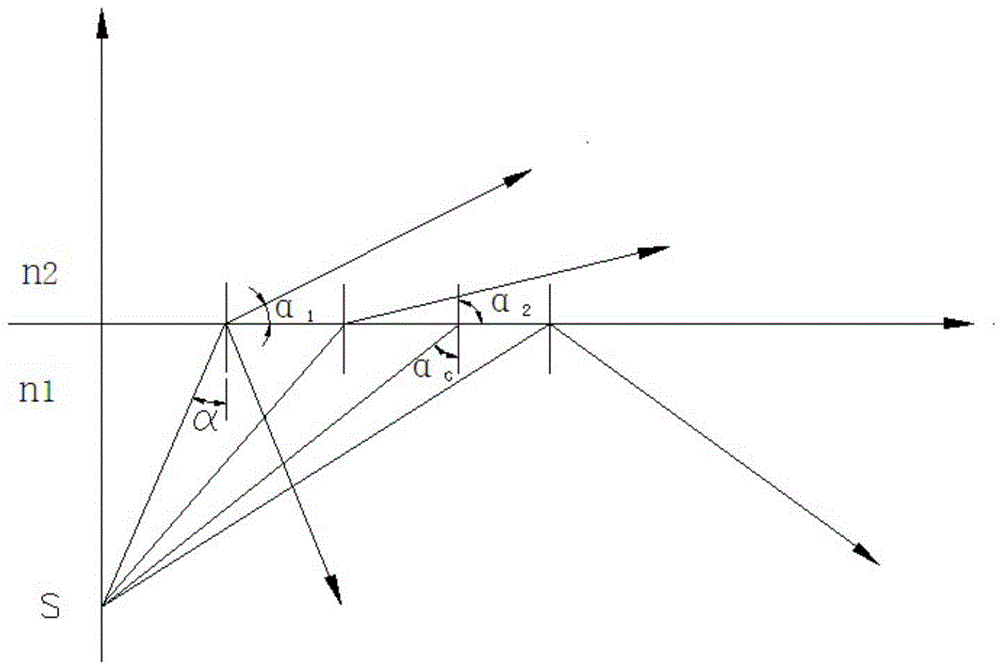

Defogging strengthening method for transmissivity/dark channel prior based on spectral characteristic

The invention discloses a defogging strengthening method for transmissivity / dark channel prior based on a spectral characteristic, belonging to the field for processing images and visual effects of computers. The method comprises the steps of: (1) solving a visual perceptual stimuli weight matrix of human eyes for an RGB (Red Green Blue) image; (2) calculating the visual perceptual stimuli weight matrix of the human eyes of three transmissivity channels under three independent spectral wavelength ranges; (3) solving the three corresponding transmissivity channels Tc (x, y); (4) solving a value Ac of atmospheric lights in transmissivity space so as to solve a defogging restored map Jc (x, y) and in a diffusion map t (x, y) in the transmissivity space Tc (x, y); and (5) solving an enhancement coefficient matrix C0 in the three transmissivity channels so as to form a defogging image J<RGB> (x, y) finally. Experiment shows that visuality of the images can be obviously improved by using the method provided by the invention.

Owner:NANJING UNIV

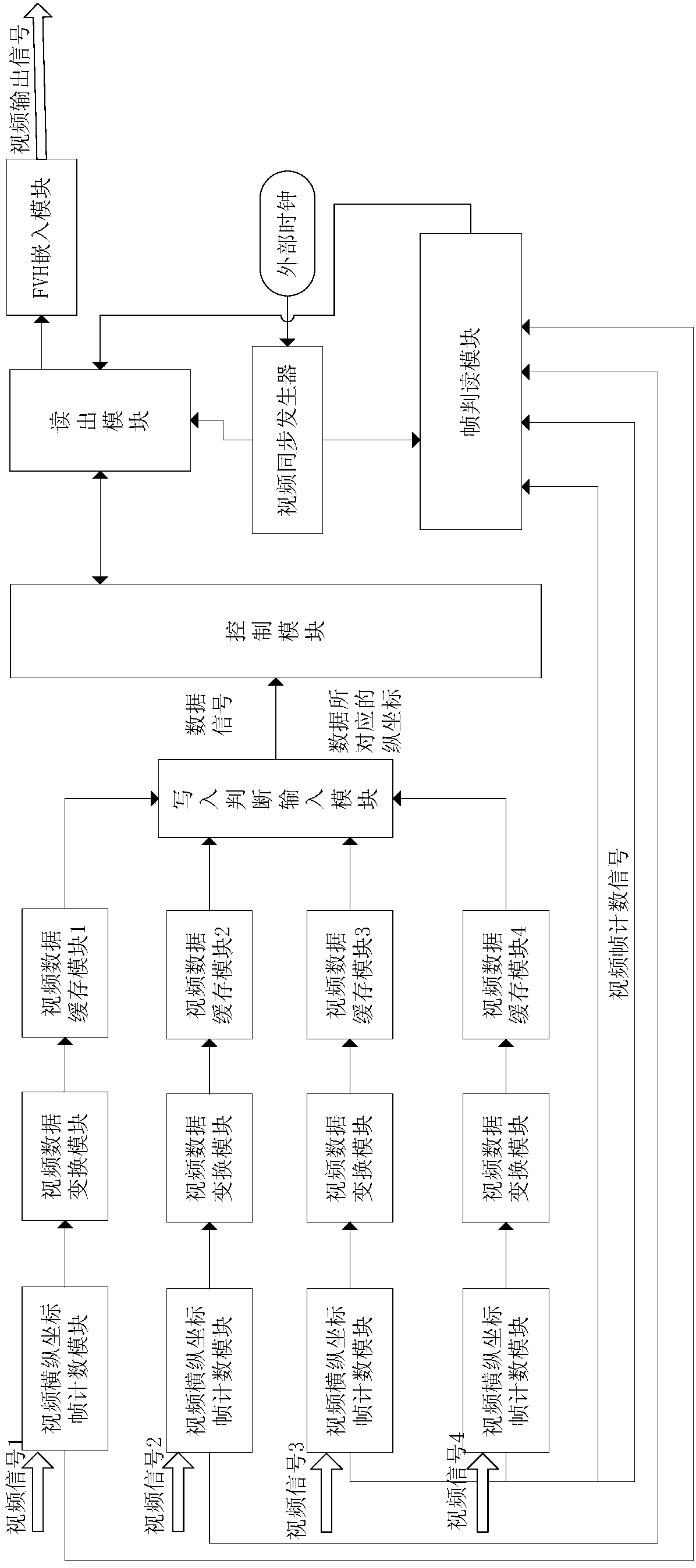

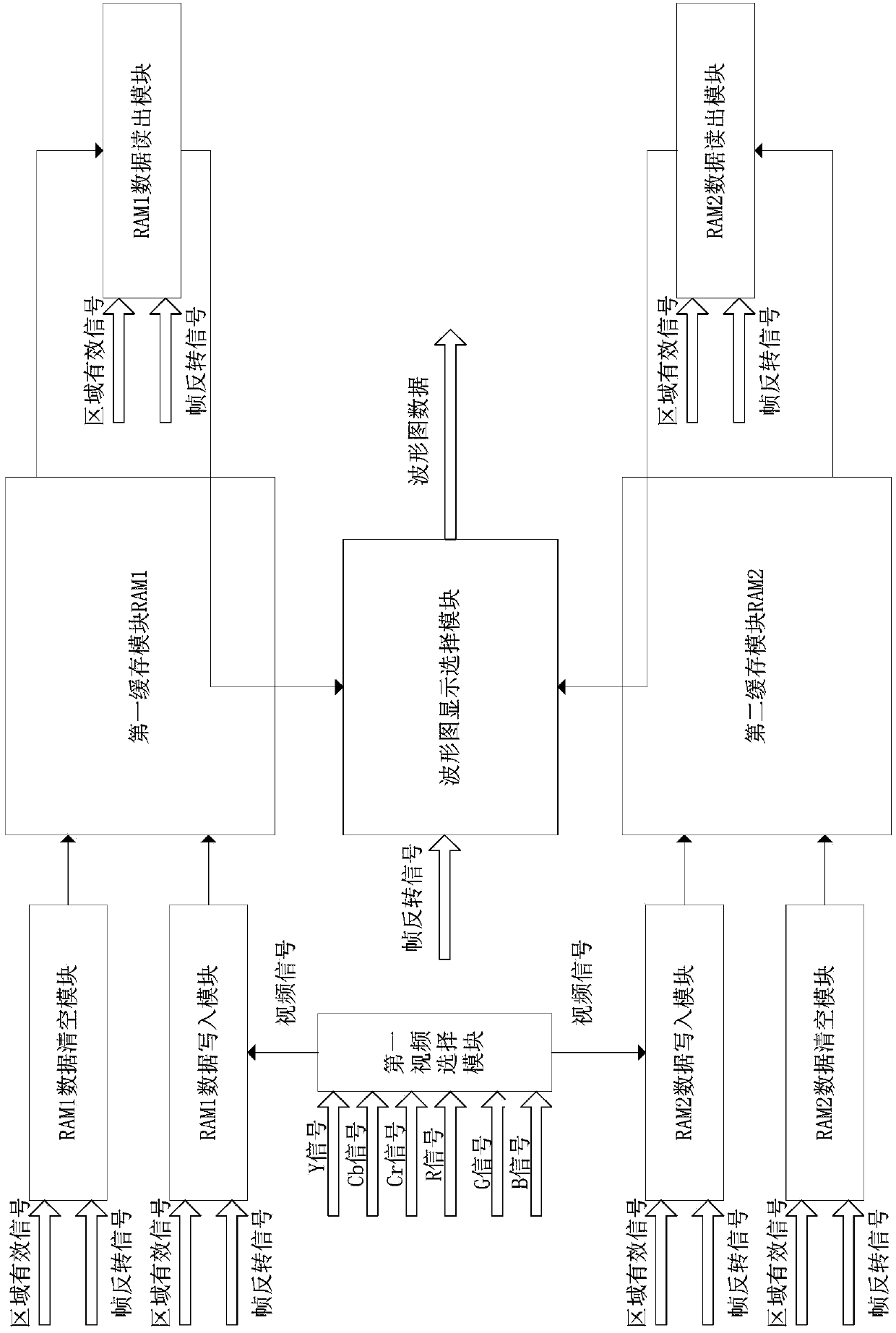

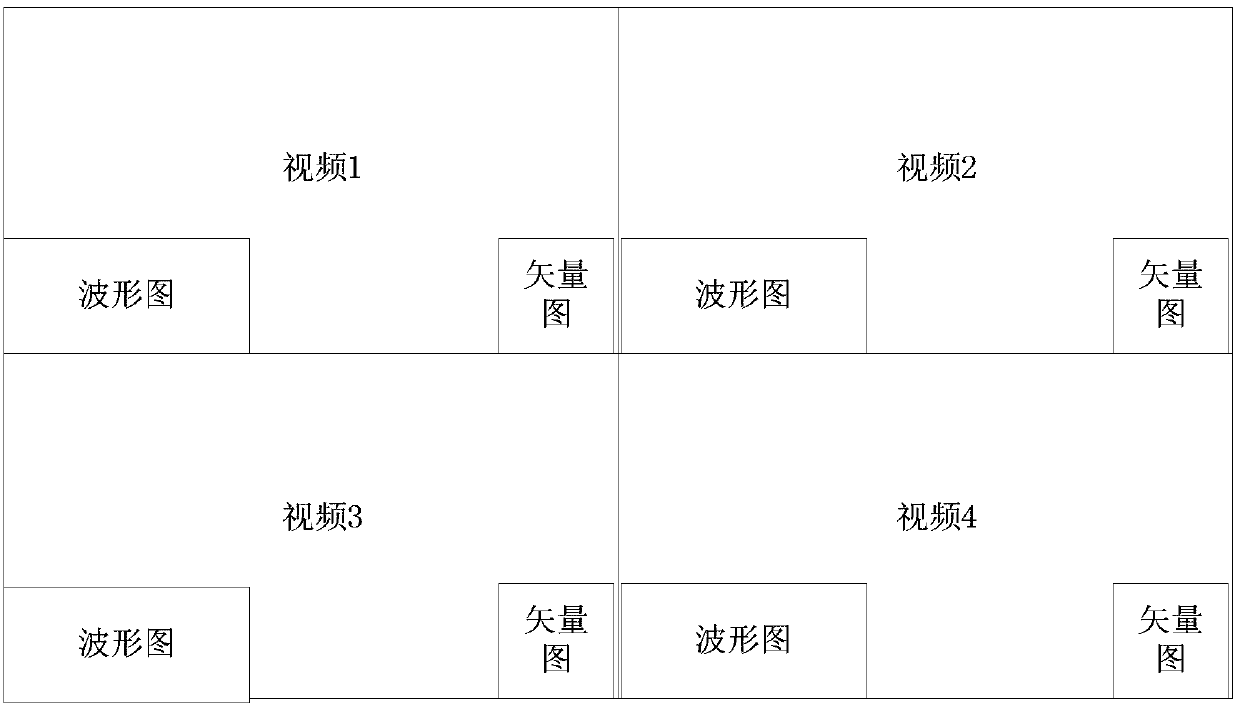

Broadcast level monitor and monitoring picture generating method

ActiveCN104735297AEnsure color consistencyHigh speedTelevision system detailsColor television detailsWaveform analysisVIT signals

The invention provides a broadcast level monitor. The broadcast level monitor comprises a signal receiving module, an FPGA video picture processing module, a display screen driving module and a display screen which are arranged in sequence, and the FPGA video picture processing module is connected with a memory module; the FPGA video picture processing module comprises a signal conversion module, a video stitching module, a video region dividing module, an waveform diagram generating module, a vector diagram generating module and an alpha aliasing module. And a monitoring picture generating method is further provided. According to the broadcast level monitor, the waveform analysis conducted on four SDI signals at the same time and the display conducted on the four SDI signals at the same time on one monitor are achieved, so that the consistency of the color of four pictures is guaranteed; by the adoption of the FPGA field-programmable gate array, parallel processing conducted on the four SDI signals is achieved, the speed is fast, the peripheral devices are few, the structure is simple, and the cost is low.

Owner:SWIT ELECTRONICS

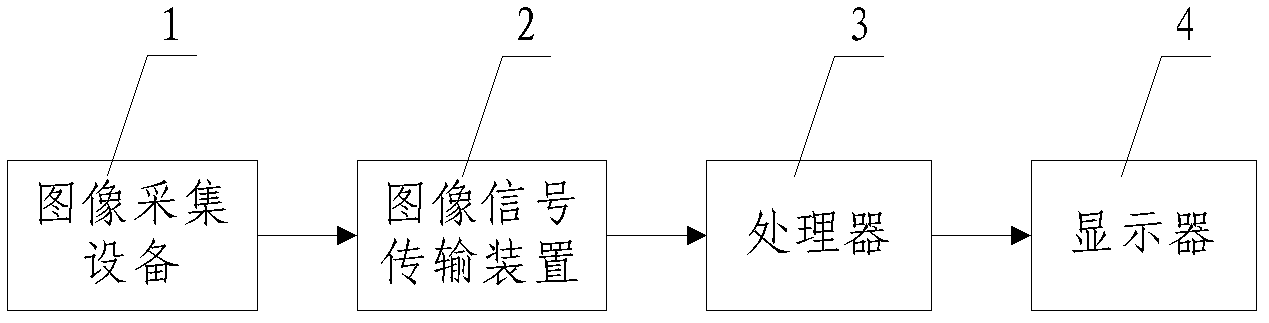

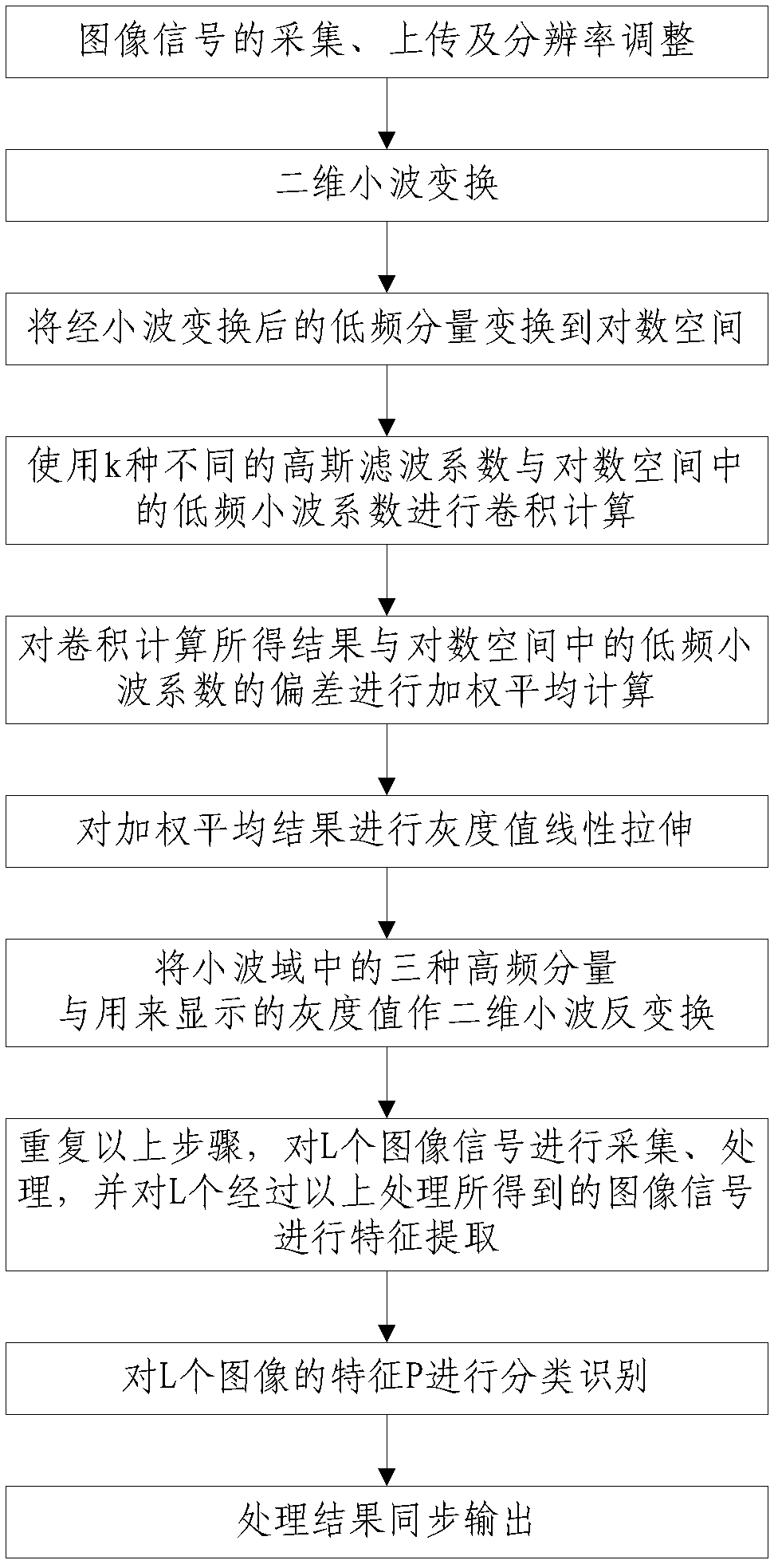

An Image Feature Extraction Method with Illumination Robustness

InactiveCN102289670AReasonable method designEasy to implementCharacter and pattern recognitionFeature extractionImage resolution

The invention discloses an image characteristic extraction method with illumination robustness. The method comprises the following steps of: 1, collecting and uploading image signals, and adjusting resolution; 2, extracting image characteristics: carrying out two-dimensional wavelet transformation, transforming a low-frequency component after the two-dimensional wavelet transformation in a logarithm space, carrying out convolution calculation by using k Gaussian filter coefficients and low-frequency wavelet coefficients in the logarithm space, carrying out weighted average on a deviation between a convolution result and a low-frequency wavelet coefficient in the logarithm space, carrying out grey value linear stretching on the weighted average result, carrying out the two-dimensional wavelet inverse transformation of three high-frequency coefficients in a wavelet domain and the grey values to be displayed, repeating the steps, collecting and processing L image signals, and extracting the characteristics of the processed image signals; and 3, synchronously outputting processing results. The method disclosed by the invention has the advantages of rational design, convenience for realizing, low investment cost, simpleness and convenience for operation, good image processing effect and strong practicability. The illumination transformation robustness is increased.

Owner:CHANGAN UNIV

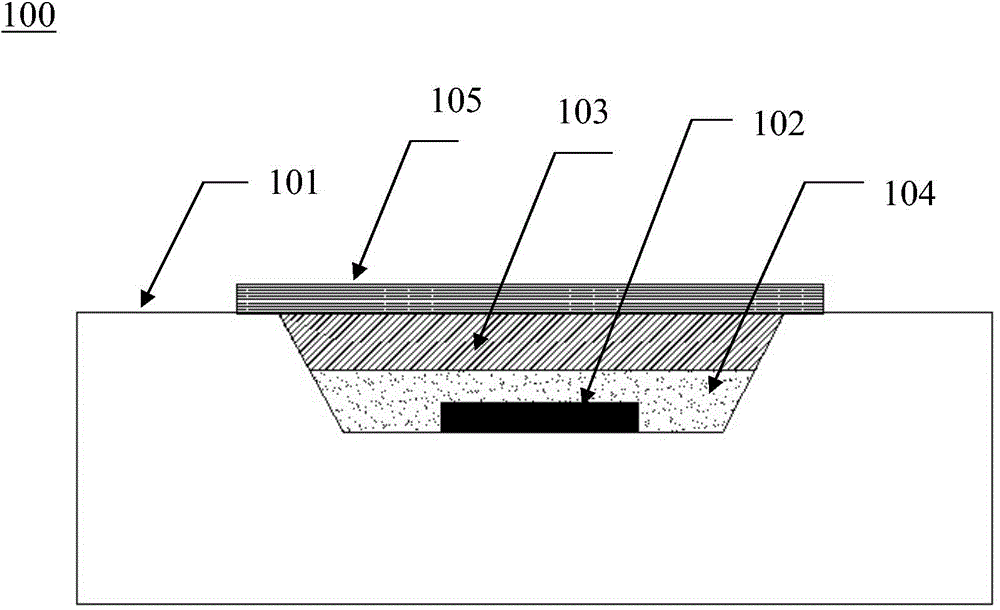

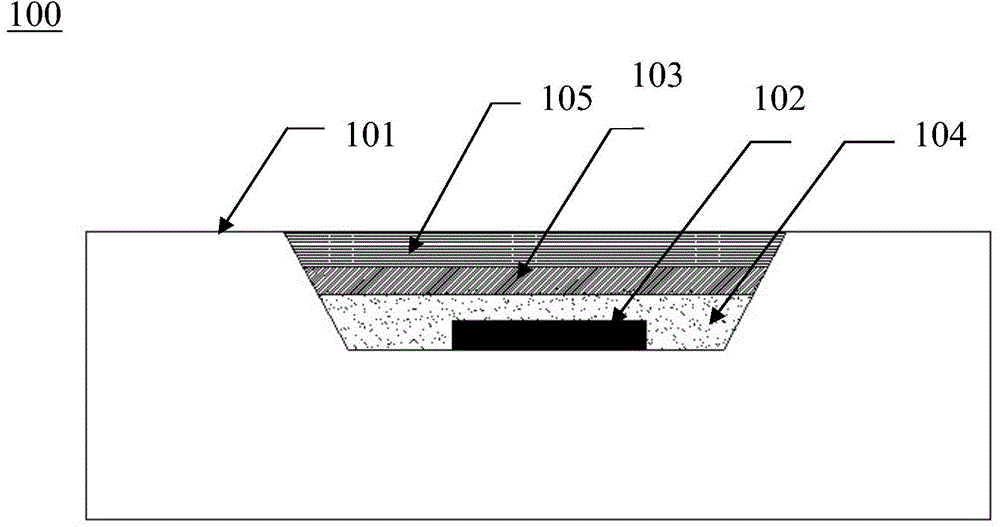

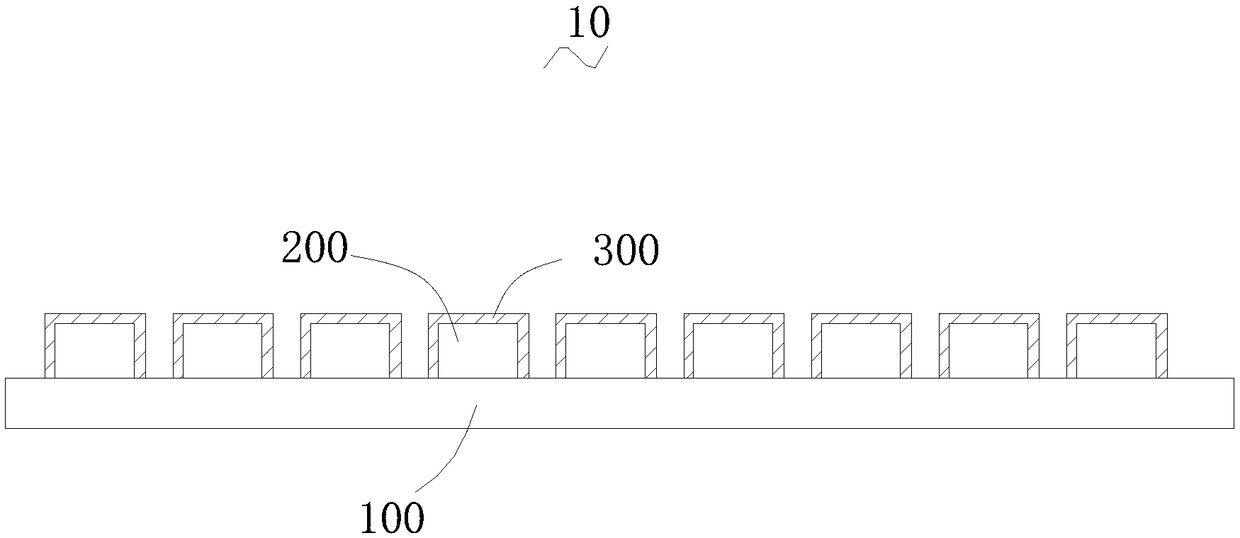

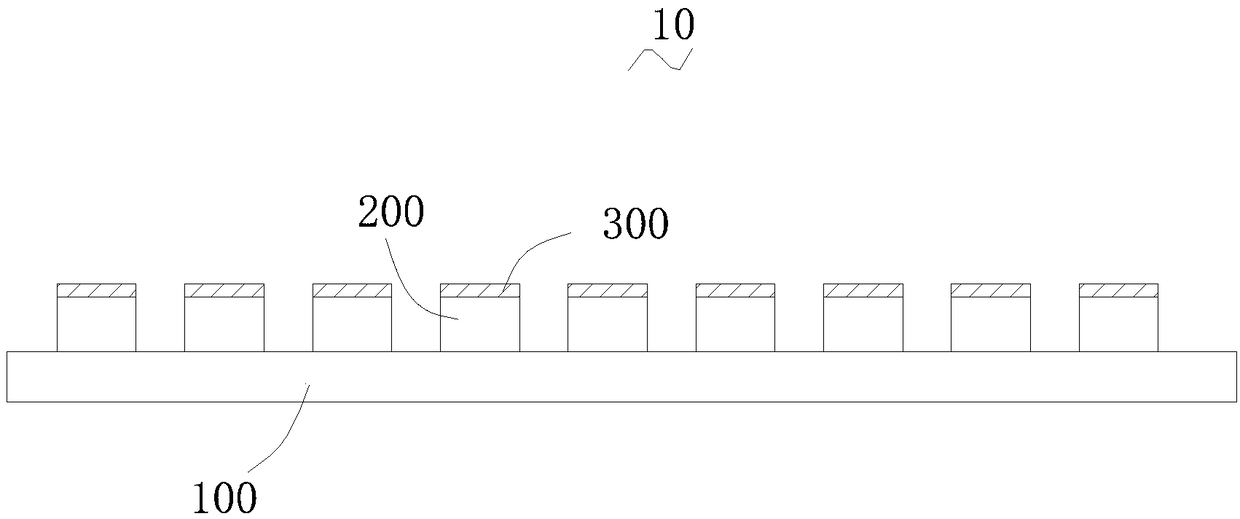

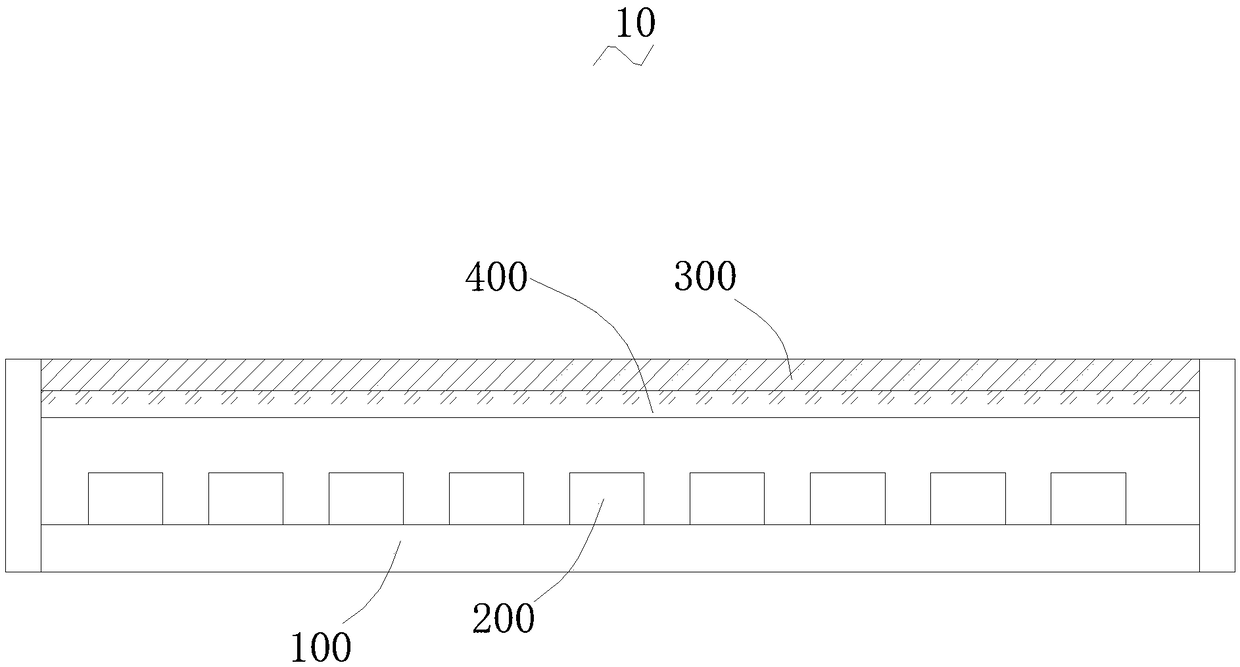

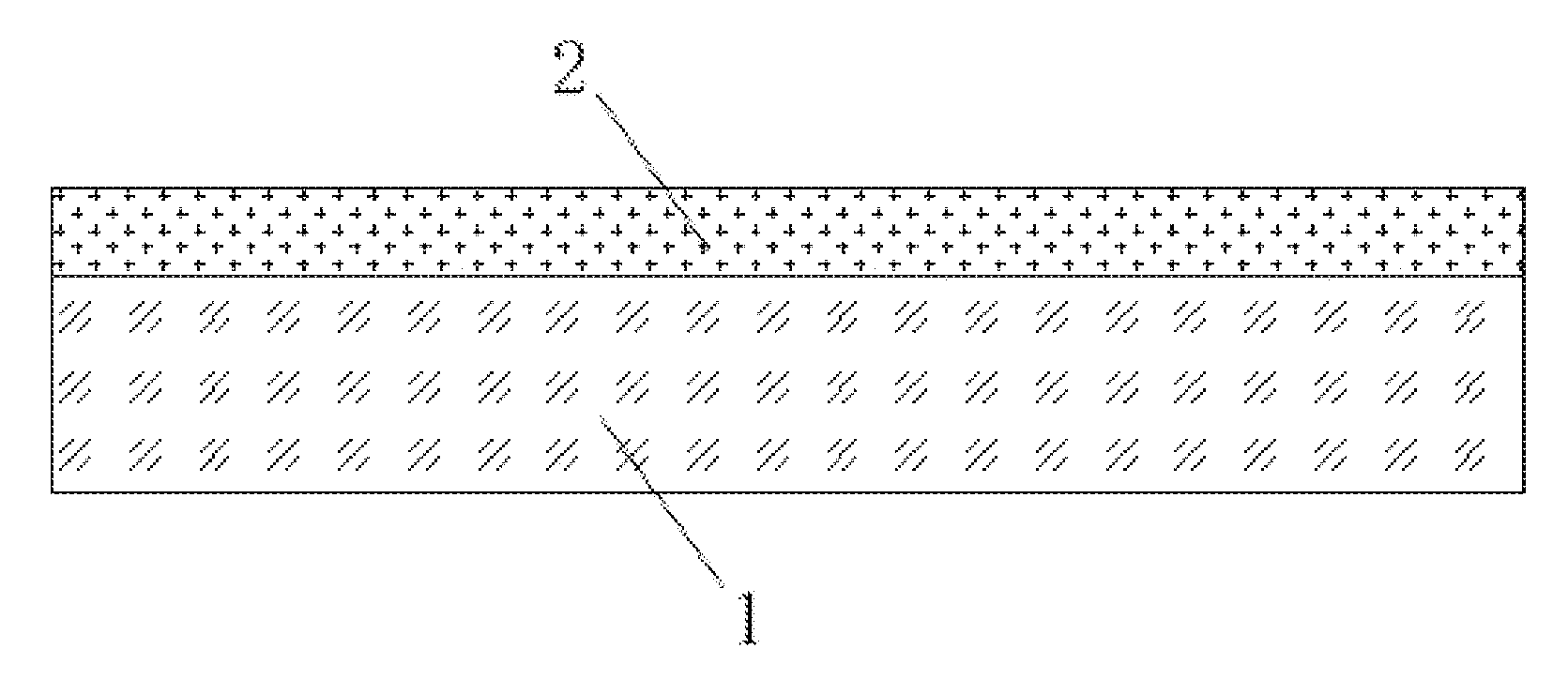

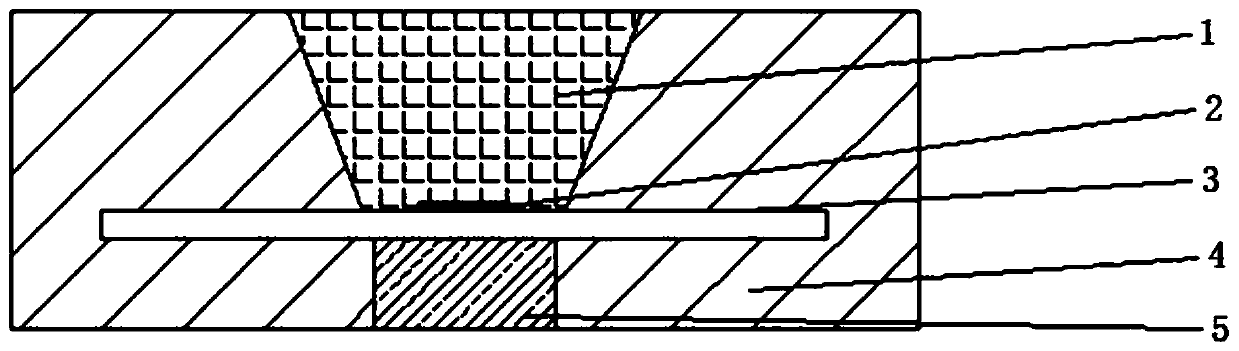

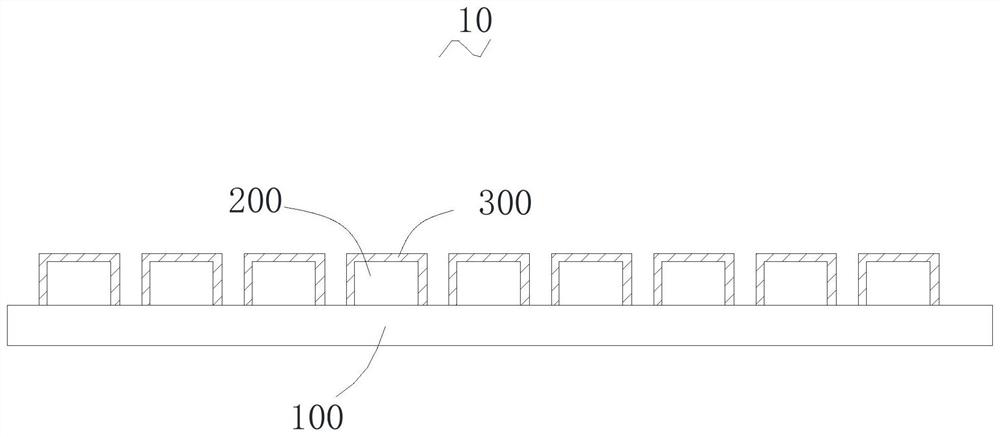

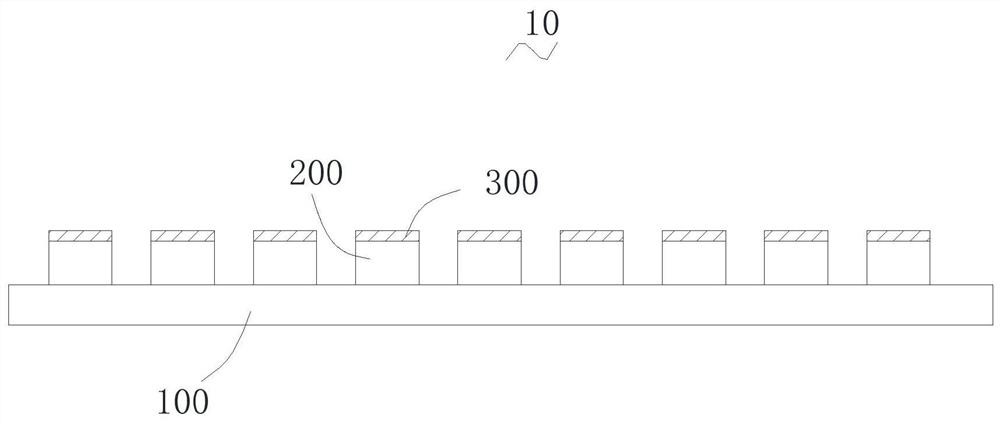

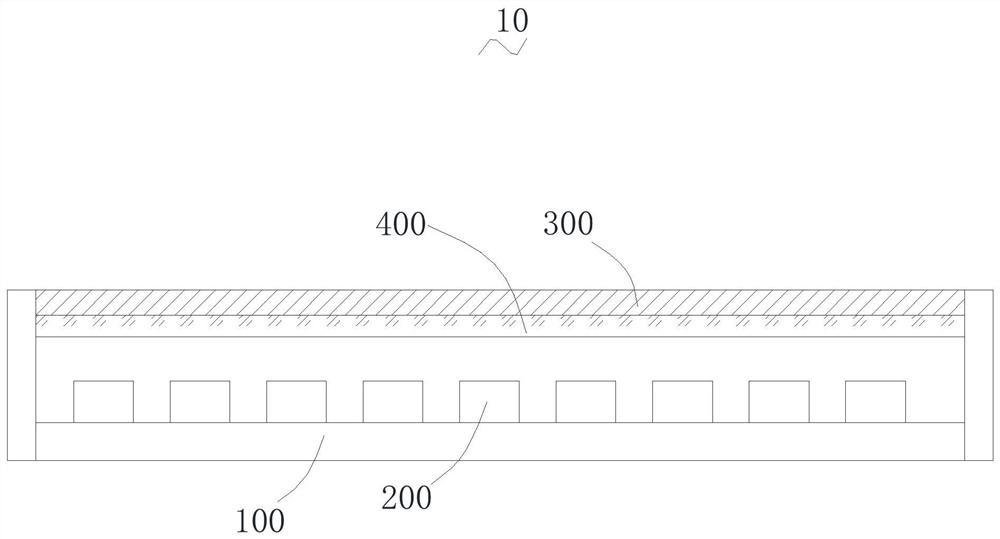

LED light-emitting device and manufacturing method thereof

ActiveCN105097999AImprove light outputLow refractive indexSemiconductor devicesRefractive indexOrganic layer

The invention relates to an LED light-emitting device and a manufacturing method thereof. The LED light-emitting device comprises a substrate, an LED chip, and an organic layer, wherein the LED chip and the organic layer are arranged on the substrate. The LED light-emitting device is characterized in that a refractive index buffer layer is arranged between the LED chip and the organic layer and is provided with a refractive index between the refractive index of the LED chip and the refractive index of silica gel; the refractive index buffer layer introduces light emitted by the LED chip into the organic layer in order to more light may pass through the organic layer; the organic layer is covered with a non-uniform luminescent powder layer including at least two luminescent powder layers arranged in a layered manner, wherein the two luminescent powder layers have different types of luminescent powders or the same type of luminescent powders with different particle sizes; the luminescent powders with the same type or same particle sizes of the luminescent powder layers are uniformly arranged; the luminescent powders with different types or different particle sizes are arranged relatively non-uniformly.

Owner:SICHUAN SUNFOR LIGHT

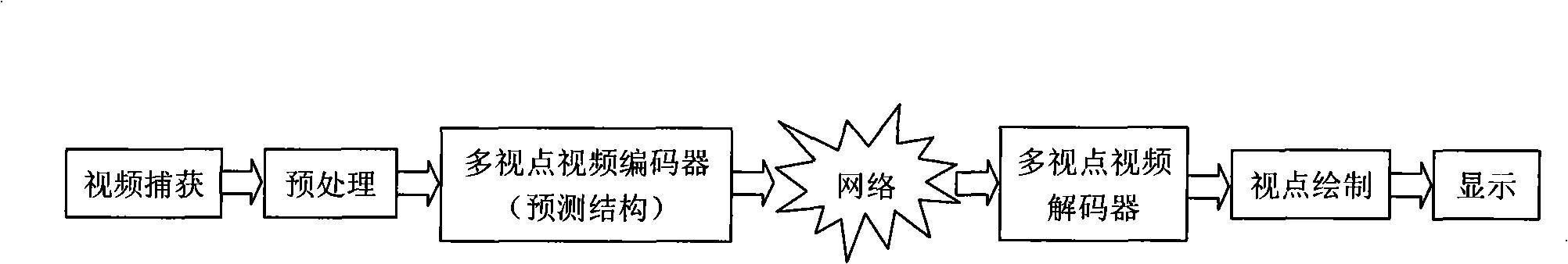

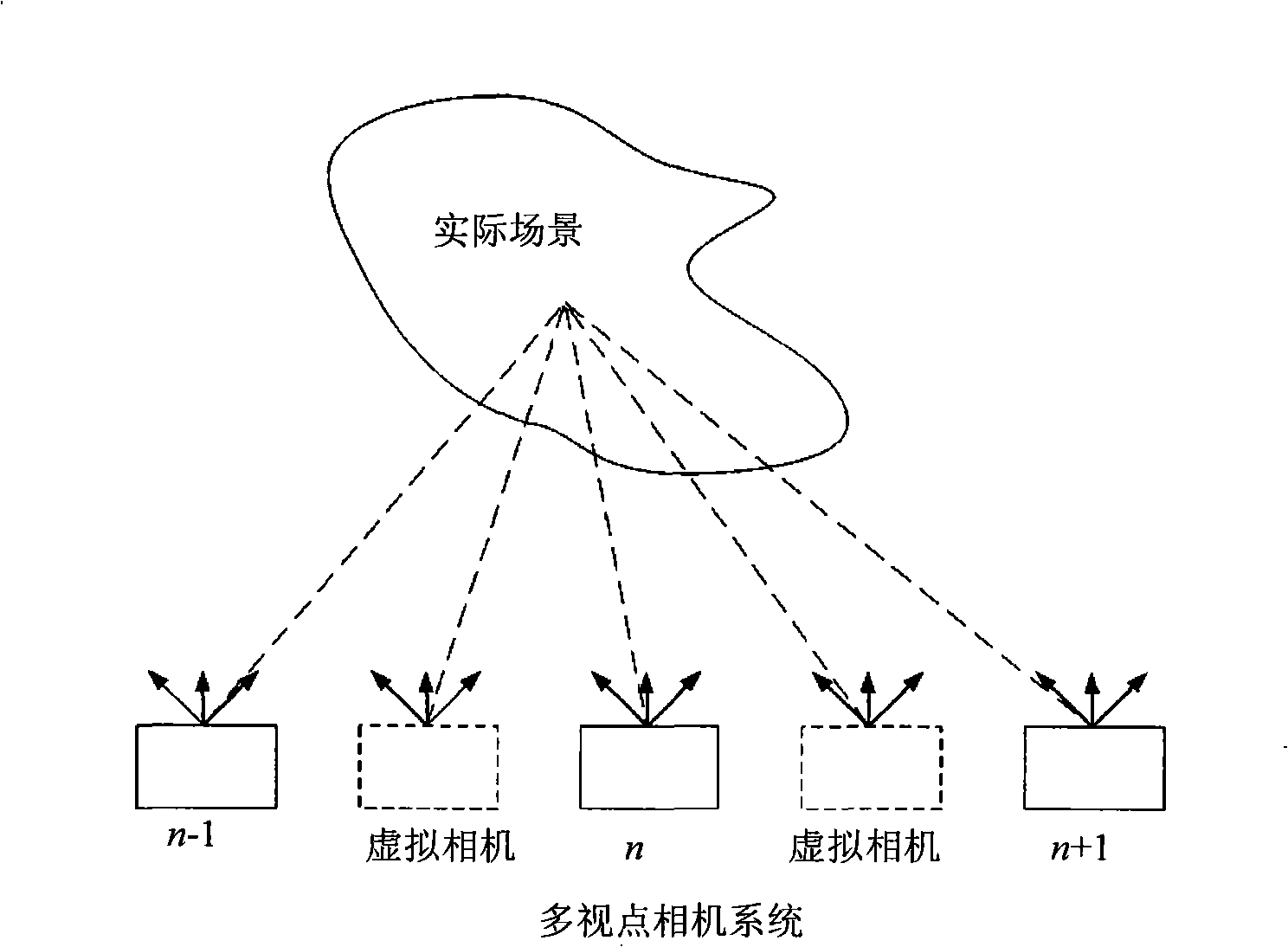

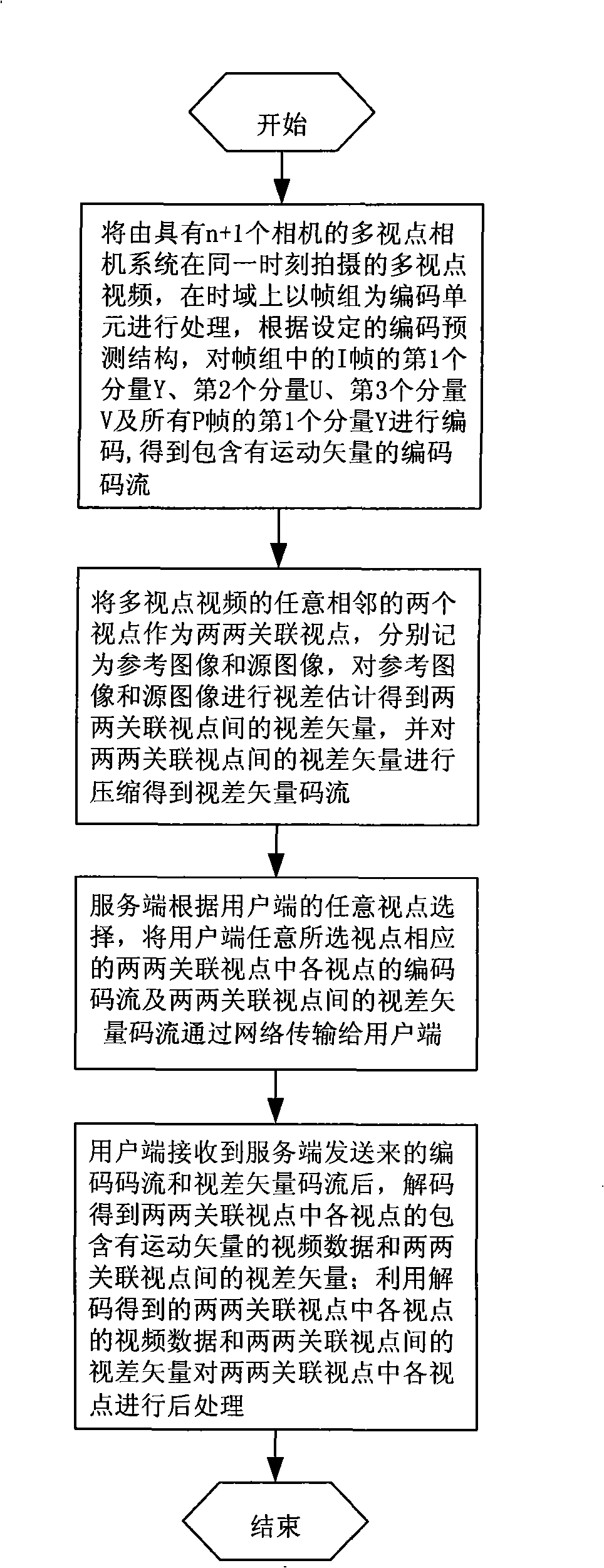

Interactive multi-view point video encoding method

InactiveCN101404765AImprove efficiencyImprove encoding speedTelevision systemsDigital video signal modificationParallaxVideo encoding

The invention discloses an interactive multi-view video encoding method. By discarding the chromaticity component of all P frames in the encoding process, the encoding compression efficiency and the encoding speed of the multi-view video are increased, and the transmission amount of the encoding stream which is transmitted by a server to a client end is reduced; colorization operation is carried out on all the P frames by using motion vector information of adjacent frames, thus reconstructing the chromaticity component information of the P frames accurately; at the client end, multiplicative error and additive error are calculated by using parallax vector information, thus realizing that the color of the image after decoding and reconstructing is corrected by using the multiplicative error and the additive error, ensuring color consistency among the view points and realizing the application of the interactive multi-view video.

Owner:上海贵知知识产权服务有限公司

Display screen

ActiveCN109244223AEnsure color consistencyAvoid the Modular EffectSolid-state devicesIdentification meansColor changesElectrical and Electronics engineering

The invention relates to a display screen, comprising a substrate and a plurality of light-emitting units, wherein each of the light-emitting units is arranged on the substrate, a thermochromic ink layer is arranged on the light-emitting unit, and the thermochromic ink layer is used for changing from a colored state to a transparent state when the temperature of the thermochromic ink layer reachesa color-changing temperature. The invention ensures that the display screen keeps the color consistency of the rest screen state, avoids affecting the brightness of the display screen when the display screen is bright, and can effectively improve the ink jet efficiency.

Owner:UNILUMIN GRP

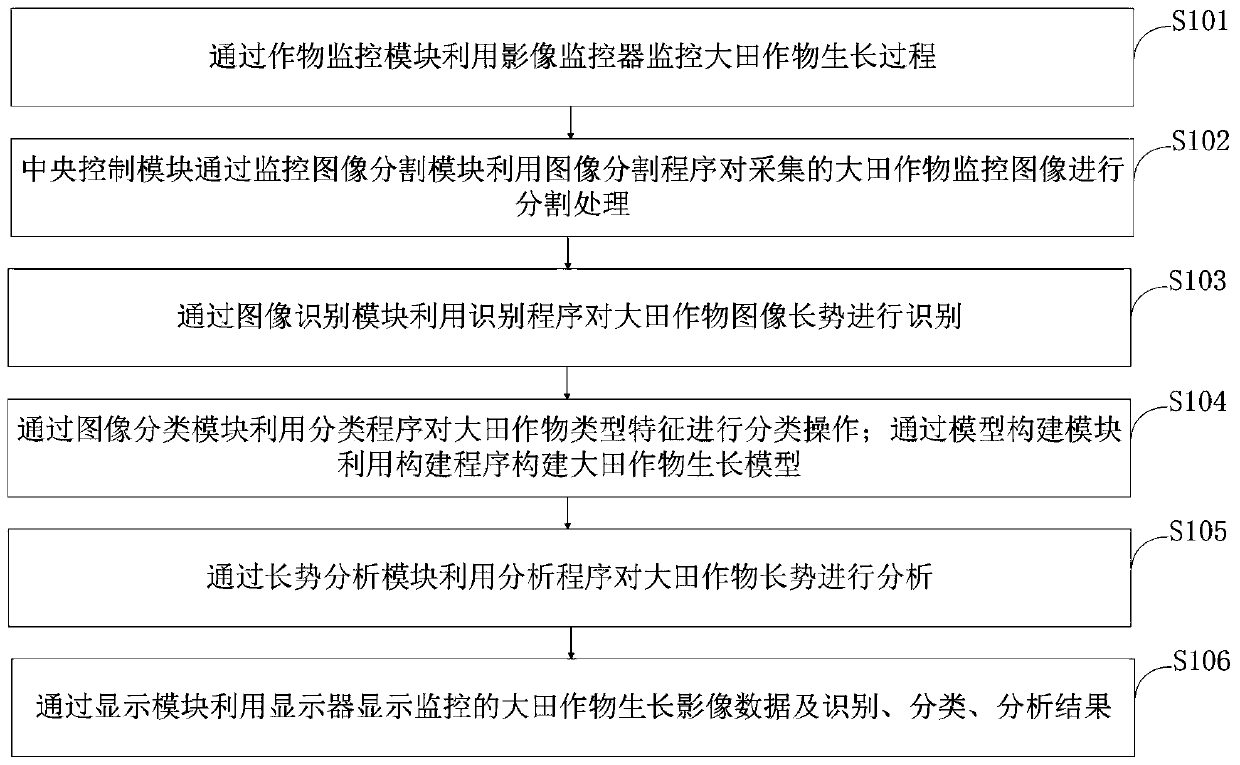

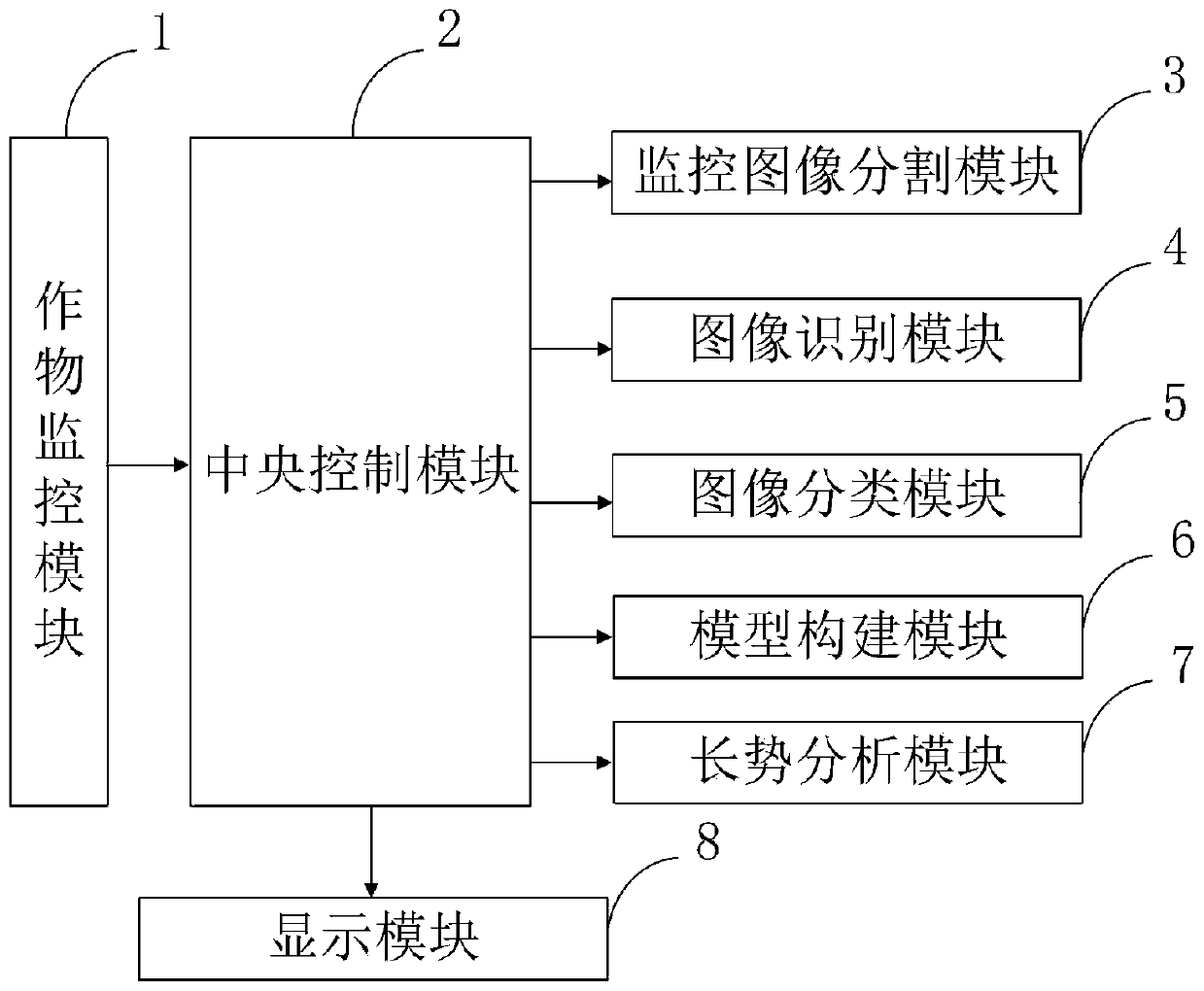

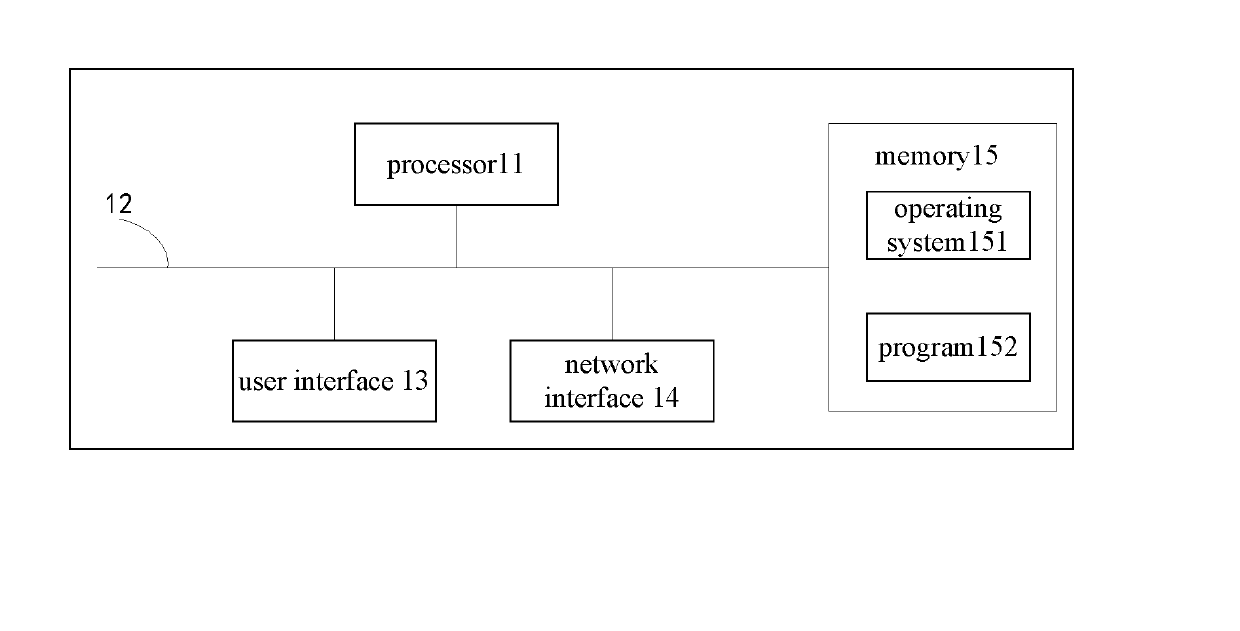

Method and system for identifying green plants in field crop growth monitoring image

PendingCN110532936ASolve human errorAccurate guidanceForecastingCharacter and pattern recognitionField cropImage segmentation

The invention belongs to the technical field of field crop growth monitoring. The invention discloses a method and a system for identifying green plants in a field crop growth vigor monitoring image.An image monitor is used for monitoring the growth process of field crops, a monitoring image segmentation module is used for carrying out segmentation processing on collected field crop monitoring images through an image segmentation program, an identification program is used for identifying the growth vigor of the field crop images, and a classification program is used for carrying out classification operation on field crop type characteristics; constructing a field crop growth model by using the construction program, and analyzing the growth vigor of the field crops by using the analysis program. The crop growth model is established, the relevance among the natural environment variable, the artificial variable and the growth state in the crop growth process is analyzed, the problem of manual misoperation in the crop planting process is solved on the basis of facts, and agricultural production is guided more accurately.

Owner:李清华

Dyeing technology for wood veneer/batten

ActiveCN105946078AEnsure color consistencyMeet needsWood compressionWood treatment detailsWood veneerManufacturing technology

The invention belongs to the technical field of wood veneer / batten manufacturing, and particularly relates to a dyeing technology for a wood veneer / batten. The dyeing technology solves the problem that the existing technology is not reasonable in design and the like. The dyeing technology for the wood veneer / batten comprises the following steps that A, separation is conducted; B, kiering is conducted; C, dyeing is conducted; D, water is removed; F, drying is conducted; and F, post-treatment is conducted. The dyeing technology has the beneficial effects that firstly, removing resin oil, a mineral line, spots, cracks and the like is the purpose of kiering, the color required by a customer is achieved, the color of the wood veneer is whiter and whiter, and the hand feeling is more comfortable and softer; secondly, the technology is simple and easy to control; thirdly, the quality and structural stability of products are improved, and practicability is higher; and fourthly, the dyeing quality is improved.

Owner:JIASHAN JIUSHUN WOOD CO LTD

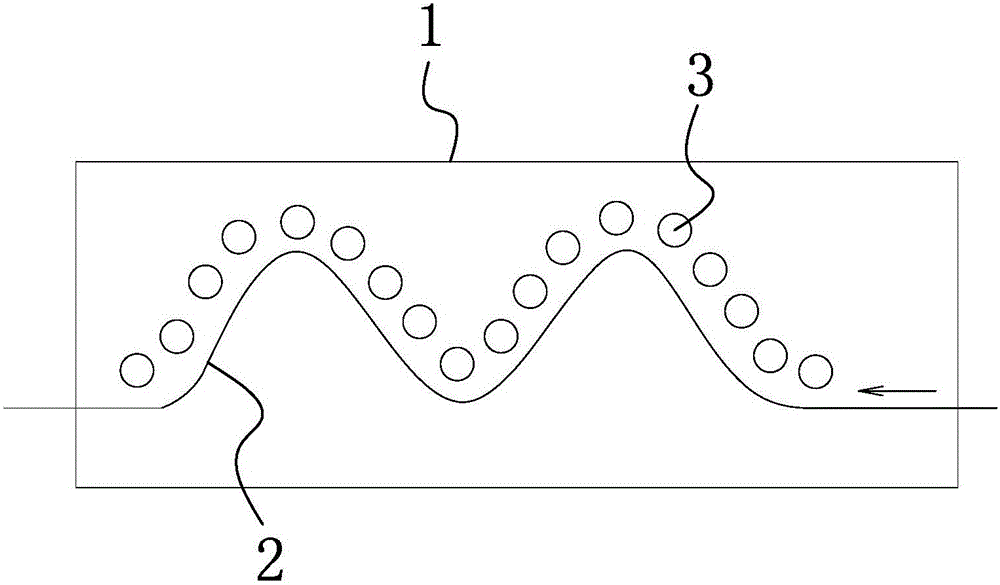

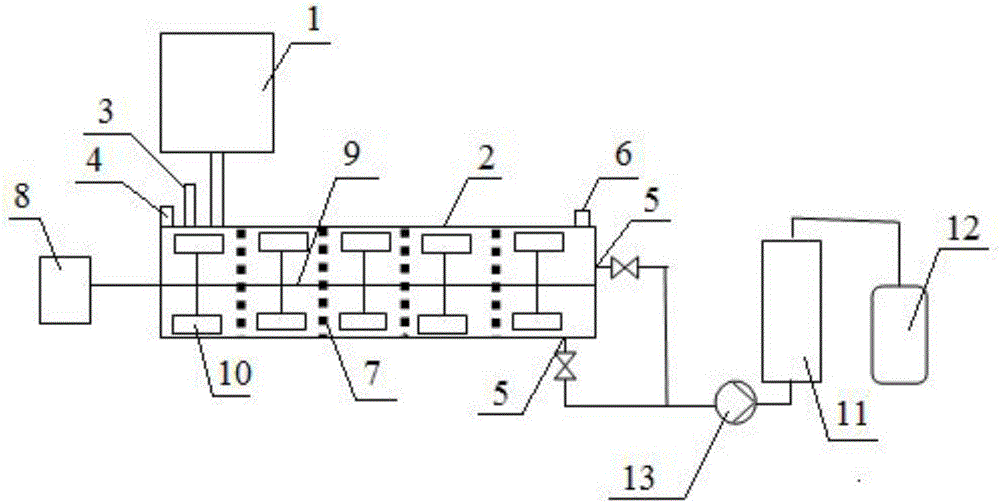

Continuous ursol dissolving device and method

InactiveCN105688706AEliminate quality impactAchieve stabilityTransportation and packagingRotary stirring mixersAramidPolymer chemistry

The invention belongs to the technical field of synthesis of high polymer and relates to a continuous ursol dissolving device and method, in particular to a continuous dissolving device and method for monomer ursol during continuous polymerization of resin for para-aramid fibers, that is, conventional intermittent dissolving is substituted by PPD continuous dissolving. Therefore, all processes of PPTA polymerization are continuous, and stability in resin molecular weight is ensured, and consistency in resin luster is achieved.

Owner:AFCHINA CORP CO LTD +1

Surface bright anodic oxidation coloring method for titanium and titanium alloy

ActiveCN105316744ANo variegationNo anti-fingerprintSurface reaction electrolytic coatingMegasonic cleaningTitanium

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

Coating liquid used for forming ultraviolet absorption coating and ultraviolet absorption glass

ActiveUS20160297707A1Avoid absorptionEnsure color consistencySynthetic resin layered productsRadiation-absorbing paintsWeather resistanceUltraviolet lights

Coating liquid used for forming an ultraviolet absorption coating on a surface of an object such as glass and the like, ultraviolet absorption glass arranged with the ultraviolet absorption coating formed by the coating liquid, and a method for preparing the ultraviolet absorption glass. The coating liquid used for forming the ultraviolet absorption coating, the ultraviolet absorption glass and the method for forming the ultraviolet absorption glass, by storing and releasing electrons excited by ultraviolet lights in an ultraviolet absorber, reduce the excited electrons that are gradually accumulated during a process in which the ultraviolet absorber absorbs the ultraviolet lights, thus protecting the ultraviolet absorber and a silicon dioxide matrix, preventing the ultraviolet absorption glass from discoloring or devitrifying, ensuring weather resistance of the ultraviolet absorption coating and ensuring color consistency of the ultraviolet absorption glass.

Owner:FUYAO GLASS IND GROUP CO LTD

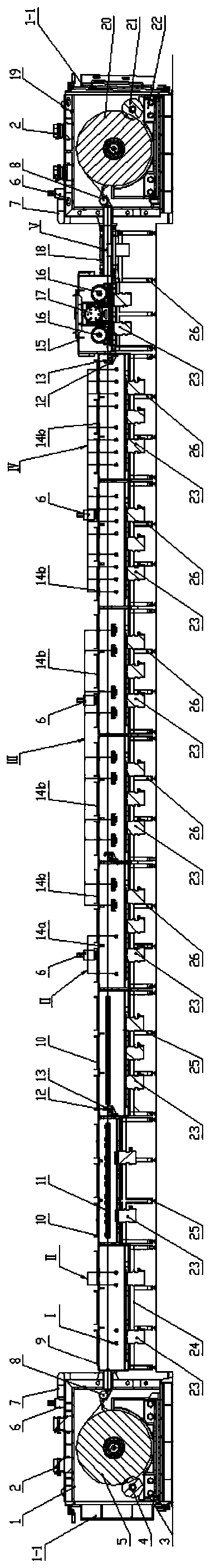

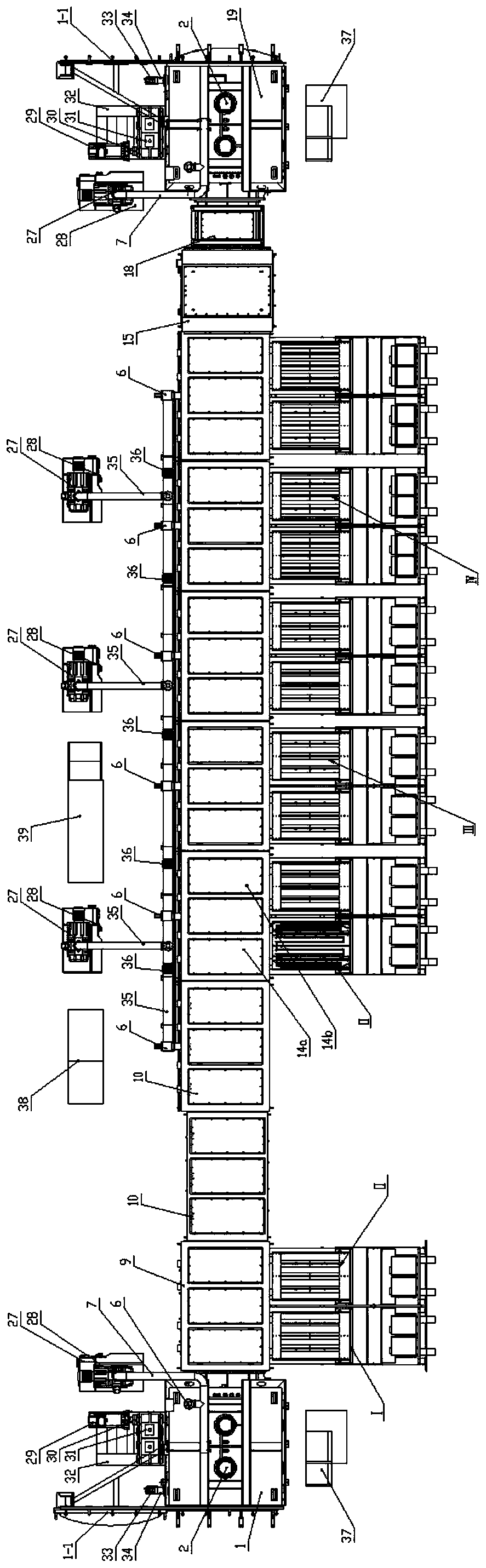

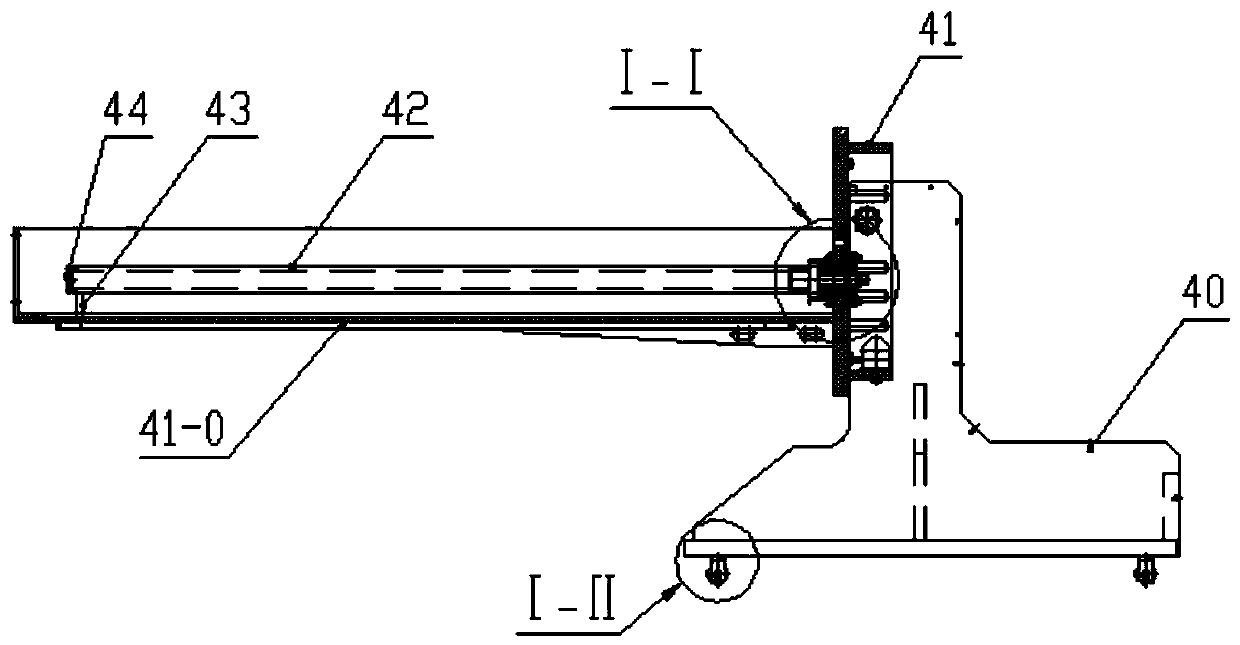

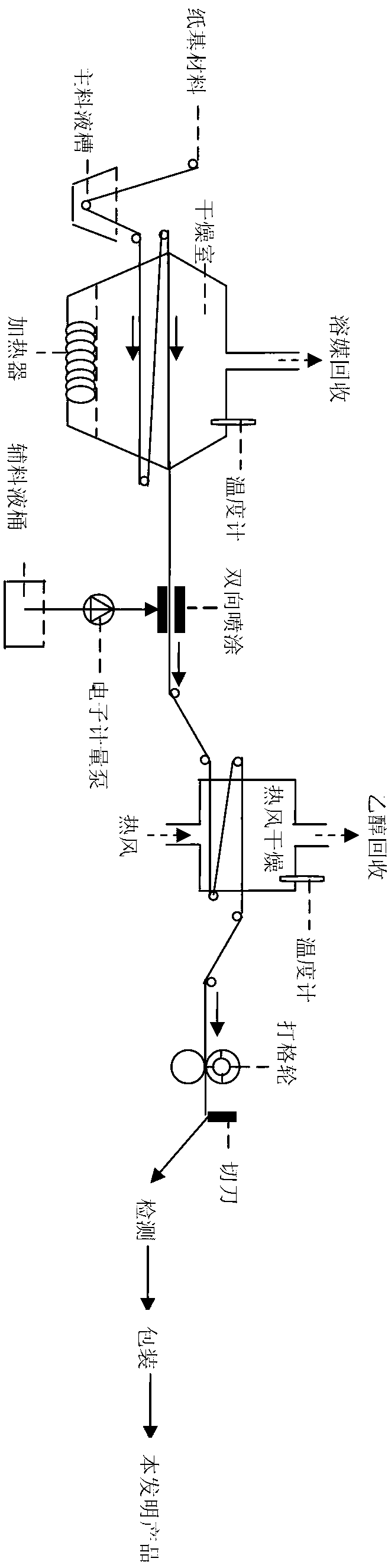

Metal foil winding type vacuum coating continuous production line

PendingCN111058009ATimely correction of process parametersGuaranteed color uniformityVacuum evaporation coatingSputtering coatingProduction lineMetal foil

The invention relates to a metal foil winding type vacuum coating continuous production line. The continuous production line comprises a coating chamber, the coating chamber is divided into a front section and a rear section, windows are correspondingly disposed on one sides of cavities at the front section and the rear section, and rails perpendicular to racks are arranged on one sides of the racks corresponding to the windows; a planar rectangular cathode arc source device is disposed in the front section, and comprises a target material and a moving trolley, and the target material is fixedon a vertical panel of the moving trolley and is positioned in a supporting drawer box; the moving trolley walks on the vertical rail, a sealing door bracket composed of a frame and a vertical panelis arranged on the moving trolley, a side of the vertical panel facing the window is a seal surface and is in seal design correspondingly with a window frame of the window, and a groove-shaped supporting drawer extending to the window is fixed on the vertical panel. A rotary columnar medium-frequency magnetron sputtering target device is disposed in the rear section, and comprises a sputtering target and a moving trolley assembly, the sputtering target is fixed on the vertical panel and is located in the supporting drawer box; and the target material and the sputtering target are respectivelypushed into or pulled out of each chamber by the moving trolley. The coating layer is uniform and stable in color, and the technological process is reliable.

Owner:DONGGUAN HUICHENG VACUUM TECH

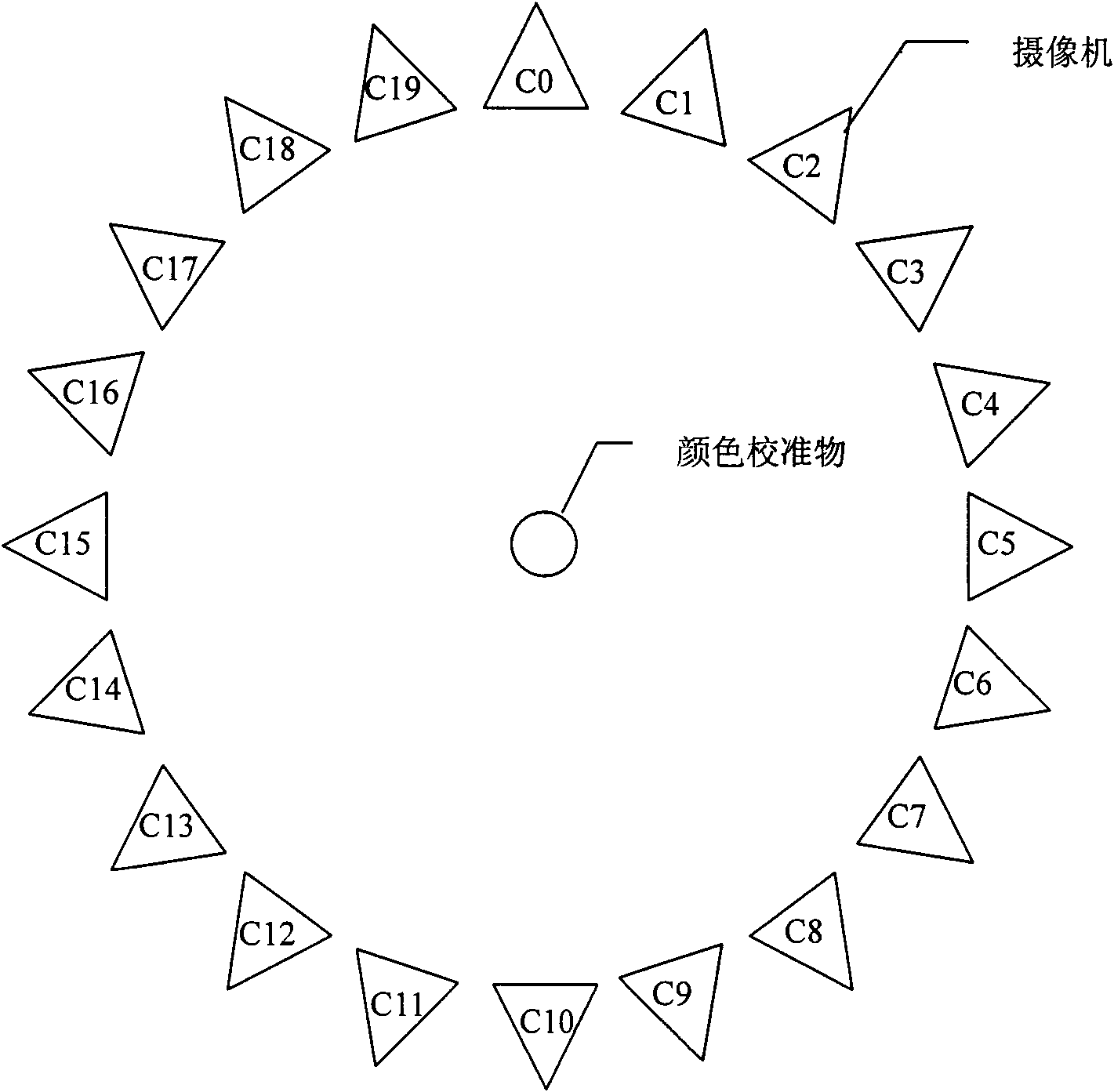

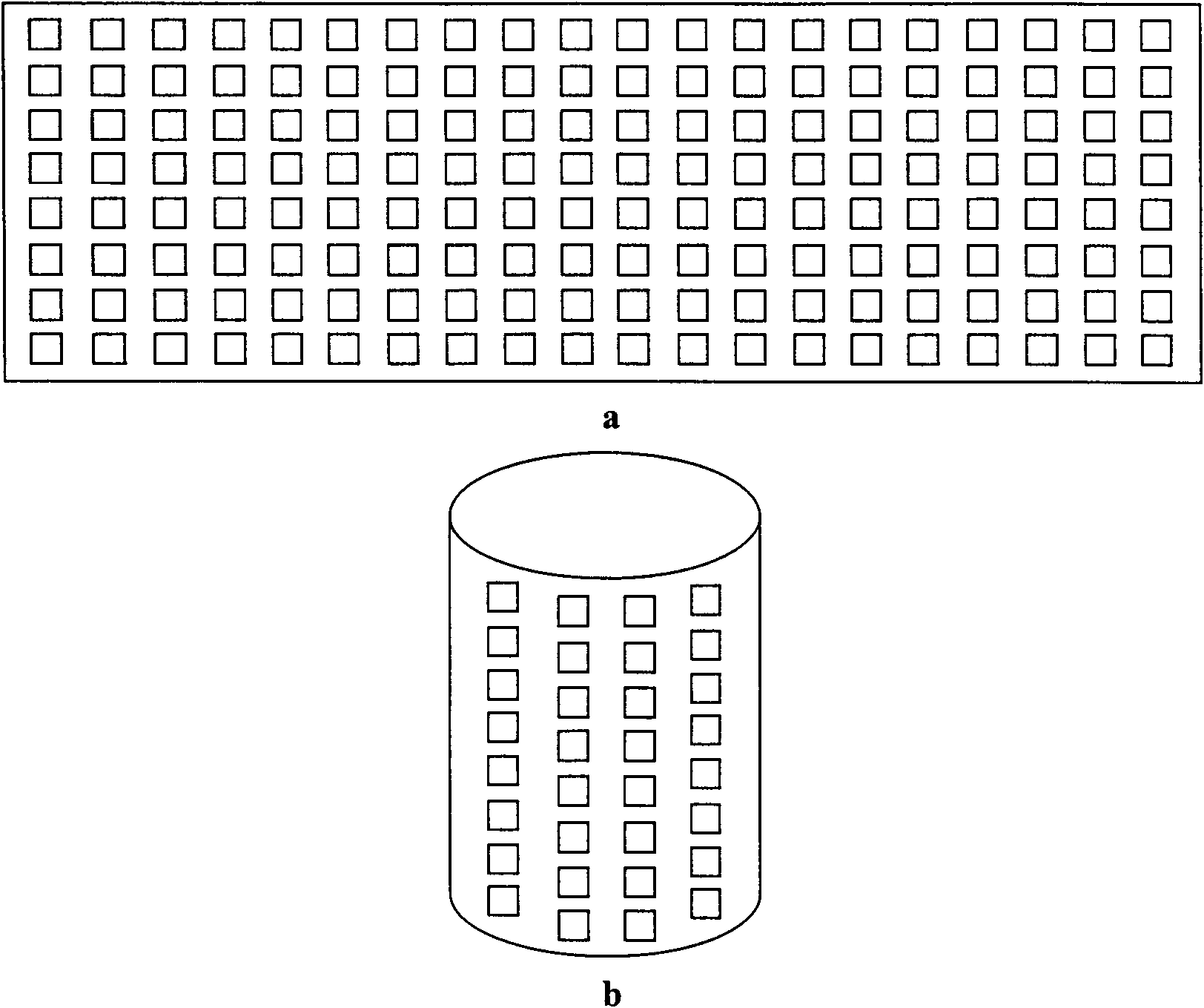

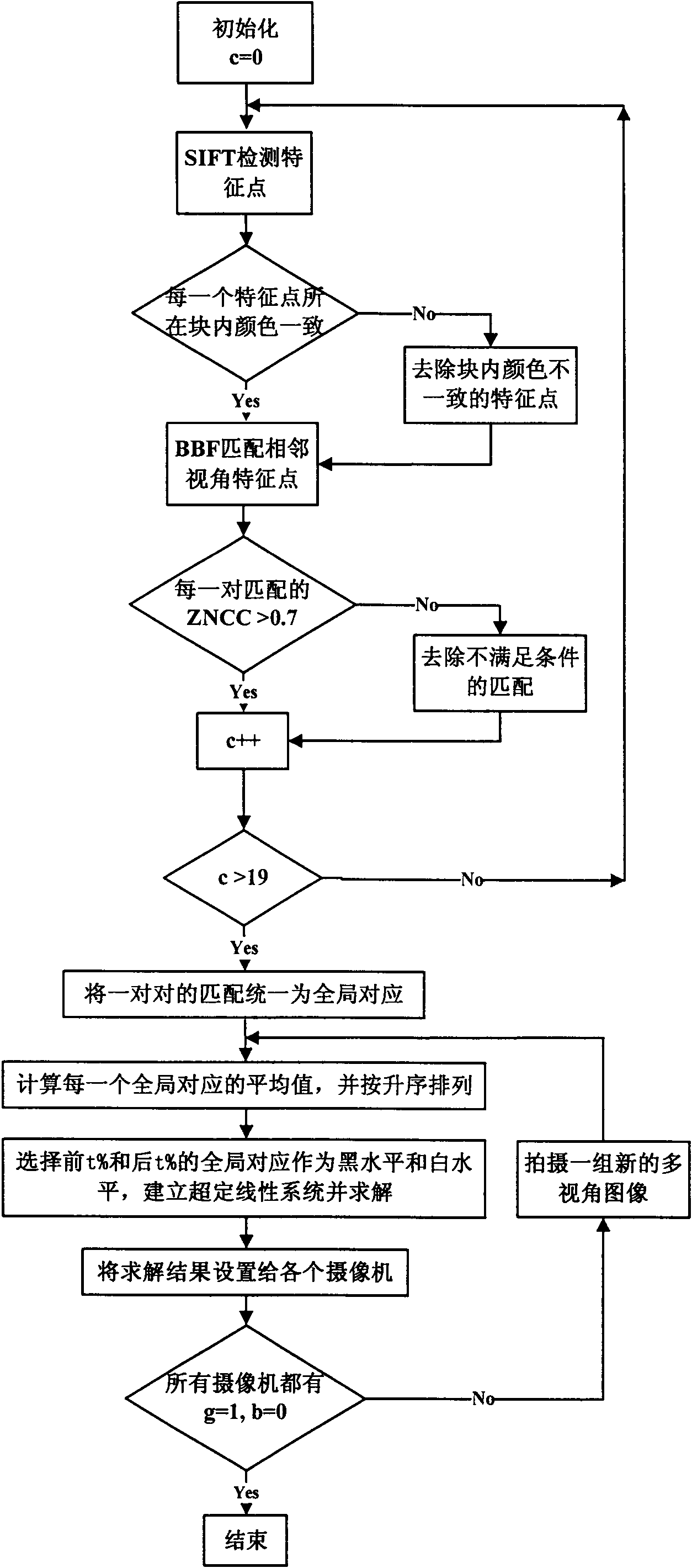

Method for carrying out global color calibration on a plurality of video cameras

ActiveCN101651844AAchieving Color ConsistencyIncrease contrastImage analysisTelevision systemsColor calibrationFully automatic

The method relates to a method for carrying out the global color calibration on a plurality of video cameras, belonging to the field of computer multimedia technologies. A calibrant is placed in the center of a scene, and N video cameras acquire an image from the calibrant in the center of the scene. The color calibration process comprises the following steps: calculating global correspondences ofall video cameras by applying a feature point detection method and relevant methods based on areas; establishing overdetermined linear equations based on the color consistency and the dynamic range constraint; and setting the obtained calibration parameters into all video cameras. The calibrant used in the method is simple, flexible and convenient for carrying; the color calibration process has simple algorithm routines, is easy to realize and fully automatic; and the color calibration merges the feature point detection method and the relevant methods based on areas together, thereby obtaining the high-precision global correspondences. The calibrant in the method and the color calibration method can be applied to any multi-video-camera array system, thereby achieving the color consistencyand the high-contrast calibration of all cameras.

Owner:TSINGHUA UNIV

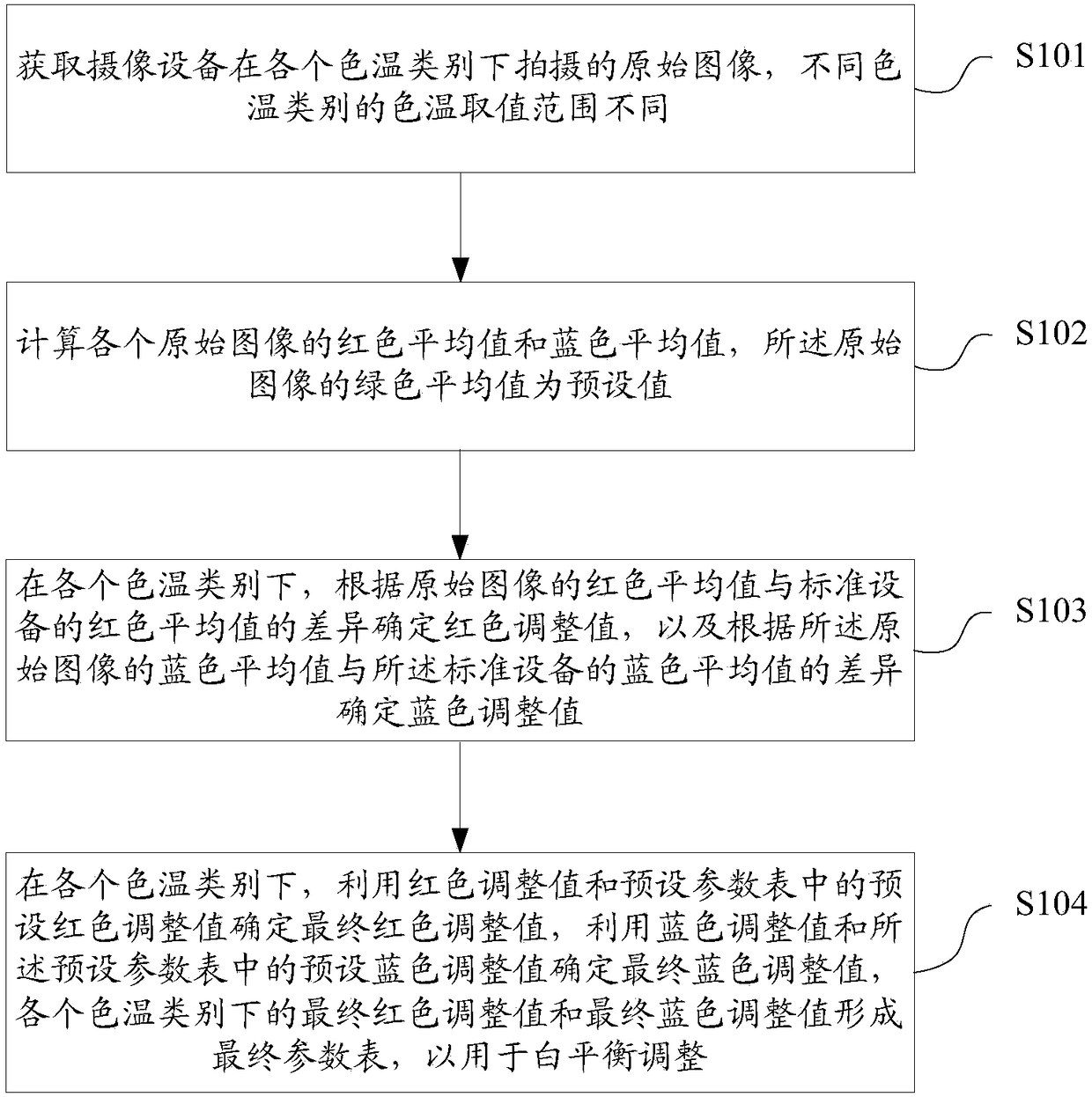

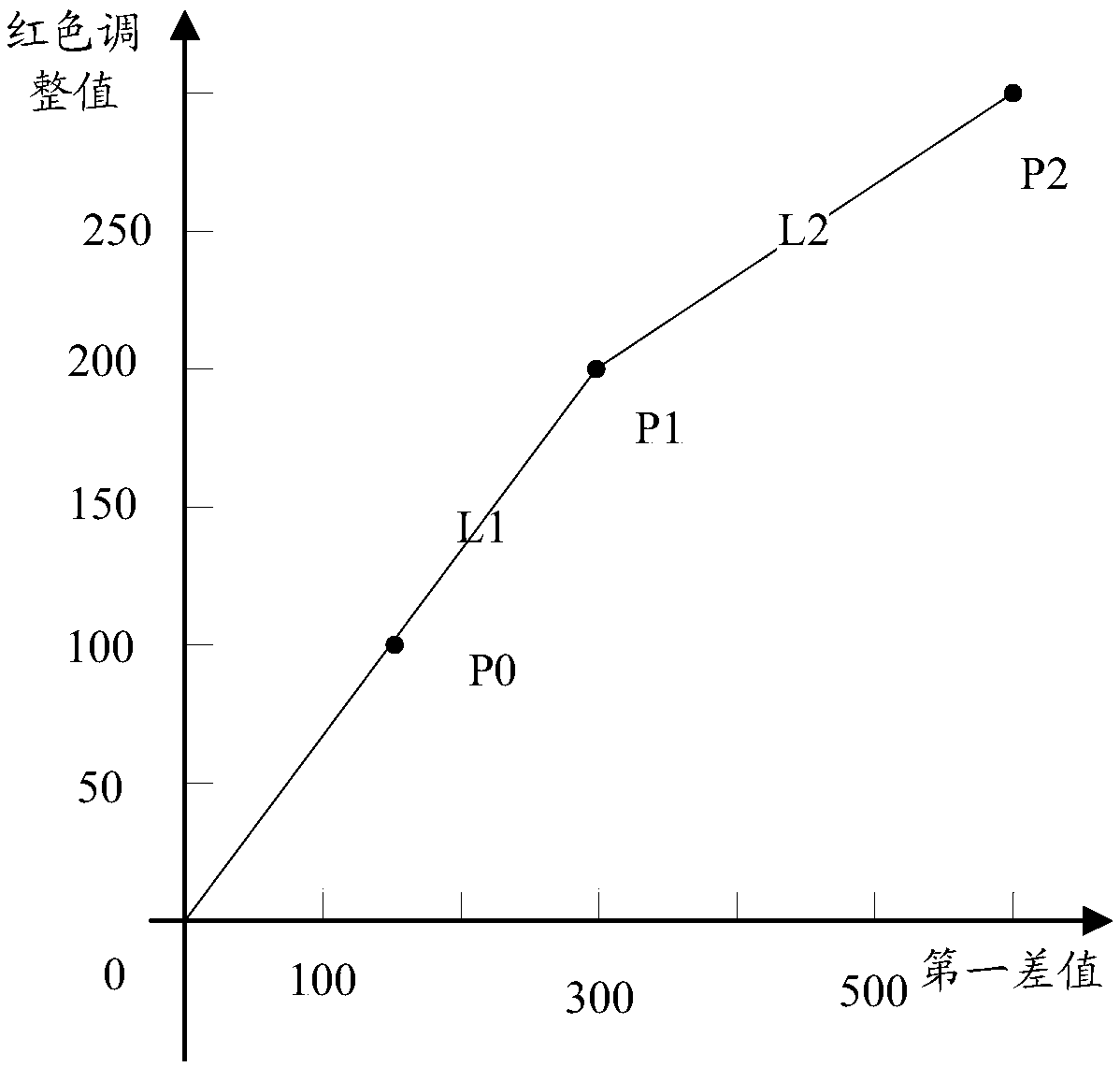

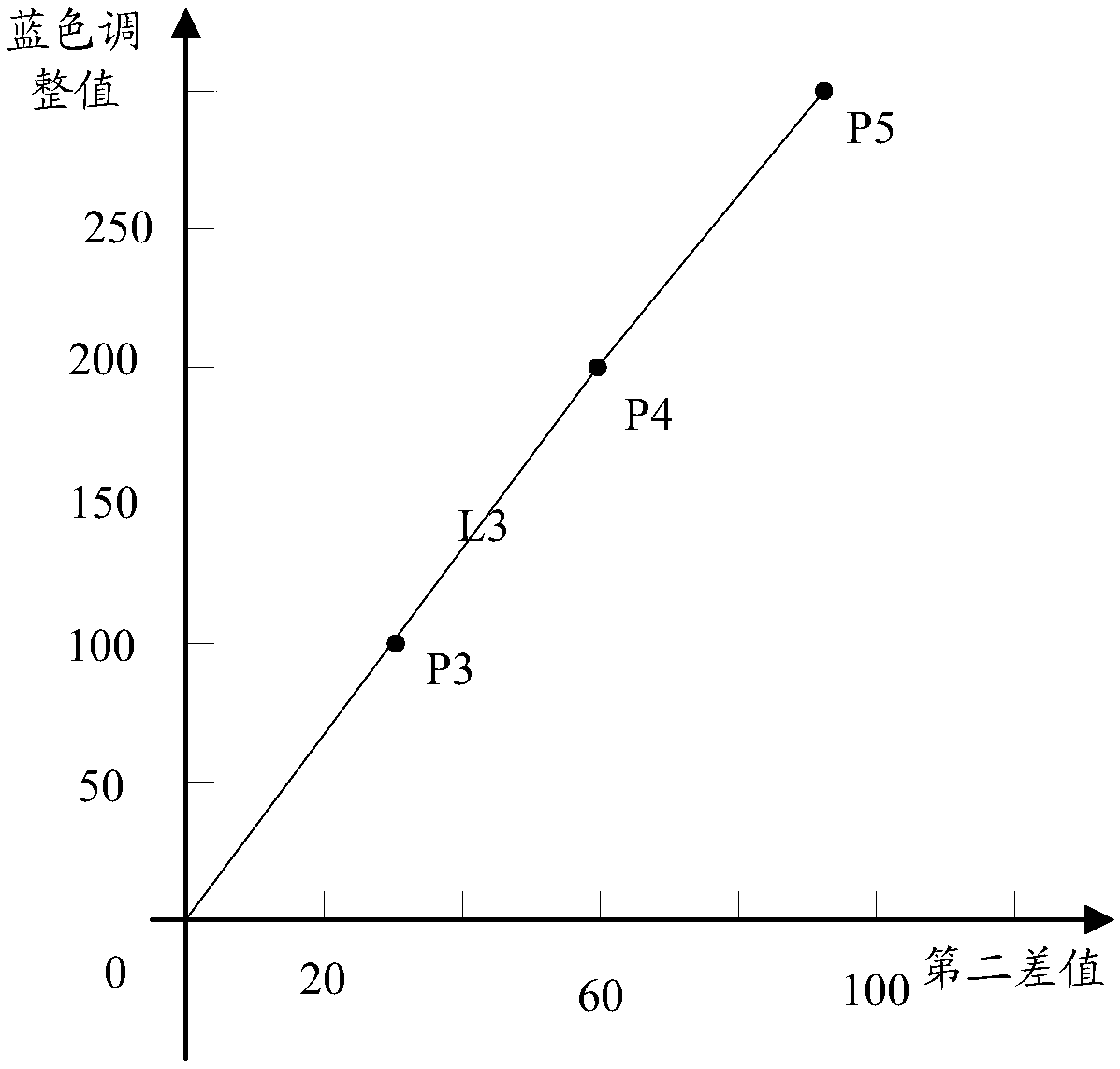

White balance parameter determination method, white balance adjustment method and device, storage medium and terminal

ActiveCN108234971AImprove accuracyAchieve consistencyColor signal processing circuitsBrightness and chrominance signal processing circuitsComputer scienceColor temperature

Disclosed are a white balance parameter determination method, a white balance adjustment method and device, a storage medium and a terminal. The white balance parameter determination method comprisesthe steps of: acquiring an original image shot by a shooting device under each color temperature category; calculating a red mean and a blue mean of each original image; under each color temperature category, determining a red adjustment value according to the difference between the red mean of the original image and a red mean of a standard device, and determining a blue adjustment value according to the difference between the blue mean of the original image and a blue mean of the standard device; and under each color temperature category, determining a final red adjustment value by using thered adjustment value and a preset red adjustment value in a preset parameter table, and determining a final blue adjustment value by using the blue adjustment value and a preset blue adjustment valuein the preset parameter table, the final red adjustment value and the final blue adjustment value under each color temperature category forming a final parameter table. The technical solution can achieve the consistency of color performance between devices after white balance adjustment.

Owner:SENSLAB INC

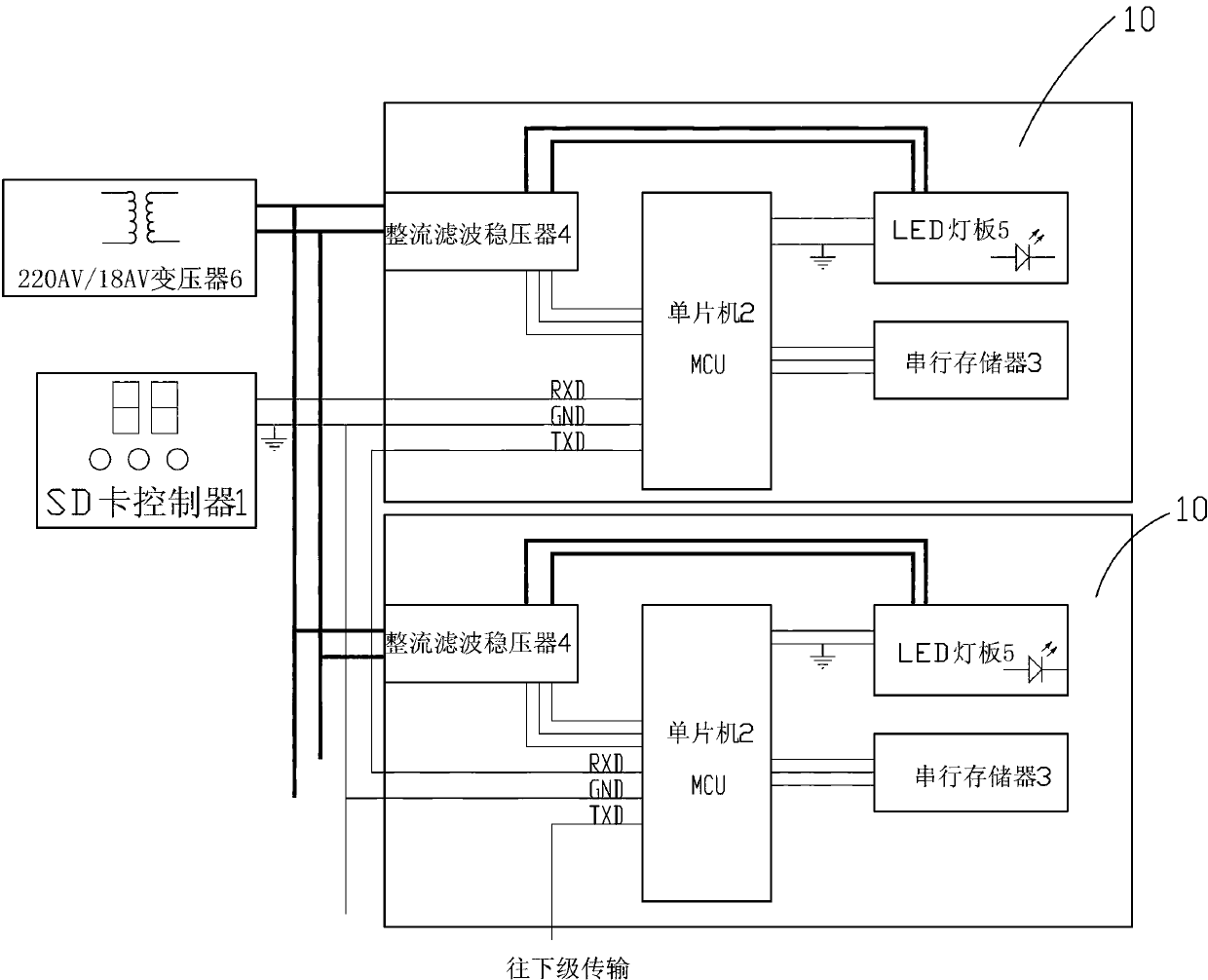

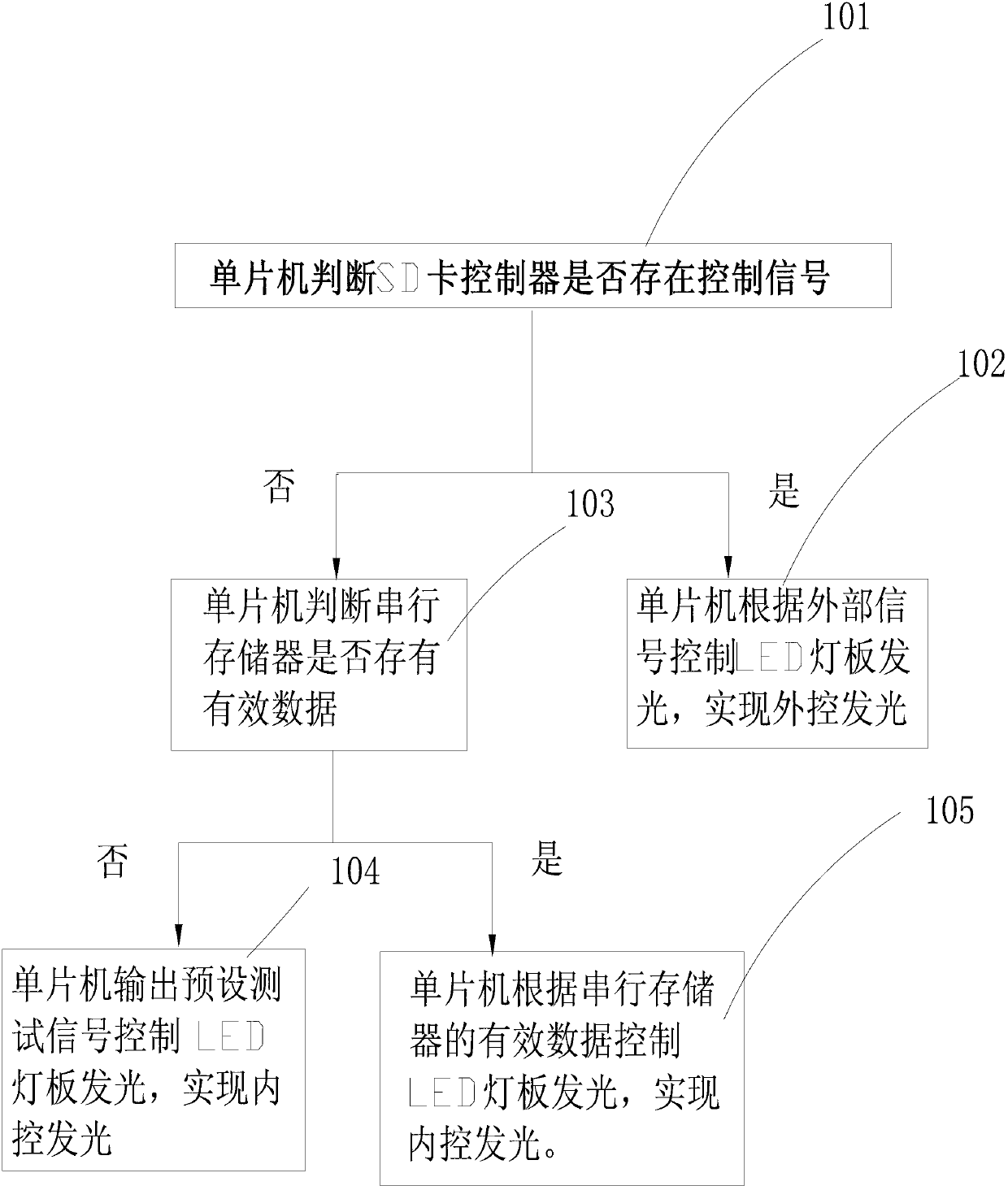

System and method for controlling LED guardrail tubes

InactiveCN103002639AAutomatic output of internal control test resultsDoes not affect the playback effectElectric light circuit arrangementMicrocontrollerMicrocomputer

The invention relates to LED guardrail tubes, in particular to a system and a method for controlling LED guardrail tubes. The system is characterized by comprising the multiple LED guardrail tubes and an SD (secure digital) card controller for controlling the LED guardrail tubes, a single chip microcomputer, a serial memory, a rectification and filter voltage stabilizer and an LED lamp panel are arranged in each LED guardrail tube, the serial memory, the rectification and filter voltage stabilizer and the LED lamp panel of each LED guardrail tube are respectively connected onto the single chip microcomputer of the LED guardrail tube, each rectification and filter voltage stabilizer is connected with the corresponding LED lamp panel, one of the single chip microcomputers is used as a first single chip microcomputer to be connected with the SD card controller, and the other single chip microcomputers are sequentially serially connected with one another and then are connected onto the first single chip microcomputer.

Owner:张会九 +1

Chips on board (COB) light bar and manufacturing method thereof

PendingCN110864268AWon't fall offSafe and reliable structureGas-tight/water-tight arrangementsSpectral modifiersOn boardEngineering

The invention relates to the technical field of light bars, and more specifically, relates to a chips on board (COB) light bar and a manufacturing method thereof. The COB light bar comprises a secondsilica gel part and a light panel arranged in the second silica gel part, the light panel is provided with chips, and the chips are covered with a first silica gel part. It is guaranteed that the theCOB light bar has certain overall dimensions, the dosage, thickness and width of silica gel are ensured, as the COB light bar is composed of the multiple chips, the light mixing effect is very good, so that the color temperature of the COB light bar can be controlled, the color consistency is guaranteed, and the COB light bar has a novel appearance and certain water resistance and dust preventioneffects. Continuous production is realized, the production efficiency is improved, the chips are directly delivered to the application production end, the packaging section is eliminated, batch production is achieved, the cost is reduced, the application range of products is expanded, the shearing position of scissors can be seen by a visual window, the light bar can be cut and used at will, convenience is realized, and the application range of the products is expanded.

Owner:SHENZHEN COOLIGHT OPT ELE CO LTD

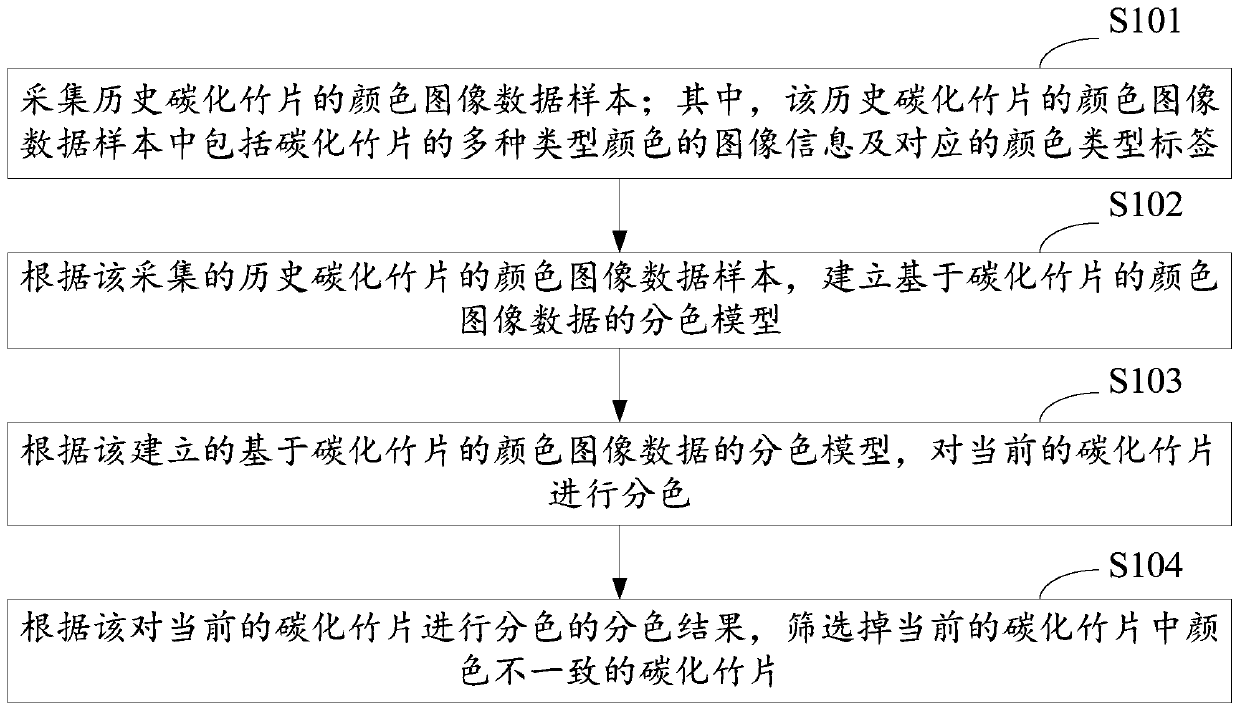

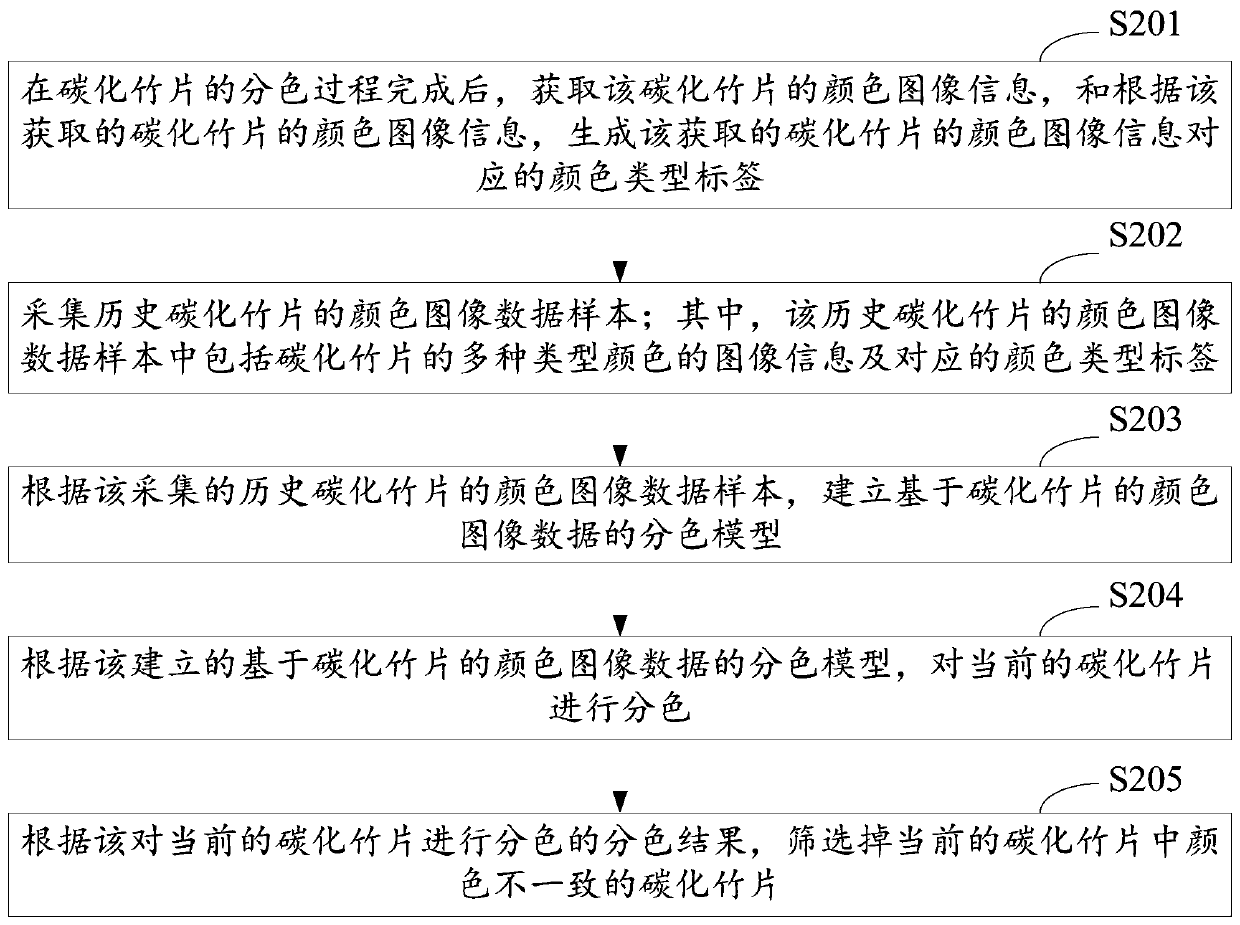

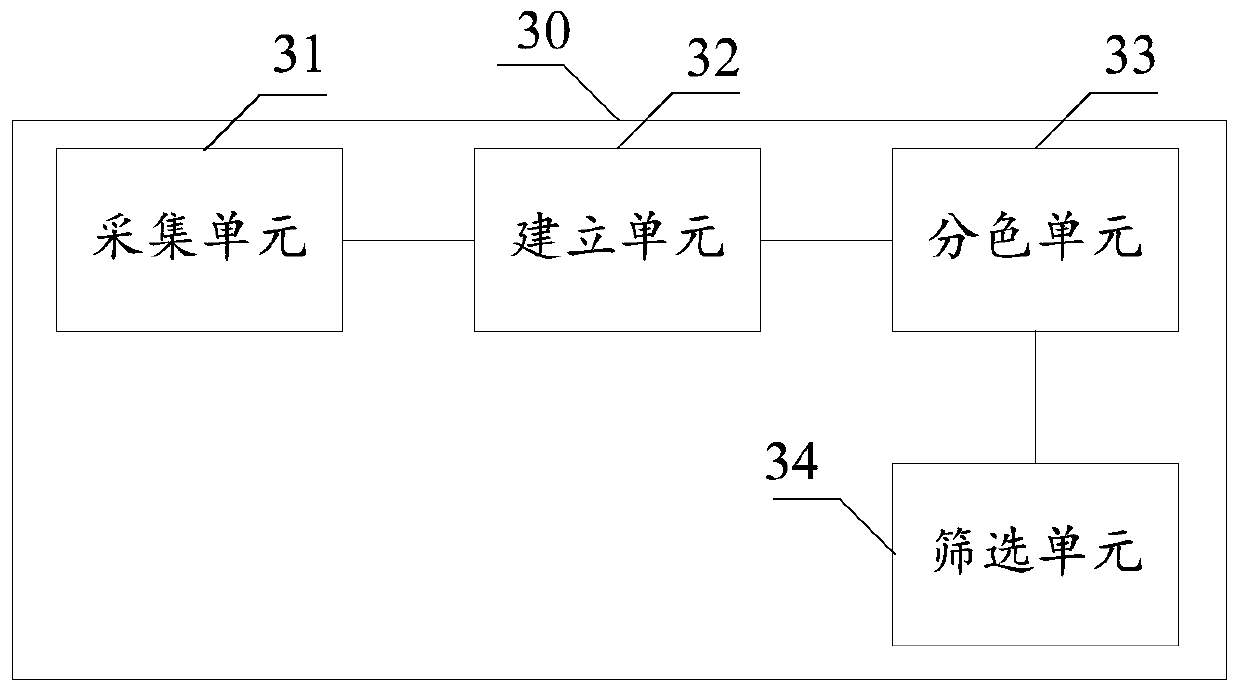

Carbonized bamboo chip color separation method and system

ActiveCN109871455AImprove the missed detection rateImprove color quality assuranceStill image data indexingSpecial data processing applicationsColor imagePattern recognition

The invention discloses a carbonized bamboo chip color separation method and system. The method comprises the following steps of: obtaining a target object, color image data samples of the historicalcarbonized bamboo chips are collected; according to the collected color image data sample of the historical carbonized bamboo chip, obtaining a color image sample; establishing a color separation model based on the color image data of the carbonized bamboo chips; and according to the established color separation model based on the color image data of the carbonized bamboo chips, the current carbonized bamboo chips are subjected to color separation, and the carbonized bamboo chips with inconsistent colors in the current carbonized bamboo chips are screened out according to the color separationresult of color separation of the current carbonized bamboo chips. By means of the mode, carbonized bamboo chips can be automatically subjected to color separation without manual work, the color separation efficiency and the color separation accuracy are improved, the color consistency of the carbonized bamboo chips subjected to automatic color separation is guaranteed, and the color quality of bamboo products can be guaranteed.

Owner:XIAMEN UNIV OF TECH +1

Method for mixed color correction

ActiveUS20190164316A1True colorEnsure color consistencyColor signal processing circuitsTexturing/coloringIlluminanceColor correction

A method for mixed color correction is disclosed. Based on the variations of the chromaticity coordinates required for adjusting between the target color and the actually-measured color, variations of illuminances of one or two of RGB of the three colors are calculated for adjusting the actually-measured color to achieve the variations of the chromaticity coordinates required for adjusting according to the correlation between the chromaticity coordinates and the tristimulus values, until the required variations of chromaticity coordinate are within a required range. This method can quickly and accurately correct and adjust the actually-measured color, guarantee the consistency of lamp colors, and is convenient for application.

Owner:GUANGZHOU YAJIANG PHOTOELECTRIC EQUIP CO LTD

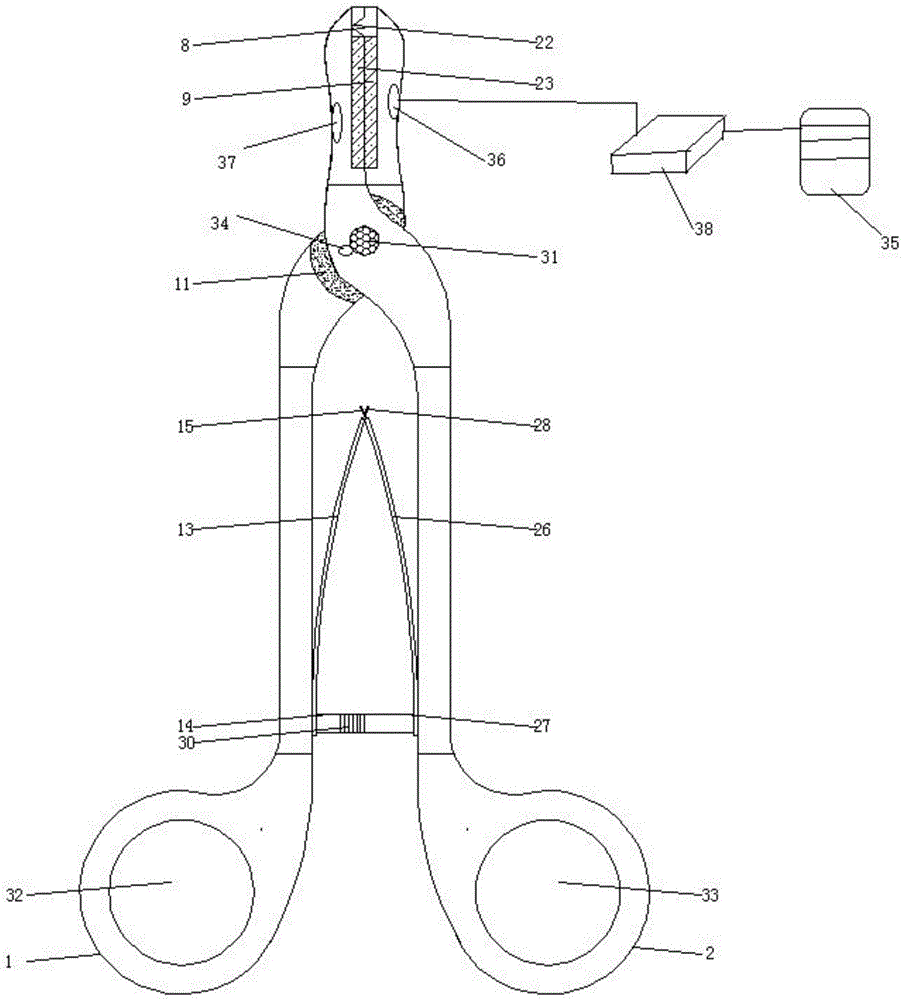

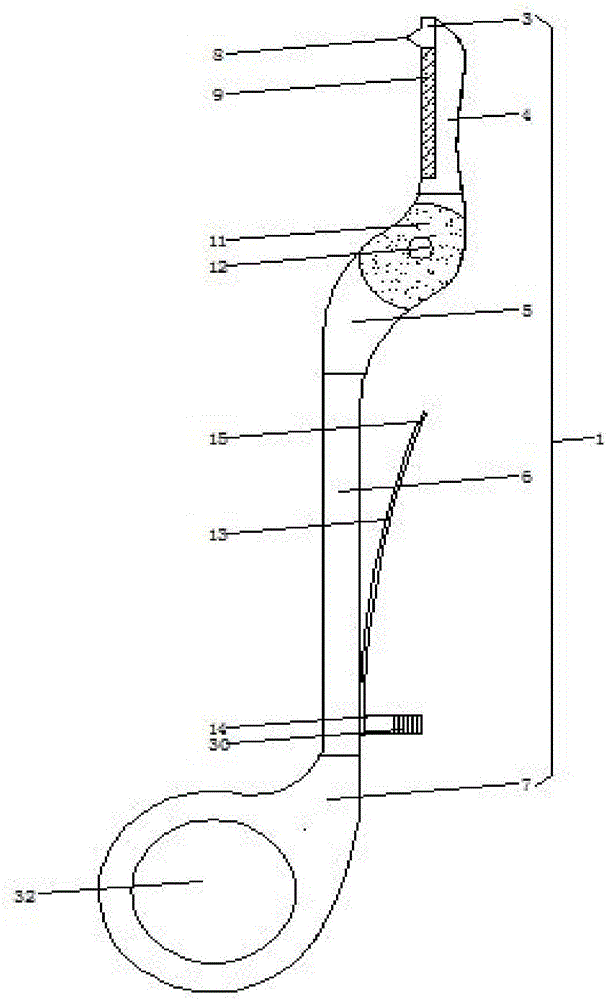

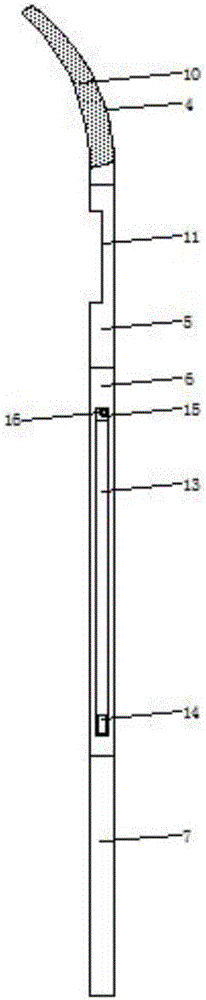

Surgical clamp type tweezers

InactiveCN106580399AOpen fullySolve the phenomenon of muscle fatigueImage enhancementDiagnostic signal processingSurgical ClampsTweezers

The invention relates to a pair of surgical clamp type tweezers, which comprises a left tweezer body and a right tweezer body, wherein the left tweezer body is sequentially composed of a first clamping part, a first occlusion part, a first connecting part, a first connecting rod and a first handheld part from top to bottom; the right tweezer body is sequentially composed of a second clamping part, a second occlusion part, a second connecting part, a second connecting rod and a second handheld part from top to bottom; a second occlusion surface is formed on the left side of the second occlusion part; and the left tweezer body and the right tweezer body are hinged through positioning nails. The surgical clamp type tweezers disclosed by the invention further comprise a pressure detector, a biological information detector and an image acquisition unit. The clamp type tweezers can be effectively and automatically reset by a first elastic piece and a second elastic piece, the equipment clamping strength of a user is reduced, and the stability in the clamping process is improved. According to the inner arc design on the outer sides of the first occlusion part and the second occlusion part, the actions of opening the wounds and the like can be effectively made, and the defect that the traditional clamp type tweezers have a straight design is overcome; and moreover, the surgical clamp type tweezers disclosed by the invention have the advantages of high intelligent degree.

Owner:侯信明

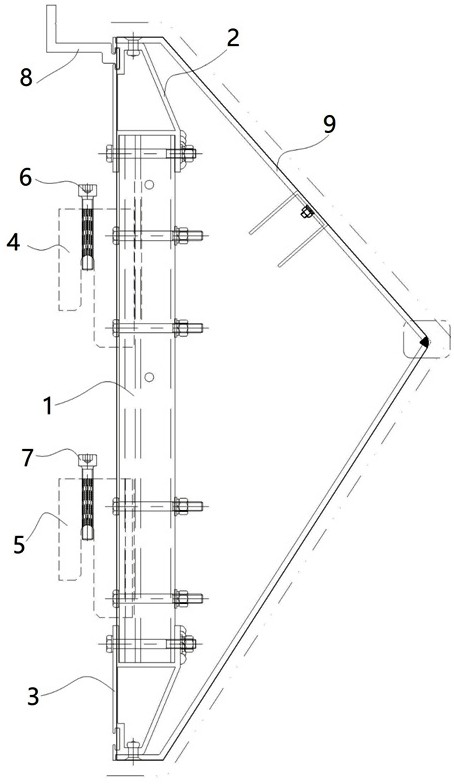

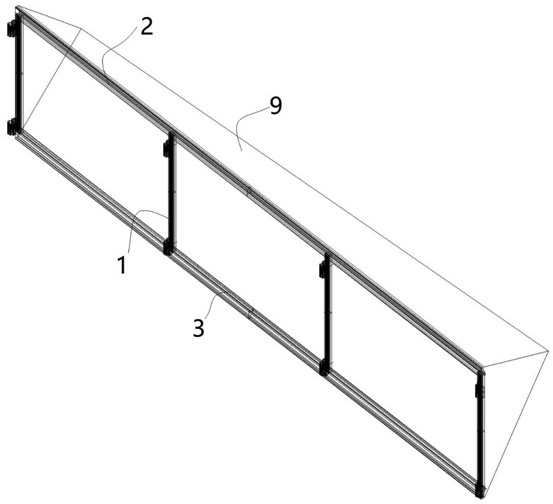

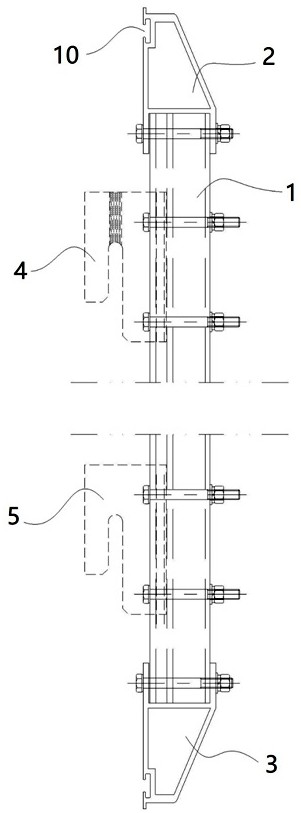

Unit type aluminum plate curtain wall system capable of adapting to any shape and construction technology of unit type aluminum plate curtain wall system

PendingCN114737703AThe power transmission path is clearReliable structureWallsMaterials processingMechanical engineering

The invention provides a unit type aluminum plate curtain wall system capable of adapting to any shape and a construction technology thereof. The unit type aluminum plate curtain wall system comprises an aluminum framework and special-shaped aluminum plates. The aluminum framework comprises a stand column, an upper cross beam, a lower cross beam, an upper hanging piece and a lower hanging piece. The upper ends of the stand columns are fixed to an upper cross beam, and the lower ends of the stand columns are fixed to a lower cross beam. The upper hanging piece is arranged on the upper portion of the inner side of the stand column, and the lower hanging piece is arranged on the lower portion of the inner side of the stand column. And the special-shaped aluminum plate is fixed on the outer side of the aluminum framework. The curtain wall system component is convenient to assemble and process, low in cost, capable of improving profile processing efficiency, simple in field construction hanging, few in spare parts, free of complex procedures such as welding and the like, capable of meeting deviation requirements of a plurality of links such as field construction and material processing, and capable of guaranteeing color consistency of the profile and the aluminum plate and not affecting attractiveness.

Owner:BEIJING CONSTR ENG GRP CO LTD

Method for mixed color correction

ActiveUS10755448B2Achieving Color ConsistencyTrue colorColor signal processing circuitsTexturing/coloringIlluminanceColor correction

A method for mixed color correction is provided. Based on the variations of the chromaticity coordinates required for adjusting between the target color and the actually-measured color, variations of illuminances of one or two of RGB of the three colors are calculated for adjusting the actually-measured color to achieve the variations of the chromaticity coordinates required for adjusting according to the correlation between the chromaticity coordinates and the tristimulus values, until the required variations of chromaticity coordinate are within a required range. This method can quickly and accurately correct and adjust the actually-measured color, guarantee the consistency of lamp colors, and is convenient for application.

Owner:GUANGZHOU YAJIANG PHOTOELECTRIC EQUIP CO LTD

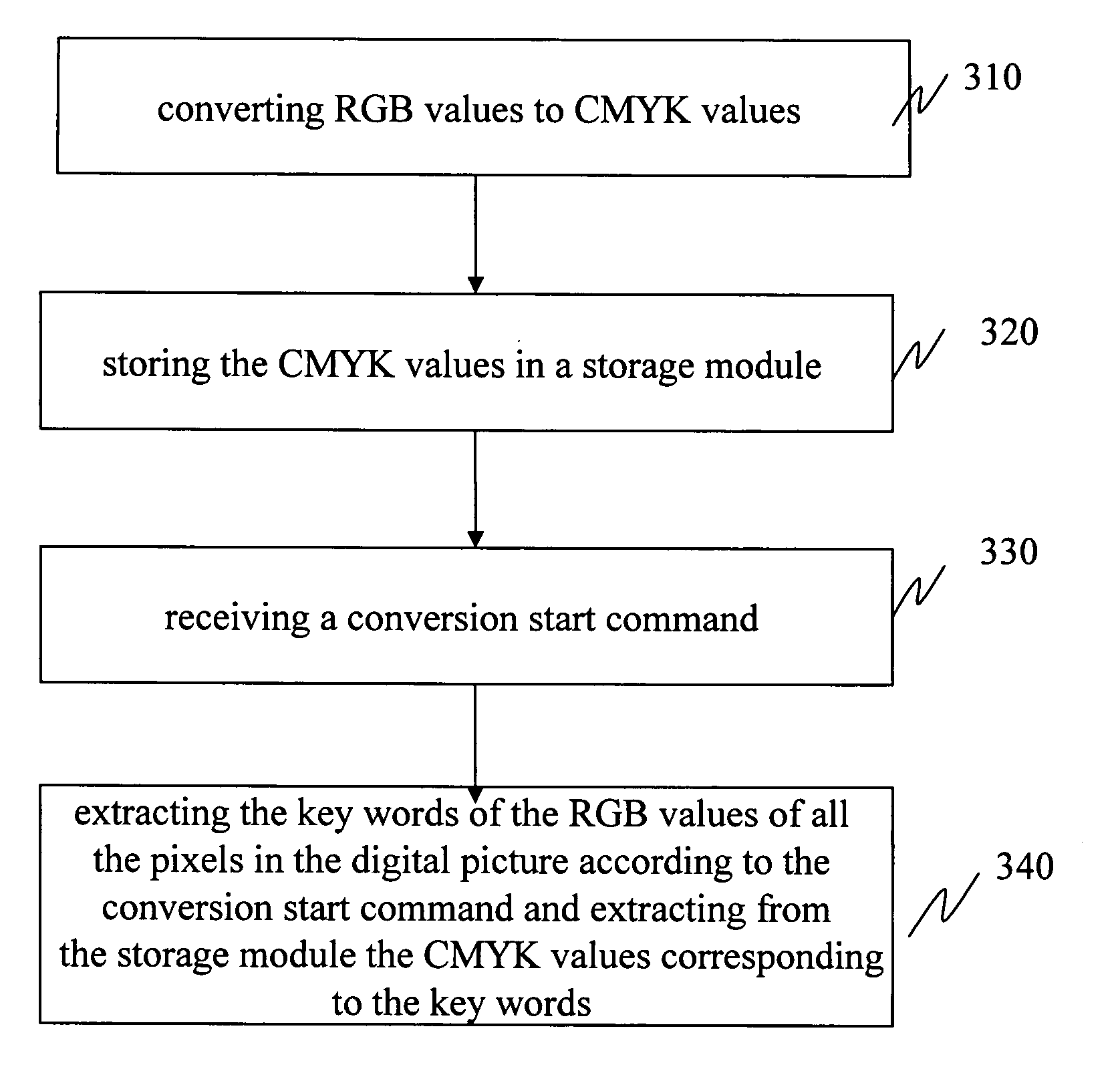

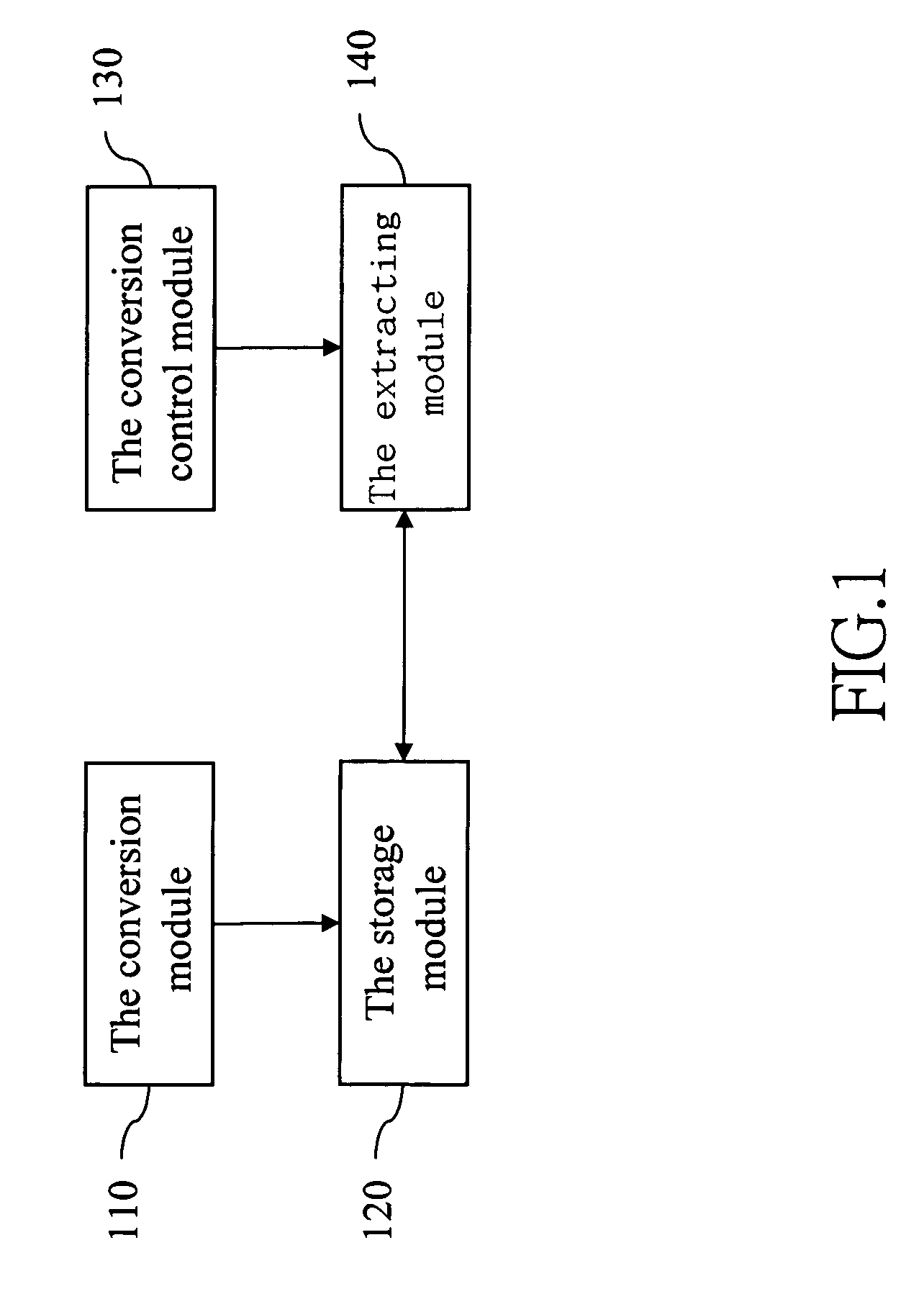

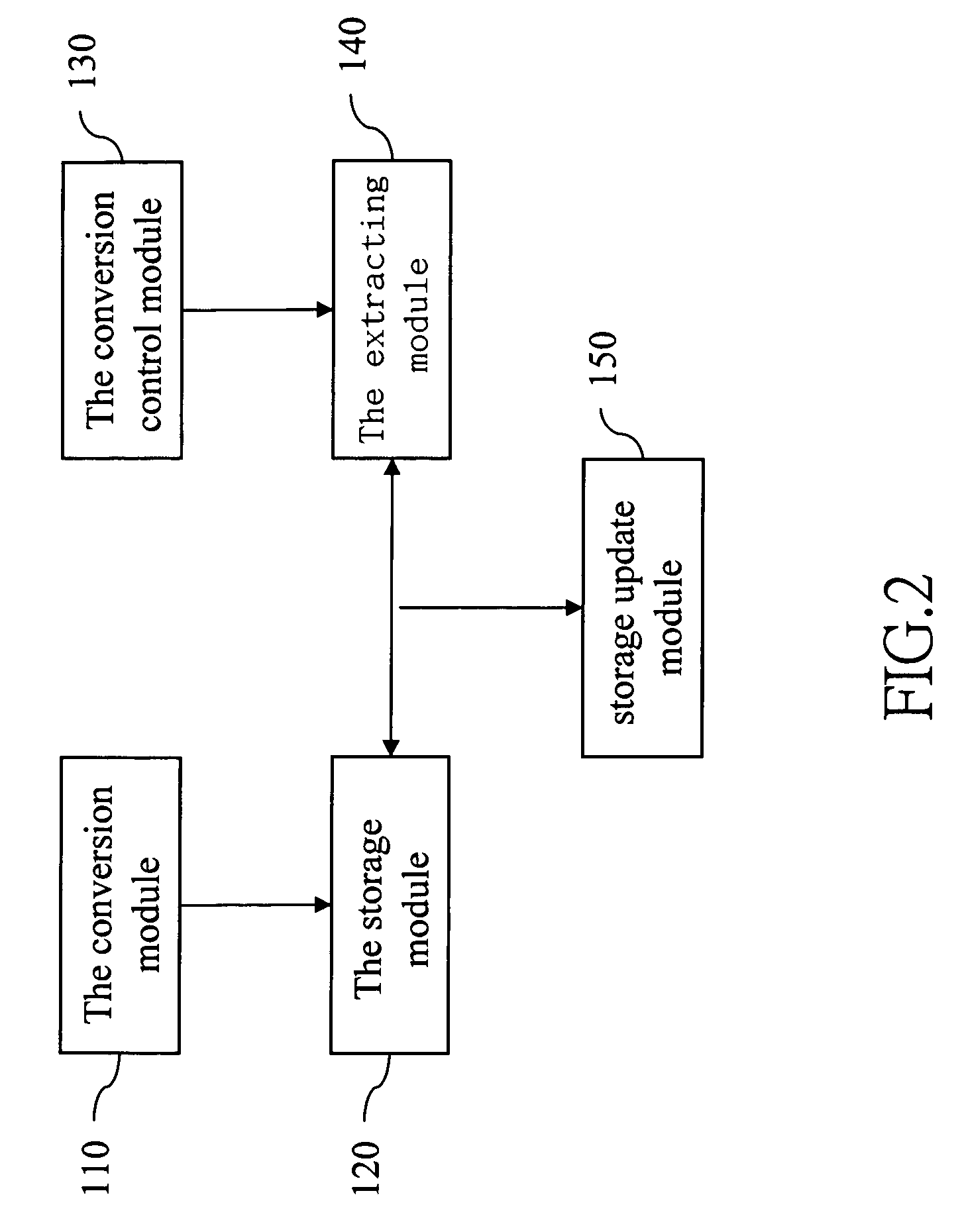

High speed color match processing system and method thereof

InactiveUS20060139664A1Improve processing speedReduce usageDigitally marking record carriersDigital computer detailsComputer graphics (images)Digital pictures

A high-speed color match processing system and the method thereof convert RGB values into CMYK values and store them in a storage module. According to a conversion start command, the key words of RGB values of all pixels in the current digital picture are extracted. The corresponding CMYK values are searched using the key words in the storage module. The RGB values are then converted into the CMYK values.

Owner:PRIMAX ELECTRONICS LTD

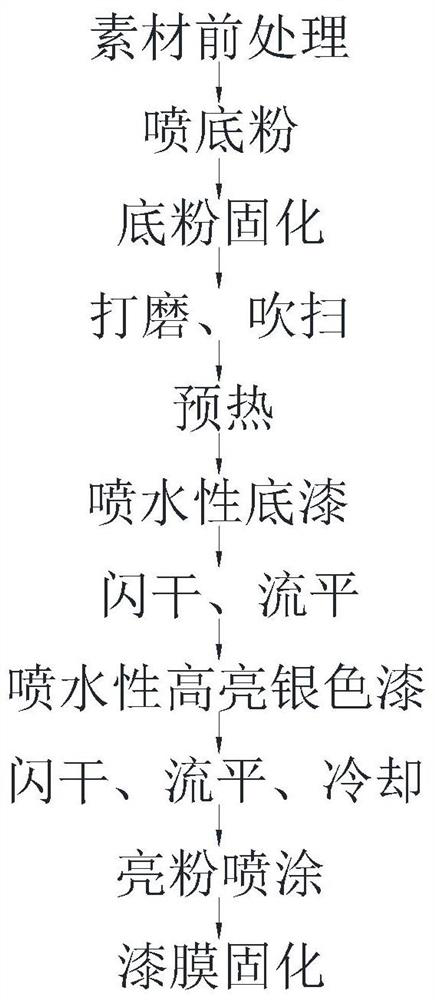

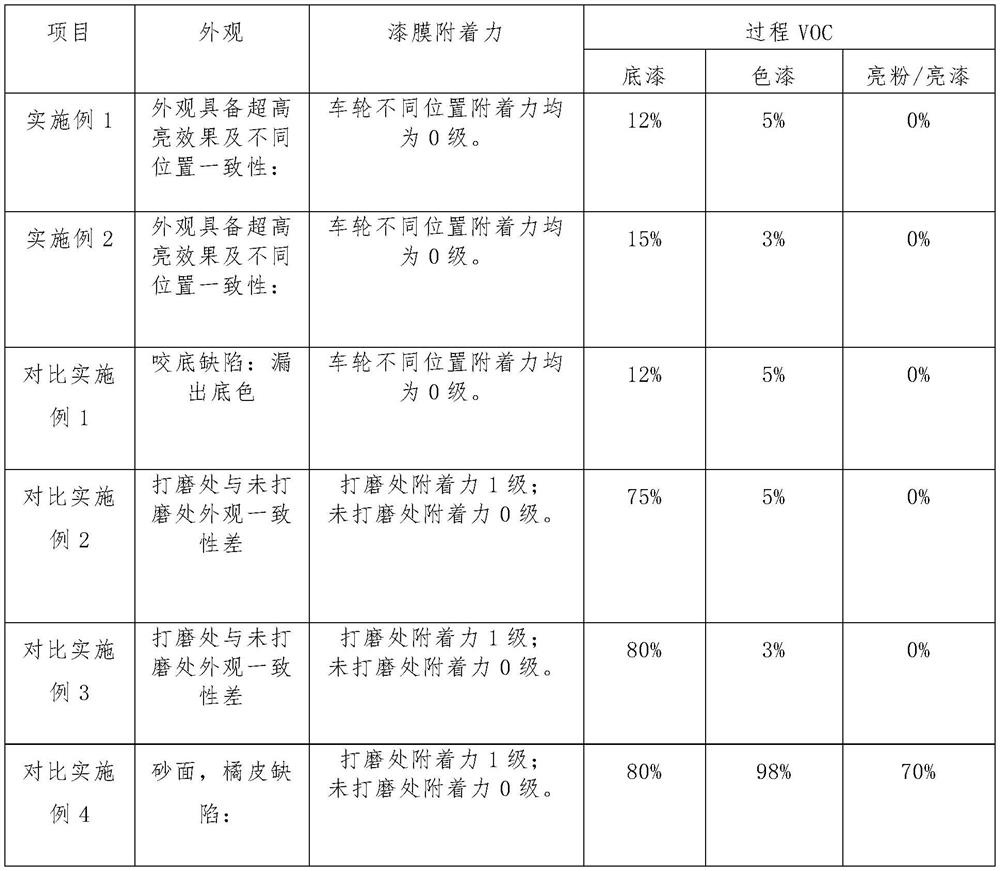

Water-based coating process for high-brightness silver wheel

ActiveCN114713478AEnsure color consistencyGuaranteed high glossSpecial surfacesCoatingsOrganic filmMetallurgy

The invention provides a high-brightness silver wheel water-based coating process, which belongs to the technical field of wheel coating, and comprises the following steps of material pretreatment, bottom powder spraying, bottom powder curing, polishing and purging, preheating, water-based primer spraying, flash drying and leveling, water-based high-brightness silver paint spraying, flash drying, leveling and cooling, bright powder spraying and paint film curing. And an infrared resonance rapid flash-drying process is adopted after the water-spraying primer and the water-spraying high-brightness silver paint are subjected to flash-drying. According to the water-based coating process for the high-brightness silver wheel, an infrared resonance rapid flash-drying process is provided based on the difference between the resonance frequency of water molecules of water paint and the resonance frequency of organic film-forming matter molecules, and the problems that water-based primer is completely sprayed, high-water-content high-brightness silver and high-water-content primer are subjected to wet-on-wet operation, bottom biting is caused, and gloss loss is caused are solved; the appearance color consistency, high brightness, ultra-fine texture and paint film reliability of different positions of the high-brightness silver wheel are guaranteed, and VOC of construction is reduced.

Owner:BAODING CITY LIZHONG WHEEL MFG

Paper cigarette lozenge and preparation method thereof

The invention discloses a paper cigarette lozenge and a preparation method of the paper cigarette lozenge, and belongs to the field of novel tobaccos. The paper cigarette lozenge comprises the following components, by weight, 0.2-25% of edible nicotine and / or nicotine-beta-cyclodextrin microcapsules, 65-85% of paper base materials, 0-6% of tea green pigments or citroxanthin, 5-20% of maple syrups and 0.5-3% of vitamin C, wherein nicotine content of the paper cigarette lozenge is 0.2-15%. The method includes the steps that the paper base materials are used for adsorbing main material liquid, auxiliary material liquid is sprayed on the paper base materials in a two-way mode after the paper base materials are dried, lastly the paper base materials are dried, divided and packaged, and then finished products are produced. The paper cigarette lozenge has the following advantages that the paper cigarette lozenge is similar to common paper in appearance and rapidly dissolved in the mouth, so that physiological needs of customers are met; no excipient or diluent or binder needs to be added or used, consumption of auxiliary materials is little, and production cost is low; the paper cigarette lozenge is comfortable in taste and has no residue; the production process is simple, and solvents can be recovered and recycled.

Owner:中国烟草总公司山东省公司

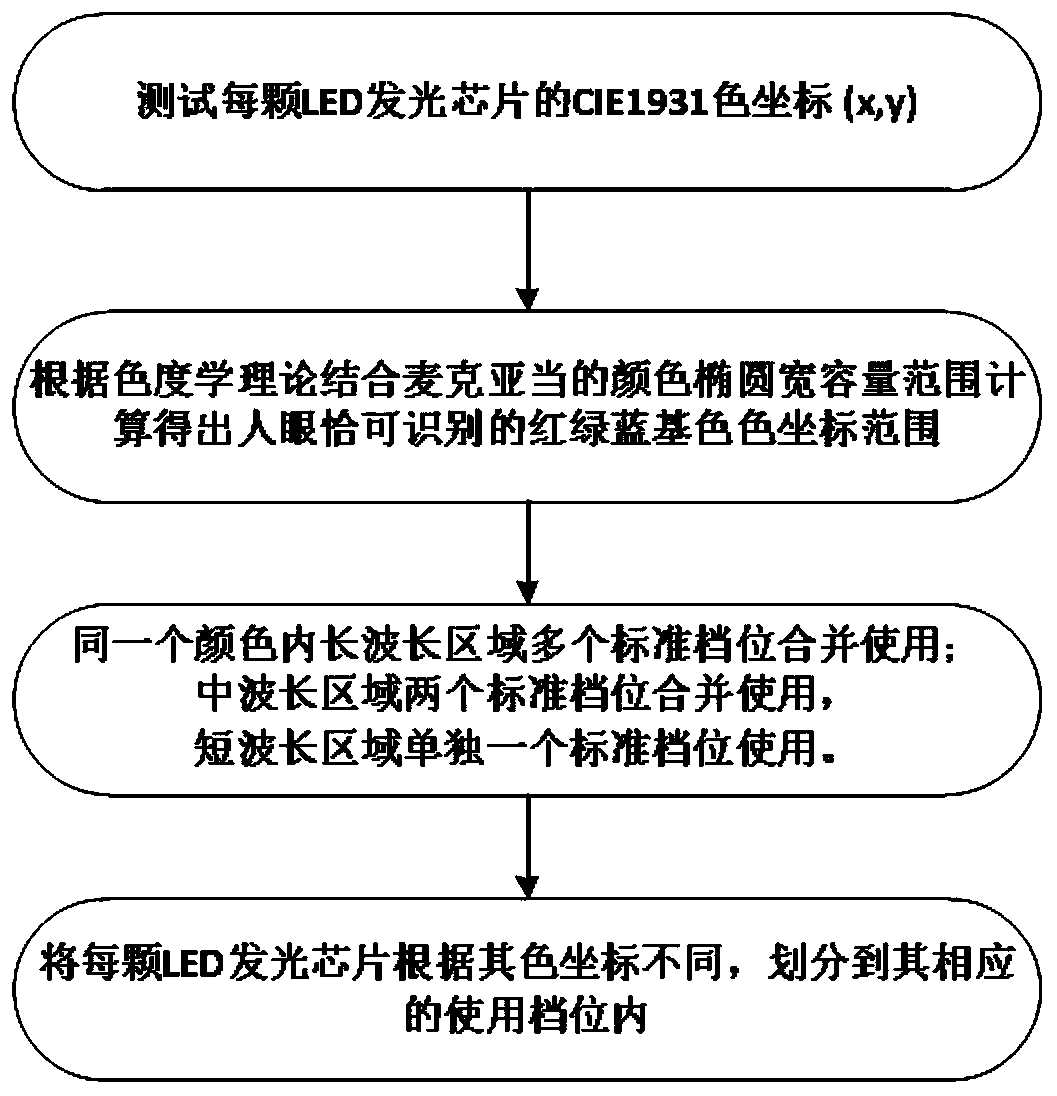

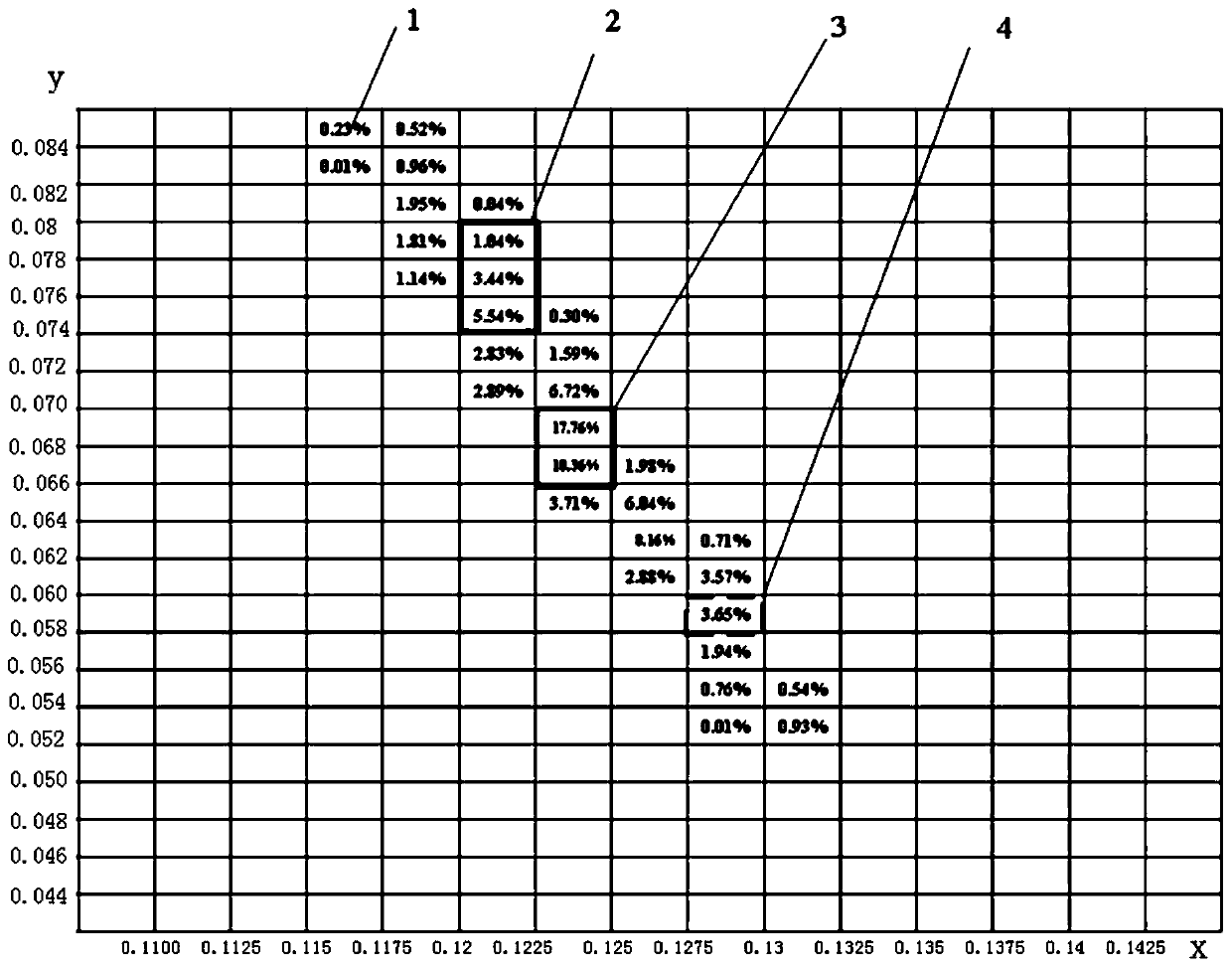

Light-emitting chip gear dividing method according to different color coordinate areas

The invention relates to an light-emitting chip gear dividing method according to different color coordinate areas. The method comprises the following steps that a CIE 1931 color coordinate of an LEDlight-emitting chip is tested; a naked eye just noticeable CIE 1931 color coordinate range is determined as a standard gear according to the Maxadam color ellipse width capacity range of the chromaticity theory in combination with screen display effects; according to the naked eye just noticeable CIE 1931 color coordinate range, in the same color, 2-4 standard gears in a long wavelength area is combined into a using gear, 2 standard gears in a middle wavelength area is combined into a using gear, and 1 standard gear in a short wavelength area is used as a using gear; and the LED light emittingchip is divided into the corresponding using gears according different color coordinates of the chip. According to the method, color consistency of a display screen can be guaranteed, and the numberof gear dividing is small; and meanwhile, mixing treatment can be omitted by a chip manufacturer in each using gear, so that cost is saved.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

Method for improving color difference of LED printed circuit boards

InactiveCN110461097AGuaranteed viscosityGuaranteed uniformityPrinted circuit liquid treatmentScreen printingLED display

The invention provides a method for improving the color difference of LED printed circuit boards, which is characterized by comprising the following steps: S1, color difference analysis; and S2, colordifference improvement. The color difference improvement process includes the following sub-steps: S21, increasing the ink collecting frequency for the first time; S22, increasing the ink collectingfrequency for the second time; and S23, improving the uniformity of the ink and ensuring the viscosity of the ink. Through a large number of creative experiments, the inventor has found a method for improving the color difference of LED printed circuit boards, which can ensure the viscosity and uniformity of ink in the screen printing process and better ensure the color difference consistency of finished products. The problem of 'mosaic' effect in the splicing of LED display screens, especially indoor bare display screens, is solved.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

display screen

ActiveCN109244223BEnsure color consistencyAvoid the Modular EffectSolid-state devicesIdentification meansPhysical chemistryEngineering

The present invention relates to a display screen, comprising a substrate and a plurality of light-emitting units, each of the light-emitting units is arranged on the substrate, and a temperature-sensitive color-changing ink layer is arranged on the light-emitting unit, and the temperature-sensitive color-changing ink layer is used for When the temperature of the thermochromic ink layer reaches the discoloration temperature, it changes from a colored state to a transparent state. The invention enables the display screen to maintain the color consistency of the off-screen state while avoiding affecting the brightness of the display screen when the screen is on, and can effectively improve the efficiency of inkjet.

Owner:UNILUMIN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com