Patents

Literature

107results about How to "Reduce construction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

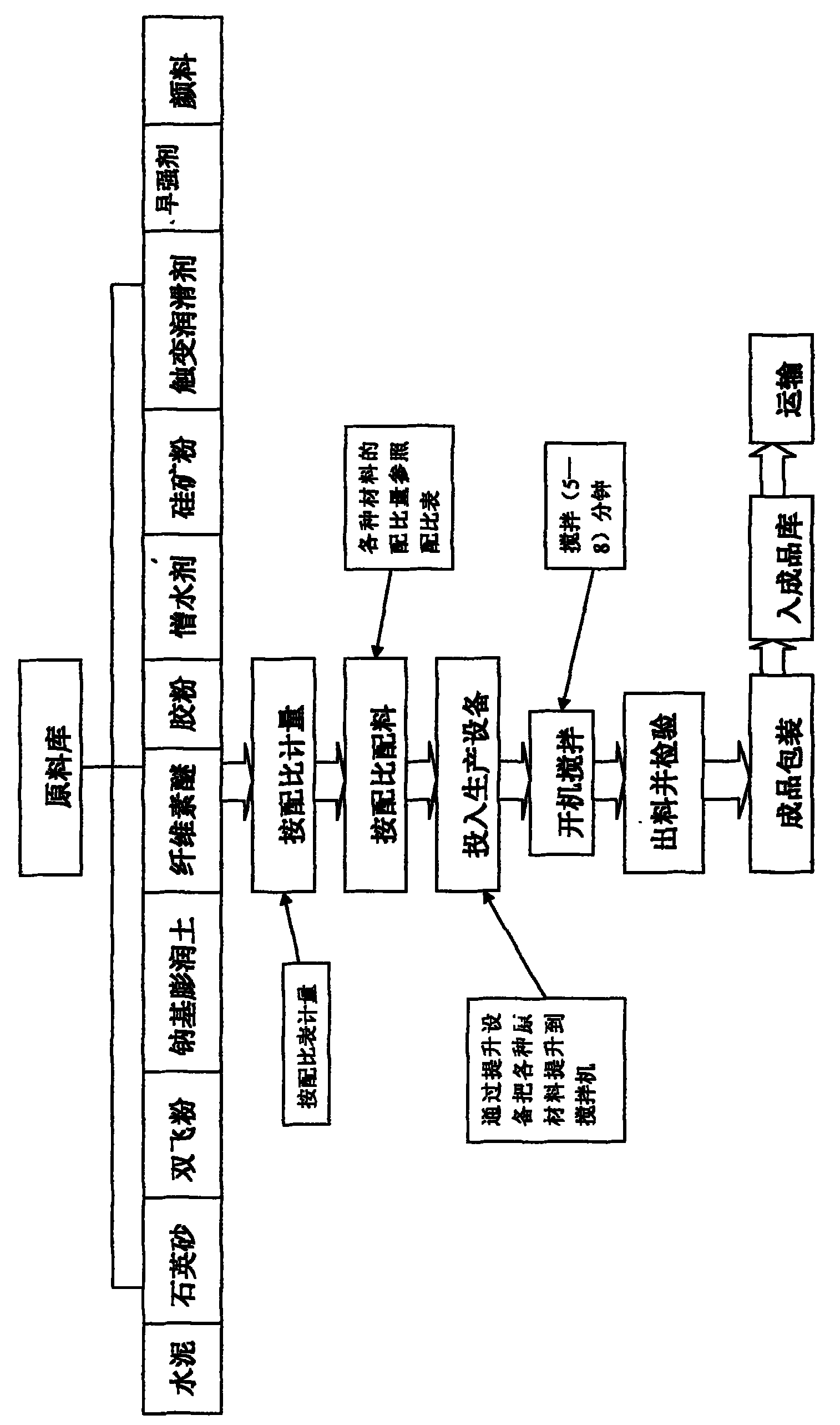

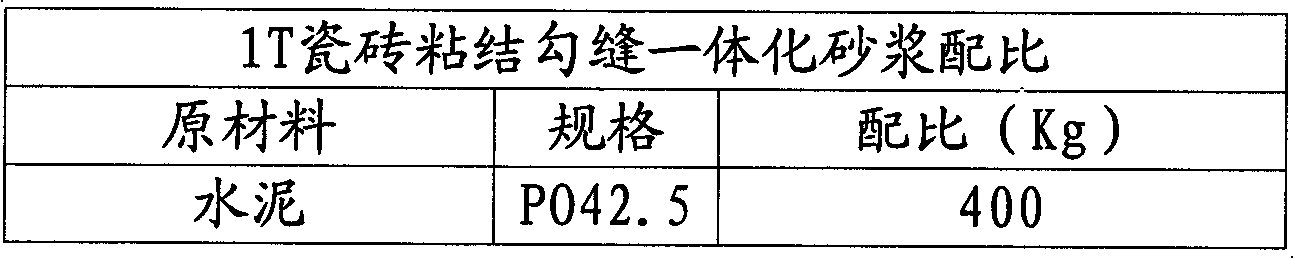

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

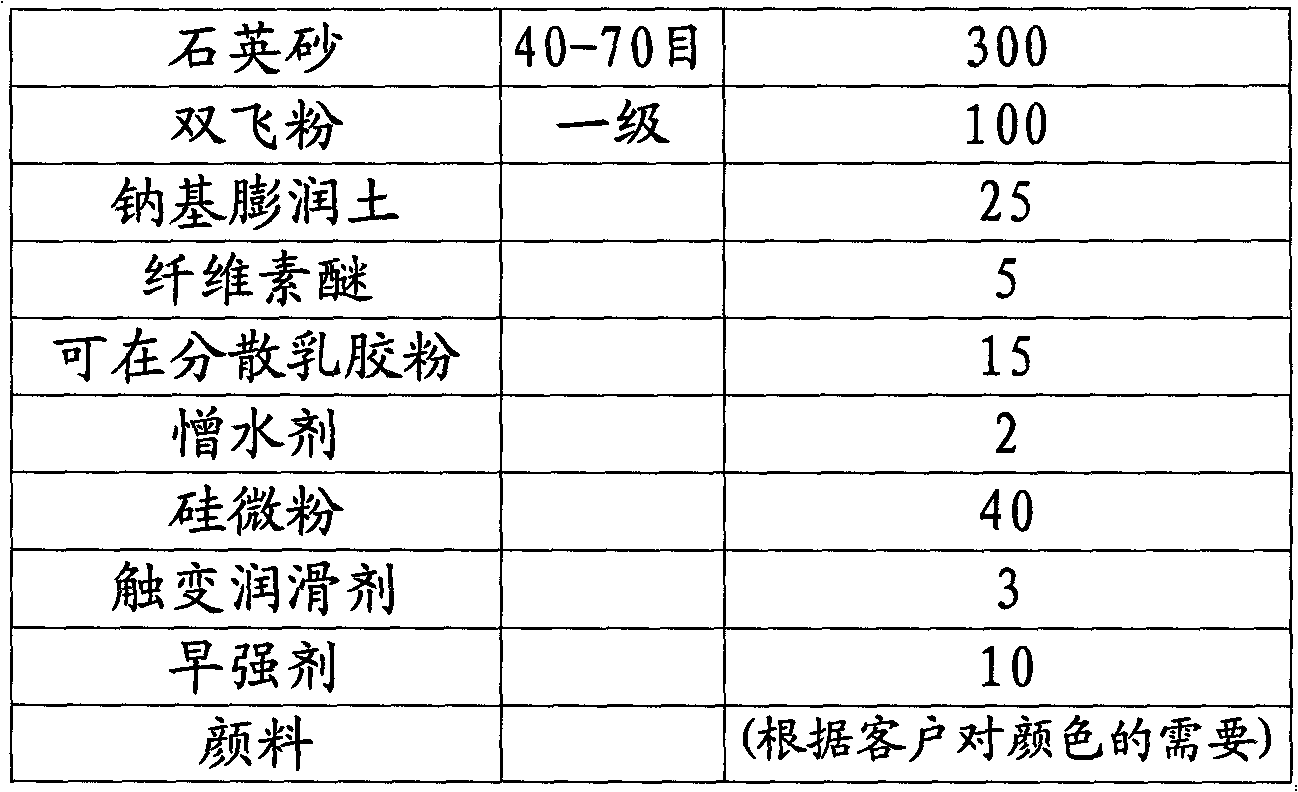

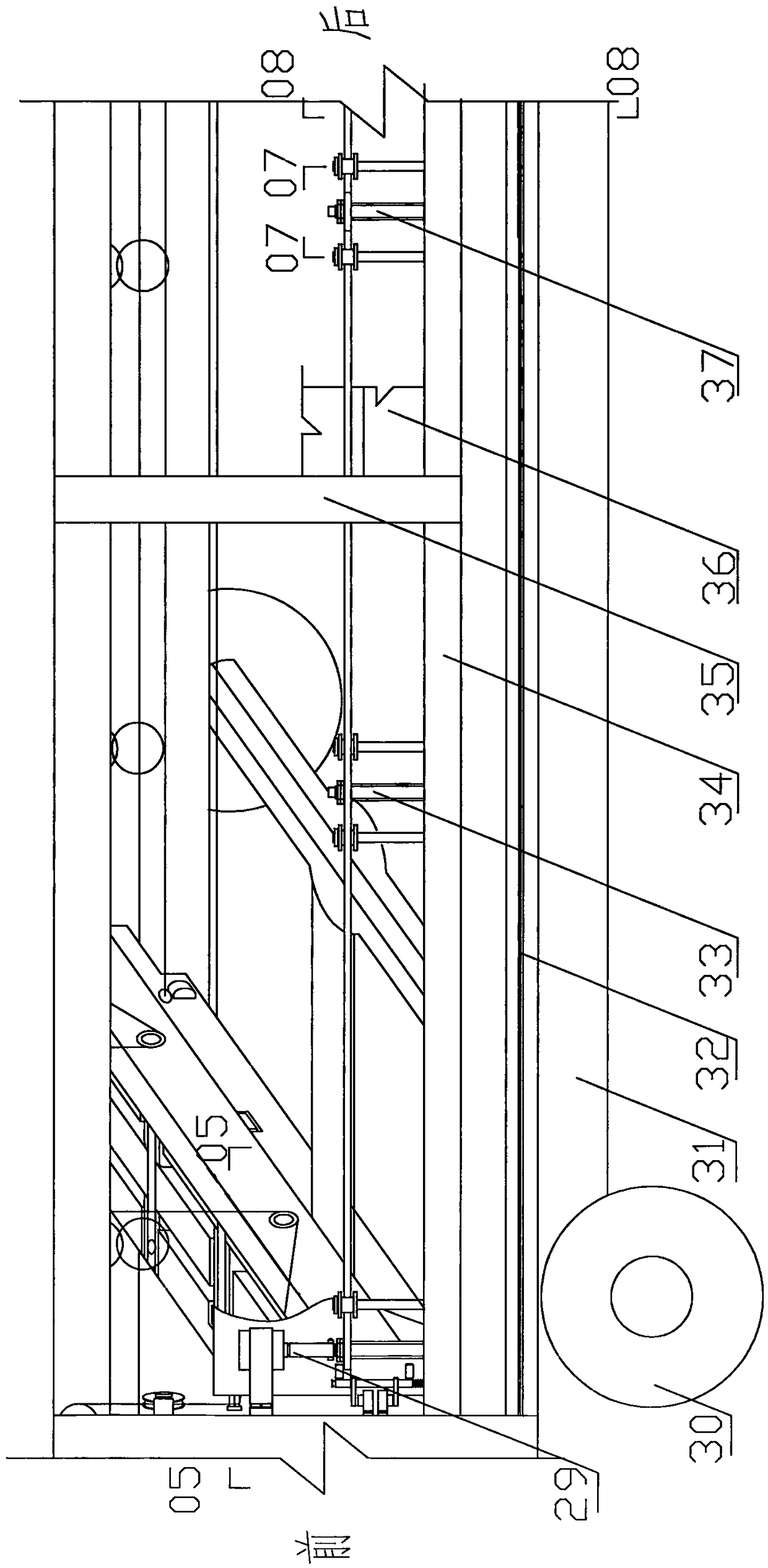

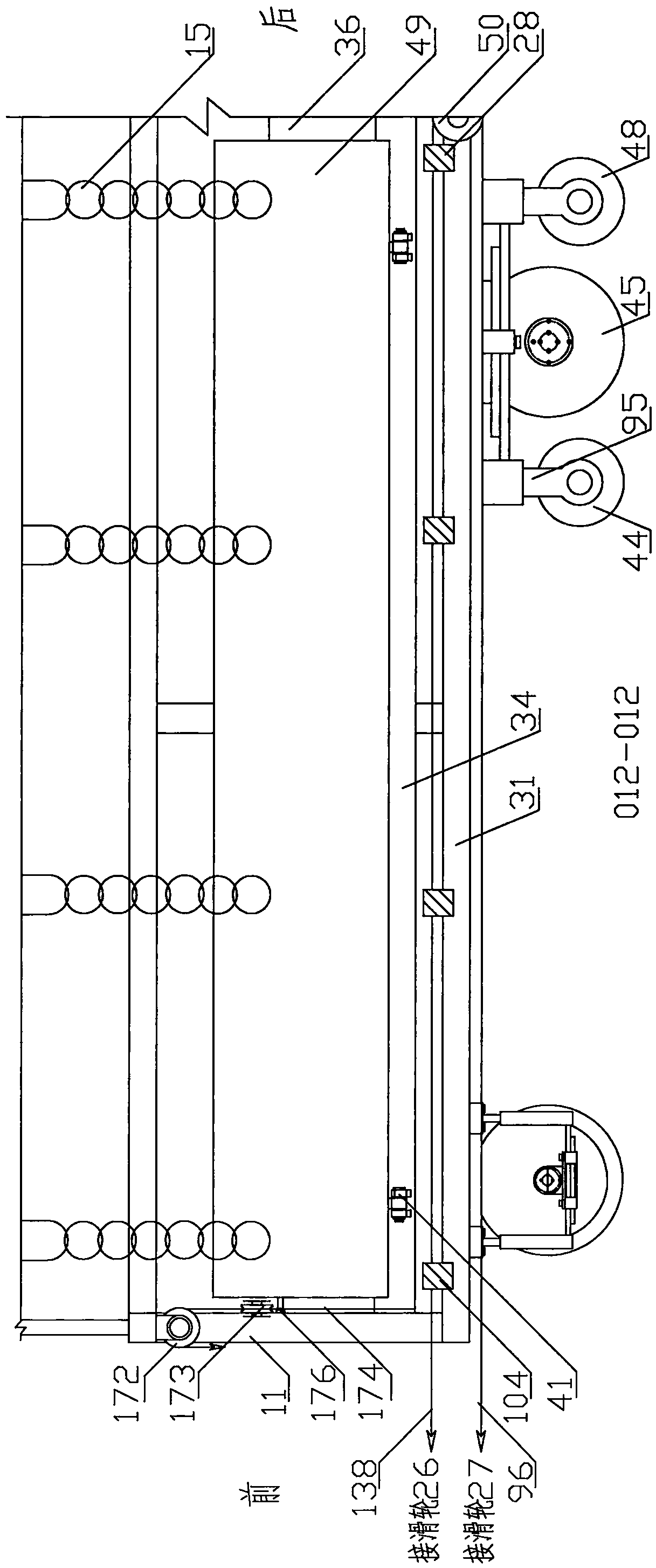

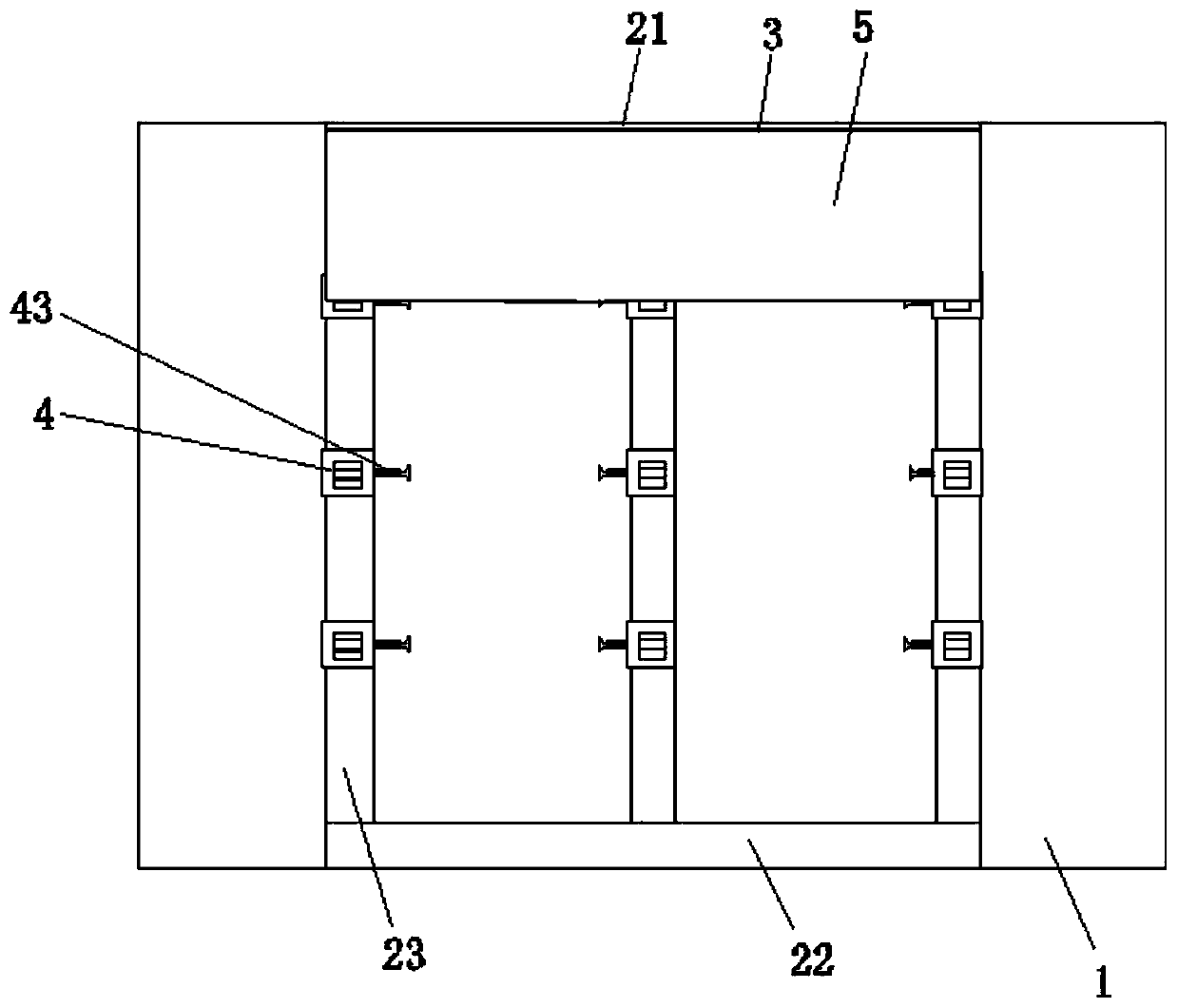

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

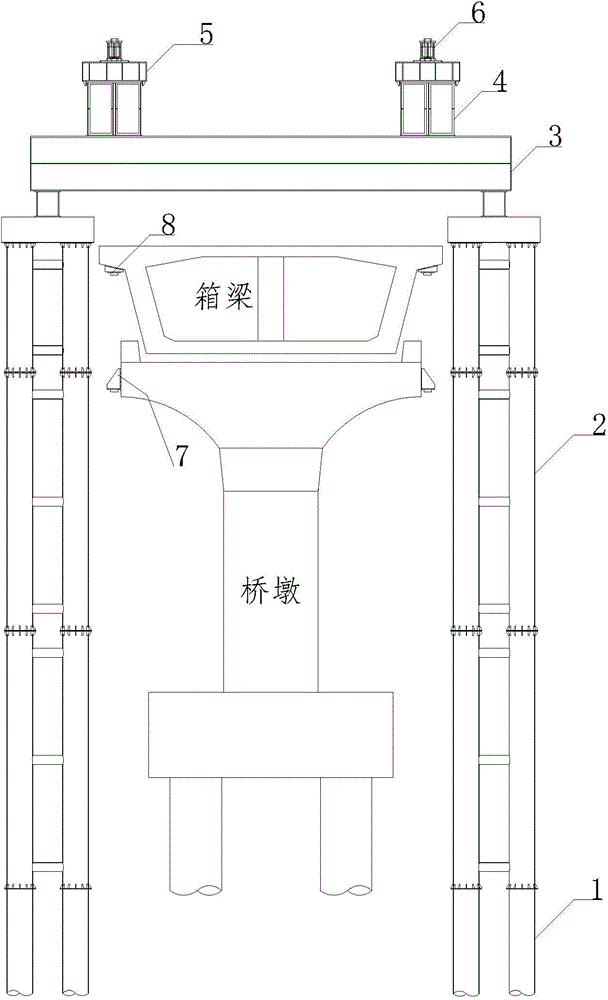

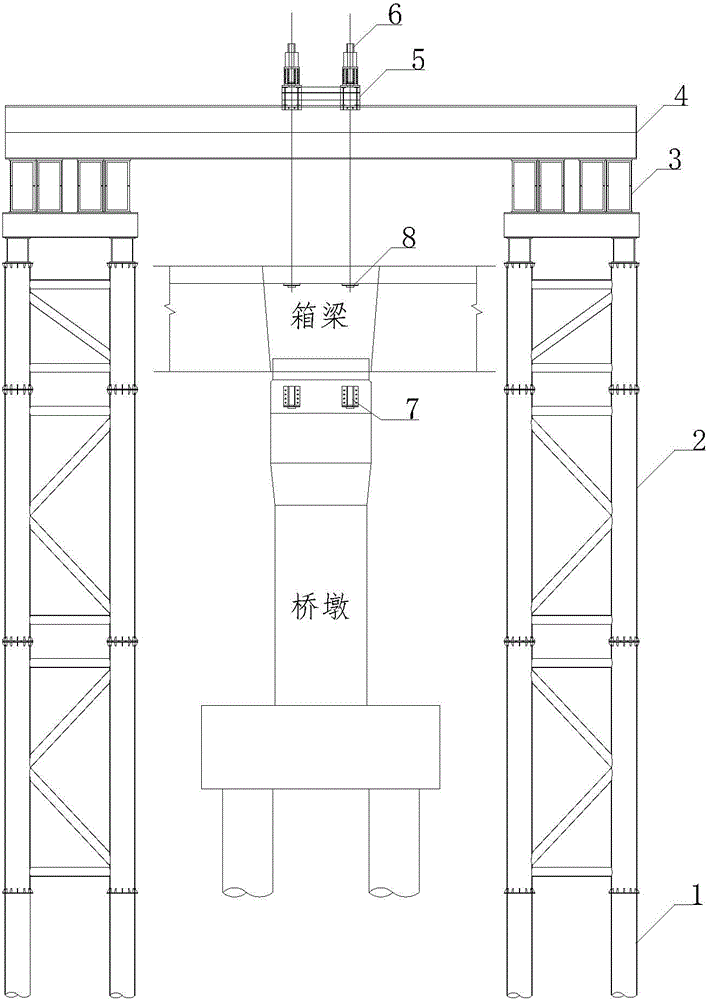

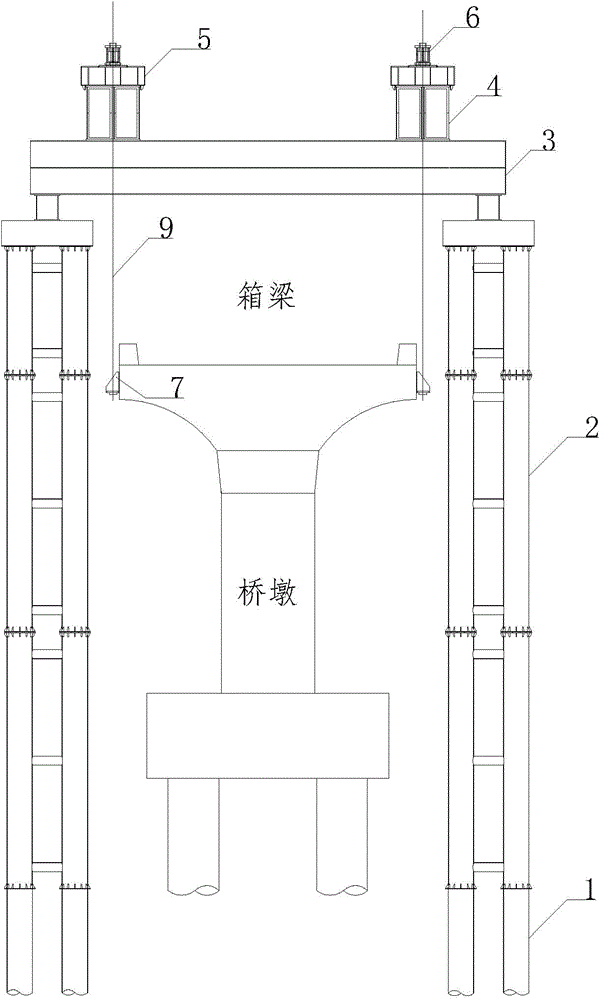

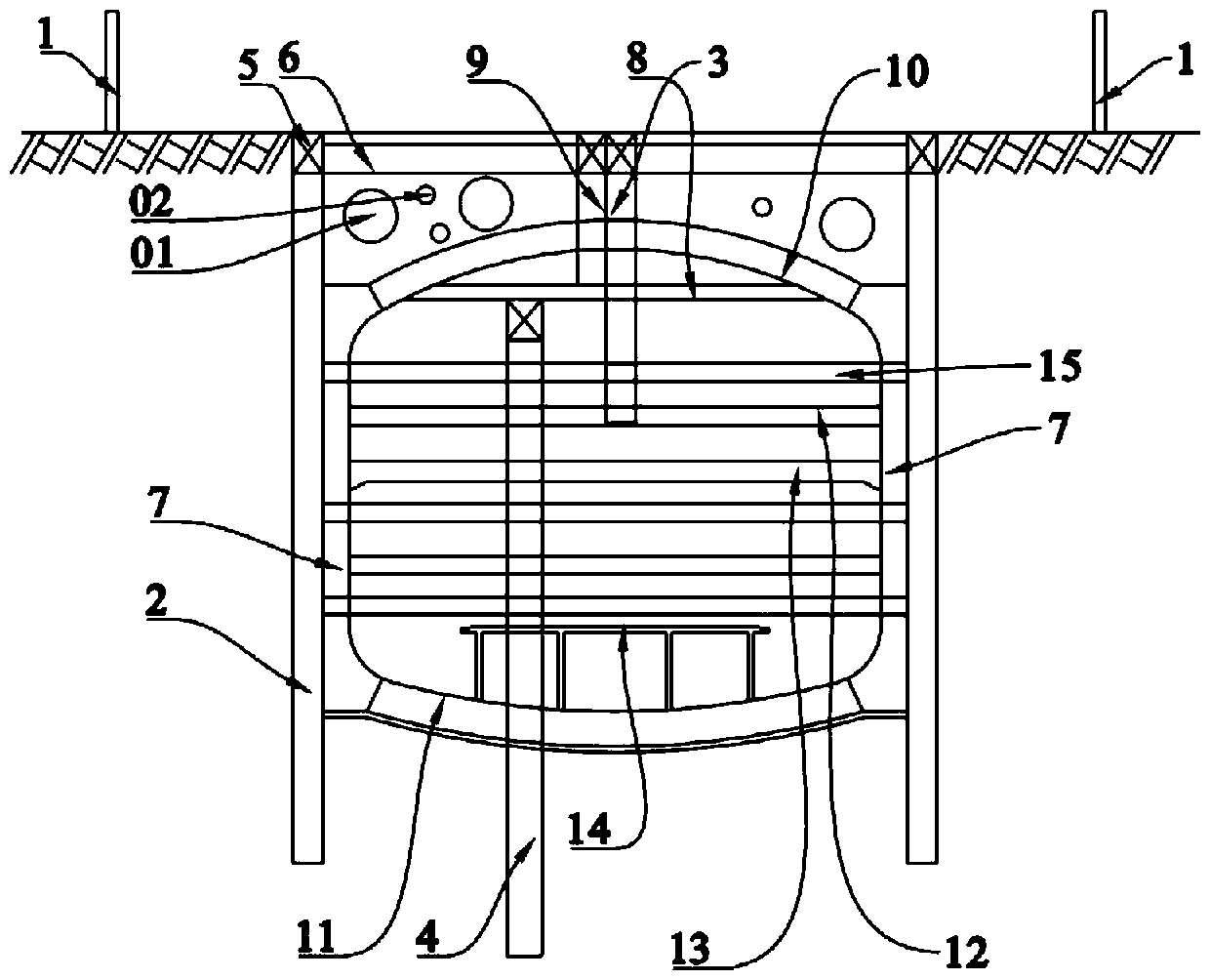

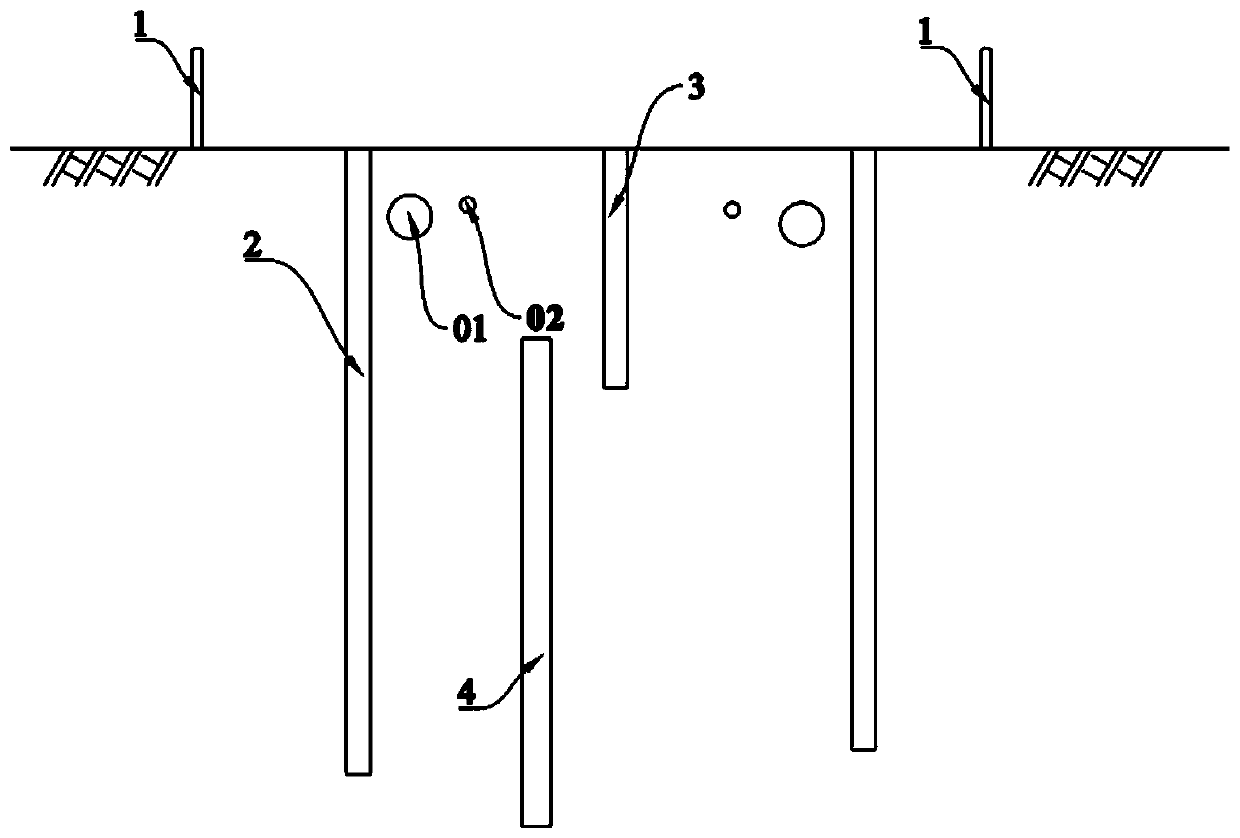

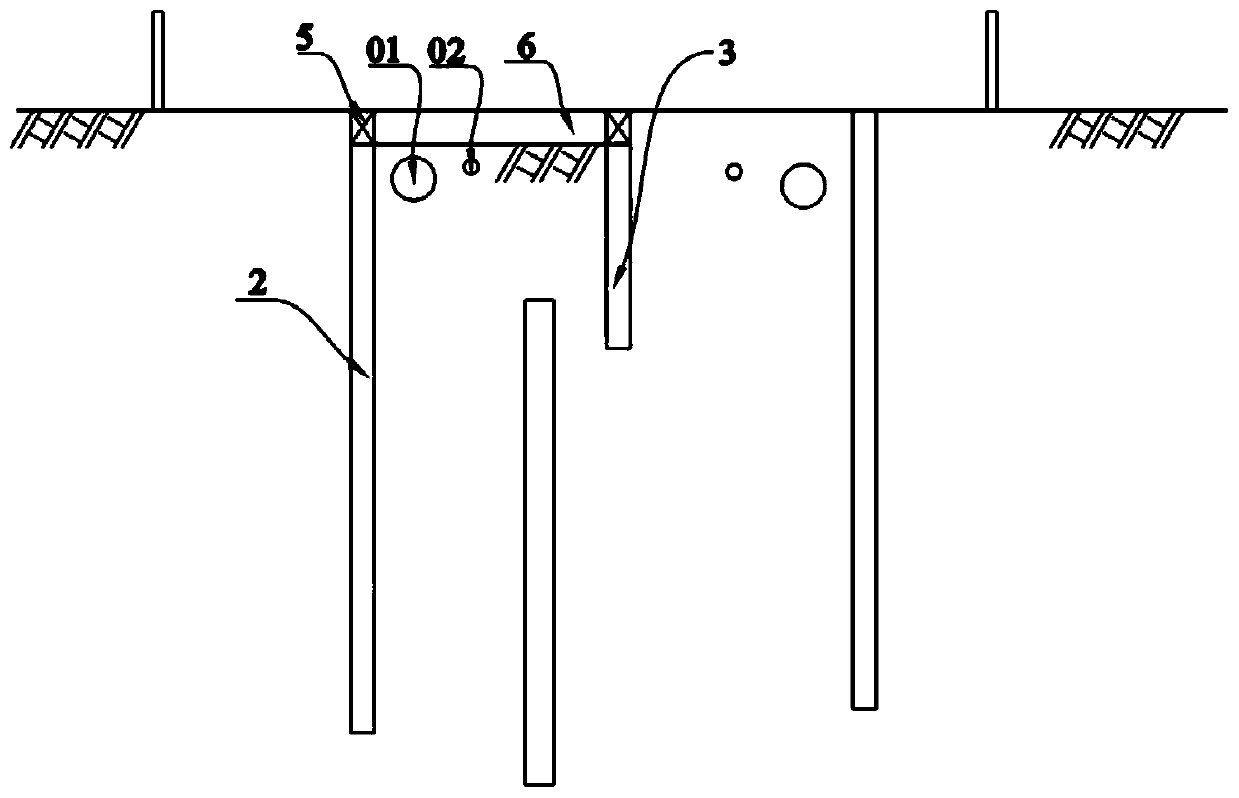

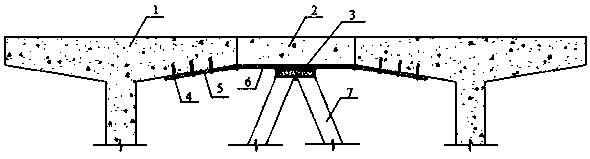

Dragging, translating and lowering device and method for dismantling pier top beam section and pier

ActiveCN104963301AGood adaptabilityReduce construction processBuilding repairsContinuous beamPipe support

The invention provides a dragging, translating and lowering device for dismantling a pier top beam section and a pier. The device comprises four supporting points, wherein each supporting point comprises four steel pipe piles, four steel pipe supporting frames, four transverse girders, four longitudinal translation beams, two longitudinal translation devices and two lifting and lowering systems; transverse translation beams can move in a transverse direction; the longitudinal translation devices are arranged at the upper parts of the transverse translation beams; the lifting and lowering systems are fixed on the longitudinal translation devices; the transverse translation beams are used for adjusting transverse positions of the lifting and lowering systems; the longitudinal translation devices are used for adjusting longitudinal positions of the lifting and lowering systems; and the lifting and lowering systems are used for lifting or lowering the pier top beam section and the pier. A dragging, translating and lowering method for dismantling the pier top beam section and the pier, provided by the invention, is capable of economically and efficiently solving a dismantling problem of a pier top box beam and pier structure under in the absence of the hoisting of a crane, suitable for dismantling the pier top beam section and the pier of a beam bridge or a bridge with a concrete girder and especially suitable for dismantling engineering for the pier top box beam and pier structure of a multi-span continuous beam bridge using a whole-span lowering dismantling technology.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

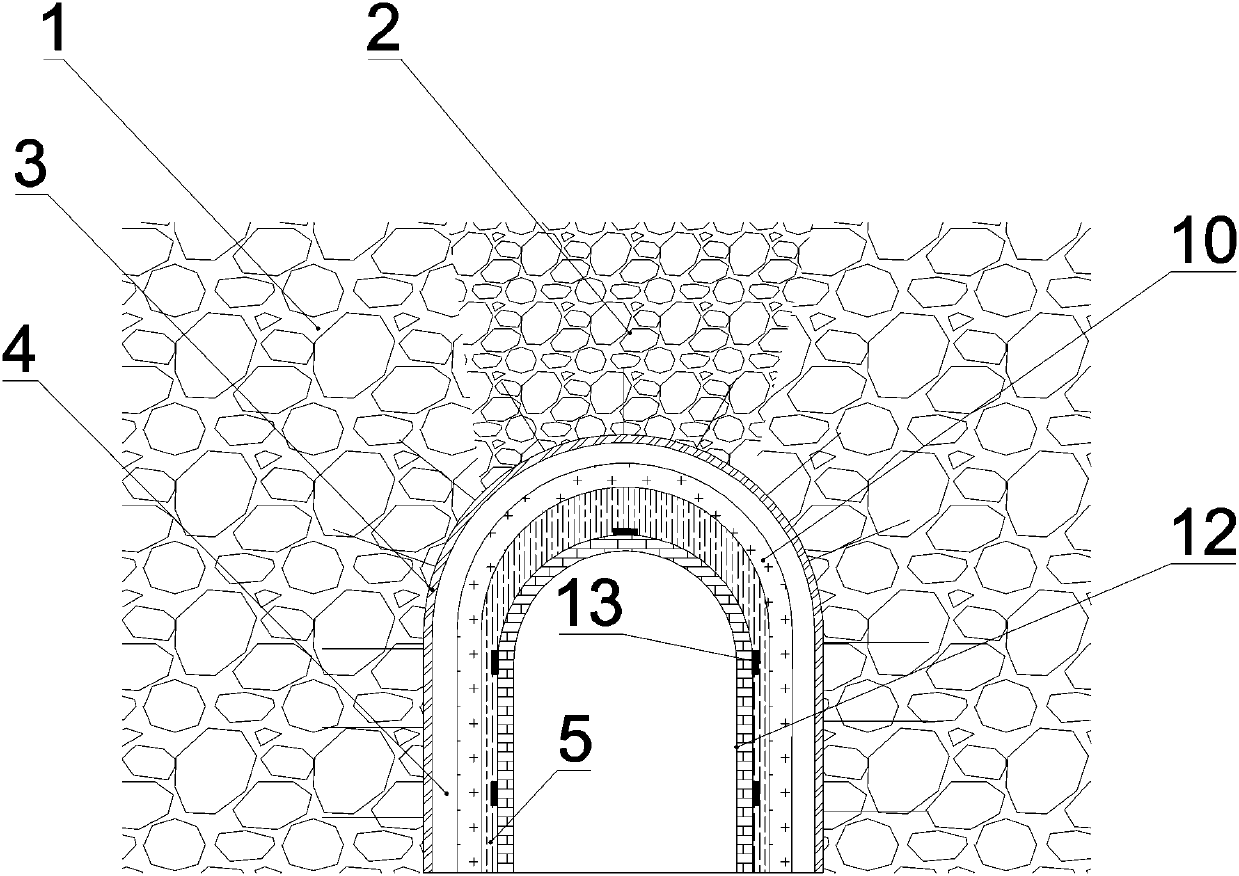

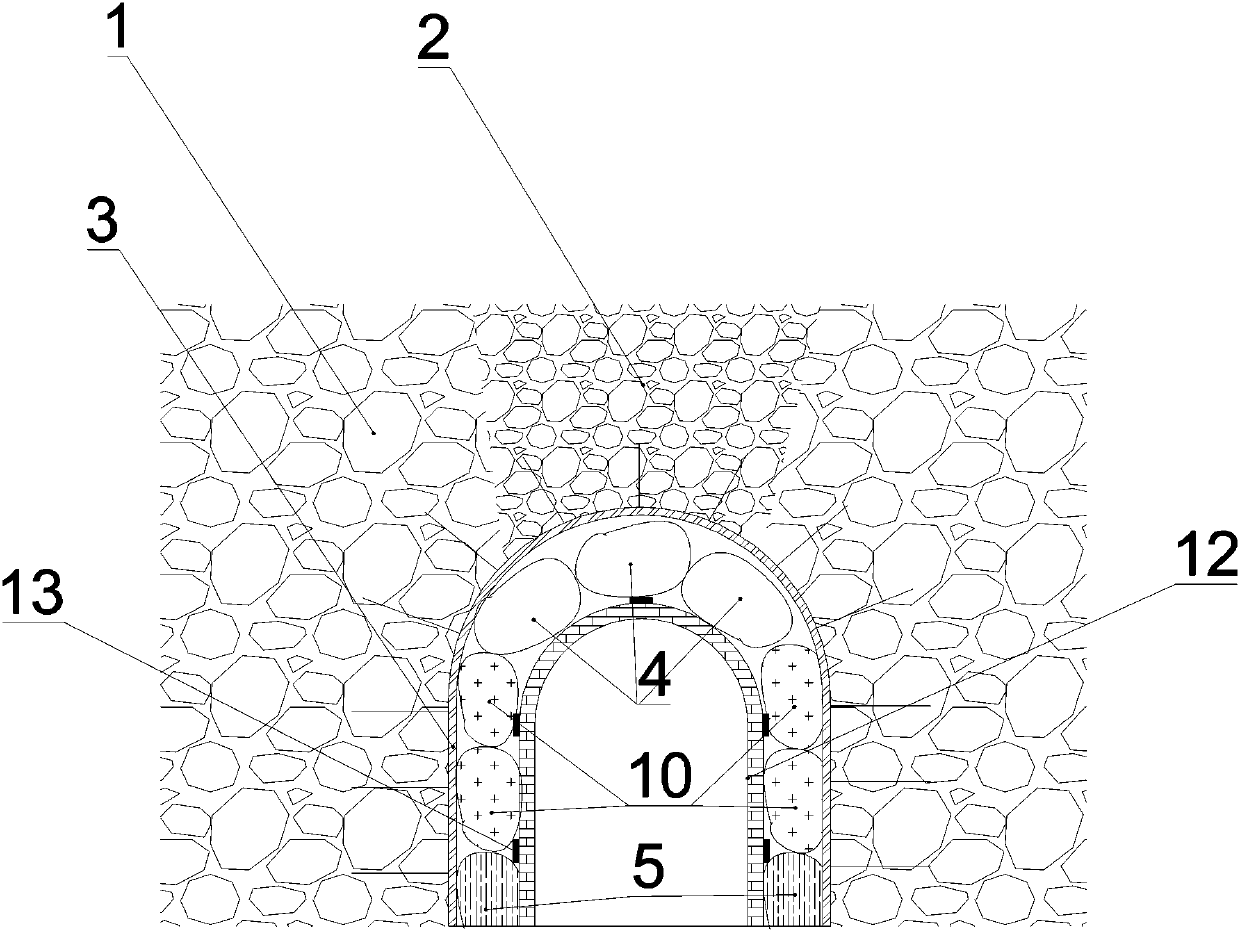

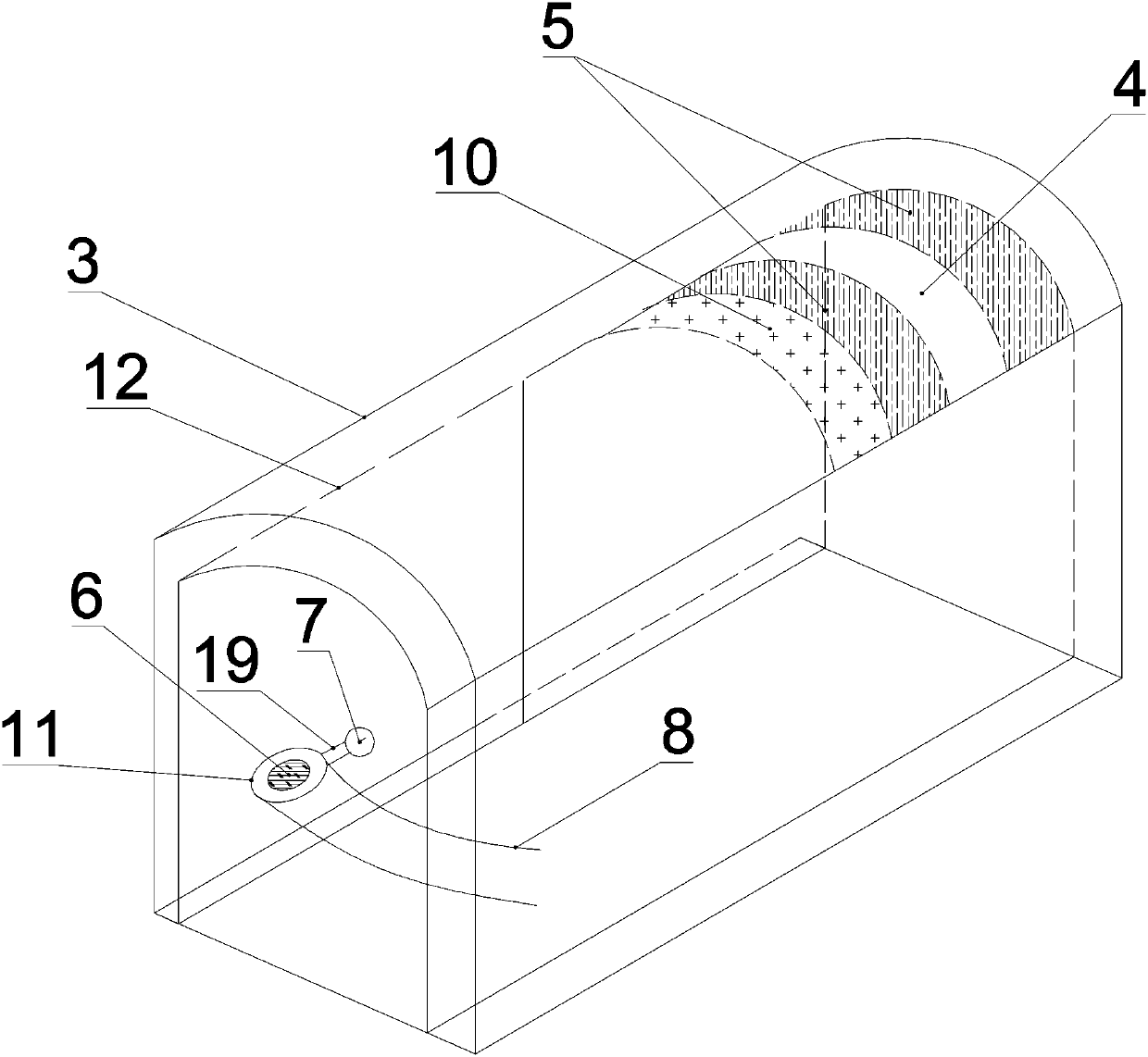

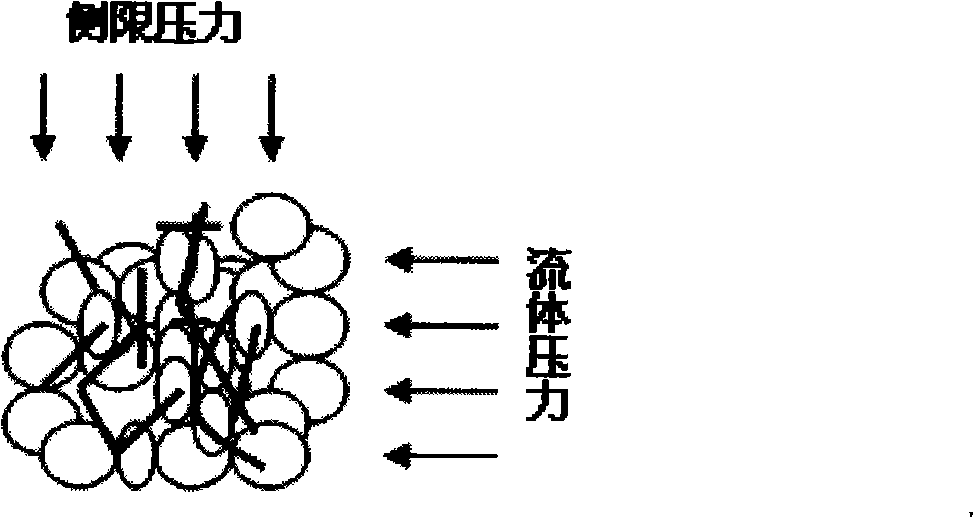

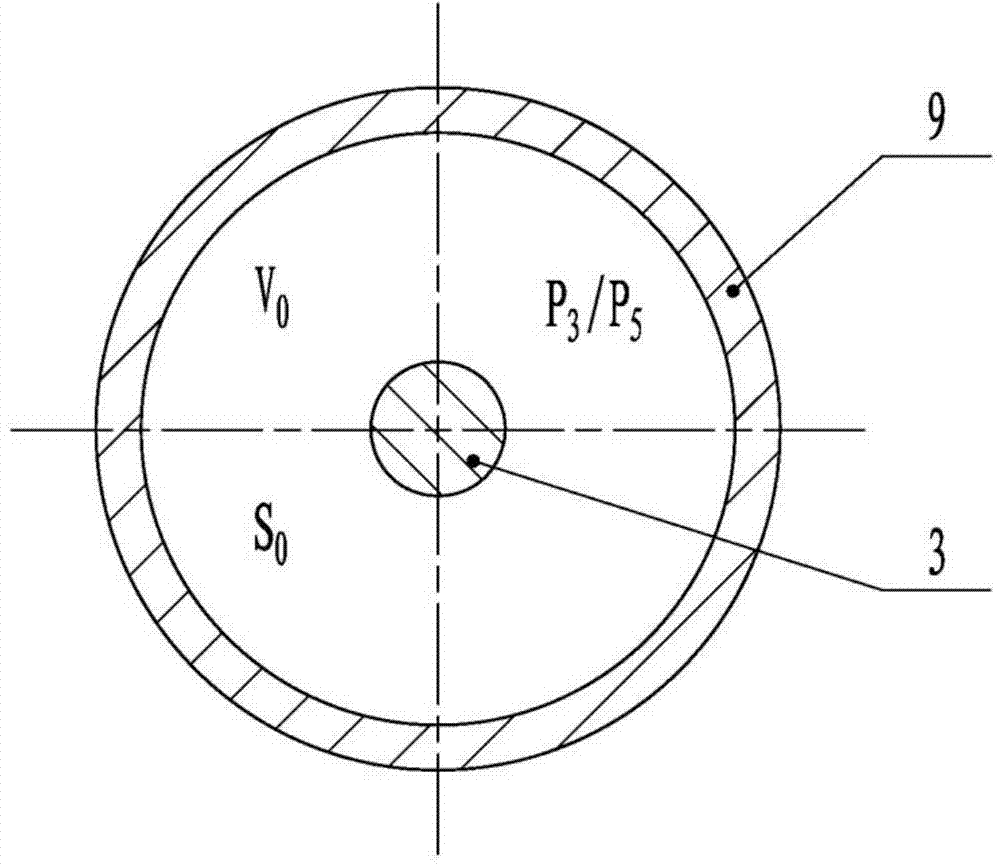

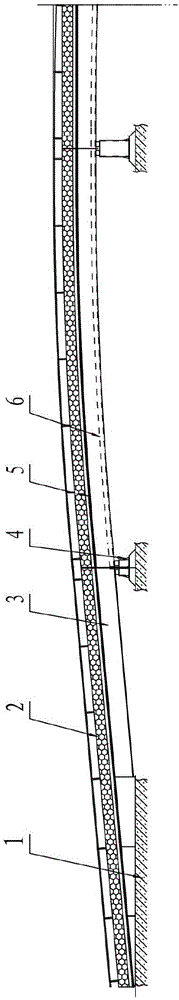

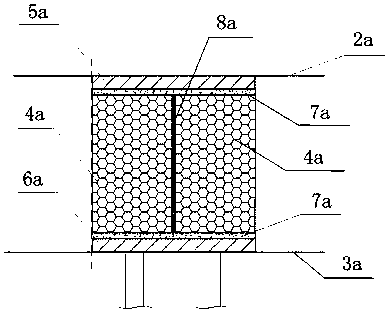

Split-cabin lining pressure-relief support structure with multiple fillers, and construction method

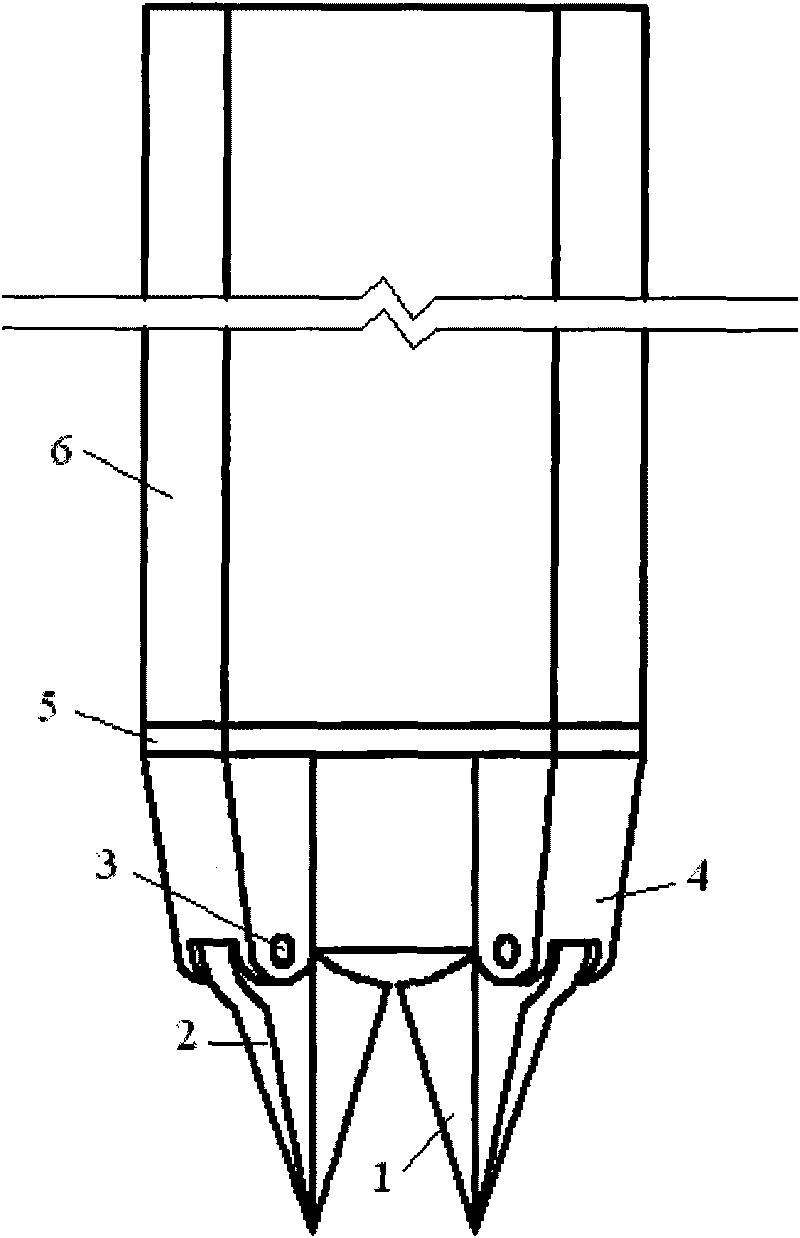

ActiveCN109653765AEven by forceSolve the problem of significant uneven forceUnderground chambersTunnel liningStress conditionsExpanded clay aggregate

The invention provides a split-cabin lining pressure-relief support structure with multiple fillers, and a construction method. The split-cabin lining pressure-relief support structure comprises an intact surrounding rock interspersed with a surrounding rock plastic zone. Two linings are arranged on the inner side walls of the intact surrounding rock and the surrounding rock plastic zone, and a gap is formed between the two linings; a clast cabin is arranged on the inner side wall, close to the intact surrounding rock and the surrounding rock plastic zone, in the gap; a liquid clast layer is arranged in the clast cabin, and a ceramsite cabin and a water-filling jig are arranged in gaps between the clast cabin and the two linings. The split-cabin lining pressure-relief support structure andthe construction method have the advantages that the surrounding rock is supported by the cabins with the different fillers in a stacking mode of up-down, left-right, front-back, etc. according to stress conditions and rock deformation of a tunnel at different positions, pressure relief is realized through the fluidity of the fillers in the cabins in case of the rock deformation, and accordingly,the advantages of different materials are combined and utilized maximally.

Owner:CHINA THREE GORGES UNIV

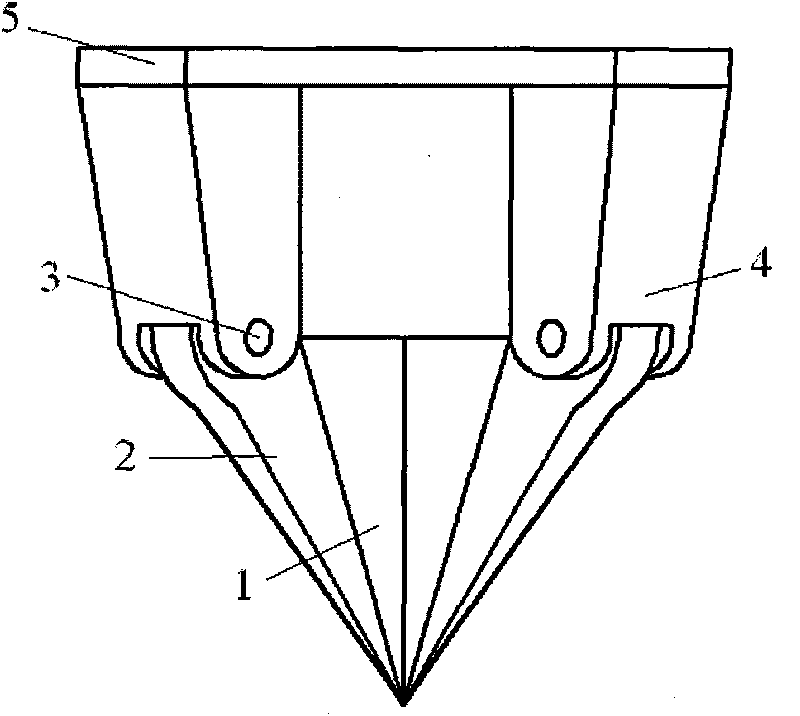

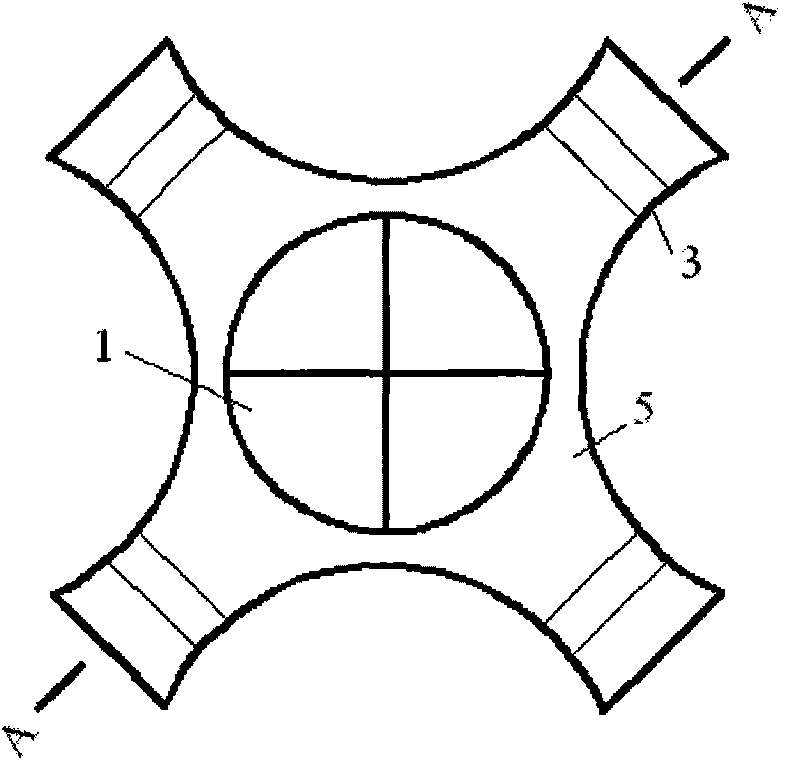

Valve pile tip structure device of cast-in-place X-shaped concrete pile and using method thereof

The invention relates to a valve pile tip structure device of a cast-in-place X-shaped concrete pile and a using method thereof. In the valve pile tip structure device, an X-shaped pile die is fixedly connected with a connecting section, the lower end of the connecting section is fixedly connected with a transition section, the lower part of the transition section is rotatablely connected with the upper part of a strengthening rib through a connecting hinge, and the strengthening rib is fixedly connected with a valve; and when the X-shaped pile die is dropped down, the valve pile tip is aligned with a pile position, and a curved surface triangular steel sheet is closed and inserted in a soil body, the X-shaped pile die is vibrated to reach a designed depth so that concrete enters an inner cavity of the valve, and the X-shaped pile die is pulled up to automatically open the curved surface triangular steel sheet so as to form the cast-in-place X-shaped concrete pile. The valve pile tip structure device overcomes the defects that a precast pile shoe is precast in a factory, has long consumed time, large volume and inconvenient transportation, moves and deflects downwards and even breaks away from the pile die, cannot be used repeatedly, has high manufacturing cost, and the like. The valve pile tip structure device avoids repeated physical work, does not need to be precast in the factory, shortens the construction period, and reduces the cost.

Owner:HOHAI UNIV +1

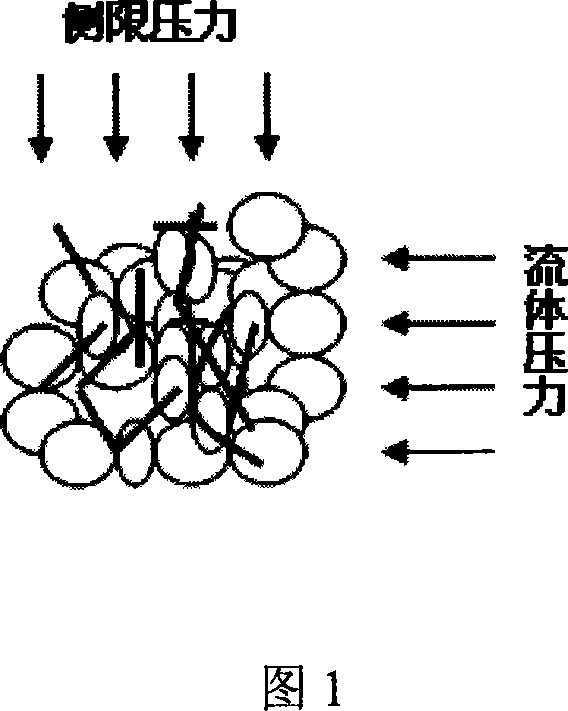

Non-screen pipe compound fracturing fabric network framework gravel-filling sand prevention method

InactiveCN101220736APermeability does not impairSolve the main problem of sand controlFluid removalFiberFormate

The invention provides a compound fracturing fabric network framework gravel insertion sand prevention method which does not use a sieve tube. A prepad fluid which includes two parts is poured into a well, the first prepad fluid is a weak water solution prepared by a micro emulsion solution and formate which are disclosed in a patent document with the patent application number of 200610009675.8, the blending ratio is that each 10 tons of water is added with micro emulsion and formate, both of which take up 2 percent of water weight; the second prepad fluid is viscoelastic load fluid with the blending ratio of 40 tons of water added with guar gum which takes up 2 percent of the water weight and 20 tons of sand. The invention has the advantages that the construction is easy and convenient which is laborsaving and timesaving; at the same time, the invention is suitable for a thin oil well, a gas well, a viscous crude well and has wide adaptation range to well temperature, and can greatly improve production efficiency and the productive capacity of the oil well, guarantee the regular production of the oil and gas well and also the comprehensive economic benefit is prominent.

Owner:哈尔滨市宏昌石油助剂有限公司

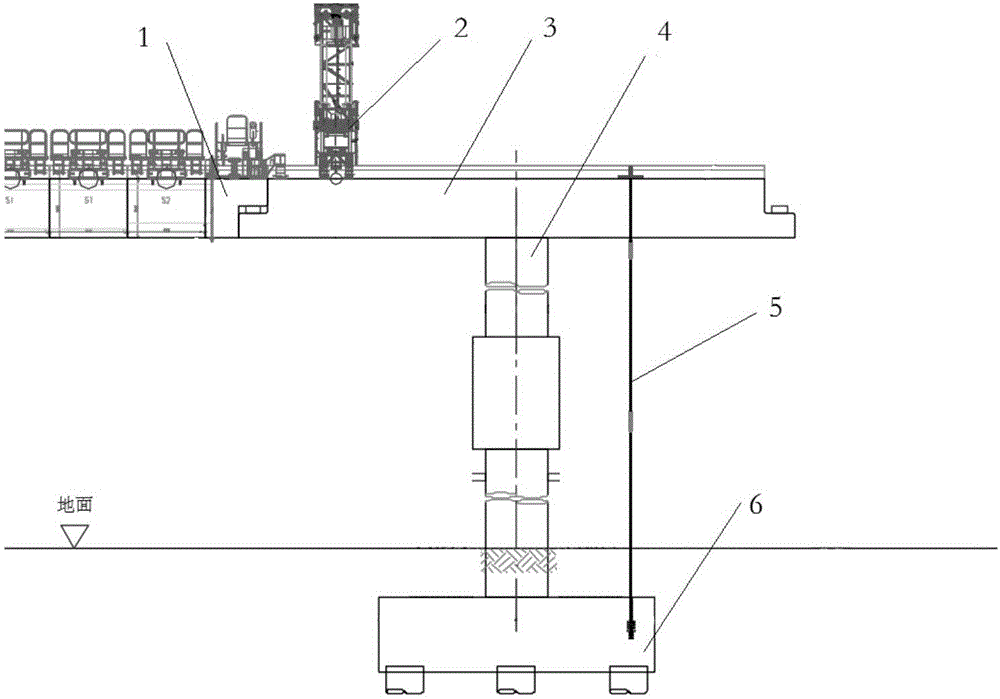

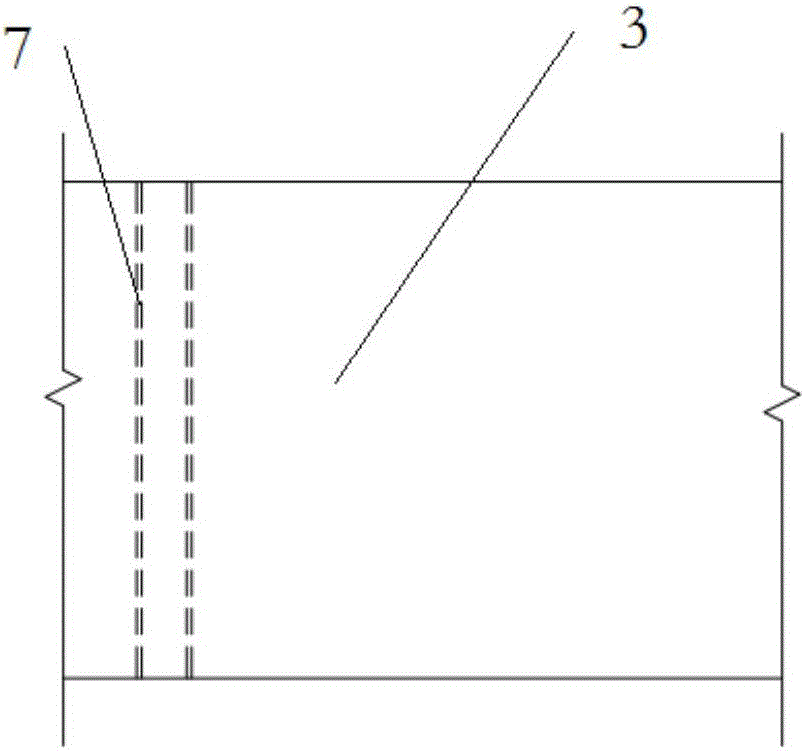

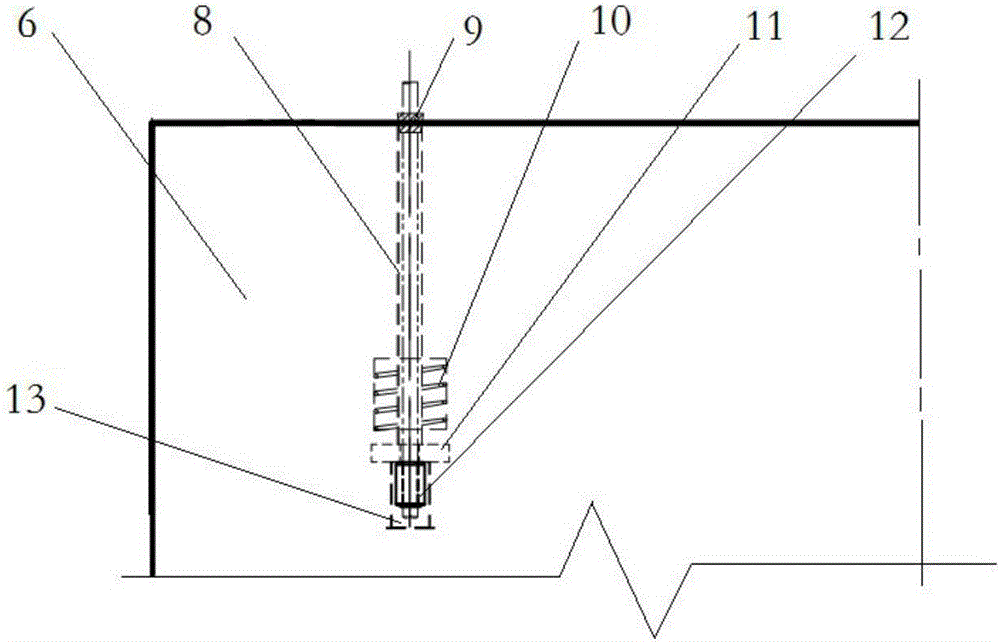

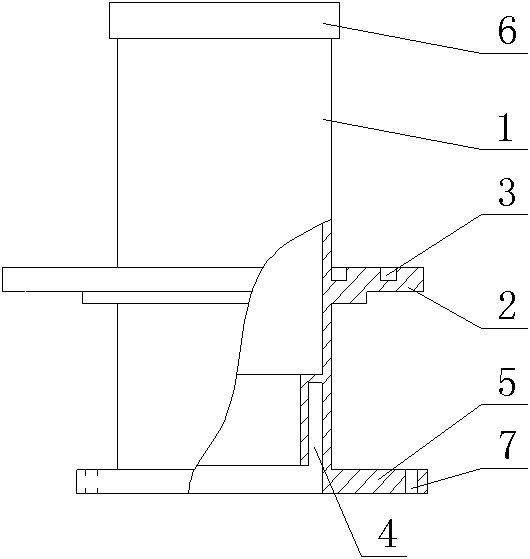

Large-cantilever bent cap tensioning anchorage temporary support device and construction method thereof

ActiveCN106436583AReduce investmentReduce construction processBridge erection/assemblySteel barSteel columns

The invention provides a large-cantilever bent cap tensioning anchorage temporary support device. The device comprises a bent cap pre-embedded steel circle pipe arranged on a long-span bent cap, a cushion cap pre-embedded steel circle pipe arranged on a cushion cap and a plurality of standard-knot fine rolled deformed steel bars connected through deformed steel bar sleeves. The upper position and the lower position of the bent cap pre-embedded steel circle pipe are arranged corresponding to the upper position and the lower position of the cushion cap pre-embedded steel circle pipe, and the standard-knot fine rolled deformed steel bars are connected in sequence to form a screw-thread steel column. The upper end of the screw-thread steel column penetrates through the bent cap pre-embedded steel circle pipe, the end is fixed with a screw-thread steel subplate, a screw-thread steel gasket and a screw-thread steel nut in sequence, and the lower end of the screw-thread steel column is screwed in the cushion cap pre-embedded steel circle pipe to be fixed. The invention further provides a construction method of the large-cantilever bent cap tensioning anchorage temporary support device. The construction process is less and the method is simple. When a bent cap and a cushion cap are poured, only a pre-embedded work needs to be done well, and when a bridge construction machine is about to be in place, only a small amount of manual work is needed to install the fine rolled deformed steel bars. Compared with other construction methods, a lot of personnel investment and equipment investment can be reduced, and the range of application is wide.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

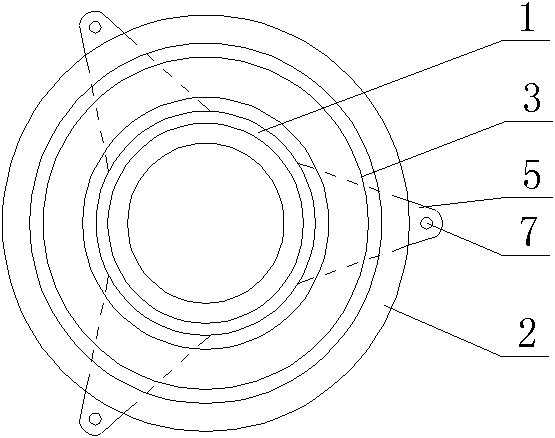

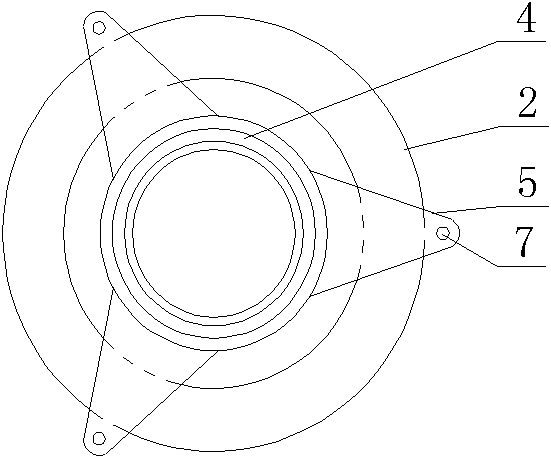

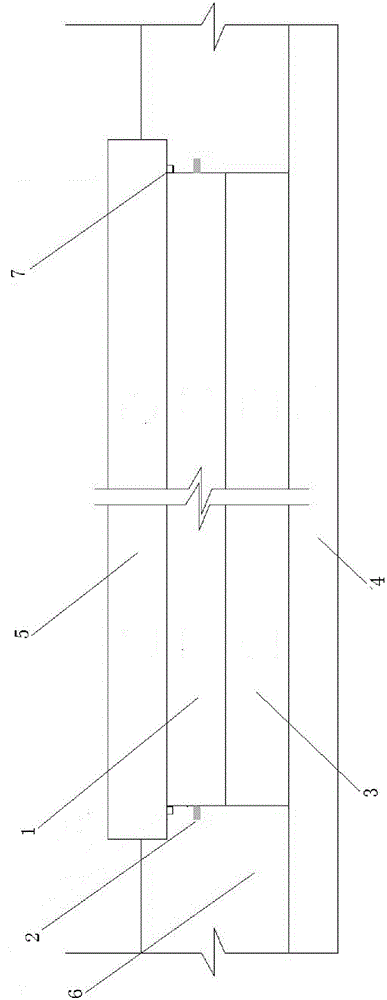

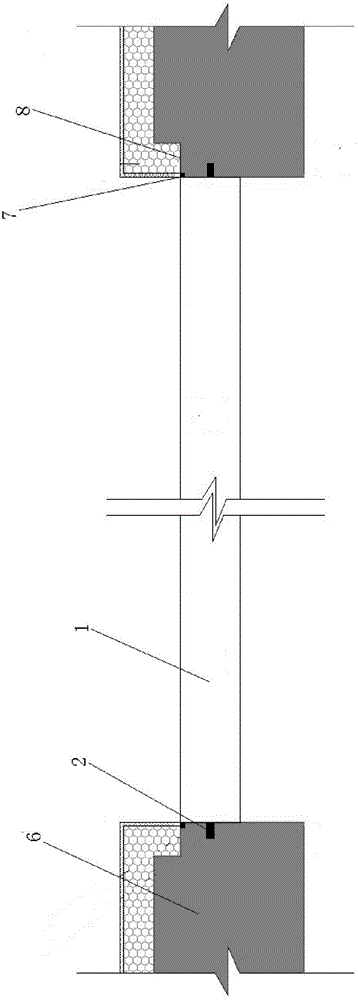

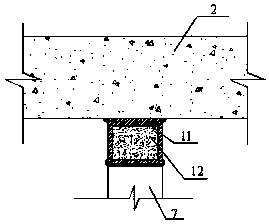

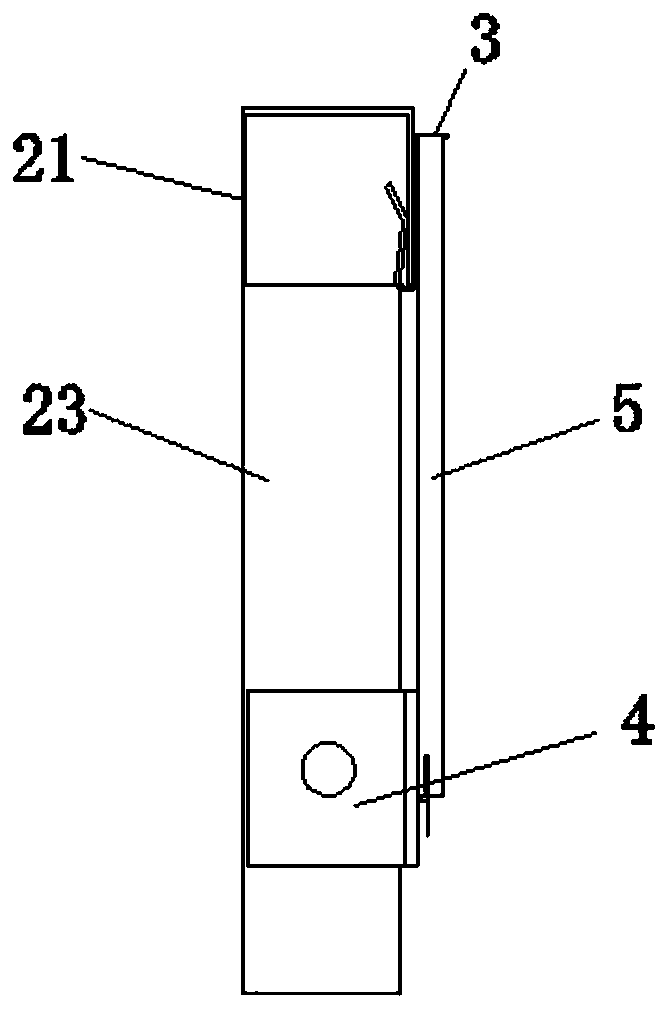

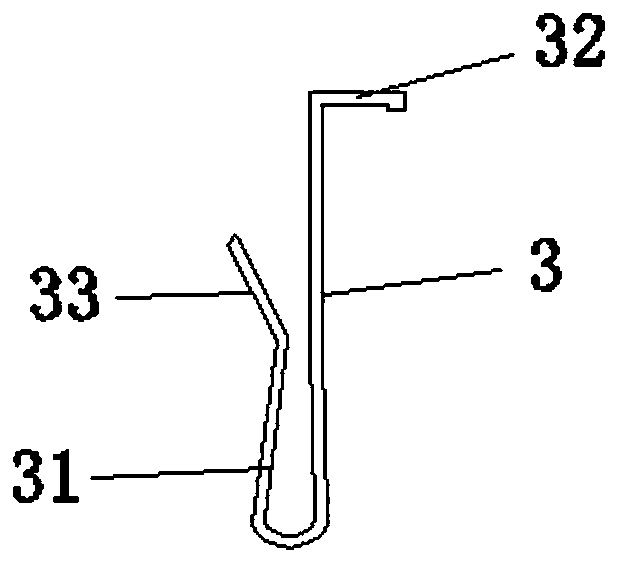

One-time embedded water-stop section for construction engineering drainage and construction method thereof

ActiveCN102095033AImprove reliabilityReduce contact areaSleeve/socket jointsPipesArchitectural engineeringEnergy source

The invention discloses a one-time embedded water-stop section for construction engineering drainage and a construction method of the one-time embedded water-stop section, which belong to the technical field of construction engineering embedded parts and construction thereof. The construction method comprises the following steps of: mounting a bottom die of a cast-in-place floor; mounting the one-time embedded water-stop section for the construction engineering drainage on the bottom die according to a design requirement, wherein the outer side of the bottom edge of the one-time embedded water-stop section for the construction engineering drainage is provided with a connecting supporting seat; fixing the one-time embedded water-stop section for the construction engineering drainage on the bottom die; covering a top cover on the top part of the one-time embedded water-stop section for the construction engineering drainage; casting concrete in situ on the bottom die; compacting the concrete by vibrating; and maintaining the cast floor. In the construction method, the water-stop section is embedded once, so that the construction processes are greatly reduced, the construction efficiency is significantly improved, and simultaneously a casing pipe is not required to be embedded and the energy source and the cost are saved. The construction method is particularly suitable for the construction of the one-time embedded water-stop section for the construction engineering drainage on construction engineering cast-in-place occasions.

Owner:CHENGDU NO 4 CONSTR ENG

Flexible prefabricated and assembled shear wall-external window integrated construction system and method

ActiveCN105064553AImprove turnover rateMeet the requirements of green constructionWallsFrame fasteningShear wallBuilding construction

The invention discloses a flexible prefabricated and assembled shear wall-external window integrated construction system. The flexible prefabricated and assembled shear wall-external window integrated construction system comprises a wall frame into which concrete is poured. A window hole is reserved in the wall frame. A window frame bench formwork is tightly attached to the inner wall face of the wall frame. A bottom window frame formwork, a window frame and a top window frame formwork are sequentially installed inside the window hole from interior to exterior. One face of the bottom window frame formwork is fixedly connected with the window frame bench formwork. The two sides of the window frame are fixedly provided with window frame embedded parts stretching into the wall frame. According to the flexible prefabricated and assembled shear wall-external window integrated construction system and method, the window frame formworks can be repeatedly utilized, the construction flow is easy and convenient, the time limit for a project is shortened, the higher stability is achieved after the window frame is installed, and the better waterproof and heat preservation effects are achieved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

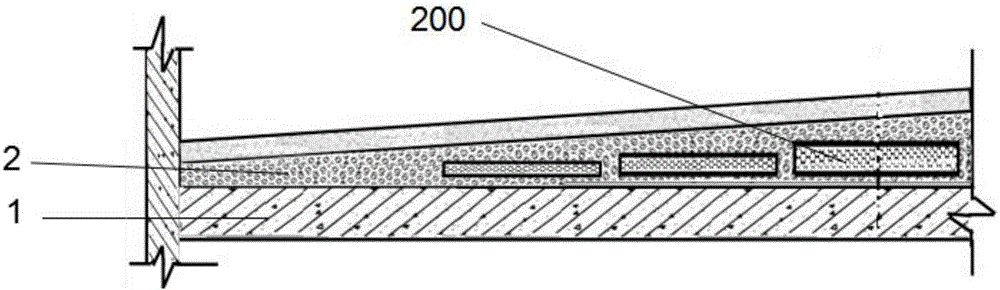

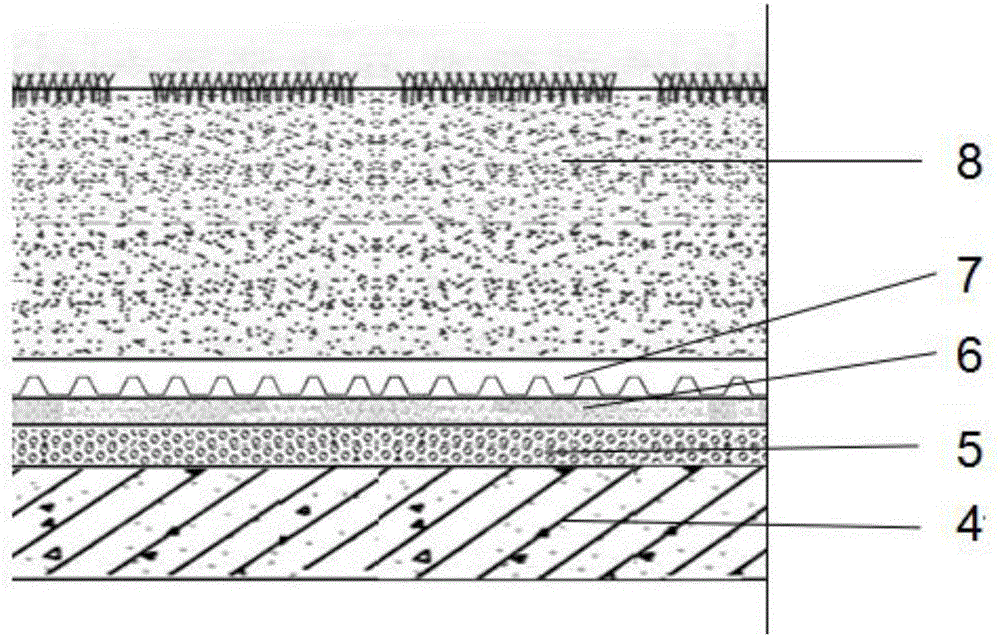

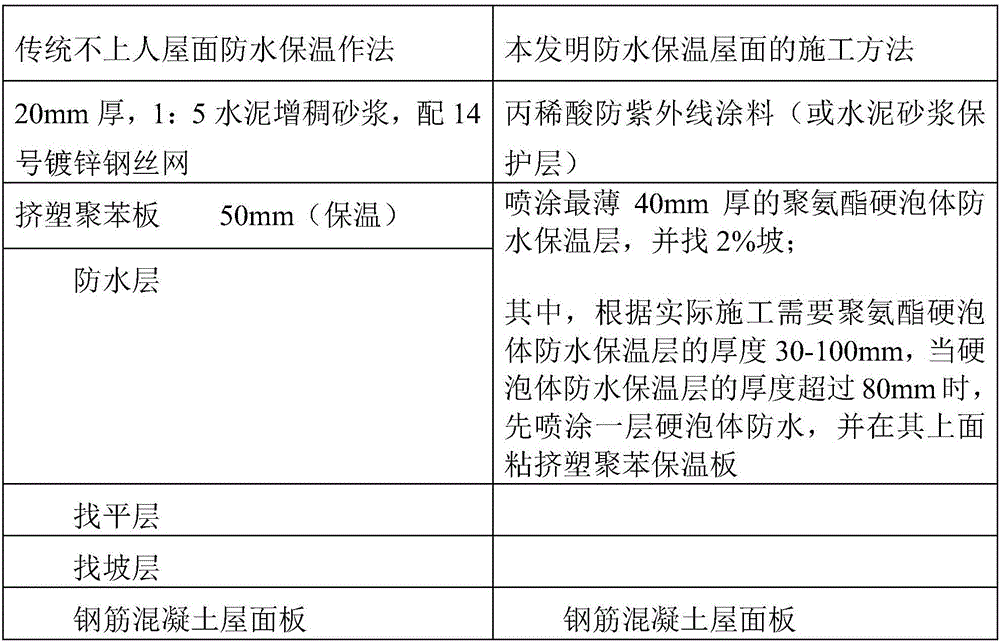

Construction method of waterproof heat preservation roof

ActiveCN106836663AReduce construction processReduce construction costsBuild-up roofsReinforced concreteEngineering

The invention provides a construction method of a waterproof heat preservation roof. The construction method comprises the steps that firstly, a polyurethane hard foam waterproof heat preservation material is sprayed to a reinforced concrete roof plate; secondly, before the polyurethane hard foam waterproof heat preservation material is foamed and cured, an extruded plastic polyphenyl heat preservation plate with the thickness being gradually decreased is laid onto the polyurethane material in the sloping direction; and thirdly, another polyurethane hard foam waterproof heat preservation material is sprayed onto the extruded plastic polyphenyl heat preservation plate, and a sloping layer with the gradient being 2% is formed. According to the method, the polyurethane waterproof heat preservation layer is directly sprayed onto the roof plate, the heat preservation performance and the waterproof performance of polyurethane are utilized, and the heat preservation layer, the waterproof layer and the sloping / leveling layer of the roof are integrated into a whole. The construction method of the waterproof heat preservation roof is simple, fast to implement and low in construction cost.

Owner:北京利信诚工程技术有限公司

Sieve tube free composite fracturing fibre sand prevention process

InactiveCN101265798ASolve the problem of not being able to prevent powder and fine sandSolve the problem of compromising reservoir permeabilityFluid removalDrilling compositionFiberGlass fiber

Owner:哈尔滨市宏昌石油助剂有限公司

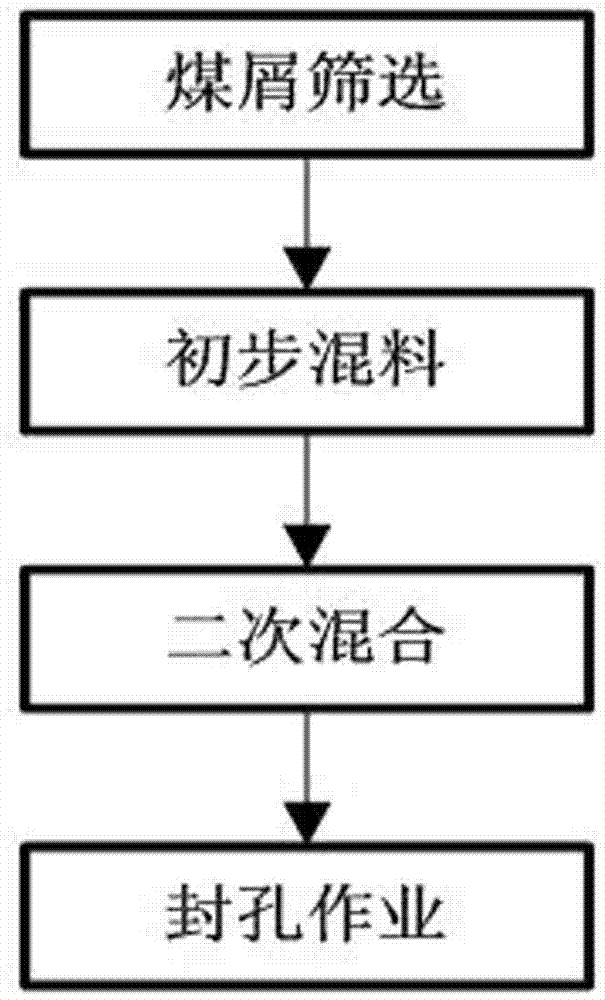

Mining coal dust based hole-sealing and grouting material, and preparation hole-sealing process

InactiveCN107011881AImprove bindingImprove compactionDrilling compositionSealing/packingAdhesiveWhole body

The invention relates to a mining coal dust based hole-sealing and grouting material. The mining coal dust based hole-sealing and grouting material consists of the following materials in parts by mass: 15.87 to 28.65 percent of coal dust, 28.65 to 31.75 percent of an adhesive, 0.48 to 0.93 percent of a crosslinking agent, 3.17 to 6.17 percent of an enhancer, 0.32 to 0.62 percent of an expanding agent, 0.14 to 0.63 percent of a flexibilizer, 0.16 to 0.57 percent of a coupling agent and the balance of water. The preparation hole-sealing process comprises four steps of screening the coal dust, mixing the materials primarily, mixing for the second time and performing hole-sealing operation. According to the grouting material, on one hand, the whole combining property of the structure, the compaction, blockage and leak blocking effects, and the weather tolerance of the grouting material are effectively improved, and on the other hand, the pulverized coal at the periphery of a drill hole can adhere to each other again to form a continuous whole body, the drilling stability is improved, the construction process of the drilling hole-sealing construction is greatly retarded while the dust pollution in the drilling construction operation field can be reduced, on-site construction operation is facilitated, the flexibility and the reliability of the drilling hole-sealing operation are improved, and wide application prospect is achieved.

Owner:HENAN POLYTECHNIC UNIV

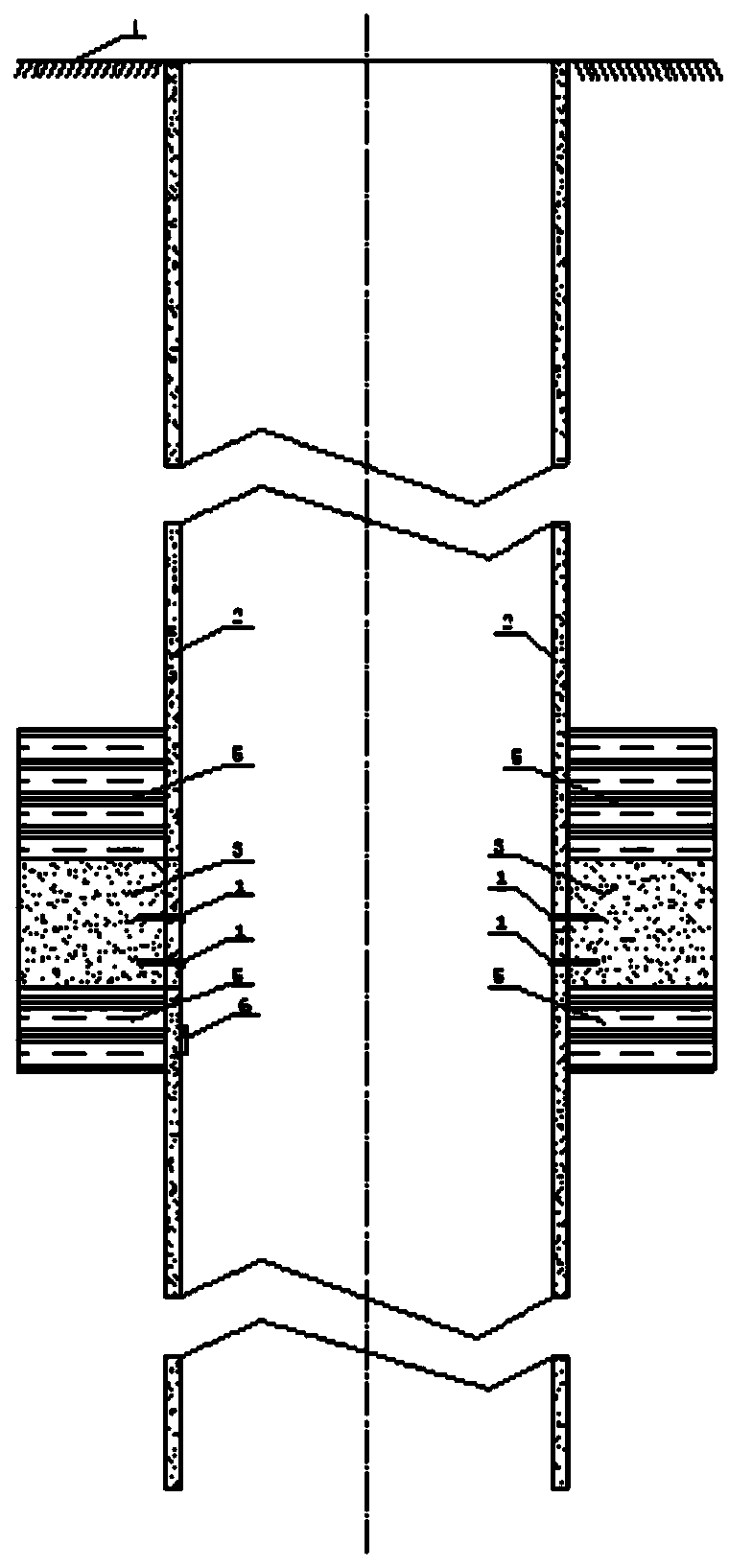

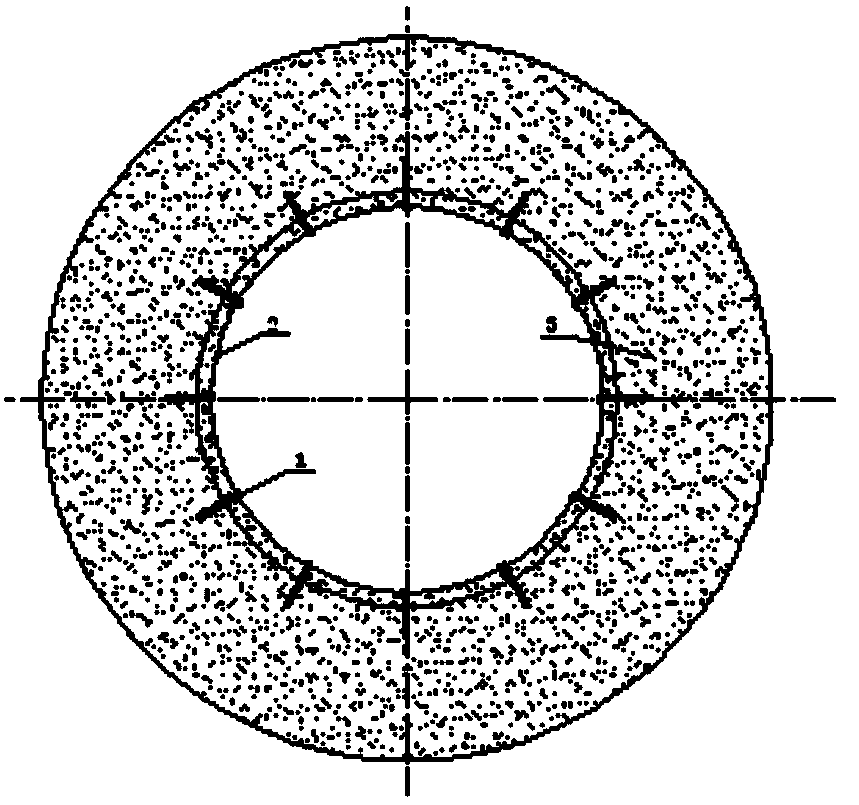

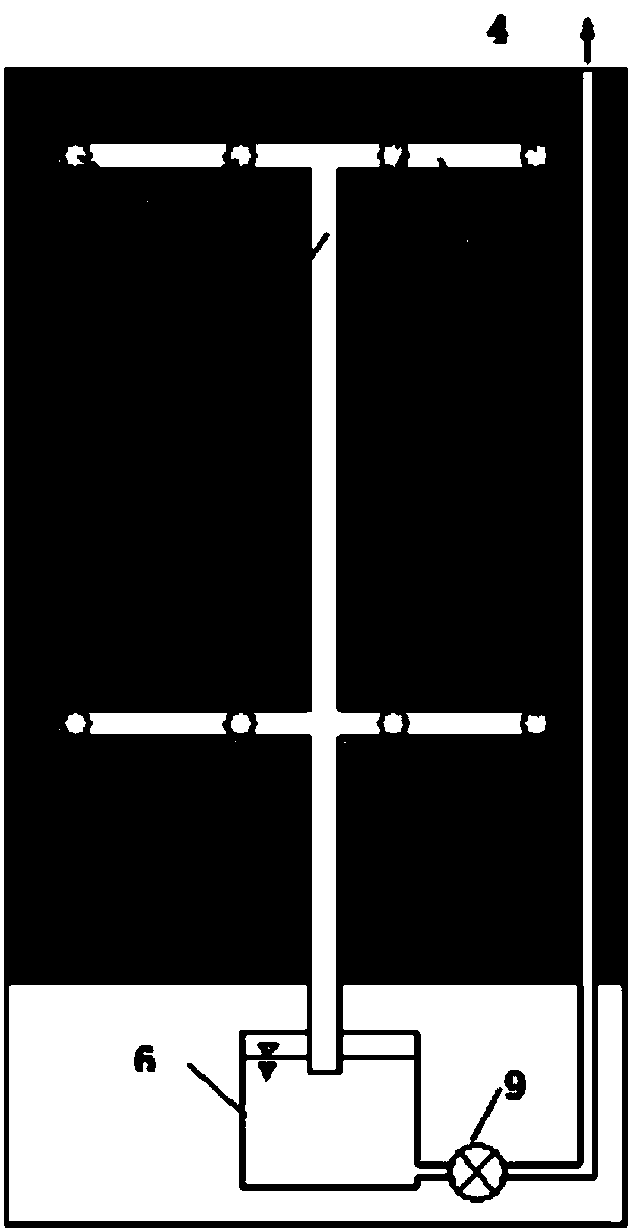

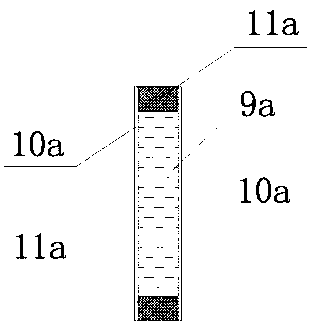

Mine vertical shaft/sieve shaft well wall structure and controllable dewatering method thereof

The invention discloses a mine vertical shaft / sieve shaft well wall structure and a controllable dewatering method thereof, and belongs to a mine vertical shaft well wall structure and a dewatering method thereof. Multiple layers of horizontal water guide pipes are arranged on the sieve shaft well wall structure, and are horizontally arranged on the well wall; multiple water dredging pipes are arranged; one ends of the water dredging pipes are communicated with the horizontal water guide pipes, and the other ends of the water dredging pipes radially extend into the well wall; dredging dry pipes are communicated every layer of the horizontal water guide pipes, and the bottom ends thereof are communicated with water collecting tanks; and automatic water pumps are mounted on the water collecting tanks. The method comprises the following steps: the vertical shaft well wall or the sieve shaft well wall structure penetrating through a water containing layer actively dredges and collects the water quantity of the water containing layer so as to reduce the water pressure stressed by the well wall and to improve the stress state of the well wall structure; the influence of the well wall water drenching on well wall reinforcements, concrete and equipment on the well wall is reduced; the safe service life of the well wall and the inside equipment is prolonged; and the collected underground water is recycled to save the water resource. The structure and the method have the following advantages: the underground water of the water containing layer is actively dredged to reduce the water pressure stressed by the well wall, so that the safety and the durability of the well wall structure are guaranteed; the construction process is simple; and the cost performance is high.

Owner:CHINA UNIV OF MINING & TECH

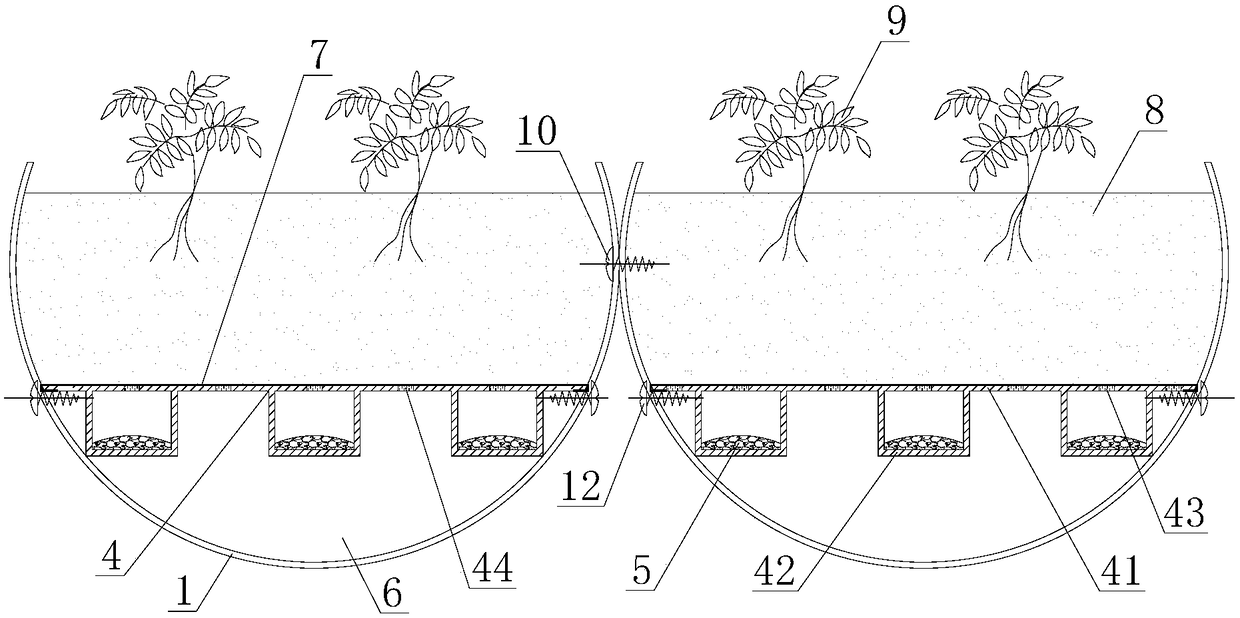

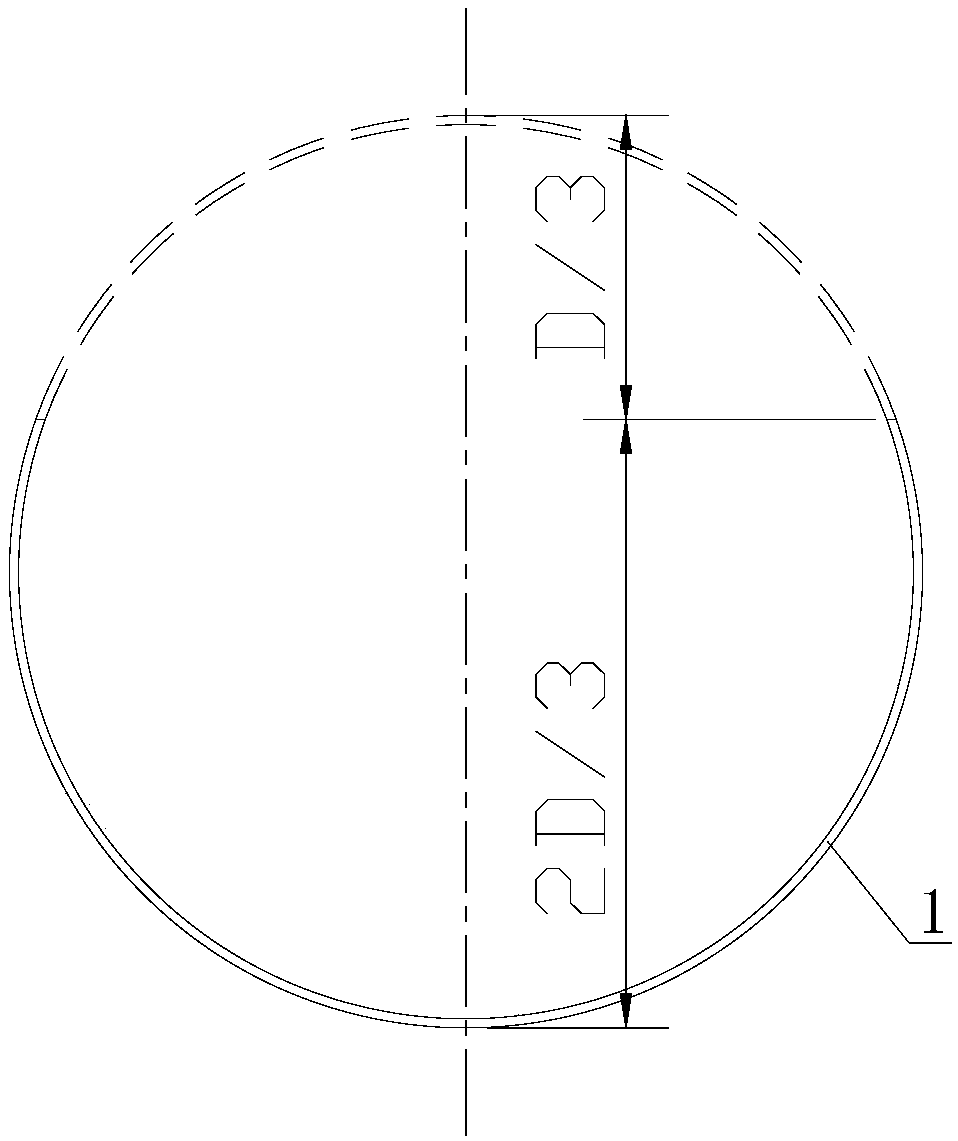

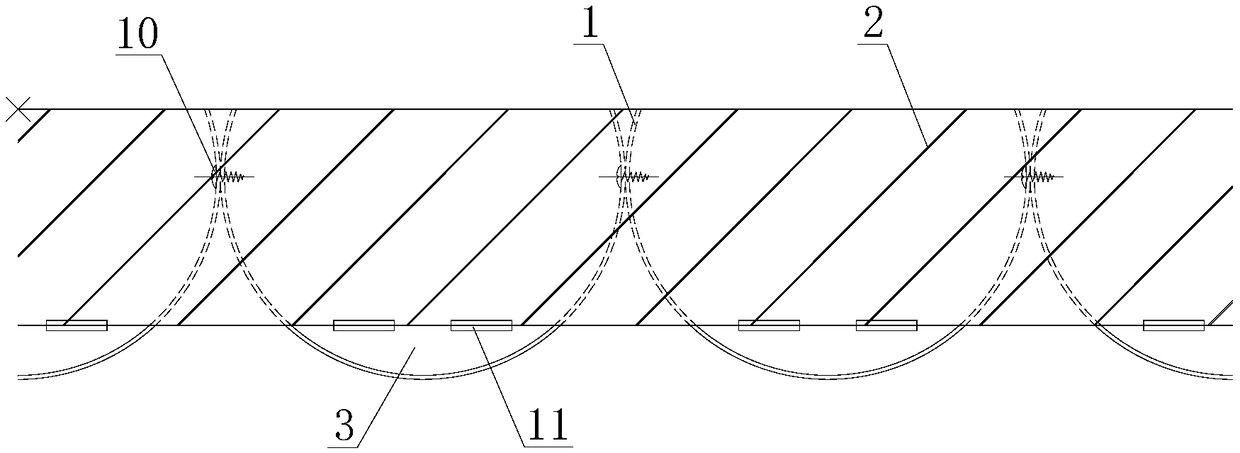

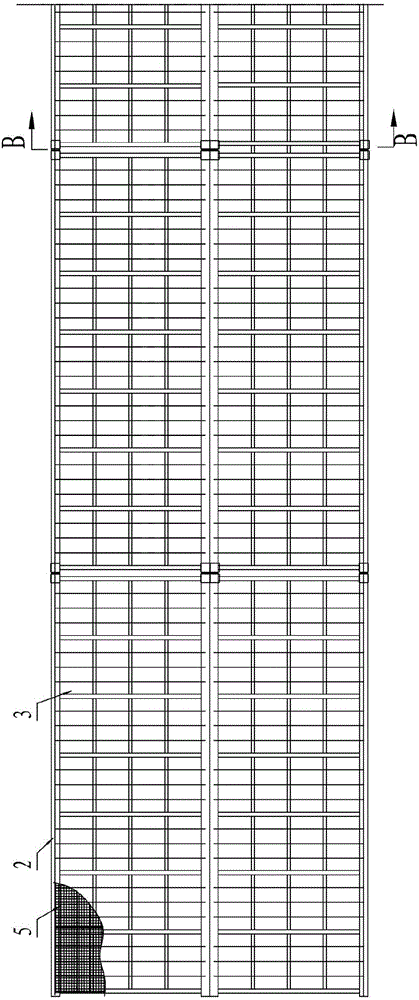

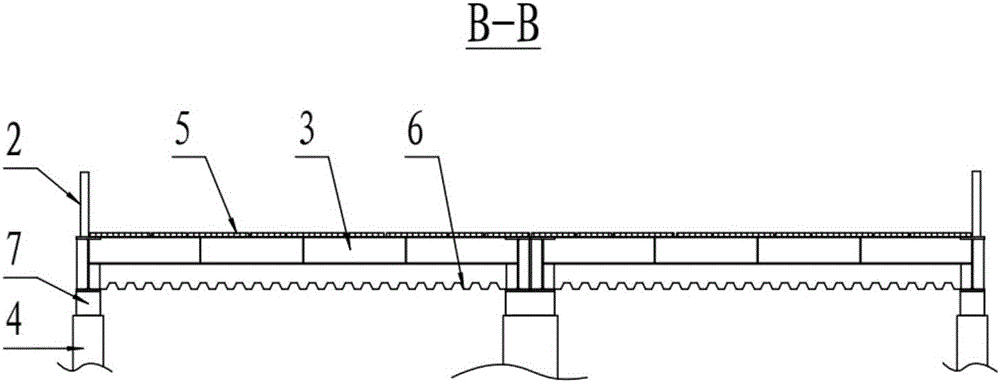

Simple unit modular green roof

ActiveCN109025086AReduce remodelingLess remodeling workRoof improvementClimate change adaptationModular constructionModularity

The invention provides a simple unit modular green roof, comprising a plurality of drainage pipes arranged in parallel. The radial section of each drainage pipe has a major arc shape with the upper part cut, the joint of the two adjacent drainage pipes are fixedly connected, two ends of the plurality of drainage pipes are fixedly connected with end baffles, the end baffle of the draining end is movably connected with a drain valve at the lower side, a water storage and drainage bracket is horizontally fixed in each drainage pipe and comprises a drainage top plate provided with a plurality of drainage holes, the bottom surface of the drainage top plate is fixedly provided with a plurality of groove-type reservoirs at intervals, and a super absorbent resin is placed in the reservoirs. The bottom surface of the reservoir that is not fixed of the drainage top plate, the outer wall of the reservoir and the inner wall of the drainage pipe form a drainage channel, a filter layer enclosing theperipheral edge of the drainage top plate is fixedly laid on the surface of the drainage top plate, the planting soil is applied on the filter layer, and plants are planted in the planting soil. Thepresent application is based on unit modular construction to increase the green roof construction speed and the module water storage capacity.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

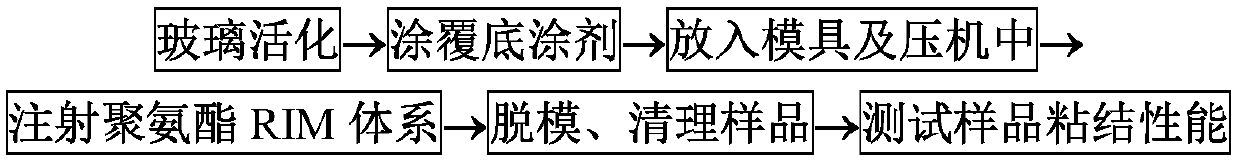

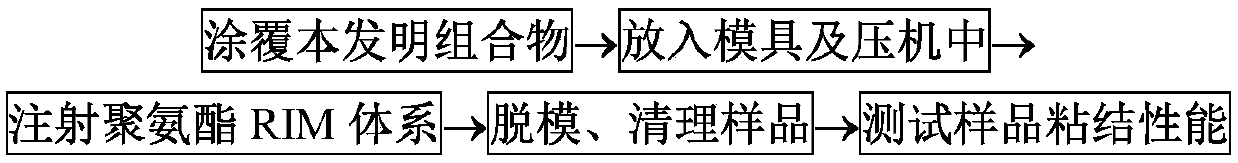

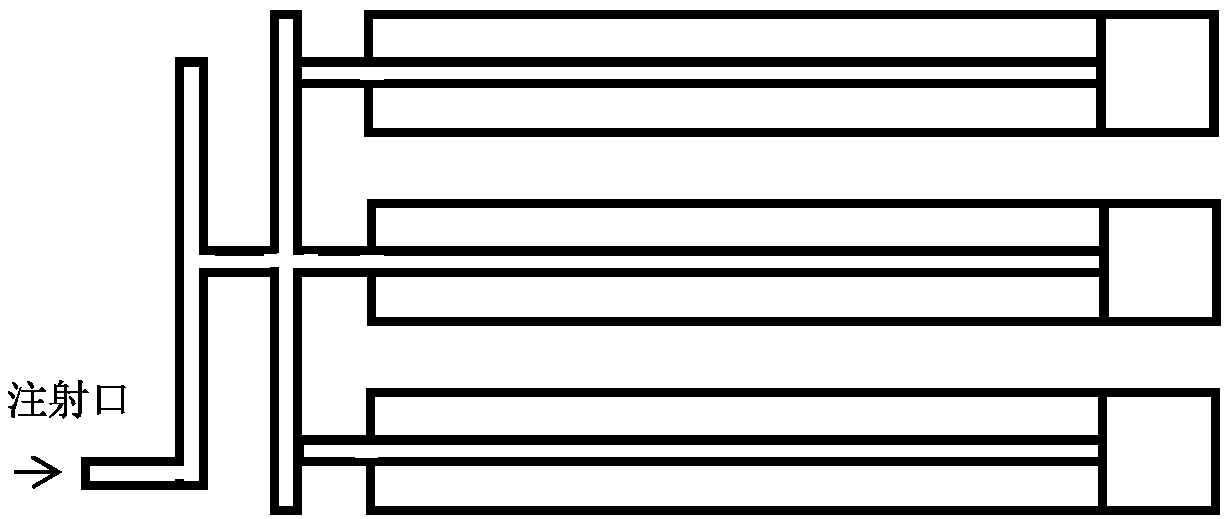

Composition for treating glass and application of composition

InactiveCN110526587AReduce construction processReduce processing timeSynthetic resin layered productsPolyurea/polyurethane coatingsOrganic solventSilanes

The invention relates to a composition for treating glass and application of the composition. The composition is prepared from a silane coupling agent, a silane-terminated polyurethane prepolymer, anoptional organic solvent and an optional catalyst. According to the composition, a surfactant and a primer coating of the glass are combined together, thus a three-step method for sealing the vehicleglass in the prior art can be improved to a two-step method, the construction processes can be reduced, the processing time can be saved, and the production efficiency is improved greatly.

Owner:COVESTRO DEUTSCHLAND AG

Outer making up and inner casting non-bearing wall and constructing method

A non-bearing wall is composed of its shell and its sandwich. Said shell is made up of thin polystyrene-cement sheets or the thin sheets of other light materials through splicing. Said sandwich is prepared from light filler and foam cementing body through pouring. Its advantages are light weight, high strength and insulating of sound and heat, not cracking and low cost.

Owner:陈星

Construction method of rail traffic column-free station in areas with dense underground pipelines

ActiveCN109868838AReduce riskReduce difficultyArtificial islandsUnderwater structuresLine tubingUnderground pipeline

The invention discloses a construction method of a rail traffic column-free station in areas with dense underground pipelines. By arranging guard piles, separation piles and temporary vertical columns, construction of an underground station is divided into two individual operation blocks, the influence of construction on existing pipelines can be reduced, and the risk and difficulty of station construction are lowered; pouring of the top plate of the column-free station and transferring of load borne are facilitated through the temporary vertical columns, and meanwhile the upper area can further provide space for containing the municipal underground pipelines, so that construction of the station body structure is facilitated. Furthermore, the problem that the underground pipelines have noplace to be replaced during excavation of an underground station foundation ditch and pouring of the station body can be avoided through transfer of the pipelines, and thus the municipal pipelines areprotected advantageously. According to the construction method of the rail traffic column-free station in the areas with the dense underground pipelines, the prominent problems that the disturbance of the underground pipelines are lowered through construction of the station, and transferring arrangement is difficult during the period of construction of the free-column station are solved, construction of the column-free station body structure is facilitated, and advantages that the station structure is simple, the construction technology is small, the construction difficulty is small, the costis relatively low, and the using range is wide are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

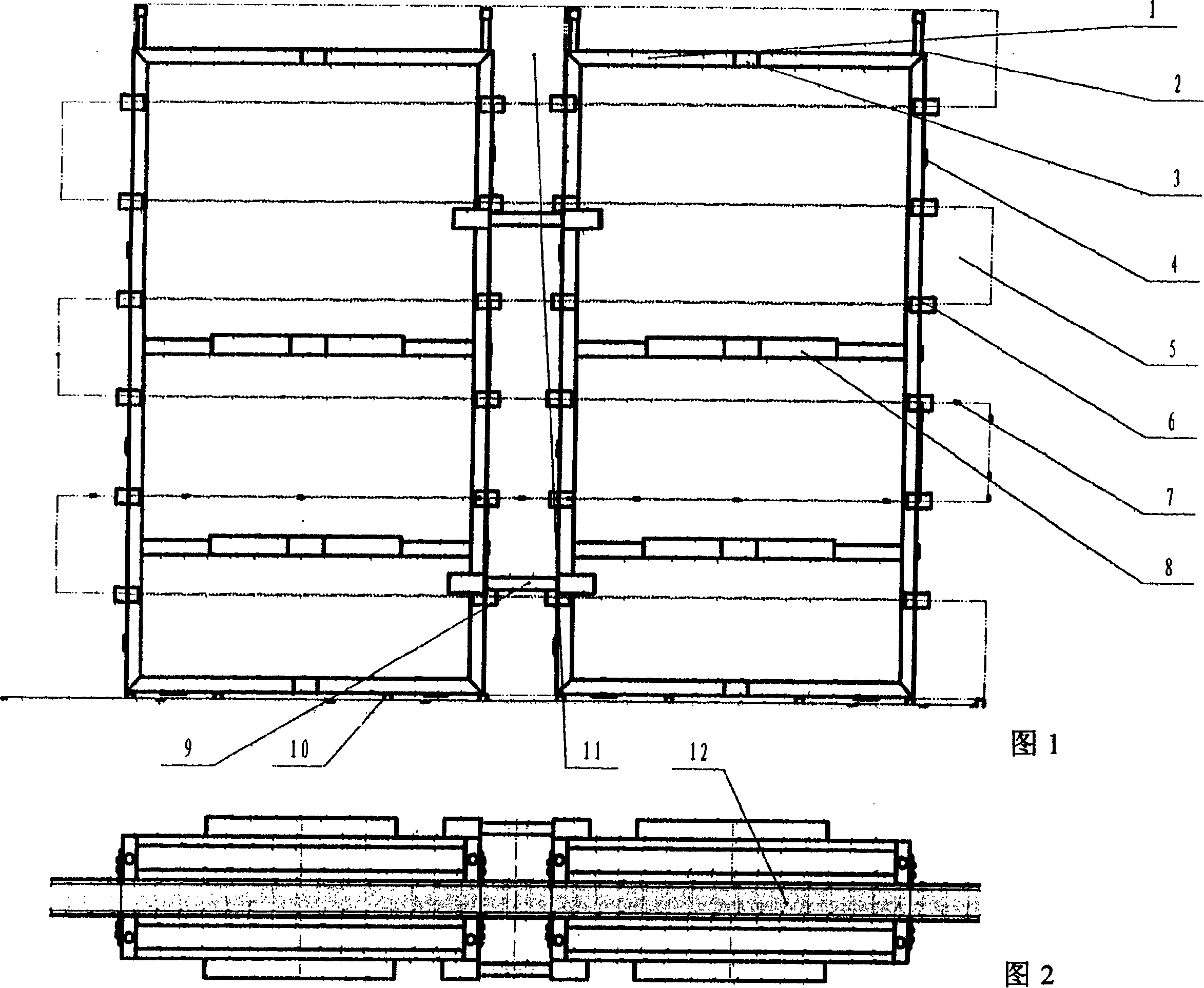

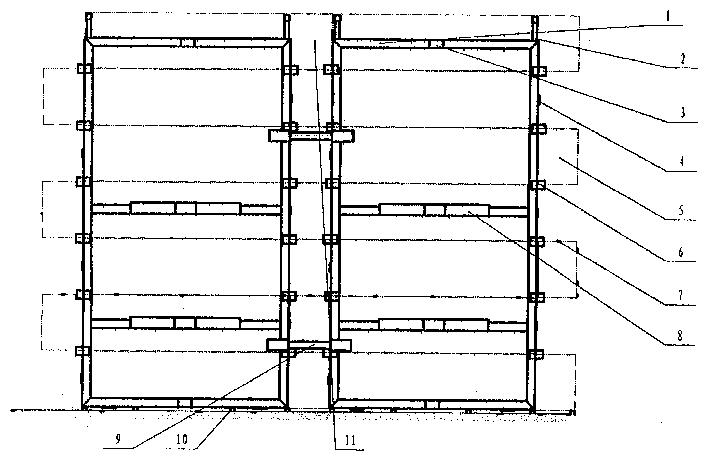

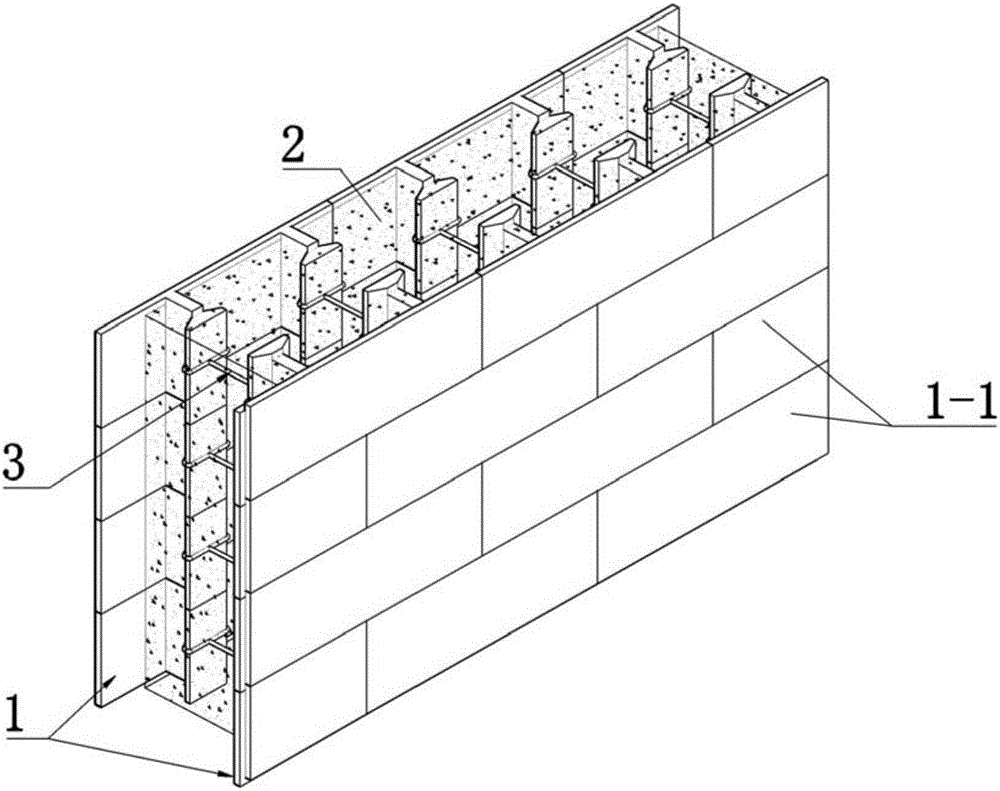

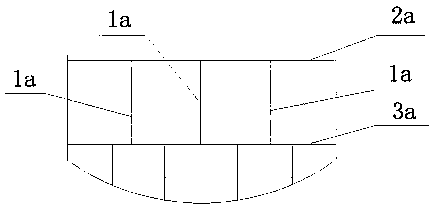

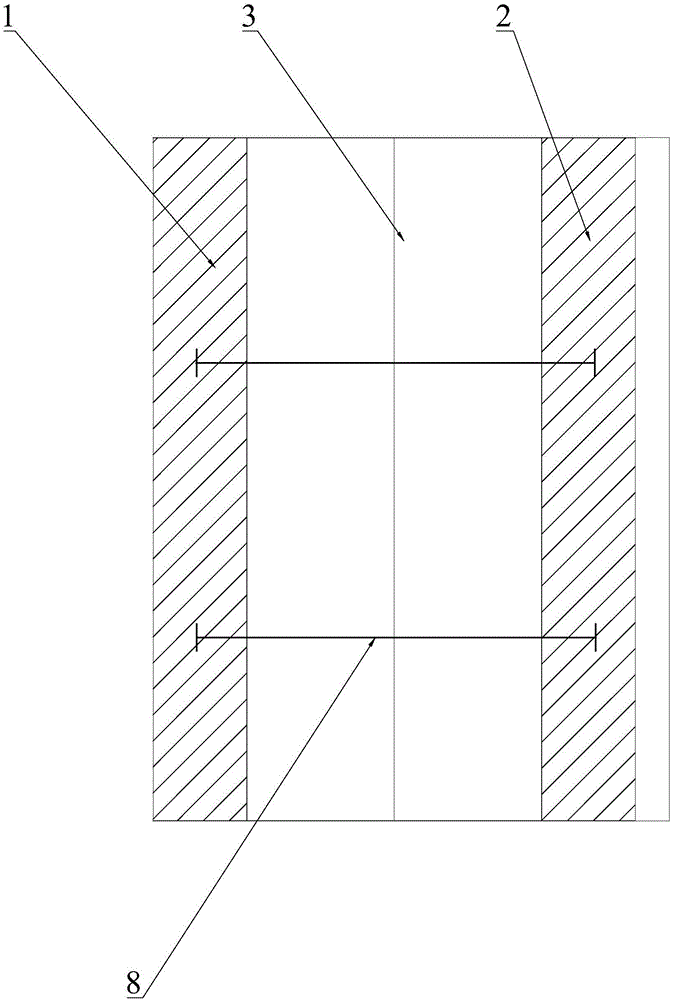

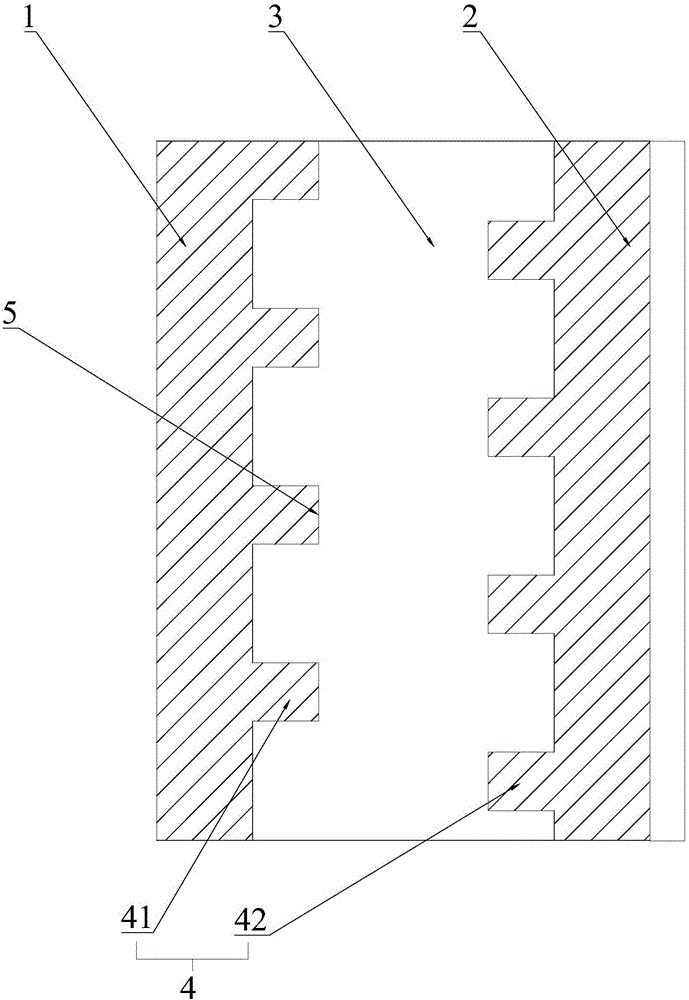

Composite rammed-earth wall, template device adopted in construction thereof and construction method thereof

InactiveCN105804294AHigh strengthPlay a protective effectWallsBuilding material handlingArray data structureWeather resistance

The invention relates to a composite rammed-earth wall, a template device adopted in the construction thereof and a construction method thereof. The wall comprises two wallboards which are arranged in a mirror symmetry manner and a rammed-earth main body filling between the two wallboards, wherein each wallboard is formed by splicing a plurality of unit wallboards according to a way of multiple layers in a vertical direction and multiple wallboards at each layer, each unit wallboard is of a reinforced concrete structure, and a reinforced bar connection part is arranged between every two opposite unit wallboards; a template structure comprises wall templates arranged on two surfaces, side baffle plates arranged at two sides and a plurality of groups of template fixing assemblies, wherein the wall templates on two surfaces form the two wallboards, during the construction process of the wall, the side baffle plates at two sides temporarily limit two sides of filled rammed earth, and the plurality of groups of template fixing assemblies are detachably clamped on the upper end parts of the two wall templates. The construction method comprises: performing construction by adopting the template device, first ramming a first layer of the wall, and then gradually ramming the wall upwards layer by layer until a set height of the wall is achieved. The rammed composite wall is relatively high in strength and relatively good in weather resistance and durability.

Owner:TIANJIN CHENGJIAN UNIV

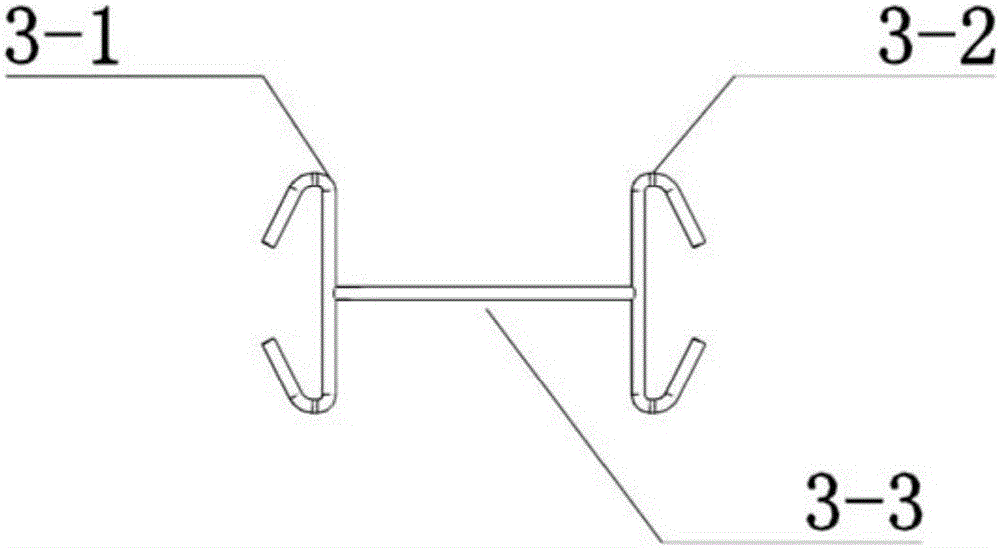

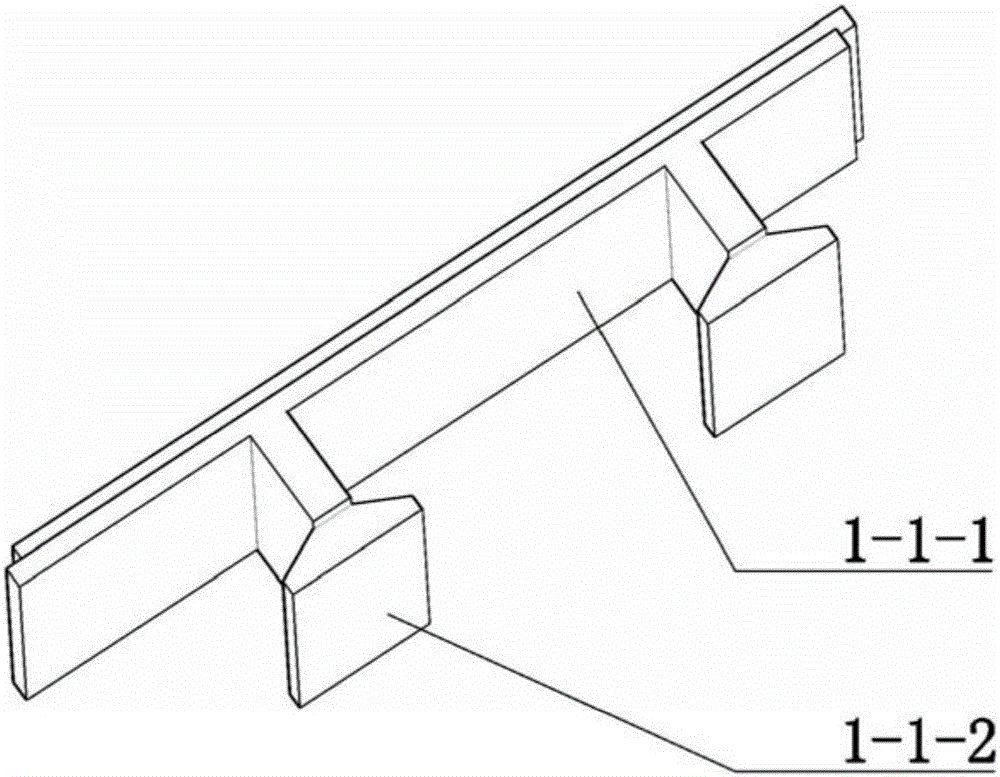

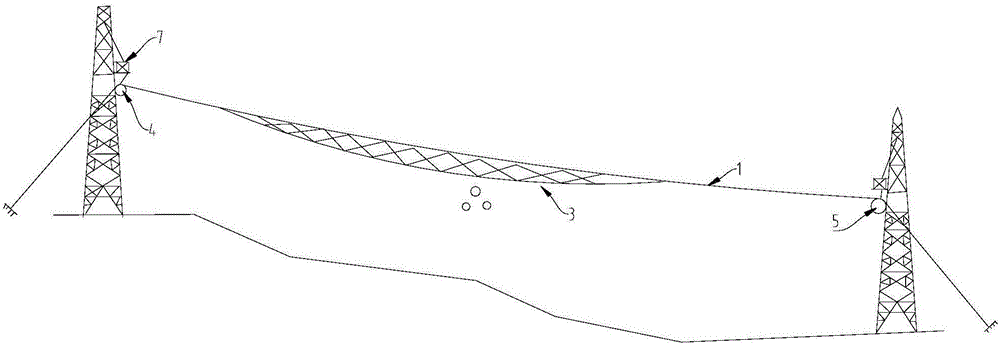

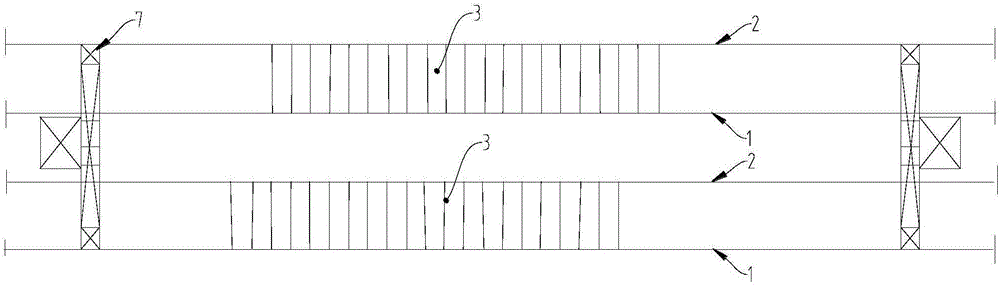

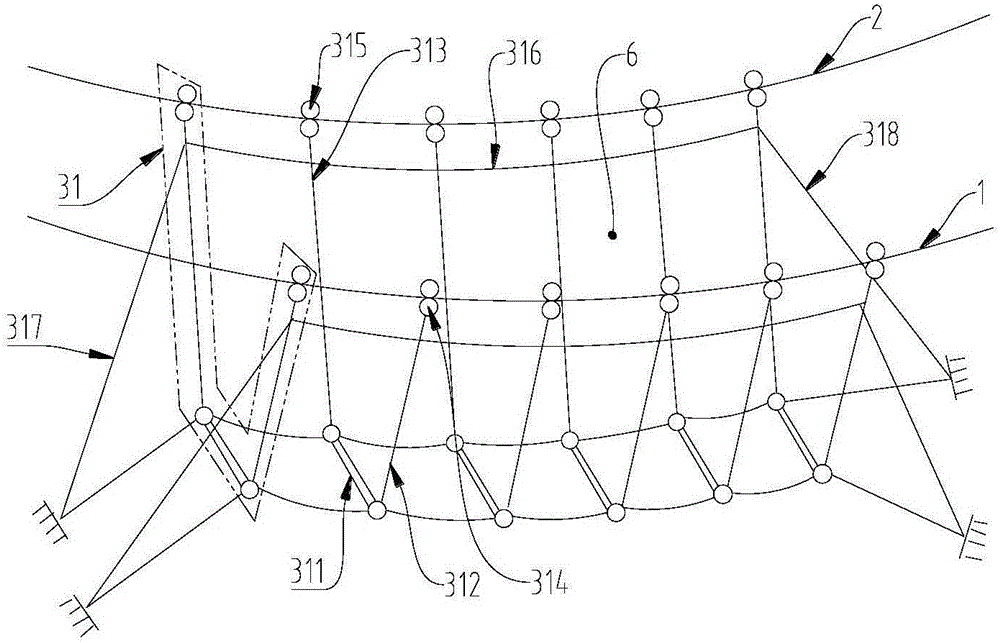

Crossing bridge stand of power transmission lines and construction technology thereof

InactiveCN106099757AReduce swingImprove wind resistanceApparatus for overhead lines/cablesElectricityArchitectural engineering

The invention discloses a crossing bridge stand of power transmission lines and belongs to the field of electricity stringing engineering. The crossing bridge stand is designed to increase the safety of live-line crossing construction. The crossing bridge stand includes a first bearing tope, a second bearing rope, a net blocking apparatus and a bearing apparatus. One ends of the first bearing rope and the second bearing rope penetrate corresponding left-side bearing pulleys and are anchored to the ground, and the other ends penetrate corresponding right-side bearing pulleys and are anchored to the ground. The net blocking apparatus suspends on the first bearing rope and the second bearing rope. The net blocking apparatus is anchored to the ground through a left-side insulating traction line and a right-side insulating traction line. The net blocking apparatus forms a channel through the extending direction of the first bearing rope and the second bearing rope. The crossing bridge stand not only forms an insulating barrier below a line, but also forms an insulating barrier on two sides of the line, such that a clearance protection distance is formed to a crossed object upon spreading of the line, which increases safety of the live-line crossing construction. The construction technology reduces construction procedures, saves human resource and time cost.

Owner:SICHUAN NO 3 ELECTRIC POWER CONSTR

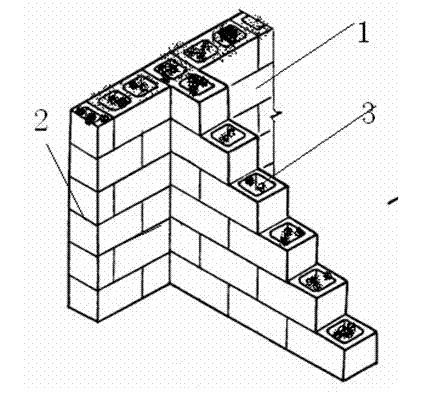

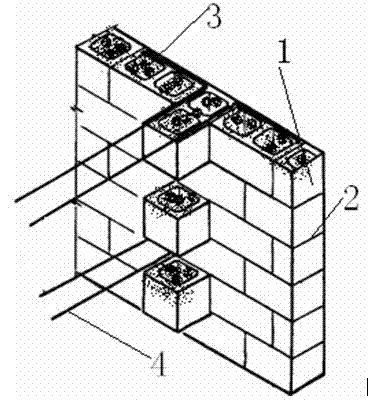

Cement-maize straw building block

InactiveCN103539406ALow priceImprove insulation effectSolid waste managementHigh energyThermal insulation

Aiming at the defects of high energy consumption and high manufacturing cost, the invention provides a low-cost, energy-saving and environment-friendly, fire-proof and mothproof and durable wall building block, namely a cement-maize straw building block, for rural houses in cold areas in the North. According to the invention, ordinary portland cement and coal ash serving as cementing materials, crushed maize straws serving as coarse aggregate and rice husks serving as fine aggregate are mixed with water and stirred sufficiently to be formed, and then the formed product is cured to obtain the cement-maize straw building block; and the cement-maize straw building block can be used in a bearing wall body or a filled wall body of a single-layer house or a multi-layer house. The wall body built of the building blocks has excellent thermal insulation performance, bearing effect and durability. In addition, the materials of the cement and maize straw building block is low and the construction process is simple.

Owner:QIQIHAR UNIVERSITY

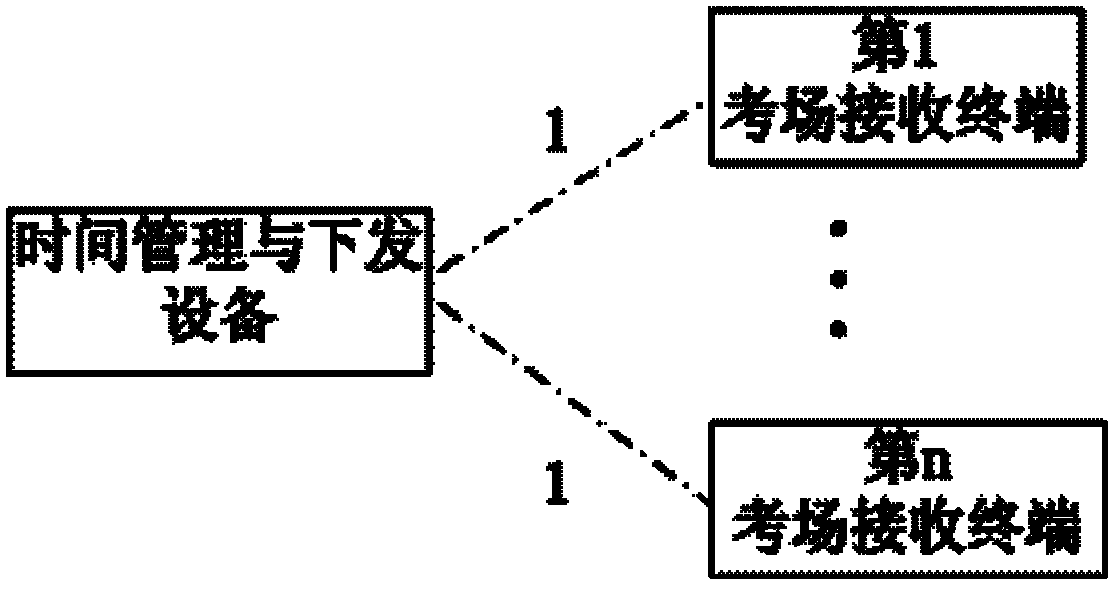

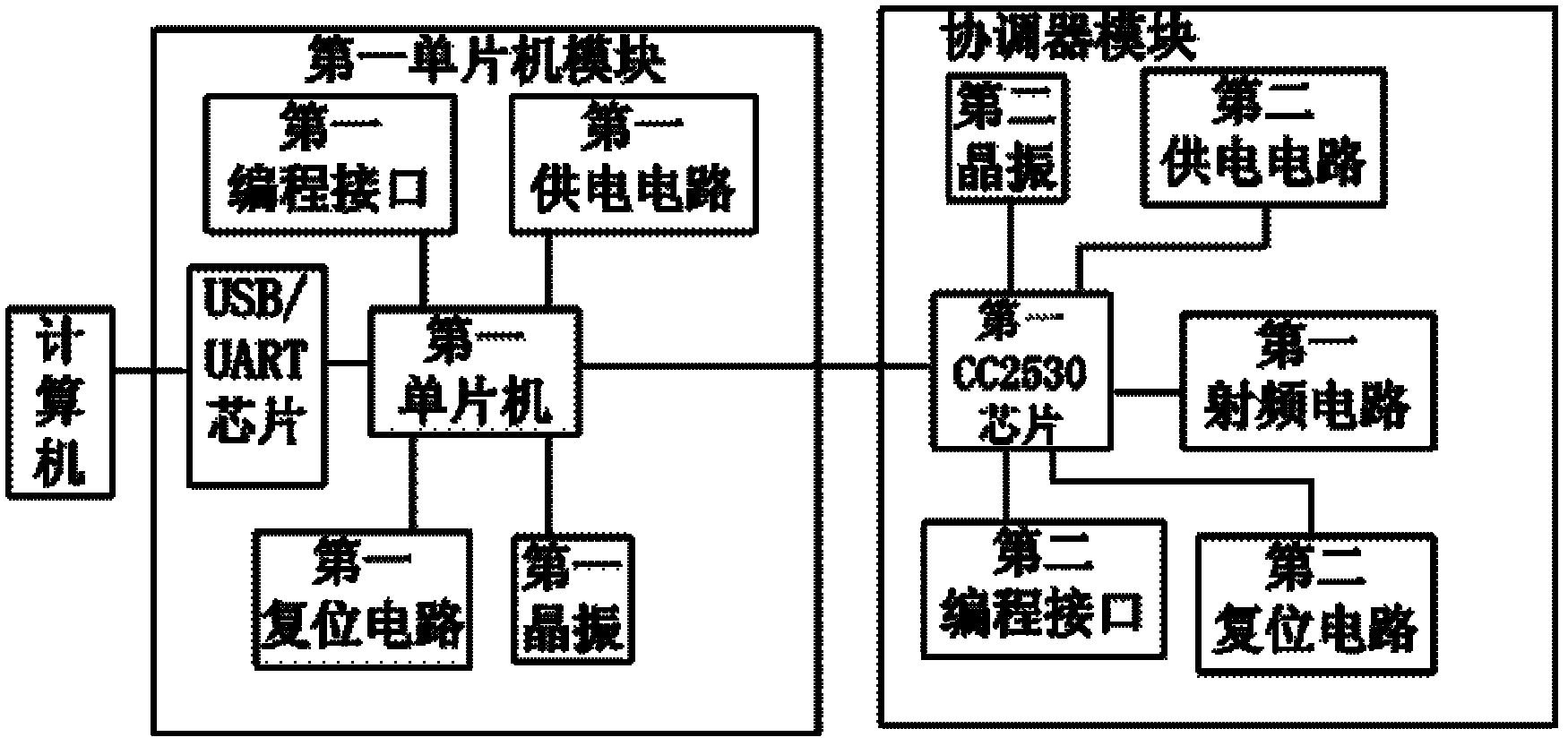

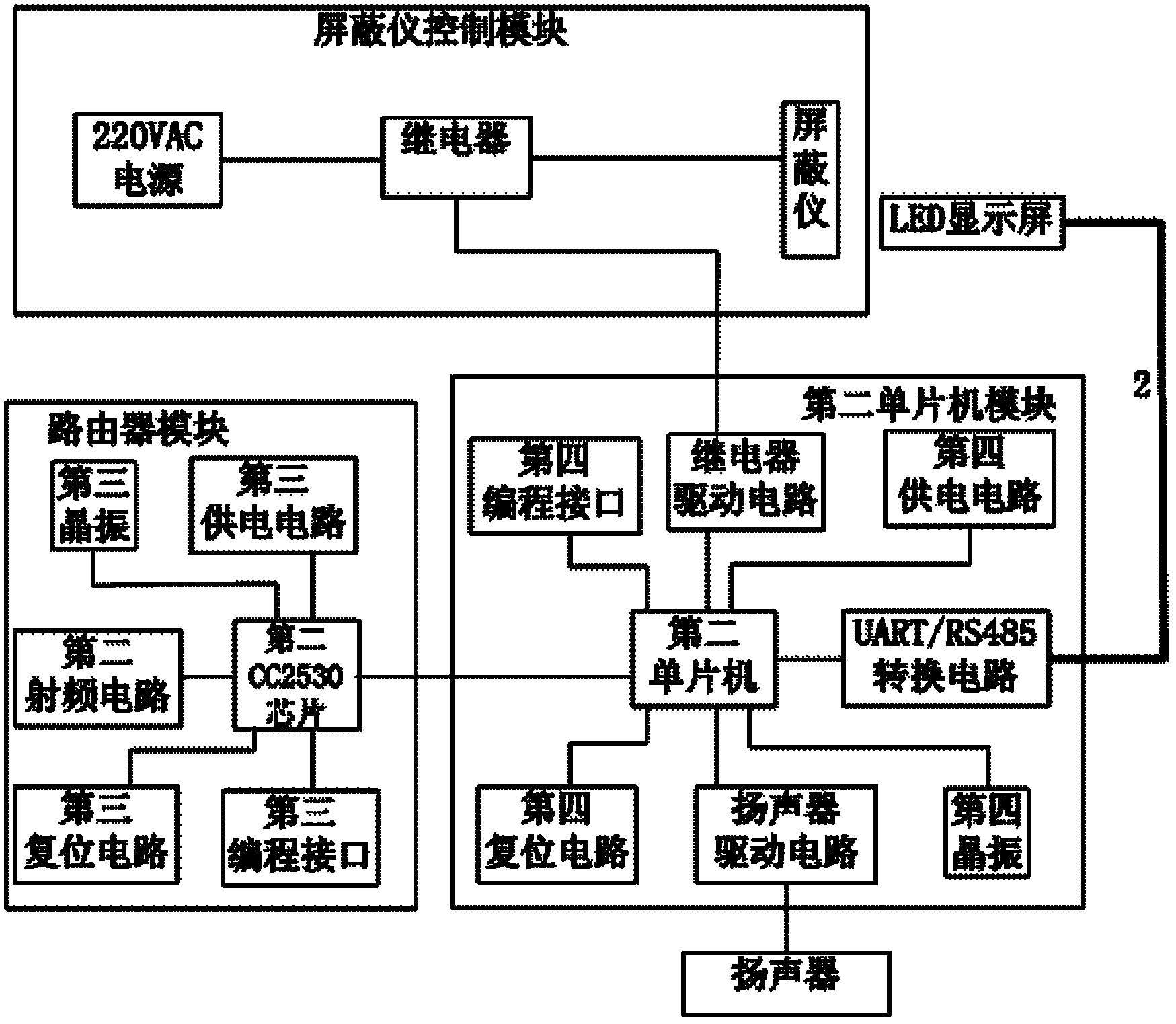

Novel intelligent examination hall management system

InactiveCN102662359AReduce misuseReduce the possibility of misuseTotal factory controlProgramme total factory controlWireless sensor networkingTime management

The invention discloses a novel intelligent examination hall management system belonging to a wireless sensor network and the technical field of automation. The structure is as follows: a time managing and issuing device is respectively connected with a first examination hall receiving terminal to an nth examination hall receiving terminal through a ZigBee / IEEE802.15.4 channel. The novel intelligent examination hall management system disclosed by the invention has the beneficial effects of: 1) ensuring the fairness of an examination, reducing the possibility of misoperation of a test supervisor, 2) having reliable and stable wireless connection and strong anti-interference performance, 3) greatly reducing the handling capacity of the test supervisor so as to obviously reduce the possibility of misoperation, and improving the fairness of a listening test and various large examinations, and 4) being simple in implementation and low in cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

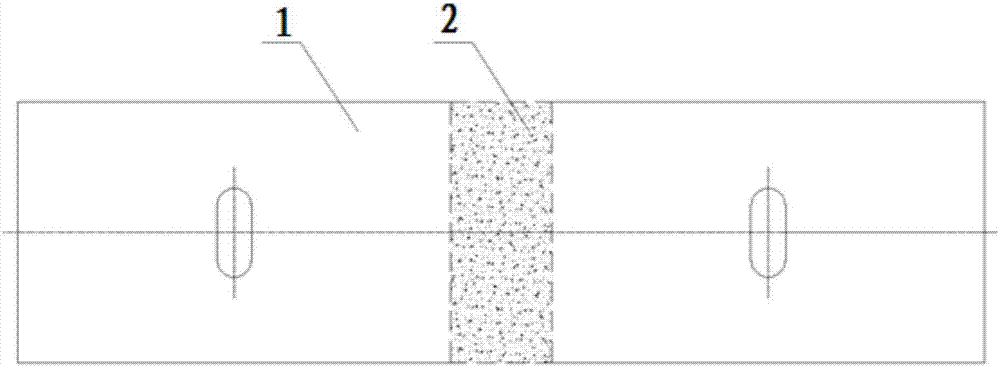

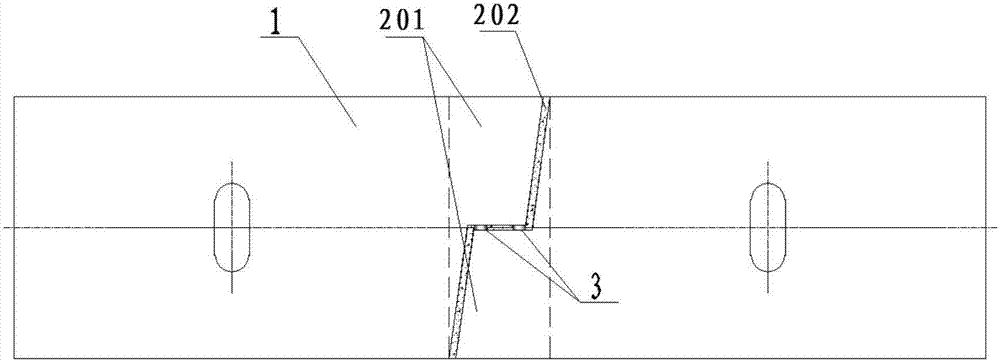

Ultra-short closure section of rotation construction bridge and construction method thereof

ActiveCN107100088AShorten construction timeLess interferenceBridge erection/assemblyLeft halfContinuous beam

The invention relates to the technical field of construction of continuous beams, in particular to an ultra-short closure section of a rotation construction bridge and a construction method thereof. The ultra-short closure section of the rotation construction bridge comprises a first rotation beam body, a second rotation beam body and a closure section body, wherein the first rotation beam body is connected with the second rotation beam body by the closure section body; the closure section body comprises a pre-pouring closure section body and a post-pouring closure section body; the pre-pouring closure section body is divided into a left half part and a right half part along the longitudinal axis of the bridge; an end of the first rotation beam body is fixedly connected with one end of the left half part; an end of the second rotation beam body is fixedly connected with one end of the right half part; after the first rotation beam body and the second rotation beam body rotate and are closed, a post-pouring closure gap is formed; the post-pouring closure section body is arranged in the post-pouring closure gap; and the left half part, the right half part, the first rotation beam body and the second rotation beam body are connected to form a whole continuous beam. A folding hanging bracket is not required, construction at the present stage can be finished by a simple template, steel is saved, the cost is low, and the construction time of the closure section is shortened to a great extent.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

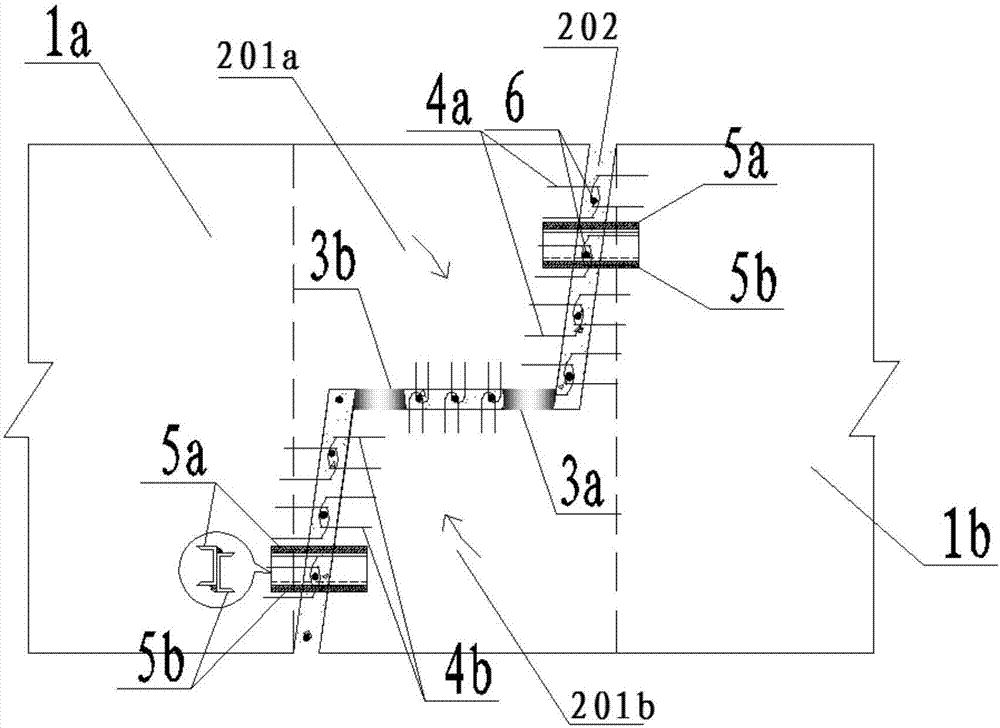

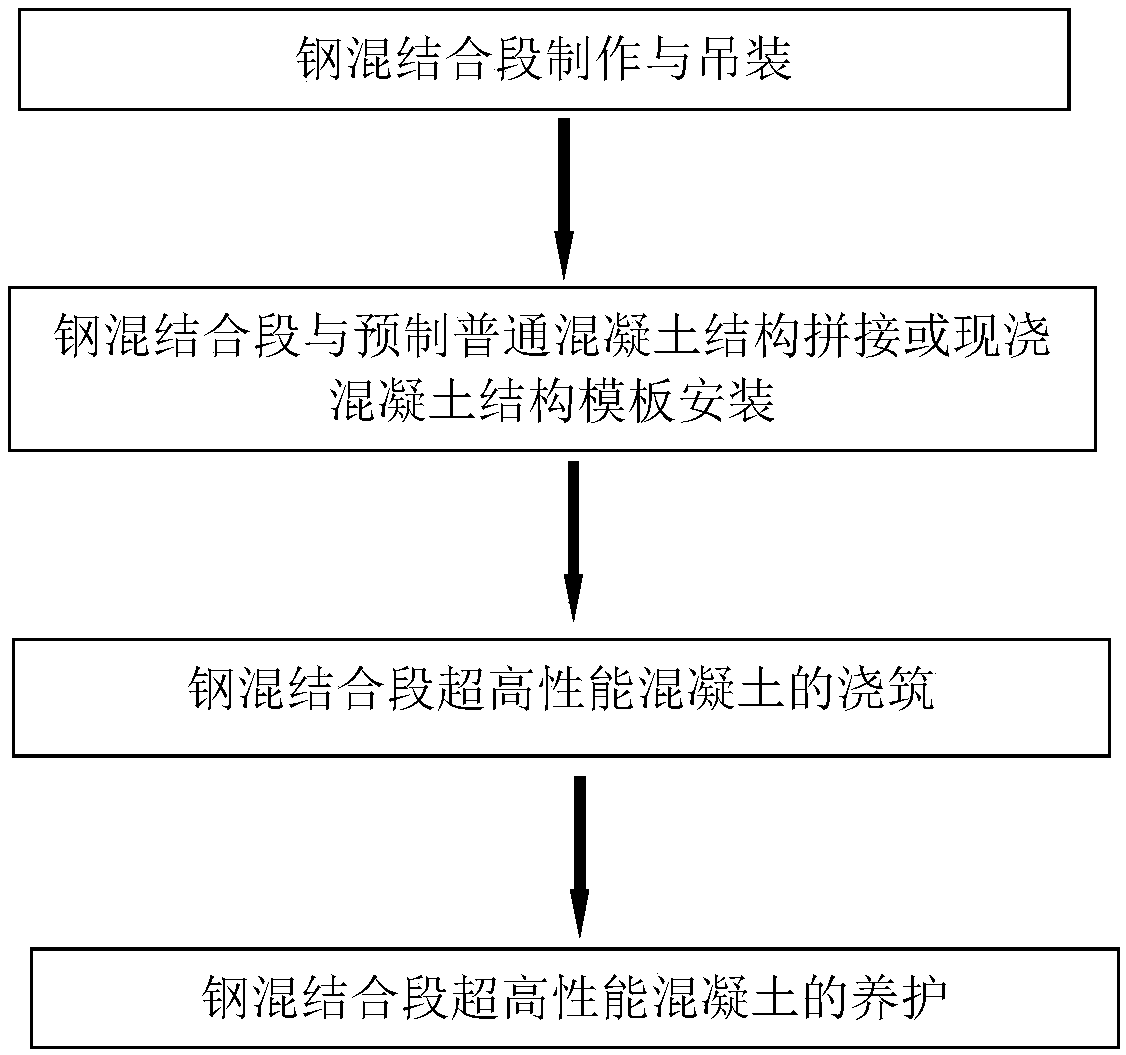

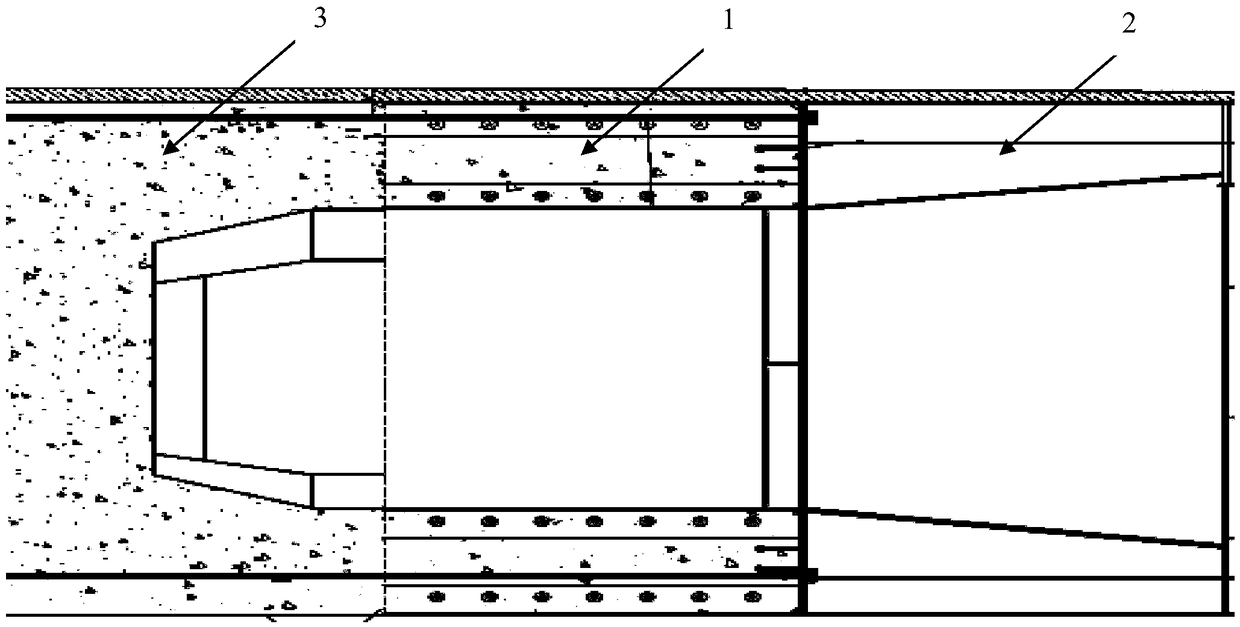

Construction method of steel-concrete joint section

The invention provides a construction method of a steel-concrete joint section, which relates to the field of bridge construction and is carried out according to the following steps: 1) manufacturingand hoisting of the steel-concrete joint section; 2) splice that steel-concrete joint section with the precast ordinary concrete structure or installing the cast-in-situ concrete structure formwork; 3) pour the ultra high performance concrete of the steel-concrete joint section; 4) curing the ultra high performance concrete of the steel-concrete joint section. The invention is fast, convenient, reliable, suitable for the construction of the long-span mixed bridge, greatly shortens the construction period and improves the construction quality.

Owner:HUNAN UNIV +1

Combination T beam bridge assembly type cross connection reinforced structure and reinforcing method thereof

ActiveCN108517793AShorten hardening timeShorten maintenance timeBridge erection/assemblyBridge strengtheningCross connectionT-beam

The invention discloses a combination T beam bridge assembly type cross connection reinforced structure and a reinforcing method thereof. A top plate is fixedly connected to joint seams and the lowersurfaces of two adjacent T-shaped girders, a steel concrete combination base plate is fixedly connected to the lower surface of the top plate, the bottoms of two inclined supports are fixedly connected to T-shaped horseshoe parts of the two T-shaped girders, the tops of the two inclined supports are fixedly connected to the steel concrete combination base plate, and the two ends of a horizontal support are fixedly connected with the T-shaped horseshoe parts of the two T-shaped girders; the two inclined supports and the horizontal support form a triangular support structure. Accordingly, the defects that for a traditional cross connection reinforcing method, the construction period is long, the effect is poor, many limiting factors exist, and the construction condition requirements are highare overcome, the technical problem that combination T beam bridge cross connection urgently needs to be improved is solved. The structure can be widely applied to cross connection reinforcing of a combination T beam bridge and a concrete box beam bridge, and meanwhile the structure can also serve as a diaphragm plate of a new bridge for use.

Owner:江苏梦联桥科技有限公司

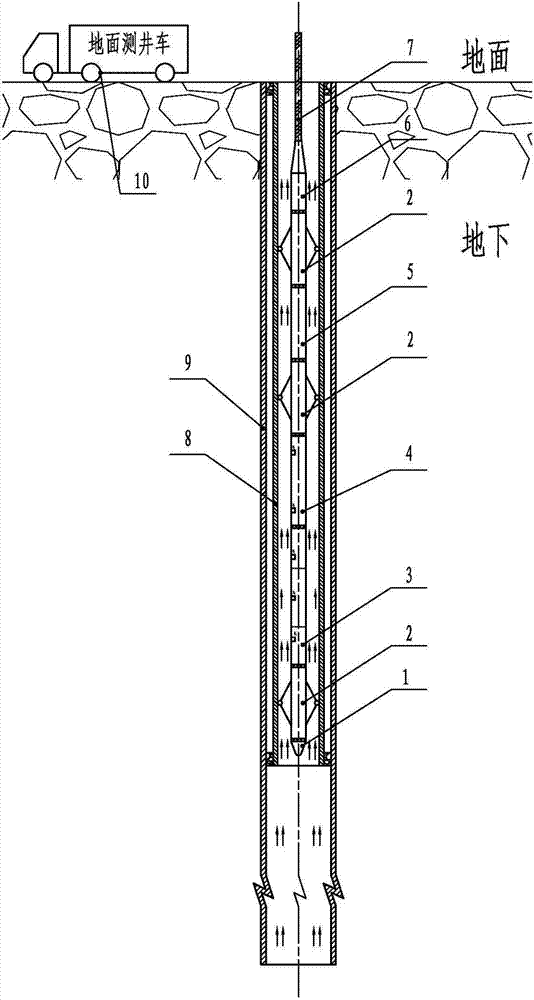

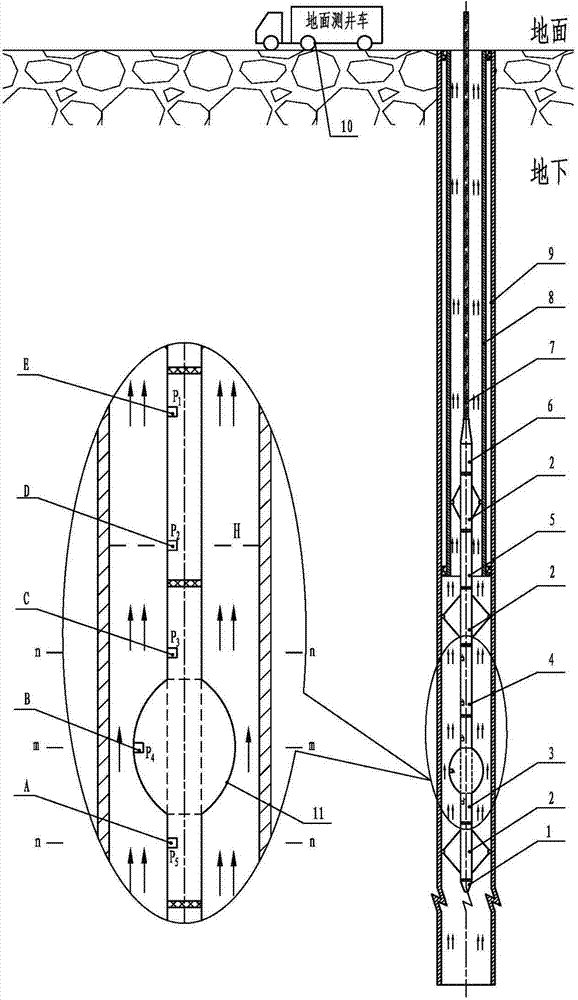

Device and method for measuring underground flow rate of petroleum well

The invention discloses a device and a method for measuring underground flow rate of a petroleum well. The device comprises a ground logging truck, and an instrument string which is connected through a cable and arranged in a sleeved oil pipe of an underground sleeve, wherein the instrument string comprises a halter, a first centering device, a magnetic positioning shot, a second centering device, a pressure difference density meter, a flow logger, a third centering device and a plug; a circuit system control motor or a hydraulic driving arm is mounted on the flow logger; static pressure sampling openings are respectively formed in the control motor or the hydraulic driving arm and the pressure difference density meter; the control motor or the hydraulic driving arm is opened or closed to measure underground flow rate of the petroleum well. According to the device, minimum annular section area between the arm and the sleeve is adjusted through the flow logger, so that the flow logger can be adapted to oil wells with various size and aperture; the construction processes are decreased; the working cost is saved; the working hours are reduced; the flow logger is applied to measuring of flow rate of a vertical shaft and a large-inclination-degree well, and the measuring precision is high.

Owner:西安威盛电子科技股份有限公司

Road system capable of being quickly assembled and constructed

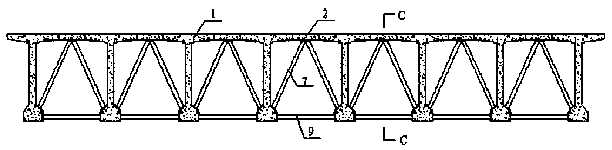

ActiveCN106087699AShorten the construction periodNo snowBridge structural detailsDriving safetyRoad construction

The invention discloses a road system capable of being quickly assembled and constructed. The road system comprises a truss structure layer, a grid road surface layer and upright columns. The truss structure layer is supported by a foundation and the upright columns, the grid road surface layer is laid on the upper portion of the truss structure layer and is connected with the truss structure layer by bolts, and truss modules are butted to one another to form the truss structure layer; grid modules are butted to one another to form the grid road surface layer. The road system has the main advantages that the truss structure layer and the grid road surface layer can be modularly produced in factories and can be quickly assembled in construction sites, and accordingly the road construction cycle can be greatly shortened; problems of snow accumulation and water accumulation of existing grid road surface layers and freezing of existing road surfaces can be solved, accordingly, the driving safety can be guaranteed, the gradient of road surfaces can be increased, and bridge construction occupied areas can be saved; the road surfaces can be maintained easily, conveniently and feasibly; the road system is low in construction cost, and as proved by measurement, the construction cost of the road system can be reduced by approximately 1 / 2 as compared with the construction cost of the traditional road structure; the road system is modularly assembled and constructed and further can be modularly detached.

Owner:SHANGHAIGUAN SHIPBUILDING IND

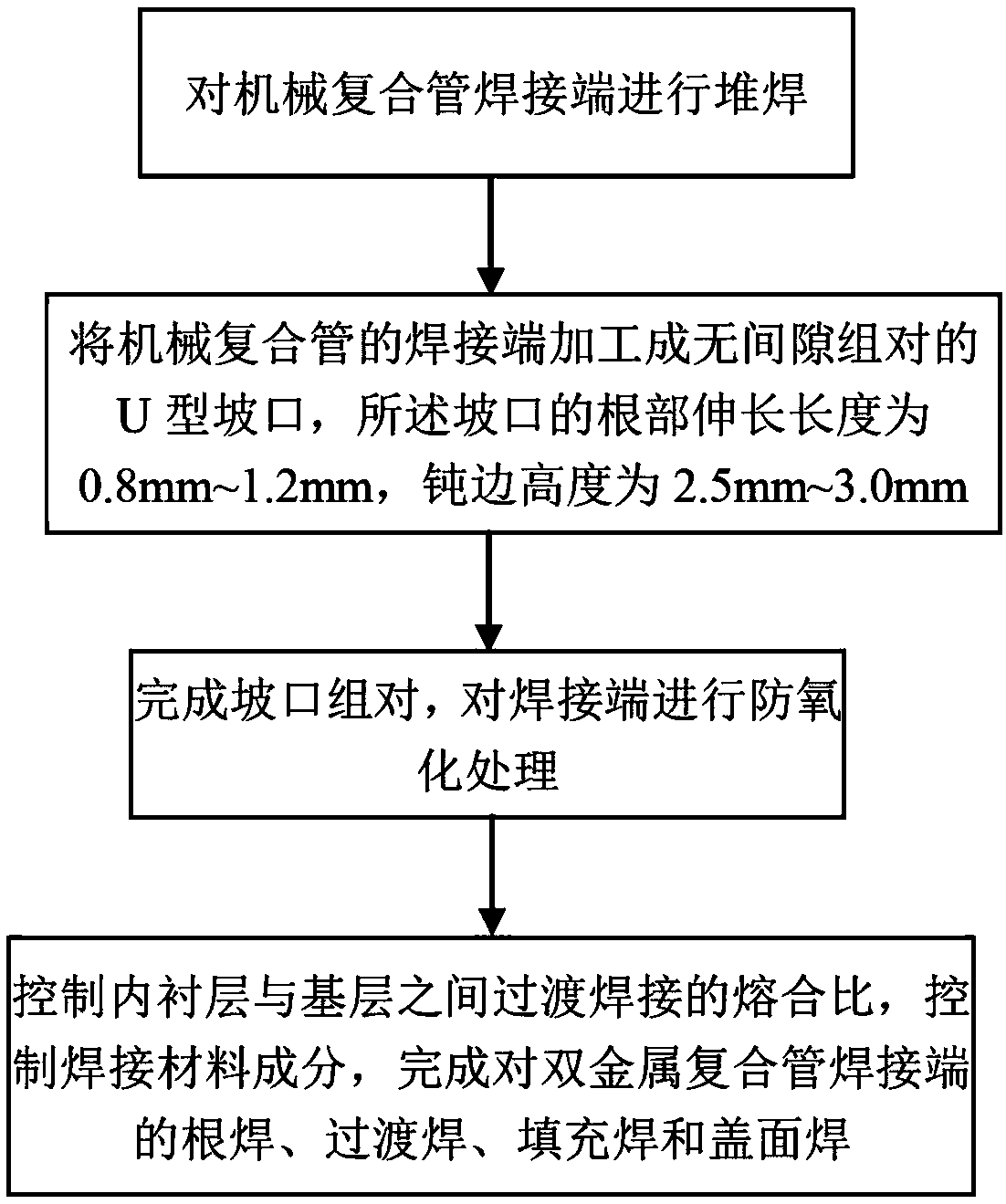

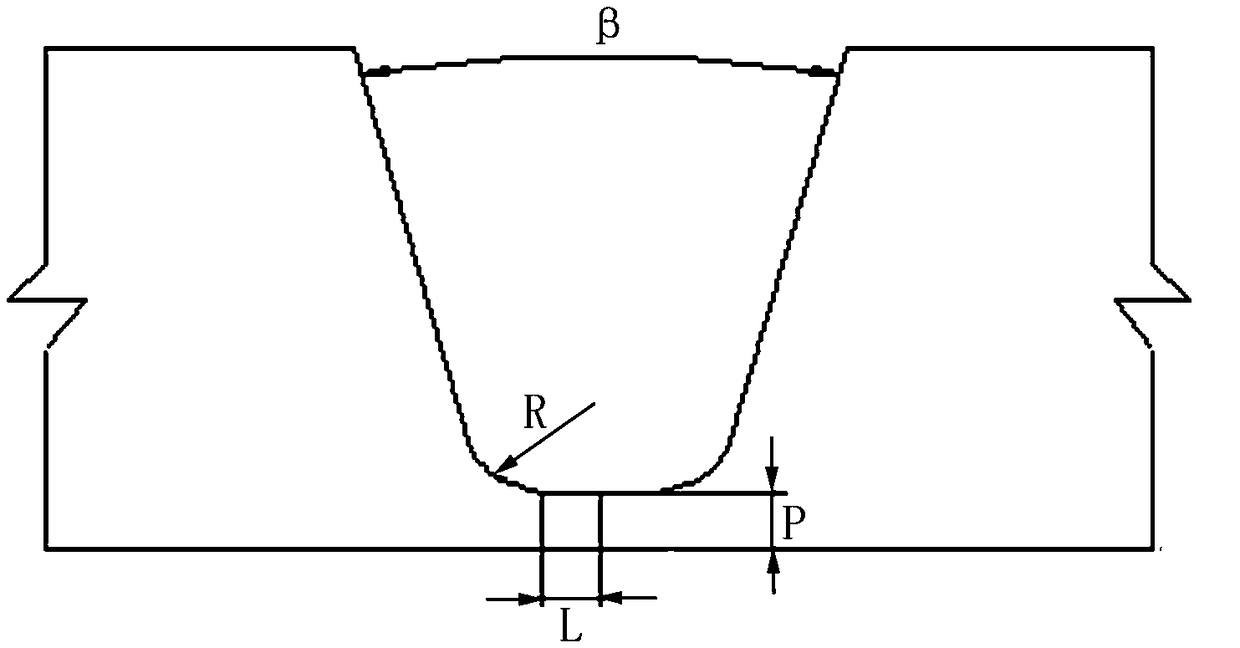

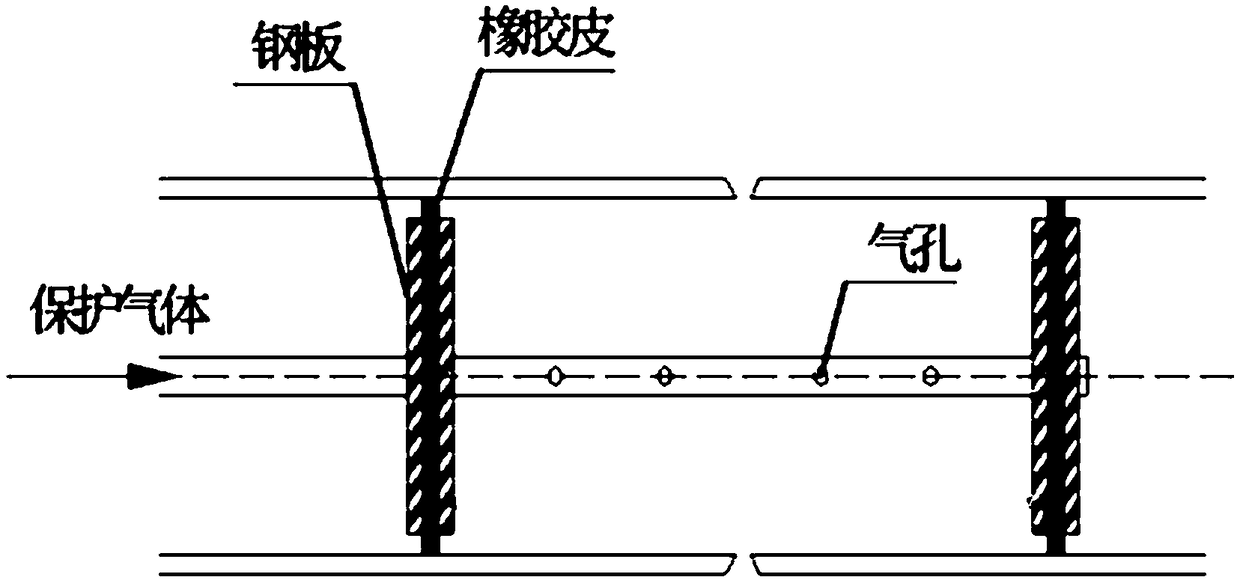

Welding construction method of mechanical composite pipes for petroleum and natural gas transportation

InactiveCN108608096AChange the welding processImprove stressArc welding apparatusWorkpiece edge portionsStress conditionsComponents of crude oil

The invention provides a welding construction method of mechanical composite pipes for petroleum and natural gas transportation. Each mechanical composite pipe is composed of a lining layer and a basic layer. The welding construction method comprises the following steps of carrying out surfacing on the welding ends of the mechanical composite pipes; machining the welding ends of the mechanical composite pipes into U-shaped grooves in a zero-clearance assembled mode, specifically, the extension length of the root of each groove is 0.8 mm-1.2 mm, and the thickness of the root face is 2.5 mm-3.0mm; completing groove assembly and carrying out anti-oxidation treatment on the welding ends; and controlling the fusion ratio of base metal for transitional welding of each lining layer and the corresponding basic layer to be 20%-30%, controlling compositions of welding materials and completing root welding, transitional welding, filling welding and cosmetic welding of the welding ends of the dual-metal composite pipes. By means of the welding construction method, the stress condition of butt welds can be improved, cracks are avoided, the welding process is simplified, and the welding efficiency is improved.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

Assembled keel partition wall mounting structure

PendingCN110607857AAdvantages of installation structureEasy and fast installationWallsKeelWall mount

The invention provides an assembled keel partition wall mounting structure. The mounting structure comprises a keel frame, a ceiling clamping piece, a transverse clamping piece and a wallboard, wherein the keel frame is arranged on a wall, and comprises a ceiling keel, a floor keel and a vertical keel; the ceiling keel is arranged at the top of the wall in the horizontal direction; the floor keelis arranged at the bottom of the wall in the horizontal direction; the vertical keel is arranged in the vertical direction; the top and the bottom of the vertical keel are connected with the ceiling keel and the floor keel; the bottom of the ceiling clamping piece is clamped with the ceiling keel; the transverse clamping piece is fixed on the vertical keel; the wallboard comprises multiple unit panels assembled; and the bottoms of the unit panels are clamped with the transverse clamping piece. Compared with the prior art, the mounting structure has the advantages of mounting convenience, simple construction, low labor and material cost, capability of realizing quick dismounting and convenience for later maintenance.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Welded aluminum honeycomb light enclosure wall for warship

PendingCN108001613AReduced overall build weightIncrease the use of spaceHull bulkheadsHull panellingsAluminum honeycombFire resistance

The invention discloses a welded aluminum honeycomb light enclosure wall for a warship. A welded aluminum honeycomb board is used as the main building material of the light enclosure wall of the warship, and the welded aluminum honeycomb board arranged between the upper and lower decks of the warship as a cabin separation is divided into a steel hull light enclosure wall and an aluminum hull lightenclosure wall. The steel hull light enclosure wall includes the welded aluminum honeycomb board, upper and lower steel fences, steel-aluminum composite transition joints, and welded joints; and thealuminum hull light enclosure wall includes the welded aluminum honeycomb board and the welded joints. The welded aluminum honeycomb board is made of novel pure metal material and is ultra light in weight, high in strength, capable of being pre-buried, capable of being re-welded, and good in decorativeness, and has excellent properties such as impact resistance, fire resistance, vibration damping,sound insulation, and the like. After the welded aluminum honeycomb board is used for building light enclosure walls, an inner decorative board is eliminated, and the total construction weight of theoriginal light enclosure walls and the decorative board is reduced by 1 / 2 and the use space in the cabin is increased; and at the same time, construction procedures and materials are reduced, and construction costs are reduced.

Owner:企力(大连)海事科技有限公司

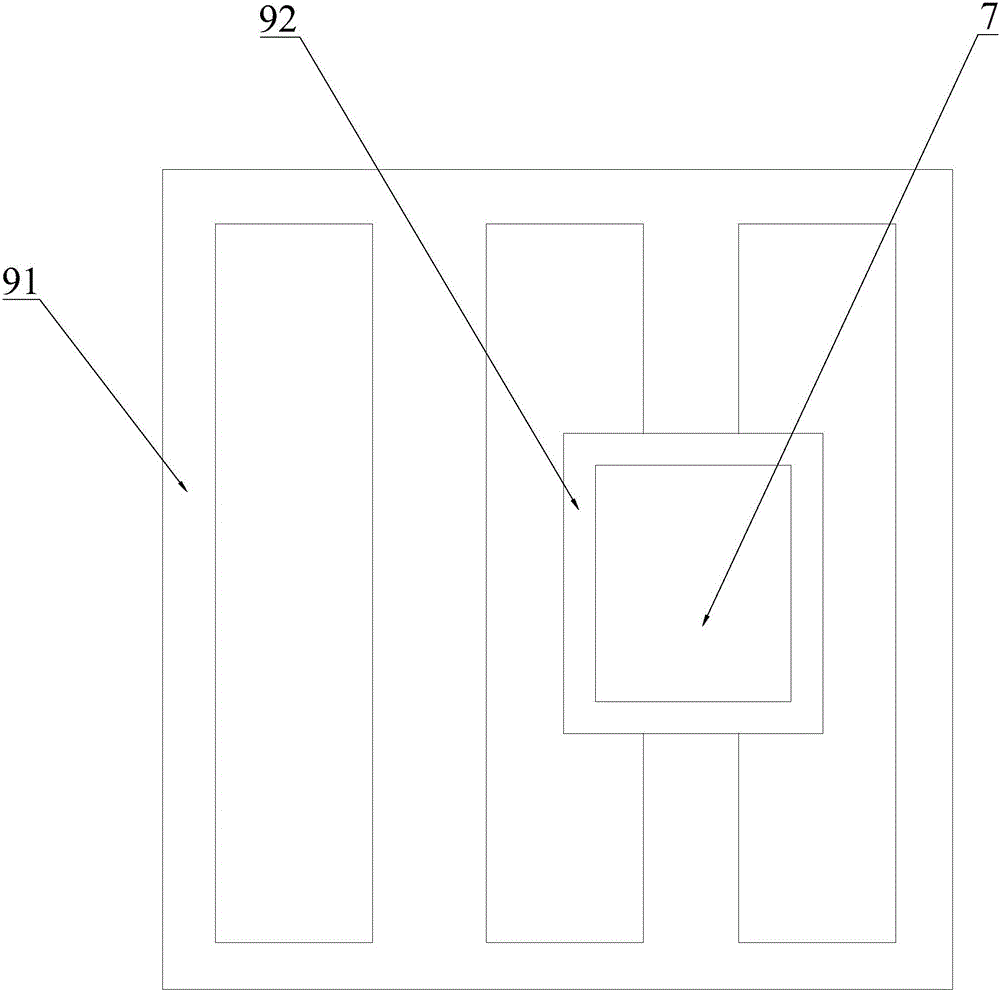

Sandwich insulation external wall panel and manufacturing method thereof

InactiveCN105863101ALow costUniform construction qualityWallsHeat proofingInsulation layerEngineering

The invention discloses a sandwich insulation external wall panel and a manufacturing method thereof. The sandwich insulation external wall panel does not need independent connecting pieces, enables a first plate, a second plate and a heat insulation layer to be connected stably, and has good heat insulation performance. According to the technical scheme, the sandwich insulation external wall panel is characterized by comprising the first plate, the second plate and the heat insulation layer arranged between the first plate and the second plate, wherein the sides, close to the heat insulation layer, of the first plate and the second plate and the heat insulation layer are provided with ribs and grooves matched with the ribs correspondingly, and the structural strength of the first plate and the second plate is enhanced; since the ribs increase the thickness of local areas of the first plate and the second plate, and enough fixing areas are provided for subsequent arranging of embedded hangers, hoisting of the whole external wall panel and bonding and anchoring with concrete; and the independent connecting pieces for fixing the first plate, the second plate and the heat insulation layer are omitted, the phenomenon of cold and hot bridges is avoided, the integrity and leakproofness of the heat insulation layer are guaranteed, and the heat insulation performance is guaranteed.

Owner:NINGBO PRECA CONSTR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com