Flexible prefabricated and assembled shear wall-external window integrated construction system and method

A technology of prefabricated assembly and construction method, applied in the direction of wall, formwork/formwork/work frame, and on-site preparation of building components. problems, to achieve the effect of improving the turnover rate of the formwork, reducing the construction process, and making the construction process simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

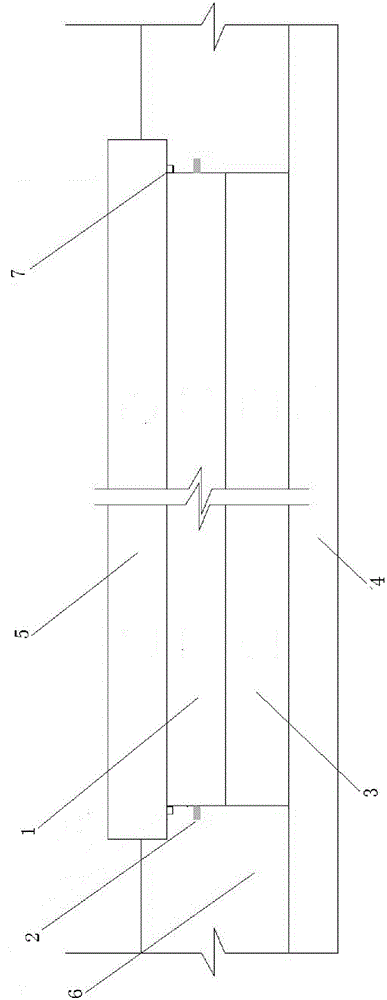

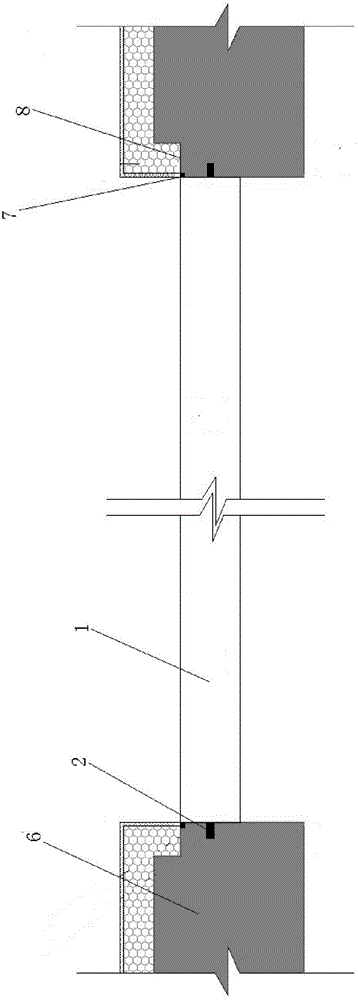

[0029] Such as figure 1 The shown flexible prefabricated shear wall-outer window integrated construction system includes a wall frame for pouring concrete therein, window holes are reserved on the wall frame, and the wall frame The window frame table form 4 is close to the inner wall, and the window frame bottom form 3, the window frame 1 and the window frame top form 5 are successively installed in the window hole from the inside to the outside; The window frame formwork 4 is fixedly connected, and the two sides of the window frame 1 are fixed with window frame embedded parts 2 extending into the wall frame.

[0030] The outer wall surface of the wall frame is symmetrically arranged with L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com