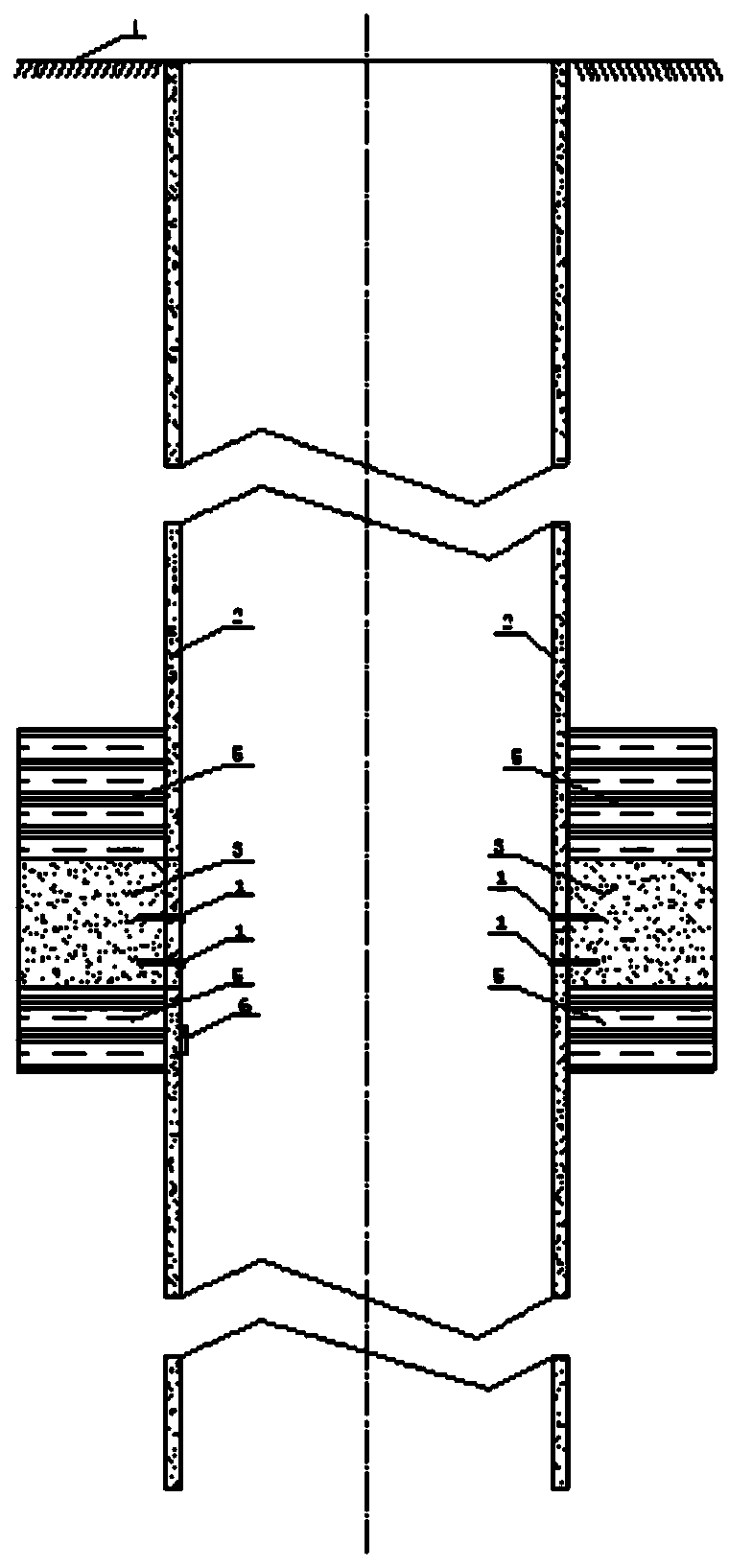

Mine vertical shaft/sieve shaft well wall structure and controllable dewatering method thereof

A shaft wall and shaft technology, which is used in drainage, shaft equipment, mining equipment, etc., can solve the problems of long shaft lifting time, difficulty in forming curtains, and potential safety hazards, so as to eliminate long-term erosion, prolong service life, and reduce shaft wall. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

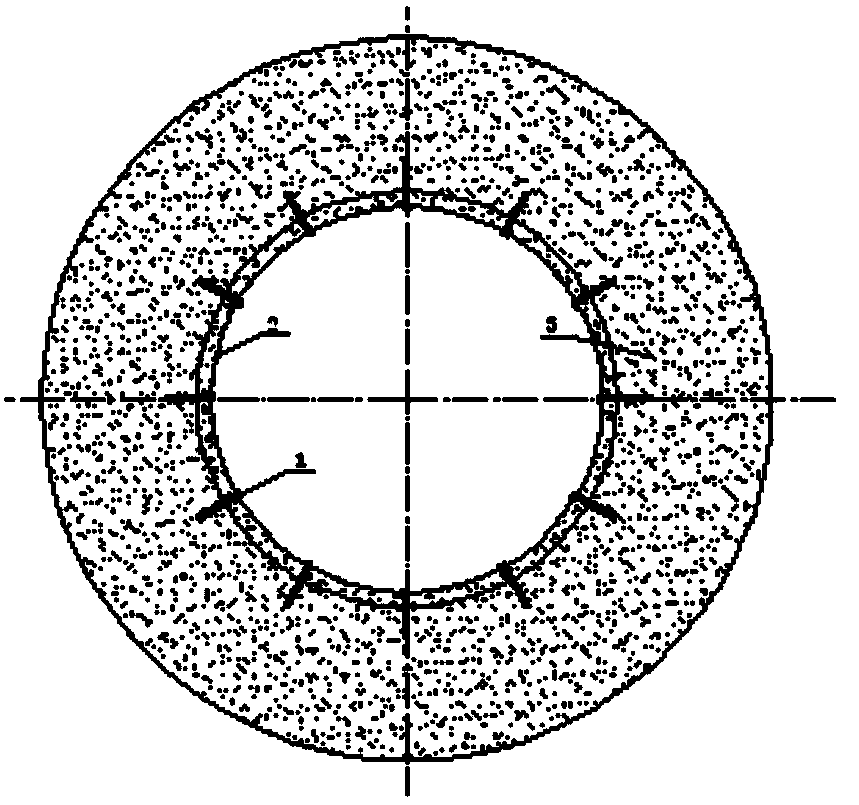

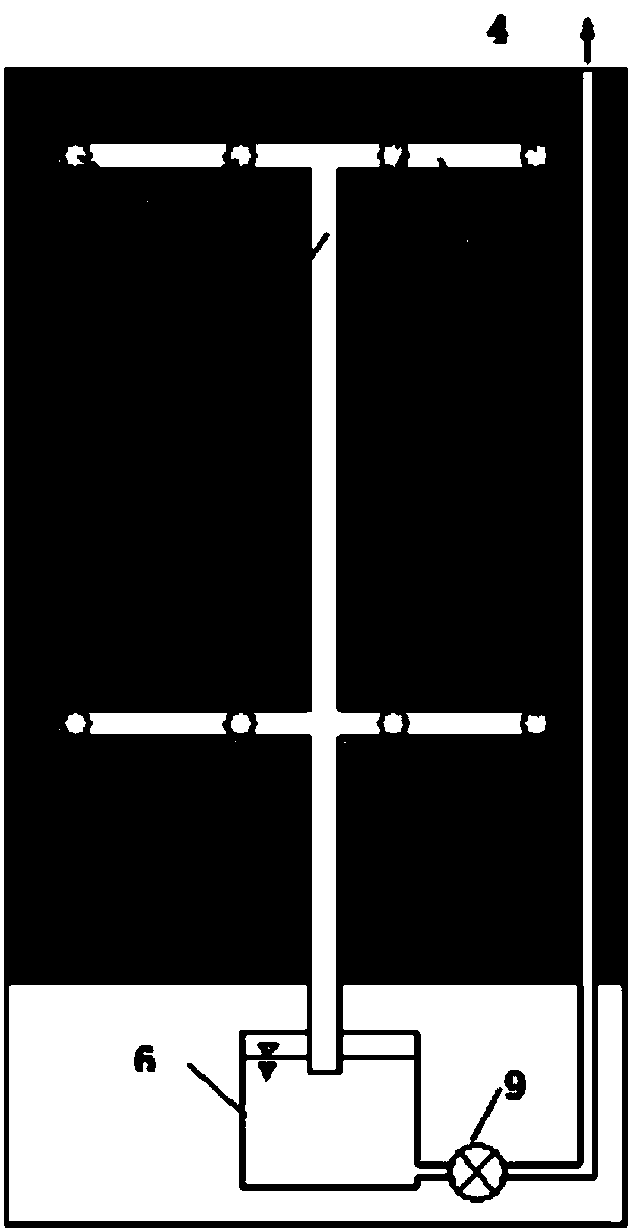

[0026] Embodiment: Screen Well Wall Structure Install intelligent control dredging water pipes on the screen well wall, the intelligent control dredging water pipes are composed of dredging water pipe 1, horizontal water diversion pipe 7, dredging main pipe 8, water collection tank 6 and water pump 9 Screen well wall structure, the horizontal water diversion pipe 7 has multiple layers, arranged horizontally on the well wall, the dredging water pipe 1 has multiple roots, one end communicates with the horizontal water diversion pipe 7, and the other end extends radially into the well wall; the dredging main pipe 8 communicates with the horizontal water diversion pipe 7 of each floor, and the bottom end communicates with the water collection tank 6. An automatic drainage pump 9 is installed on the water collection tank to discharge the water collected in the water collection tank to the outside of the well in time to form water drainage, Hydrophobic systems for control, collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com