Construction method for basement floor post-cast strip waterproofing structure

A basement floor and construction method technology, applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems affecting the construction quality of basement structures, affecting normal use functions, post-pouring belt leakage, etc., to facilitate construction Operation and quality control, simple structure, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

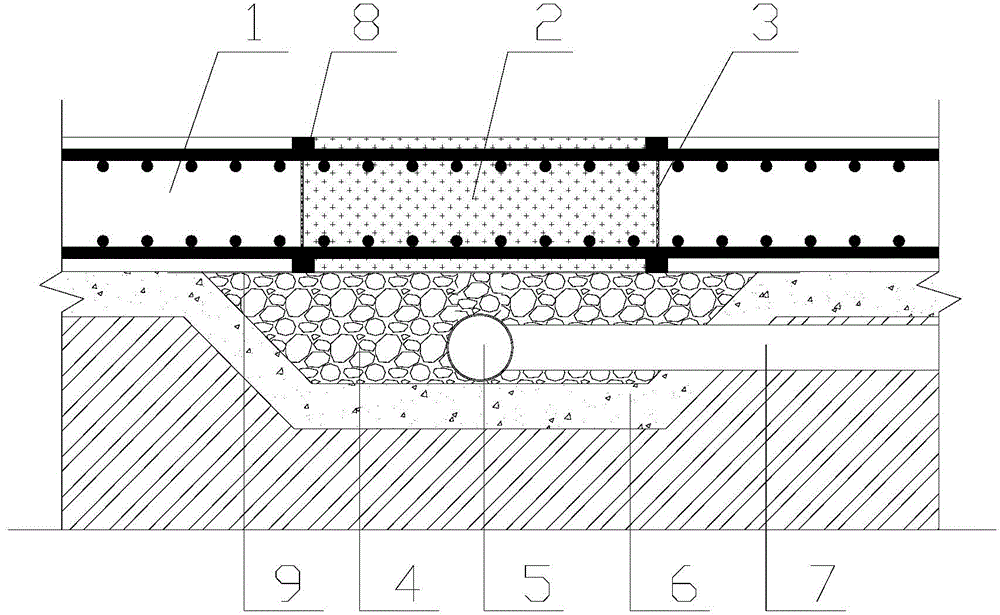

[0017] The construction steps of the post-cast waterproof structure of the basement floor provided by the present invention are as follows:

[0018] 1. After the construction of the foundation cushion 6 is completed, the drainage main pipe 5 and the drainage branch pipe 7 are buried in the filter tank to the bottom sump. The upper part of the drainage main pipe 5 is provided with a φ8-10mm drainage hole. The lower part of the post-pouring belt is covered with graded gravel to form a gravel filter layer 4, and the gradation of the gravel should be 10-31.5; finally, a layer 1.5m wide and 1.5m thick is laid on the gravel filter layer along the direction of the post-casting zone 2 0.5mm plastic film isolation layer9.

[0019] 2. Before the reinforcement of the base plate is bound, place mortar stoppers 8 at the lower part of the post-pouring belts on both sides, and place the lower steel bars of the bottom reinforcement mesh in the grooves of the mortar stoppers 8 to prevent the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com