Assembled keel partition wall mounting structure

An installation structure and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of increased construction cost of partition walls, inconvenient dismantling and maintenance, and high cost of light steel keels, so as to reduce the construction process and install Convenient, quick and simple, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

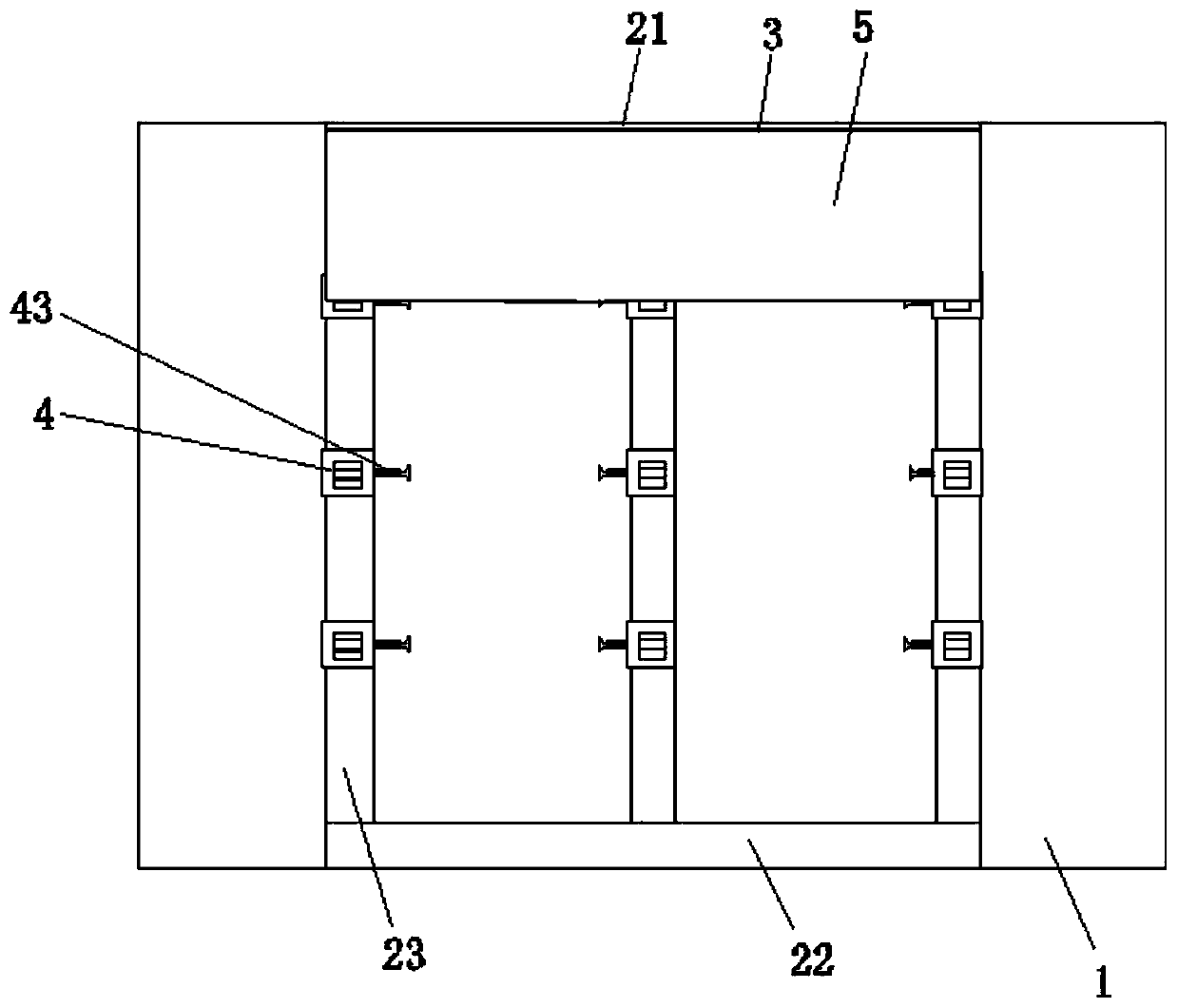

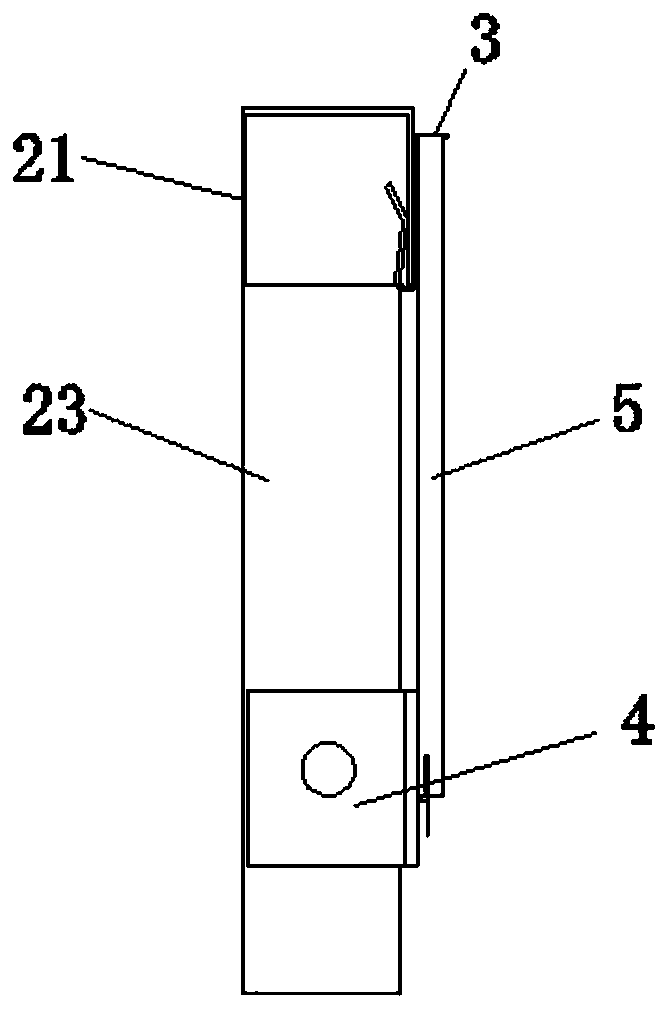

[0038] see Figure 1 to Figure 2 , the figure shows the installation structure of a prefabricated keel partition wall provided by Embodiment 1 of the present invention, which includes: a keel frame, which is arranged on the wall 1, including a top keel 21, a ground keel 22 and a vertical To the keel 23, the top keel 21 is arranged on the top of the wall 1 along the horizontal direction, the ground keel 22 is arranged on the bottom of the wall 1 along the horizontal direction, the vertical keel 23 is arranged in the vertical direction, and the vertical keel 23 The top and the bottom are respectively connected to the top keel 21 and the ground keel 22; the top clip 3, the bottom of the top clip 3 is engaged with the top keel 21; the horizontal clip 4 is fixed on the vertical keel 23 ; The wall panel includes a plurality of spliced unit panels 5 , and the bottom of the unit panel 5 is clamped with the horizontal clip 4 .

[0039] The installation structure of a prefabricated k...

Embodiment 2

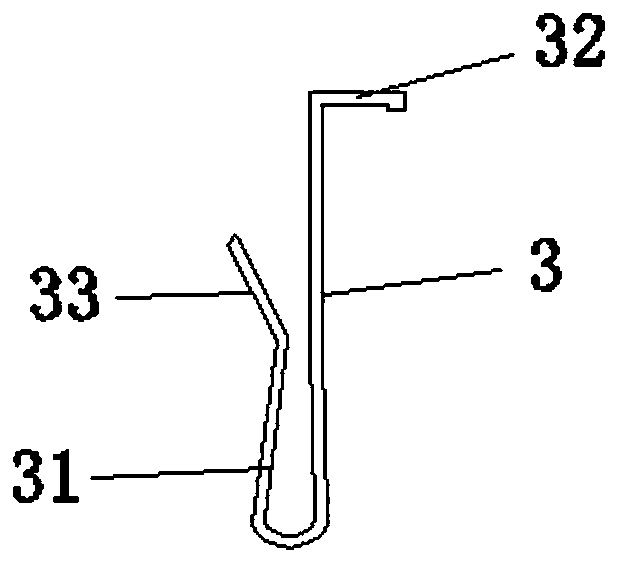

[0048] see Figure 2 to Figure 4 , the figure shows the installation structure of a prefabricated keel partition wall provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: along the top The front of the clip 3 is provided with a hook 31, and the hook 31 is engaged with the top keel 21; the reverse side of the top clip 3 is provided with a top 32; The opening faces upwards; the card top 32 is arranged on the top of the top card 3; the bottom of the hook 31 is arc-shaped; the top size of the hook 31 is smaller than the bottom size; the top of the hook 31 is provided with an outward socket 33. Through the setting of the above structure, the top clip 3 can be firmly clamped and fixed on the top keel 21, and the top clip 3 can be directly used as the closing strip structure at the top of the unit panel 5. In addition, the bottom of the hook 31 It is arc-sh...

Embodiment 3

[0050] see Figure 5 to Figure 8, the figure shows the installation structure of a prefabricated keel partition wall provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The piece 4 is "U"-shaped; the horizontal clip 4 is provided with a fixing hole 41; the side of the horizontal clip 4 is provided with a hook piece 42; Through the setting of the above structure, the "U"-shaped design can directly clamp the horizontal clip 4 on the vertical keel 23, and then pass the screw 43 through the fixing hole 41 to fix it, and the slot 51 at the bottom of the unit panel 5 is inserted into the hook sheet 42, the installation work of the unit panel 5 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com