Screw cover mounting structure and air conditioner

A technology of installation structure and screw cover, which is applied in the direction of air conditioning system, space heating and ventilation, heating and ventilation cover/cover, etc. It can solve the problems of small size of screw cover, confusion of disassembly and installation site, loss of screw cover, etc., to achieve Easy to disassemble and install, good protection, beautiful overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

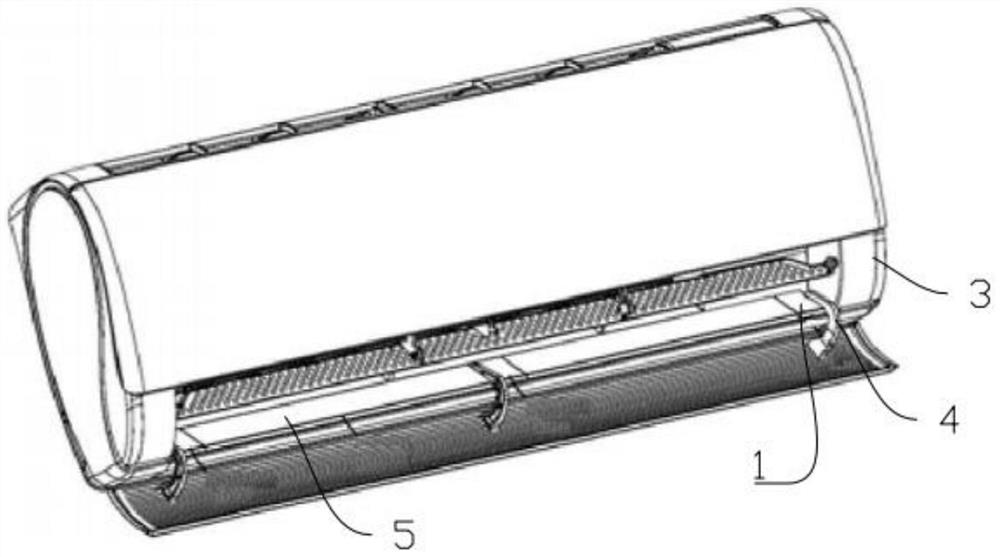

[0041] like Figure 1~4 As shown, this embodiment provides a screw cover installation structure, including a screw cover 1 and a mounting part 2, the mounting part 2 is arranged on the mounting plate 5 of the middle frame 3 at a position close to the connecting bracket 4 of the wind deflector, and the mounting plate 5 Set it at the air outlet of middle frame 3. Screw holes are provided in the installation part 2, and the middle frame 3 is fixedly connected with the base of the air conditioner through the screw holes by using screws.

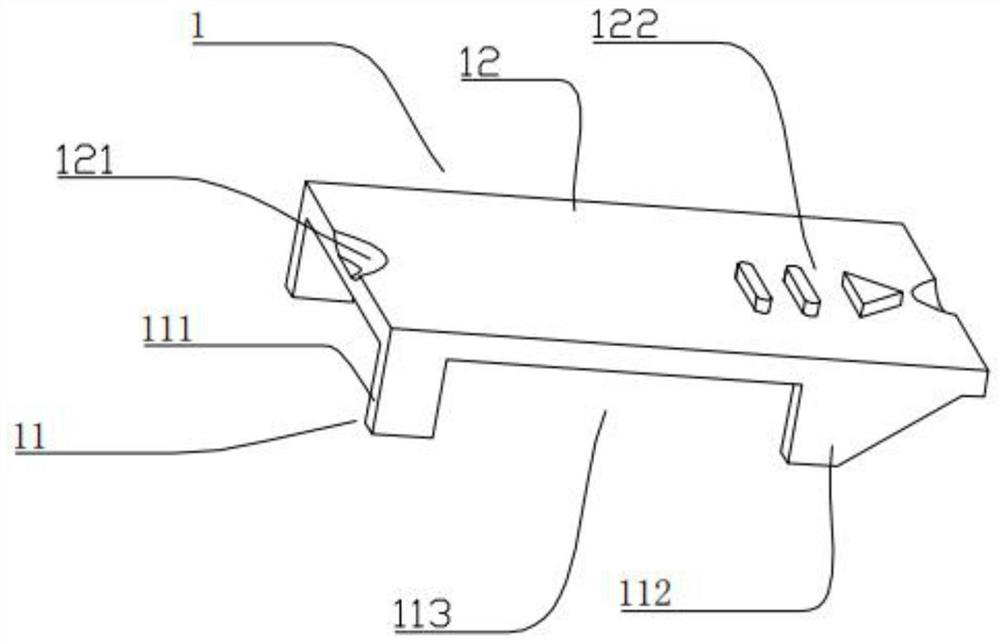

[0042] like figure 2 As shown, the screw cover 1 includes a body 12 and sliding structures 11 arranged on both sides of the body 12 , the mounting part 2 is provided with a slide rail 21 , and the screw cover is slidably mounted on the sliding rail 21 of the mounting part 2 through the sliding structure 11 .

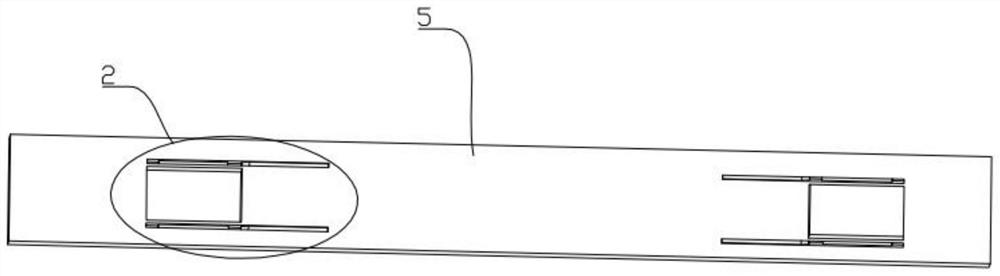

[0043] like Figure 3-4As shown, the mounting part 2 includes a mounting groove 22 and a slide rail 21, and a screw hole is provided i...

Embodiment 2

[0051] like Figure 1~2 and Figure 5-6 As shown, this embodiment further improves the slide rail 21 of the installation part 2 on the basis of the first embodiment. The structure of the screw cover 1 described in this embodiment is exactly the same as that of the screw cover in Embodiment 1, and will not be repeated here.

[0052] The screw cover 1 includes a body 12 and sliding structures 11 arranged on both sides of the body 12 , and a slide rail 21 is provided on the installation part 2 , and the screw cover is slidably installed on the slide rail 21 of the installation part 2 through the sliding structure 11 .

[0053] The sliding rail 21 includes a first rail 211 and a second rail 212 , and the first rail 211 is disposed on both sides of the installation slot 22 . The first track 211 includes ribs 217 for supporting the screw cover 1, the ribs 217 are connected to the inner walls of both sides of the installation groove 22, and the ribs 217 are parallel to the installa...

Embodiment 3

[0060] like Figure 1~2 and Figure 7-9 As shown, this embodiment further improves the slide rail 21 of the installation part 2 on the basis of the second embodiment. The structure of the screw cover 1 described in this embodiment is exactly the same as that of the screw cover in Embodiment 1 and Embodiment 2, and will not be repeated here.

[0061] The screw cover 1 includes a body 12 and sliding structures 11 arranged on both sides of the body 12 , and a slide rail 21 is provided on the installation part 2 , and the screw cover is slidably installed on the slide rail 21 of the installation part 2 through the sliding structure 11 .

[0062] The sliding rail 21 includes a first rail 211 and a second rail 212 , and the first rail 211 is disposed on both sides of the installation slot 22 . The first track 211 includes ribs 217 and baffles 218, the ribs 217 are connected to the inner walls of the installation groove 22 sides, and the ribs 217 extend parallel to the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com