Construction method of steel-concrete joint section

A steel-concrete combination and construction method technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of poor durability, complex structure of steel-concrete joints, and high construction costs, so as to enhance safety and reliability, avoid Difficult to pour and compact, the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

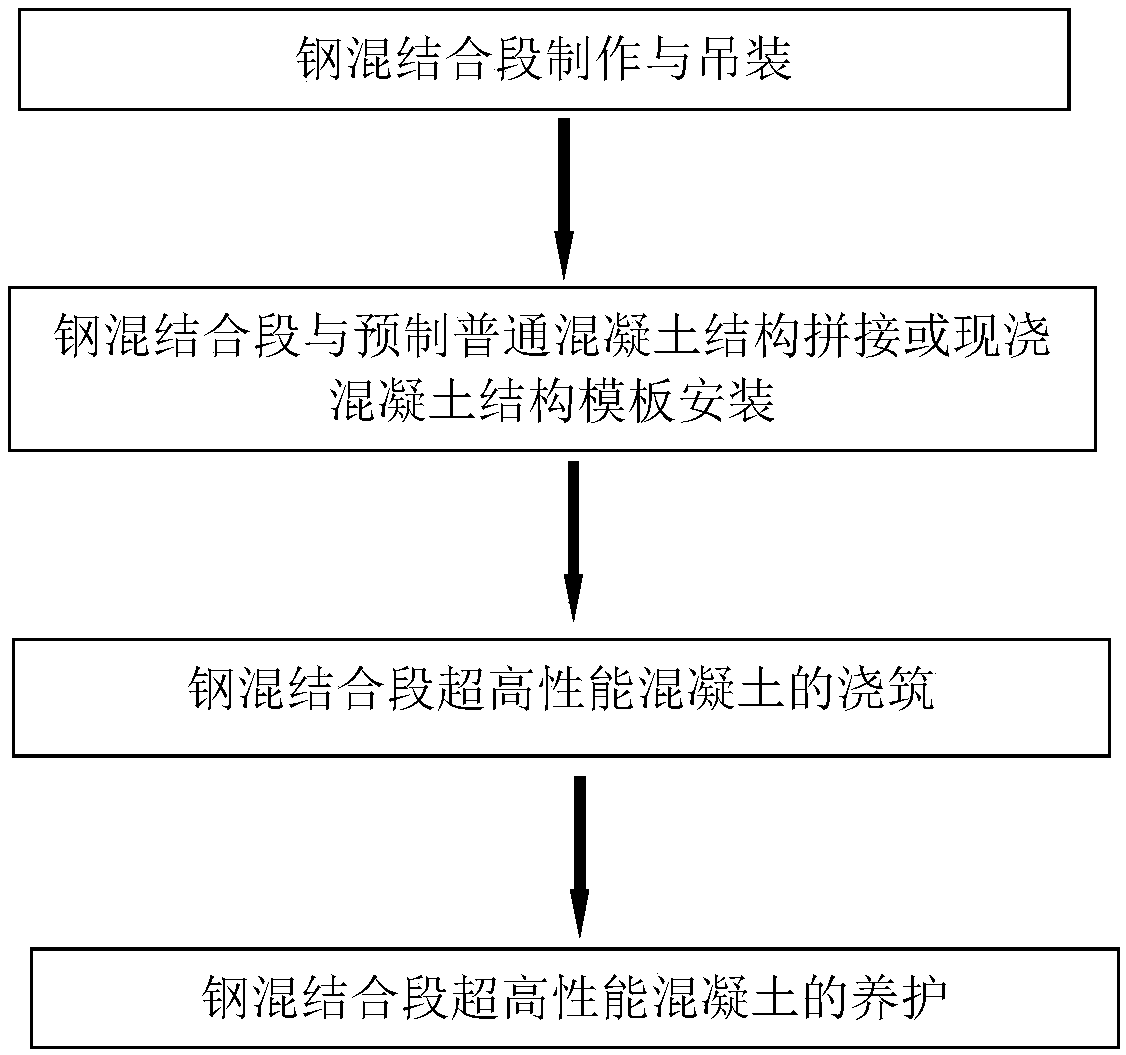

[0043] A construction method for a steel-concrete joint section, comprising the following steps:

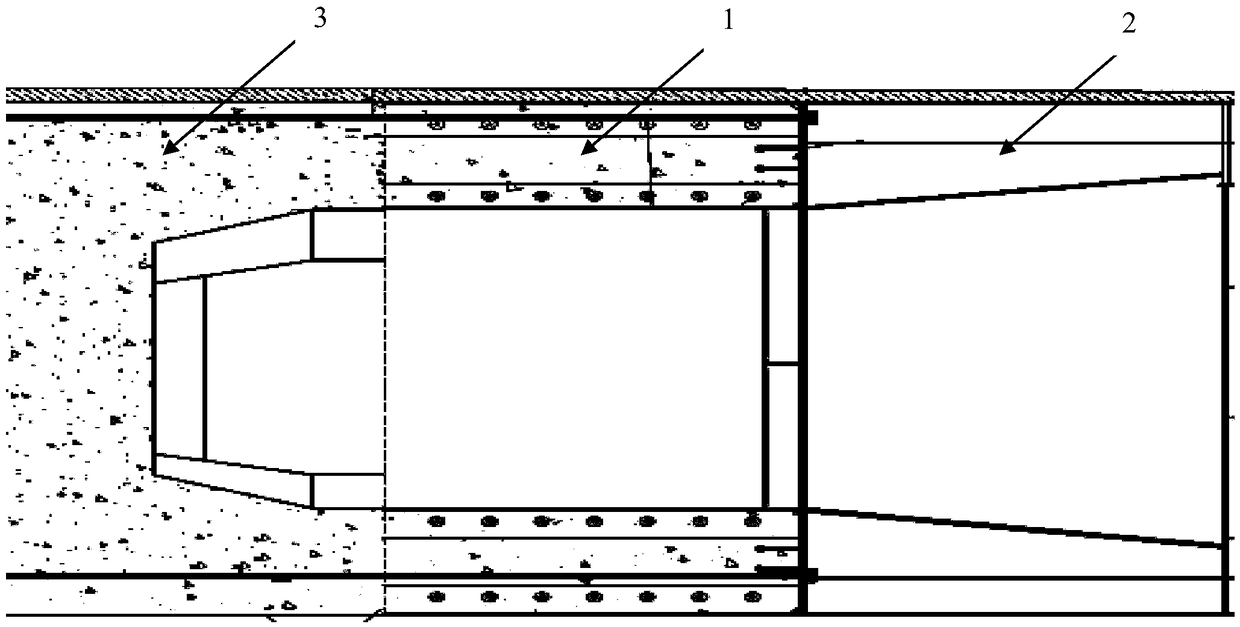

[0044] 1) Before the construction of the steel-concrete joint section 1, the support should be set up reasonably according to the calculation to ensure that the settlement of the support is within a reasonable range; in order to ensure the manufacturing accuracy of the steel-concrete joint section 1, the steel-concrete joint section 1 is manufactured in the factory or on the construction site. Put the PBL shear key through the steel bar; use a large floating crane to hoist the steel-concrete joint section 1 to the support, and choose the lifting point reasonably to prevent the deformation of the steel-concrete joint section 1; finally, accurately position the steel-concrete joint section 1 position.

[0045] 2) After the steel-concrete joint section 1 is hoisted to the support, move the prefabricated ordinary concrete structure on the support until it is connected with the steel-...

Embodiment 2

[0049] A construction method for a steel-concrete joint section, comprising the following steps:

[0050] 1) Before the construction of the steel-concrete joint section 1, the support should be set up reasonably according to the calculation to ensure that the settlement of the support is within a reasonable range; in order to ensure the manufacturing accuracy of the steel-concrete joint section 1, the steel-concrete joint section 1 is manufactured in the factory or on the construction site. Put the PBL shear key through the steel bar; use a large floating crane to hoist the steel-concrete joint section 1 to the support, and choose the lifting point reasonably to prevent the deformation of the steel-concrete joint section 1; finally, accurately position the steel-concrete joint section 1 position.

[0051] 2) After the steel-concrete combination section 1 is hoisted to the support, install the bottom formwork of the adjacent cast-in-place ordinary concrete structure, bind the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com