Patents

Literature

95results about How to "Solve void" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

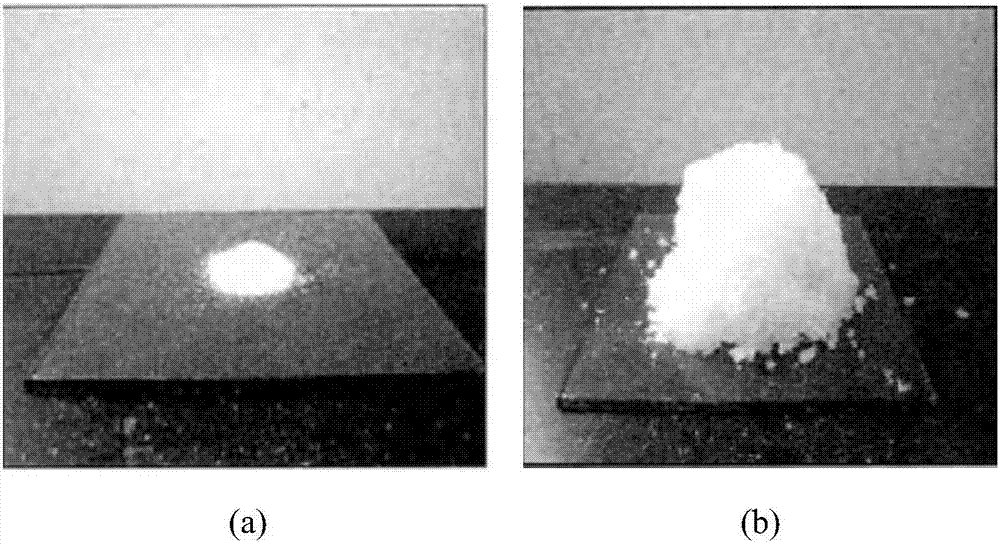

Self-compacting, self-stressing and self-curing high-strength concrete and preparation method thereof

InactiveCN107311567AWith self-maintenance functionSolve voidCeramic shaping apparatusCement mixing apparatusHigh strength concreteChipseal

The invention belongs to the technical field of building materials, and particularly relates to self-compacting, self-stressing and self-curing high-strength concrete and a preparation method thereof. The self-compacting, self-stressing and self-curing high-strength concrete is prepared by mixing cement, fly ash, mineral powder, microbeads, medium sand, gravel, an expanding agent, high molecular absorbent resin SAP, a polycarboxylate superplasticizer and water according to a certain ratio. Through the adoption of the polycarboxylate superplasticizer and addition of a mineral admixture, the concrete is not required to be vibrated and can be compacted through self-leveling; through the addition of the high-efficiency expanding agent, the concrete generates initial self-stress, drying self-shrinkage of the concrete is reduced, and disengagement, a pitted surface and other engineering problems of steel tube concrete are solved; through the addition of the pre-absorbent high molecular resin SAP into the concrete, the problem that the steel tube concrete is difficult to cure is solved. Therefore, the self-compacting, self-stressing and self-curing high-strength concrete has a wide engineering application prospect.

Owner:WUHAN UNIV

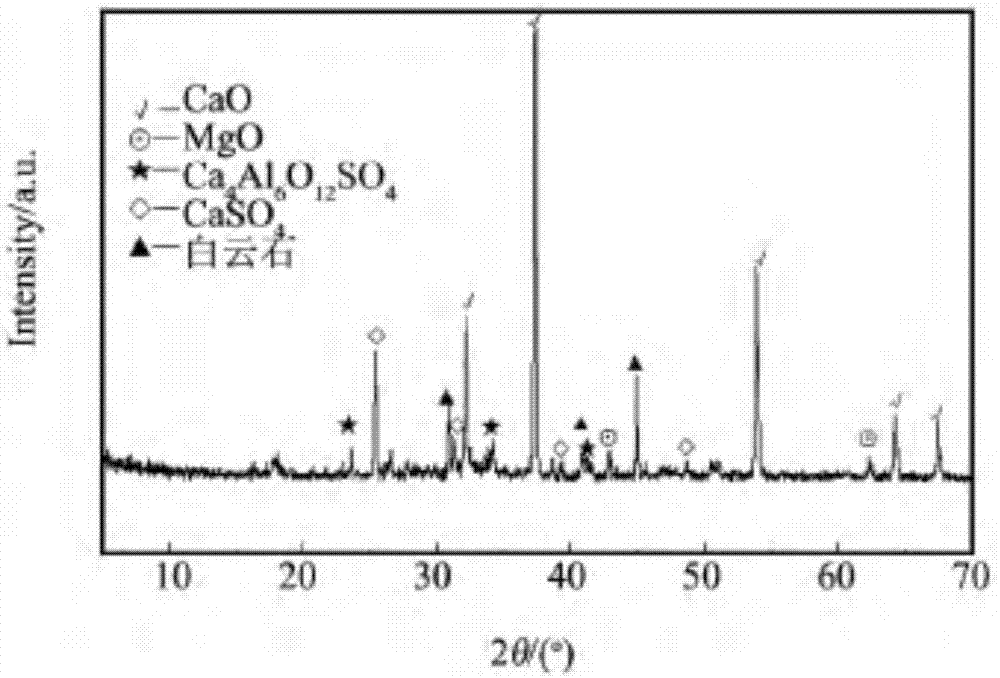

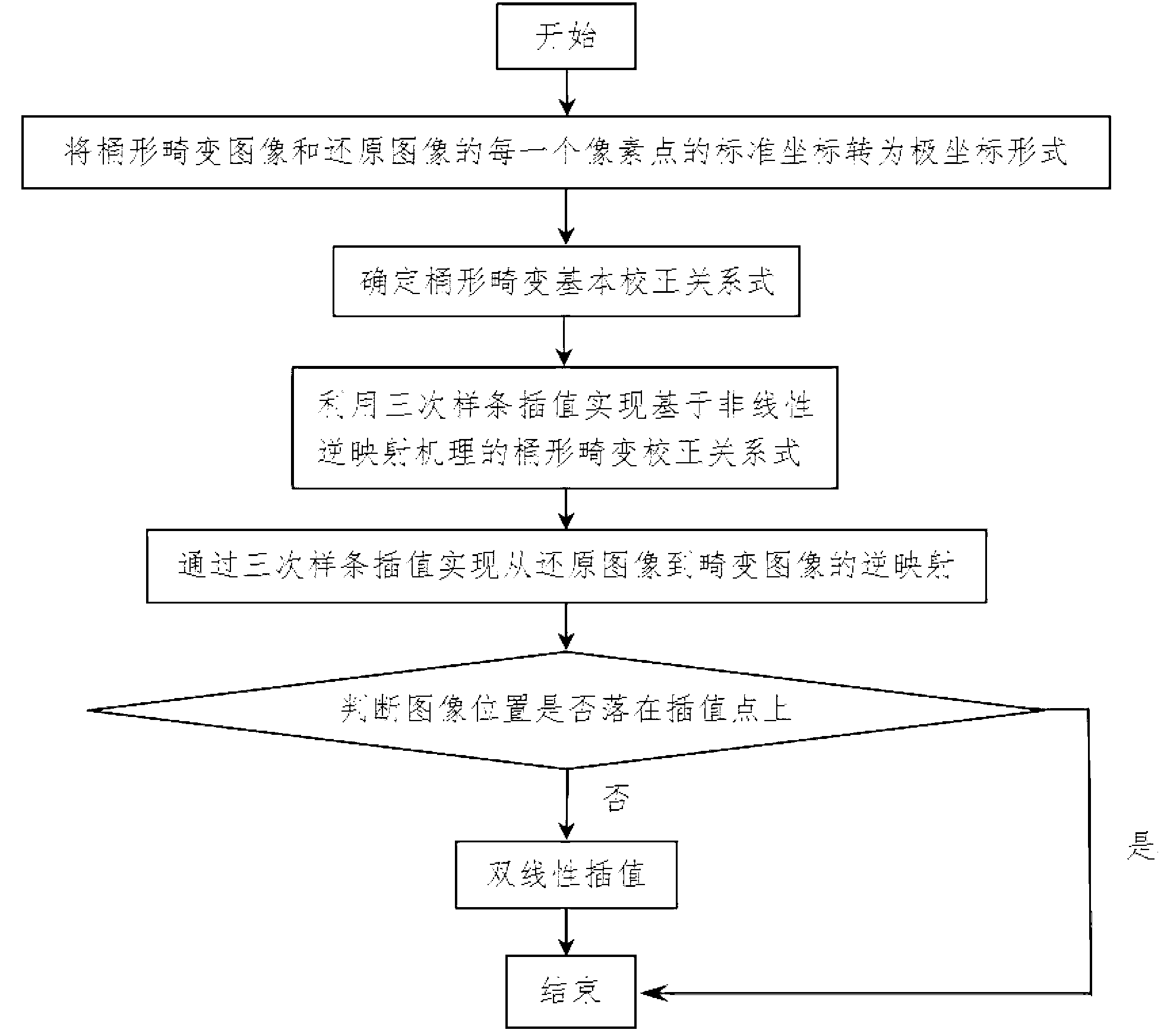

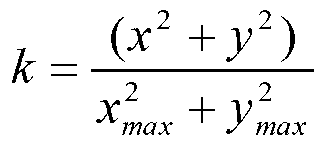

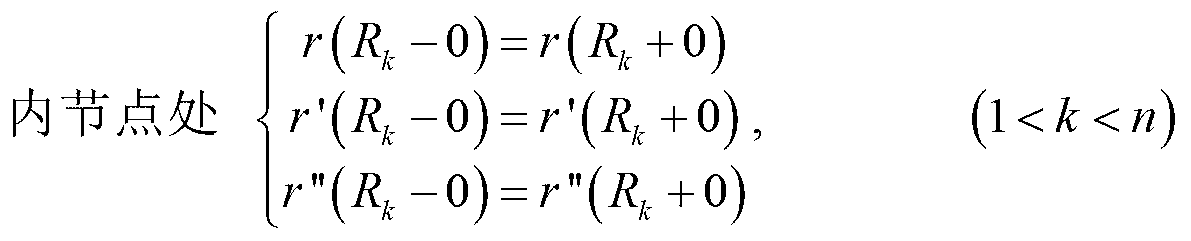

Serious barrel distortion image correction method based on nonlinearity inverse mapping principle

The invention provides a serious barrel distortion image correction method based on a nonlinearity inverse mapping principle. The correction method includes the steps: firstly, confirming the basic correction relation of a barrel distortion image; further, solving the barrel distortion correction relation based on the nonlinearity inverse mapping principle; calculating the polar radius, corresponding to the polar radius in the barrel distortion image, of each pixel in a restore image point-by-point; then mapping the barrel distortion image and the restore image from a polar coordinate system to a standard coordinate system; and giving pixel grey values of the corresponding position of the barrel distortion image to the restore image. Therefore, correction is accomplished. By means of the serious barrel distortion image correction method based on the nonlinearity inverse mapping principle, all cavities in a serious barrel distortion correction image are eliminated completely, the restored grey values at the cavity position can reflect the grey information of an original image correctly, therefore, the information of the restore image is integral and correct, and image quality is improved further.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

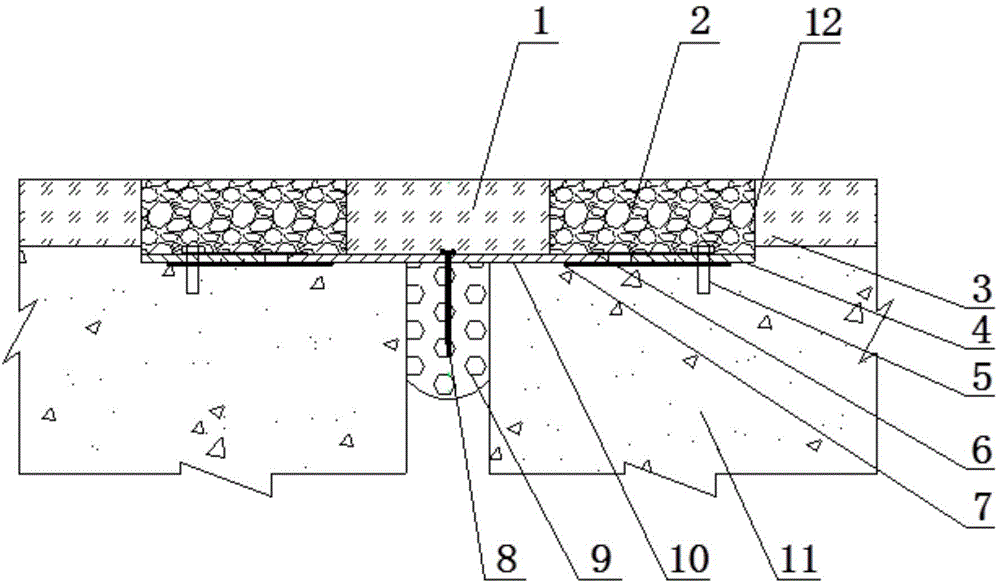

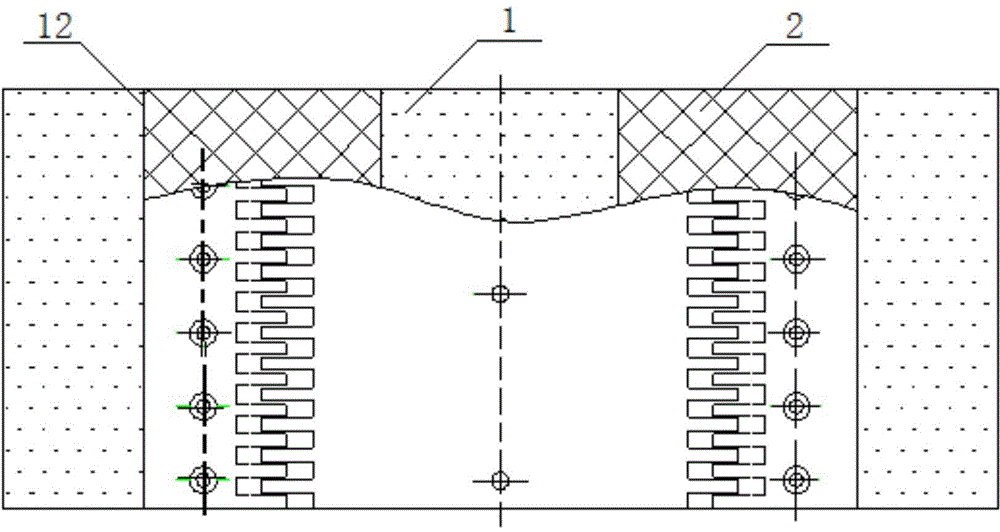

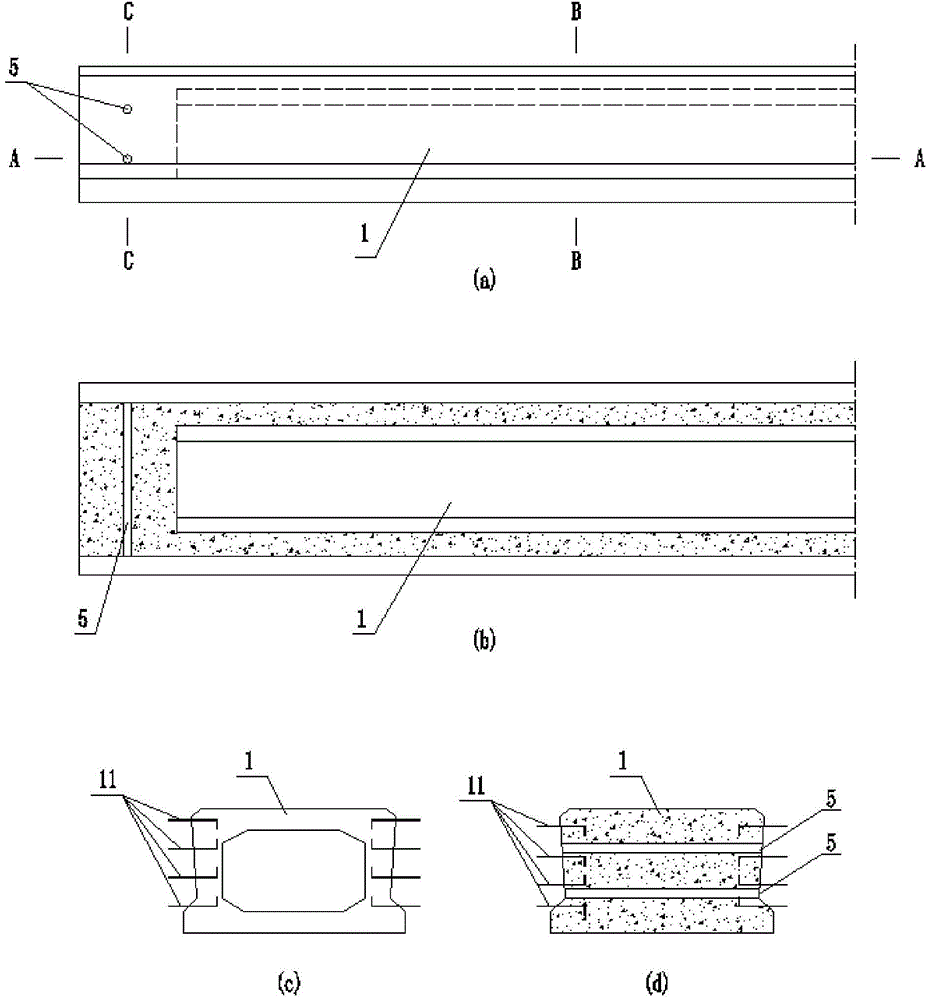

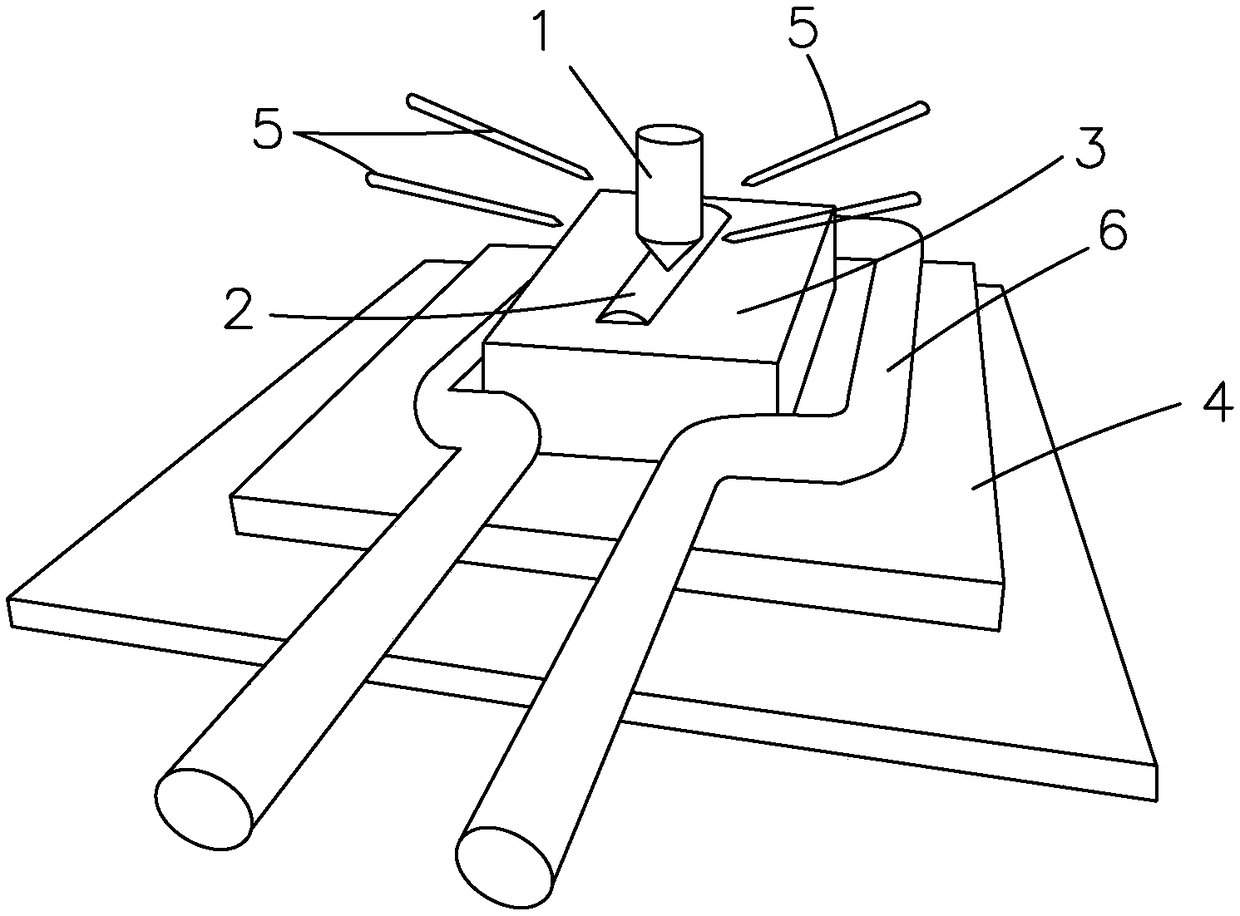

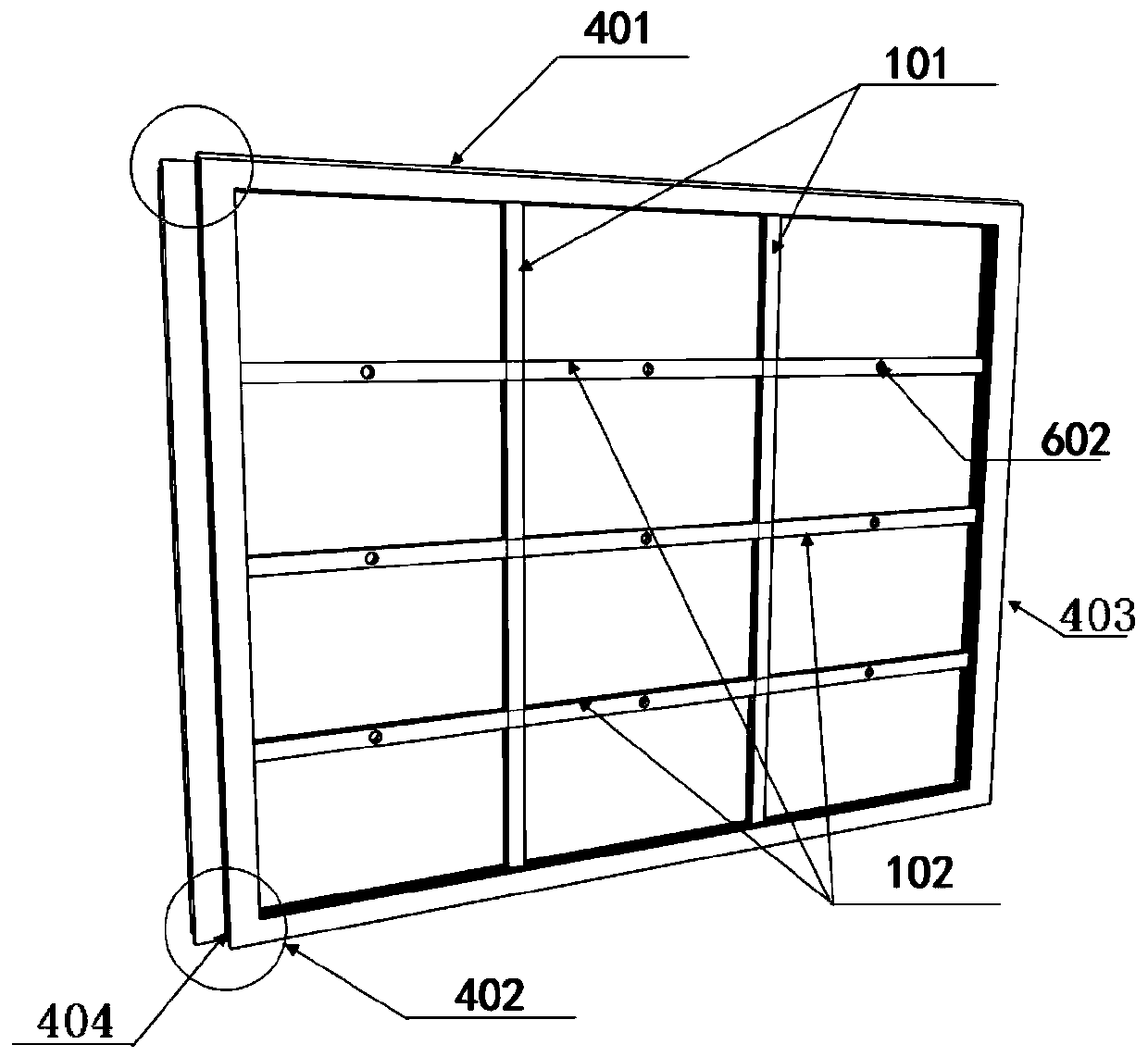

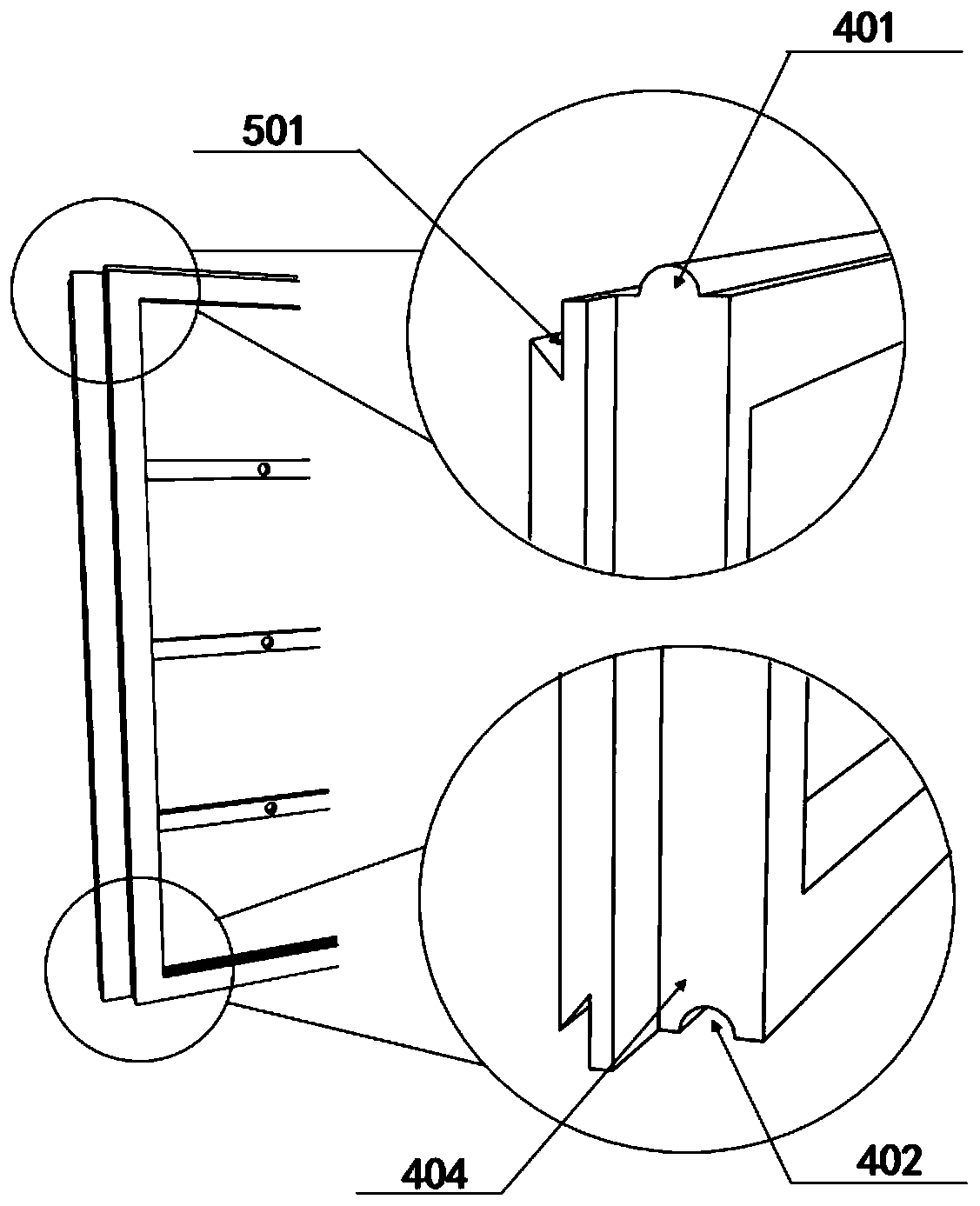

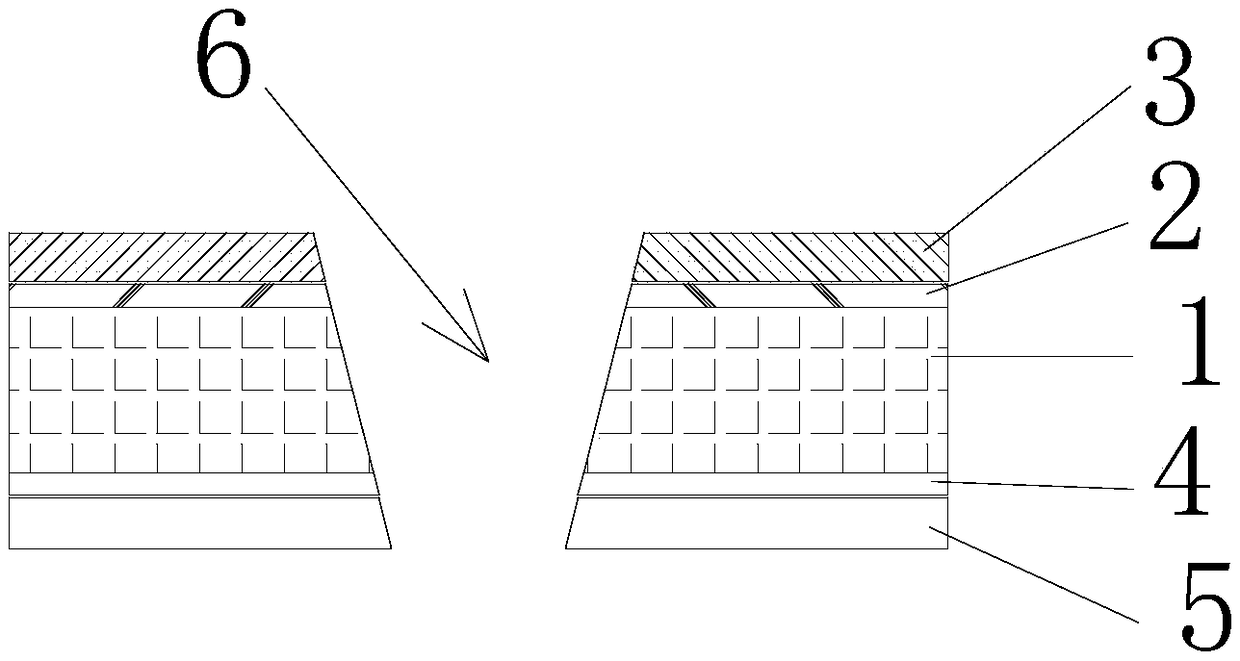

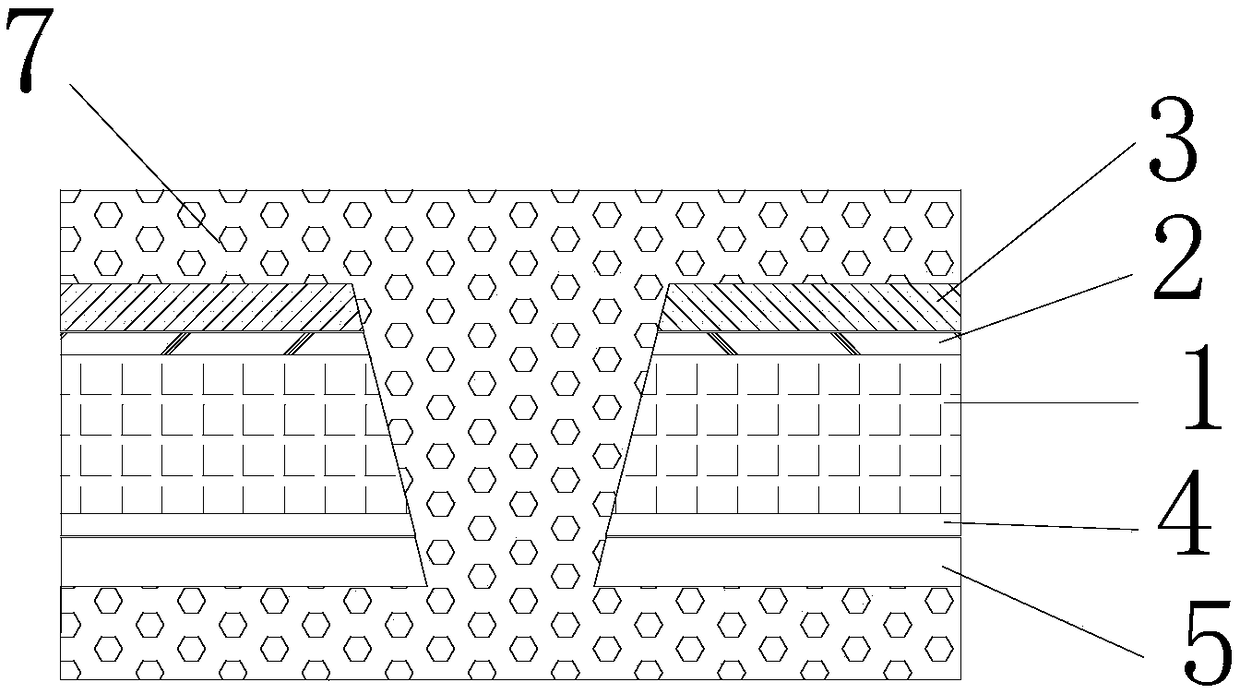

Slipping type seamless telescopic device

InactiveCN104818669AReduce warpingAlleviation deficiencyBridge structural detailsElastomerArchitectural engineering

The invention discloses a slipping type seamless telescopic device. A telescopic seam is arranged between main beams, upper surfaces of the main beams are provided with comb plates, and the comb plate arranged at the upper part of the telescopic seam is a trans-seam comb plate, and a fixing comb plate is connected with the trans-seam comb plate; a top paving layer is arranged at the upper part of the trans-seam comb plate, and both sides of the top paving layer are respectively provided with elastomer prefabricating blocks; left and right sides of the elastomer prefabricating blocks are respectively arranged with bituminous concrete paving layers. The slipping type seamless telescopic device and a bridge face paving layer can be formed to be a continuous body, so as to guarantee stable and comfortable driving; the driving noise is small and waterproof performance is good, and the slipping type seamless telescopic device is convenient to clean and remove snow, and other maintaining works; the structural design is more reasonable, and construction is convenient; the comb plates are respectively arranged beneath the paving layer and above the main beam, and can be fixedly moved; and thereby, the problem of empty lower part of the tooth end of the comb plate is effectively solved, and the shortcoming that the traditional seamless telescopic device is easy to crack is overcame.

Owner:JSTI GRP CO LTD +1

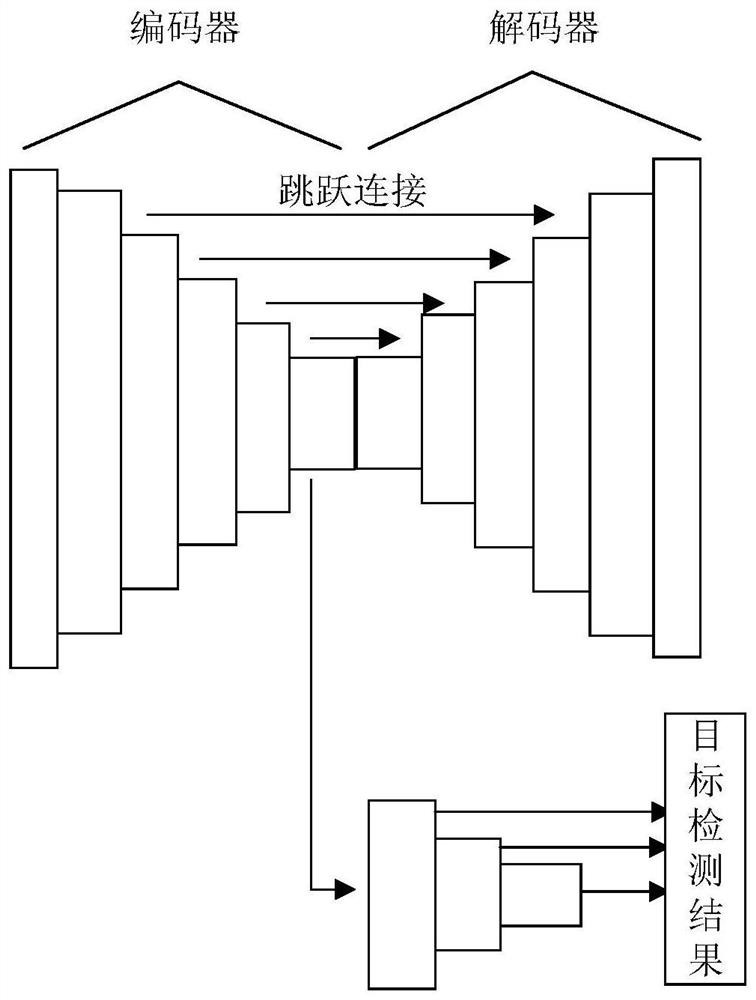

Signal processing method based on deep neural network

ActiveCN112203093ASolve voidAchieving the purpose of joint trainingImage enhancementImage analysisDeep neural networksNetwork model

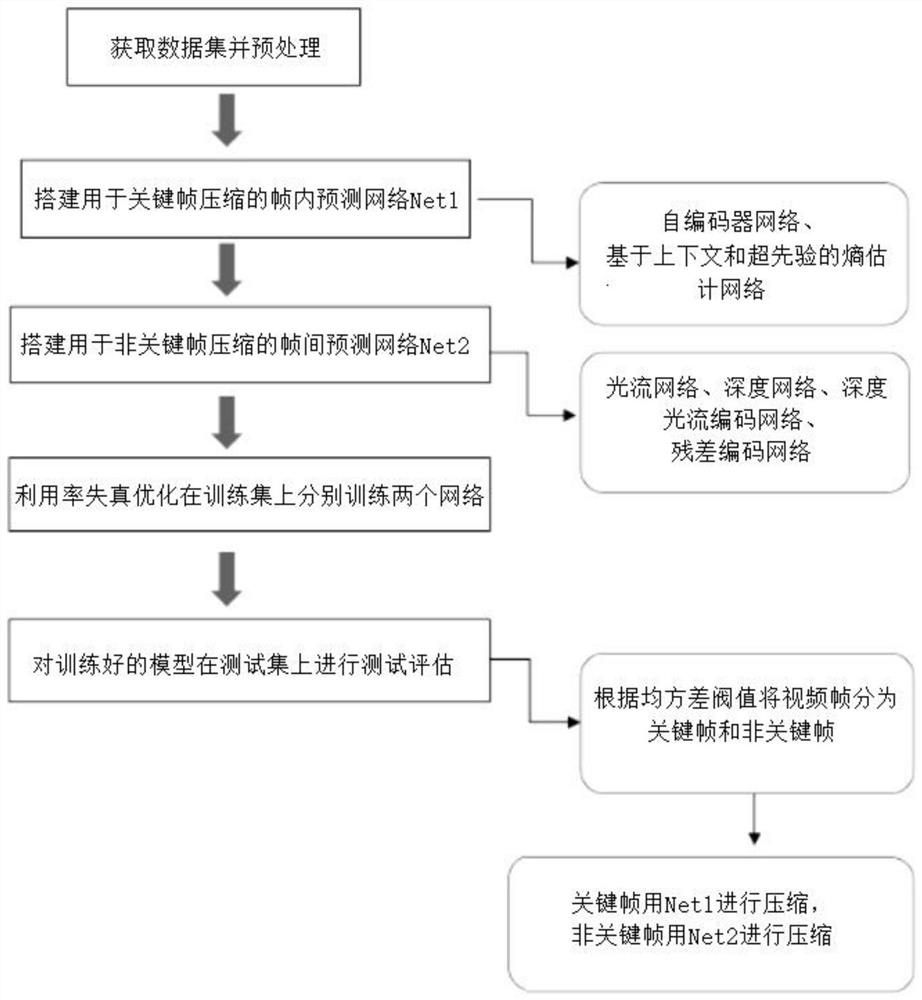

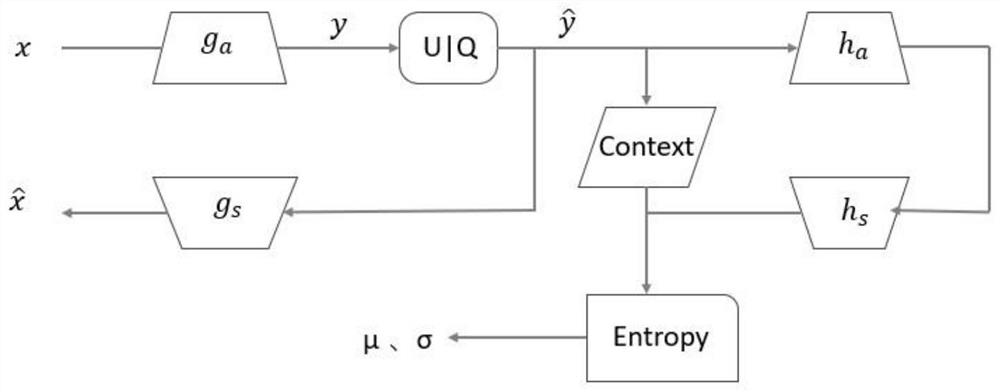

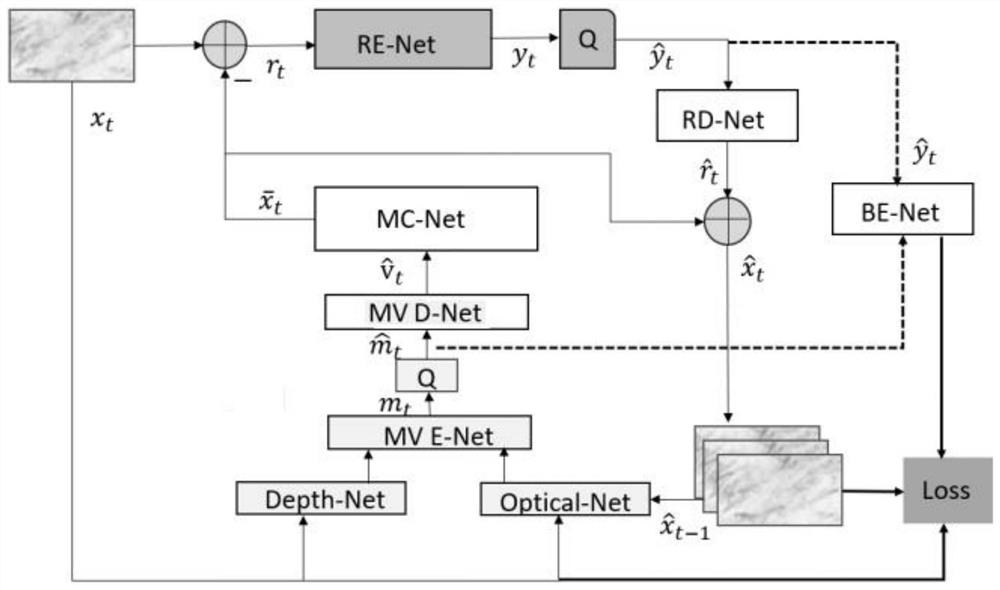

The invention discloses a signal processing method based on a deep neural network, and the method comprises the steps: firstly dividing a video frame into a key frame and a non-key frame according tothe threshold value of the mean square error between a current frame and a previous frame, and carrying out the compression of training network models of the key frame and the non-key frame; for a non-key frame, an entropy model auto-encoder based on context and super prior is adopted to perform intra-frame prediction; for a non-key frame, optical flow information and depth information are extracted and combined to generate motion information so as to carry out frame reconstruction, then extraction coding is carried out on a residual error between a reconstructed frame and a real frame, and finally a current frame is generated at a decoding end according to the transmitted motion information and residual error information in combination with a previous frame. The end-to-end video compression method makes full use of the strong nonlinear expression ability of the deep neural network and the advantages of joint training, and the compression effect of the end-to-end video compression method exceeds h.264.

Owner:苏州天必佑科技有限公司

Virtual viewpoint synthesizing method based on layered processing

InactiveCN104869386AGuaranteed correctnessProtect smoothnessSteroscopic systemsColor imageViewpoints

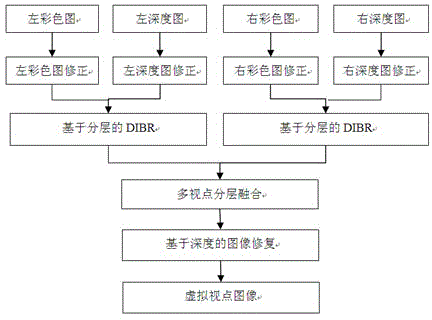

The invention discloses a virtual viewpoint synthesizing method based on layered processing. Firstly preprocessing of depth correction and color correction is performed on depth maps of left and right viewpoints; then the image of a virtual viewpoint is generated by adopting layered 3D Warping; color images and depth images of left and right reference viewpoints generated by DIBR are integrated according to layered information, and then filtering processing is performed on the integrated depth maps; then the image of the virtual viewpoint is corrected according to the depth maps, and holes in the image are eliminated; and finally image interpolation and post processing are performed, a ghost phenomenon in the image is removed and finally a high-quality new viewpoint is generated. An intermediate viewpoint can be rapidly synthesized according to any two viewpoints, and picture quality of the newly synthesized viewpoint is relatively high.

Owner:SOUTHEAST UNIV

Data acquisition method and device for automatic foreground extraction

PendingCN109829932AData augmentation is of great valueSolve roughImage enhancementImage analysisBackground informationAutomation

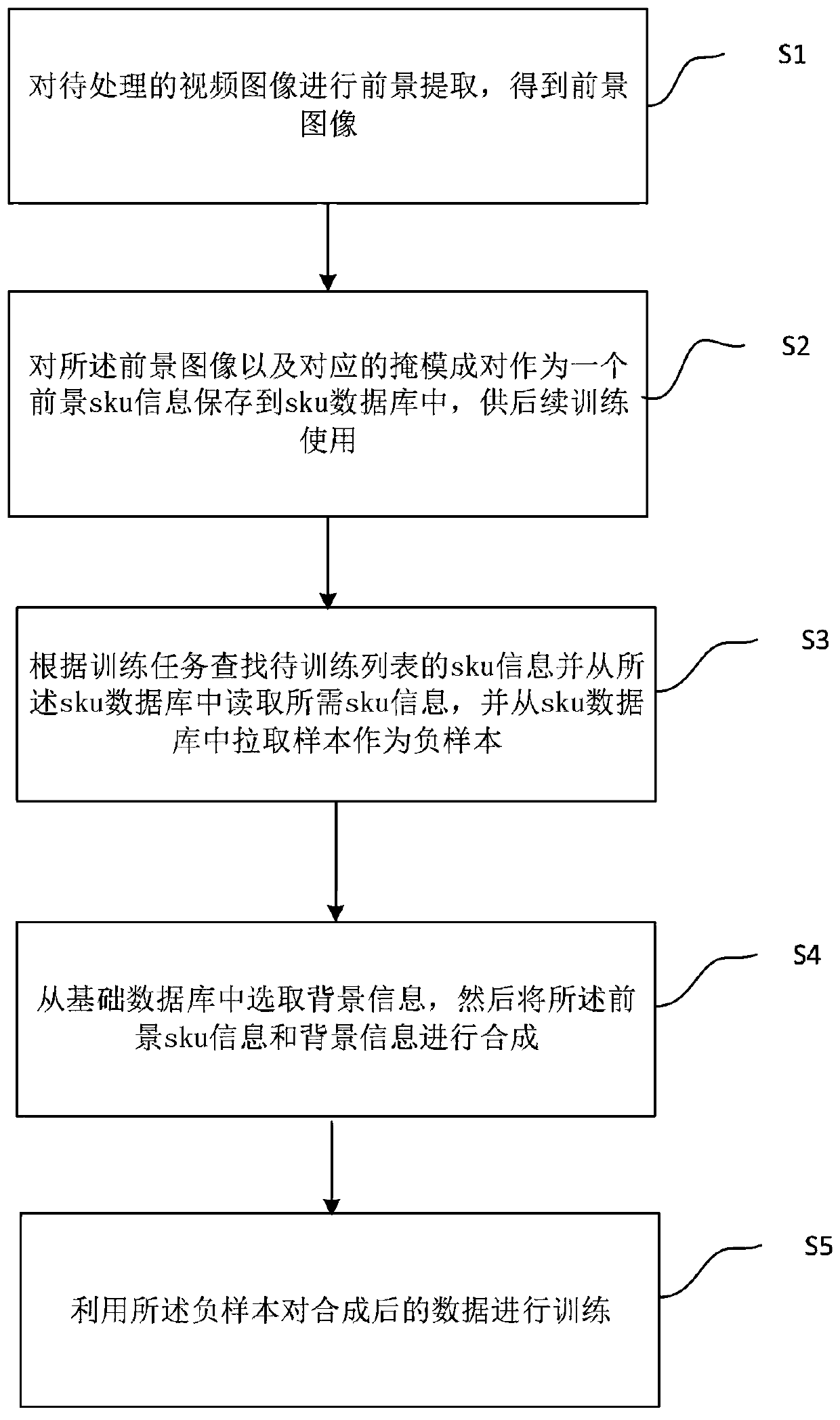

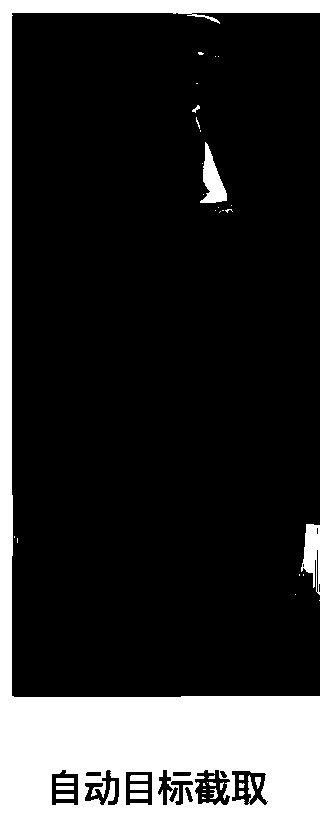

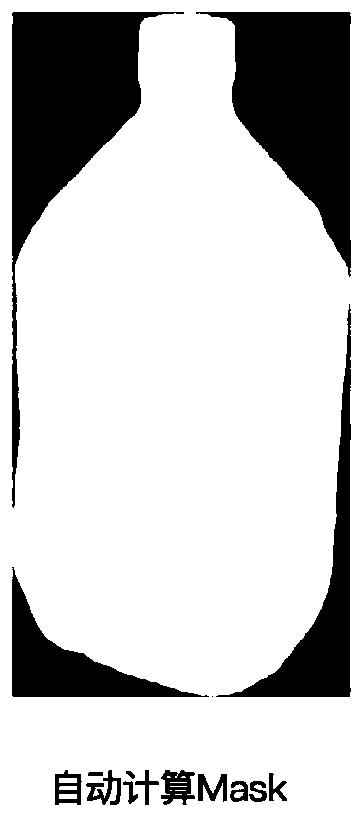

The invention provides an automatic foreground extraction data acquisition method and device, and the method comprises the steps: carrying out the foreground extraction of a to-be-processed video image, and obtaining a foreground image; storing the foreground images and the corresponding masks in pairs as foreground sku information in a sku database for subsequent training; searching sku information of a to-be-trained list according to a training task, reading required foreground sku information from the sku database, and pulling a sample from the sku database as a negative sample; selecting background information from a basic database, and synthesizing the foreground sku information and the background information; and training the synthesized data by using the negative sample. No manual assistance is needed for foreground extraction, and full automation is achieved; Various complex backgrounds can be fused, and the data augmentation value is huge.

Owner:创新奇智(上海)科技有限公司

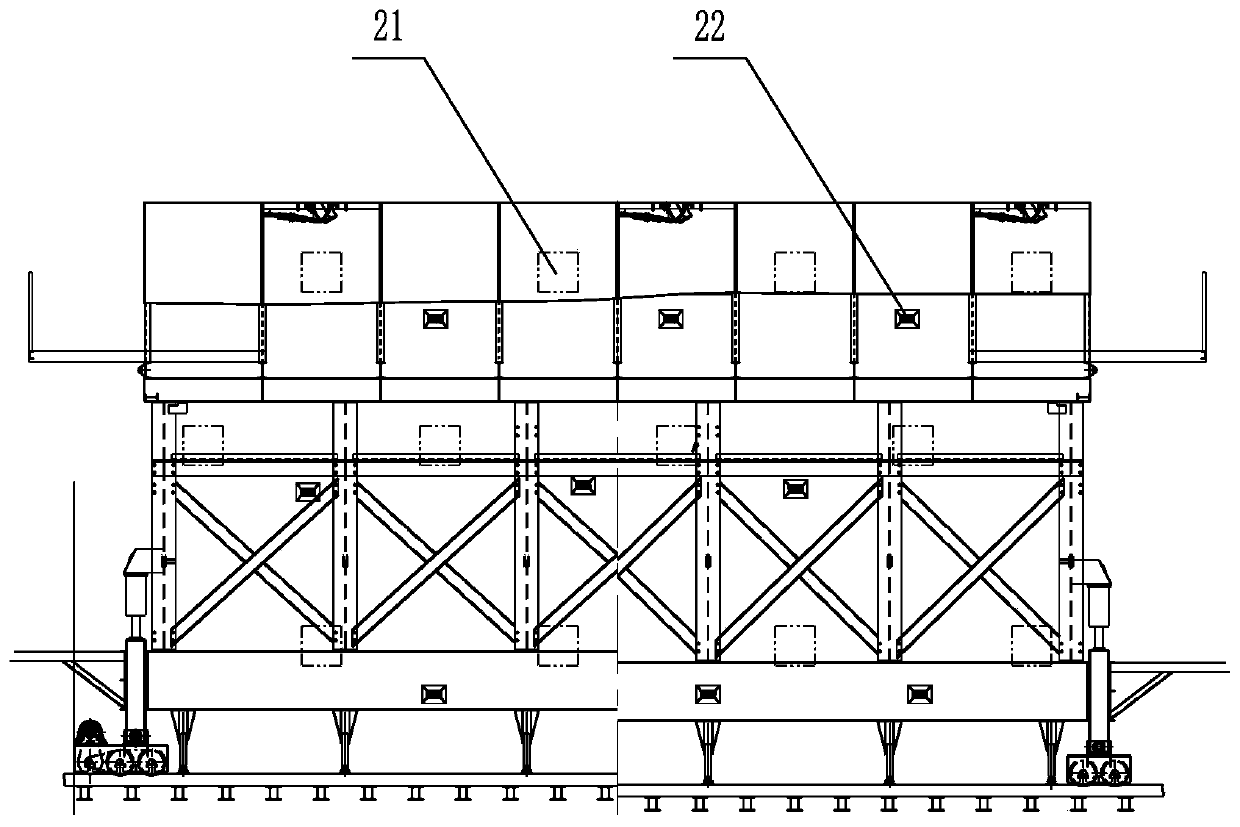

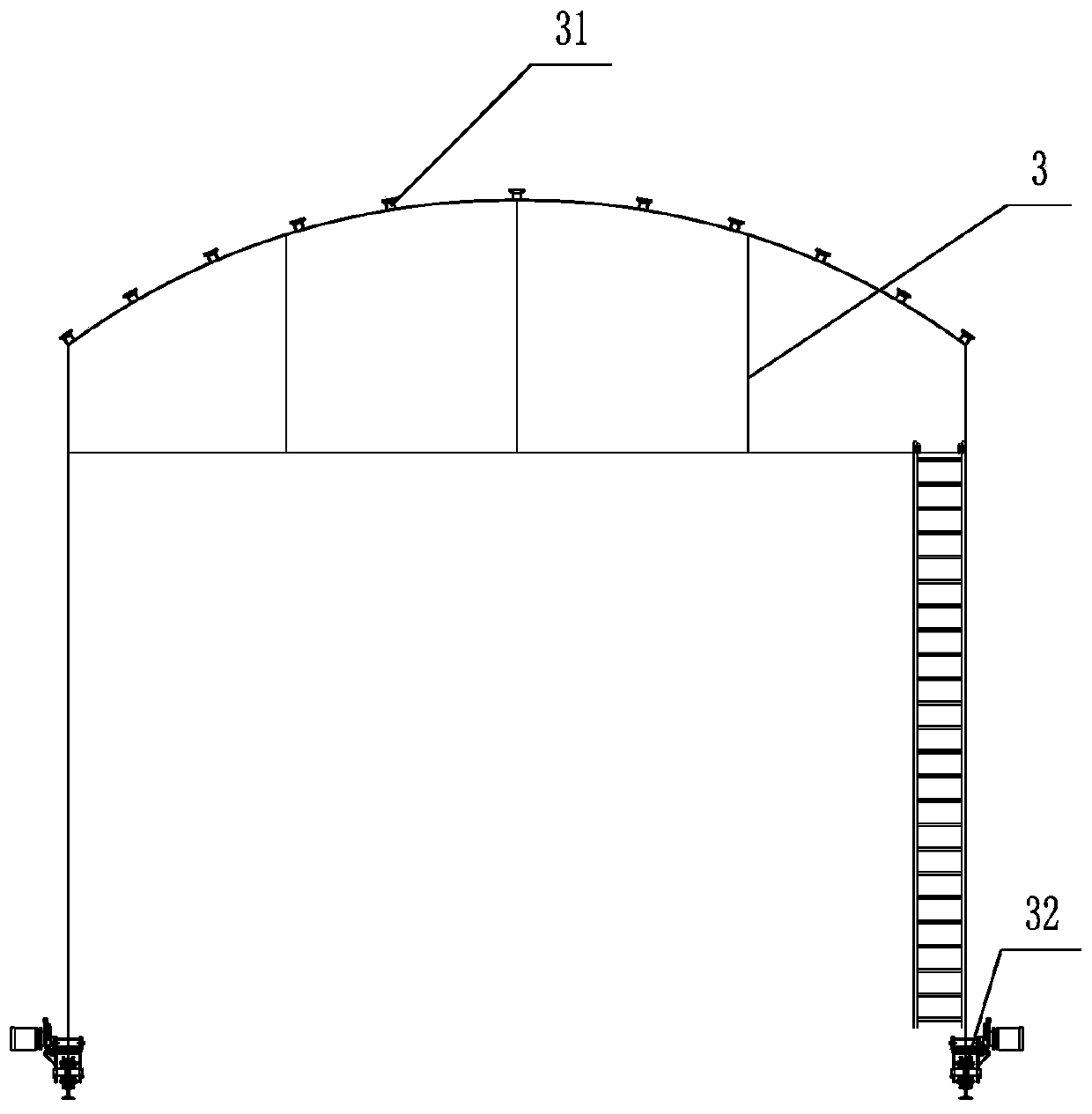

Anti-disengaging tunnel secondary lining concrete pouring constructing method and formwork system

InactiveCN104895586ASolve voidIntegrity guaranteedUnderground chambersTunnel liningPistonStructural engineering

The invention discloses an anti-disengaging tunnel secondary lining concrete pouring constructing formwork system. The system mainly comprises a formwork body and a hydraulic jack, and an inversely-protruding round steel cylinder is arranged on the formwork body to form a T-shaped formwork. Accordingly, a corresponding anti-disengaging tunnel secondary lining concrete pouring constructing method is built. The method includes the steps that the T-shaped formwork with the concrete storage function is used, after concrete pouring vibration and before concrete prehardening, a piston in the T-shaped formwork is pushed through the hydraulic jack so as to press in concrete in the inversely-protruding round steel cylinder, and therefore the problem of disengaging normally occurring in tunnel concrete secondary lining is solved. Compared with a commonly-used method for processing disengaging through embedded pipe slip casting, the constructing method and the formwork system have the advantages of being simple and convenient to use; the problem of disengaging generated in secondary lining concrete pouring in a tunnel is solved, and the integrity of concrete secondary lining can be guaranteed.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

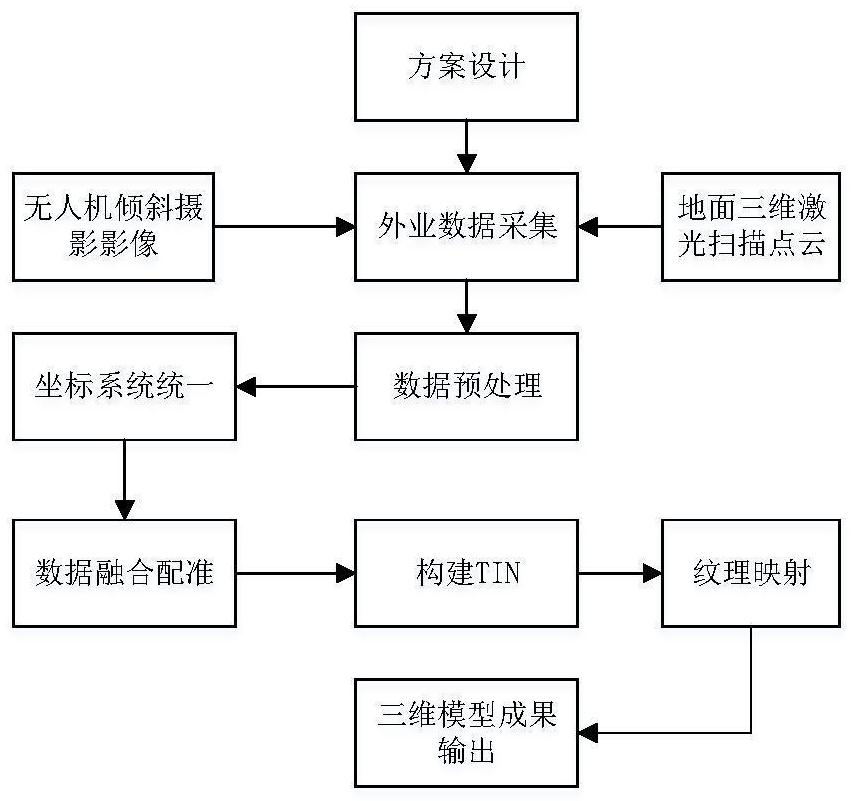

Three-dimensional reconstruction method based on multi-source data fusion

The invention provides a three-dimensional reconstruction method based on multi-source data fusion. The method comprises the following steps: firstly, acquiring image and laser point cloud data by an oblique photography technology and a laser radar technology; secondly, unifying space coordinate systems of the two kinds of data to carry out data coarse registration; besides, an improved ICP algorithm is designed, and point clouds are resampled by using a voxel grid method on the basis of a traditional ICP algorithm, so that the convergence speed of the algorithm is accelerated, and the registration precision is improved. Experimental results show that the completeness of the three-dimensional model is ensured by the multi-source data fusion method, the limitation of modeling by a single technology is made up, and the method has a good application prospect.

Owner:ZHEJIANG HUAYUN ELECTRIC POWER ENG DESIGN CONSULTATION CO LTD

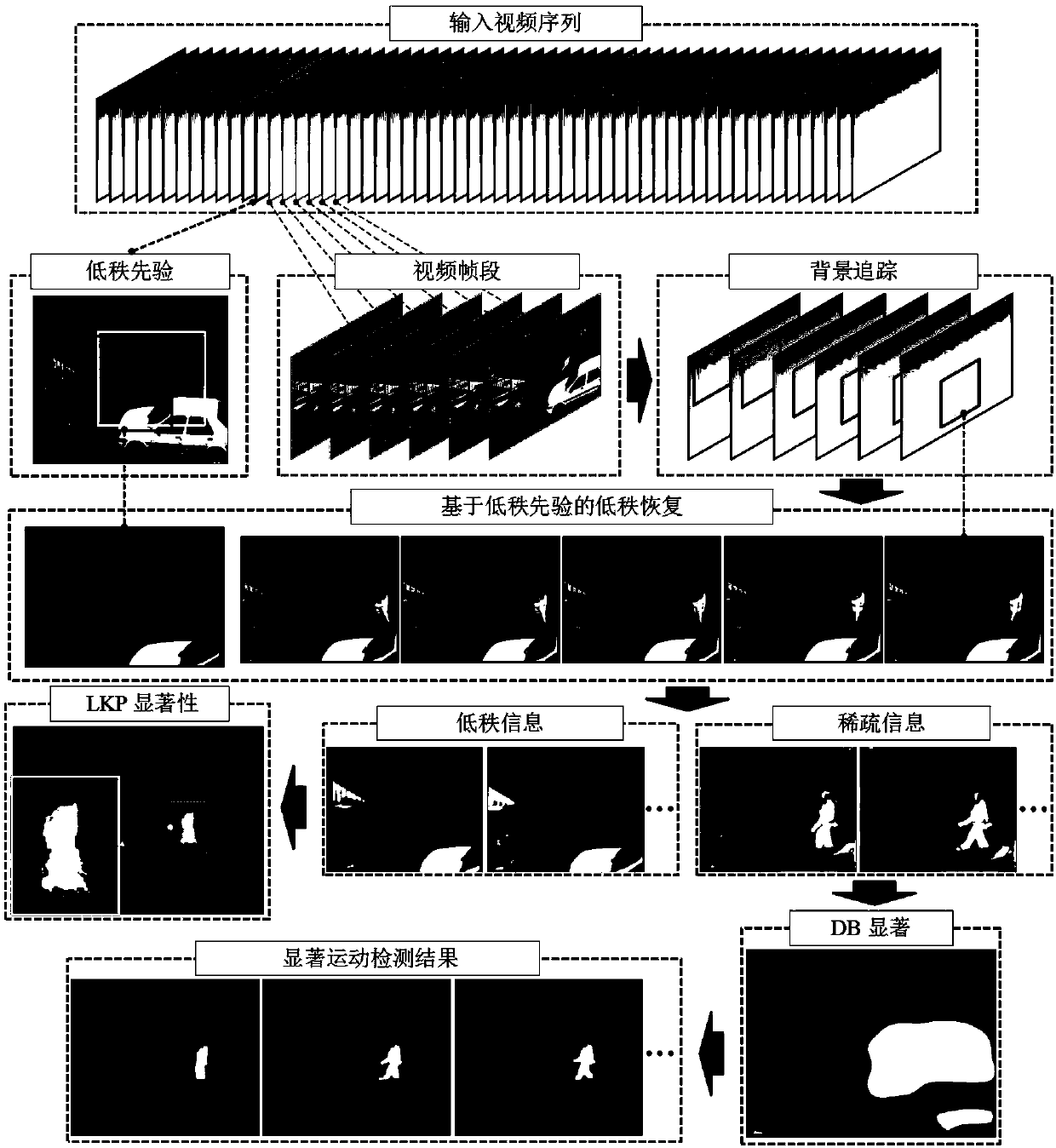

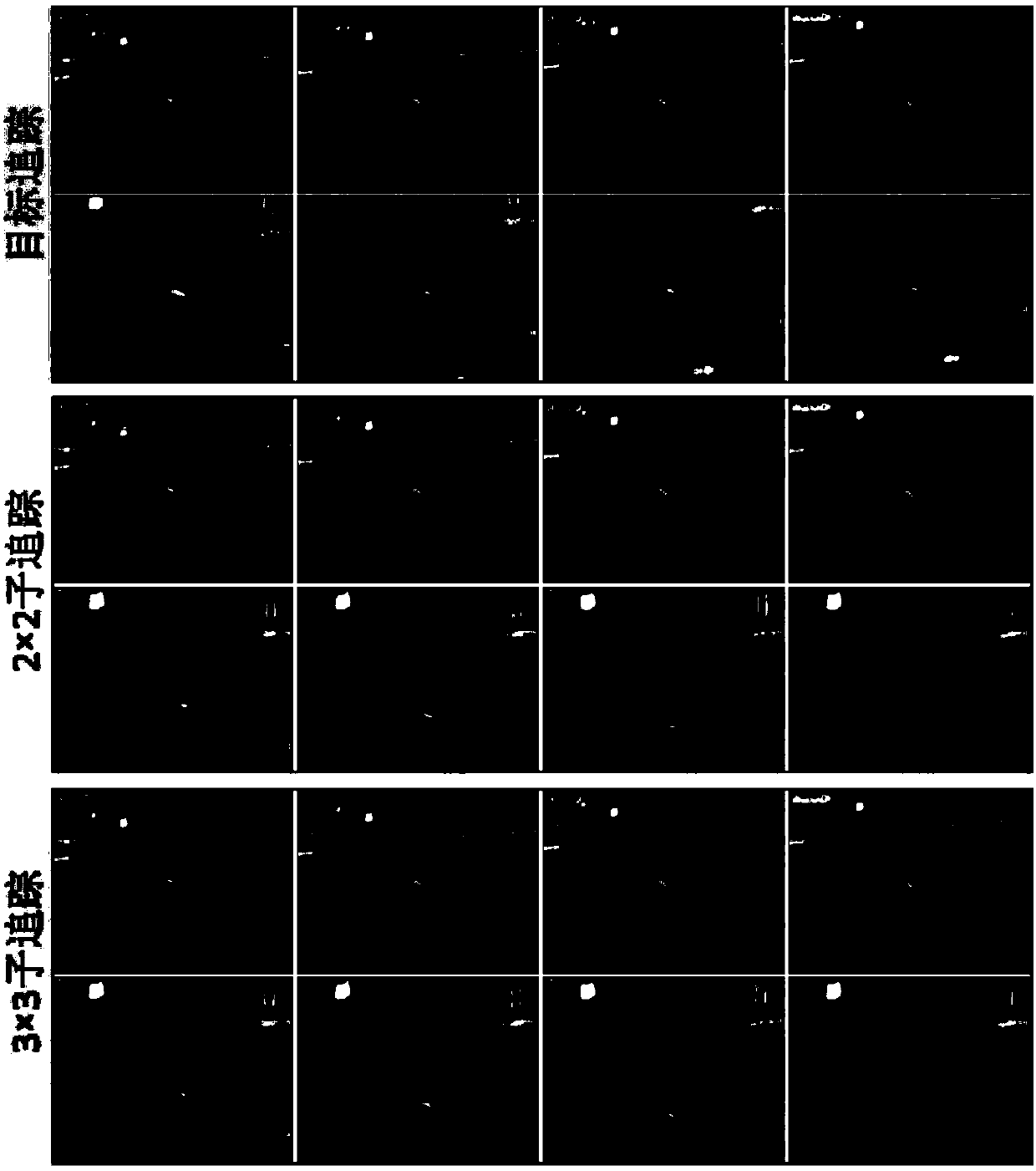

Real-time object tracking method based on low-rank correlation information among video frames

InactiveCN107945207AEliminate camera shakeEliminate distractionsImage enhancementImage analysisBackground informationSide effect

The present invention discloses a real-time object tracking method based on low-rank correlation information among video frames. According to the method, a video is divided into frame segments with each frame segment comprising k frames, low rank analysis is performed on the divided video frame segments with consistent background, and therefore a trajectory of a marked object can be obtained. Themethod comprises the following steps: low-rank analysis based on bilateral random mapping is used to accurately track short-term stable video frame segment background; in order to eliminate side effects caused by the visual changes resulted from observation angle changes, prior low rank background is combined with a previous frame segment to solve of robust significant motion detection-based RPCAlow rank recovery of a current frame segment; a series of feature clues extracted from a stable frame segment are used to speed up updating of low-rank background information and overcome some stubborn problems effectively. Via the method, moving objects can be accurately detected from a video, and the same effect can be attained in a dynamic video; the method is characterized by high detection rate, good robustness, strong anti-interference and the like.

Owner:BEIJING UNIDRAW VR TECH RES INST CO LTD

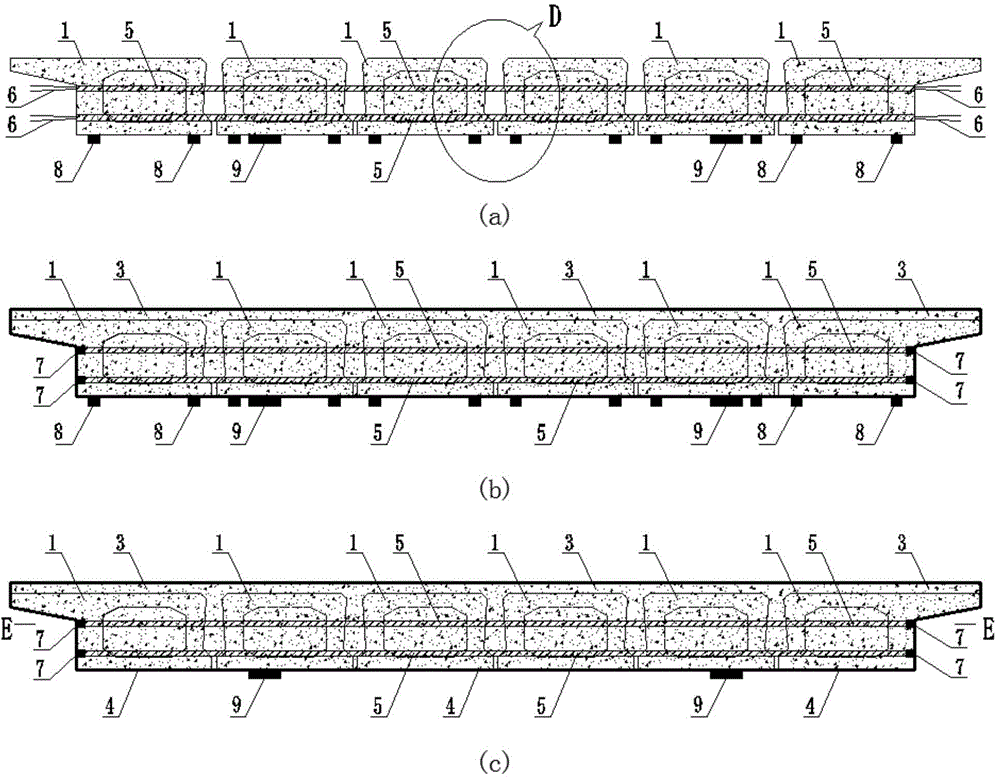

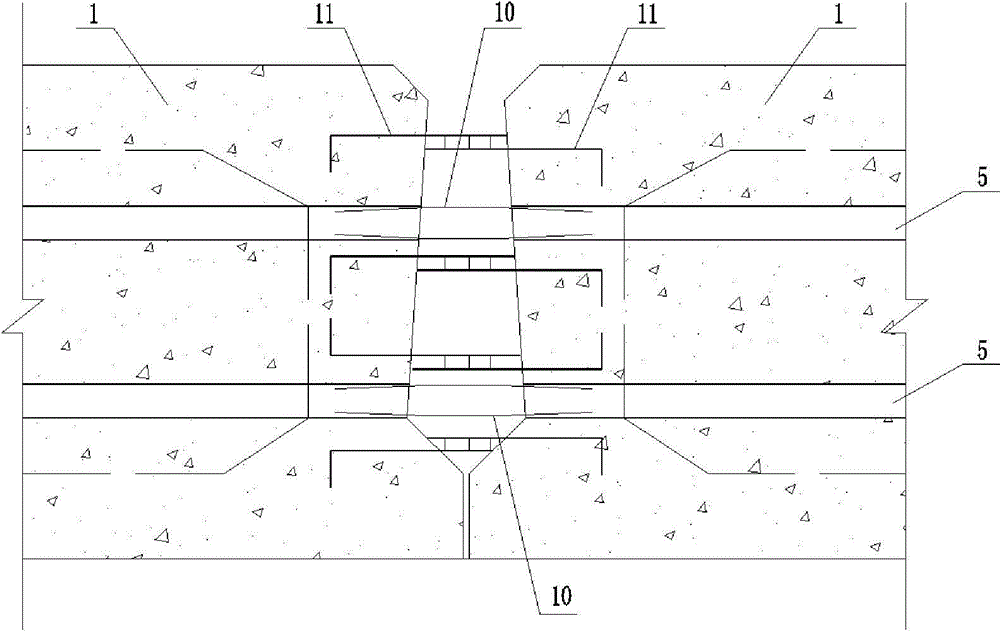

Upper structure of hollow board beam bridge and construction method thereof

ActiveCN104594193AImprove overall stiffnessEven by forceBridge structural detailsBridge erection/assemblyRebarHinge joint

The invention discloses an upper structure of a hollow board beam bridge. Hinge joints are formed among a plurality of hollow boards constructing a hollow board beam; concrete is cast on the hinge joints and the cast-in-situ layer of a bridge floor; the two end parts of the hollow boards are solid bodies; transverse steel bars are arranged on the two side faces of the hollow boards; the hollow board solid bodies together with the hinge joints and the concrete on the cast-in-situ layer of the bridge floor construct end transverse beams; prestressed steel bars transversely penetrating through a prestressed pipeline are arranged in the end transverse beams; the end transverse beams are supported by two supports. The construction method comprises the following steps: prefabricating the hollow boards; mounting a temporary support and a permanent support; mounting the hollow boards; transversely inserting the prestressed steel bars into the prestressed pipeline; casting concrete on the hinge joints and the cast-in-situ layer of the bridge floor; removing the temporary support. By adopting the end transverse beams provided with the prestressed steel bars, the overall rigidity of the upper structure of the hollow board beam bridge is effectively enhanced, and the hollow boards are stressed in a balanced way; the single board stress phenomenon is reduced, the local stress of the hinge joints on at the beam ends is reduced, and damage is prevented; each support is stressed, so that the problem of disengagement of the supports is solved; construction becomes simple and convenient, and the support maintenance workload and maintenance cost are low.

Owner:SHENYANG JIANZHU UNIVERSITY

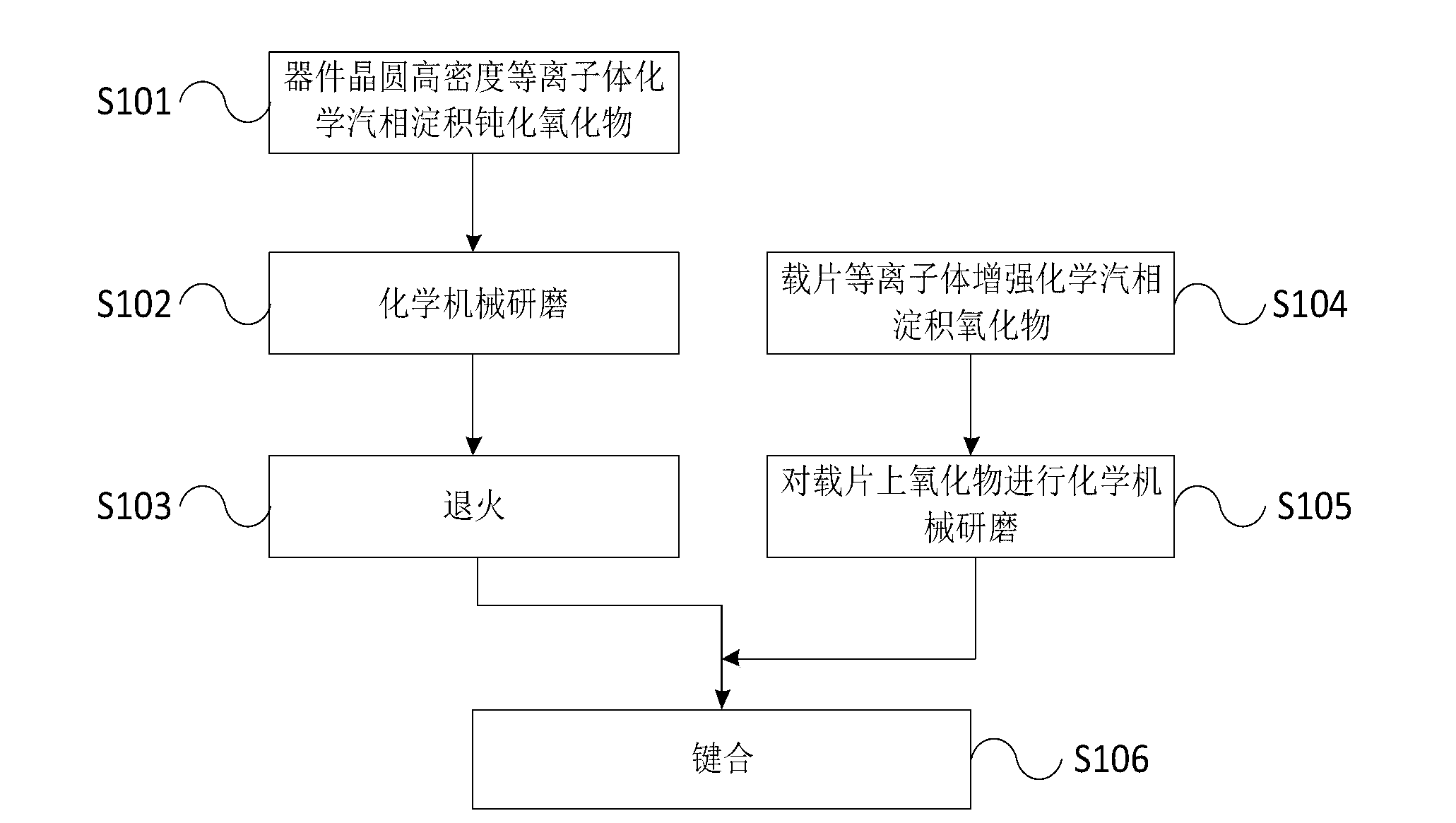

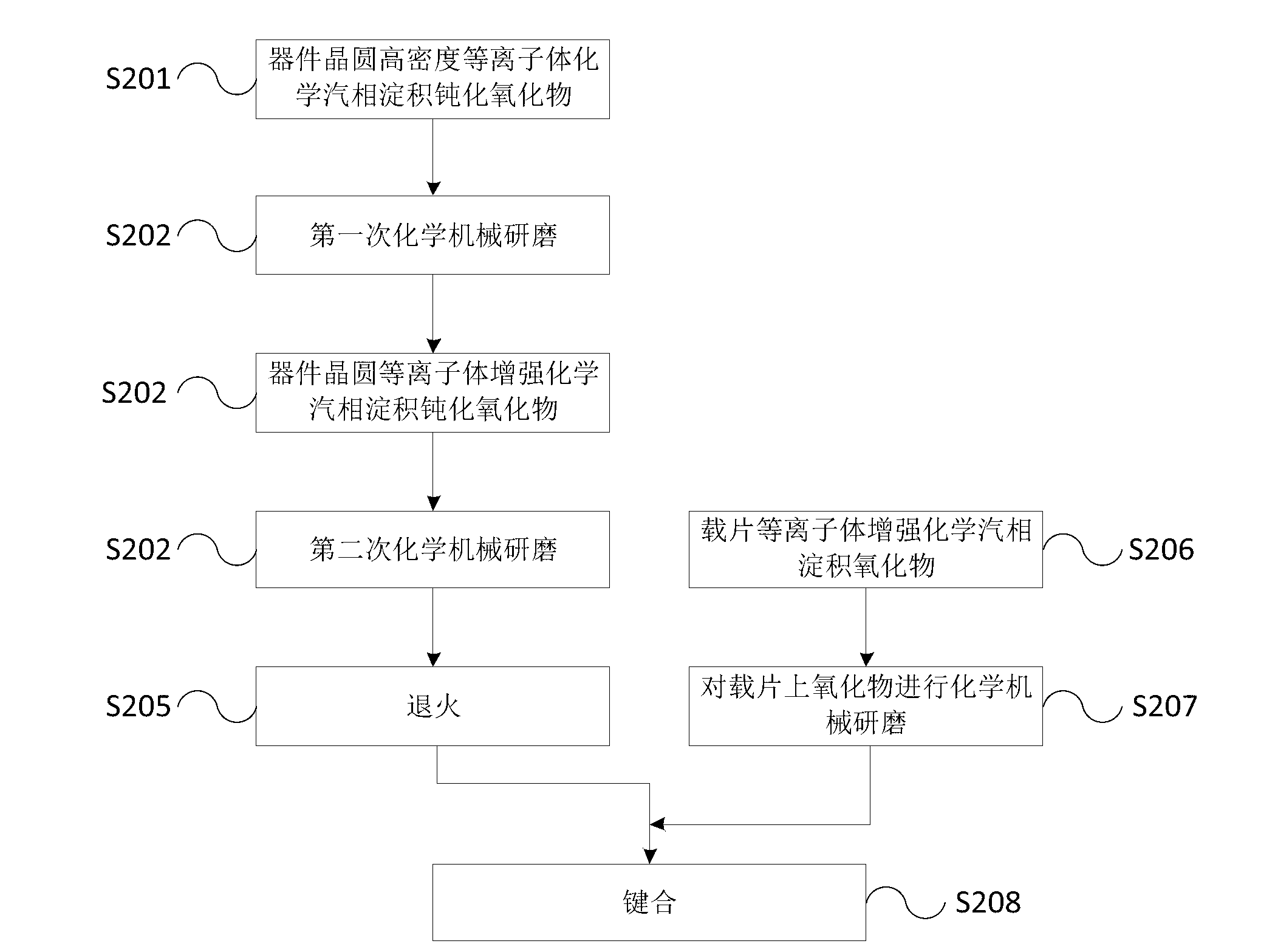

Image sensor wafer bonding method

ActiveCN103065945AAchieve flatnessSolve voidSemiconductor/solid-state device manufacturingHigh densityGas phase

The invention relates to the field of semiconductor manufacturing, in particular to an image sensor wafer bonding method. The image sensor wafer bonding method includes a first step of utilizing the high-density plasma chemistry vapor deposition technique to deposit passivation layer oxide on a device wafer, a second step of carrying out a first chemical mechanical lapping to the device wafer with the deposited passivation layer oxide, a third step of depositing the passivation layer oxide again on the original oxide of the device wafer through adoption of the plasma chemistry vapor deposition technique, a fourth step of carrying out a second chemical mechanical lapping to the device wafer, a fifth step of carrying out annealing treatment to the device wafer after the second chemical mechanical lapping, and a sixth step of bonding the treated device wafer and a ground slide which is subjected to the plasma enhanced chemistry vapor deposition oxide treatment and the chemical mechanical lapping. The image sensor wafer bonding method has the advantages that the plasma enhanced chemistry vapor deposition and the second chemical mechanical lapping are added to the device wafer after the original first chemical mechanical lapping, and consequently the plainness of the surface of the wafer is more effectively achieved, and the problem that holes are likely to generate after bonding is solved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Special soldering paste for light-emitting diode (LED) and preparation method thereof

InactiveCN108994478AHigh material strengthEasy to weldWelding/cutting media/materialsSoldering mediaDirect effectsHeat conducting

The invention discloses a special soldering paste for a light-emitting diode (LED). An existing soldering paste has a welding void problem when being applied to an LED device, and an interface heat-conducting effect is directly influenced by more interface voids formed during welding, so that the optical efficiency and the service life of the LED light are reduced; and on the other hand, the packaging area of the LED is large, more soldering pastes are required, and the cost of the soldering paste is high, so that the production cost is high. According to the special soldering paste for the LED provided by the invention, compared with an existing common Sn63Pb37 soldering plate, the soldering voidage of the Sn63Pb37 soldering paste is generally lower than 15 percent, while the soldering voidage of the soldering paste provided by the invention is lower than 8 percent, the welding surface can form a completely tiled soldering tin layer, and a welding void is not easy to form, so that theheat conductivity of the welding interface can be ensured, and the reliability and the service life of the LED are improved; and under the situation that a soldering effect is ensured, the ingredients and the matching ratio of soldering tin powder and a soldering flux are optimized, the content of tin is reduced, the soldering paste cost can be reduced by more than 10 percent, the LED packaging cost is reduced, and the production economic benefit is improved.

Owner:广东仁开科技有限公司

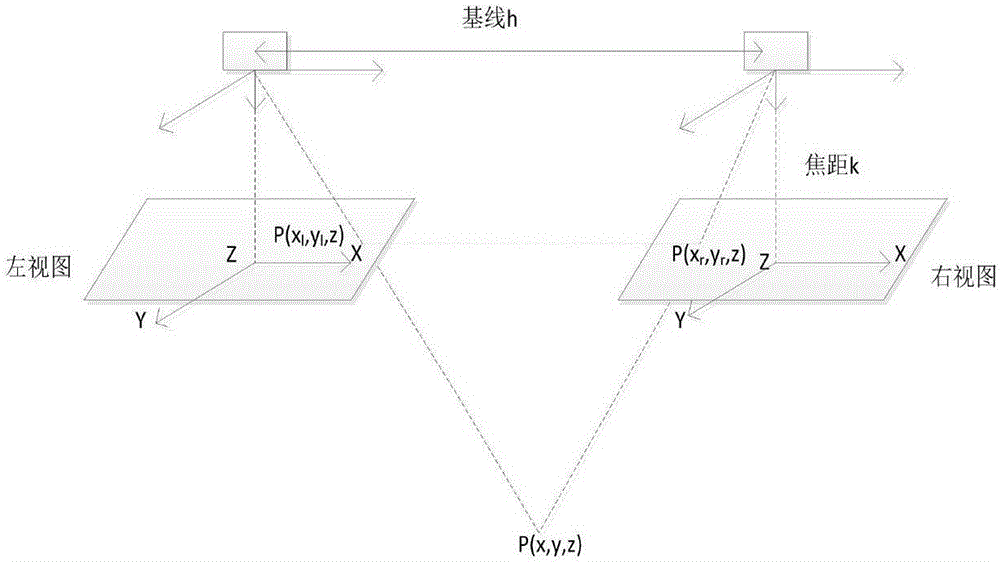

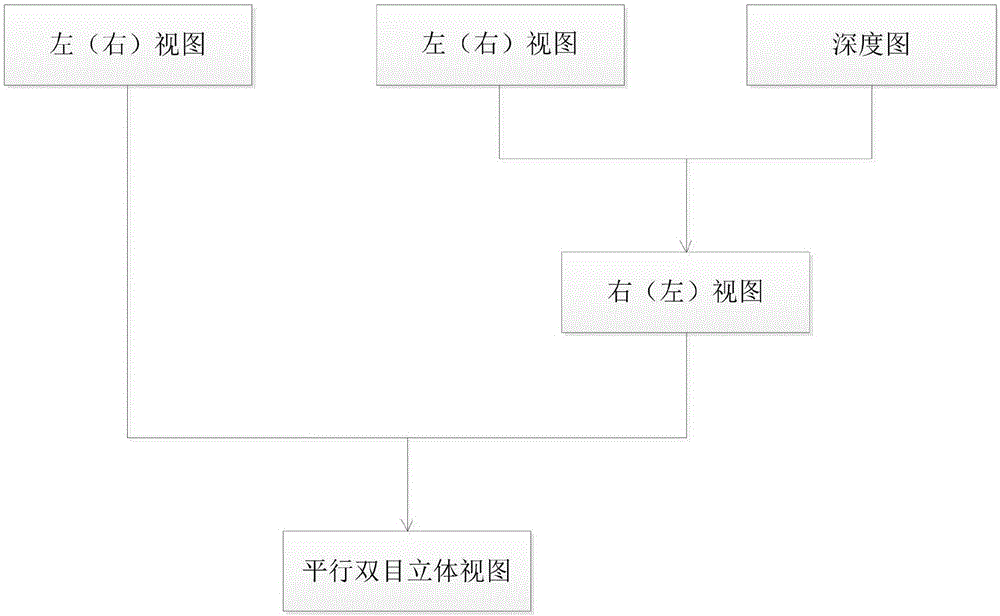

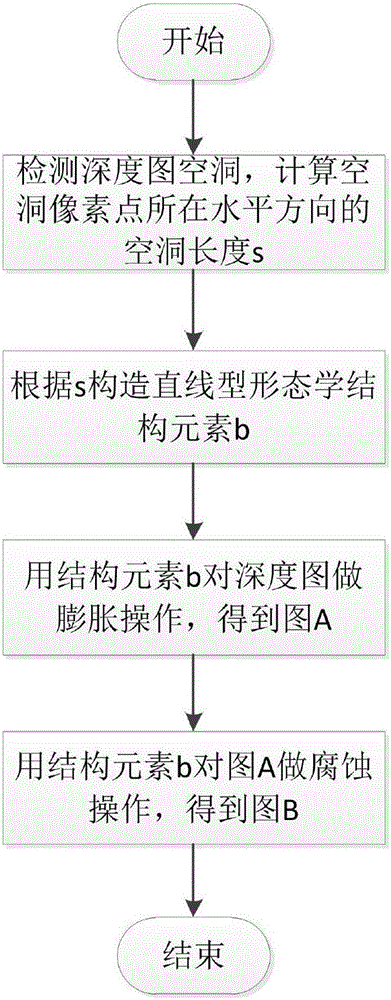

Three-dimensional image generating method based on depth map

The invention discloses a three-dimensional image generating method based on a depth map, and aims to solve the problems of large information quantity, high occupancy of transmission bandwidth resources, low transmission efficiency and the like due to direct transmission of a left view and a right view in a conventional parallel binocular three-dimensional visual transmission process. The three-dimensional image generating method based on the depth map comprises the following steps: firstly, preprocessing a depth image by morphology and bilateral filtering to reduce cavities in the depth image; secondly, providing a viewpoint image to generate another viewpoint image through restoration in conjunction with the depth map according to a principle of a binocular parallel three-dimensional imaging system; and finally, filling up cavity points of a restored view according to depth information and original view information to obtain a final left-right view three-dimensional image pair. Compared with direct transmission of the left view and the right view in a conventional method, the three-dimensional image generating method has the advantages of smaller information quantity of the depth map than that of an ordinary image, higher transmission speed and efficiency of the depth image, low occupancy of a transmission bandwidth, and capabilities of saving resources and increasing efficiency.

Owner:湖南优象科技有限公司

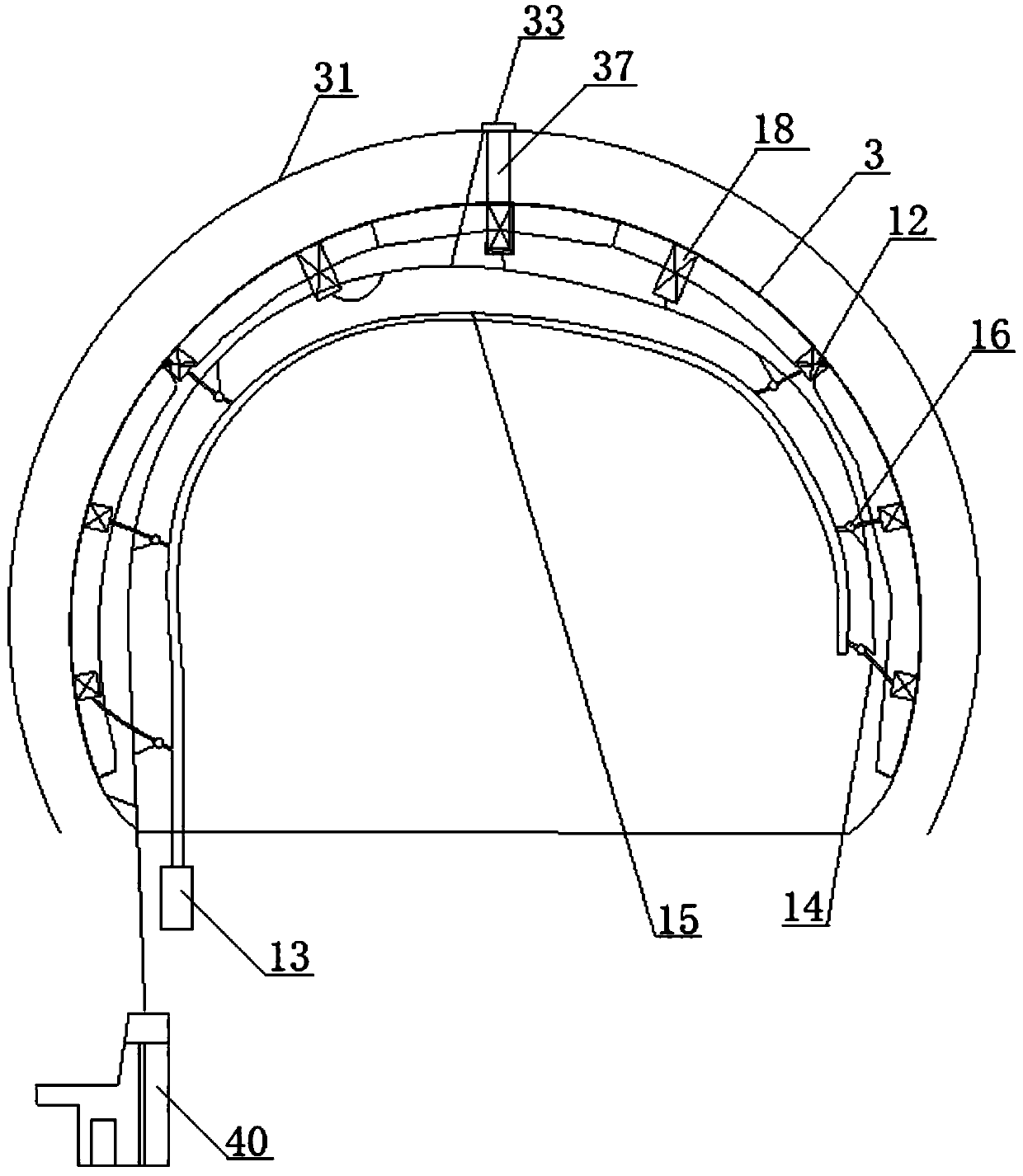

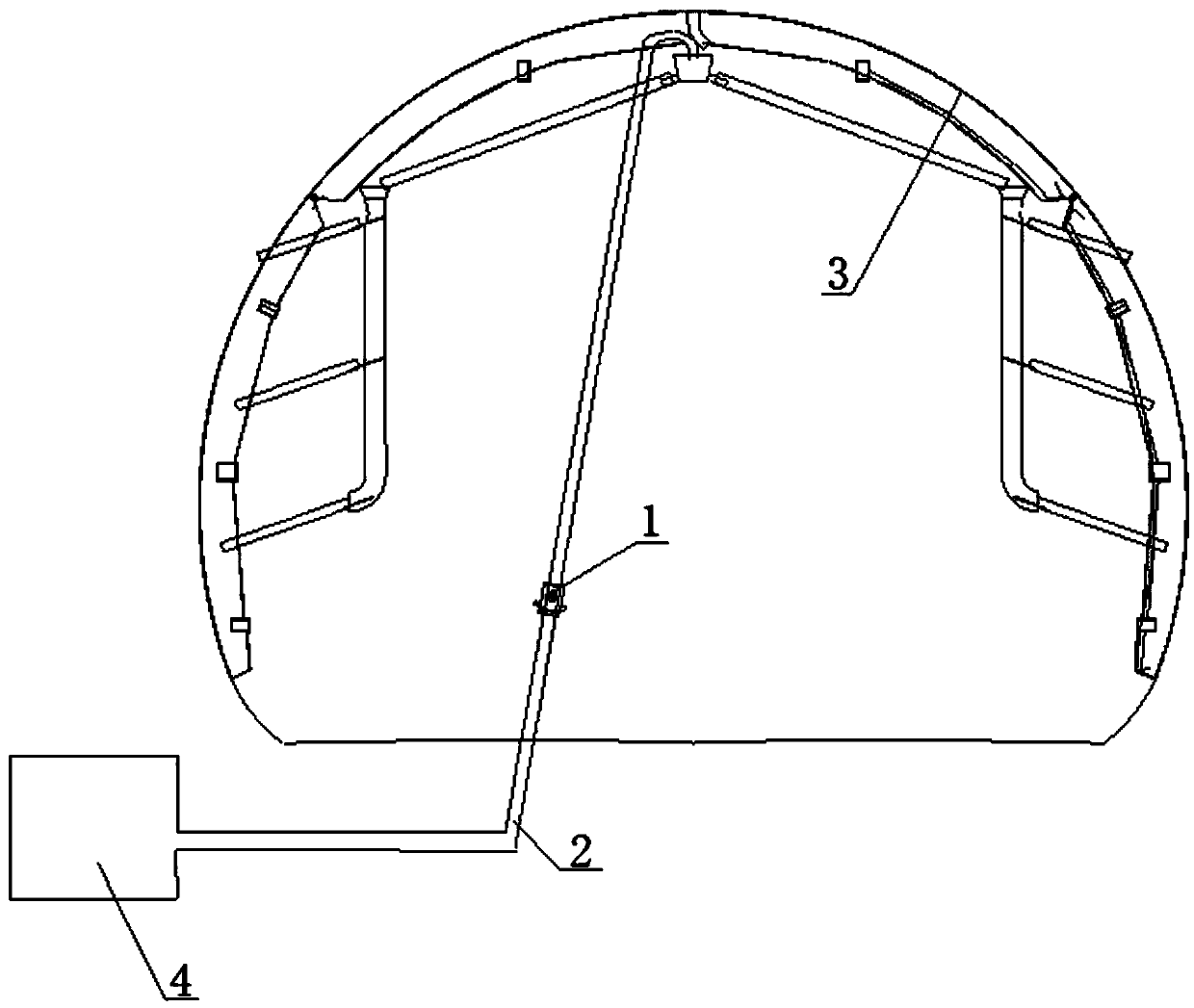

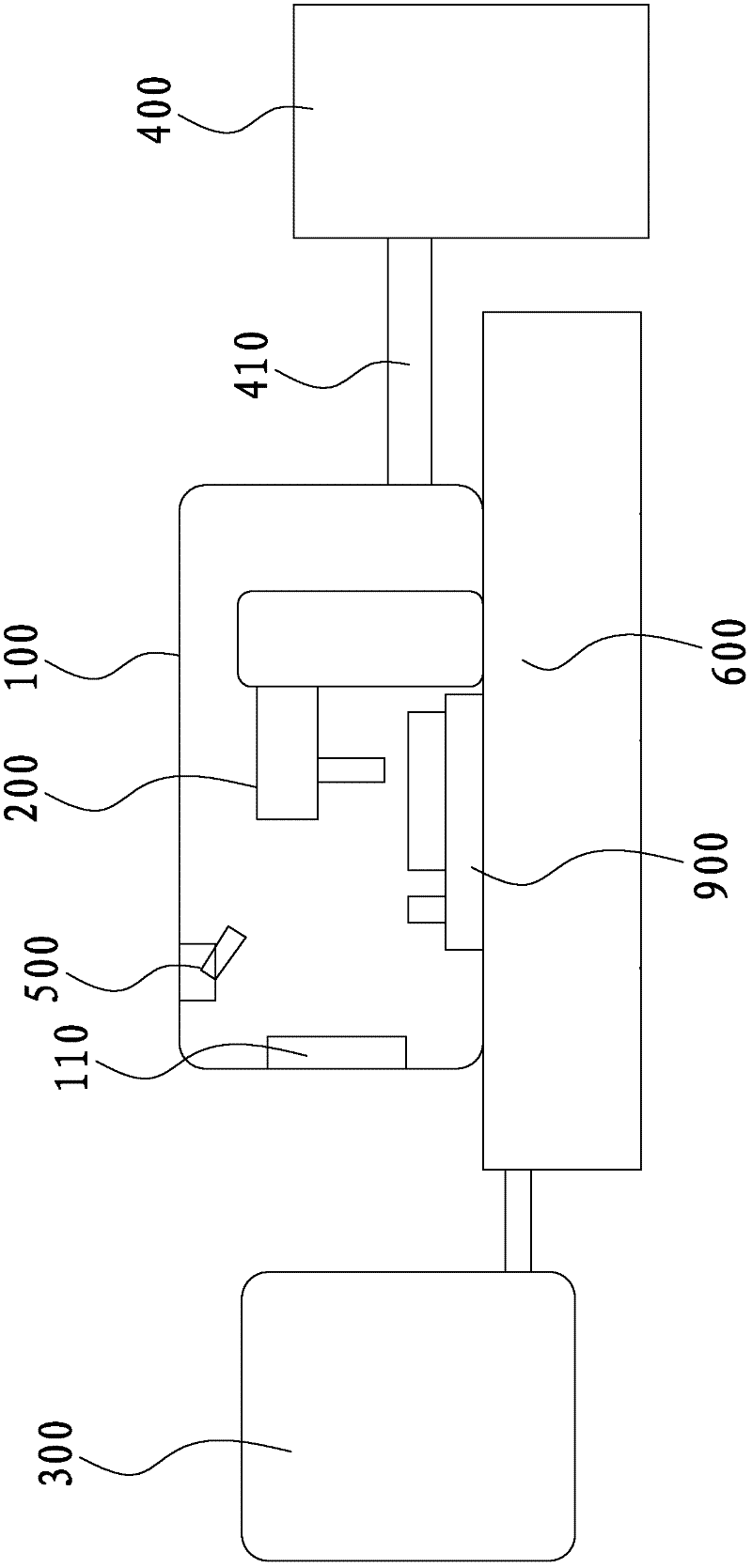

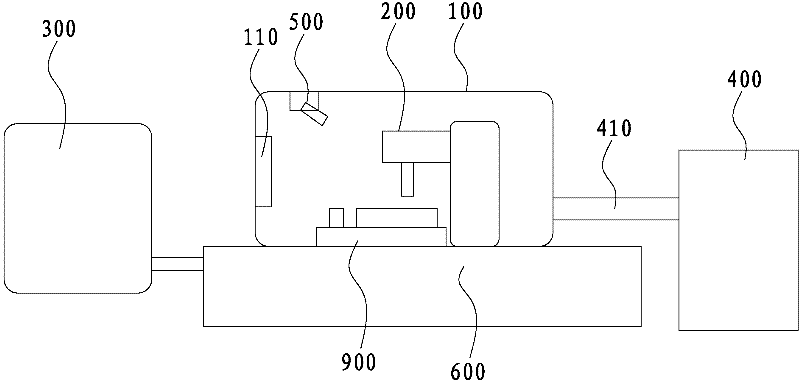

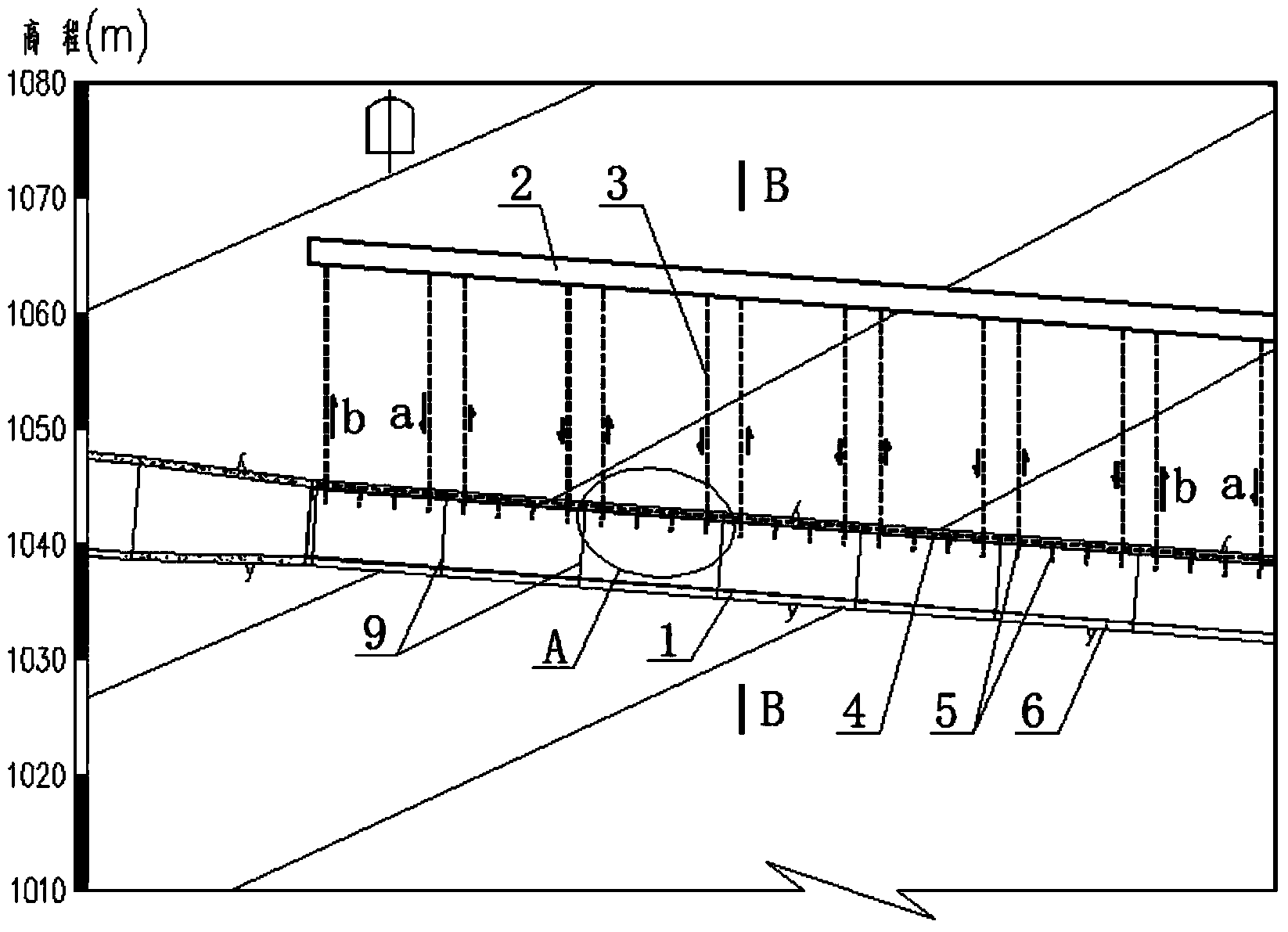

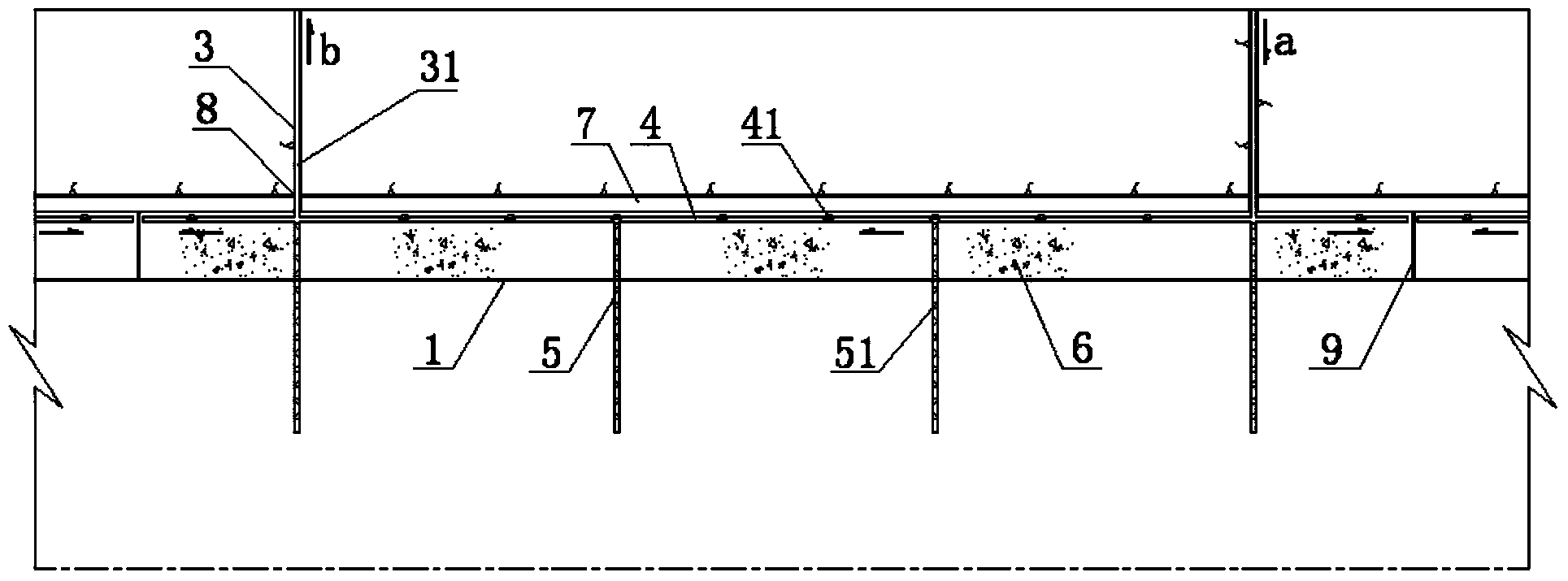

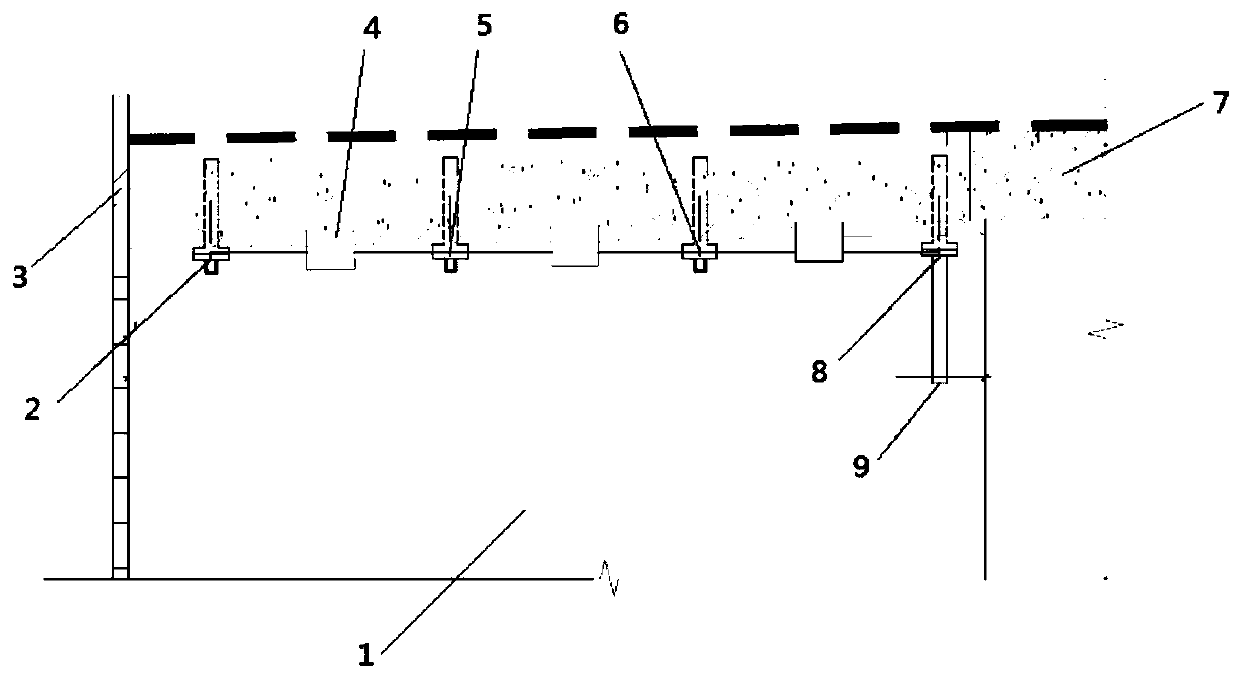

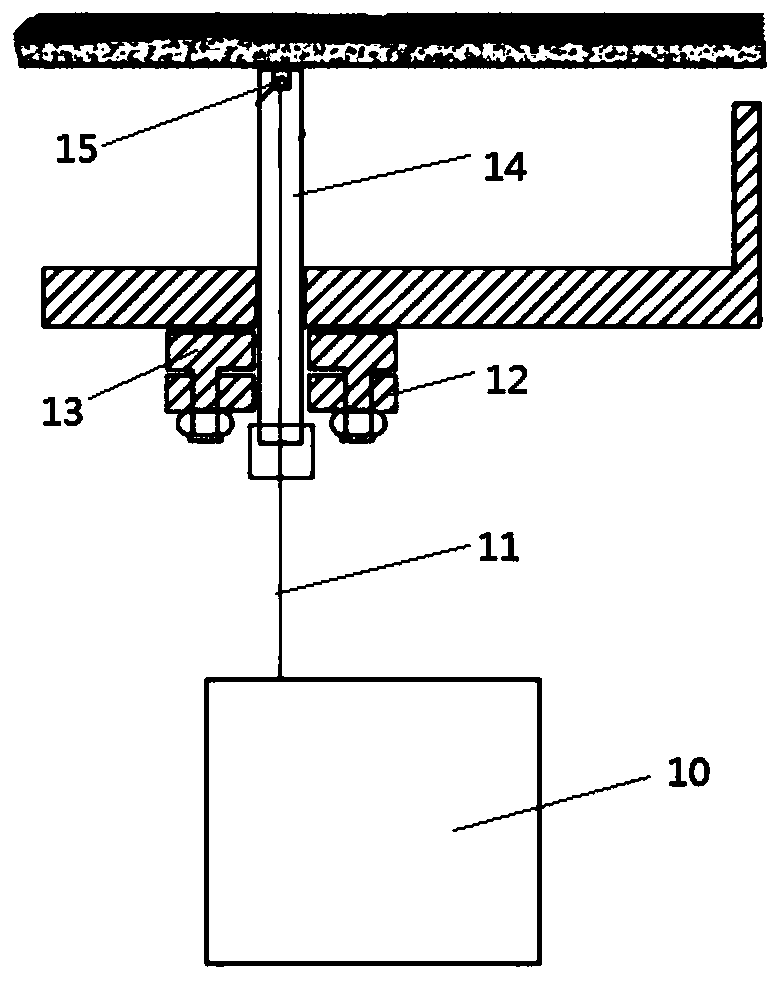

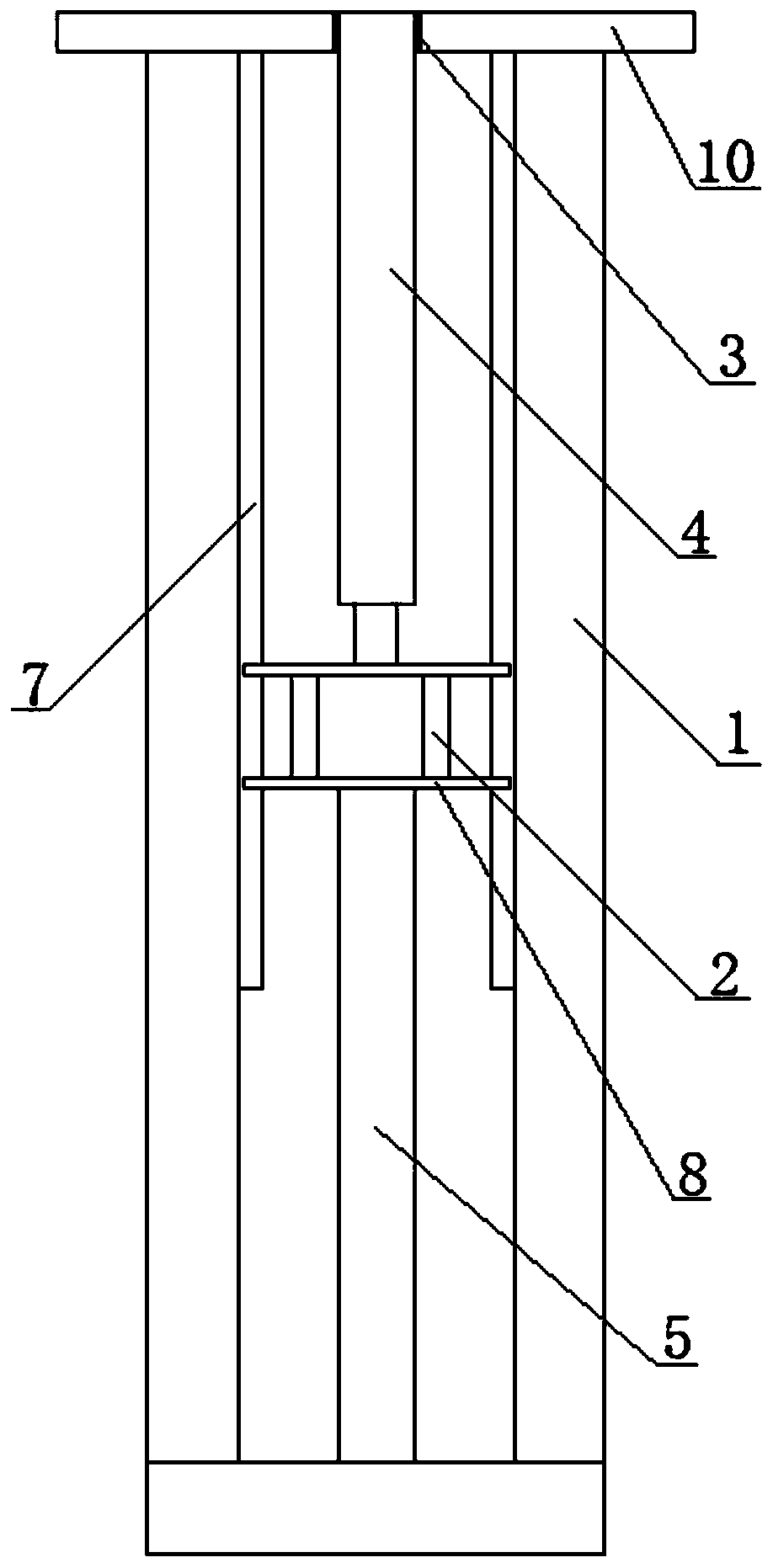

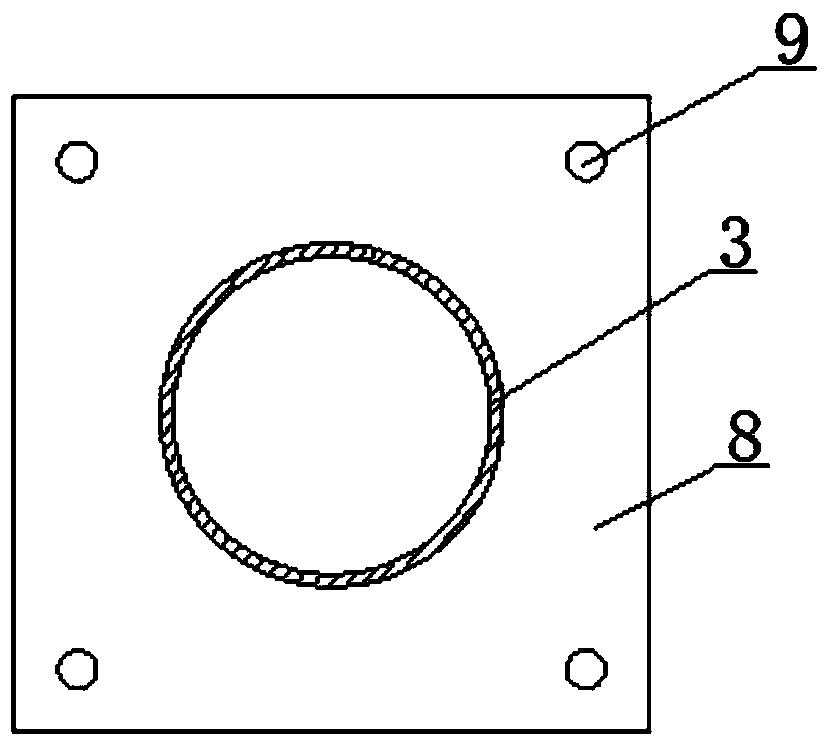

Tunnel two-lining concrete pouring system

PendingCN109630159AMeet construction needsSolve the lack of compactness of concreteUnderground chambersTunnel liningEngineeringElectromagnetic valve

The invention relates to a tunnel two-lining concrete pouring system which comprises a flow monitoring device, a molding temperature monitoring device, a pressure visualization soft lapping device, aplurality of high-frequency pneumatic vibrators (12), a gas compressor (13), and an electric cabinet (40), wherein a three-dimensional laser scanner of the flow monitoring device and a flow sensor (1)are all connected with the electric cabinet (40), a temperature sensor (5) of the molding temperature monitoring device is arranged on a back surface of a tunnel two-lining trolley steel molding plate (3), the temperature sensor (5) is connected with the electric cabinet (40), the pressure visualization soft lapping device comprises a rubber plate (6), the rubber plate (6) is additionally arranged at the bottom of a lapping plate (8), a pressure sensing chip (9) is arranged on the rubber plate (6), the pressure sensing chip (9) is connected with the electric cabinet (40), the high-frequency pneumatic vibrators (12) are arranged on the back surface of the two-lining trolley steel molding plate (3), a shunt pipe (14) is provided with a pneumatic switch electromagnetic valve (16), and the gas compressor (13) is connected with the electric cabinet (40). By the adoption of the tunnel two-lining concrete pouring system, automation of two-lining concrete pouring is achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

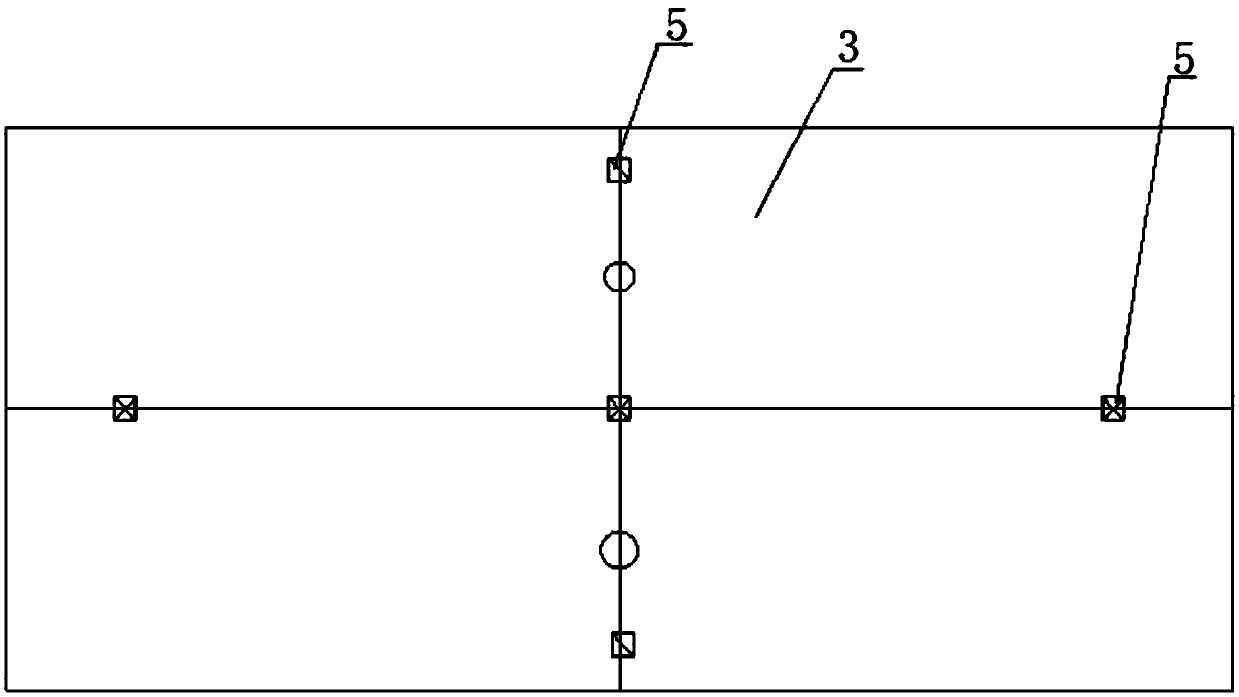

Tunnel secondary lining construction process monitoring system

PendingCN110185472AGuaranteed distanceInhibition of segregationMeasurement devicesUnderground chambersStop timeMonitoring system

The invention discloses a tunnel secondary lining construction process monitoring system. The tunnel secondary lining construction process monitoring system comprises a sensor A, a sensor B, a sensorC, a display terminal and an adhering type vibrator. The sensor A is arranged on a secondary lining trolley and used for monitoring a concrete flowing route. The sensor B is used for monitoring preset-elevation pouring. The sensor C is used for monitoring the position of concrete in a bin. The display terminal is connected with the sensor A, the sensor B and the sensor C and used for achieving data acquisition and monitoring. The adhering type vibrator is connected with the display terminal and can be driven by the display terminal. According to the tunnel secondary lining construction processmonitoring system, a plurality of sensors with different functions are arranged, so that monitoring can be carried out in a tunnel secondary lining construction process in terms of whether concrete flows through a certain specific portion or not, the vibration starting and stopping time and vibration time control of the vibrator, whether concrete is poured in place or not and the like, corresponding executing equipment can be controlled according to monitoring results, and the concrete pouring quality is improved.

Owner:四川奥达智远科技有限公司

Electromagnetic shielding encapsulation method and encapsulation structure

ActiveCN105140138ASolve voidCause damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectromagnetic shielding

The invention relates to an electromagnetic shielding encapsulation method and encapsulation structure. The structure comprises a substrate (1); a radio frequency chip (2) and a plurality of electronic devices are arranged on the front surface of the substrate (1) through surface mount technology; the radio frequency chip (2) and the plurality of electronic devices are covered with a dry film (5); filling grooves (6) located at the peripheries of the radio frequency chip (2) and the plurality of electronic devices are formed at the dry film (5) through exposure development; metal fillers (7) are arranged in the filling grooves (6); and the upper surfaces of the dry film (5) and the metal fillers (7) are provided with a metal layer (8). With the electromagnetic shielding encapsulation method and the encapsulation structure of the invention adopted, the problems of defects existing in encapsulation and laser slotting in traditional technologies can be solved.

Owner:JCET GROUP CO LTD

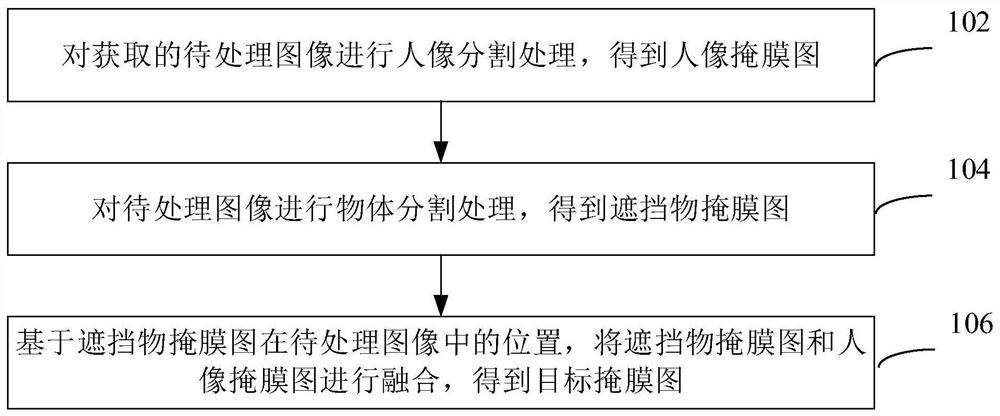

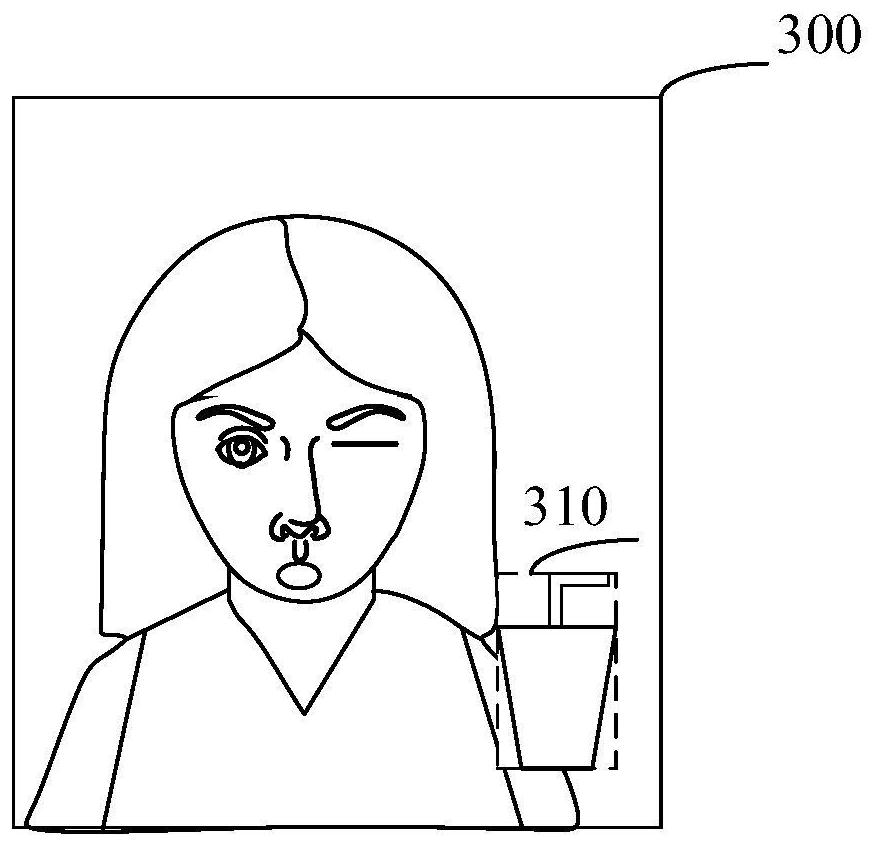

Image processing method and device, electronic equipment and computer readable storage medium

PendingCN112102340ASolve voidGood effectImage enhancementImage analysisImaging processingComputer graphics (images)

The invention provides an image processing method and device, electronic equipment and a computer readable storage medium. The method comprises the steps of performing portrait segmentation processingon an acquired to-be-processed image to obtain a portrait mask image; performing object segmentation processing on the to-be-processed image to obtain an occlusion mask image; and based on the position of the shelter mask image in the to-be-processed image, fusing the shelter mask image and the portrait mask image to obtain a target mask image. By adopting the method, the problem of blocking object segmentation holes can be solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Repairing method and repairing workstation for circuit board

ActiveCN102573326AImprove reliabilityGuaranteed validityPrinted circuit assemblingEngineeringSoldering

The invention discloses a repairing method and a repairing workstation for a circuit board, which are suitable for the technical field of maintenance equipment. The repairing method comprises the following steps of: arranging a work chamber which can be enclosed and of which the vacuum degree can be adjusted; arranging a manipulator part with a heating unit in the work chamber, wherein the manipulator part is controlled by a control table arranged outside the work chamber; and placing a repaired piece into the work chamber, vacuumizing the work chamber, operating the control table to drive the heating unit on the manipulator part to heat soldering spots on the repaired piece, and thus repairing the repaired piece. The repairing workstation comprises the work chamber which is connected with a vacuum generator, wherein the manipulator part is arranged in the work chamber, and the control table capable of controlling the manipulator part is arranged outside the work chamber. By the repairing method and the repairing workstation, the defects of air bubbles, cavities and the like inside the soldering spots of the repaired piece can be overcome; and the method and the workstation are high in reliability.

Owner:HUAWEI DEVICE CO LTD

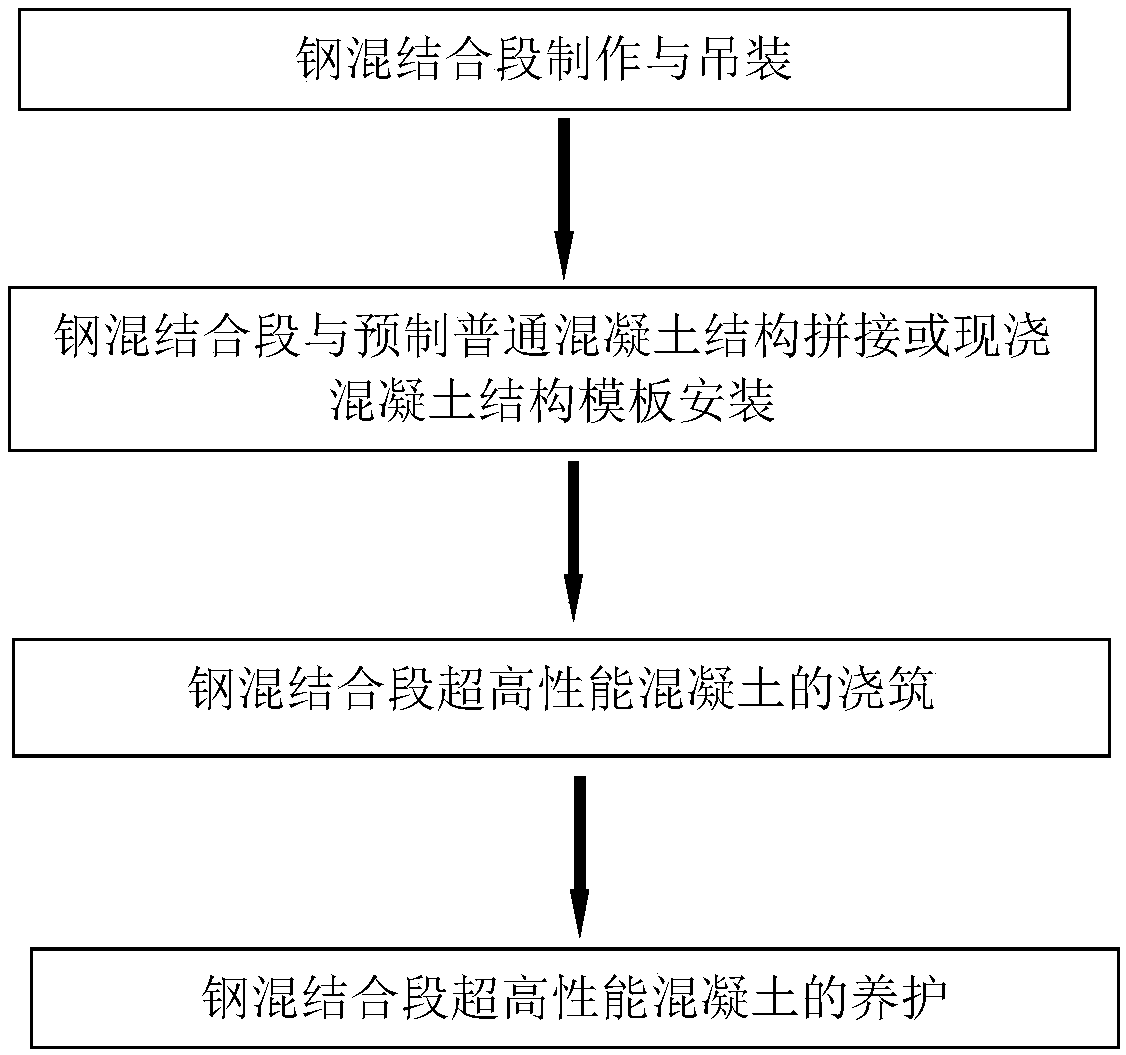

Construction method of steel-concrete joint section

The invention provides a construction method of a steel-concrete joint section, which relates to the field of bridge construction and is carried out according to the following steps: 1) manufacturingand hoisting of the steel-concrete joint section; 2) splice that steel-concrete joint section with the precast ordinary concrete structure or installing the cast-in-situ concrete structure formwork; 3) pour the ultra high performance concrete of the steel-concrete joint section; 4) curing the ultra high performance concrete of the steel-concrete joint section. The invention is fast, convenient, reliable, suitable for the construction of the long-span mixed bridge, greatly shortens the construction period and improves the construction quality.

Owner:HUNAN UNIV +1

Ultrasonic and induction heating-assisted laser cladding method of composite nanometer coating

ActiveCN108588708ASolve the problem that it is easy to generate tensile stress and greatly increase the crack sensitivitySolve the problem of greatly increased crack susceptibilityMetallic material coating processesUltrasonic assistedOptoelectronics

The invention provides an ultrasonic and induction heating-assisted laser cladding method of a composite nanometer coating. A laser, a precoated layer, a base body, a working table, an ultrasonic vibrator and an induction heating coil are arranged. The ultrasonic and induction heating-assisted laser cladding method of the composite nanometer coating comprises the following concrete steps of (10) after preprocessing the base body, placing the precoated layer on the base body, placing the base body with the precoated layer onto the working table, and moving a laser head of the laser to a position to be cladded of the base body; (20) starting the induction heating coil, and using the induction heating coil for heating the base body and the precoated layer to 200 to 400 DEG C; (30) switching on the laser and the ultrasonic vibrator, wherein the laser is used for laser-cladding the base body through the laser head, and the ultrasonic vibrator is used for ultrasonic-assisting the laser cladding process; (40) after finishing laser cladding, switching off the ultrasonic vibrator and the laser; (50) switching off the induction heating coil; and (60) taking out the base body subjected to laser cladding.

Owner:FUJIAN UNIV OF TECH

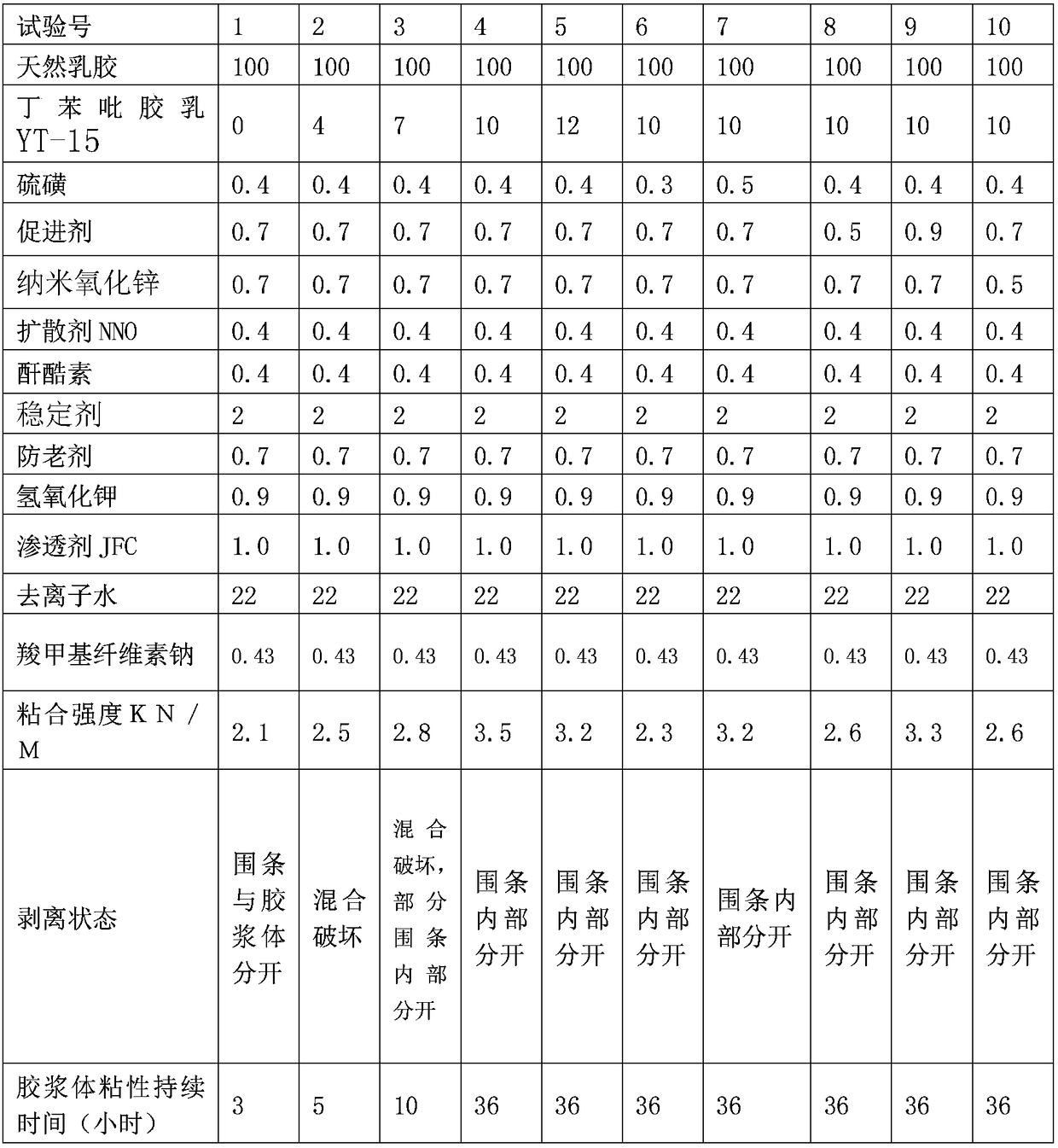

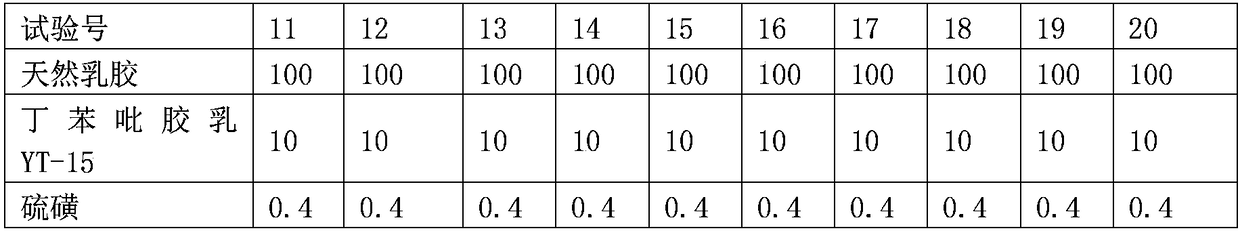

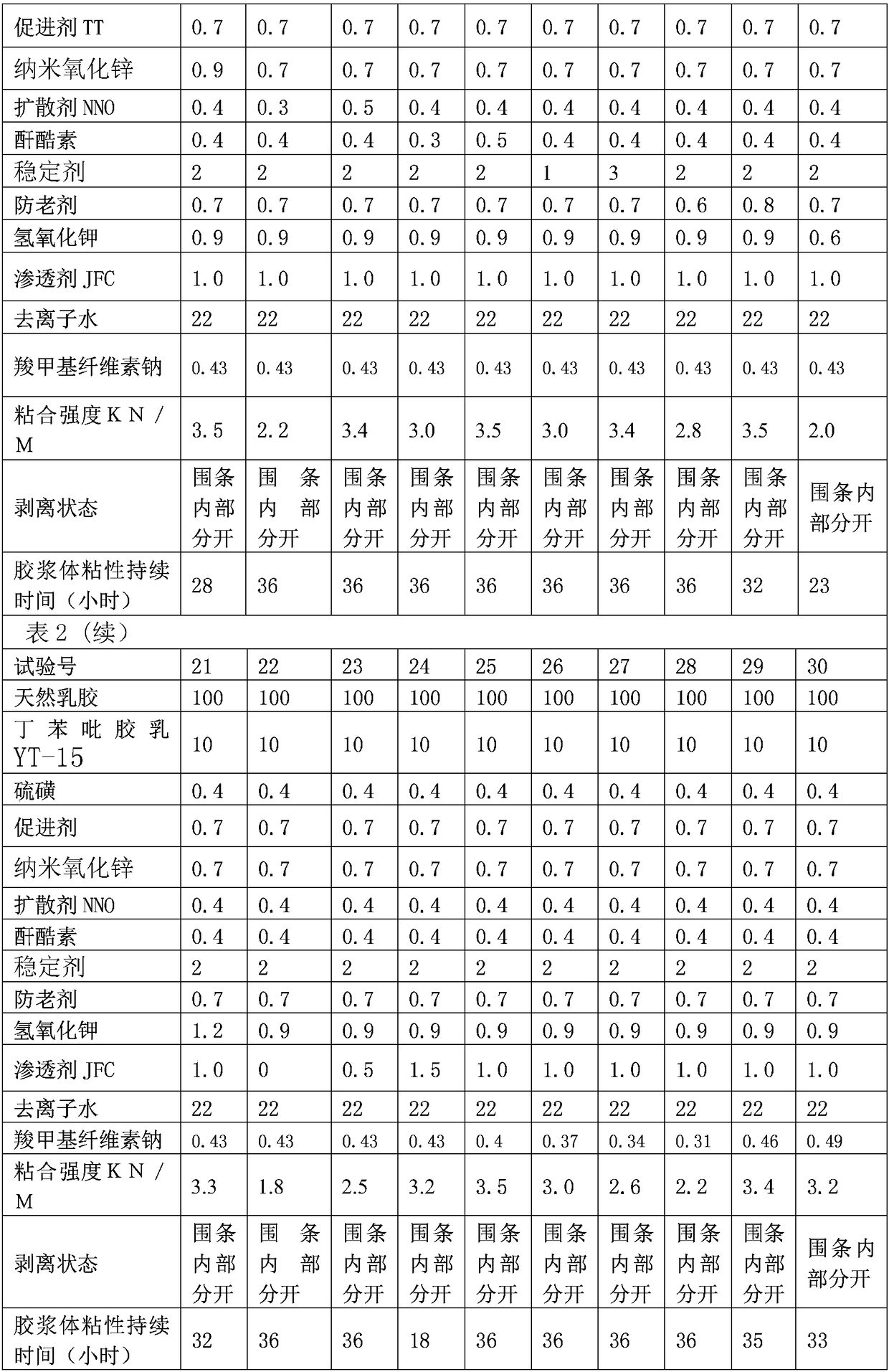

Water-borne rubber cement for cotton canvas rubber shoe foxing bonding and preparation method thereof

InactiveCN109294478AUniform vulcanizationConsistent vulcanizationNatural rubber adhesivesNon-macromolecular adhesive additivesFiberRubber material

The invention discloses a water-borne rubber cement for cotton canvas rubber shoe foxing bonding and a preparation method thereof. A combination of natural latex and pyridine-styrene-butadiene rubberlatex is adopted as the host material, a vulcanized and cross-linked adhesive, a bonded part and cotton canvas fiber form a high strength and uniform adherend, and the final bonding strength is high.The rubber cement has long-lasting surface stickiness, has low temperature requirement for the bonded part, and lowers the requirement of the bonded rubber material for thermal insulation performance.The three major quality problems of cotton canvas rubber shoes, i.e. lace delamination, base fabric disengaging and undersole delamination are effectively solved, and the quality defect of glue failure during use of cotton canvas rubber shoes can be thoroughly eliminated.

Owner:JIHUA 3537 SHOE MAKING

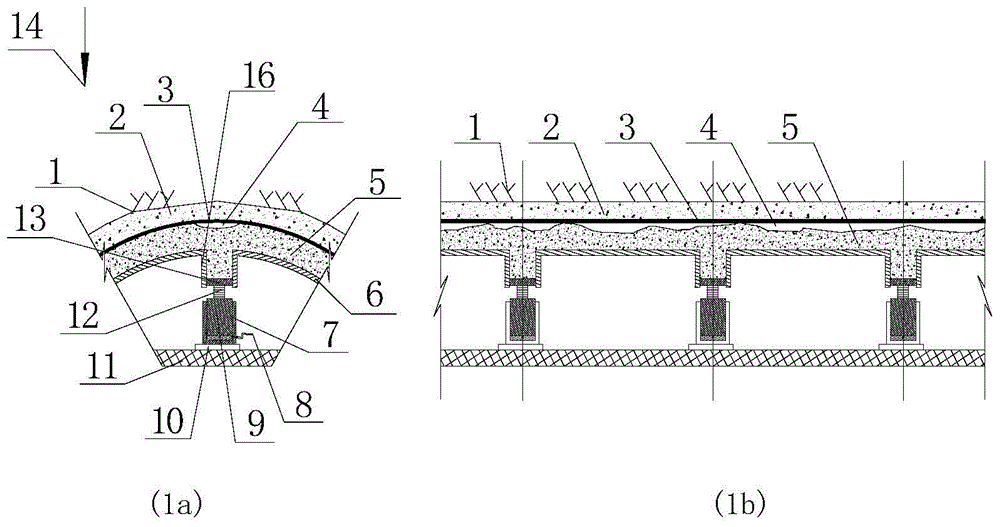

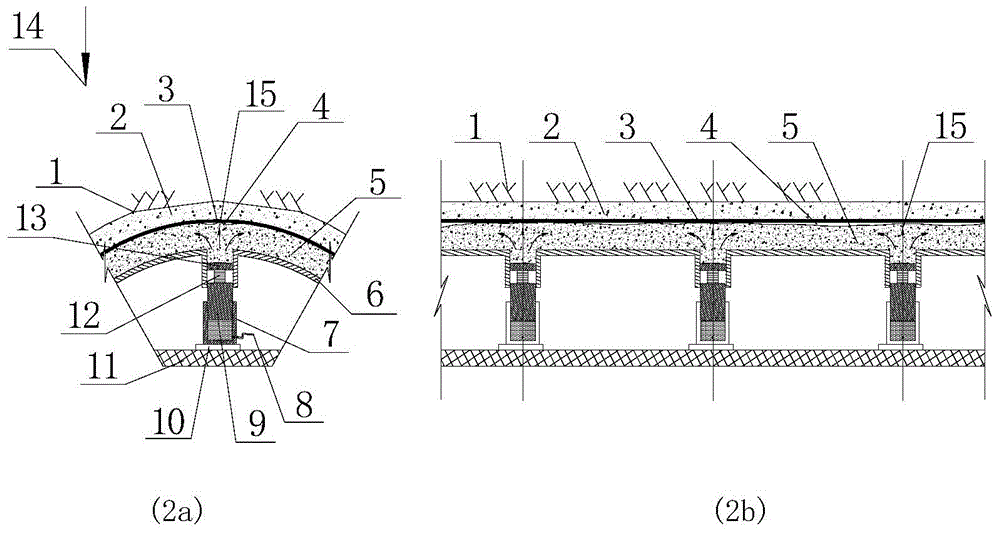

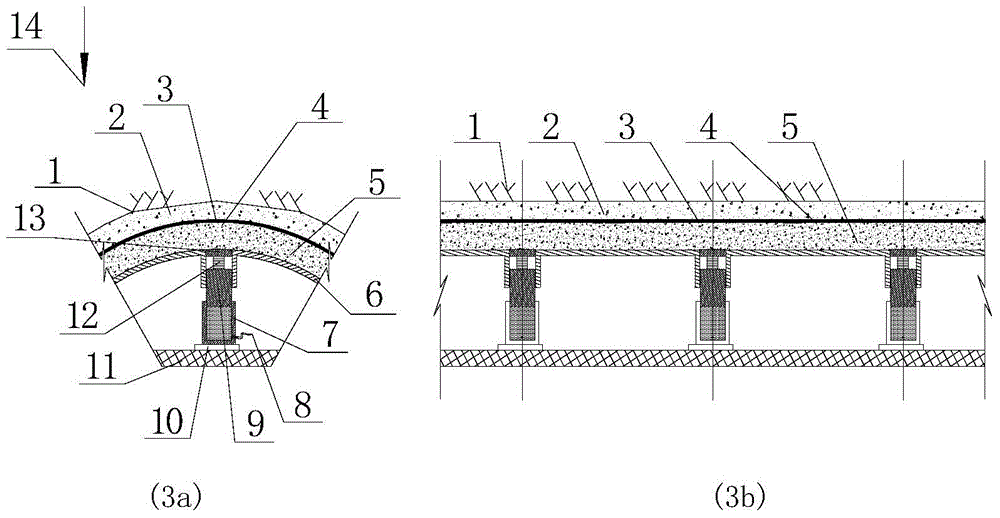

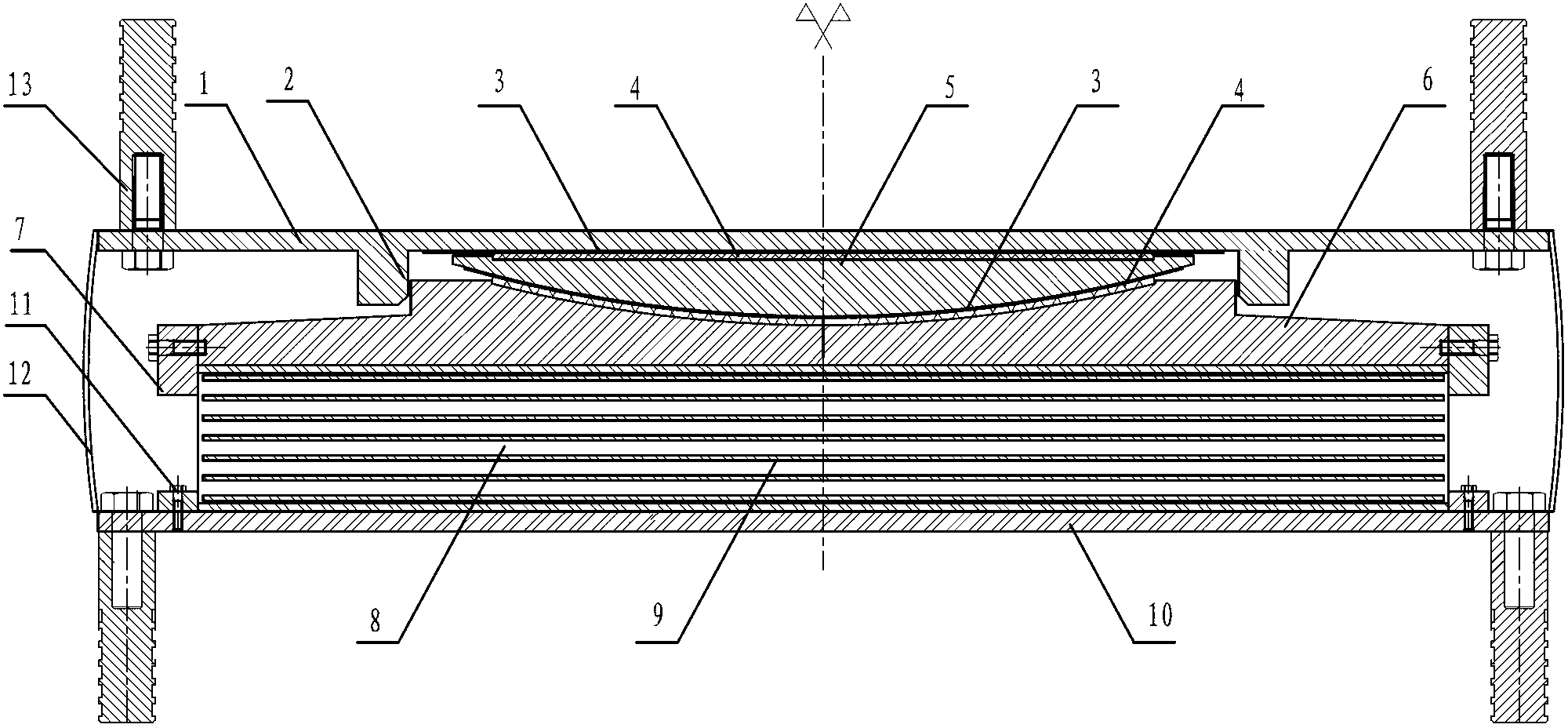

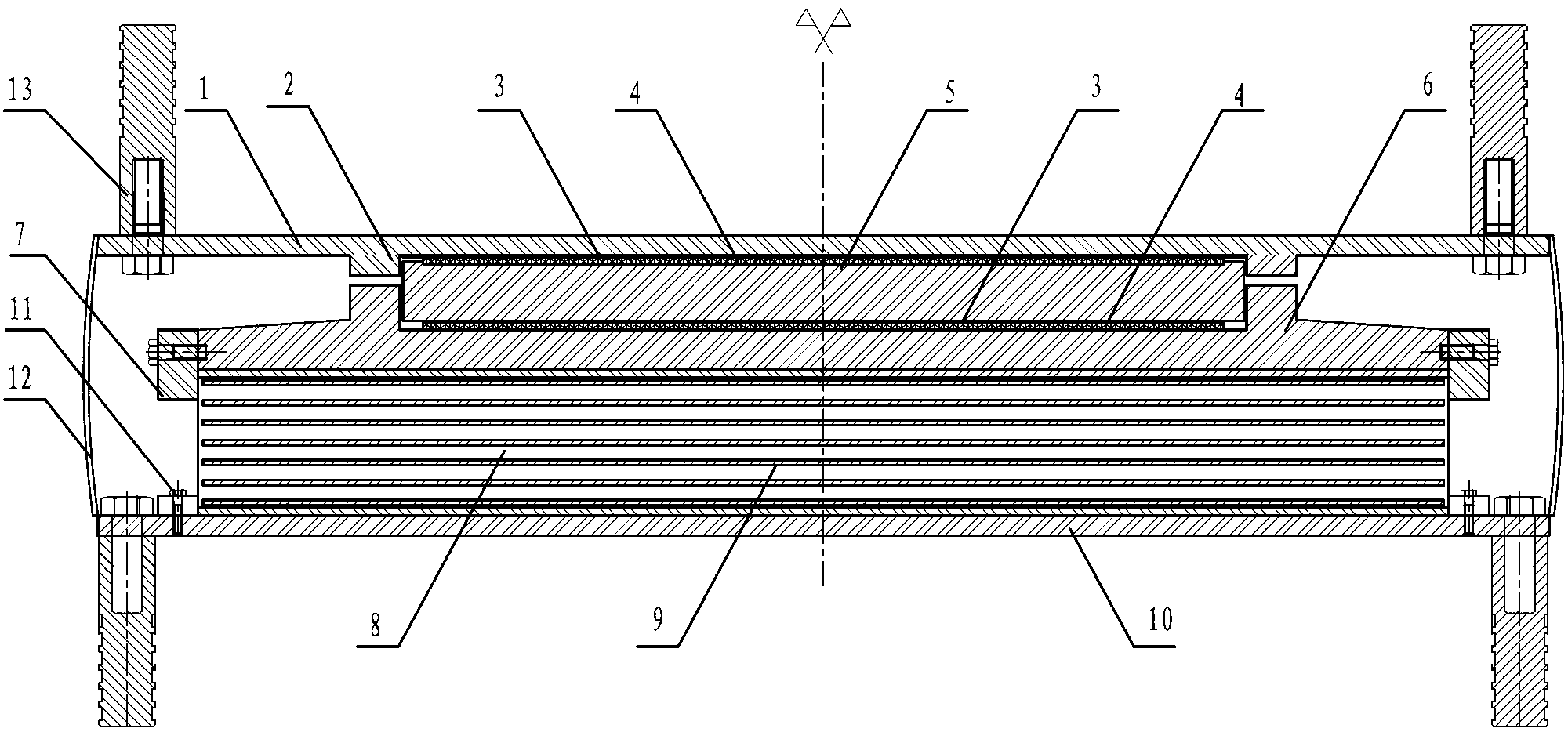

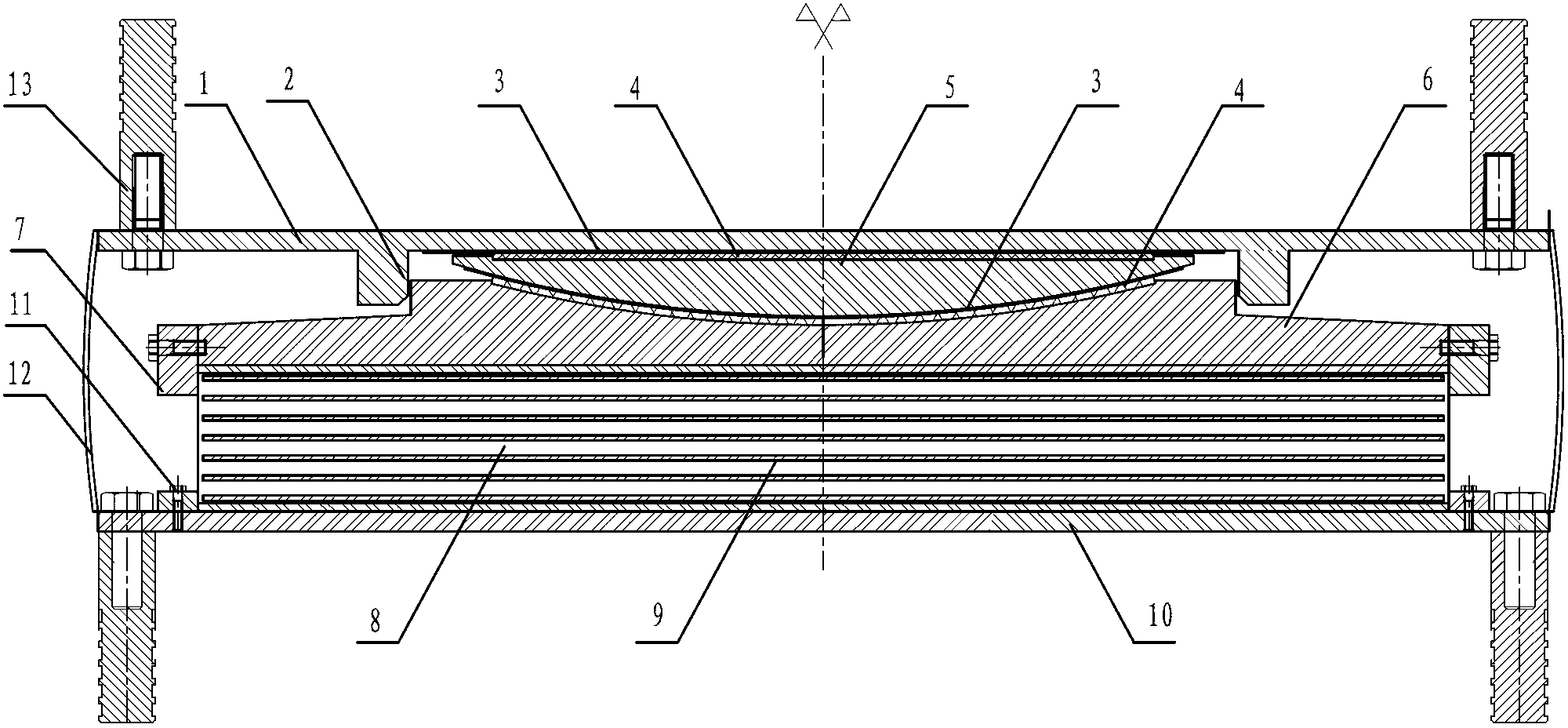

Steel curve face rubber shock reduction and insulation support

A steel curve face rubber shock reduction and insulation support belongs to the technical field of bridge engineering. The support comprises an upper support plate, a cylinder (ball) pendulum, a lower support plate, rubber and an inner steel plate. The cylinder (ball) pendulum is arranged between the upper support plate and the lower support plate. The cylinder pendulum is a part of a cylinder, the lower arc face of the cylinder pendulum clings to a support lower steel plate in the bridge direction. The ball pendulum is a segment, and the lower arc face of the ball pendulum clings to the support lower steel plate. A plate rubber support is arranged under the lower support plate and comprises the rubber and the inner steel plate. The support is low in construction cost and convenient to assemble and maintain.

Owner:DALIAN UNIV OF TECH

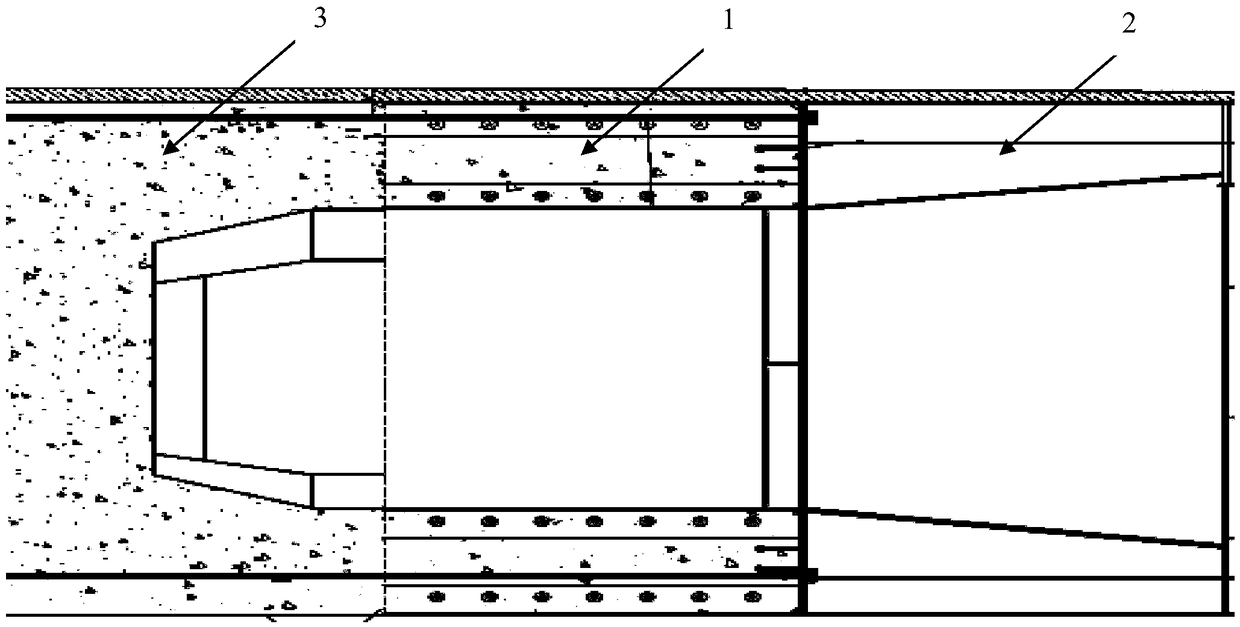

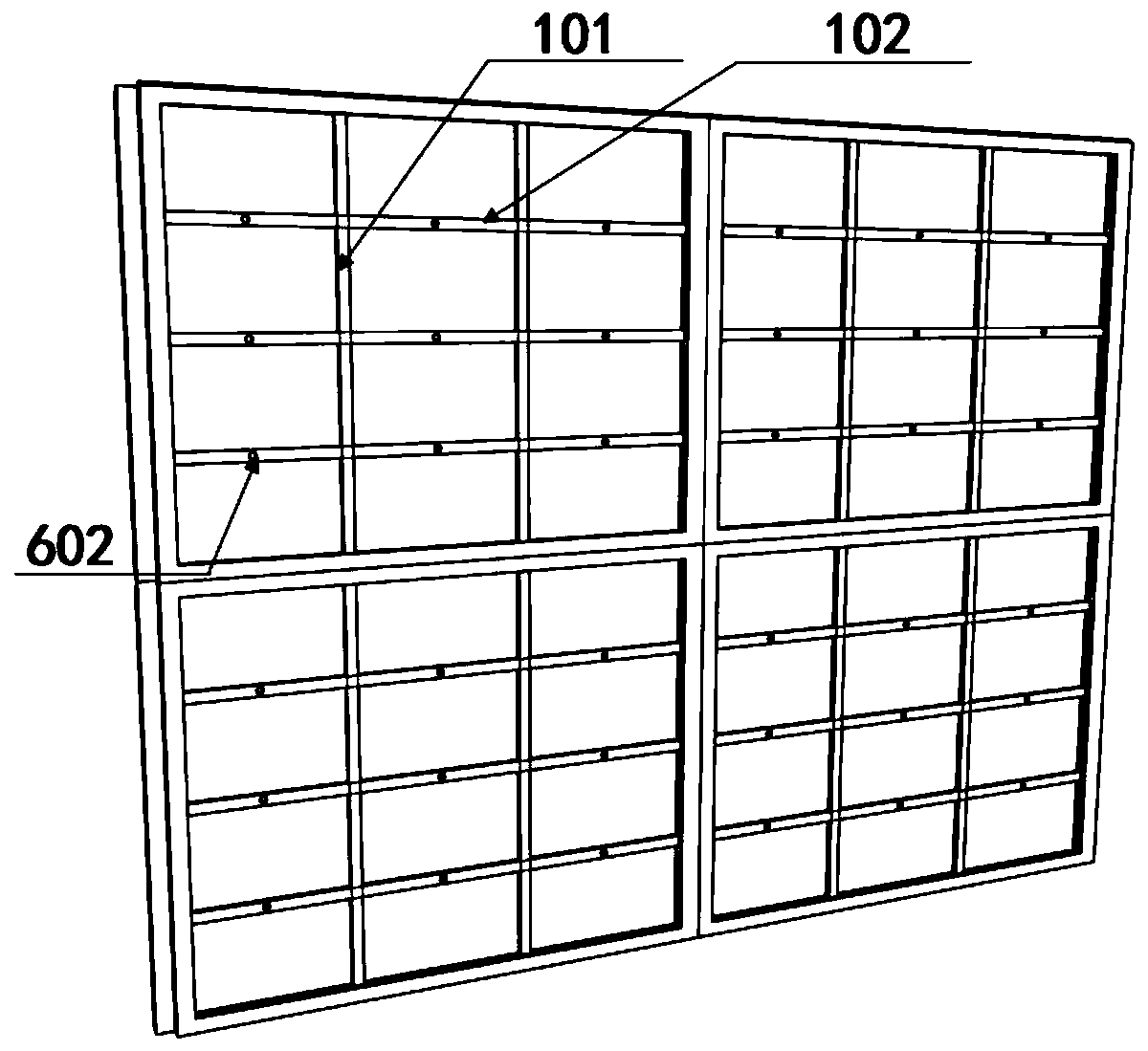

Ultra-high-performance concrete combined permanent template and application thereof

PendingCN109853367AHigh strengthIncreased durabilityArtificial islandsBridge structural detailsLap jointTongue and groove

The invention belongs to the technical field of building materials, and discloses an ultra-high-performance concrete combined permanent template and application thereof. The outer side of a permanenttemplate is flat or curved surface, and the inner side is ribbed; the four side portions are thickened, and a tongue-and-groove is formed, and a lap joint of the tongue-and-groove is hydrophobic; andafter the tongue-and-groove is lap jointed, a caulking groove smaller on the outside and bigger on the inside is formed in the outer side of a template. According to the high-performance-concrete combined permanent template, a tongue-and-groove design is used on all four sides, on the one hand, the penetration length of an external substance is greatly increased; on the other hand, a lap joint surface of the tongue-and-groove is hydrophobic, infiltration of the external substance can be effectively prevented by coating a hydrophobic paste before installation, and durability can be effectivelyimproved; ultra-high-performance concrete is used as a caulking agent, the caulking groove and a bolt hole are both smaller on the outside and larger on the inside, release of an ultra-high performance concrete caulking agent can be effectively prevented, and structural durability is improved.

Owner:SOUTH CHINA UNIV OF TECH +2

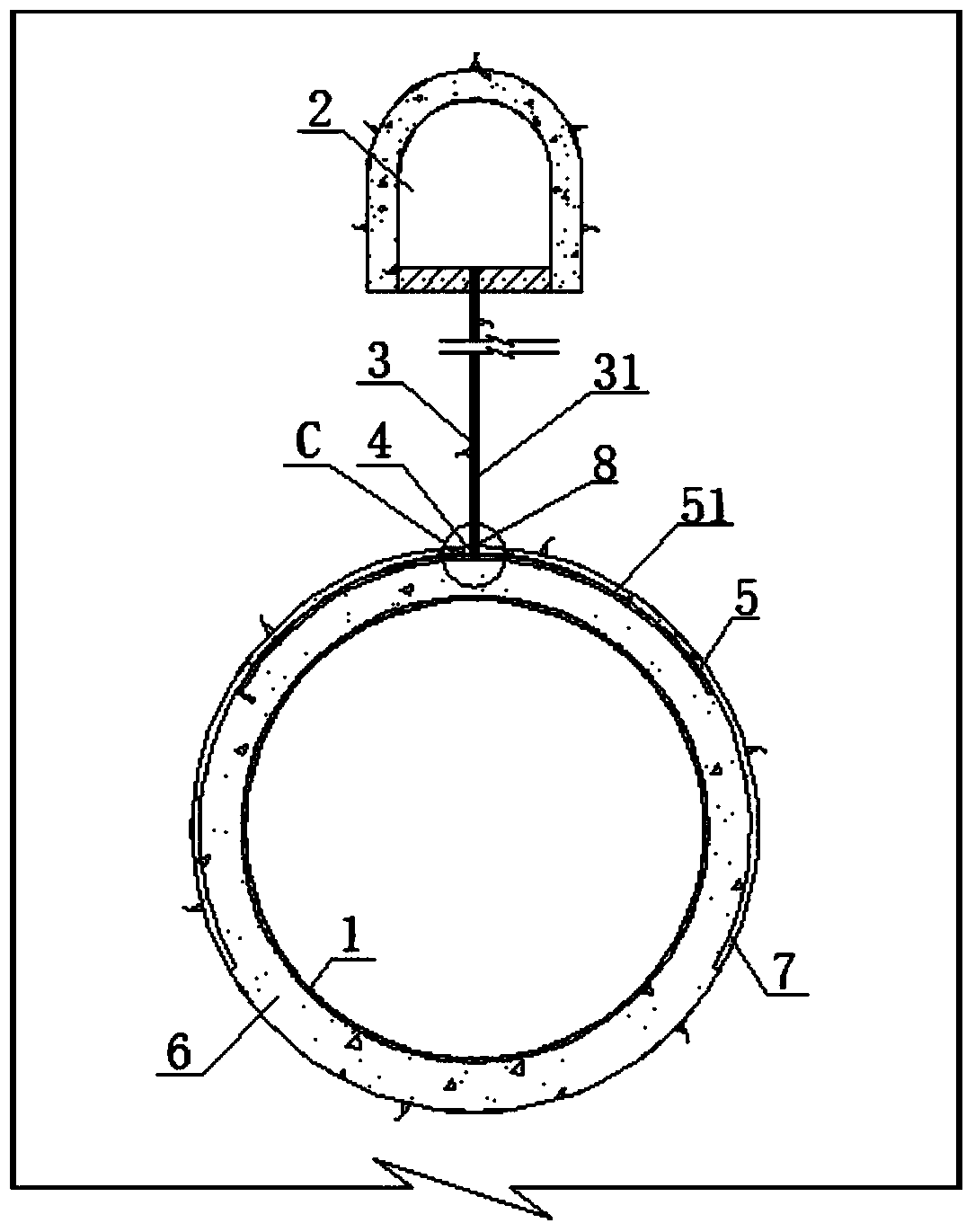

Embedded type penstock backfill grouting structure and grouting technology

ActiveCN104018475AIntegrity guaranteedImprove securityWater-power plantsConventional hydroenergy generationStructural engineeringLinkage concept

The invention discloses an embedded type penstock backfill grouting structure and a grouting technology. The grouting structure comprises a penstock and a water draining opening formed in the outside the penstock, wherein a plurality of longitudinal grouting pipes and a plurality of transverse grouting pipes are embedded in the outer side of the penstock through backfill concrete, pneumatically placed concrete is arranged on the outer surface of the backfill concrete, the water draining opening is provided with rock holes in which grouting pipes are embedded, and the grouting pipes are communicated with the longitudinal grouting pipes and the transverse grouting pipes. The grouting technology comprises the steps of drilling, pipe embedding, grouting, grouting completing, hole sealing and quality checking. The grouting structure is arranged in cooperation with the water draining opening, the grouting pipes embedded in the rock holes are communicated with the grouting pipes embedded outside the penstock, grouting is performed by adopting the pushing grouting method, so that the penstock and surrounding rock bear force in a linkage mode, it is guaranteed that pressure of internal water is transmitted fully, whole stress of the penstock, the concrete and the surrounding rock is guaranteed, and the problem of the void between the backfill concrete and the surrounding rock is solved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

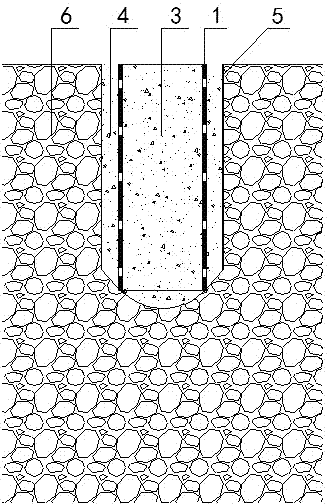

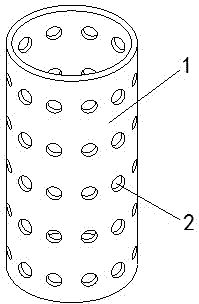

Ultra-high performance concrete and common concrete combined pile and construction method thereof

InactiveCN104762961ASimple structureGood mechanical propertiesBulkheads/pilesEconomic benefitsMechanical property

The invention relates to an ultra-high performance concrete and common concrete combined pile and a construction method thereof. The combined pile comprises an ultra-high performance concrete prefabricated barrel, a plurality of holes are formed in the side wall of the ultra-high performance concrete prefabricated barrel, the ultra-high performance concrete prefabricated barrel is placed in a pile hole, the center line of the ultra-high performance concrete prefabricated barrel coincides with that of the pile hole, common concrete is poured in the ultra-high performance concrete prefabricated barrel to form a common concrete inner core, the common concrete flows out of the holes in the outer wall of the ultra-high performance concrete prefabricated barrel from inside to outside to form a common concrete bonding outer layer, and the common concrete bonding outer layer is located between the outer wall of the ultra-high performance concrete prefabricated barrel and the inner wall of the pile hole. The ultra-high performance concrete and common concrete combined pile is simple in structure construction, novel in material and good in mechanical property, the pile diameter can be reduced, manufacturing cost can be saved, the problems happening to pile foundation construction are effectively solved, the quality and durability of the pile are improved, the good mechanical property and economic benefits are achieved, and the quite wide application prospect is achieved.

Owner:FUZHOU UNIV

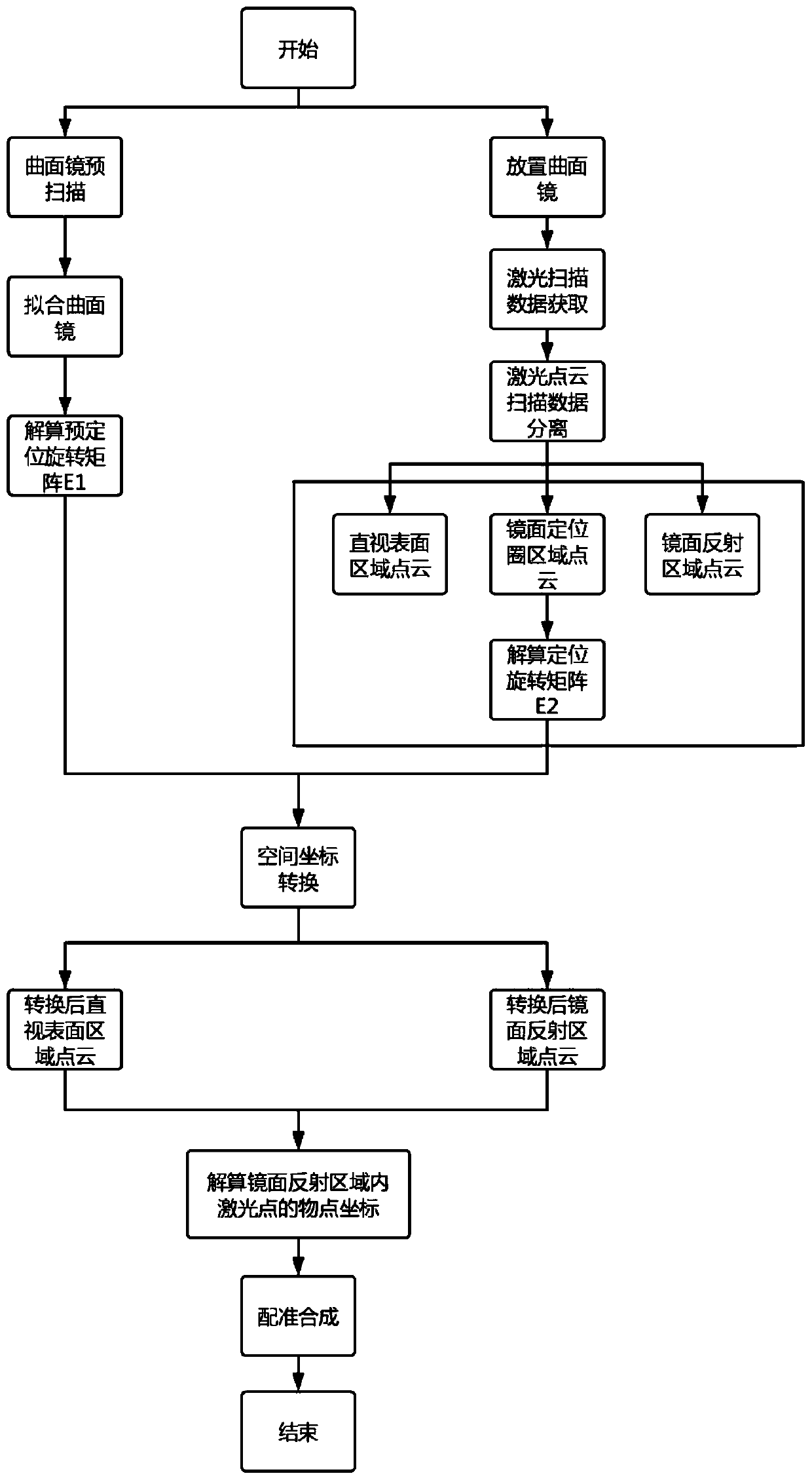

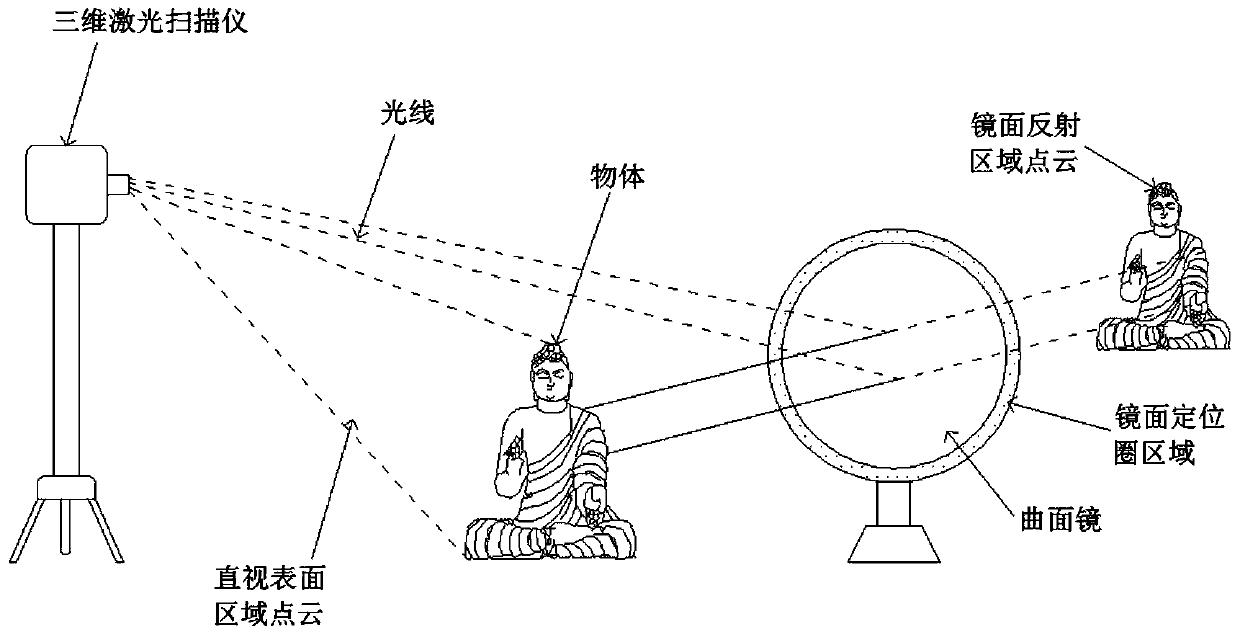

Method for acquiring and resolving laser scanning data reflected by any curved mirror

ActiveCN110954017ASolve the lack of point cloud dataSolve voidUsing optical meansLaser scanningEngineering

The invention belongs to the technical field of surveying and mapping, and discloses a method for acquiring and resolving laser scanning data reflected by any curved mirror, which comprises the following steps of: pre-scanning the curved mirror, fitting the curved mirror, and resolving a pre-positioned rotation matrix; then, placing the curved mirror at a dead angle of a working space, scanning anobject through a three-dimensional laser scanner, separating obtained laser point cloud scanning data to acquire positioned point cloud coordinates and calculate a positioned rotation matrix and carrying out space coordinate conversion, converting the positioned point cloud coordinates into pre-positioned space coordinates, calculating object point cloud coordinates on the object corresponding to the laser image points in the laser point cloud reflected by the curved mirror, and carrying out registration synthesis to obtain complete point cloud of the object. According to the invention, theproblems of point cloud data loss and holes in the non-direct-view area of the scanned object in the prior art are solved, and the complete point cloud of the object can be obtained.

Owner:WUHAN UNIV

Vault concrete pouring early warning device and construction method thereof

InactiveCN109944607AAvoid defectsCombine completeMining devicesUnderground chambersClerestoryMaterials science

The invention relates to the technical field of tunnel construction, in particular to a vault concrete pouring early warning device. The device comprises a secondary lining trolley, the front end of the secondary lining trolley is provided with a trolley end die, and four pouring holes are formed in the center line of a vault of the secondary lining trolley in the vertical direction of the trolleyand are the fourth pouring hole, the third pouring hole, the second pouring hole and the first pouring hole from left to right in sequence; an overflowing groove is formed in the end, extending intothe pouring holes, of an embedded pouring pipe, four probes are fixedly installed in the overflowing groove, and a through groove for a wire to conveniently penetrate through is formed in the middle of the embedded pouring pipe; one end of the wire is electrically connected with the probes, and the other end of the wire is electrically connected with an early warning box. According to the vault concrete pouring early warning device, during secondary lining vault pouring, through the early warning box, whether or not full pouring of the vault part is achieved can be visually known, the concealed work of pouring is converted into visible work, and the lining vault defects are prevented.

Owner:中交中南工程局有限公司 +1

Manufacturing method for COF flexible substrate and capable of avoiding cavities in through holes as well as product thereof

The invention provides a manufacturing method for a COF flexible substrate and capable of avoiding cavities in through holes, comprising the following steps: (1) performing laser drilling; (2) coatingfilms in the through holes; and (3) filling the through holes and electroplating copper. The invention also provides a product obtained by adopting the manufacturing method. The manufacturing methodprovided by the invention can form the through holes with different up-down apertures by virtue of lasers, thus the cavities in the through holes are effectively avoided.

Owner:MFLEX YANCHENG CO LTD

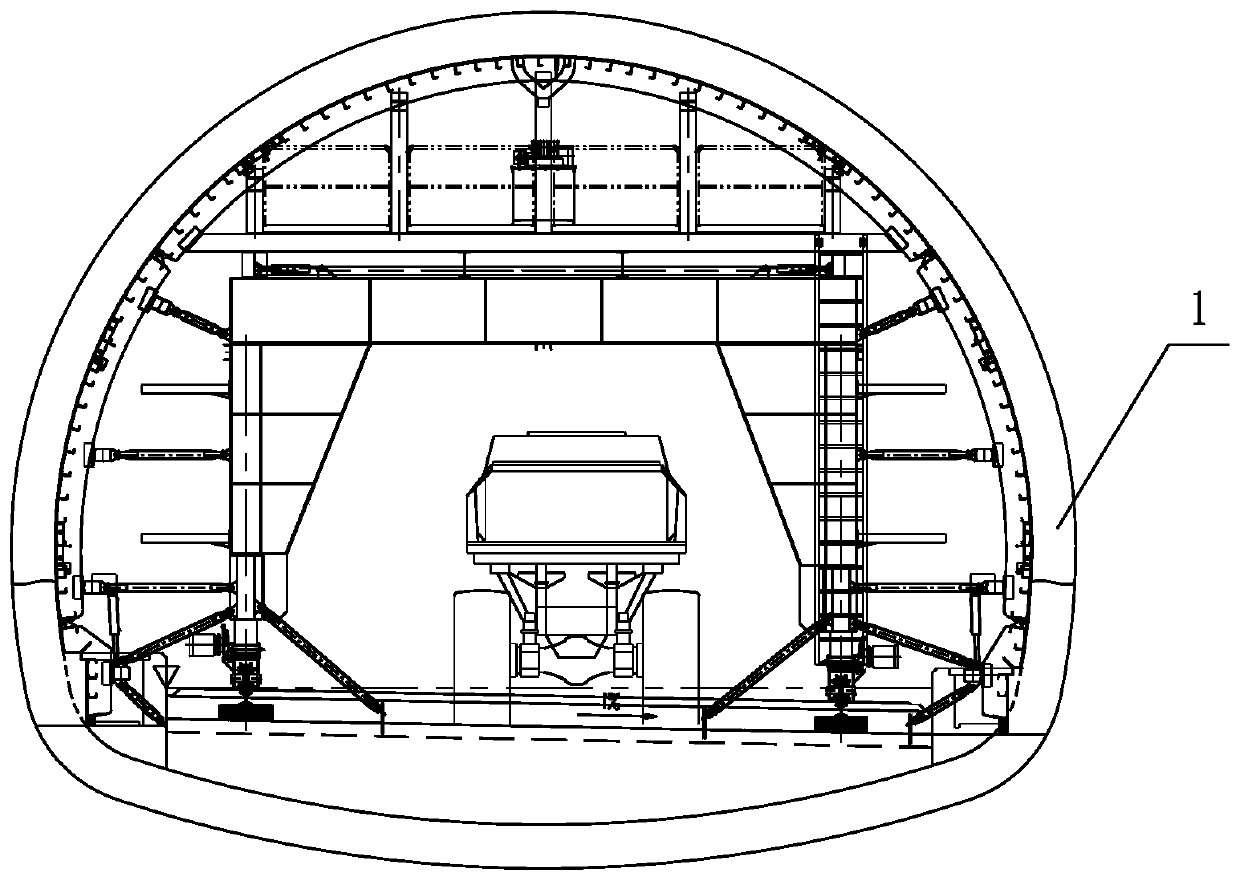

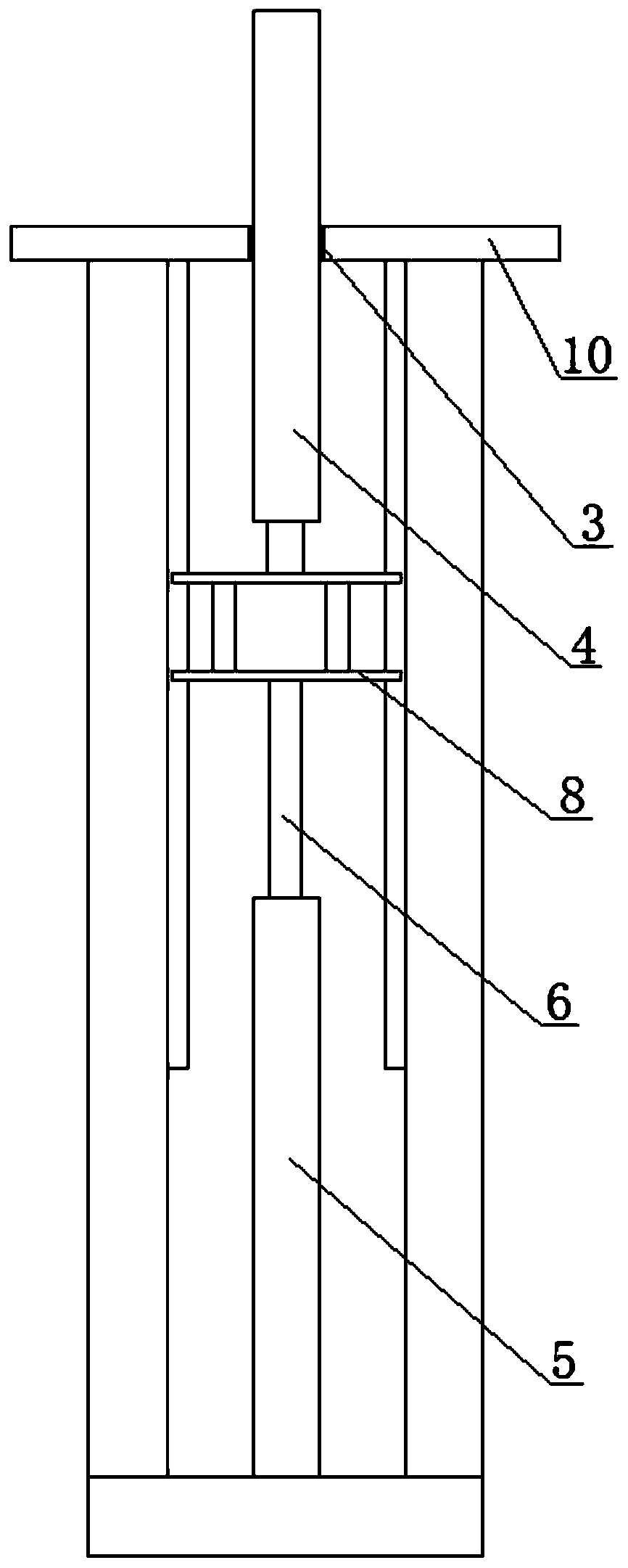

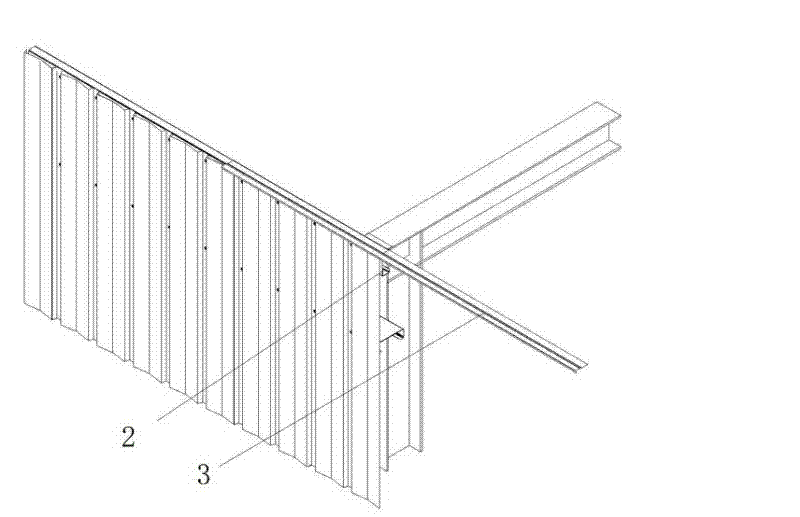

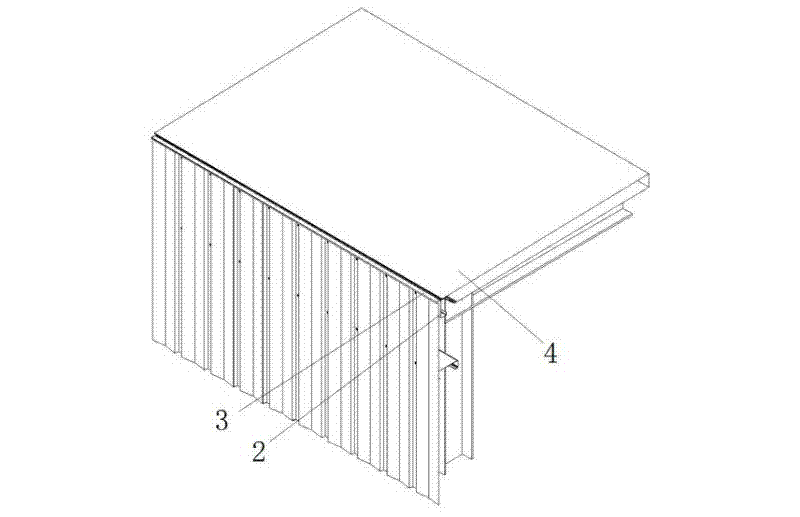

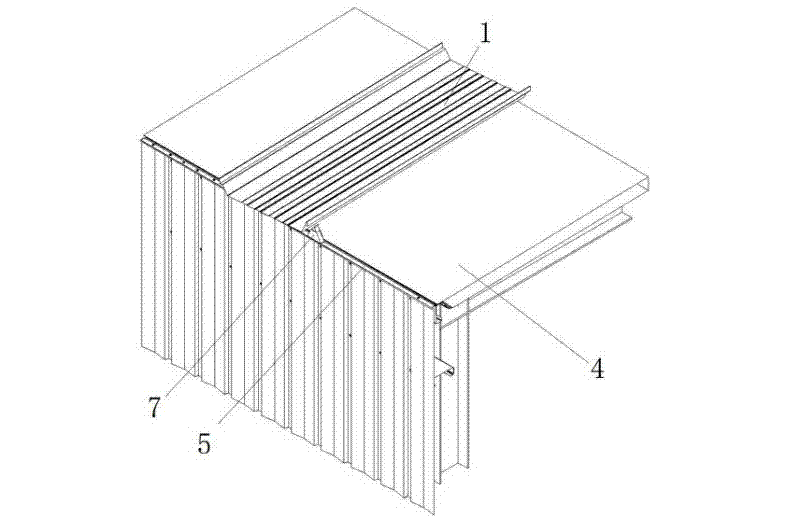

Automatic insertion type vibrating device for tunnel secondary lining concrete

PendingCN109798129ARealize automatic plug-in vibrationSolve voidUnderground chambersBuilding material handlingGas compressorEngineering

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Roofing eave waterproof structure

The invention mainly discloses a roofing eave waterproof structure. In the roofing eave waterproof structure, an eave supporting closing edge is arranged at the junction of a roof panel and a wall plate; roofing heat-preserving cotton is paved on the roof surface to press part of the eave supporting closing edge; and the roof panel is covered on the roofing heat-preserving cotton and is fixedly connected through a roofing fastener. The roofing eave waterproof structure is designed from the angle of preventing wind, water and snow and all the accessories are coordinated, so that the requirements of rigidity and wind suction resistance are met and rainwater penetration can be avoided simultaneously.

Owner:JINGGONG IND BUILDING SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com