Embedded type penstock backfill grouting structure and grouting technology

A pressure steel pipe, backfill grouting technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve the problems of long construction period, large blindness, complicated process, etc., and achieve the effect of shortening the construction period and solving the void

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

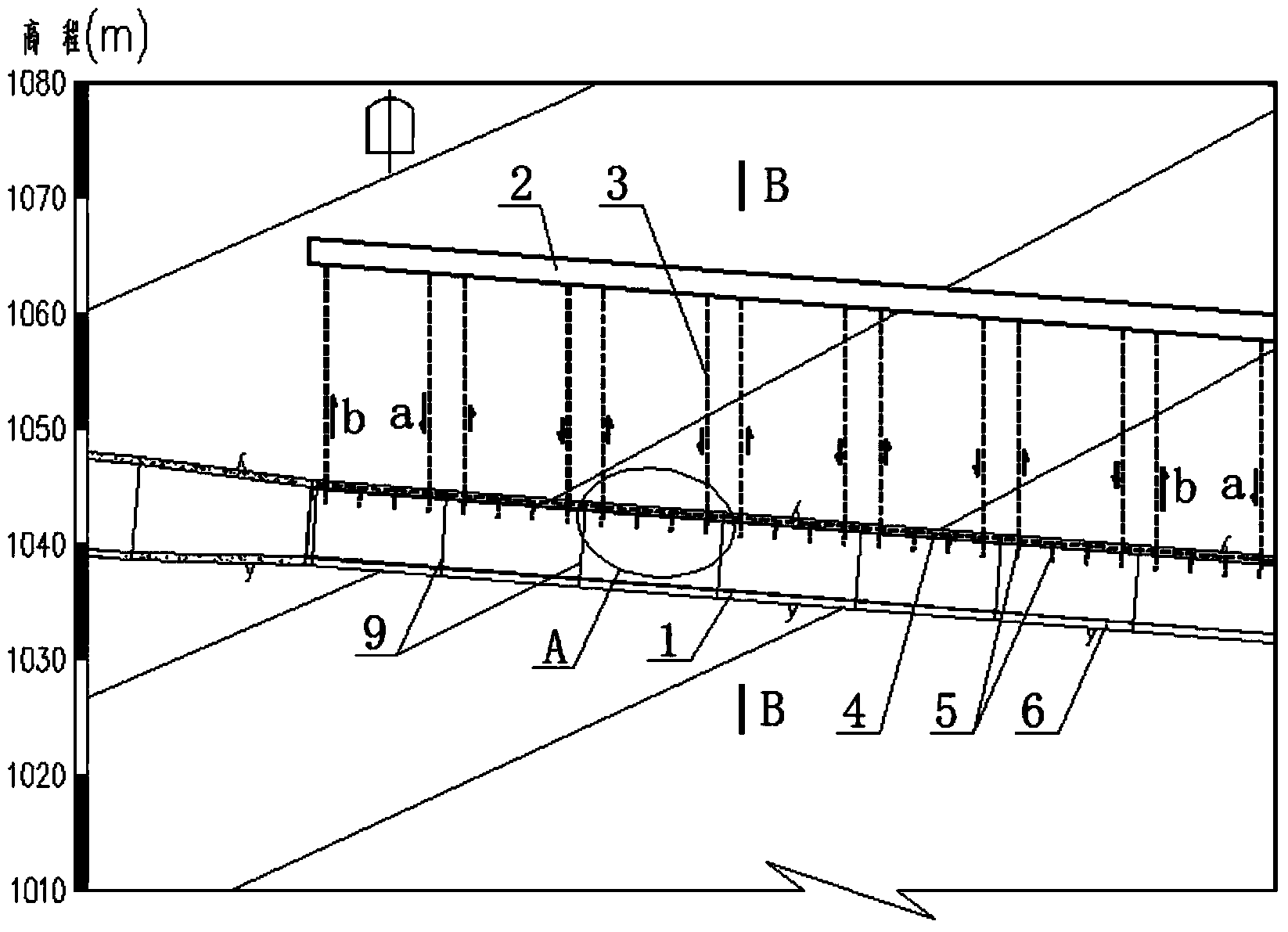

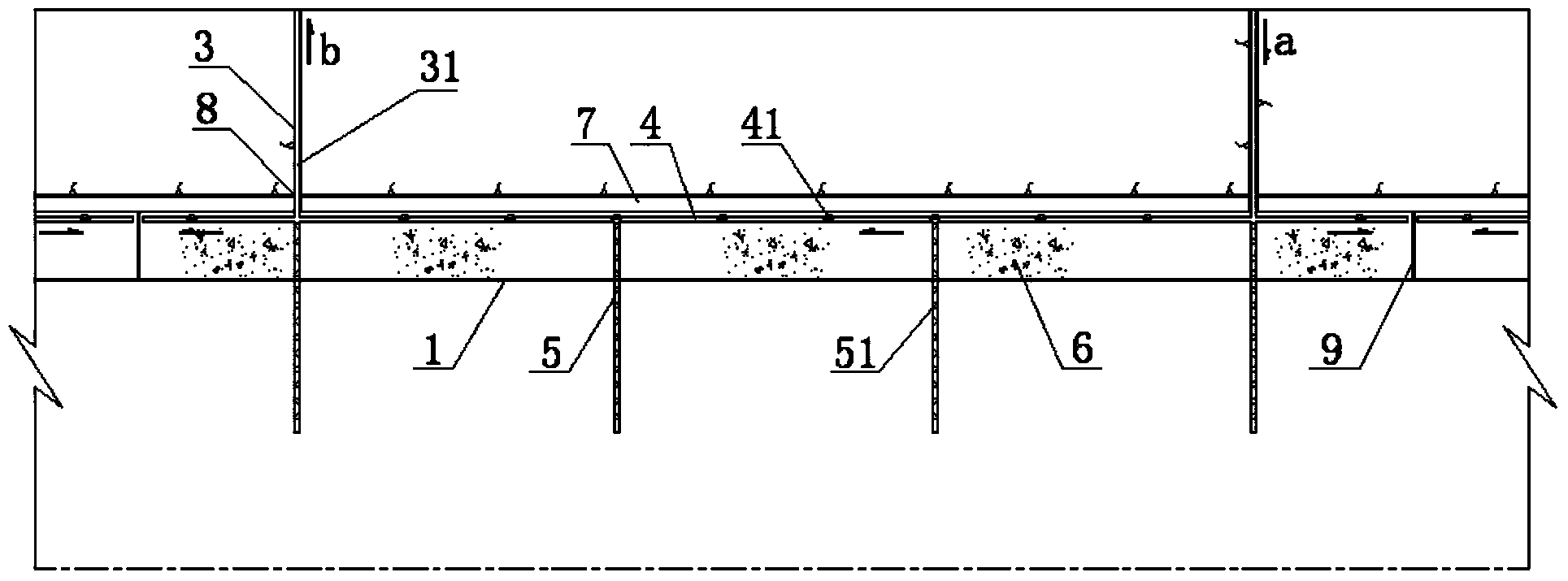

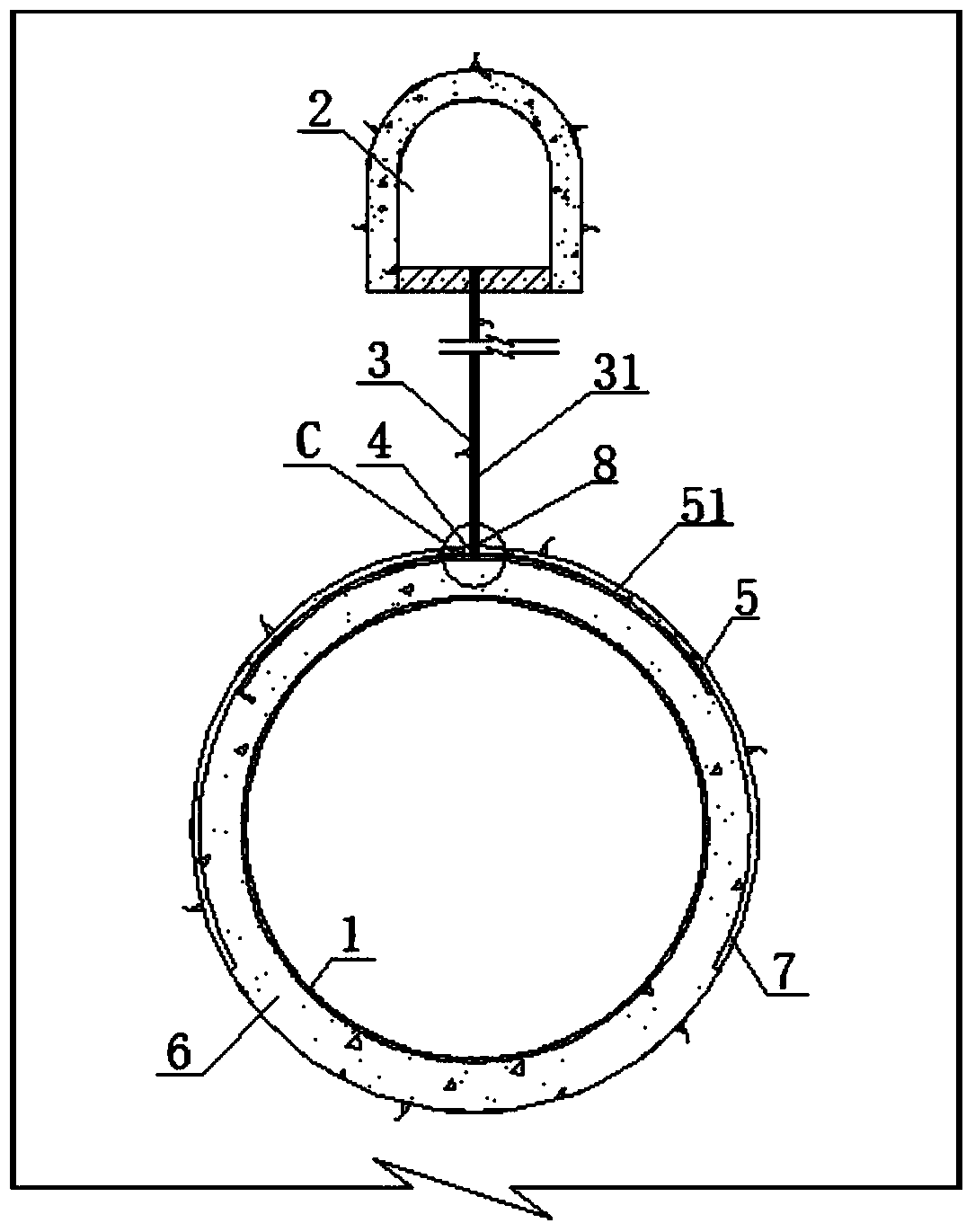

[0028] Such as Figure 1 to Figure 4 As shown, a buried penstock backfill grouting structure according to the present invention includes a penstock 1 and a drainage hole 2 arranged outside the penstock 1, and the outside of the penstock 1 is pre-embedded with a number of longitudinal grouting through the backfill concrete 6 The pipe 4 and the transverse grouting pipe 5 are provided with shotcrete 7 on the outer surface of the backfill concrete 6, the drainage hole 2 is provided with a rock hole 3, and a grouting pipe 31 is embedded in the rock hole 3, and the grouting pipe 31 is respectively It communicates with the longitudinal grouting pipe 4 and the transverse grouting pipe 5 .

[0029] The diameter of the rock hole 3 is 75mm.

[0030] The top of the longitudinal grouting pipe 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com