Patents

Literature

459results about How to "Guaranteed force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

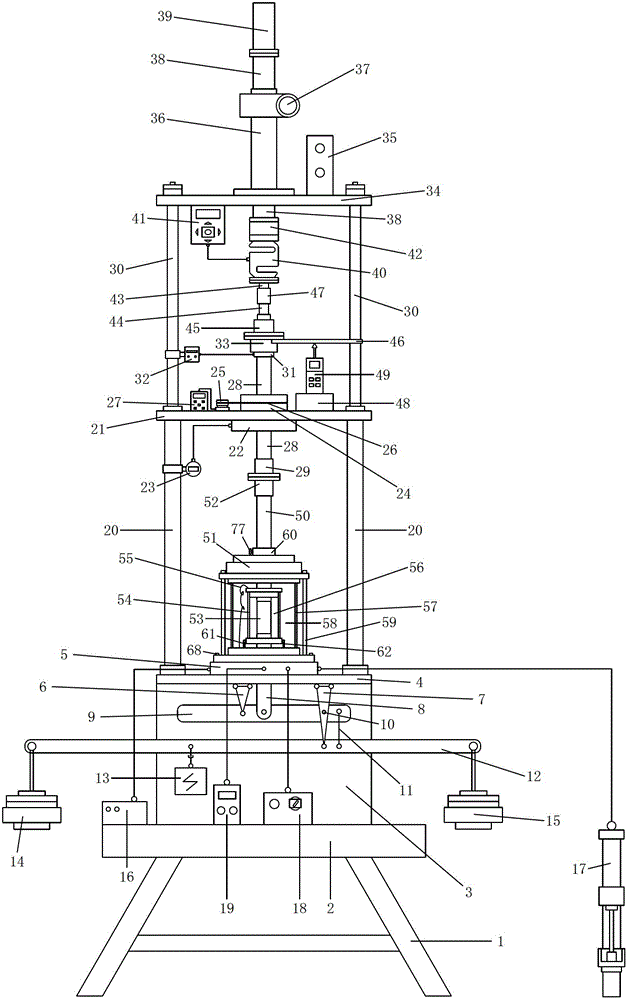

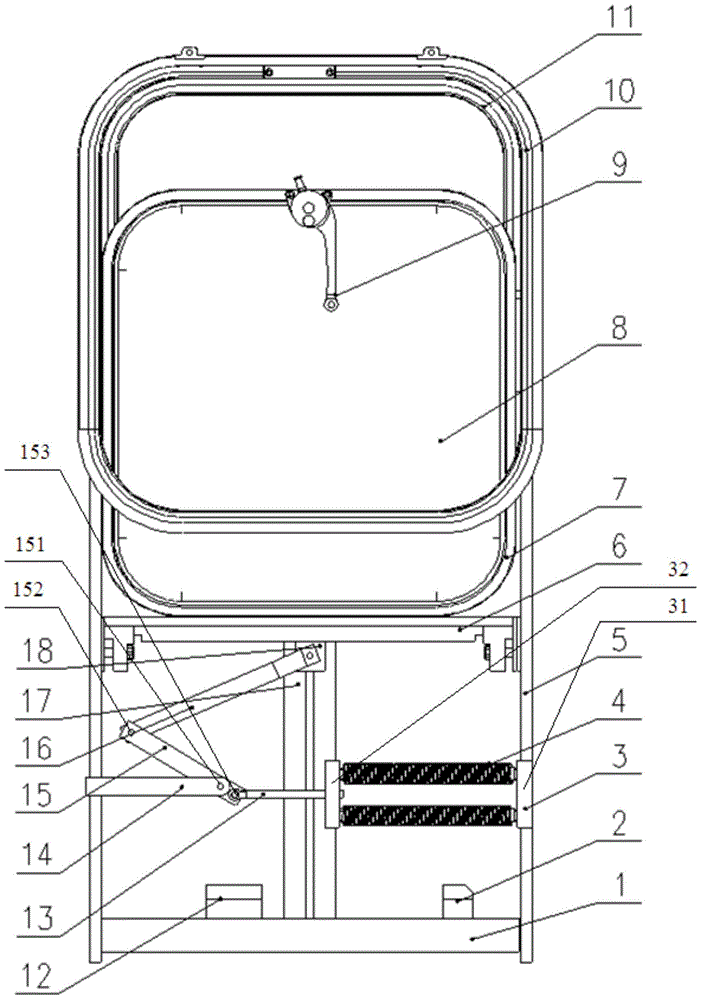

Multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions

InactiveCN103149101AStable controlCode of PracticeInvestigating material ductilityAxial displacementAmbient pressure

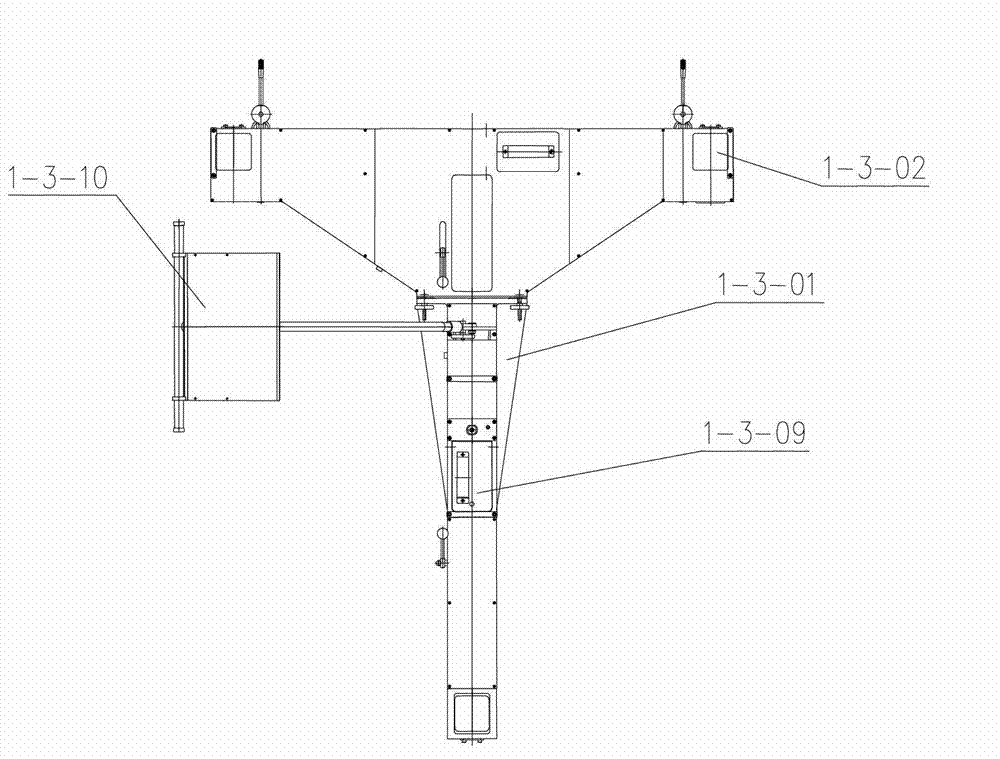

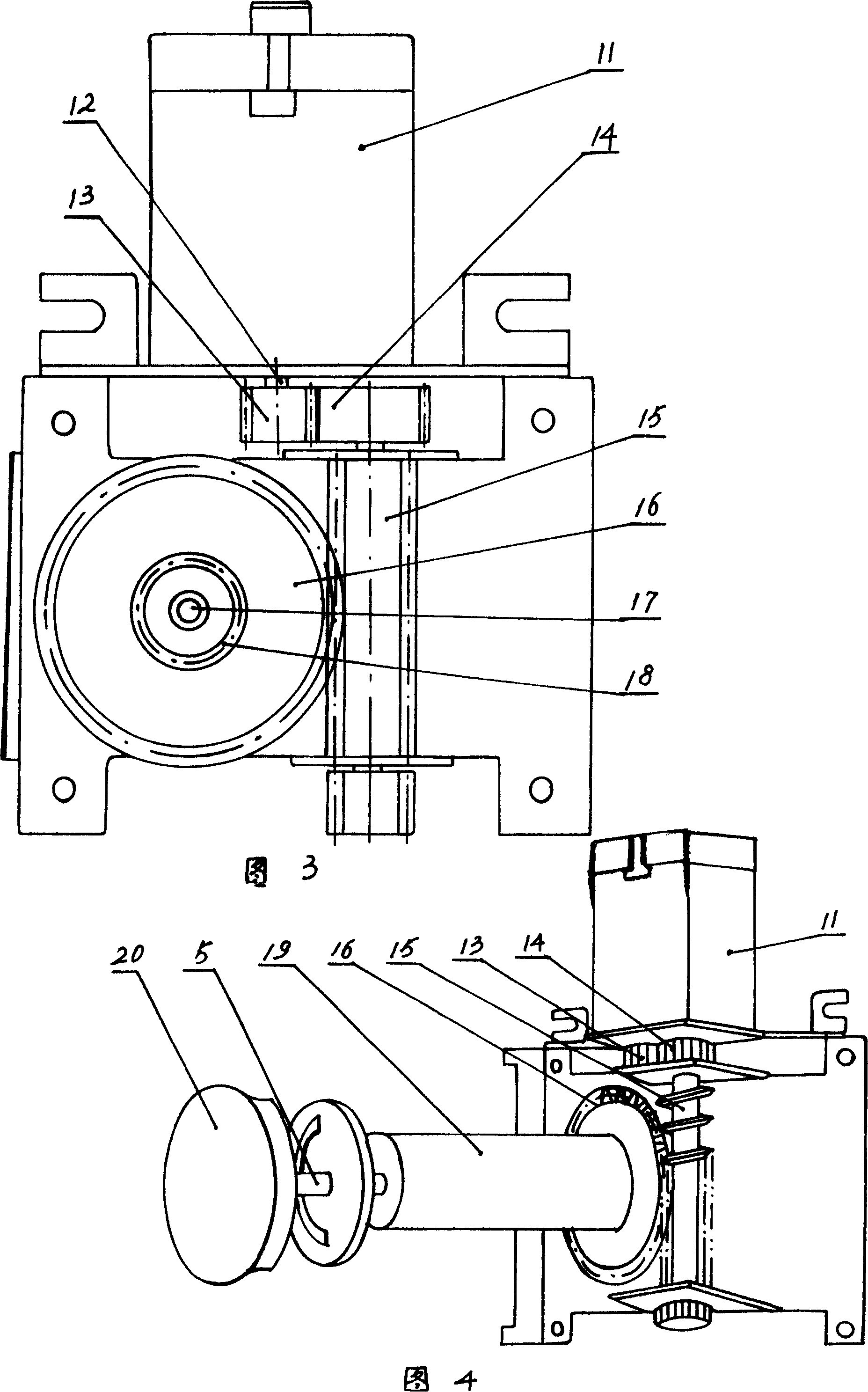

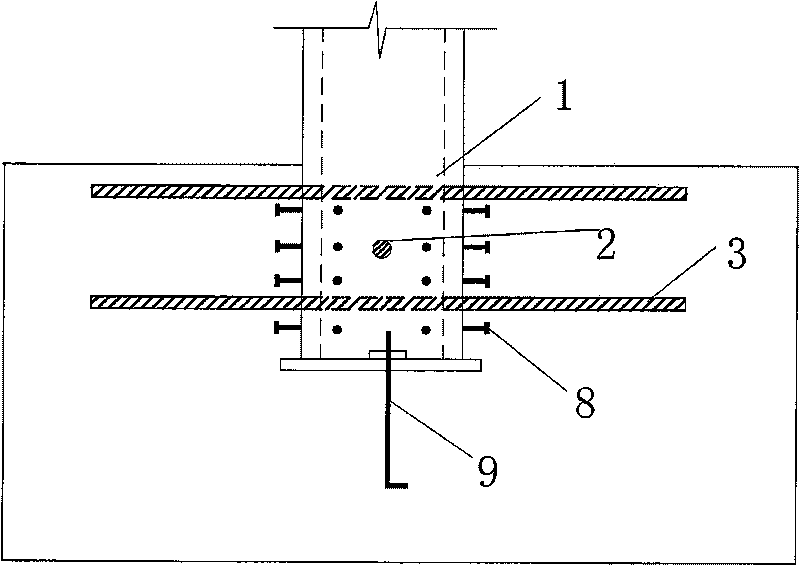

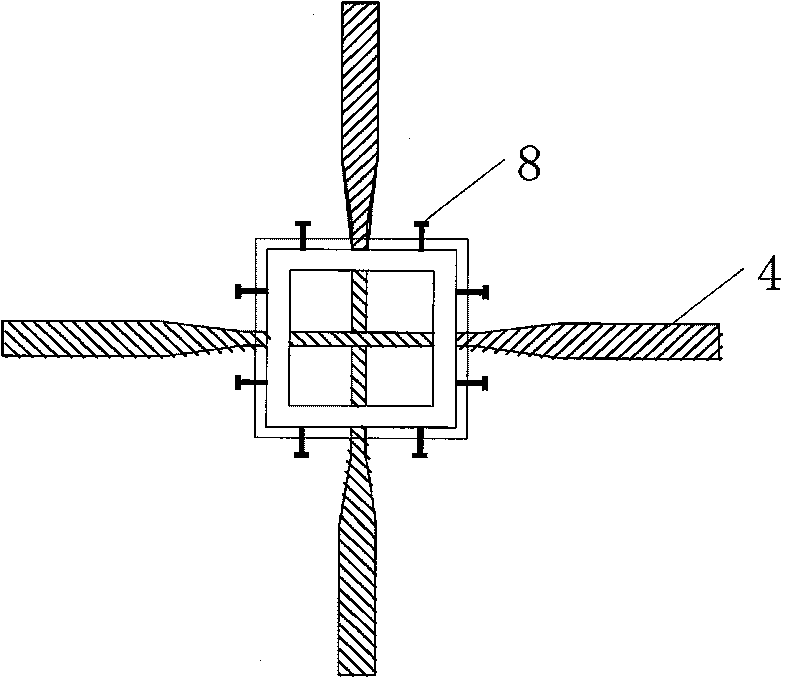

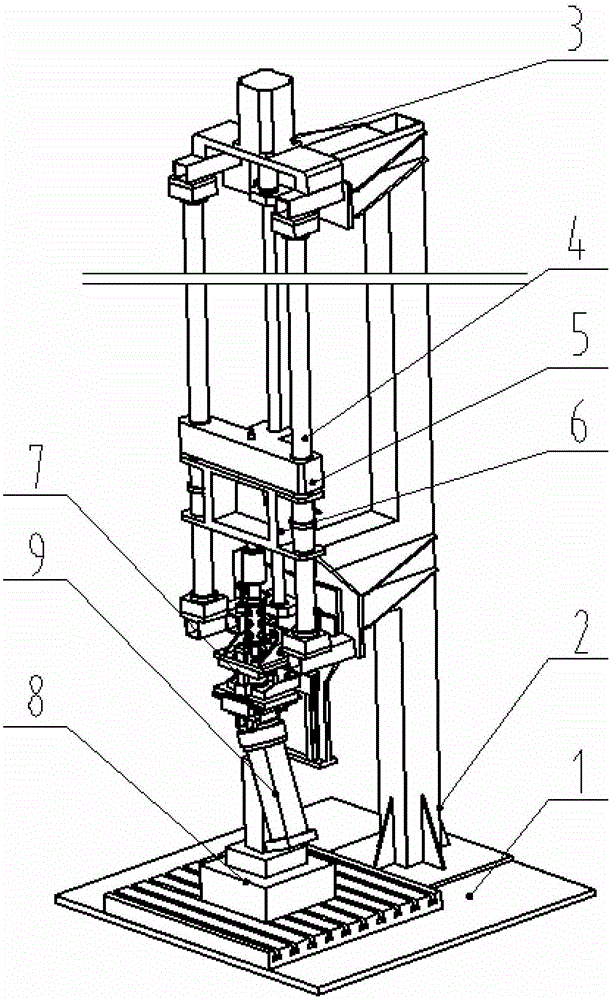

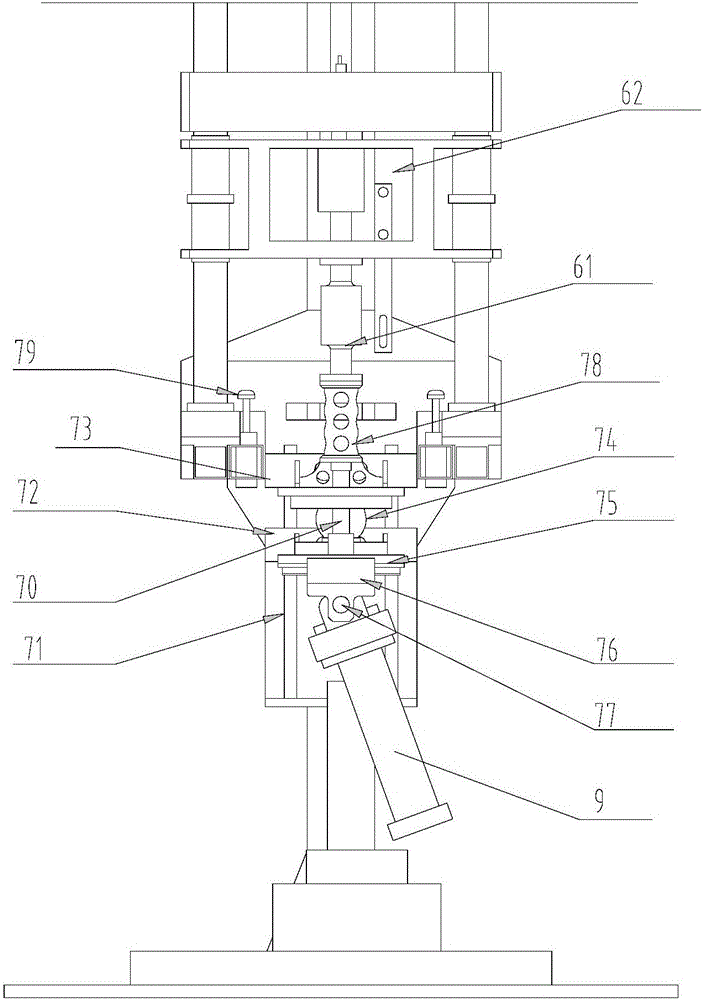

The invention discloses multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions, which structurally comprises a main body part, power supply equipment, an axial loading and measuring mechanism, a torque loading and measuring mechanism, a volume-changed water level controlling and measuring mechanism, an ambient pressure loading and measuring mechanism, a pore pressure measuring mechanism, a creeping and loading mechanism, an axial displacement measuring mechanism and a lubricating mechanism. A torque separator can apply any combined axial action and torque action; a multifunctional lever part not only can apply a tension action to a sample through a lever, but also can apply a pressure action to the sample through the lever; and a detachable split volume-changed measuring water jacket structure is remarkably changed on the aspect of soil body sample body-changed measurement. The machine provided by the invention is simple in structure, convenient to operate and high in accuracy rate and success rate.

Owner:XIAN UNIV OF TECH

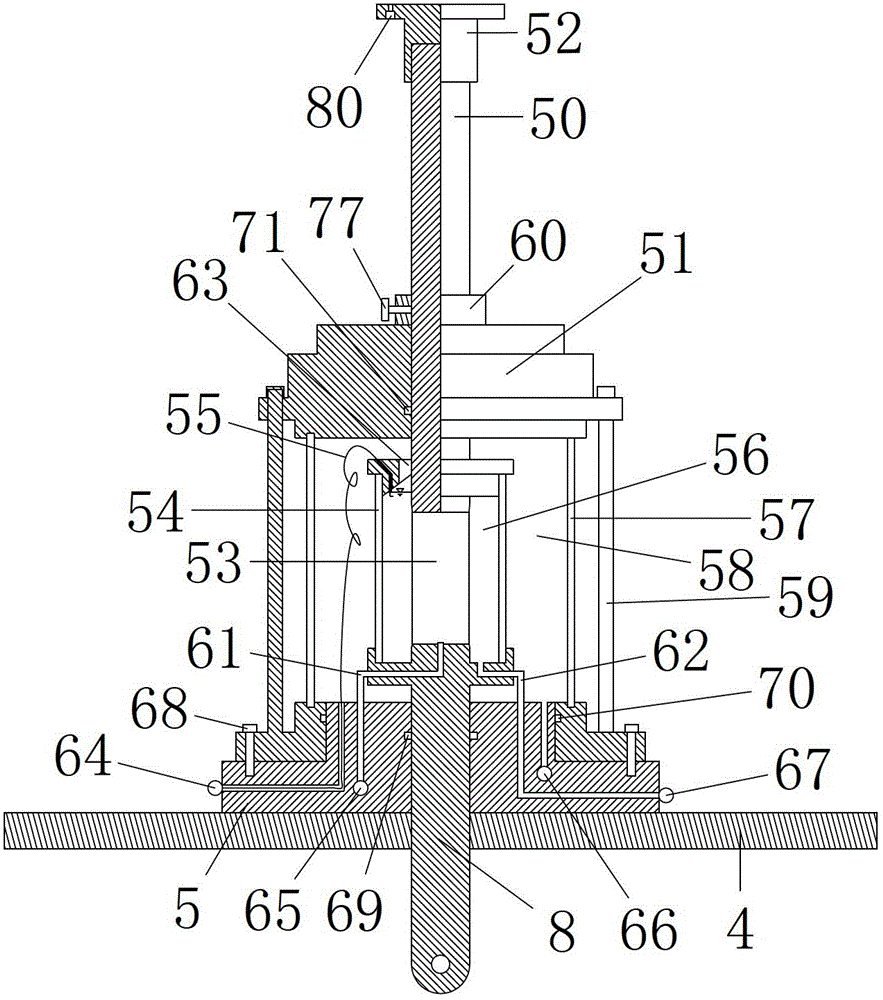

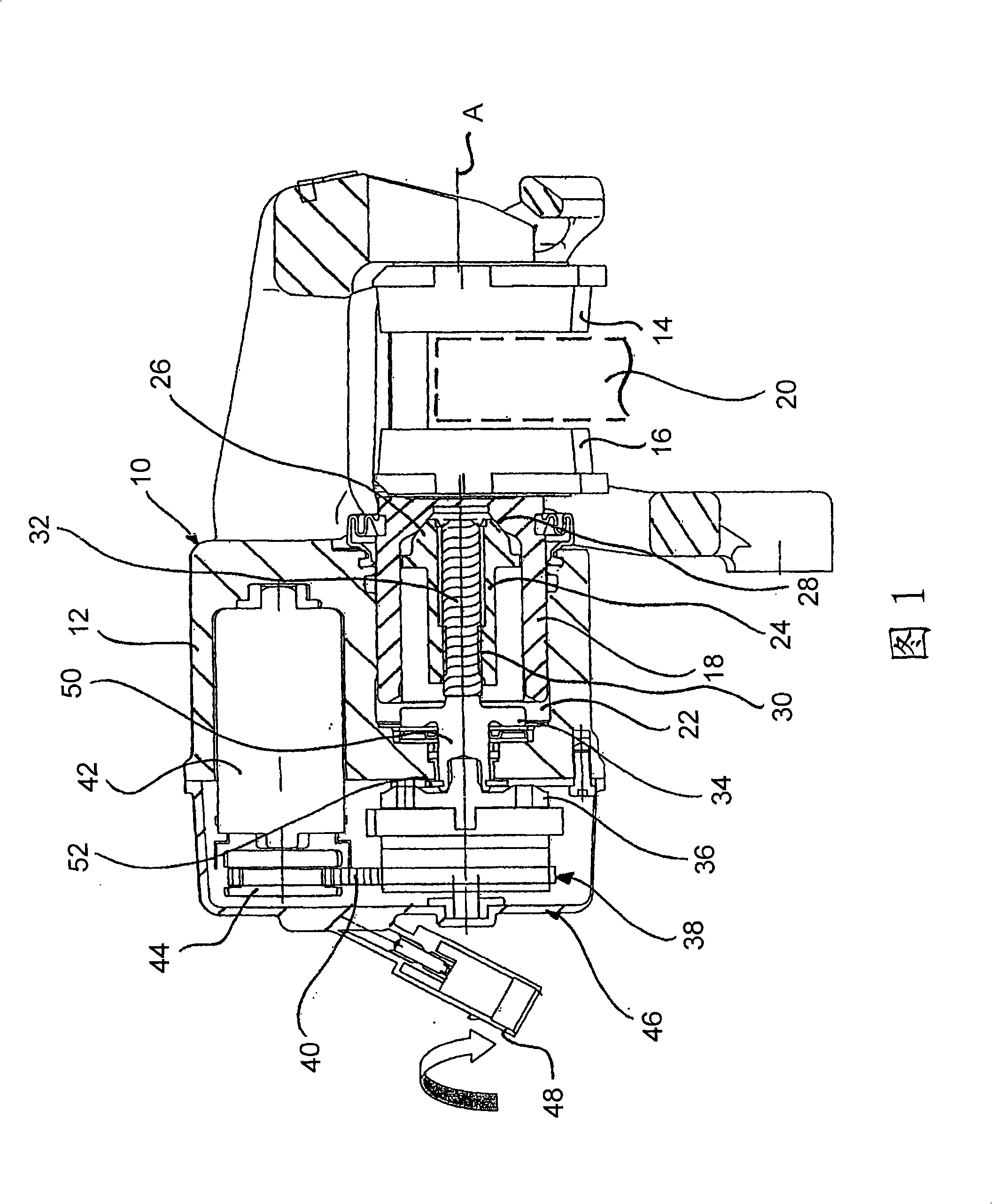

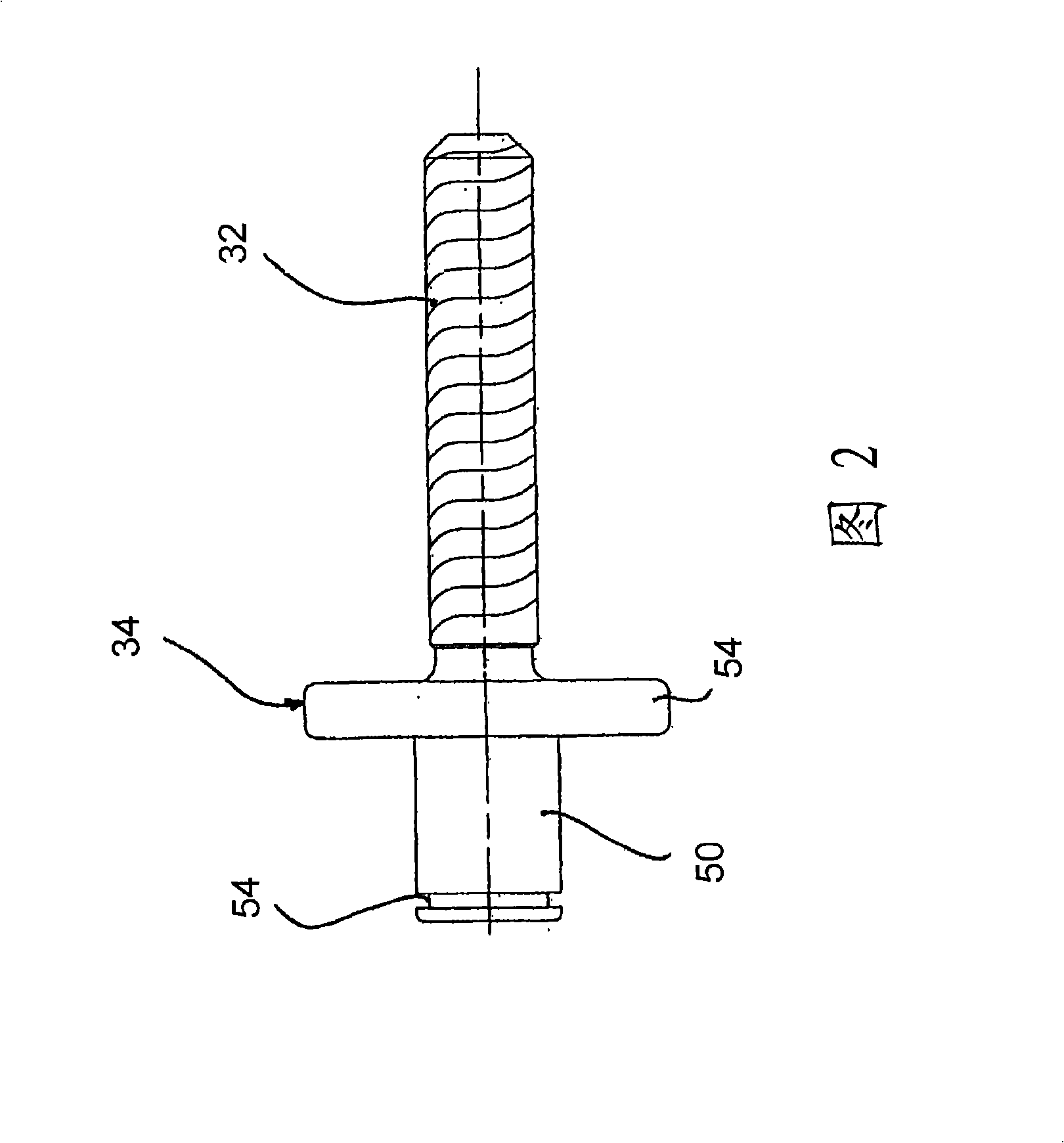

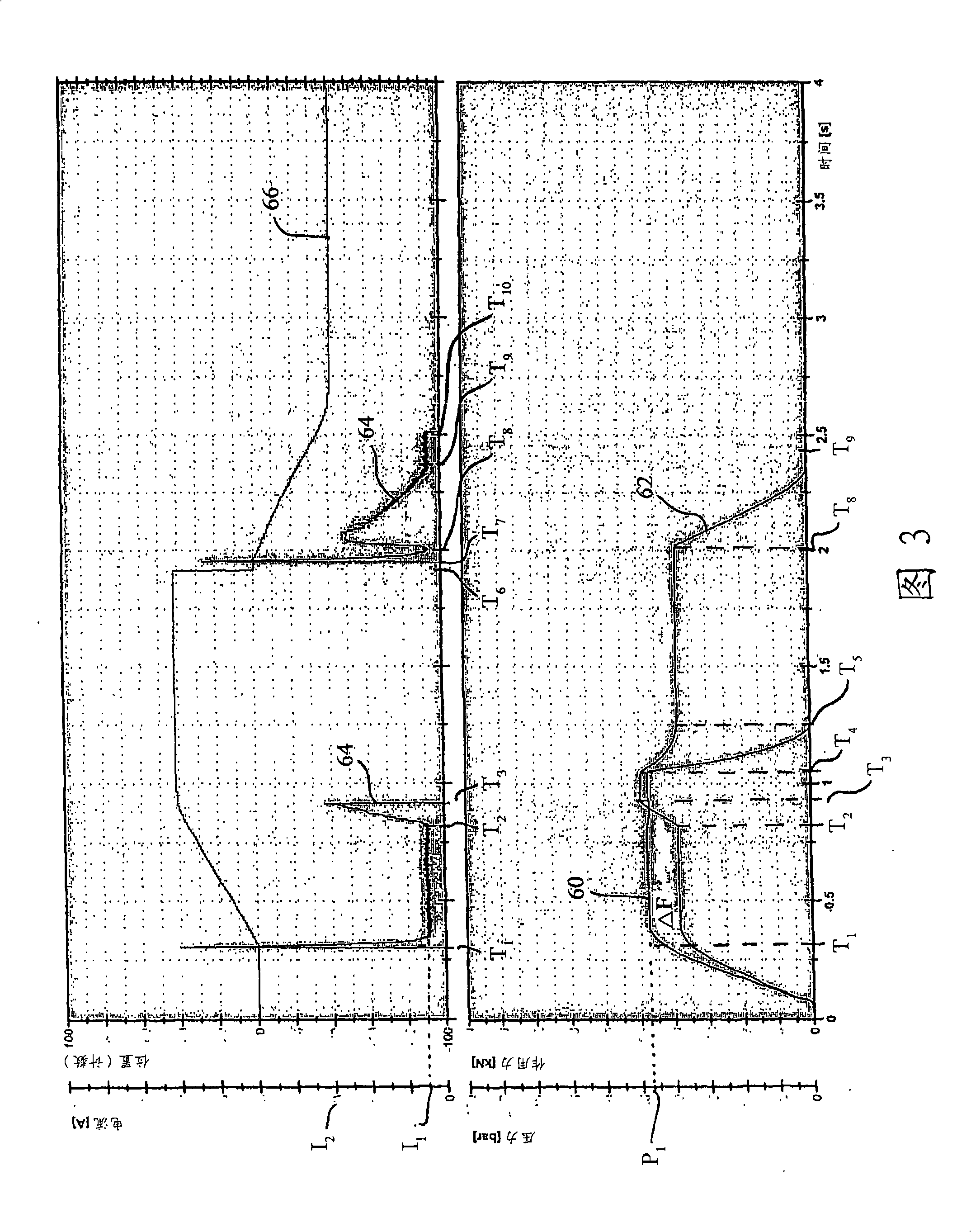

Vehicle brake, in particular caliper brake

InactiveCN101273213AEasy to removeGuaranteed forceBrake actuating mechanismsActuatorsSelf lockingCalipers

The invention relates to a vehicle brake (10), in particular caliper brake, having a housing (12), having a brake piston (18), which is held in the housing (12) and is linearly displaceable relative thereto, for displacing a brake lining (16), and having a mechanical actuator arrangement for displacing the brake piston (18), wherein the brake piston (18) in the housing (12) can be displaced by filling a hydraulic chamber (22) via a hydraulic brake circuit, and wherein the mechanical actuator arrangement has a threaded spindle (32) which is rotatably mounted in the housing (12) and can be driven in rotation, wherein the brake piston (18) can be displaced linearly relative to the housing (12) as a result of a rotary movement of the threaded spindle (32).; In said vehicle brake, it is provided according to the invention that the threaded spindle (32) is provided with a multiple-start self-locking thread with n flights, wherein the number n and the thread pitch are selected such that the thread is close to the self-locking limit.

Owner:LUCAS AUTOMOTIVE GMBH

Processing method of green bud tea

The invention discloses a processing method of green bud tea, comprising the following steps: paving tea leaves on a tea groove, wherein the paving thickness is 10-15cm; ventilating with an assistant blower, wherein the paving time is 10-14h; water-removing the tea leaves, wherein the cylinder temperature of the tea inlet end is 269-275 DEG C, the middle section temperature is 253-260 DEG C, the tea outlet end temperature is 219-225 DEG C, the leaves temperature is 102-108 DEG C, and; the water removing time is 1min25s-1min30s; directly putting the water removed tea leaves to a vibration groove, and putting the tea leaves into a wind selector, sending the selected tea leaves to a microwave water removing machine through a transporter, wherein the temperature of the water removing machine is 120 DEG C, the tea leaves temperature is 46-49 DEG C, the rotary speed is 1100r / min, and the water removing time is 50s; grading, carding, shaping, drying, infrared flavor enhancing. The method canincrease the shape, color and smell of green bud tea.

Owner:贵州湄潭兰馨茶业有限公司

POSS (Polysilsesquioxane)-containing antireflective film coating liquid and preparation method and application thereof

The invention discloses a POSS (Polysilsesquioxane)-containing antireflective film coating liquid and a preparation method and application thereof, and belongs to the field of film coating liquids. The preparation method of the POSS-containing antireflective film coating liquid comprises the following steps of: adding the following raw materials in percentage by weight: 0.01%-20% of POSS derivatives, 0-10% of nanometer silicon dioxide granules, 0%-10% of hollow silicon dioxide, 0%-5% of non-silicon nanometer oxide granules, 0%-10% of organic silicon compounds, 0%-50% of deionized water and 0%-2% of catalysts into a solvent; and reacting at 20-150 DEG C for 0-45 hours to obtain the POSS-containing antireflective film coating liquid. The POSS-containing antireflective film coating liquid disclosed by the invention can be applied to photovoltaic glass, display screen base plate glass, building glass and automobile glass; and the obtained antireflective film has the advantages of good film layer uniformity, high adhesive force and rigidity and good weather resistance.

Owner:武汉绿凯科技有限公司

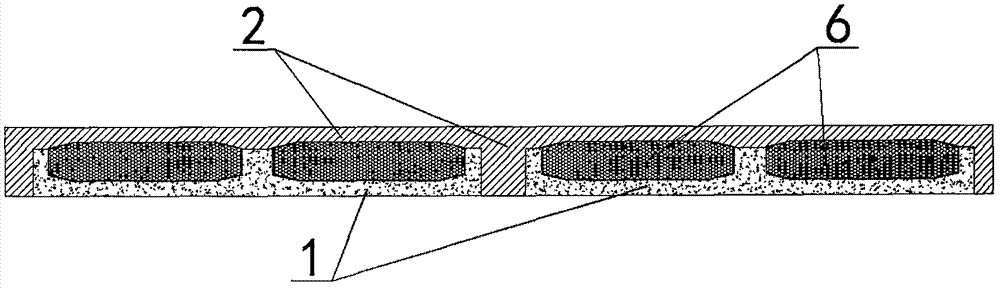

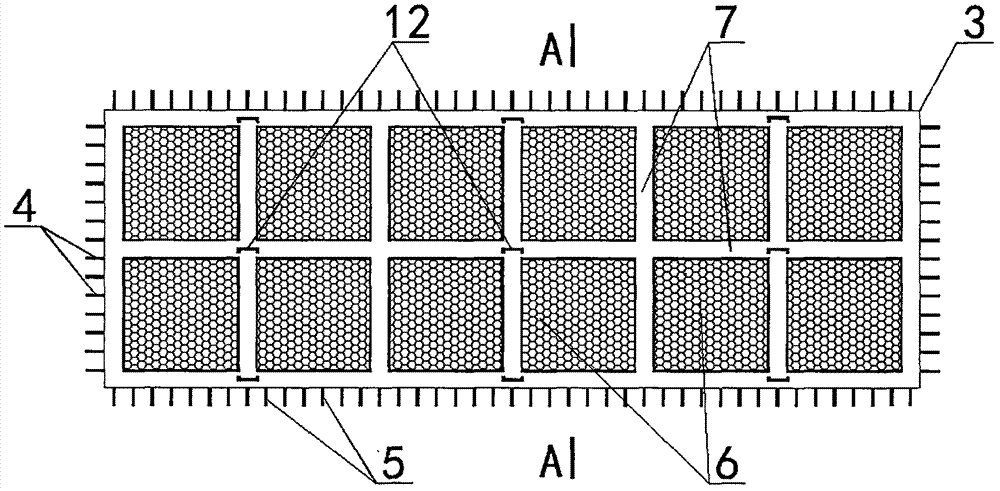

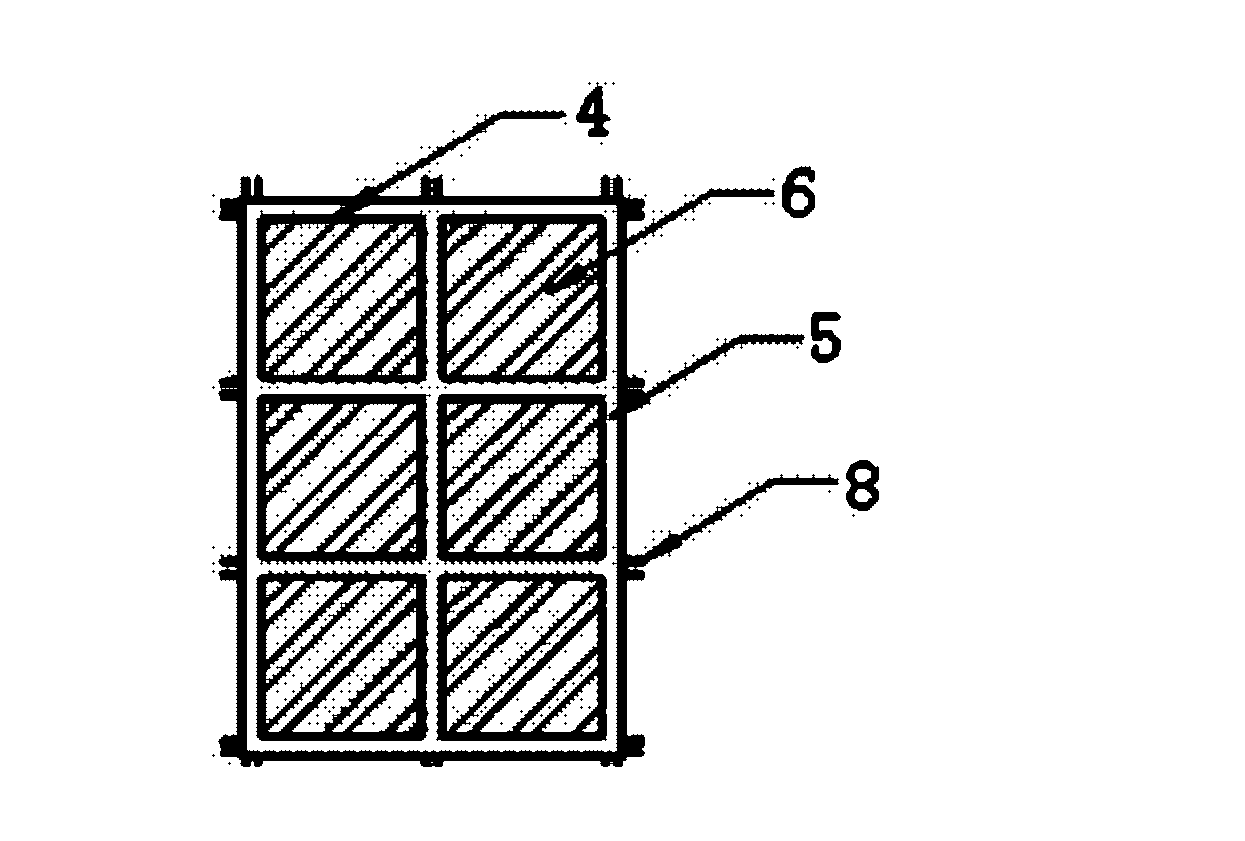

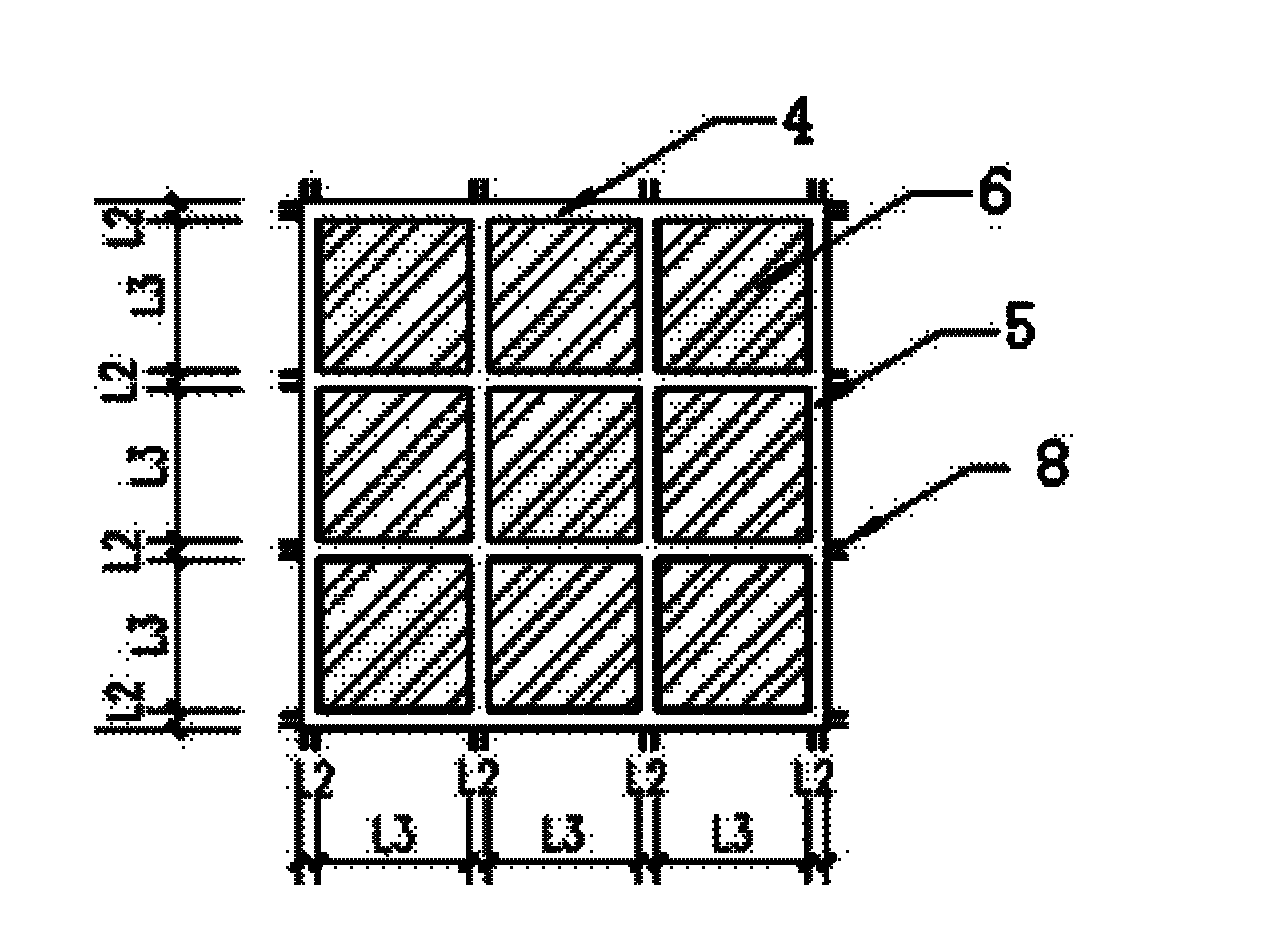

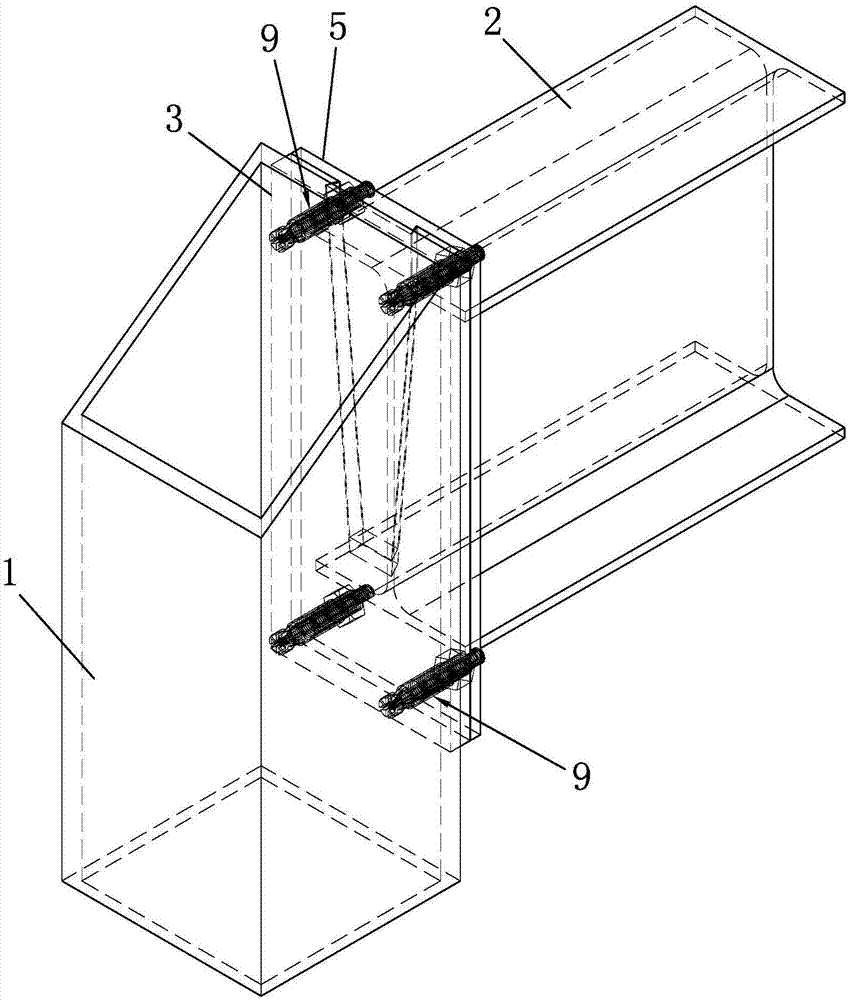

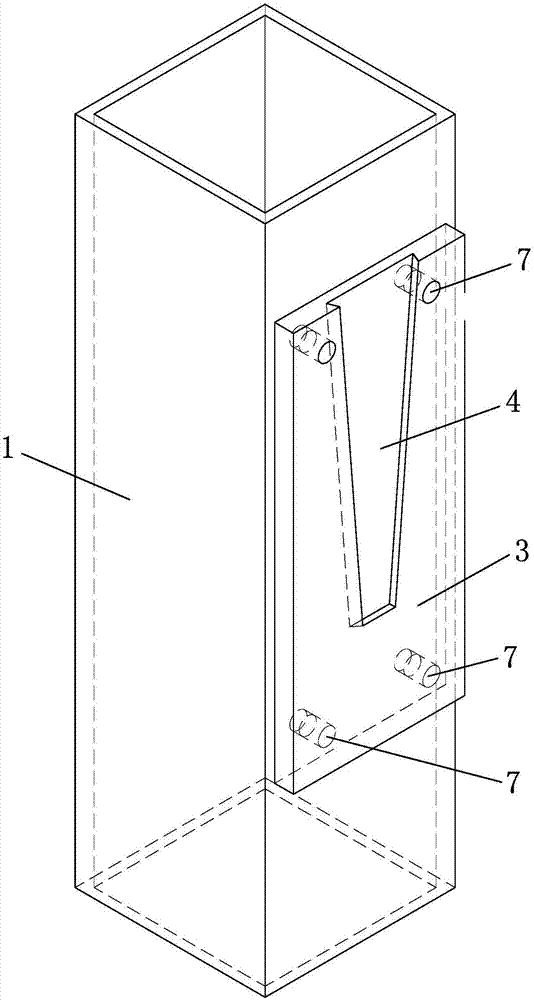

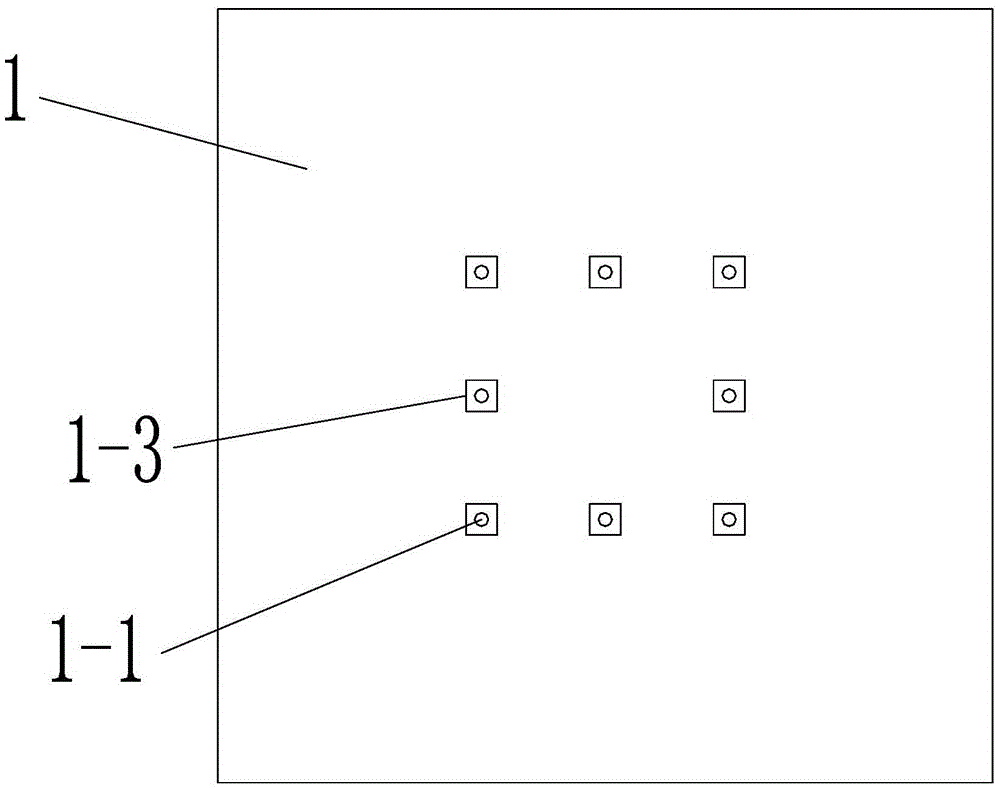

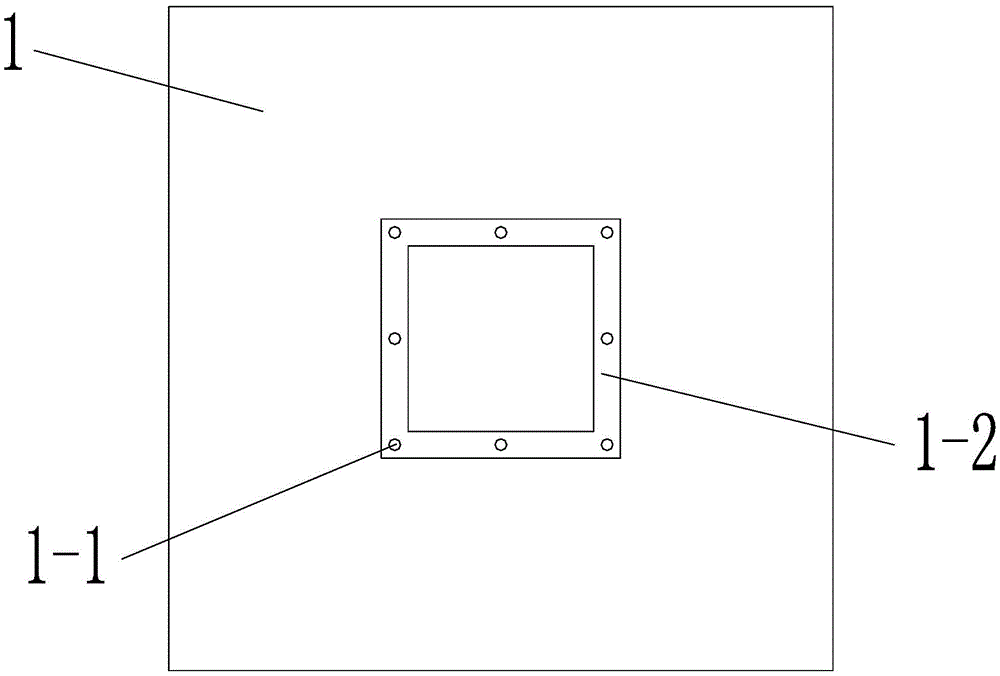

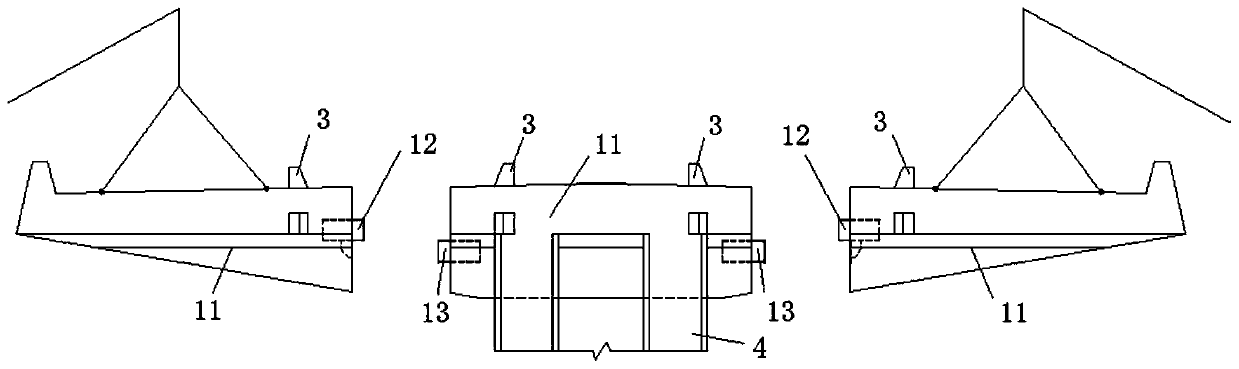

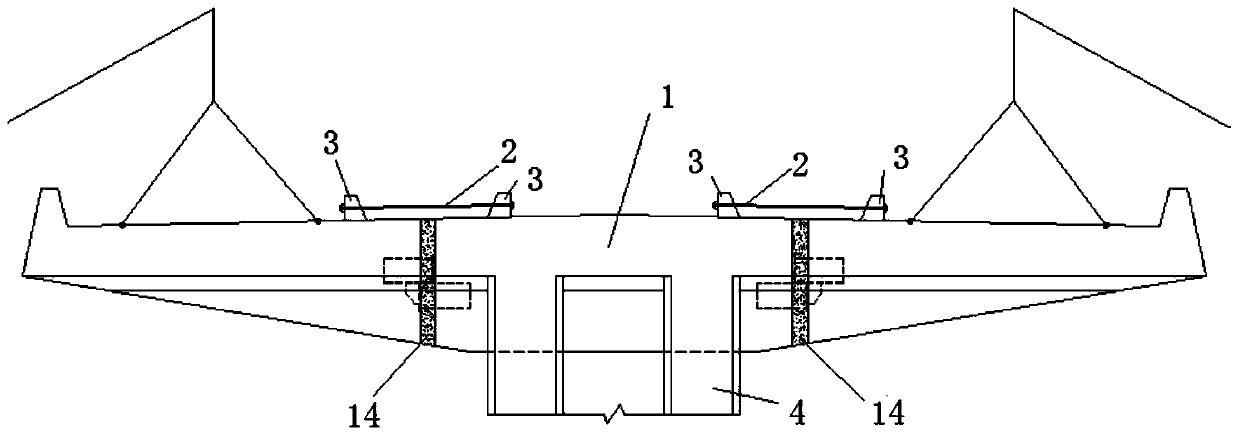

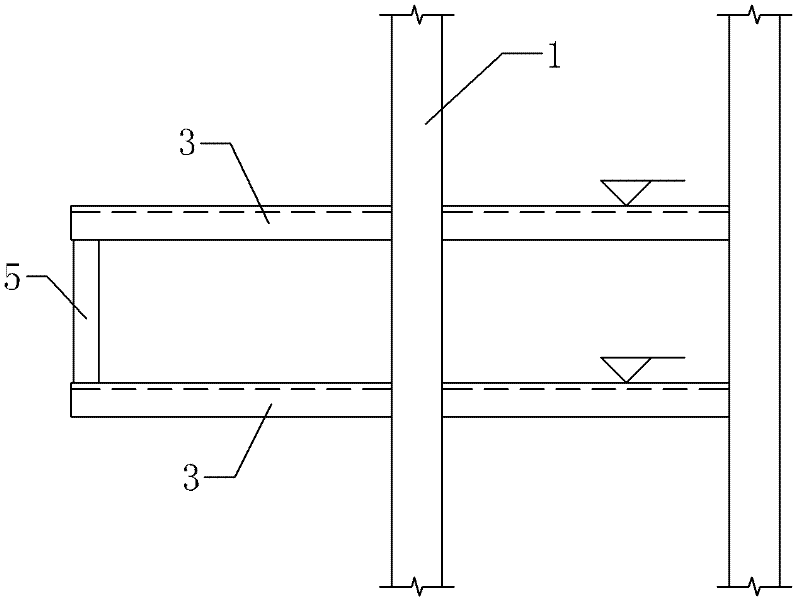

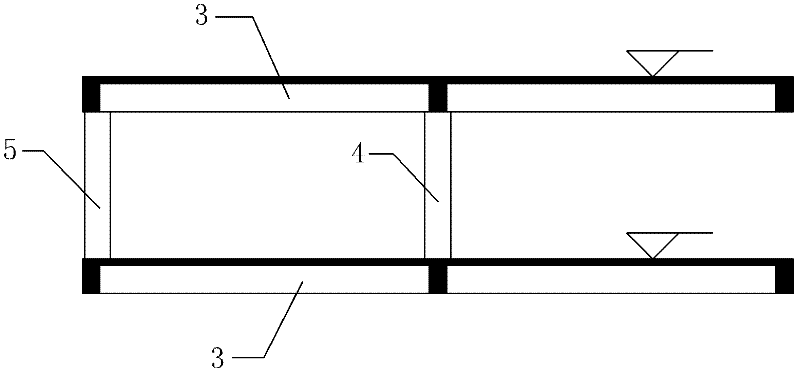

Prestressed hollow composite slab

ActiveCN107313539ALight weightApplicable span is largeFloorsBuilding reinforcementsPre stressComposite slab

The invention relates to a prestressed hollow composite slab and a manufacturing method thereof, and belongs to the field of normal building construction. The composite slab comprises prefabricated pieces (1) and composite layers (2). Thickness of a bottom plate (3) of each prefabricated piece (1) is greater than or equal to 35 mm and less than or equal to 60 mm, prestressed steel wires (4) in the bottom plate are located at the upper parts of transversal steel bars (5), and the length of each prestressed steel wire (4) and each transversal steel bar (5) extending out of the corresponding bottom plate (3) is greater than or equal to 50 mm; the width of each prefabricated piece is greater than or equal to 1500 mm, light-weight material filling pieces (6) are arranged at the upper part of each prefabricated piece (1); the heights of concrete solid ribs (7) between adjacent filling pieces are greater than or equal to 50 mm; the transversal steel bars (5) between adjacent prefabricated pieces (1) are overlaid in a joint area (8), upper part steel bars (10) of the composite slab are bound, composite layer concrete is poured, and the composite slab is formed. According to the prestressed hollow composite slab and the manufacturing method thereof, the self-weight of the composite slab is light, the stiffness in the longitudinal direction and the transversal direction is high, the application range is large, and transportation and installation are convenient. The prestressed hollow composite slab and the manufacturing method thereof have good economic efficiency and applicability, and play a role on promoting the development of building technology.

Owner:徐焱

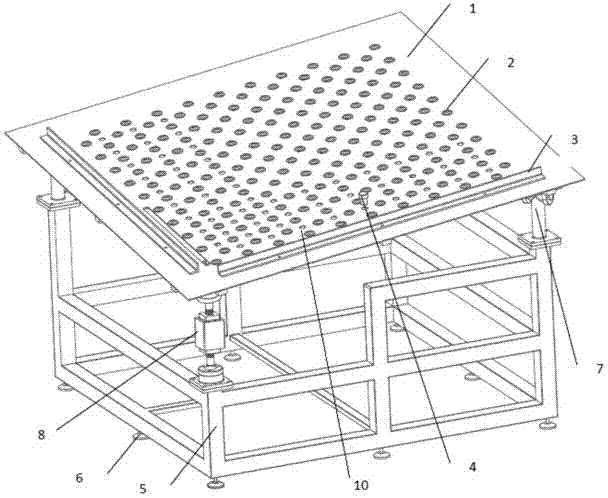

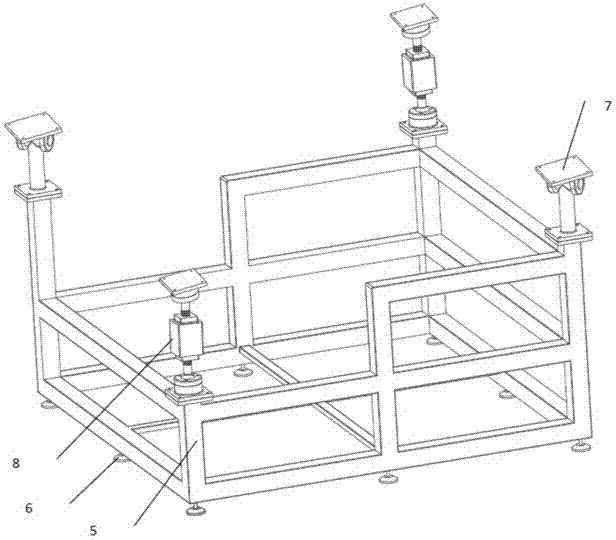

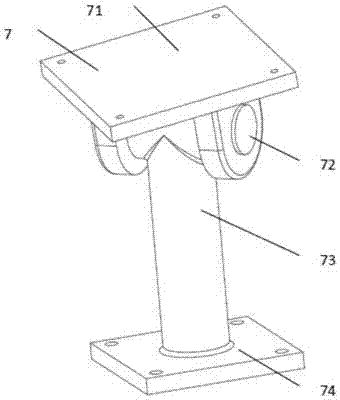

Flexible gravity centering table

ActiveCN103769488AProtective contactGuaranteed forceMetal-working feeding devicesPositioning devicesEngineeringGravitation

According to a flexible gravity centering table, a working table inclines downward in the direction from a feed station area to a discharge station area, universal wheels are arranged on the working table, and therefore workpieces are transferred to the discharge station area at the lower portion of the working table; driven-in pin type stop dogs are further arranged in the discharge station area, and therefore the layout and form of the stop dogs can be conveniently and freely adjusted in a plugging mode, and the positions of the stop dogs of the flexible gravity centering table can be randomly changed for special-shaped pieces.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

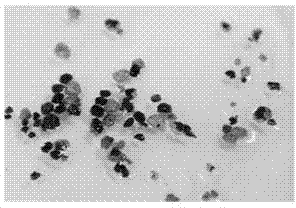

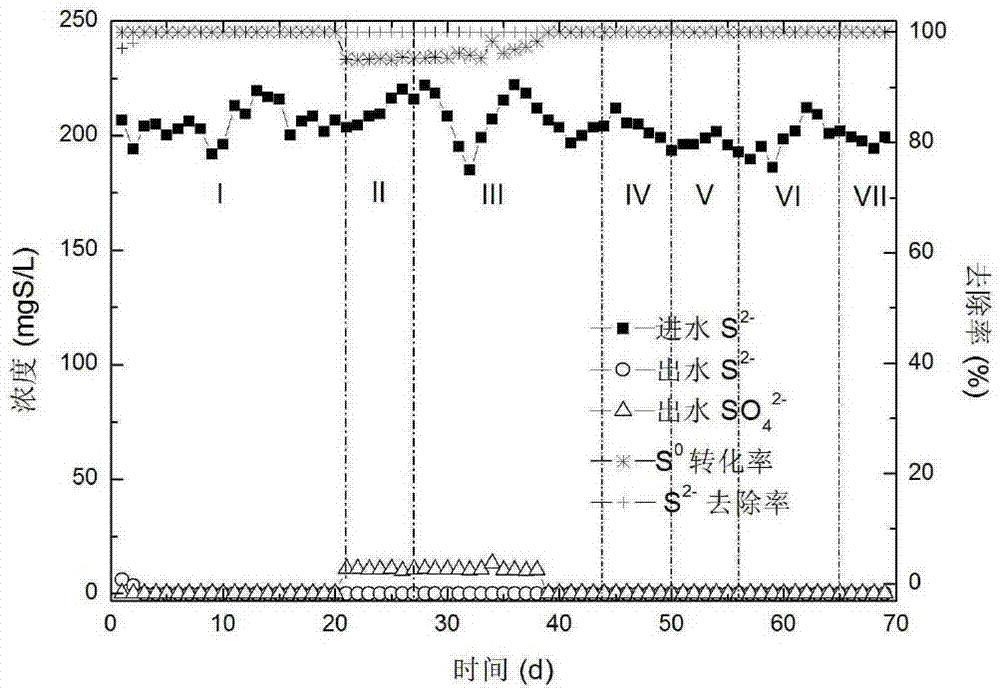

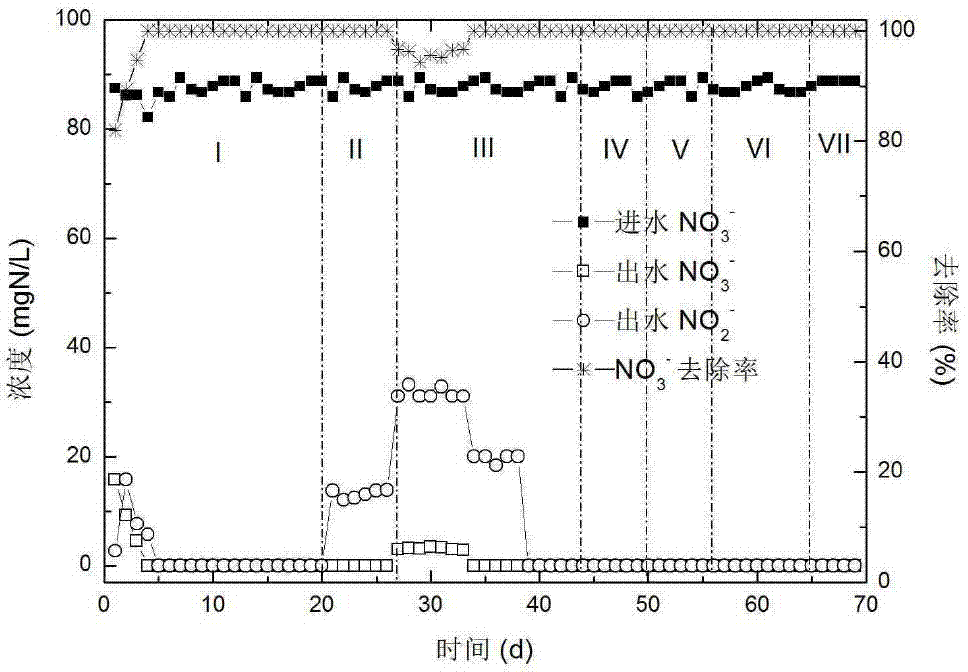

Rapid culture method for mixed culture denitrification desulphurization granule sludge

ActiveCN104773937ASimplify the cultivation stepsShort training periodTreatment with anaerobic digestion processesBiological sludge treatmentBiologyChloride sodium

The invention relates to a rapid culture method for granule sludge and provides a rapid culture method for mixed culture denitrification desulphurization granule sludge. The rapid culture method provided by the invention overcomes the problems of a long period, high operation cost and poor effects of a mixed culture denitrification granule sludge process due to introduction of harmful microbes in culture of mixed culture denitrification desulphurization granule sludge in the prior art. According to the invention, since activated sludge is used as inoculation sludge and granulation of the sludge is directly realized under the condition of addition of sodium chloride, the tedious steps of culture of sulfate reduced granule sludge at first and domestication of the mixed culture denitrification desulphurization granule sludge next are omitted, culture time for the granule sludge is shortened, and operation cost is saved; moreover, usage of methane-producing sludge as the inoculation sludge and introduction of harmful microbes are prevented, and high-efficiency operation efficacy of the denitrification desulphurization granule sludge is guaranteed; meanwhile, elemental sulfur is recovered, and reclamation of wastes is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cab side window for rail transit locomotive

ActiveCN104963591AEven by forceExtended service lifeWing arrangementsWing suspension devicesEngineeringBlock match

The invention provides a cab side window for a rail transit locomotive. The cab side window comprises a bottom cross beam, a side window fixing frame, a glass supporting beam, a glass fixing frame, side window glass, a crank-connecting rod-sliding block mechanism and sliding rails. The length direction of the sliding rails is vertically arranged, the sliding rails are located in the center of the side window fixing frame in the width direction, the bottom ends of the sliding rails are fixedly connected to the bottom cross beam, and the top ends of the sliding rails are directly or indirectly connected to the side wall of a locomotive cab fixedly. A sliding block matched with the sliding rails is connected with the glass supporting beam. One end of a crank-connecting rod assembly is fixedly connected to the side window fixing frame, and the other end of the crank-connecting rod assembly and the sliding block are connected to form the crank-connecting rod-sliding block mechanism so as to support the sliding block to vertically move up and down in the sliding rails along with the side window glass. An existing crank-connecting rod mechanism which is eccentrically stressed is replaced with the crank-connecting rod-sliding block mechanism which is centrally stressed, the improved side window is balanced in stress, abrasion to an aluminum alloy window frame is reduced in the opening and closing processes of the side window, and the normal service life of the side window is prolonged.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

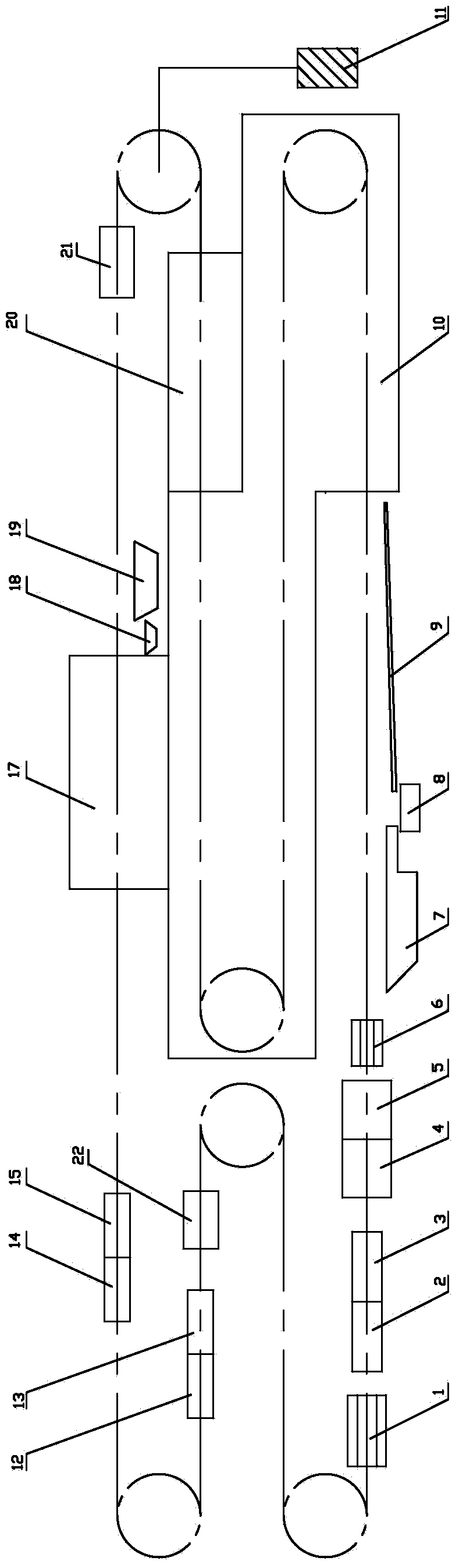

Two-hand mould PVC (polyvinyl chloride) glove production equipment

The invention discloses two-hand mould PVC (polyvinyl chloride) glove production equipment. The two-hand mould PVC glove production equipment comprises a hand mould railway line and a glove production line, wherein the hand mould railway line is arranged above the glove production line, and the hand mould railway line is a two-hand mould railway line and is composed of a two-hand mould main railway and a two-hand mould subsidiary railway; the two-hand mould main railway is an open type U-shaped railway, the two-hand mould subsidiary railway is a single-side double-layer rail, the glove production line is successively provided with a pre-dropping device, demoulding devices of No.1 and No.2 lines, counting machines of No.1 and No.2 lines, a mould-cleaning device, a PVC material groove, a PVC recovering groove, a PVC drip-drooping section, a PVC main oven, a smoke collecting section, a PU material groove, a PU drip-drooping recovering groove, a PU oven, a hemming of No.2 line, an edge-shaping machine, a hemming of No.1 line and an edge-shaping machine, wherein the smoke collecting section is respectively communicated with the PVC main oven and the PU oven, and a production line balance-weight system is arranged between the smoke collecting section and the PU material groove. Compared with the traditional single-hand mould PVC production line, the two-hand mould PVC glove production equipment provided by the invention has the advantages that the production efficiency is improved, and the energy consumption is effectively reduced.

Owner:安徽英科医疗用品有限公司

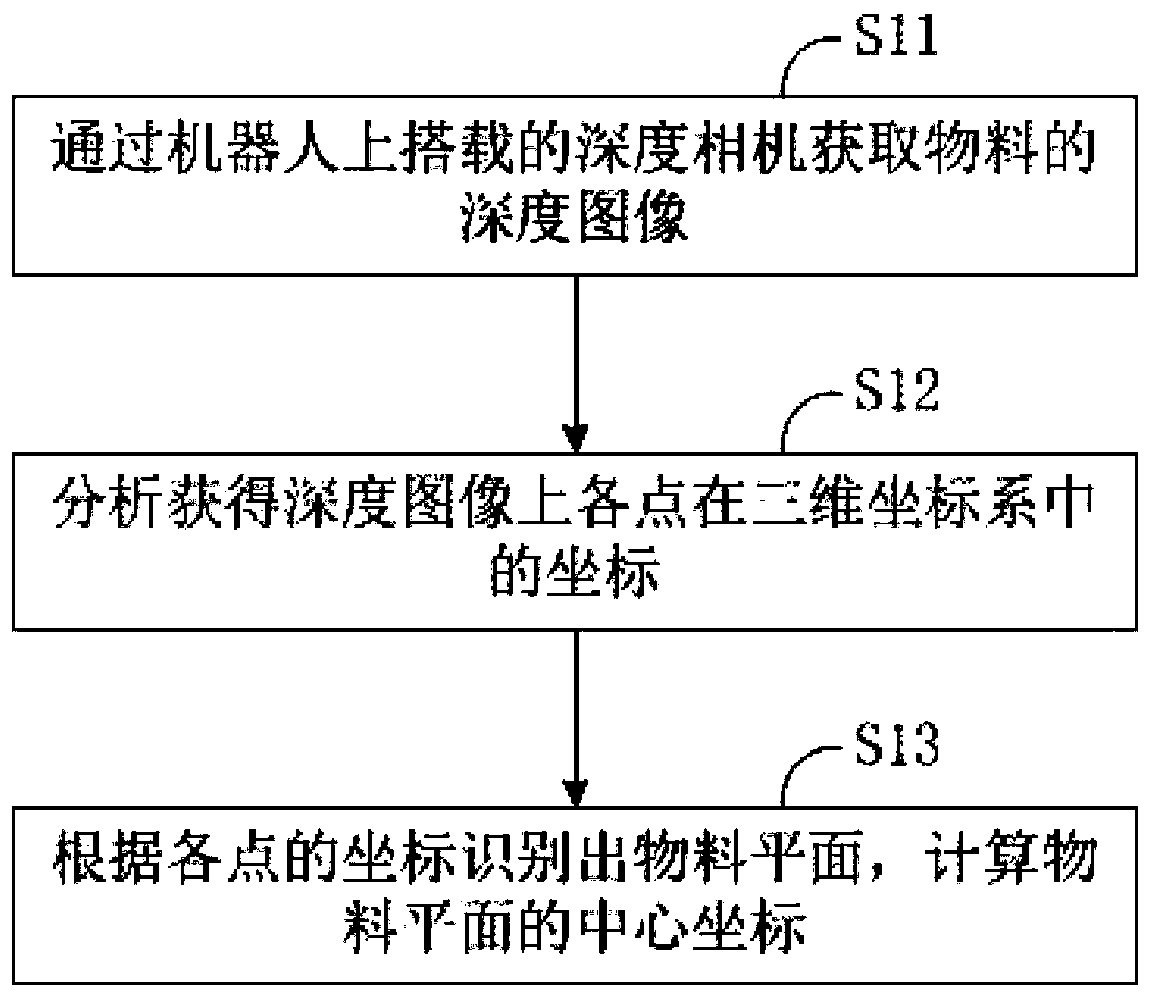

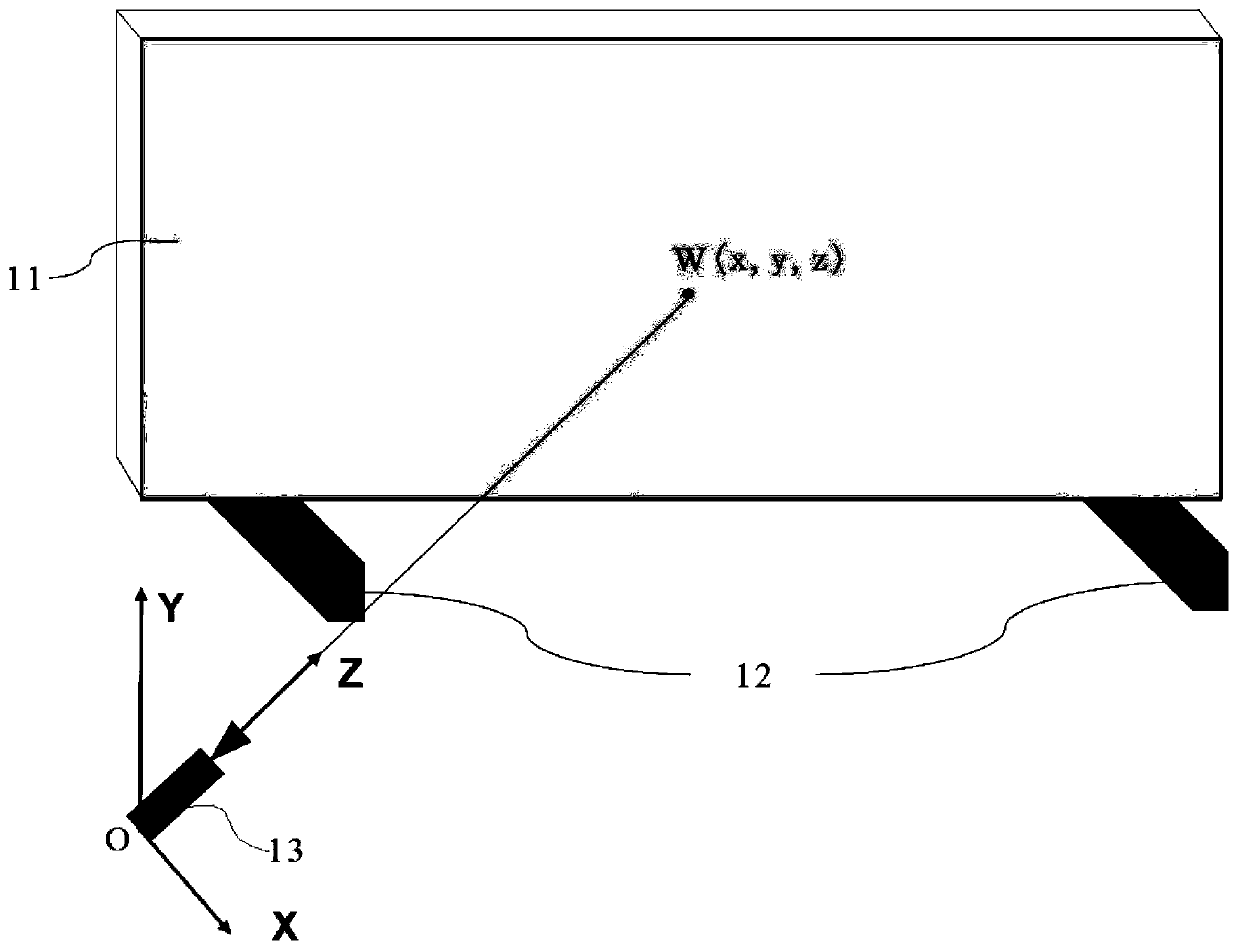

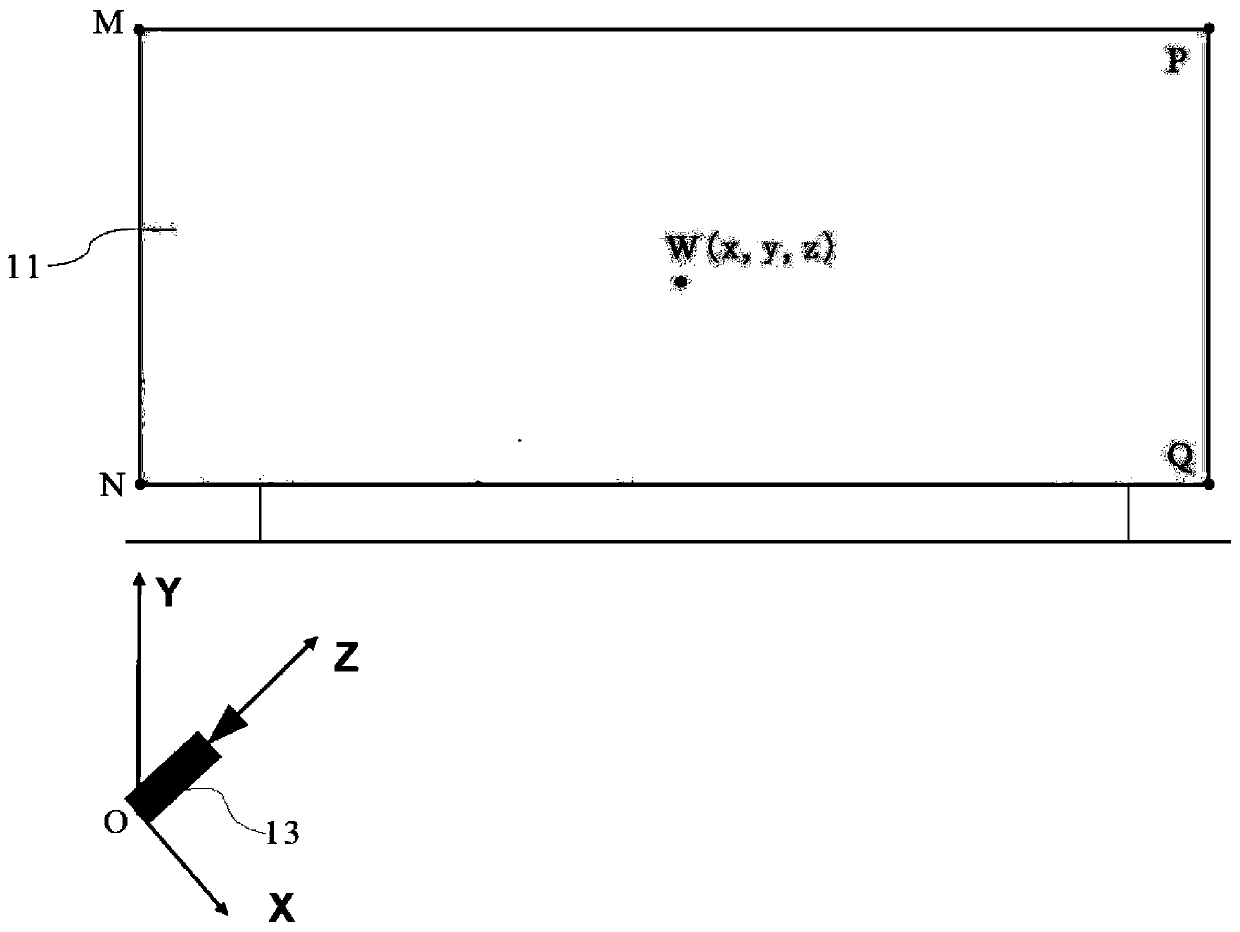

Visual positioning method of large-size material and carrying robot

ActiveCN110455189AGuaranteed forceEliminate potential safety hazardsImage enhancementImage analysisVisual guidanceImaging processing

The invention discloses a visual positioning method of a large-size material and a carrying robot, and relates to the technical field of machine vision. The visual positioning method comprises the following steps of acquiring a depth image of a material through a depth camera; carrying out analyzing to obtain coordinates of each point on the depth image in a three-dimensional coordinate system; and identifying a material plane according to the coordinates of all points, and calculating the center coordinates of the plane of the material. The depth image of the material is acquired at the viewing angle of the carrying robot through the depth camera, the plane of the material can be identified through image processing and analysis, and the coordinates of the geometric center of the materialin the three-dimensional coordinate system can be calculated, so that visual guidance is provided for the carrying robot, the carrying robot can grab the material according to the center point of thematerial, and the material is guaranteed to be uniformly stressed, balanced and the like in the carrying process. In this way, the carrying robot can be free of the auxiliary of constructors, materialconveying is independently completed, and potential safety hazards are eliminated.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

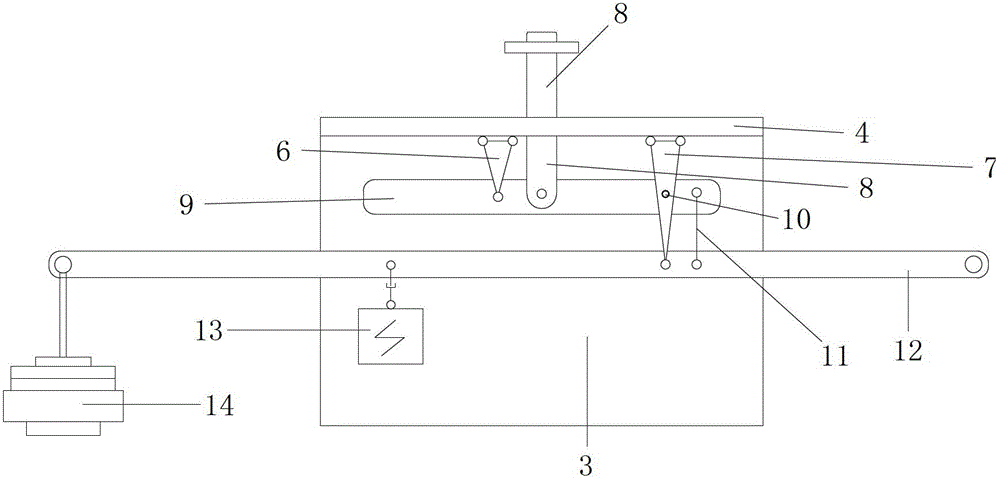

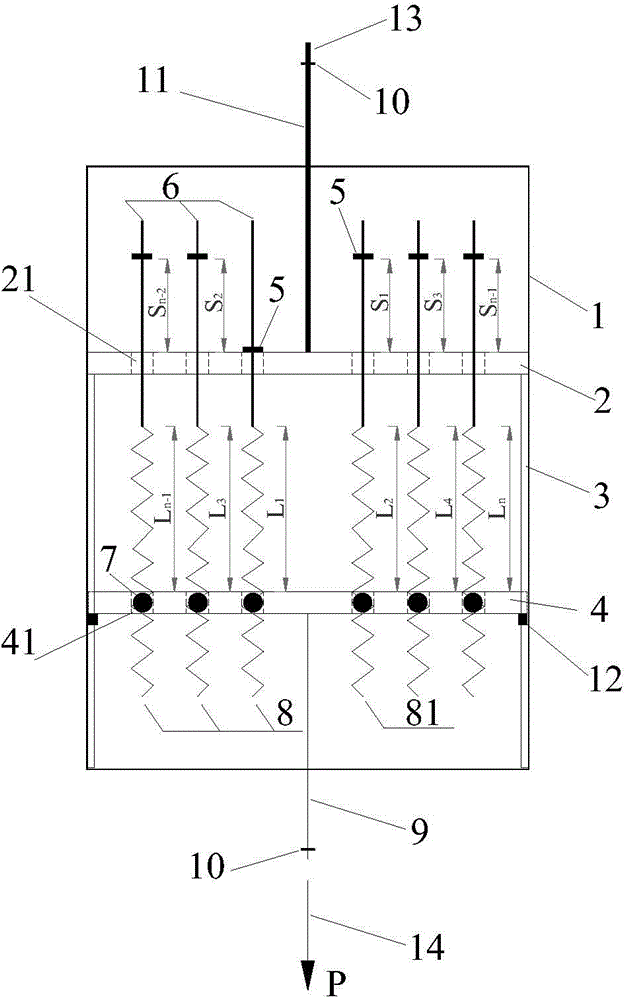

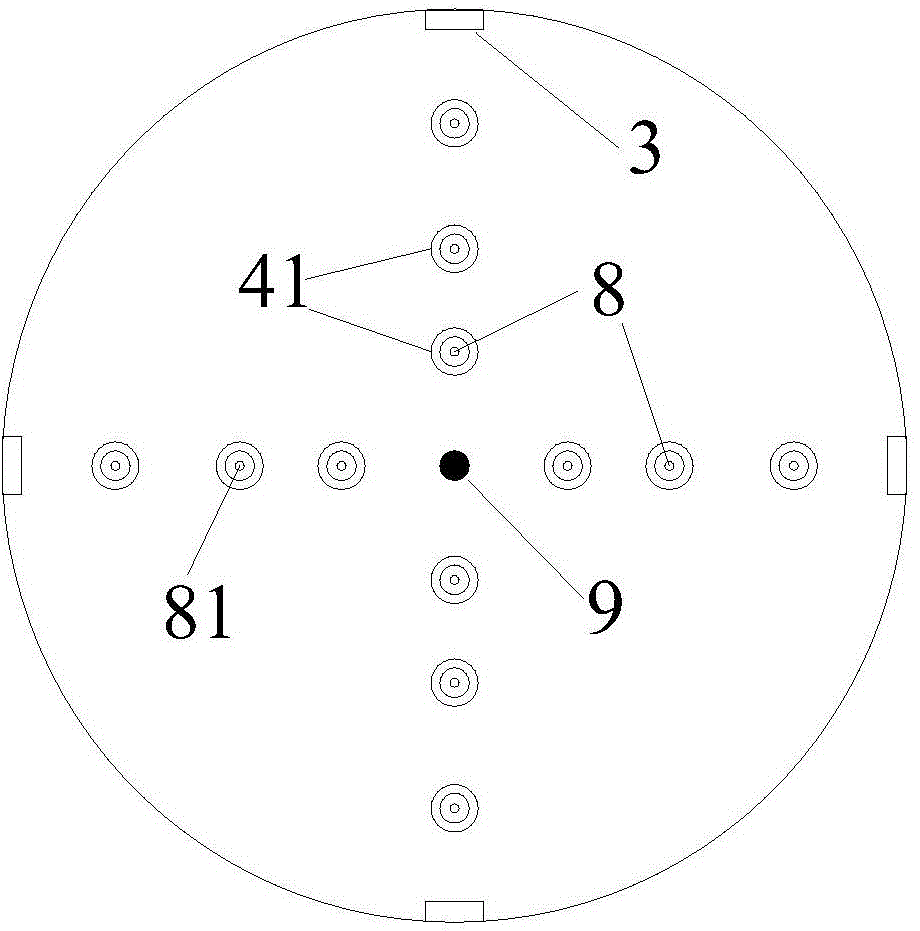

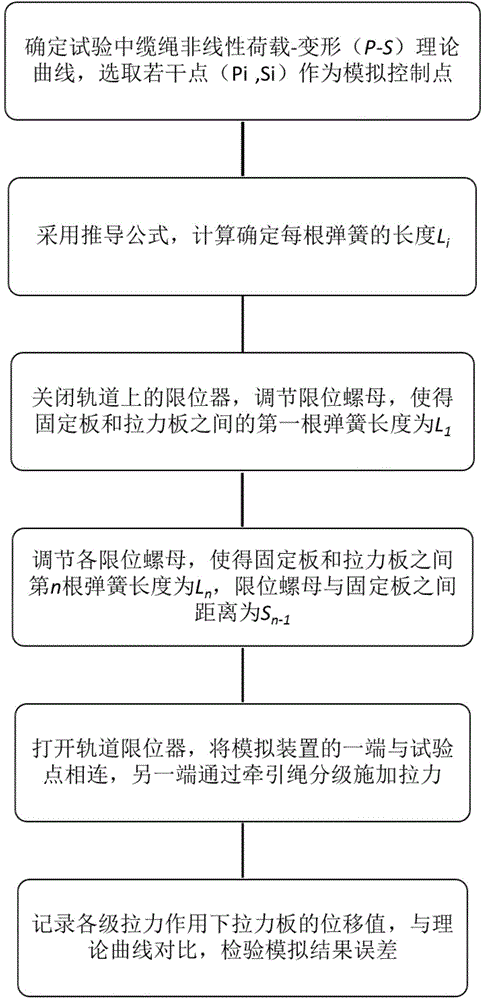

Cable simulation device and cable simulation method in ship mooring physical model test

ActiveCN104155131ALower test experience requirementsHighly theoreticalStructural/machines measurementEducational modelsPull forcePhysical model

The invention discloses a cable simulation device and a cable simulation method in a ship mooring physical model test. The cable simulation device comprises a box body, wherein tracks, spring systems, as well as a fixed plate and a tension plate which are horizontally arranged in parallel up and down, are arranged inside the box body; the tension plate can slide up and down along the tracks; the spring systems comprise a plurality of springs and connection pull rods which are different in lengths; the cable simulation method comprises the following steps: according to stress deformation characteristics of a cable to be simulated, the length of each spring and the length of each pull rod are calculated and determined, so as to constitute the spring systems and to keep connection with the tension plate; graded pulling forces are exerted; corresponding elongation of the tension plate is measured; through the spring systems with various lengths, nonlinear tension-elongation relation of the cable is simulated and the tension-elongation relation curves are drawn; the tension-elongation relation curves are compared with the stress deformation theoretical curves of the simulated cable; errors of the test results are checked. The cable simulation device provided by the invention solves technical problem of nonlinear load and deformation relation simulation of the cable in a ship mooring physical model test; the operability is good; the accuracy and the efficiency are high; the experimental effects are favorable.

Owner:嘉兴快闪新材料有限公司

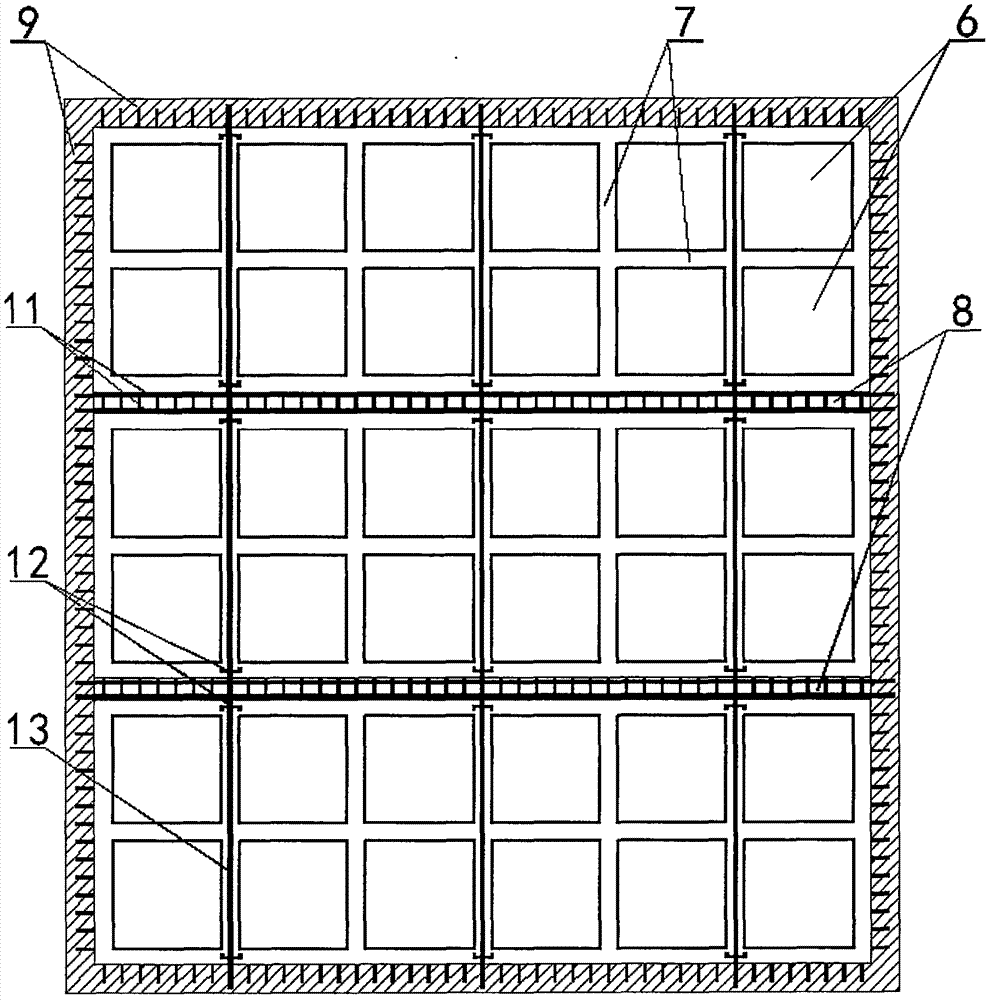

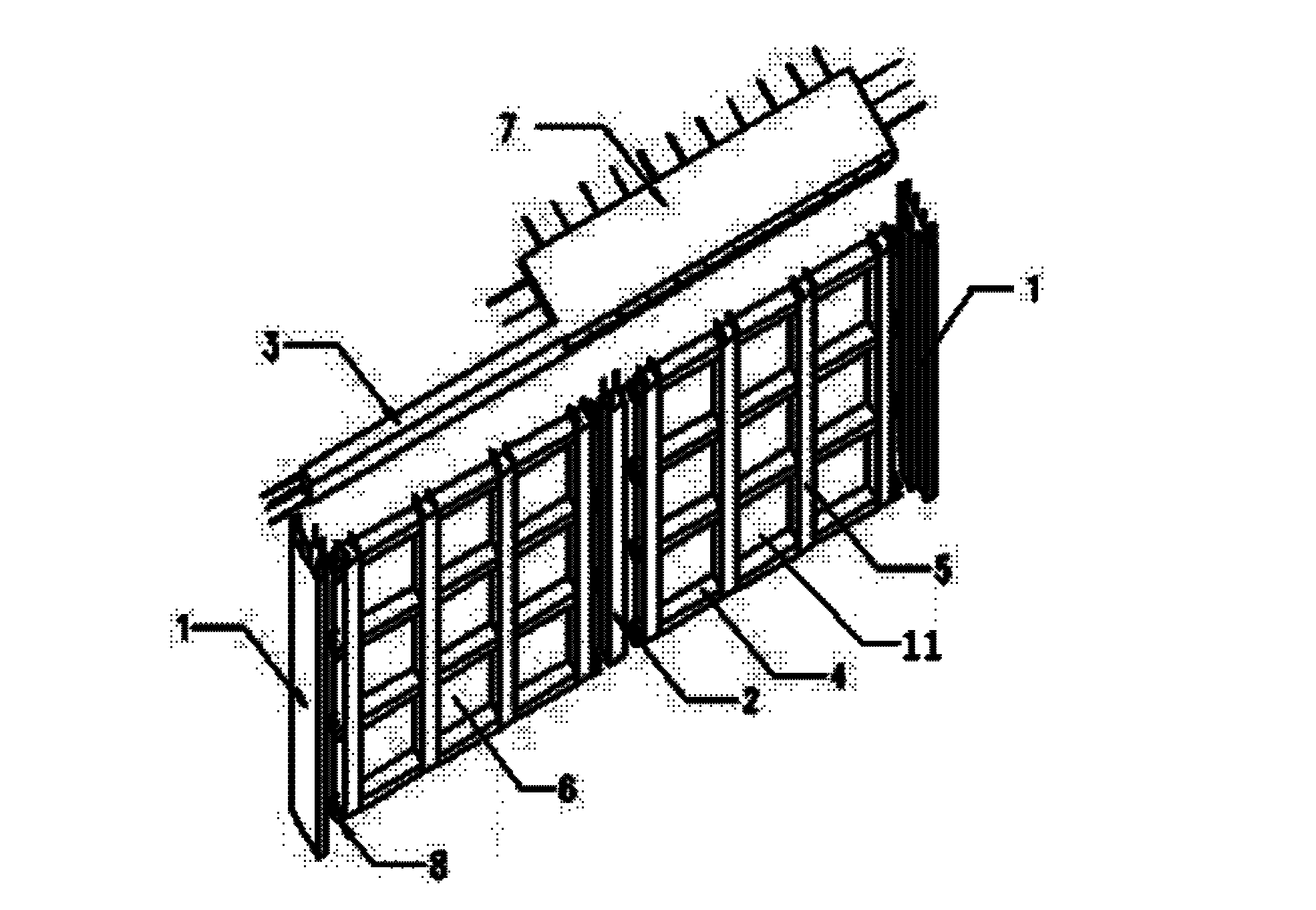

Energy dissipating and shock absorbing system having dense reinforcement structure

The invention discloses an energy dissipating and shock absorbing system having a dense reinforcement structure, which comprises a concealed frame consisting of ending columns, connecting columns and a concealed beam. A floor slab is connected to the concealed beam horizontally, a part of the concealed frame is provided with dense reinforcement composite wall boards with low yield point, and the other part of the concealed frame is provided with light dense reinforcement composite wall boards filled with bricks. The invention provides another energy dissipating and shock absorbing system having a dense reinforcement structure, which comprises a concealed frame consisting of ending columns, connecting columns and a concealed beam, floor slabs are horizontally connected to the concealed beam, and dense reinforcement composite wall boards with low yield points are arranged in the concealed frame fully. Besides, the dense reinforcement composite wall boards with low yield points comprises multiple reinforced beams and reinforced columns which form rectangular grid structures, and steel plates with low yield point are embedded into the grids. The energy dissipating and shock absorbing system having the dense reinforcement structure is simple in structure, high in energy dissipation, stable in in energy dissipation performance and fine in shock absorption.

Owner:XIAN UNIV OF TECH

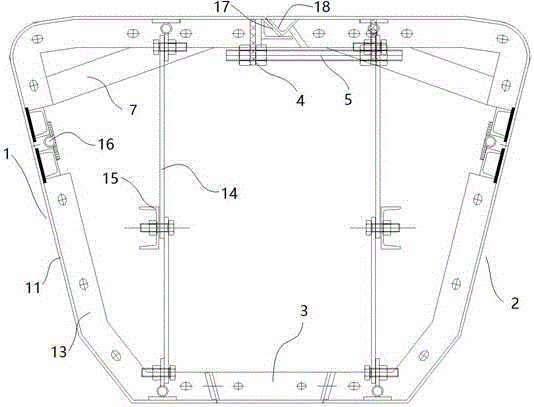

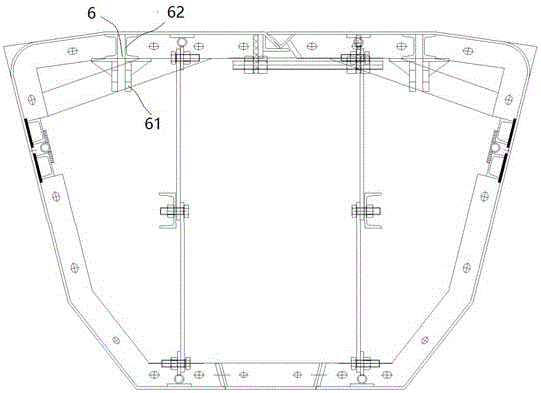

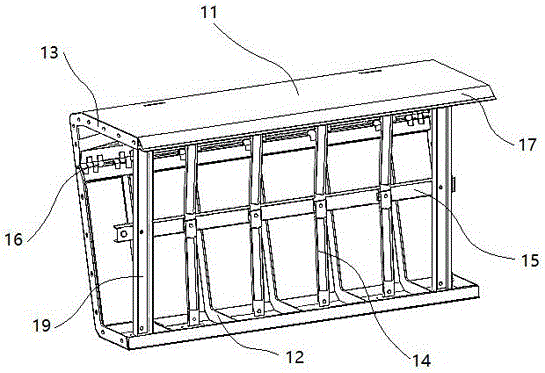

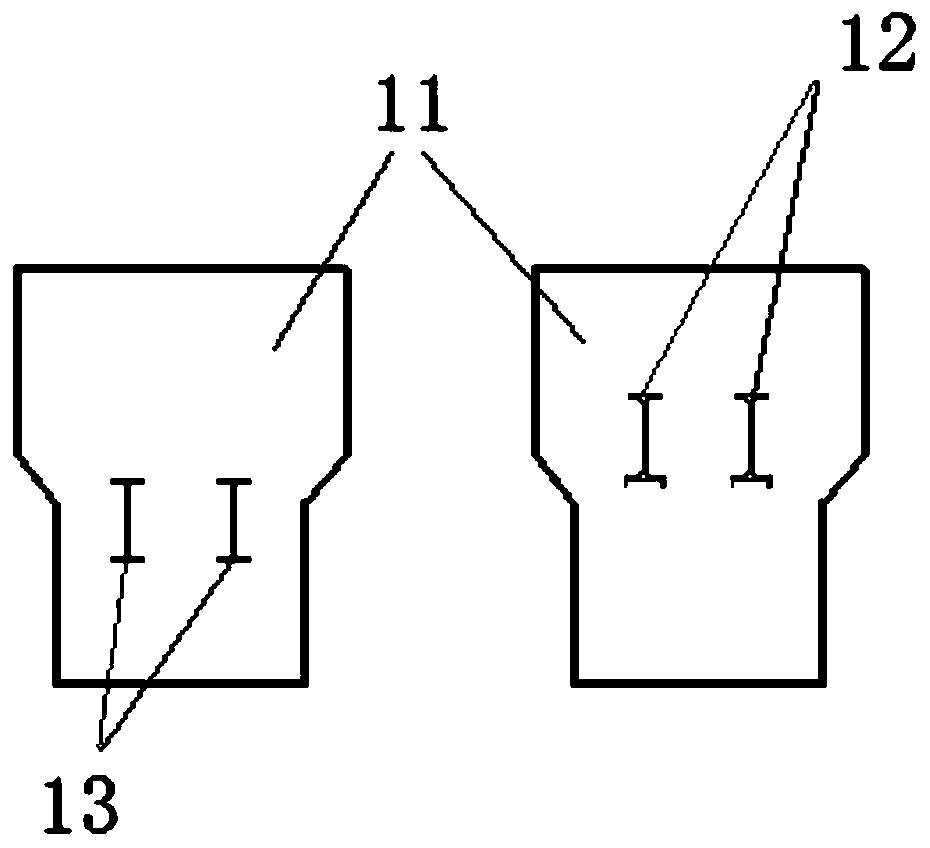

Integral disassembly box girder internal mold and use method thereof

ActiveCN106351127AGuarantee product qualityGuaranteed forceBridge structural detailsBridge erection/assemblyEngineeringBox girder

The invention relates to an integral disassembly box girder internal mold. The internal mold comprises support end molds and mid-span molds, wherein the support end molds are arranged on the end parts of the two ends of a box girder; the mid-span molds are arranged on the middle part of the box girder; a plurality of mid-span molds are spliced together; flange plates of adjacent mid-span molds stick close to each other, and are connected together through flange bolts; the support end molds are connected to the two ends through flange bolts respectively. In an integral disassembly method for the internal mold during box girder machining, a fixed support and a lower compensating plate are removed firstly during integral disassembly, a hoist tensions a pull rod to bend a brace, and an inverted-L-shaped structure and an L-shaped structure are enclosed around a hinge to be separated from the inner cavity of the box girder so as to be pulled out after being contracted. By adopting the internal mold and the use method thereof, integral demolding can be realized; moreover, the quantity of molds can be increased according to the actual length of the box girder, so that convenience and rapidness in use are realized.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

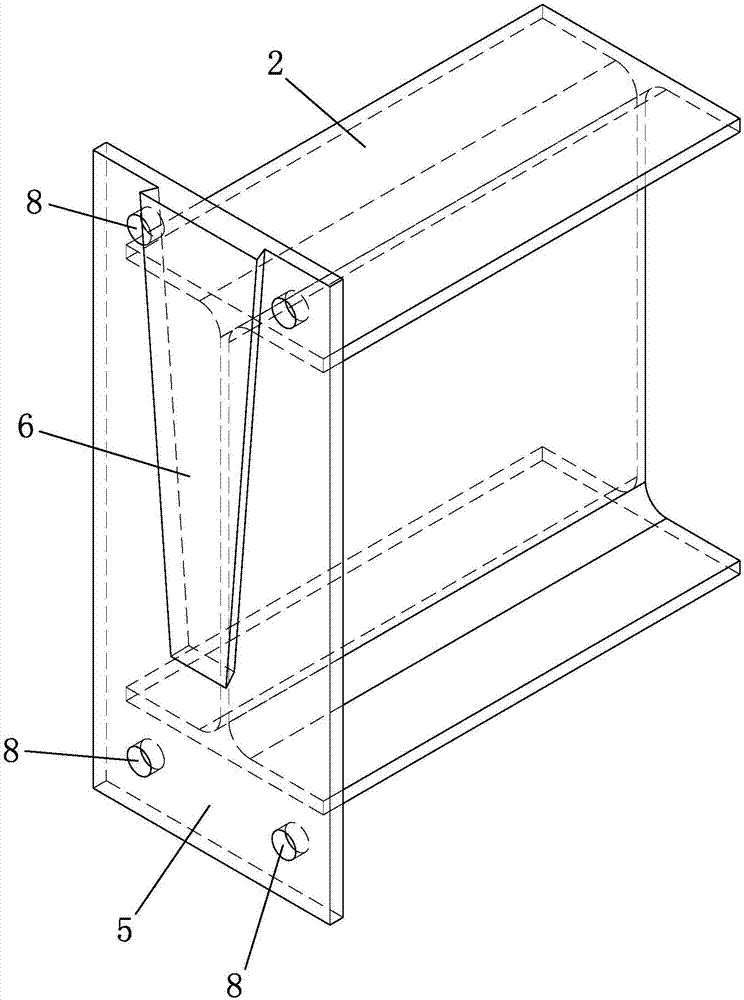

Steel structure beam column mortise-and-tenon-joint-type fast installing joint and installing method thereof

InactiveCN107476436ASmall section widthRealize self-locking connectionBuilding constructionsMortise and tenonJoints types

The invention discloses a steel structure beam column mortise-and-tenon-joint-type fast installing joint and an installing method thereof. The joint comprises a steel pipe column and a steel beam. The steel pipe column is provided with a reinforced attaching plate. An embedding groove is formed in the reinforced attaching plate. The steel beam is provided with an end plate. An embedded tenon is formed in the end plate. The embedded tenon is matched with the embedding groove. A self-locking bolt is arranged between a second bolt hole and a first bolt hole. The self-locking bolt comprises an outer bolt and an inner core bolt. The exterior of the outer bolt is provided with a hex nut. The end part of the outer bolt is provided with an internally-extending blade piece. The installing method comprises the following steps of (a) reinforced attaching plate machining, manufacturing and installing, (b) end plate machining, manufacturing and installing, (c) outer bolt and inner core bolt manufacturing, (d), steel pipe column and steel beam self-locking connecting, (e), self-locking bolt manufacturing, (f), steel pipe column and steel beam fastening and connecting, and (g), installing and detecting. The steel structure beam column mortise-and-tenon-joint-type fast installing joint has the characteristics that joint construction is fast in place, and the installing precision is high, a joint connecting structure is accurate in force transferring and fast and convenient to construct, and the problem that the bolt at a joint area is not easily constructed is solved.

Owner:浙江中南绿建科技集团有限公司

Fabricated steel and concrete combination structure

The invention discloses a fabricated steel and concrete combination structure. The fabricated steel and concrete combination structure comprises frame columns and frame beams connected with the frame columns. The frame beams are composed of pure steel beam areas and steel-concrete combination beams connected with the pure steel beam areas, wherein joint core areas of the frame beams are the pure steel beam areas, and every two adjacent pure steel beam areas are connected through the corresponding steel-concrete combination beam. The invention further discloses a fabricated steel and concrete combination frame-shear wall structure. The fabricated steel and concrete combination frame-shear wall structure comprises a fabricated steel and concrete combination frame and reinforced concrete wallboards arranged on the inner side of the fabricated steel and concrete combination frame in a filling mode. The fabricated steel and concrete combination structure solves the problems that in the prior art, a fabricated reinforced concrete structure is poor in stress and deformation capacity and a steel structure is high construction cost.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

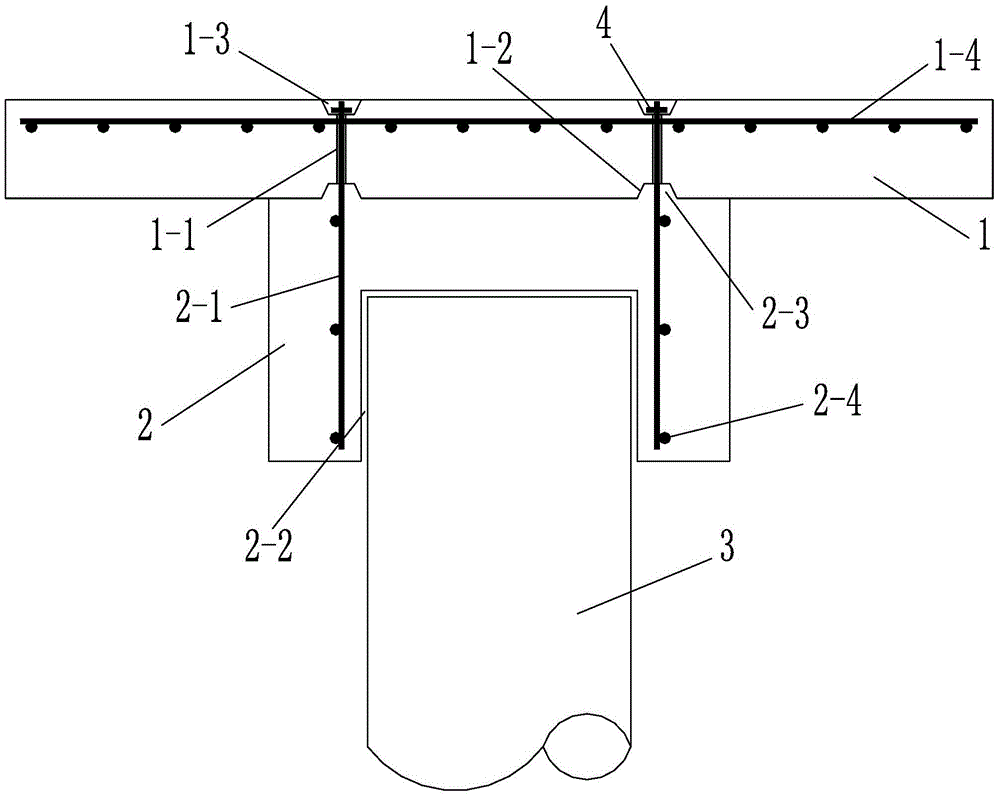

Prefabricated pile cap for composite foundation

The invention relates to a prefabricated pile cap for a composite foundation. The prefabricated pile cap comprises a top plate and a fixing sleeve connected onto the lower side surface of the top plate, wherein a plurality of locking rods are vertically distributed in the fixing sleeve and extend out of the upper end surface of the fixing sleeve, and a blind hole for sleeving a prefabricated pile is formed in the lower end of the fixing sleeve; locking through holes allowing the locking rods to penetrate through are correspondingly formed in the top plate, the top plate and the fixing sleeve are fixedly connected by the aid of locking nuts, and the locking nuts are rotationally arranged on the locking rods penetrating through the upper side surface of the top plate. With the adoption of the prefabricated pile cap for the composite foundation, the engineering construction speed and quality can be effectively increased, and the cost can be reduced. The prefabricated pile cap for the composite foundation has the advantages as follows: 1, the prefabricated pile cap for the composite foundation can be disassembled into the top plate and the fixing sleeve, so that all components cannot be overweight, construction is facilitated, and the rent of machinery can be reduced.

Owner:ARCHITECTURAL DESIGN INST FUKIEN PROV

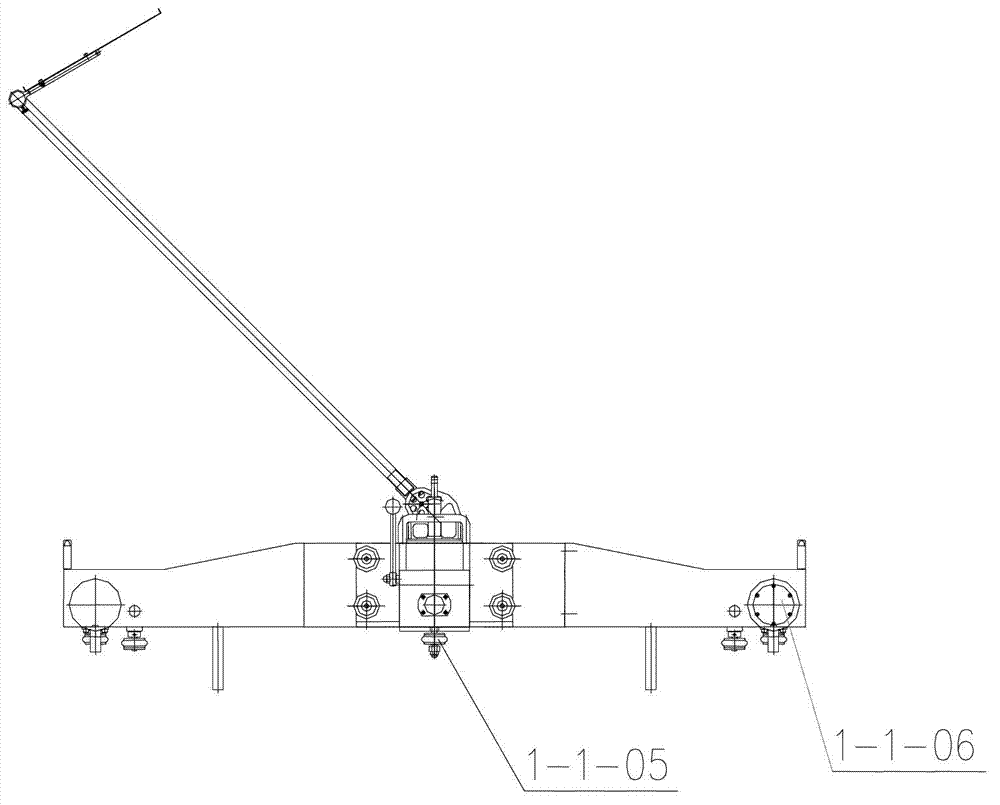

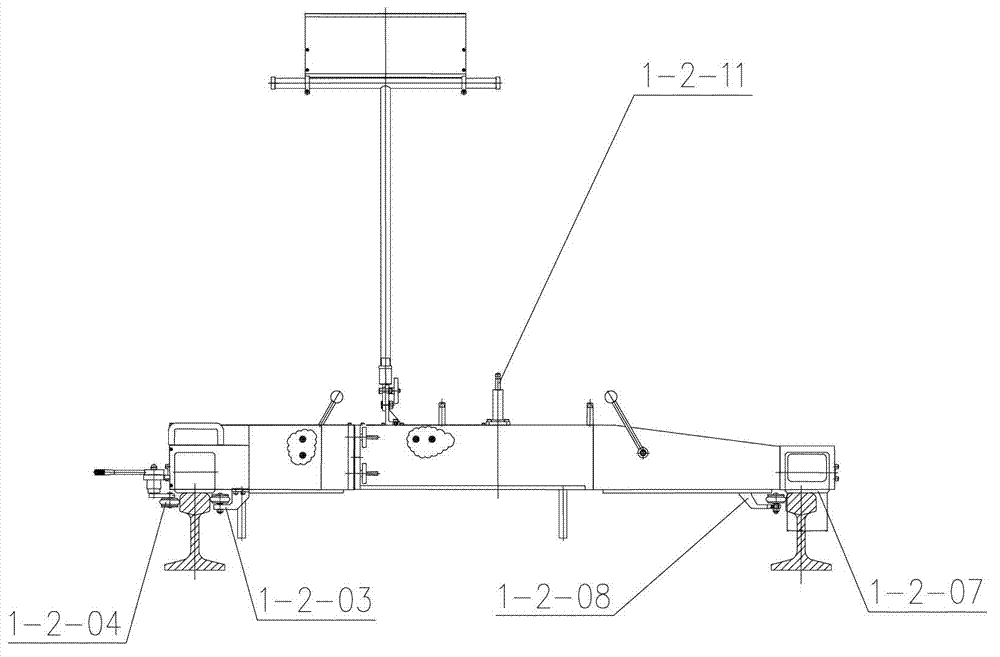

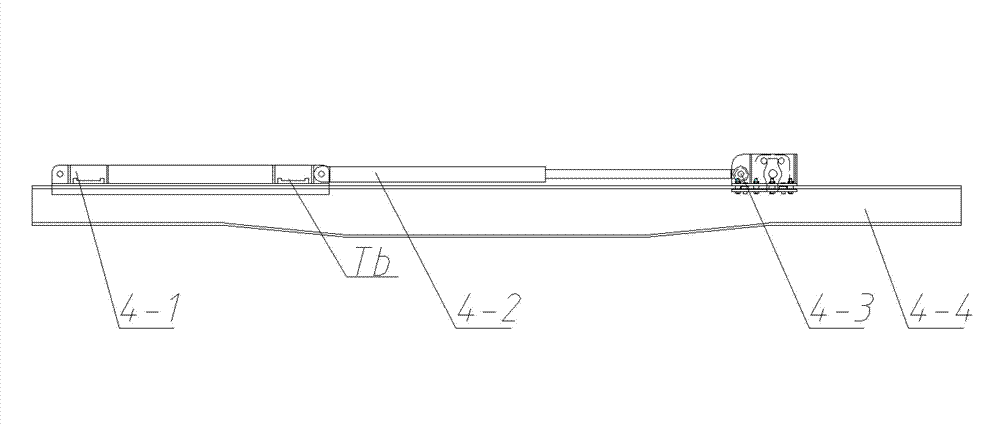

Method for detecting geometrical morphology of railway track

InactiveCN103205920AStable structureEnsure force distribution and structural stabilityMeasuring apparatusTotal stationTesting equipment

The invention discloses a method for detecting geometry morphology of a railway track. The method includes setting total-station instruments on a railway line by the aid of known control points of the railway line; placing track geometrical morphology detecting equipment on steel rails of a railway; measuring spatial three-dimensional coordinates of centers of prisms and geometrical position data of the track geometrical morphology detecting equipment by the aid of the total-station instruments; and acquiring geometrical morphology data of the railway track where the track geometrical morphology detecting equipment is located according to spatial coordinate data and the geometrical position data. The method for detecting the geometrical morphology of the railway track has the advantages that the measurement accuracy is high, and required railway track geometrical morphology detectors are simple in structure and can be mounted conveniently and quickly.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

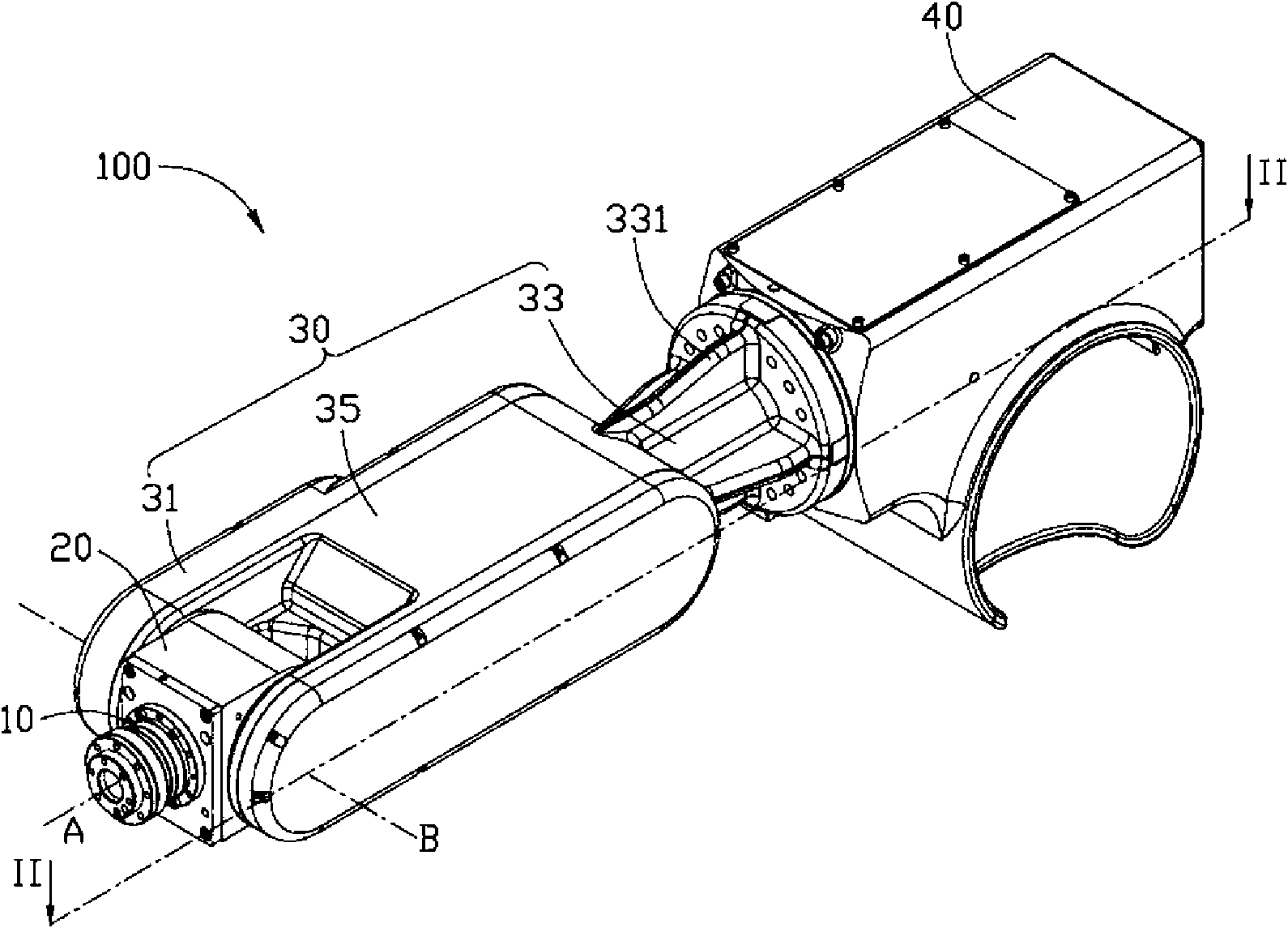

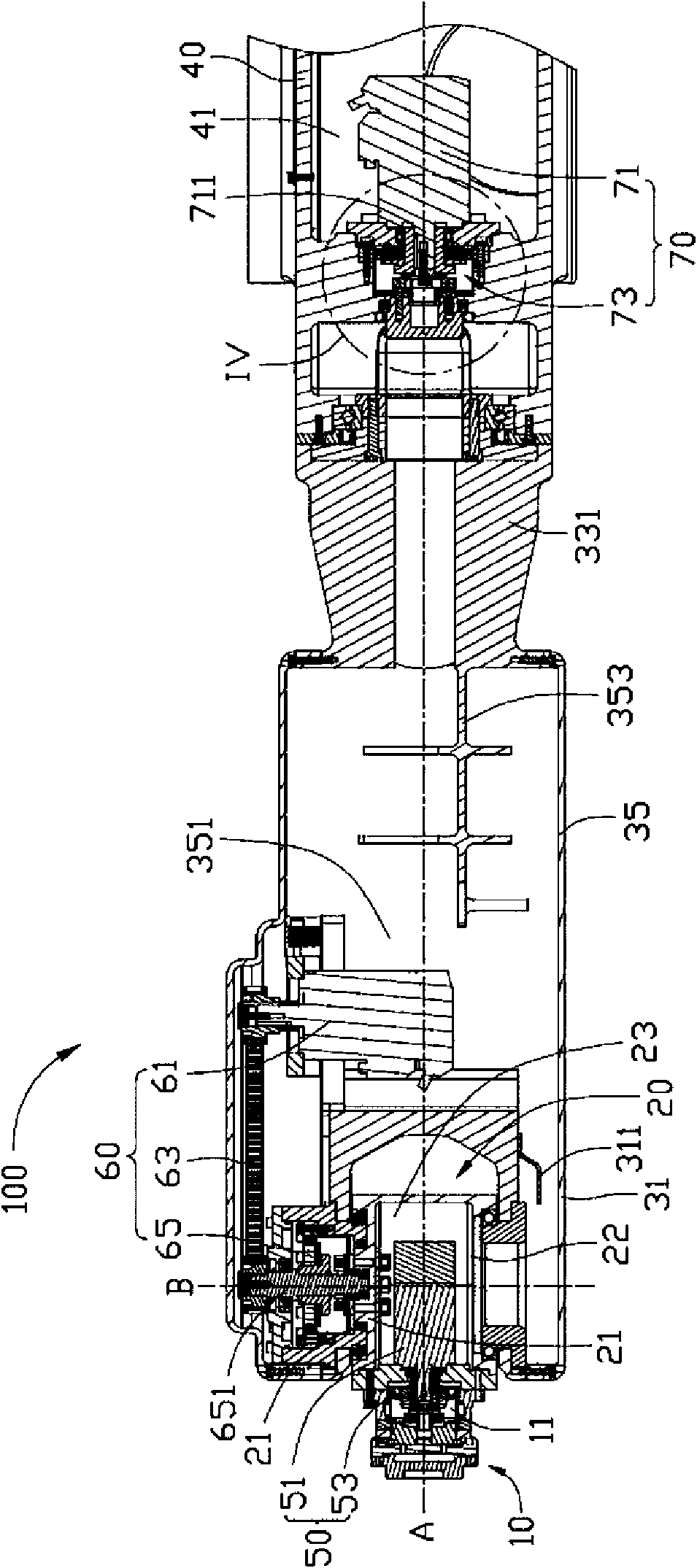

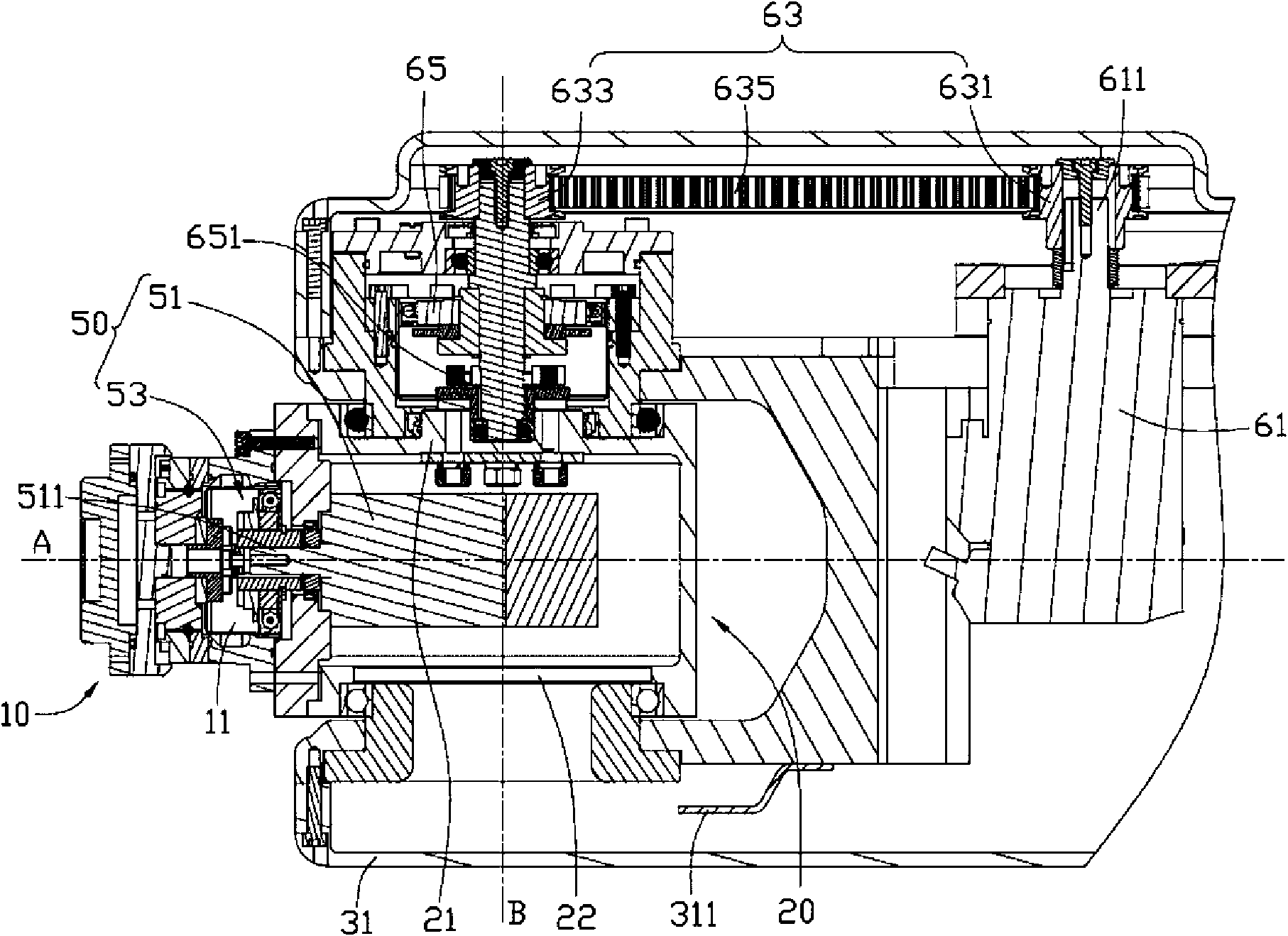

Robot structure

The invention discloses a robot structure, comprising a first shaft subassembly, a second shaft subassembly and a third shaft subassembly which are mutually pivoted and rotatable relatively, a first wrist unit at a pivoting part between the first shaft subassembly and the second shaft subassembly, and a second wrist unit at a pivoting part between the second shaft subassembly and the third shaft subassembly, wherein the first wrist unit comprises a first driving piece for driving the first wrist unit, the second wrist unit comprises a second driving piece for driving the second wrist unit, and the second wrist unit further comprises a transmission mechanism for transferring the power of the second driving piece to the second shaft subassembly, the first driving piece and the second driving piece are located at same side of the transmission mechanism, two ends of the second shaft subassembly are both pivoted with the third shaft subassembly, the first driving piece is arranged in the second shaft subassembly, the second driving piece is located in the third shaft subassembly, and the first driving piece and the second driving piece are arranged in a mutually approaching direction. The robot structure has the characteristics of small and smart structure and high carrying capacity.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

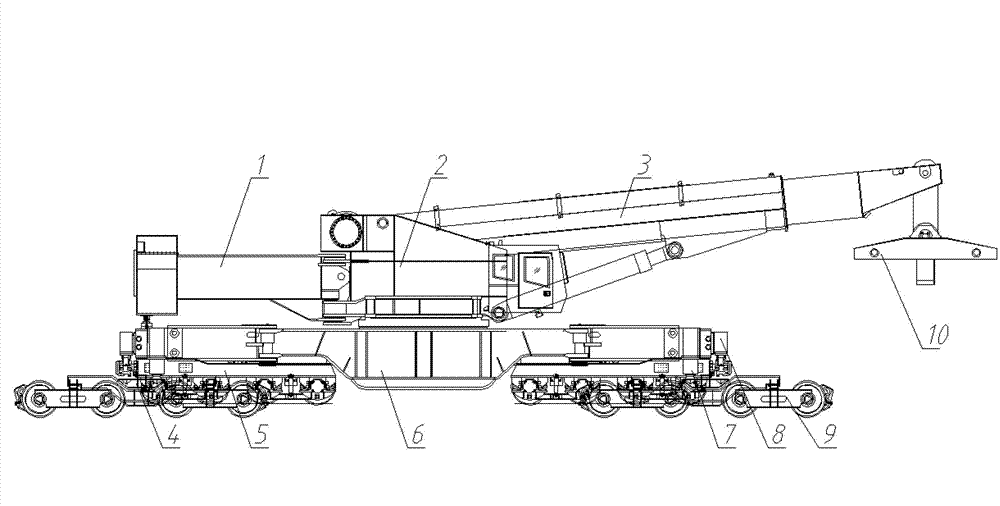

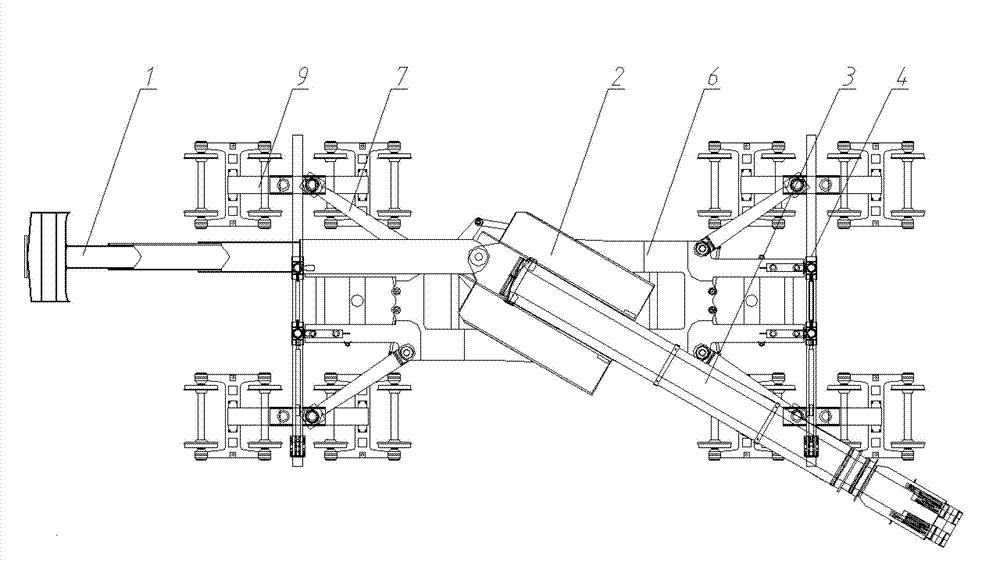

Overline operation crane for high-speed railways

ActiveCN102862580AGet rid of influenceGet rid of constraintsCranesBreakdown cranesButt jointEngineering

The invention relates to an overline operation crane for high-speed railways, belongs to the field of cranes and particularly relates to high-speed railway and rail transit cranes. Two transversing mechanisms including a front transversing mechanism and a back transversing mechanism are respectively erected on four supporting trolleys of a double-line rail, and are in butt joint with the crane through auxiliary supporting legs, and the crane is separated from the original rail line under action of auxiliary supporting leg jacking cylinders, and transverses to the middle of the double-line rail. The front transversing mechanism and the back transversing mechanism moves to be close to the center of the crane together with the front and back corresponding supporting trolleys by retracting effect of the auxiliary supporting legs. Until the auxiliary supporting legs are retracted completely, four crane supporting legs of the crane are unfolded, ball hinges at the tail ends of cylinders of the four crane supporting legs are disposed in ball hinge seats of longitudinal beams of the four supporting trolleys on the double-line rail, and then acting force of the crane to a single-line rail is distributed to the double-line rail successfully, so that operations including overline craning and the like can be carried out for the high-speed railways, and requirements for large-tonnage cranes during rescue and construction on bridge sections of the high-speed railways are met.

Owner:WUHAN BRIDGE INDUSTRIAL EQUIPMENT COMPANY LTD

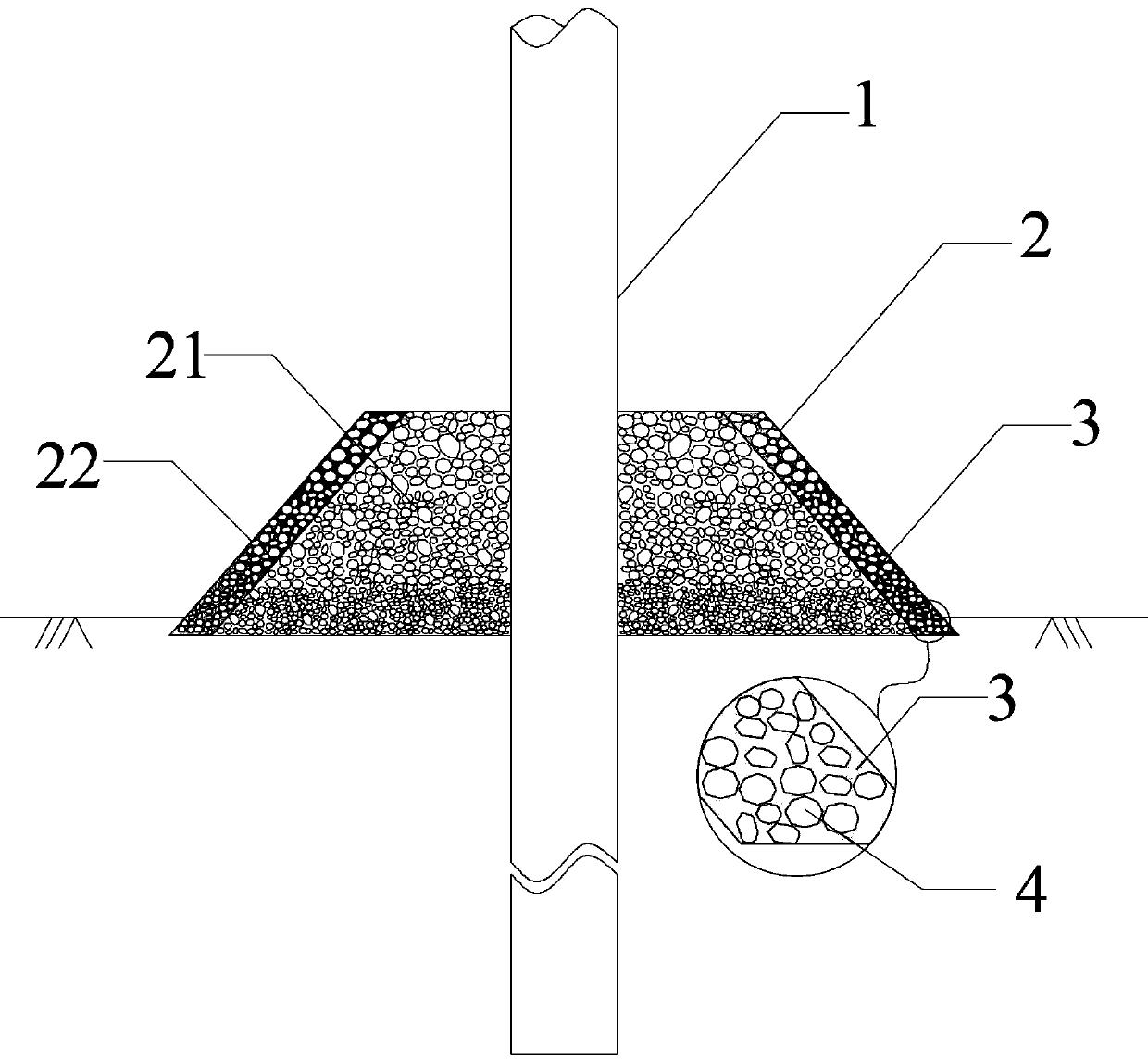

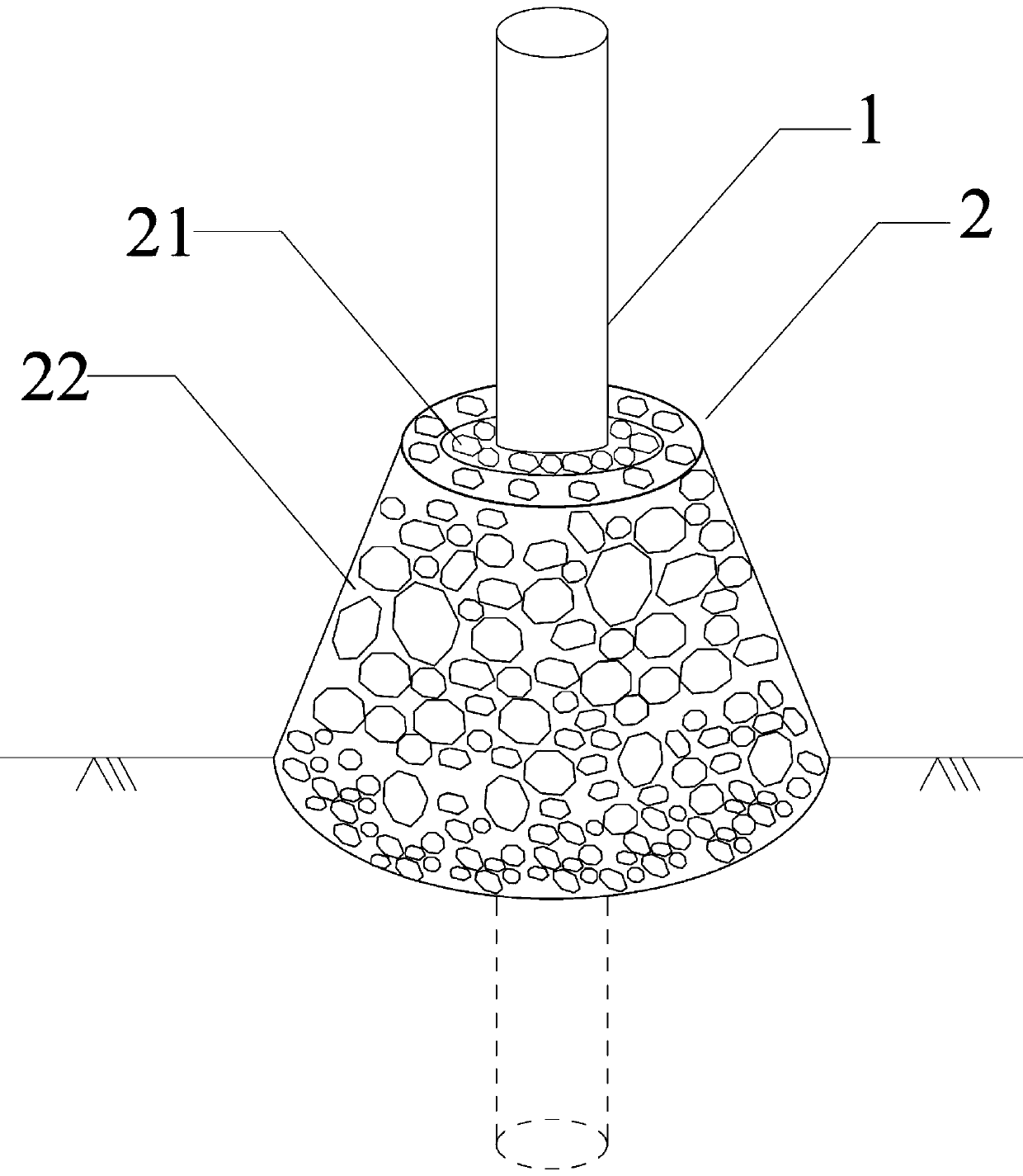

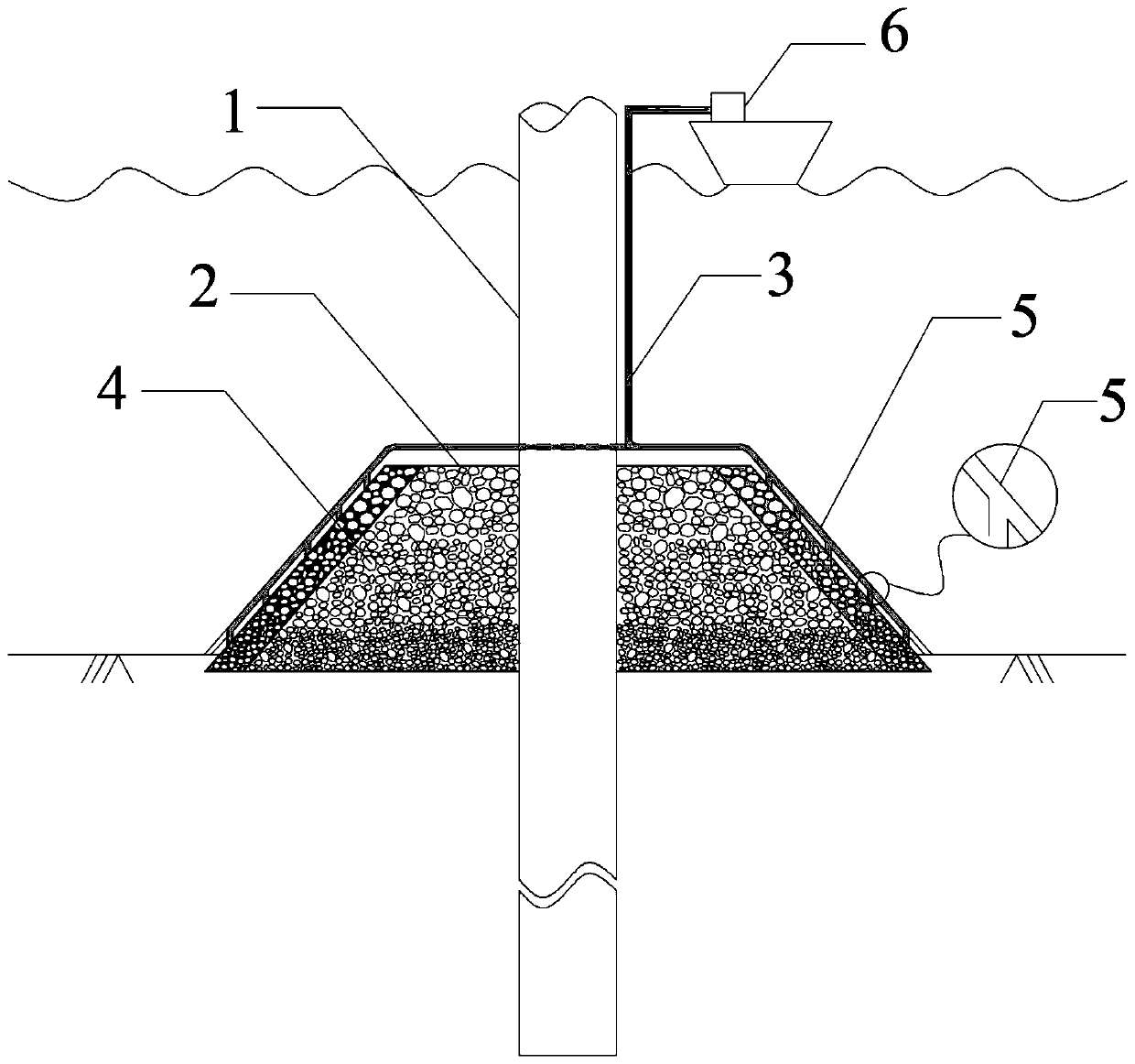

Offshore wind power single pile-friction cone composite foundation and construction method thereof

PendingCN110984213AImprove carrying capacityImprove bearing capacityFoundation engineeringCrushed stoneOffshore wind power

The invention discloses an offshore wind power single pile-friction cone composite foundation and a construction method thereof. The offshore wind power single pile-friction cone composite foundationcomprises a single pile and a friction cone, wherein a rock-fill body is arranged inside the friction cone, a cemented rock-fill body shell is arranged outside the friction cone, and the cemented rock-fill body shell is obtained by grouting and cementing the rock-fill body outside the friction cone. The construction method of the offshore wind power single pile-friction cone composite foundation comprises the following steps of 1, carrying out single pile construction by using pile sinking equipment; 2, stacking graded crushed stone materials on seabed around the single pile to form the friction cone; 3, placing a grouting device on the surface of the rock-fill body outside the friction cone; and 4, conveying underwater self-protection cementing materials through the grouting device, wherein the cementing materials fill gaps of the rock-fill body outside the friction cone to form a cemented rock-fill body. The offshore wind power single pile-friction cone composite foundation has the advantages of high horizontal bearing capacity, small pile body horizontal displacement, deformation and bending moment and the like, and has the characteristics of simple construction, high adaptability to geological conditions and the like.

Owner:CHINA THREE GORGES CORPORATION

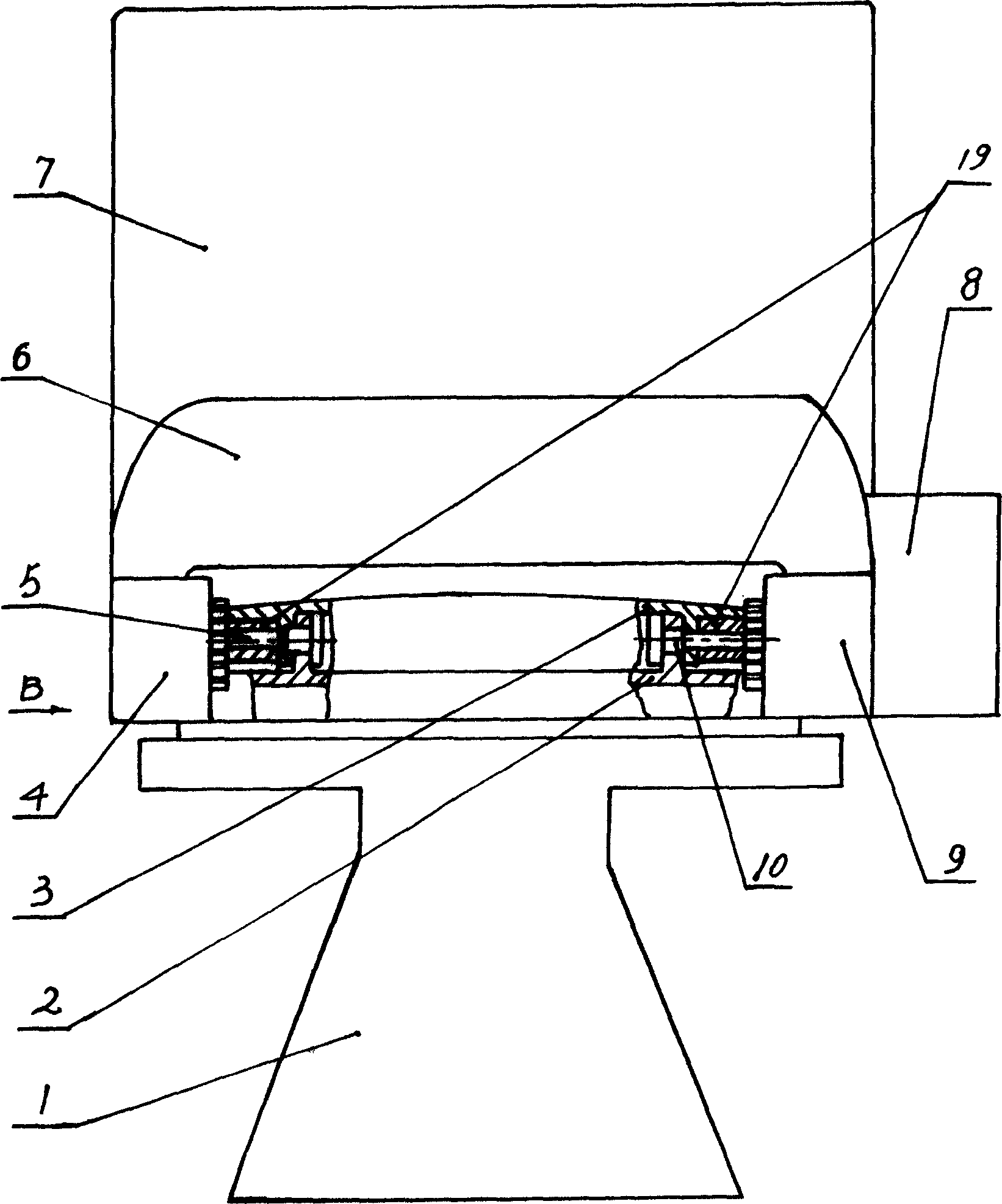

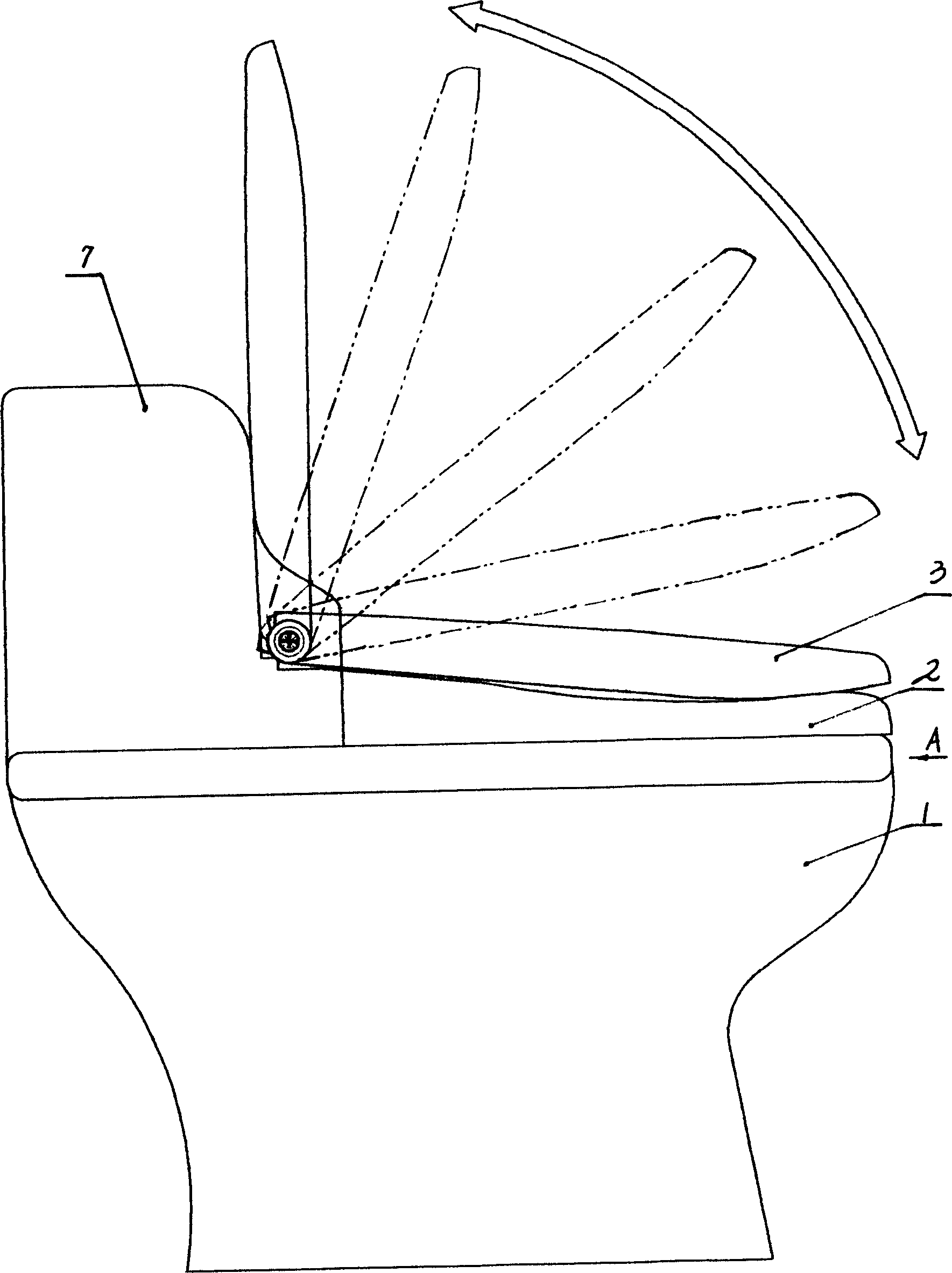

Automatic on-off device of toilet bowl

An automatic open / close device for opening or closing he seat cover and seat ring of the water closet is disclosed. It includes a water closet, a water tank installed on the water closet, a seat cover, a seat ring, two electric machine mounted on the each side of the water closet.One side of the electric machine drives the seat cover to turn(open or close) by the actuating mechanism, while the other side of the electric machine drives the seat ring to turn(open / close) by the actuating mechanism. Said open / close device adopts two micro electric machine to separately drive the seat ring and seat cover of the water closet, and is equipped with proportional electric machine power in terms of the ring or cover weight to ensure the acting force of the operation. The drive of the electric machine is controlled by the infrared induction start switch and rotary limit switch, which make it possible to operate by inducting on the infrared sensor by hand without direct contacting with the water closet seat cover or seat ring , thus avoids the virus infection.

Owner:梁正华

Detection method of track smoothness

InactiveCN106192632AImprove riding performanceSmall difference between dynamic and static valuesMeasuring apparatusDerailmentEngineering

The invention discloses a detection method of track smoothness, pertaining to the technical field of track fault detection. A vertical track is uneven in terms of height, level, torsion, surfaces and short waves as well as vertical periodicity formed during rolling and straightening of steel rails. A transverse track is uneven in terms of direction, distance, and transverse periodicity formed during rolling and straightening of steel rails. Composite unevenness is termed when vertical and transverse unevenness coexists within a certain range of tracks. Geometric deviations formed by those at curve ends, positions near to curve point of curve to spiral, points of spiral to tangent, ultra-high, versine, non-uniform or non-compatible gauge downslope starting points and ending ports and geometric deviations formed by curve point of curve to spiral and points of spiral to tangent give rise to composite unevenness. The service lifetime and maintenance period of tracks and vehicle parts are long. Vehicle vibration and track noises are reduced. Smoothness, comfortableness and good safety are obtained. The possibility of train derailment is reduced.

Owner:合肥德泰科通测控技术有限公司

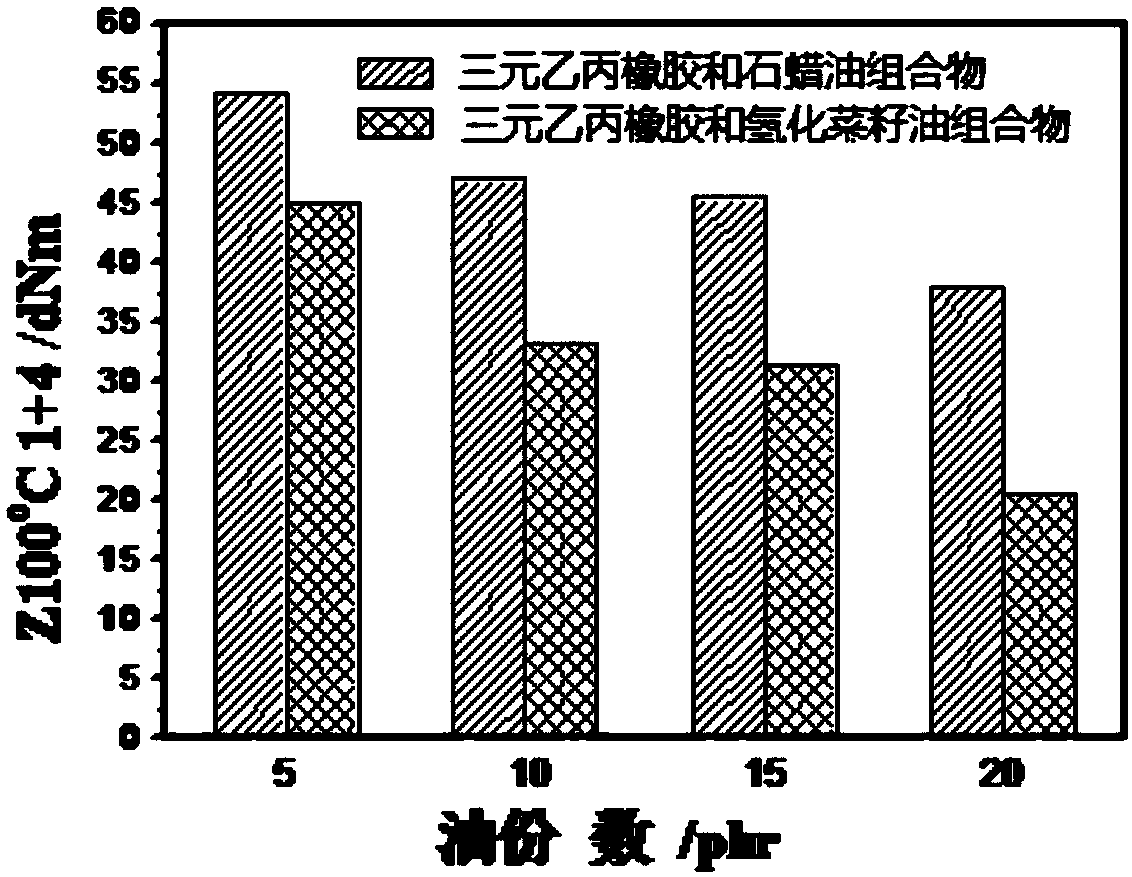

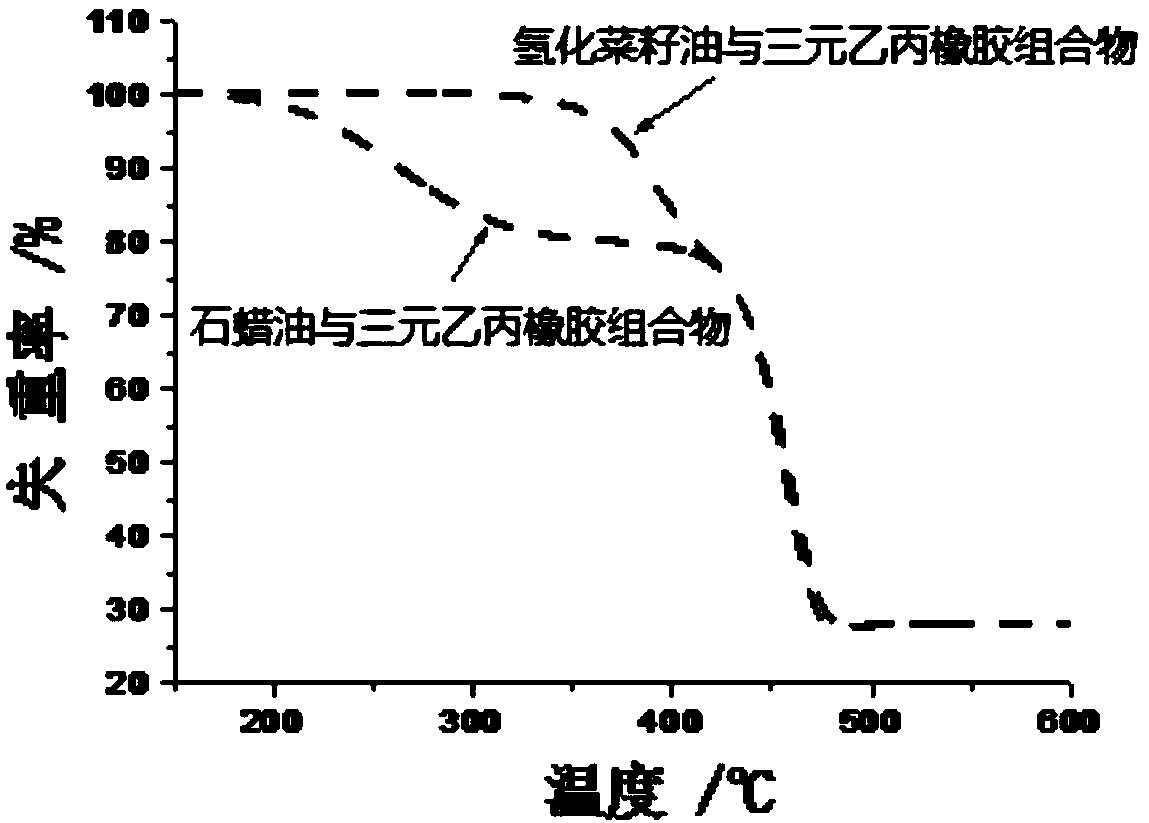

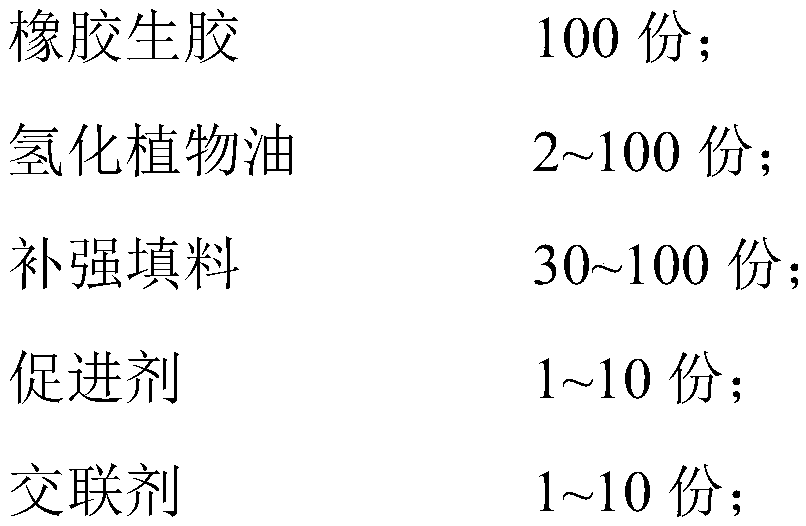

Rubber composition containing hydrogenated vegetable oil, and preparation method thereof

The invention relates to a rubber composition containing hydrogenated vegetable oil. The rubber composition comprises 100 parts of raw rubber, 2-100 parts of hydrogenated vegetable oil, 30-100 parts of a reinforcing filler, 1-10 parts of a promoter and 1-10 parts of a crosslinker, wherein the structural unit of the hydrogenated vegetable oil contains one to four double bonds, and the iodine valueis 30-120. The hydrogenated vegetable oil used as a plasticizer has an excellent compatibility with non-polar rubber, so the Mooney viscosity of non-polar rubber compounded rubber is greatly reduced,the processing property of the rubber is improved, the hardness of the vulcanized rubber is reduced, and the elongation at break of vulcanized rubber is improved. The hydrogenated vegetable oil meetsthe requirements for environmental protection and renewability, is nontoxic and non-migrating, is harmless to human health or produces no VOC emissions, and is expected to replace petroleum-based plasticizers for rubber as a next generation green plasticizer for rubber.

Owner:BEIJING UNIV OF CHEM TECH

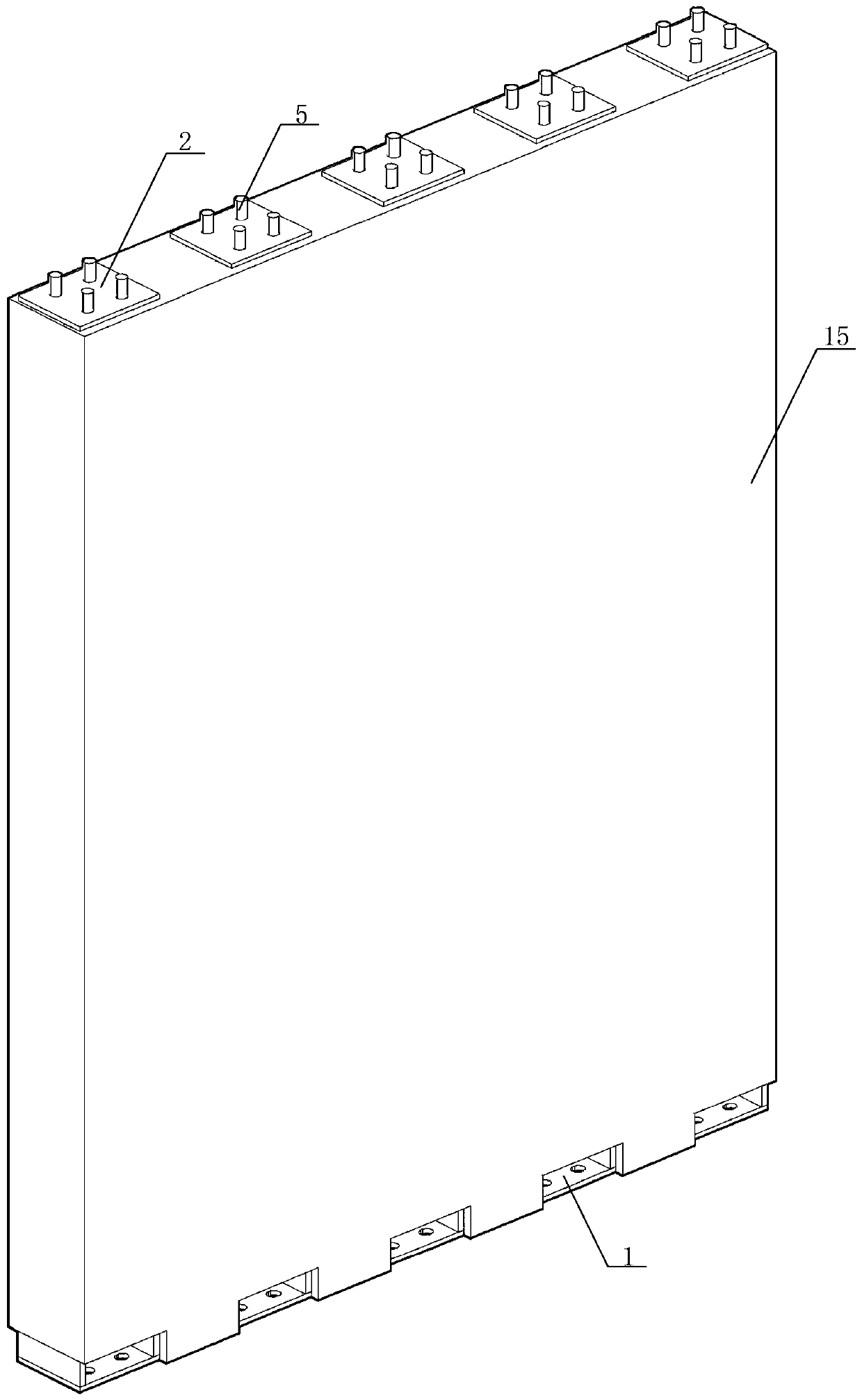

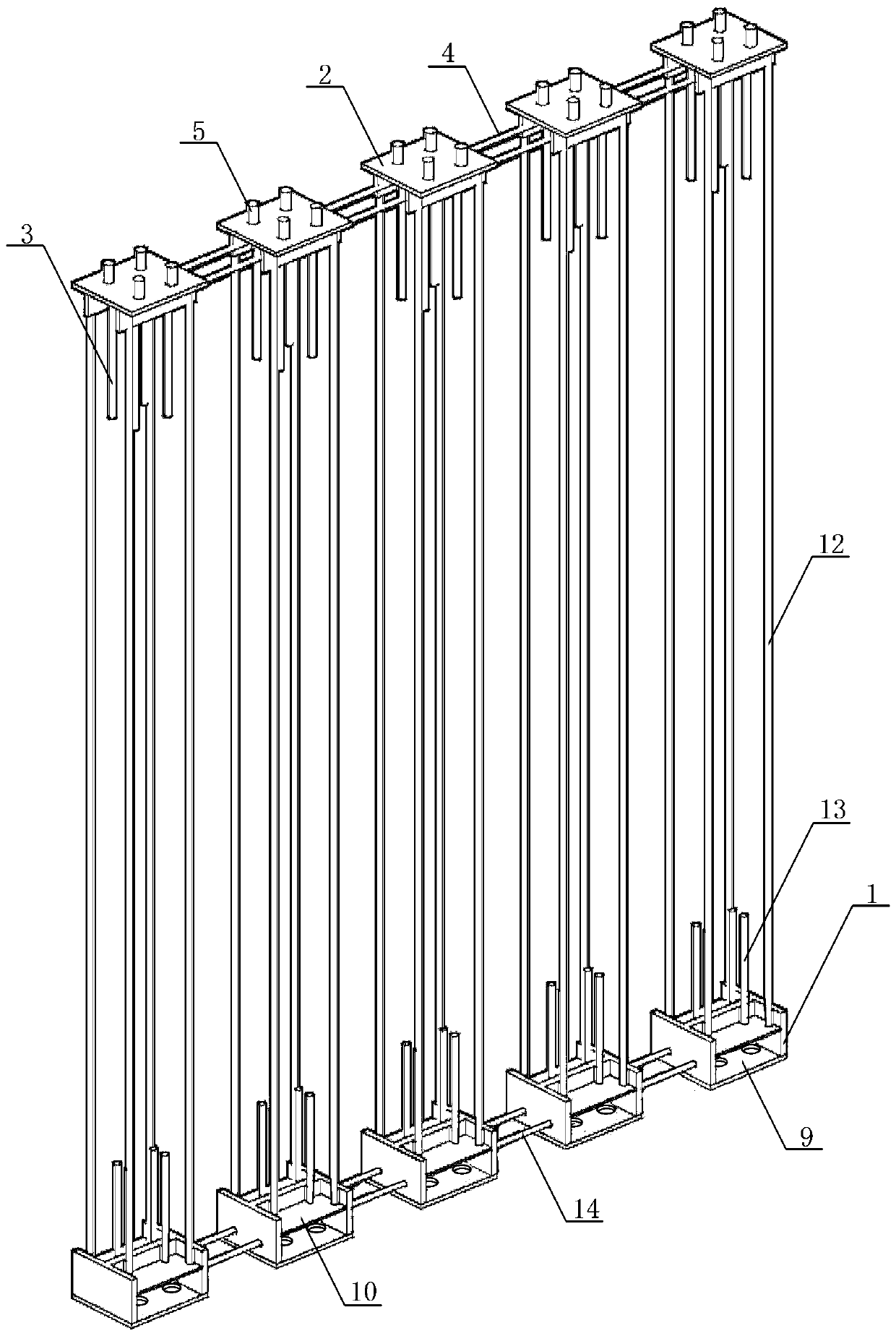

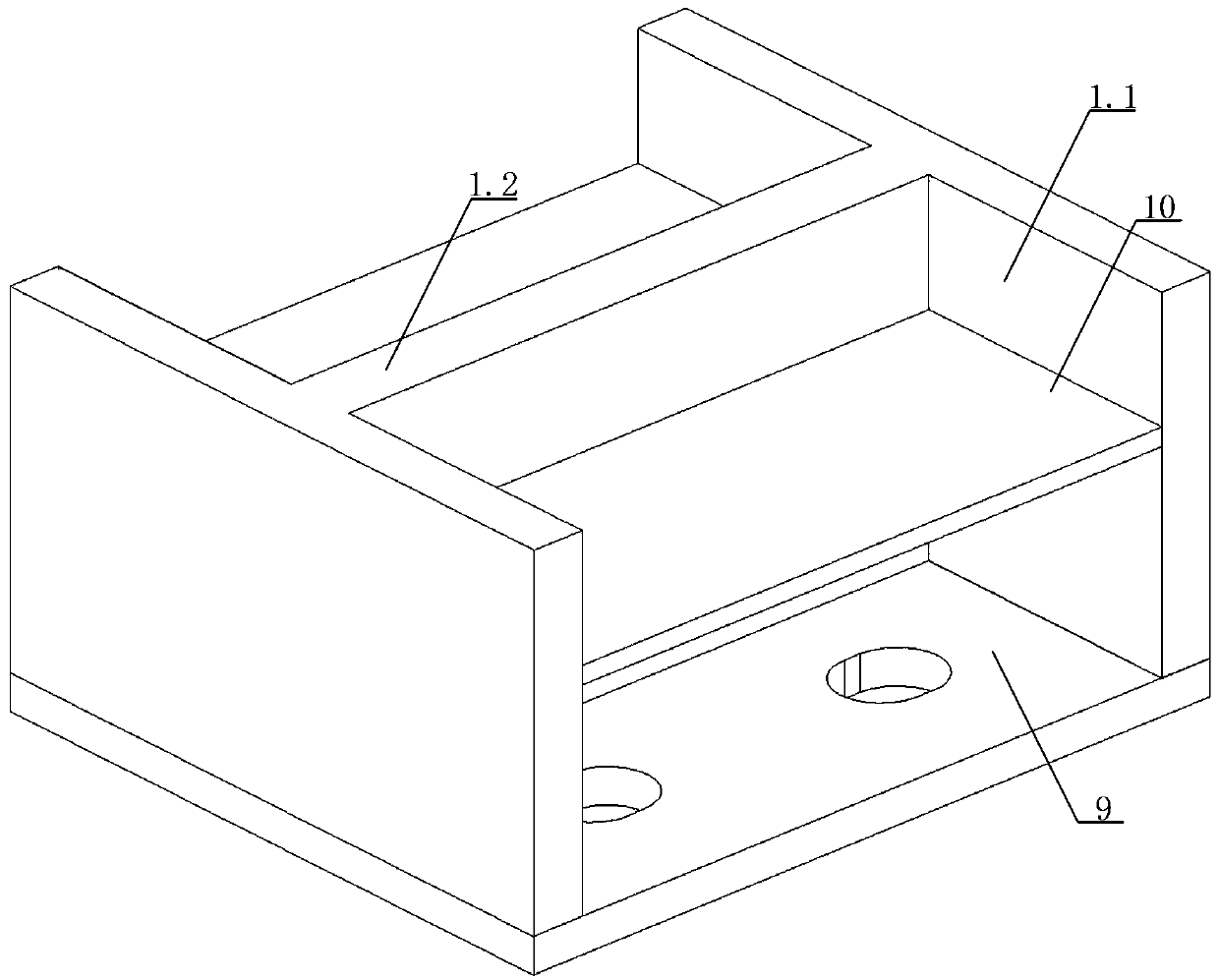

Connection construction and construction method of assembled shear wall panels and wall panels

PendingCN107605065AOvercome speedOvercome efficiencyWallsBuilding material handlingRebarCement mortar

A connection construction and a construction method of assembled shear wall panels and wall panels are provided. The wall panel comprises a concrete body and a steel framework cast in the concrete body; the steel framework comprises a set of splice assemblies arranged at evenly spaced intervals along the top of the wall panel in the length direction, bearing assemblies which are installed correspondingly to the splice assemblies at a lower end of the wall panel and a vertical through-length steel bar group which is vertically connected between the corresponding bearing assemblies and the splice assemblies. The invention designs a composite steel member for optimizing the connection nodes between the wall panels; the construction comprises splice assemblies arranged at an upper end of the wall panel and bearing assemblies correspondingly connected to a lower end of the wall panel; connecting base plates in the bearing assemblies of the upper layer wall panel are correspondingly insertedto the connecting bolts in the lower layer wall panel and the two are fastened through connecting nuts; finally, procedures such as cement mortar or gypsum blocking in seams and cavities are carriedout. The high efficiency connection of assembled shear wall is realized; the whole process is simple and quick; the connection strength is high, and it is convenient to dismantle and assemble, which is beneficial to the recycling of prefabricated components.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

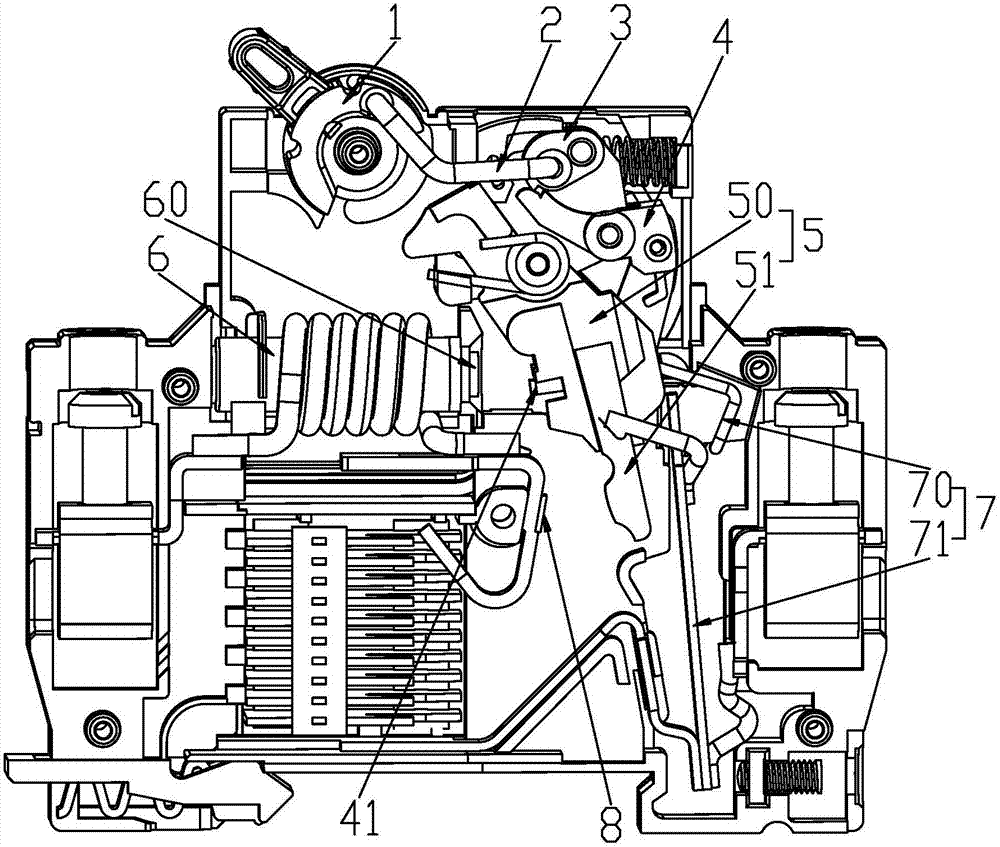

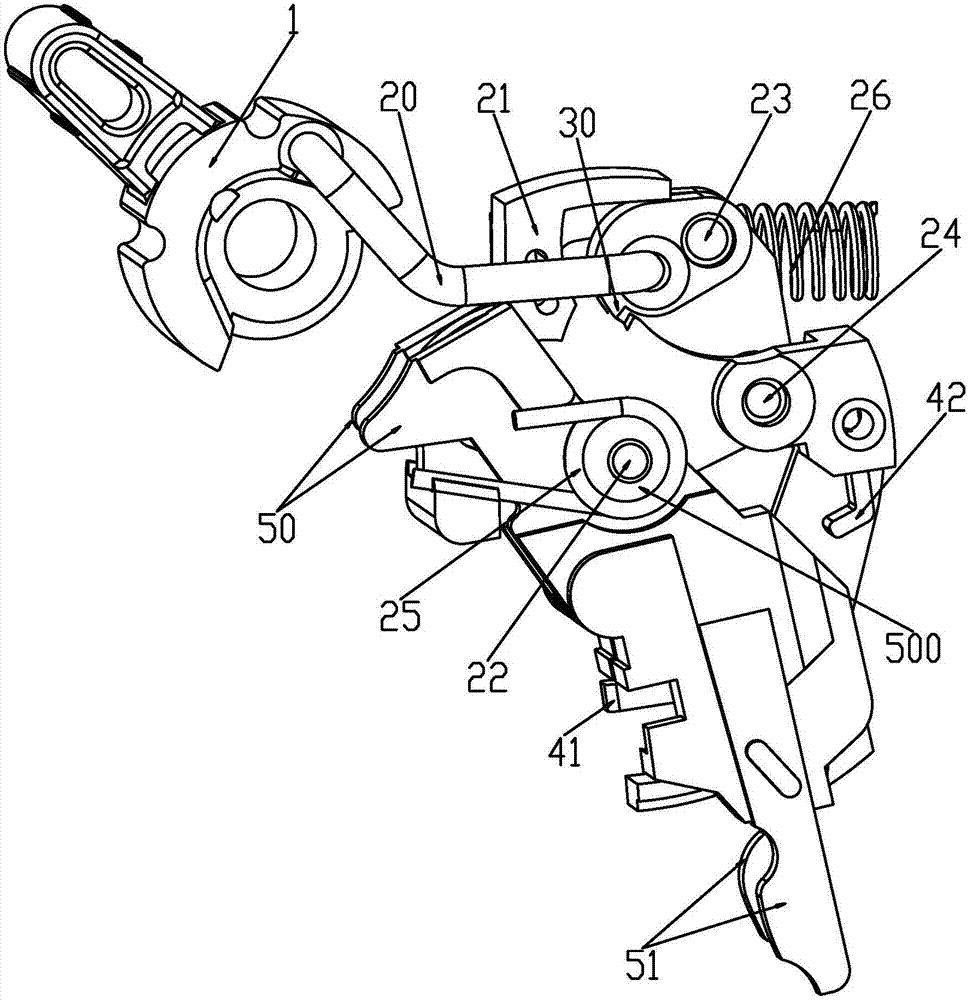

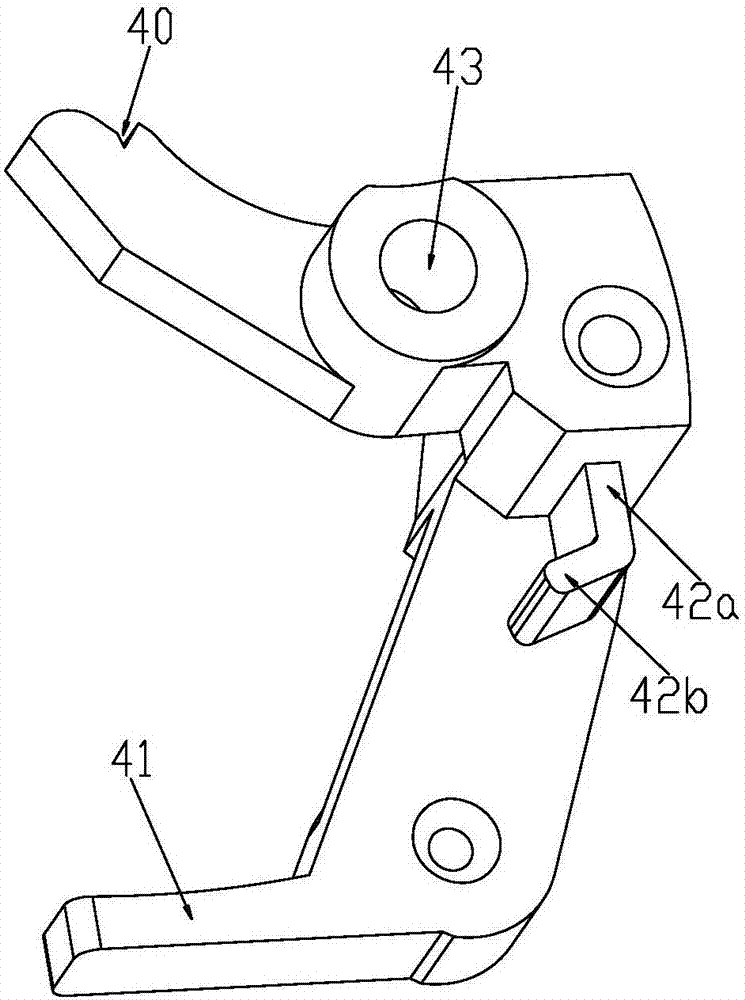

Trip structure of circuit breaker

ActiveCN107452566AQuick tripImprove breaking capacityProtective switch operating/release mechanismsEngineeringFusion welding

A trip structure of a circuit breaker comprises an operating mechanism and an electromagnetic tripper, wherein the operating mechanism is in linkage with an operating handle of the circuit breaker to drive a movable contact assembly to swing and match with a static contact, the operating mechanism comprises a jump pin and a lock which are buckled and connected, an extension end is arranged on the lock and is matched with a top rod of the electromagnetic tripper, and a trigger bulge is also arranged between the lock and the movable contact assembly; and when the circuit breaker is circuit-shorted, the top rod of the electromagnetic tripper collides with the extension end of the lock, the movable contact assembly swings to push the lock via the trigger bulge by means of an electric repulsive force between a movable contact of the movable contact assembly and the static contact, and the lock and the jump pin are pushed to be unlocked jointly by the top rod of the electromagnetic tripper and the movable contact assembly. In the trip structure of the circuit breaker, provided by the invention, the circuit breaker is rapidly tripped by additionally arranging the trigger bulge between the lock and the movable contact assembly, the trip structure is simple and reliable, a fusion welding phenomenon occurred between the movable contact and the static contact caused by long trip time can be effectively prevented, and the disconnection capability of the circuit breaker is improved.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Transverse segmental prefabricated prestressed concrete bent cap structure and assembling method thereof

PendingCN111206492AEasy to manufactureEasy to transportBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a transverse segmental prefabricated prestressed concrete bent cap structure and an assembling method thereof. The transverse segmental prefabricated prestressed concrete bentcap structure comprises a bent cap body and prefabricated stand columns. The bent cap body comprises a plurality of prefabricated sections spliced in the transverse direction; a hole through which a steel strand penetrates is reserved in each prefabricated section; every two adjacent prefabricated sections are connected through a wet joint section; an upper profile steel lap joint structure and alower profile steel lap joint structure which are matched with each other are pre-buried in the joint surfaces, close to the two sides of the wet joint section, of every two adjacent prefabricated sections respectively; the transverse steel bars on the top face, the bottom face and the vertical face of each prefabricated section extend into the range of the corresponding wet joint section, and thetransverse steel bars of each prefabricated section and the transverse steel bars of another adjacent prefabricated section are arranged in a staggered lap joint mode. The small-tonnage segmented prefabricated assembly of the large-volume prestressed concrete bent cap is achieved, stress of the bent cap structure can be better ensured, the structure quality is improved, and the construction speedis increased.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

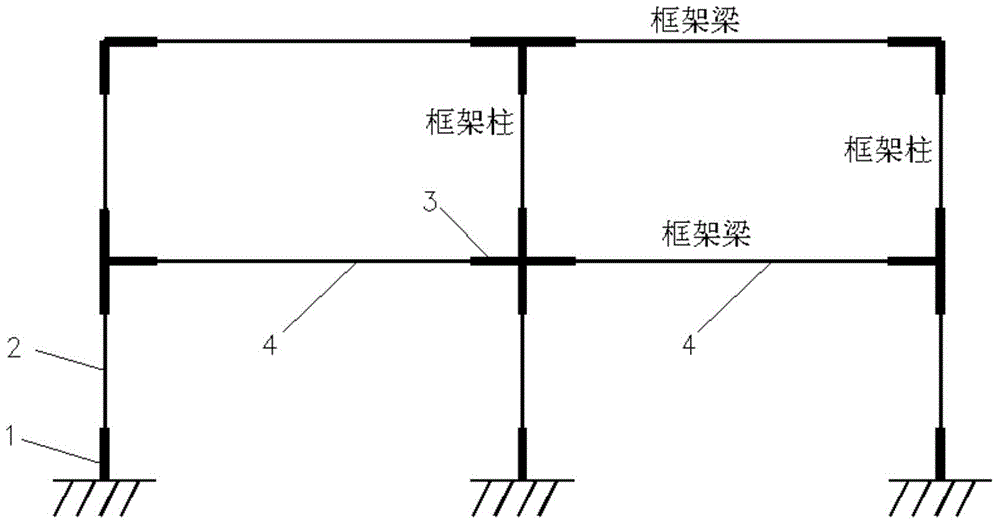

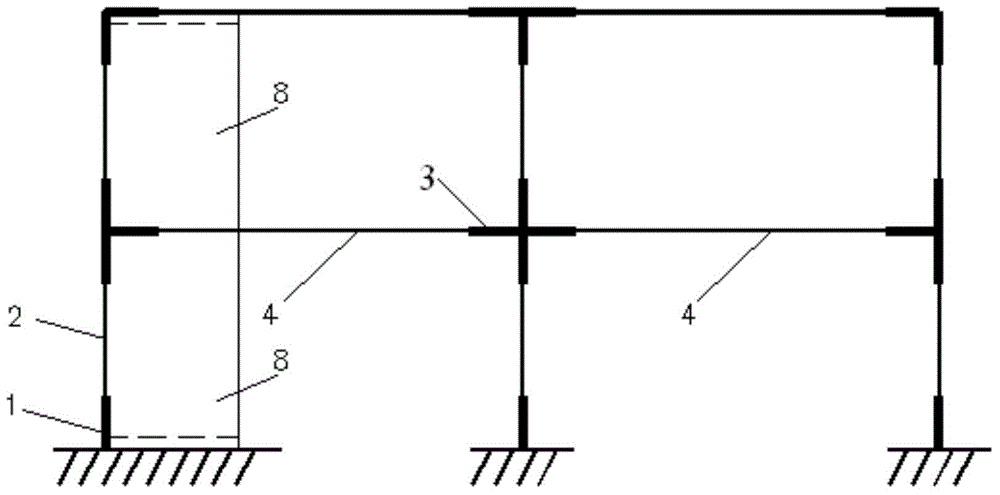

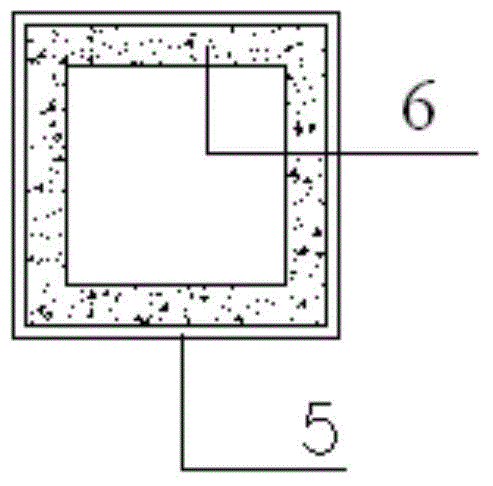

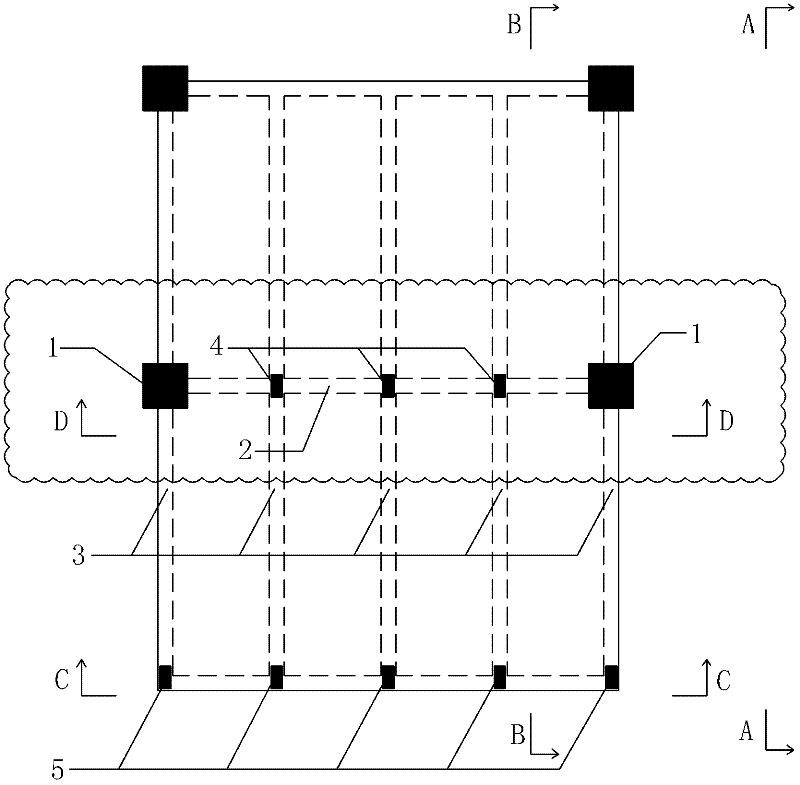

Double-layer vierendeel truss structure system of large cantilever structure

The invention discloses a double-layer vierendeel truss structure system of a large cantilever structure, comprising a floor frame. The floor frame comprises frame columns (1), frame beams (2) and cantilever beams (3). The double-layer vierendeel truss structure system of the large cantilever structure is characterized in that a plurality of main truss columns (4) are arranged between the upper and lower frame beams (2) of the floor, the upper and lower frame beams (2) of the floor are connected with the main truss columns (4) to form a first-layer vierendeel truss structure, a plurality of auxiliary truss columns (5) are arranged between the upper and lower cantilever beams (3) of the floor, the upper and lower cantilever beams (3) of the floor are connected with the auxiliary truss columns (5) to form a second-layer vierendeel truss structure, and the first-layer vierendeel truss structure and the second-layer vierendeel truss structure are connected to form the double-layer vierendeel truss structure system of the large cantilever structure. The double-layer vierendeel truss structure system of the large cantilever structure has a simple structure and is convenient to construct. A space frame structure system is formed by two layers of vierendeel trusses. The double-layer vierendeel truss structure system of the large cantilever structure can meet the structure stress and deformation requirement under the condition of adopting the small beams.

Owner:广州市设计院集团有限公司

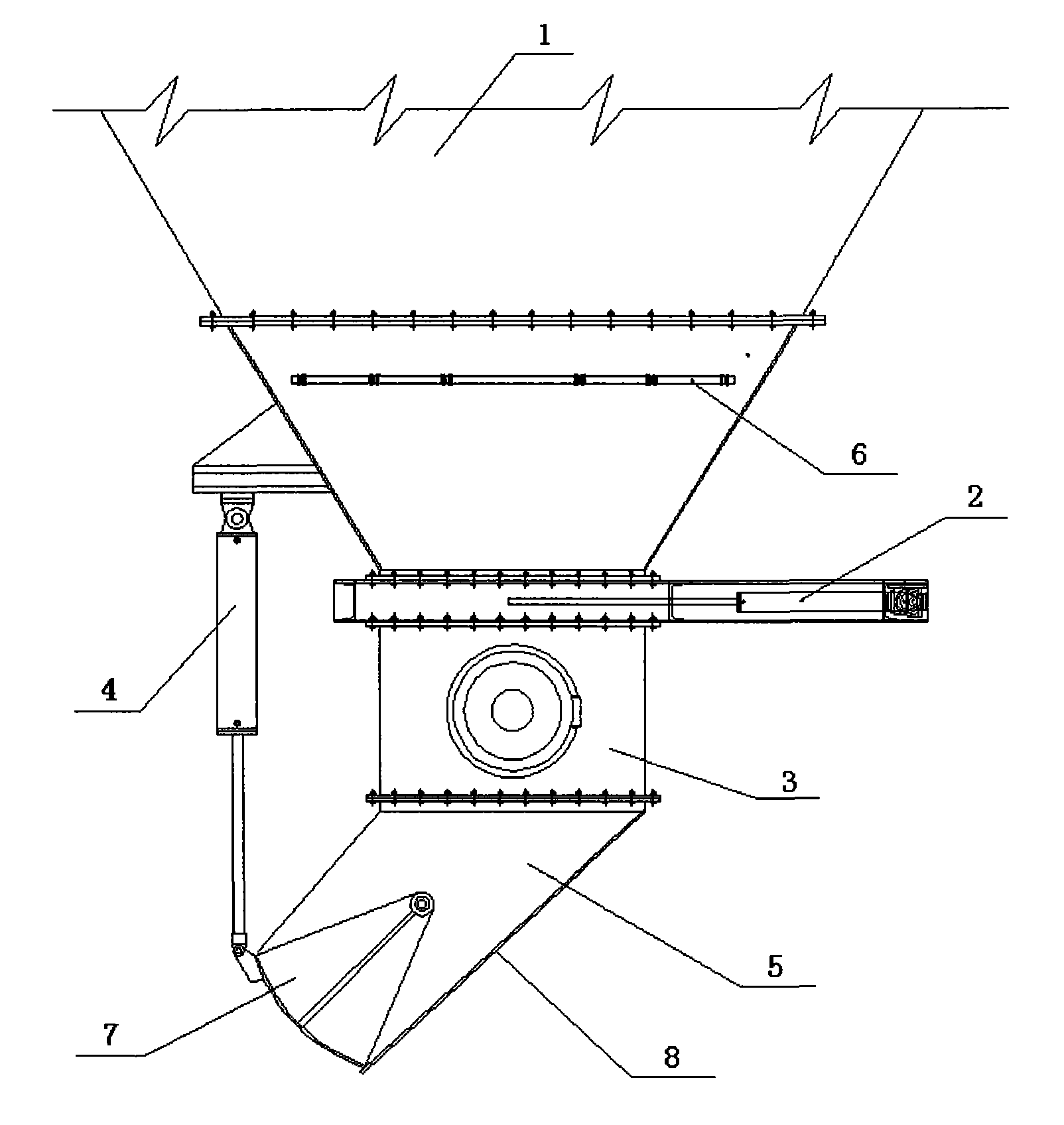

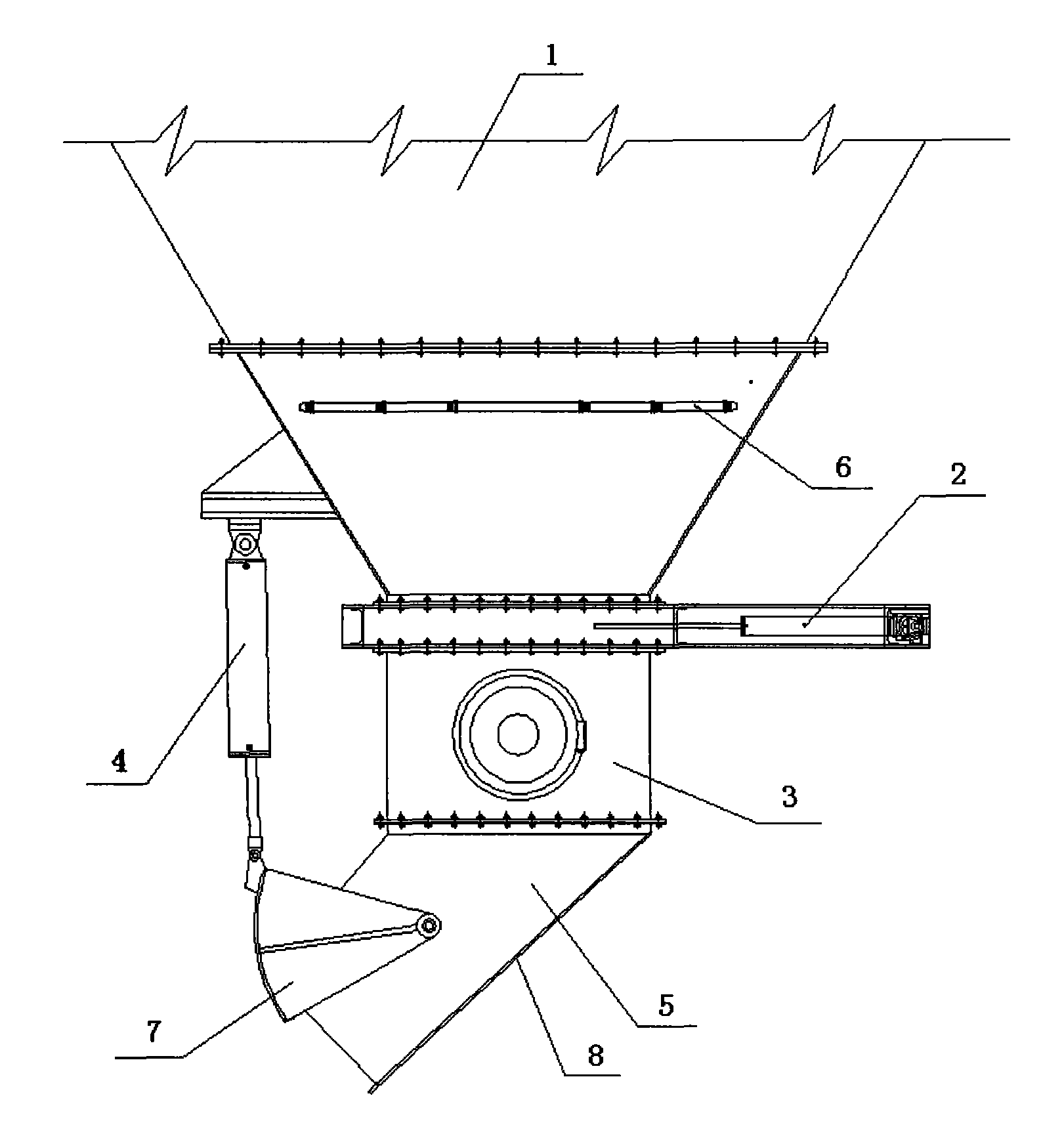

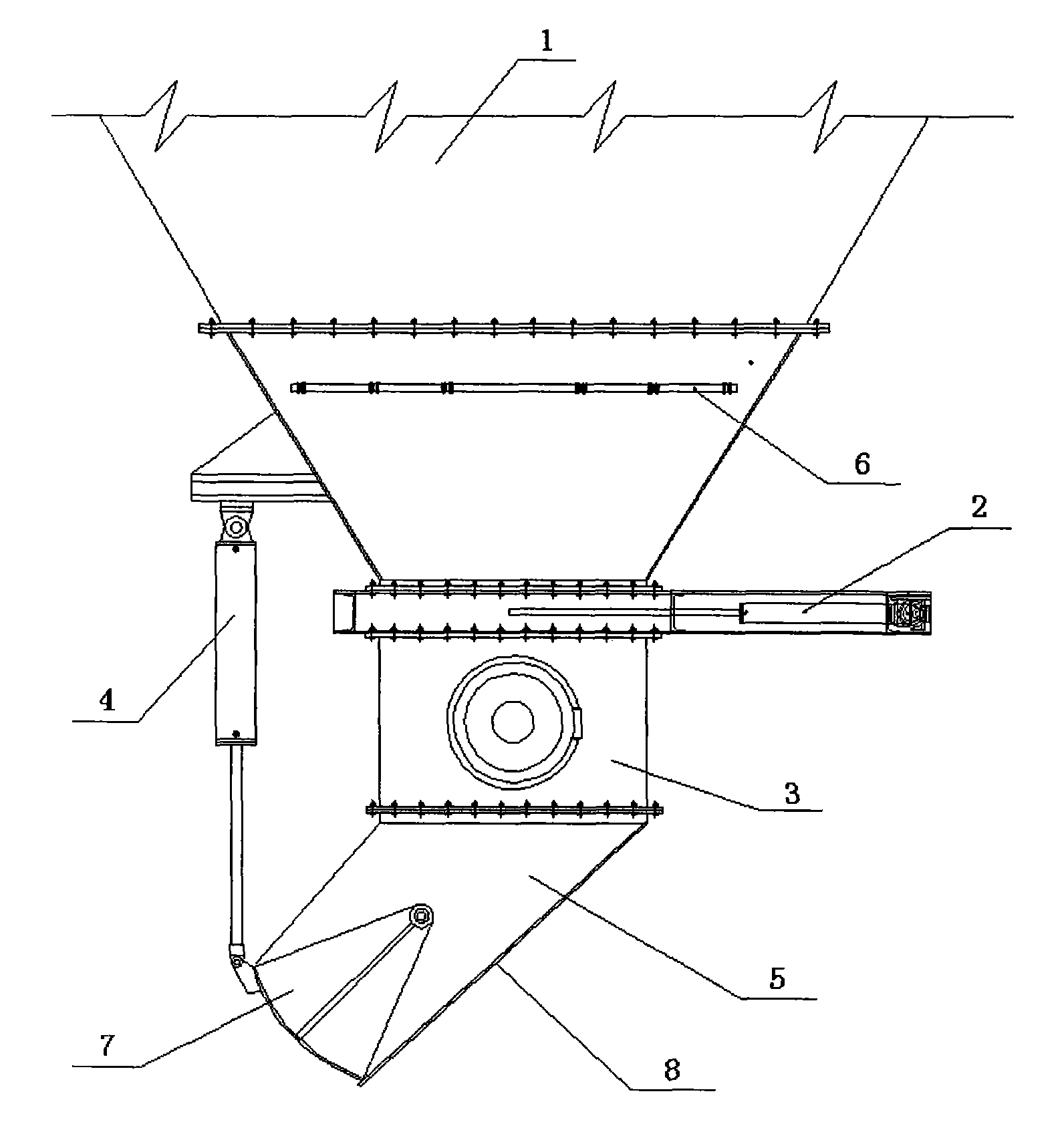

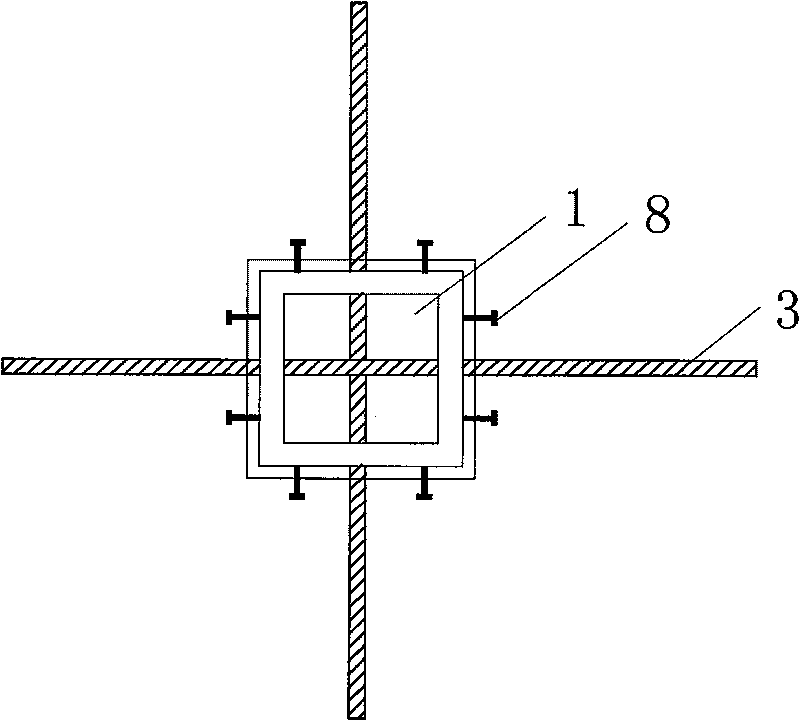

Electrical hydraulic combined discharging device

InactiveCN102001529AImprove mechanical propertiesAvoid scatterLoading/unloadingConveyor partsCoal briquetteWorking environment

The invention discloses an electrical hydraulic combined discharging device which comprises a material receiving bin, a spiral blanking barrel, a material amount adjusting device and a humidifying spraying device, wherein the material amount adjusting device is arranged between the material receiving bin and the blanking barrel; the humidifying spraying device is arranged on the inner wall of the material receiving bin and is communicated with a waterway outside the material receiving bin; and the material receiving bin is in a box type funnel shape. The electrical hydraulic combined discharging device has the advantages that the integral mechanical property is good; the scattering of coal briquettes and the impact on conveying equipment can be avoided to the maximum extent when the coal briquettes are charged and discharged; the working environment is improved, and the work efficiency is enhanced; and the production cost is reduced.

Owner:JIANGSU KACHUANG MACHINERY

Embedded steel column leg with steel pin

InactiveCN101761139AGuaranteed reliabilityGuaranteed forceBuilding constructionsSheet steelCarrying capacity

The invention discloses an embedded steel column leg with a steel pin, which belongs to one of steel-structure column leg construction practices in building structure. The flange of the embedded part of the steel column leg is provided with a hole; the steel pin pentrates the steel column leg, the two steel pins which are adjacent along the height direction are staggeredly placed and are connected with steel bars in a base. The steel plate of the embedded part of the steel column leg is thickened or the location with the hole is provided with stiffening ribs or stiffening plates, in order to prevent the extrusion or the tearing damage between the steel rod and the steel plate. Through the effect of the steel pin, the invention not only can ensure the reliability of the connection of the column leg and the base, but also can ensure the overall force of the column leg and the base when the column leg bears load, thereby increasing the carrying capacity and improving the deformation capacity.

Owner:BEIJING UNIV OF TECH

Automobile crumple type steering column impact test device and test method

PendingCN106596026AGuaranteed forceGuaranteed to collapse freelyShock testingSteering columnEnergy absorption

The present invention provides an automobile crumple type steering column impact test device. The automobile crumple type steering column impact test device comprises a bracket; the bracket is provided with a lifting frame; the lifting frame is connected with a driving device; the driving device drives the lifting frame to move up and down along a vertical direction; the lower end of the lifting frame is connected with a striking module through a locking release mechanism; an energy absorption and sliding device is arranged below the striking module; the energy absorption and sliding device is connected with the bracket; a fixing device used for fixing a tested steering column is fixed below the energy absorption and sliding device; the energy absorption and sliding device includes an energy absorption mechanism and a sliding mechanism; and when striking occurs, the energy absorption mechanism can absorb part of energy generated in striking, and the sliding mechanism can move in a vertical direction and a horizontal direction. The test device has the advantages of compact structure, strong field adaptability and high reliability. The test method carried out by the test device is simple, effective, practical and is low in test cost.

Owner:苏州世力源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com