Patents

Literature

72results about How to "Guaranteed deformability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deformation skin for aircraft

InactiveCN102700704AImproved ability to transfer loadsAchieve optimizationFuselage bulkheadsPolyurethane elastomerMorphing

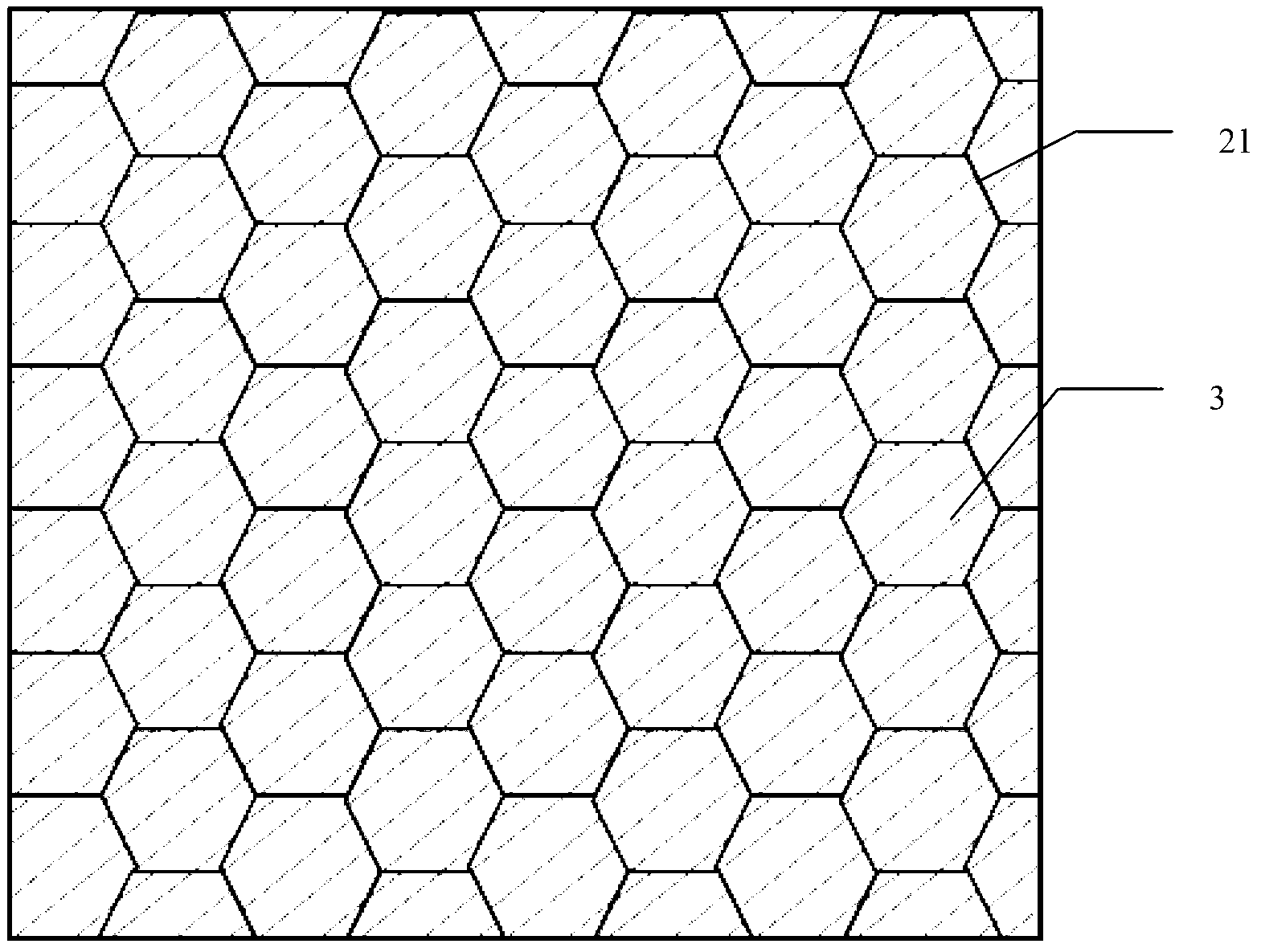

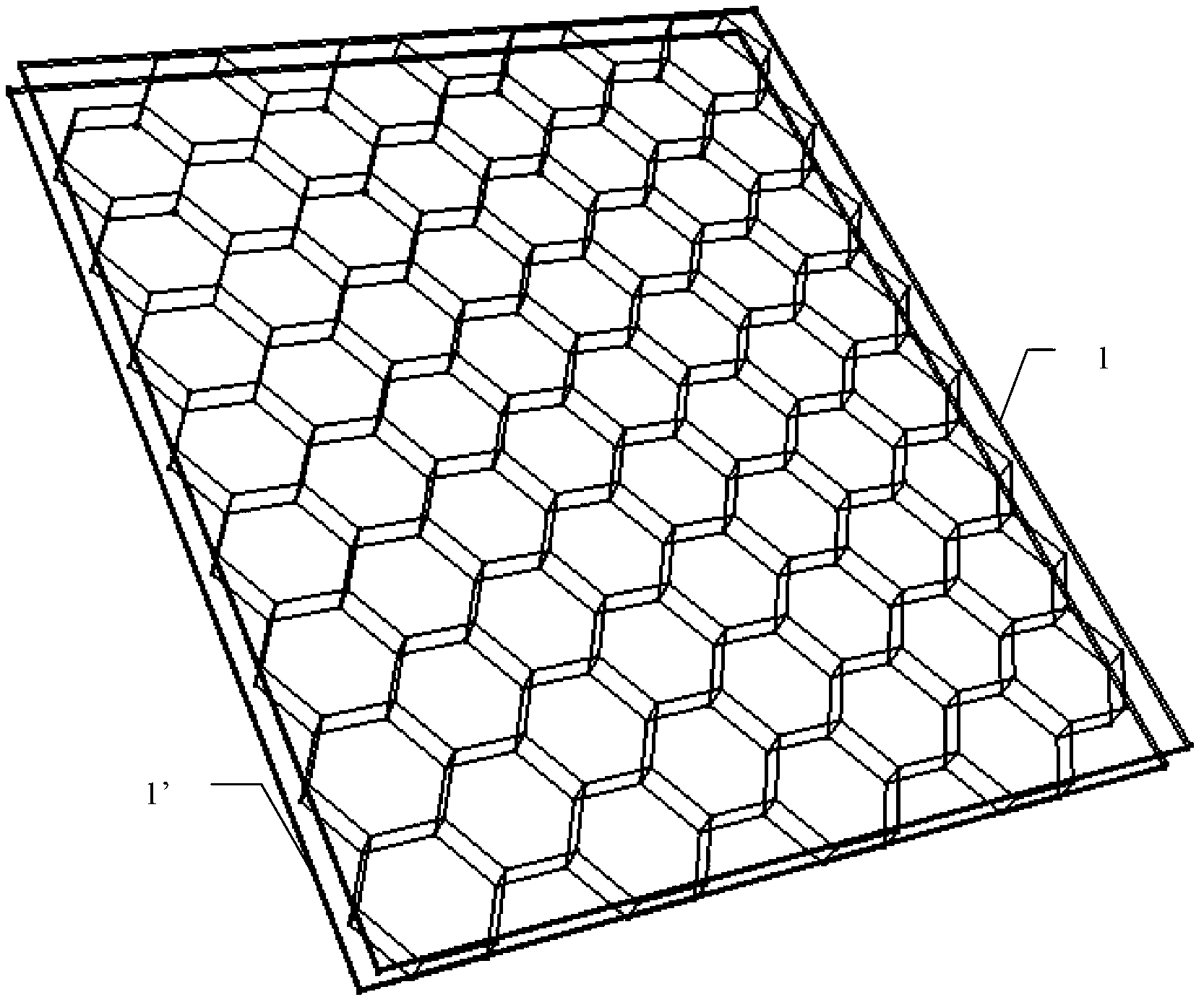

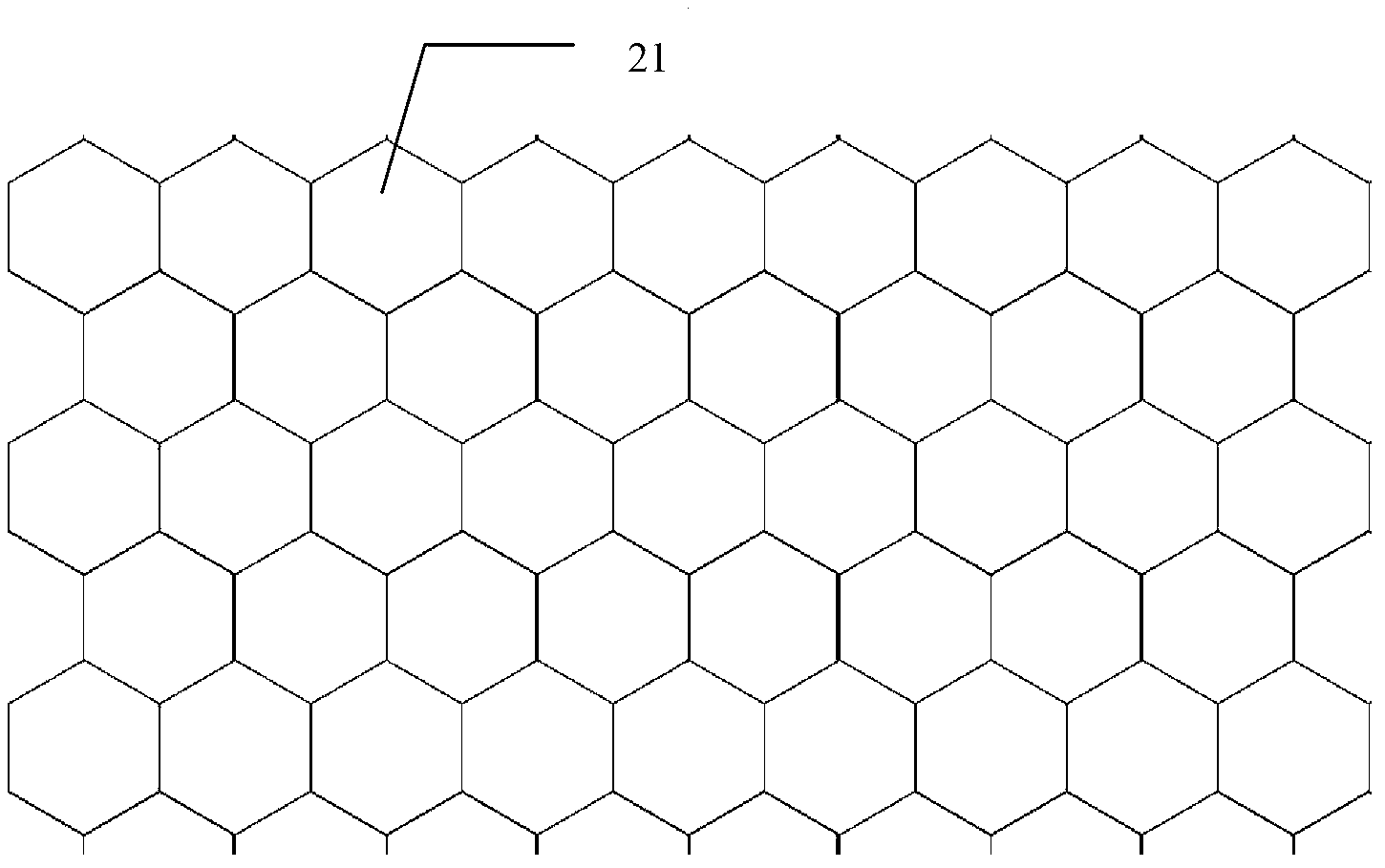

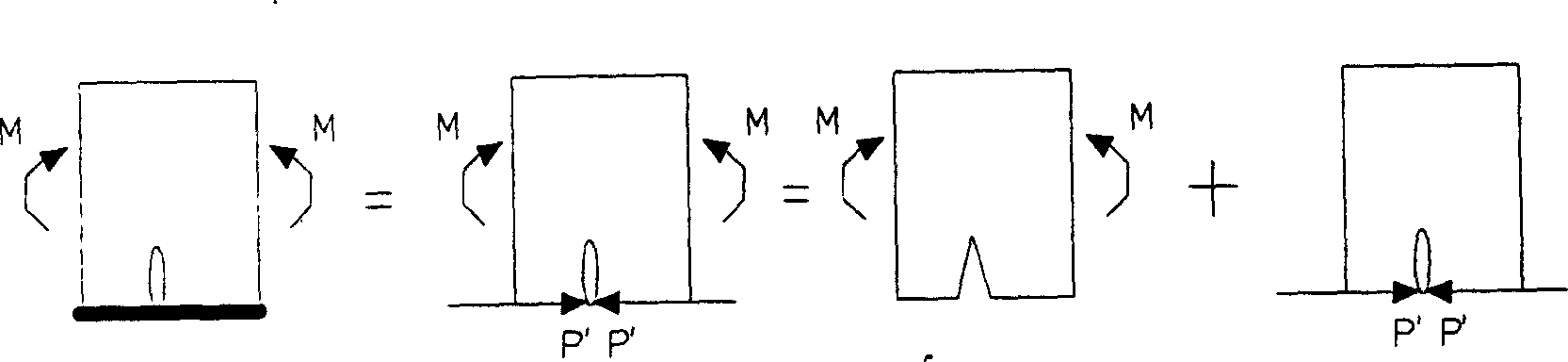

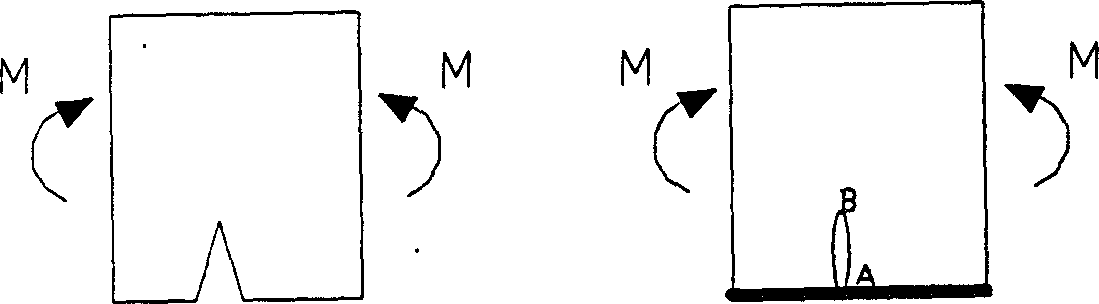

The invention discloses a deformation skin for an aircraft. The deformation skin for the aircraft is formed by connecting N continuous cellular units (21), wherein the N is a natural number. The deformation skin for the aircraft is characterized in that: elastic substrates (3) are filled in the cellular units (21). According to the deformation skin for the aircraft, the capability of the deformation skin of transferring load is improved as high as possible on the premise of ensuring the deformation capability by a method for compounding different performance materials, the problem of contradiction between higher elastic deformation and transfer of airload under the action of lower driving force is solved, the local flow fields are actively controlled further by mean of an electrostrictive effect of polyurethane elastomers, and the deformation skin has the capability of deforming in different scales. According to the deformation skin, the properties of intelligent morphing aircrafts are comprehensively optimized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

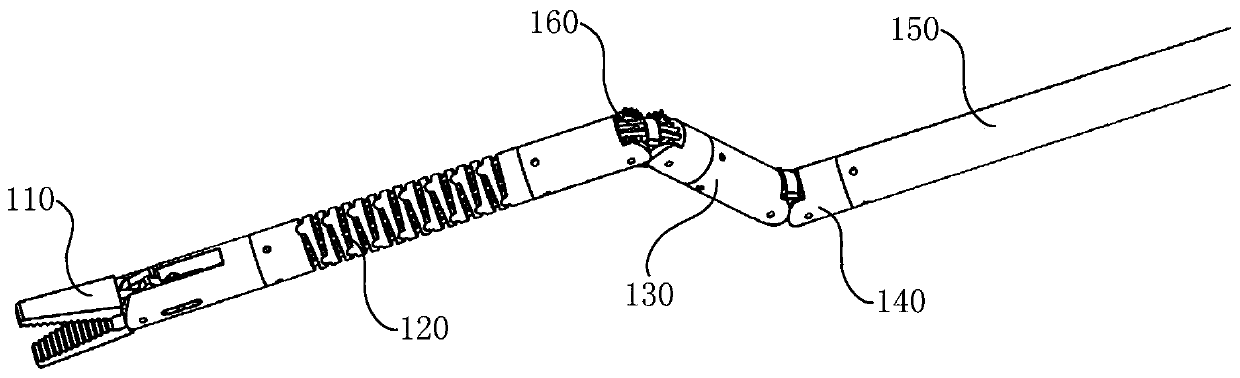

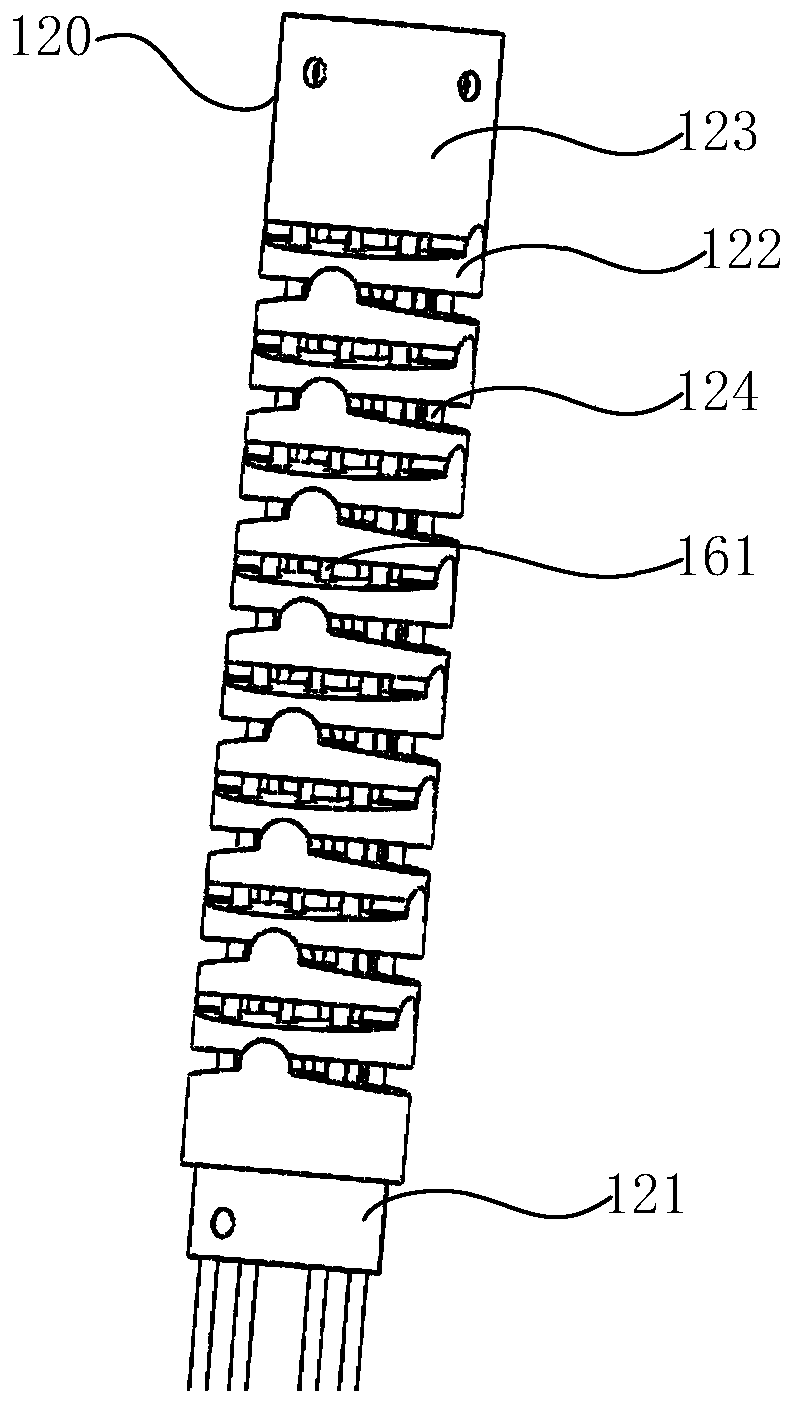

Snake-shaped surgical robot applied to minimally invasive surgery

ActiveCN111437036AEasy to operateGood resistance to deformationSurgical robotsPhysical medicine and rehabilitationMinimally invasive procedures

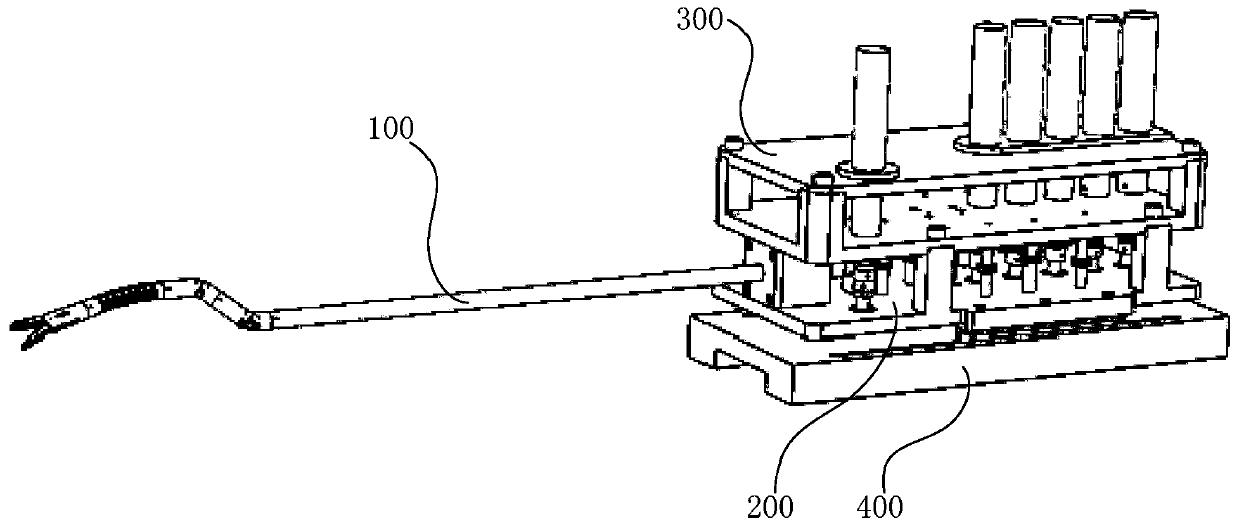

The invention provides a snake-shaped surgical robot applied to minimally invasive surgery. The snake-shaped surgical robot comprises a sliding table module, a pulley module connected to the sliding table module in a sliding manner, a driving module arranged on the pulley module and a mechanical arm connected with the pulley module, wherein the driving module provides power for the mechanical armthrough the pulley module; the mechanical arm comprises an operation actuator, a first joint which is connected with the operation actuator and can do bending motion, and a second joint which is connected with the first joint and can do swinging motion, wherein the first joint is of a continuum structure, and the second joint is of a gear meshing structure. The mechanical arm is formed by matchingthe continuum structure and the gear meshing structure; the rigidity of the mechanical arm is effectively improved in the premise that the flexible movement and the deformation capability of the tailend of the mechanical arm can be ensured; and moreover, the coupling effect of the mechanical arm of an existing surgical robot can be achieved or improved, and the motion control precision of the mechanical arm is improved. Compared with the existing surgical robot, the snake-shaped surgical robot is high in operability.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

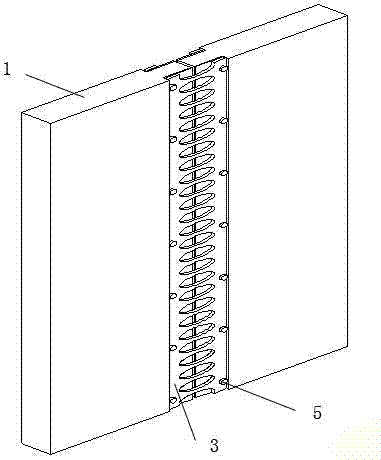

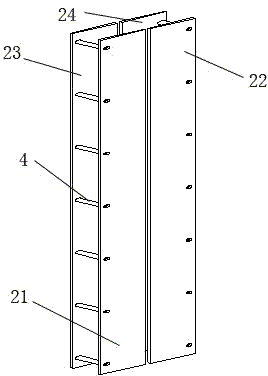

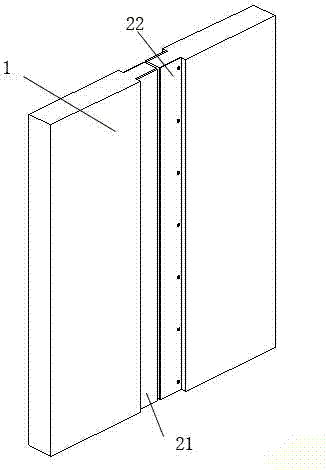

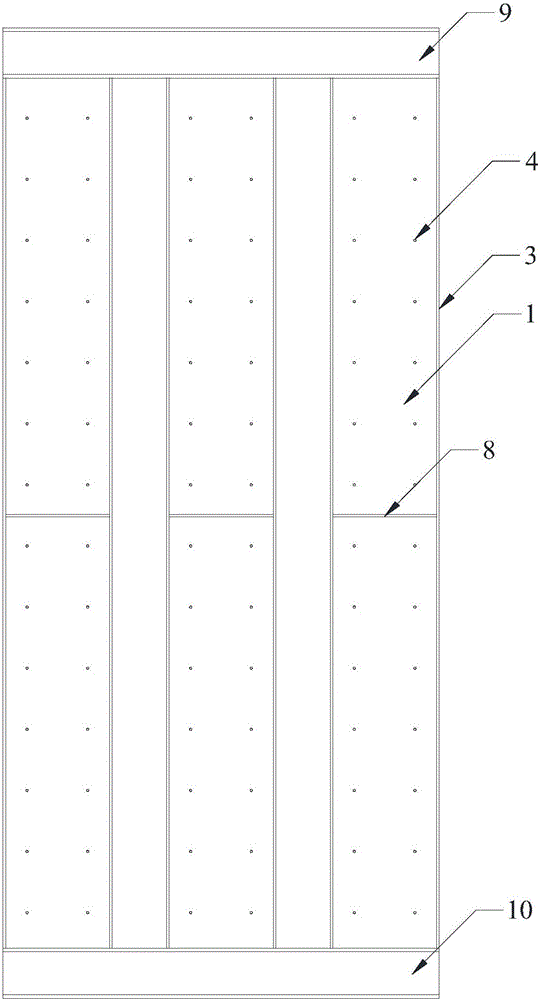

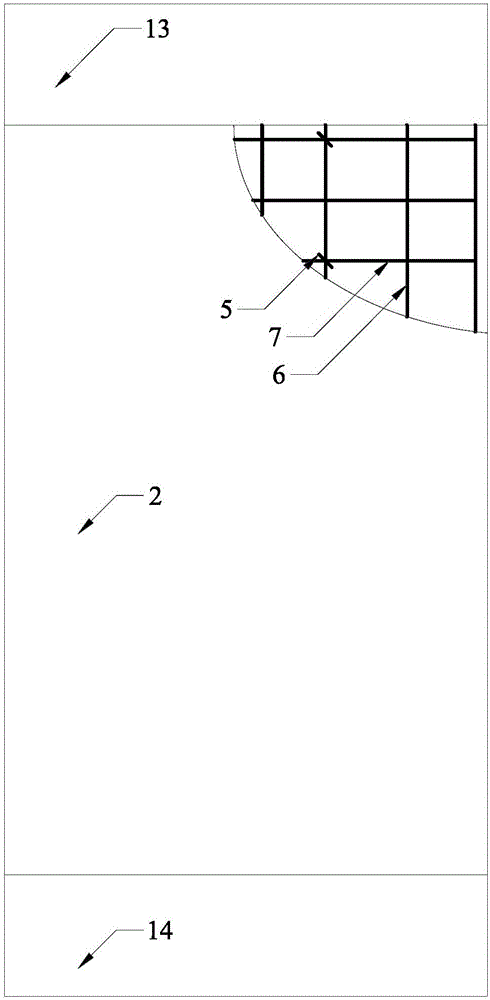

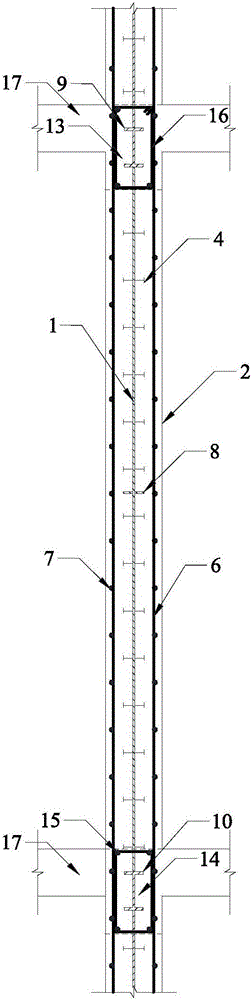

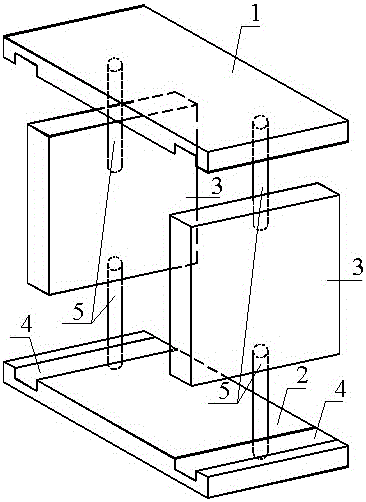

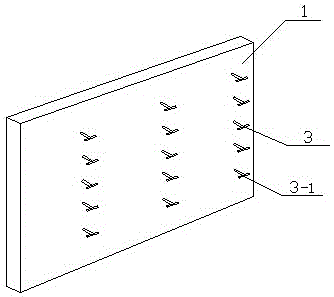

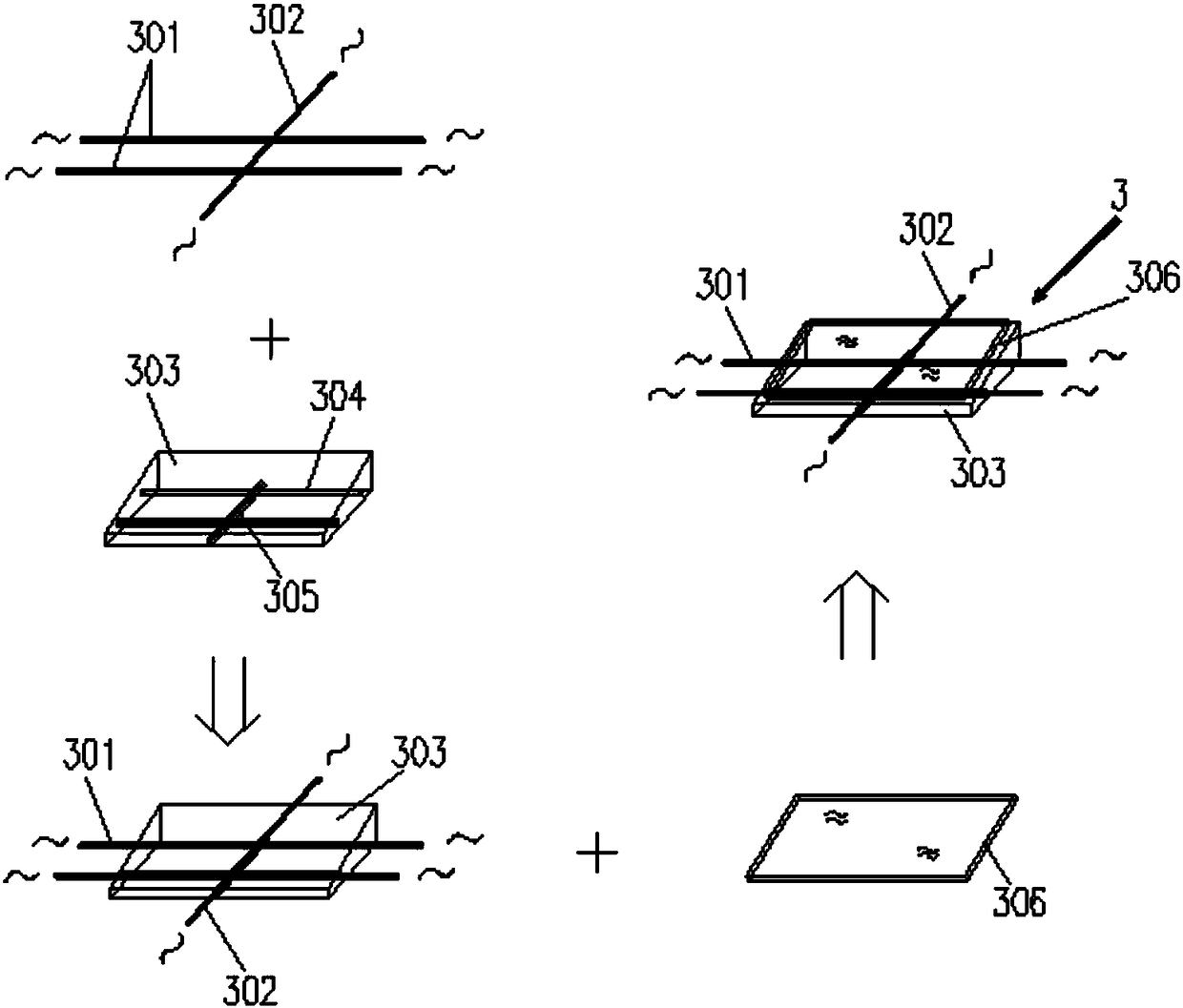

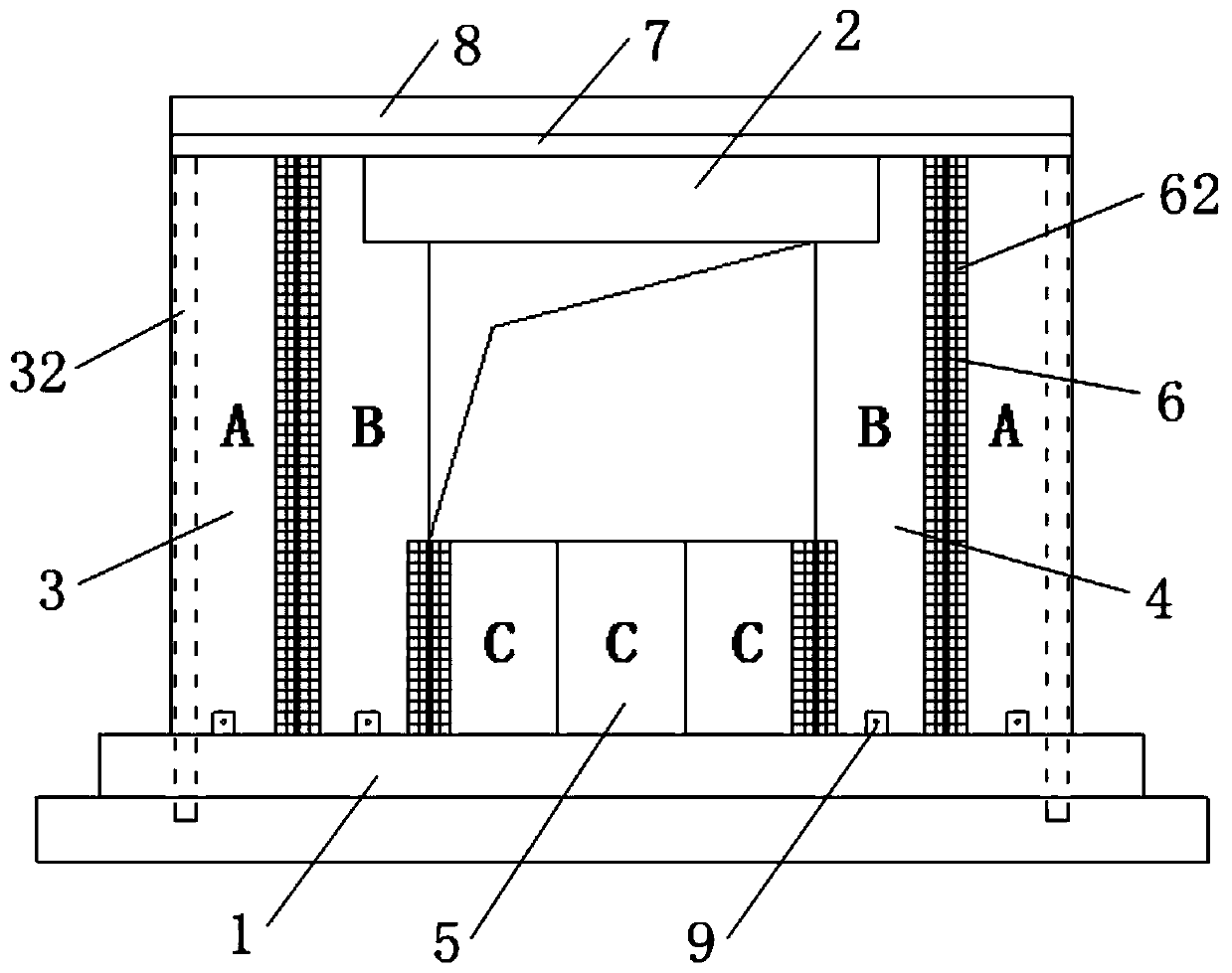

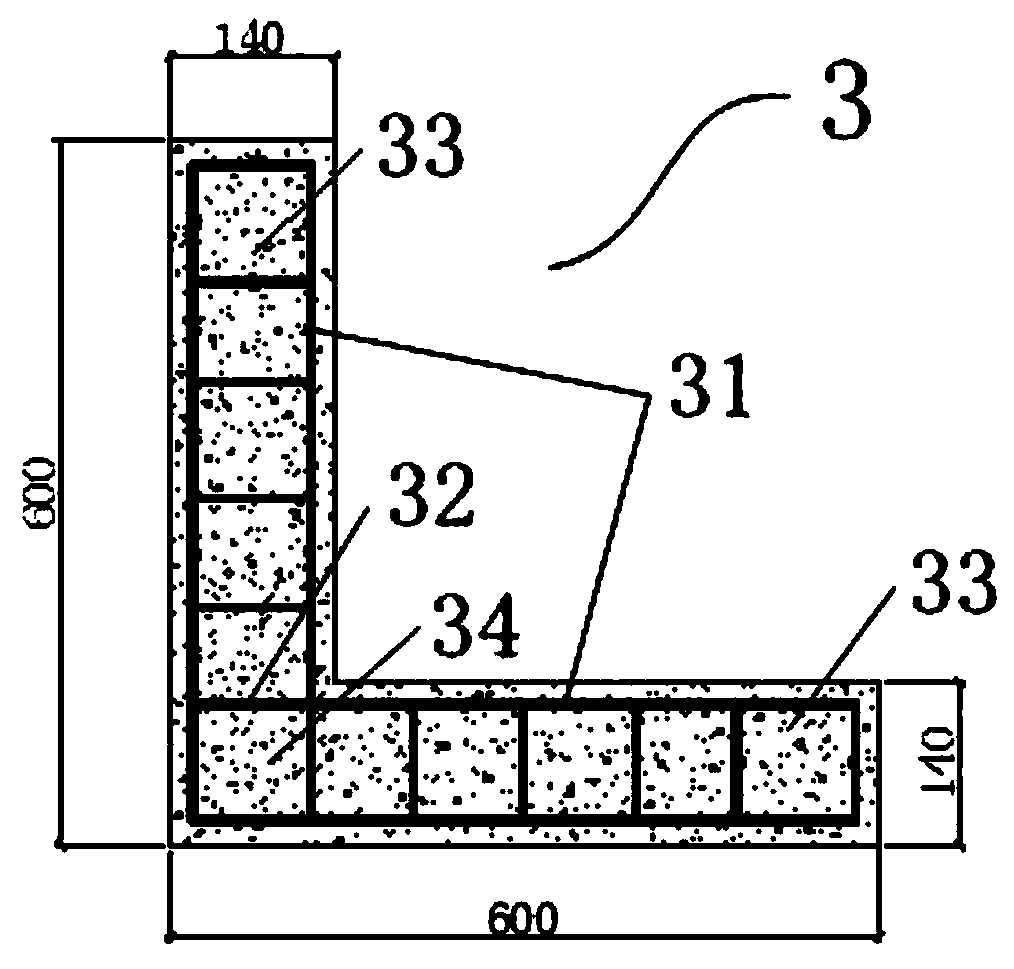

Combination slit shear wall with replaceable energy dissipation steel plates

ActiveCN103790262AImprove energy consumptionIncreased bearing capacity and stiffnessWallsShock proofingSteel platesShear wall

The invention discloses a combination slit shear wall with replaceable energy dissipation steel plates. The combination slit shear wall comprises a shear wall provided with a straight joint in the vertical direction, reinforcement constraint steel plates, the energy dissipation steel plates and threaded sleeves, wherein the reinforcement constraint steel plates are arranged on walls on the two sides of the straight joint and connected with the shear wall on the two sides of the straight joint in a casting mode. The energy dissipation steel plates are arranged on the outer sides of the reinforcement constraint steel plates and used for fixedly connecting the reinforcement constraint steel plates on the same side. The thread sleeves are used for fixedly connecting the energy dissipation steel plates with the reinforcement constraint steel plates and forming a casting frame with the reinforcement constraint steel plates. By the utilization of deformation of the two sides of the straight joint of the slit shear wall, the yield energy dissipation capacity of the energy dissipation steel plates is brought into full play, so that the energy dissipation and seismic resistant capacity of a building structure are greatly improved, and the slit shear wall has the advantages of being convenient to construct, install, repair and replace after an earthquake and meeting the requirements for seismic resistance and reduction design and functionality of the building structure.

Owner:ZHIXING S&T

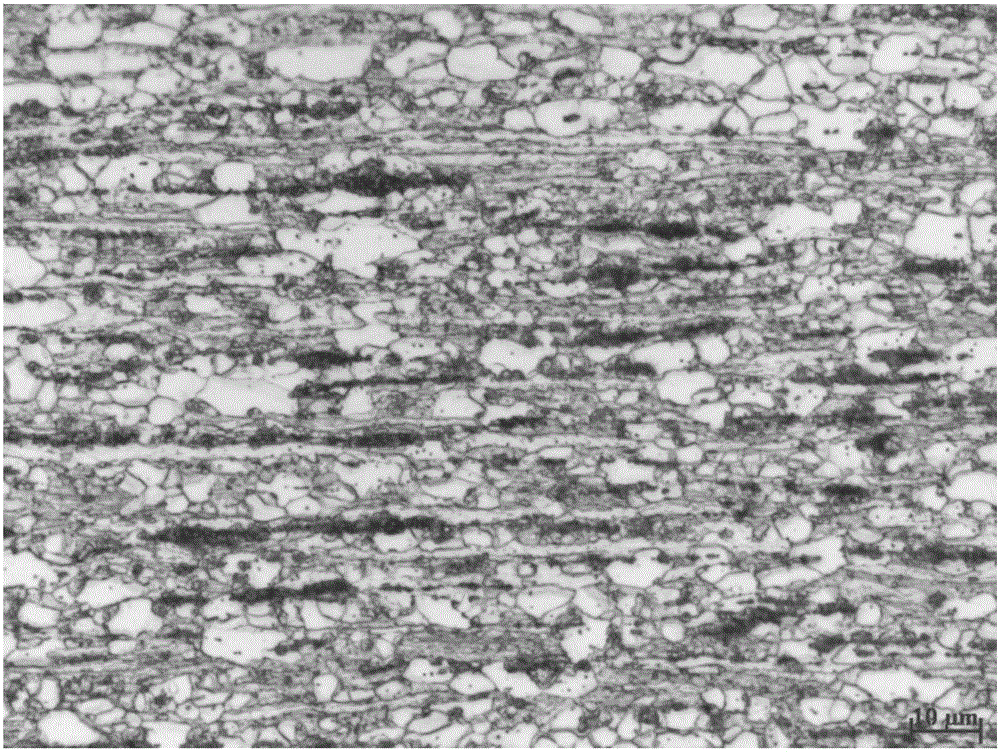

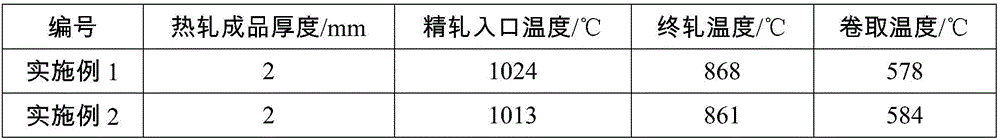

Chrome-plated board, manufacturing method thereof and crown cap

ActiveCN105838994AGuaranteed Strength LevelGuaranteed deformabilityCapsClosure capsStamping processDuctility

The invention discloses a chrome-plate board, a manufacturing method thereof and a crown cap. The chrome-plated board is composed of, by weight, 0.05-0.09% of C, 0.005-0.02% of Si, 0.2-0.6% of Mn, 0.02-0.06% of Al, 0-0.02% of P, 0-0.015% of S, 0-0.006% of N and the balance Fe and inevitable impurities. The manufacturing method of the chrome-plated board sequentially comprises the steps of steel-making, hot rolling, acid pickling and cold-rolling, continuous annealing and flattening, wherein continuous annealing is conducted at the temperature of 580-600 DEG C for 60-100 s. According to the chrome-plated board, the manufacturing method thereof and the crown cap, a cold-rolled sheet is made to be in an intermediate annealing state by adjusting the annealing temperature in the continuous annealing process, and part of non-recrystallization structures are reserved. In this way, the strength grade of band steel is guaranteed, and meanwhile the band steel is made to have certain ductility, so that the deformation capacity of the band steel in the stamping process is guaranteed.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD

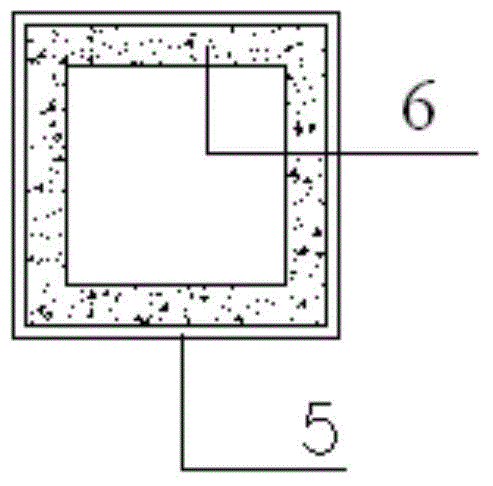

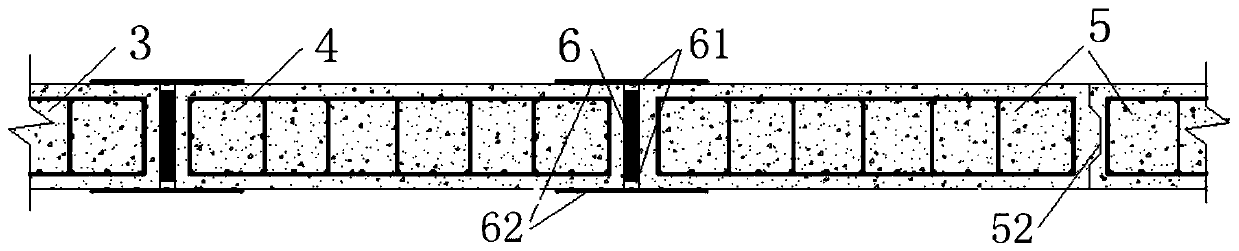

High-strength concrete composite shear wall with built-in segmented steel plates and construction method for same

ActiveCN106049708ALess prone to bucklingWork well togetherWallsHigh strength concreteHigh resistance

The invention belongs to the technical field of structure engineering and relates to a high-strength concrete composite shear wall with built-in segmented steel plates and a construction method for the same. The invention provides the high-strength concrete composite shear wall with the built-in segmented steel plates and further provides the building and construction method for the shear wall. The composite shear wall and the construction method for the same provided by the invention are characterized in that through segmented layout of the steel plate, concrete pouring and binding bar layout become convenient; a cooperative working ability of the steel plates and concrete is enhanced; bearing force is ensured; and deformability and an energy-dissipation capability of the composite shear wall can also be enhanced. In comparison with a composite shear wall covered by steel plates, the composite shear wall provided by the invention has higher resistance to high temperatures and can show better performance when a fire disaster takes place. Meanwhile, in comparison with a concrete composite shear wall with a whole steel plate, the shear wall provided by the invention has the advantages that conversion and transition among layers can be implemented through reduction of the quantity of the segmented steel plates; inter-layer rigidity transition becomes gentler; and the structure is also simpler.

Owner:TONGJI UNIV

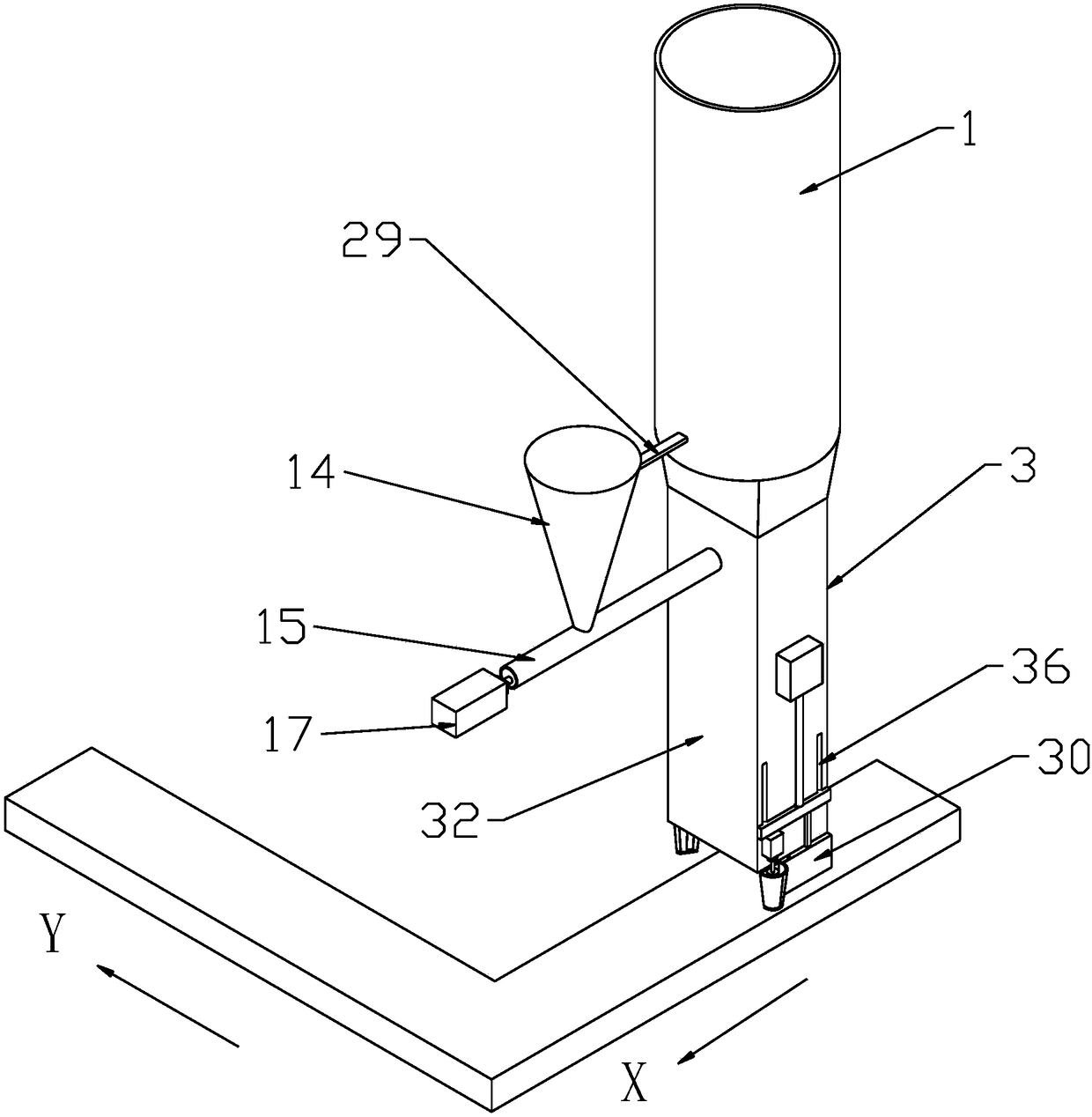

3D (Three-dimensional) printing device for printing buildings

ActiveCN108237613AIncrease binding areaEnsure integrity and stabilityAdditive manufacturing apparatusCeramic shaping apparatusEngineeringRear quarter

The invention relates to the technical field of 3D (Three-dimensional) printer manufacturing, in particular to a 3D printing device for printing buildings. The 3D printing device for printing the buildings comprises a ceramsite conveying mechanism, wherein a spiral drive device is arranged in a spray head; a nozzle is arranged at the lower end of the spray head, and is formed by two end plates oppositely arranged in parallel and two sides plates oppositely arranged in a surrounding way; the two end plates are perpendicular to a movement direction of the nozzle; multiple bulge parts and sunkenparts are arranged on the two end plates long a length direction of the nozzle; the bulge part on one end plate and the sunken part on the other end plate are arranged correspondingly so as to realizethe matching of binding surfaces of each layer of wall body; a ceramsite discharge pipe and a support plate are arranged in the nozzle; the ceramsite discharge pipe is fixed into the nozzle through the support plate; and the upper end of the ceramsite discharge pipe is sealed. The 3D printing device for printing the buildings adopting the technical scheme provided by the intention has the advantages that a printed building wall is smooth in wall surface, good in attractiveness, high in structural strength, and good in forming effect.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

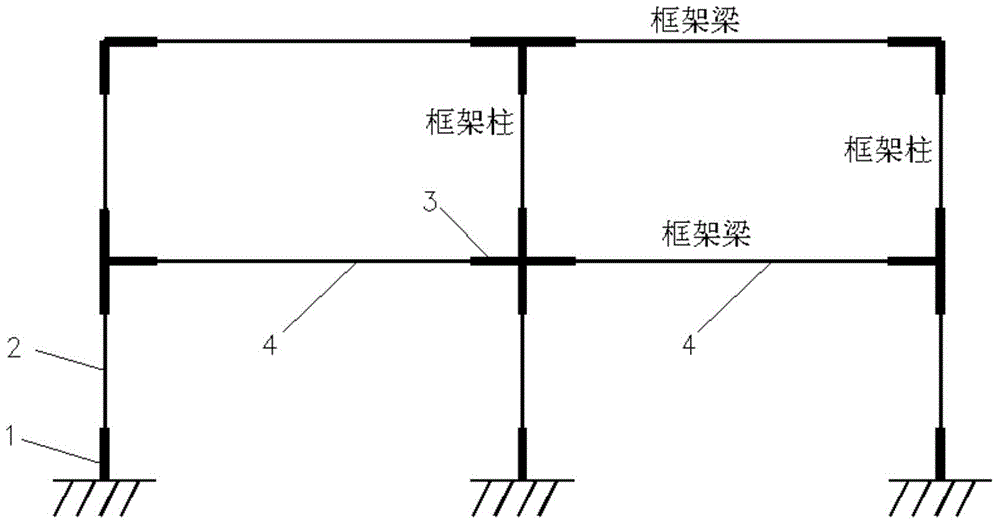

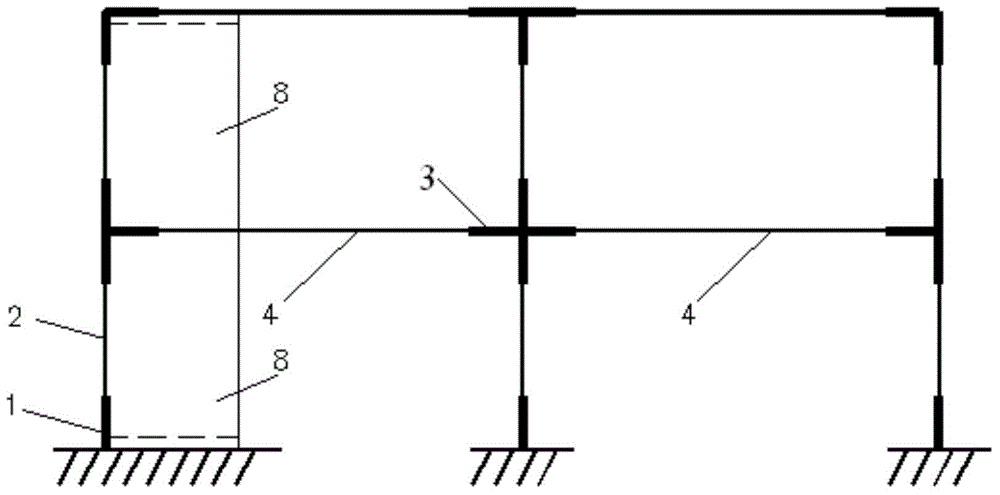

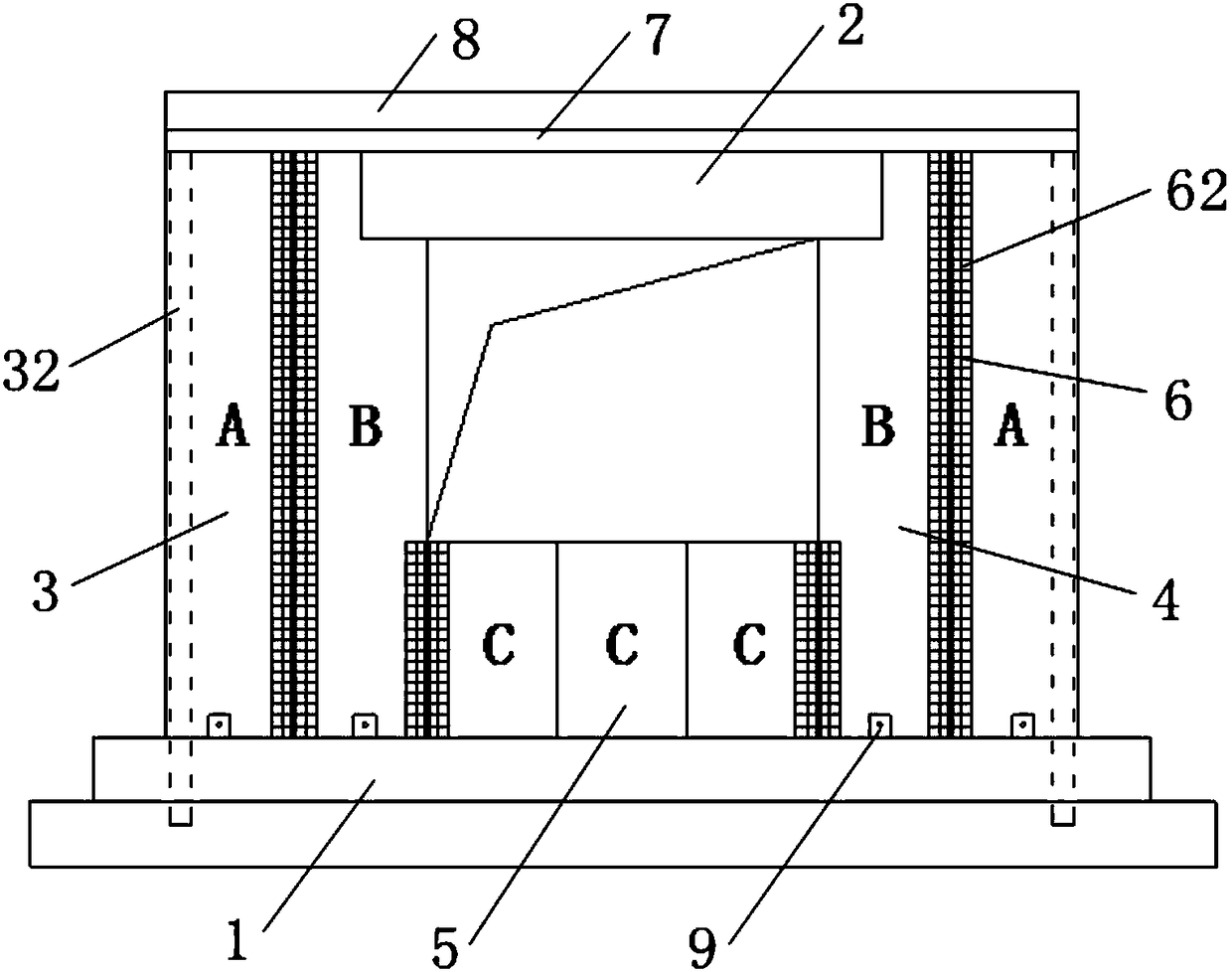

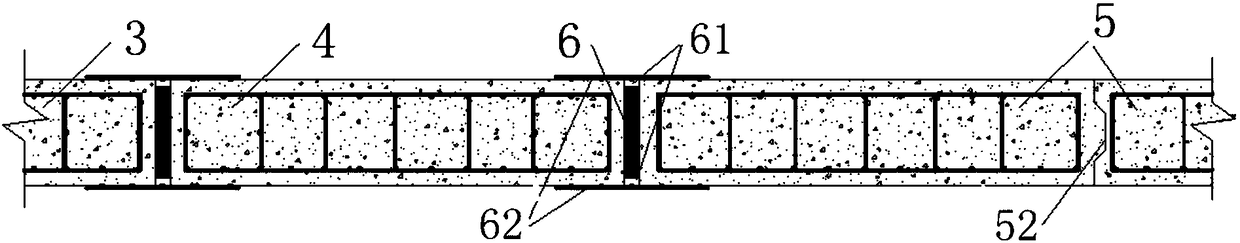

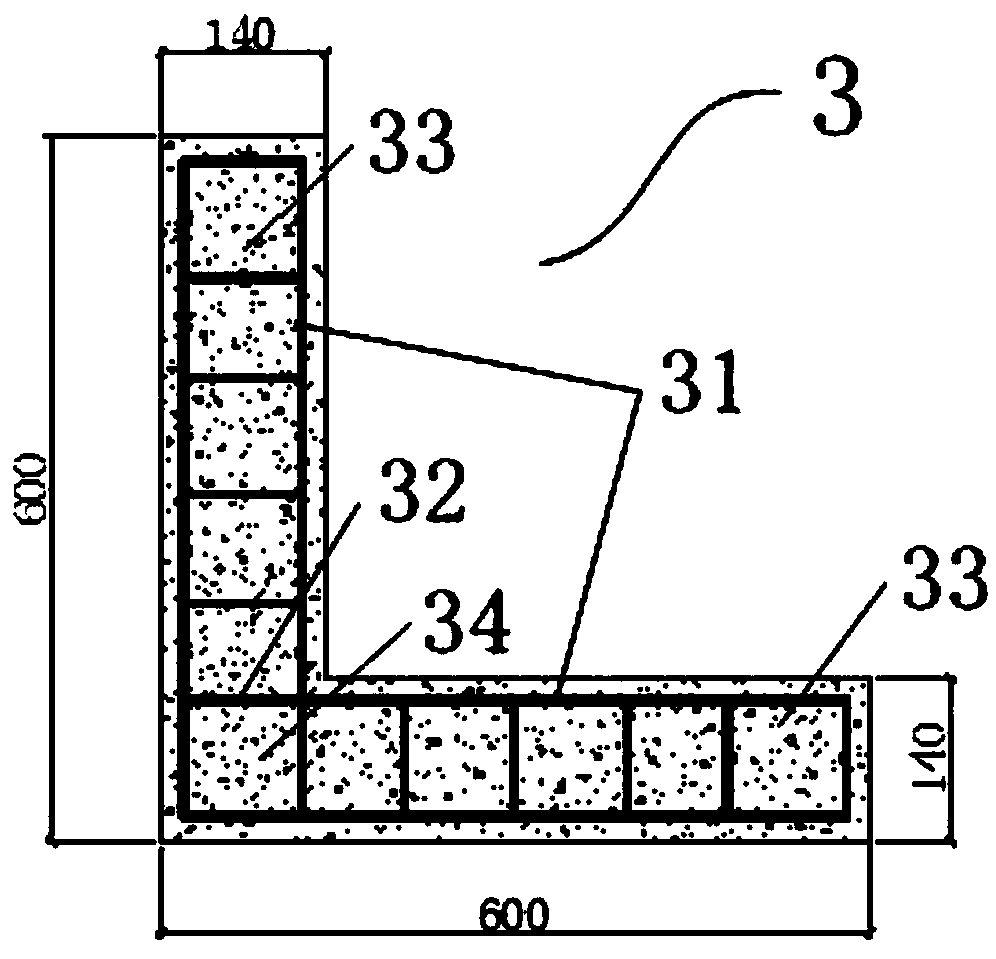

Fabricated steel and concrete combination structure

The invention discloses a fabricated steel and concrete combination structure. The fabricated steel and concrete combination structure comprises frame columns and frame beams connected with the frame columns. The frame beams are composed of pure steel beam areas and steel-concrete combination beams connected with the pure steel beam areas, wherein joint core areas of the frame beams are the pure steel beam areas, and every two adjacent pure steel beam areas are connected through the corresponding steel-concrete combination beam. The invention further discloses a fabricated steel and concrete combination frame-shear wall structure. The fabricated steel and concrete combination frame-shear wall structure comprises a fabricated steel and concrete combination frame and reinforced concrete wallboards arranged on the inner side of the fabricated steel and concrete combination frame in a filling mode. The fabricated steel and concrete combination structure solves the problems that in the prior art, a fabricated reinforced concrete structure is poor in stress and deformation capacity and a steel structure is high construction cost.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

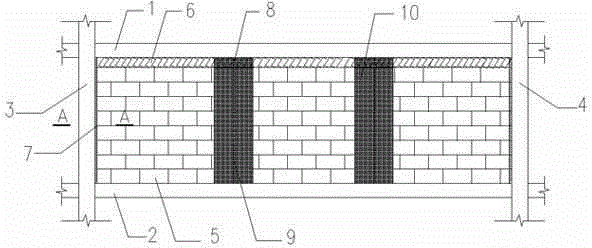

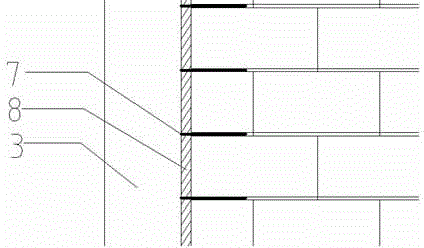

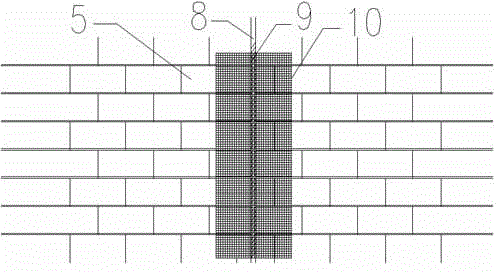

Energy-consumption steel-frame block filled wall

InactiveCN103603445AImprove deformation abilityReduce structural lateral movementWallsShock proofingRebarMortar joint

The invention discloses an energy-consumption steel-frame block filled wall, relates to the field of building design and building aseismicity and particularly relates to a collaborative anti-seismic property of the steel frame and the block filled wall. The steel-frame block filled wall comprises an upper steel frame beam, a lower steel frame beam, a left steel frame beam, a right steel frame beam and a block filled wall. The steel-frame block filled wall is characterized in that vertical continuous seams are arranged between steel frame columns and the block filled wall and in the middle of the block filled wall. Slantwise built vertical bricks are arranged between the block filled wall and the upper steel frame beam, and the vertical continuous seams are filled through elastic-plastic materials, and gridding cloth is pasted outside the vertical continuous seams. The steel frame columns and the block filled wall are connected by spot welding of thin rebars and burying the ends into mortar joints of the filled wall. According to the energy-consumption steel-frame block filled wall, during the earthquake, the elastic-plastic materials at the vertical seams are subjected to elastic-plastic deformation, additional damping is provided for consuming partial seismic energy, and the structure partial elastic-plastic interlayer displacement can be prevented, so that the structure has the good deformation capacity and ductility, and elastic-plastic deformation and energy-consumption requirements under the action of earthquake are met.

Owner:SHENYANG JIANZHU UNIVERSITY

Desert-sand light aggregate concrete fabricated shear wall structure

The invention discloses a desert-sand light aggregate concrete fabricated shear wall structure which comprises a foundation, coupling wall columns arranged on the foundation, and coupling beams connected between the coupling wall columns. The coupling wall columns are mainly composed of steel wire nets, thin-wall shape steel, steel wire cages and the like correspondingly. Desert-sand light aggregate concrete is poured on the steel wire nets and the steel wire cages, and the coupling wall columns are connected through asbestos boards, the steel wire nets, the desert-sand light aggregate concrete and the like in a poured mode correspondingly. The desert-sand light aggregate concrete fabricated shear wall structure is light in weight, materials are easy to obtain, the anti-seismic bearing capacity and deformability of components can be reliably ensured, and the good heat-insulating property is also achieved under the situation that the bearing requirement is met. The assembly attributes of simple structure and convenient and rapid transporting and mounting are achieved, and the desert-sand light aggregate concrete fabricated shear wall structure is particularly suitable for remote villages and towns which are insufficient in material supply, low in worker quality and short in technical force in Xinjiang region, and can be self-built by tile teams or farmers of the villages and thetowns.

Owner:SHIHEZI UNIVERSITY

Composite reinforced concrete beam containing crack resistant reinforcement layer and method for making same

InactiveCN1523177AGuaranteed StrengthGuaranteed deformabilityMouldsGirdersReinforced concreteMaterial Crack

The present invention relates to a composite reinforced concrete beam containing crack-resisting reinforcing layer, and it is characterized by that a composite material crack-resisting reinforcing layer can be stuck on the partial or whole tensile area of reinforced concrete beam, and its making method mainly includes the following steps: firstly, making reinforced concrete structure; then brushing a layer of interfacial adhesive glue on the treated undersurface of reinforced concrete structure and its partial side surface below contral line, then sticking composite material crack-resisting reinforcing layer on the surface of the above-mentioned interfacial adhesive glue. Said composite reinforced concrete beam has good crack-resisting property and large structure rigidity.

Owner:CHONGQING JIAOTONG UNIVERSITY

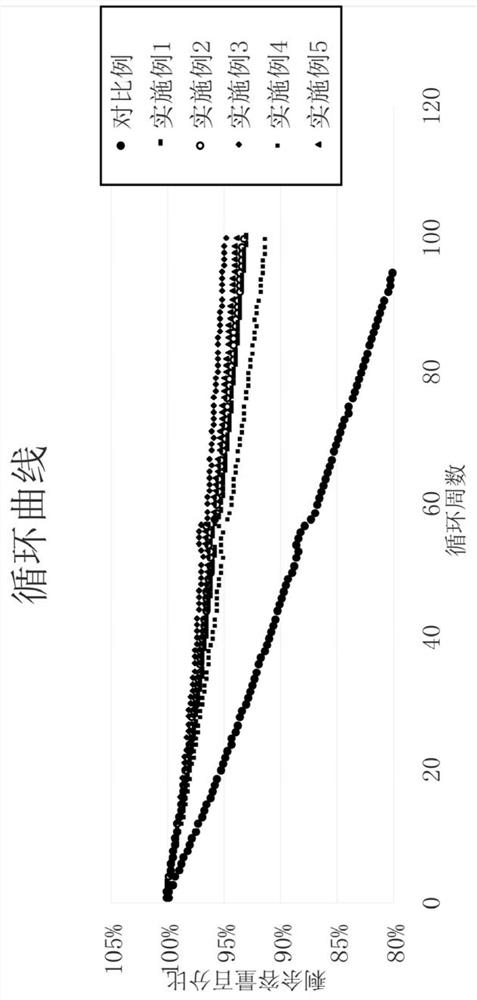

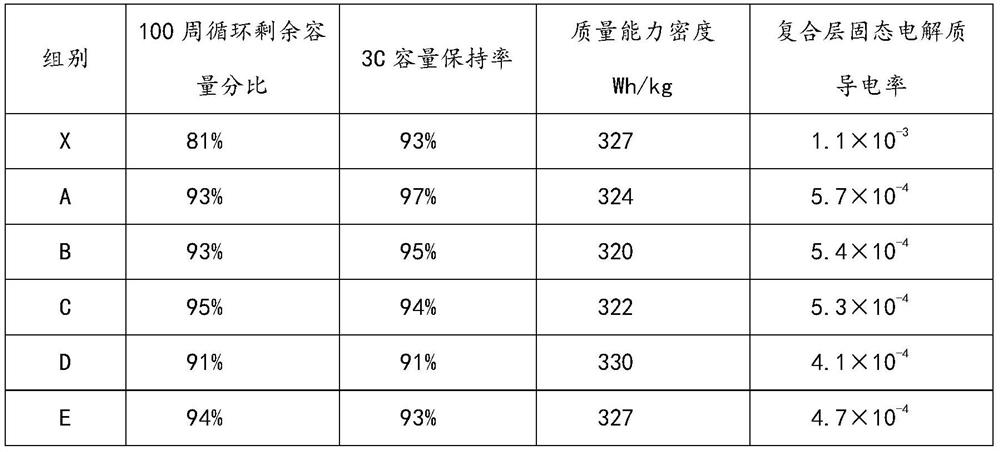

Composite electrolyte and application thereof

ActiveCN111613830AGood chemical stabilityImprove conductivitySolid electrolytesSecondary cellsSolid state electrolyteElectrolytic agent

The invention discloses a composite electrolyte and application thereof, the composite electrolyte comprises a gel electrolyte coated on a lithium negative electrode and a quasi-solid electrolyte coated on a positive electrode, and the gel electrolyte is in contact with the quasi-solid electrolyte; electrolyte is adsorbed in the quasi-solid electrolyte; both the gel electrolyte and the quasi-solidelectrolyte contain the same conductive lithium salt; the invention also discloses application of the composite electrolyte to a lithium ion battery. According to the invention, through cooperation of the two electrolytes, lithium dendrites are inhibited, and the composite electrolyte is ensured to have good conductivity.

Owner:南通赛得能源有限公司

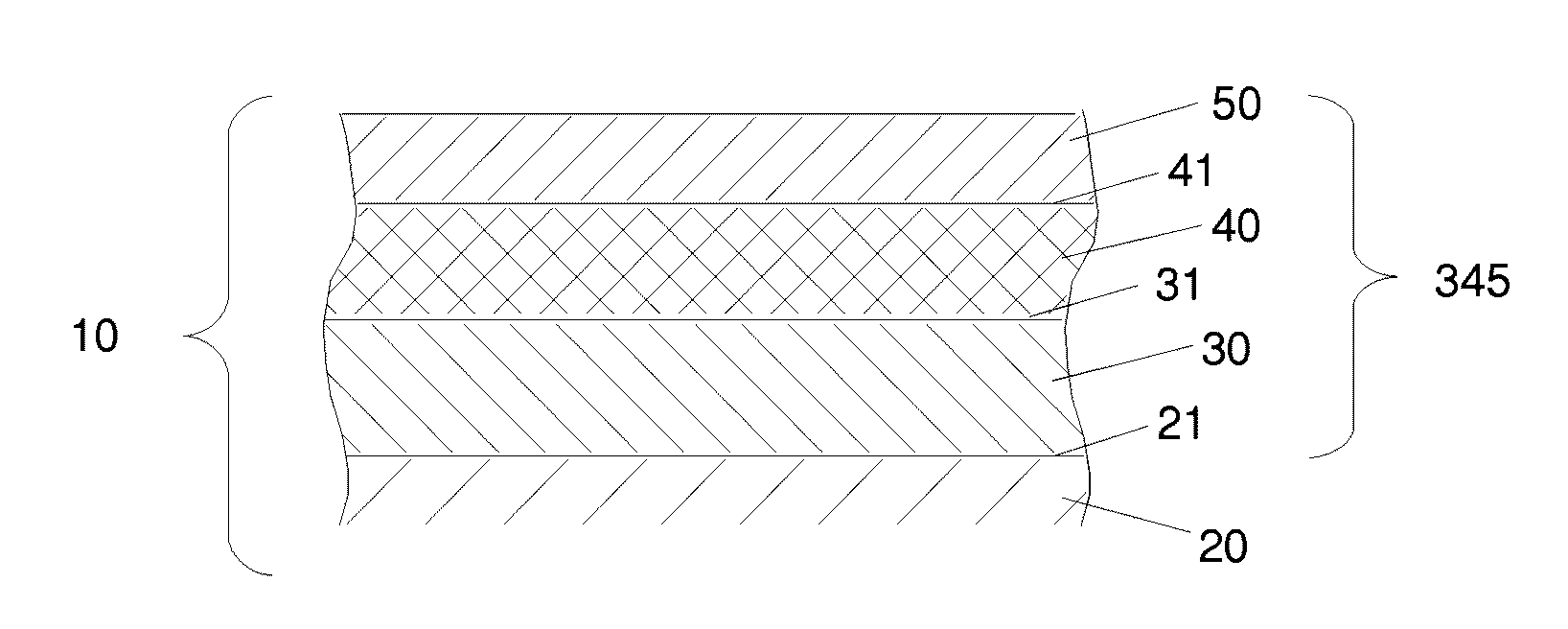

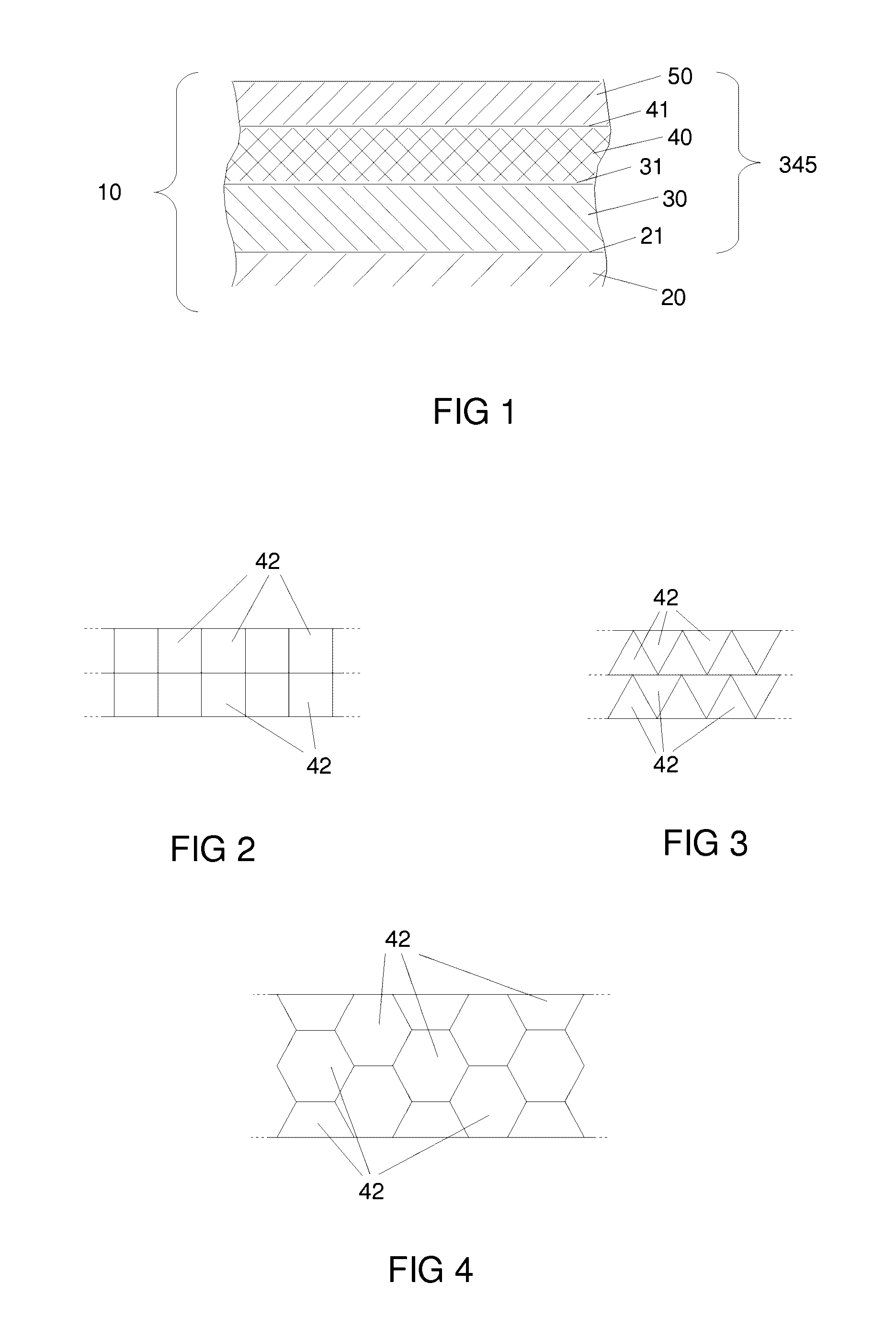

Aircraft structure with solar energy capture capacity

InactiveUS20160368613A1Easy to adaptShorten the timePower plant arrangements/mountingEnergy efficient board measuresNacelleFuselage

An aircraft structure (10), in particular the fuselage, nacelles or wings, includes, over all or part of an outer surface (21) that may undergo lightning impacts, a layer of flexible polymer (30), a photovoltaic film (40) and a protective layer (50) protecting the photovoltaic film. This aircraft structure primarily has a solar energy capture capacity making it possible to meet the needs of an aircraft as well as an ability to protect against the effects of lightning.

Owner:EURON AERONAUTIC DEFENCE & SPACE +1

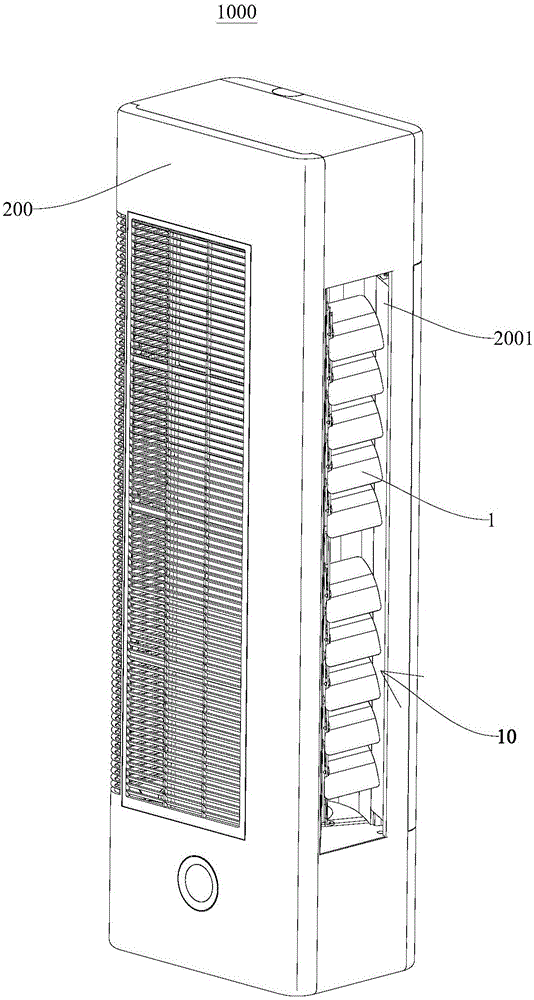

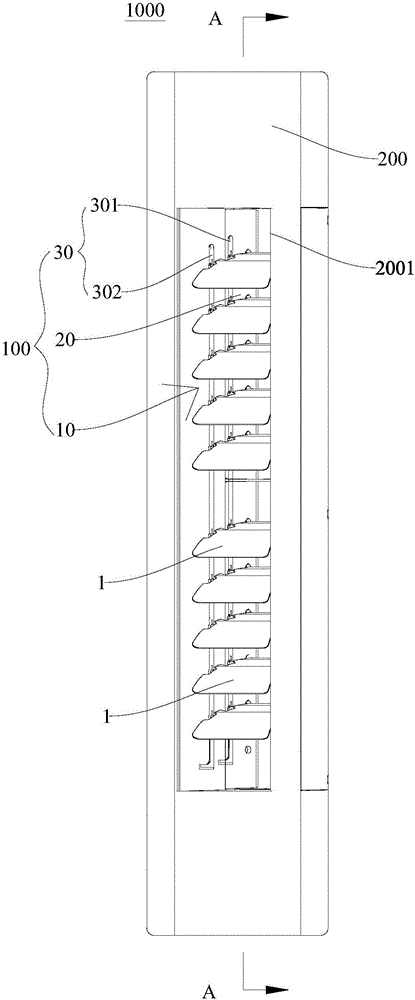

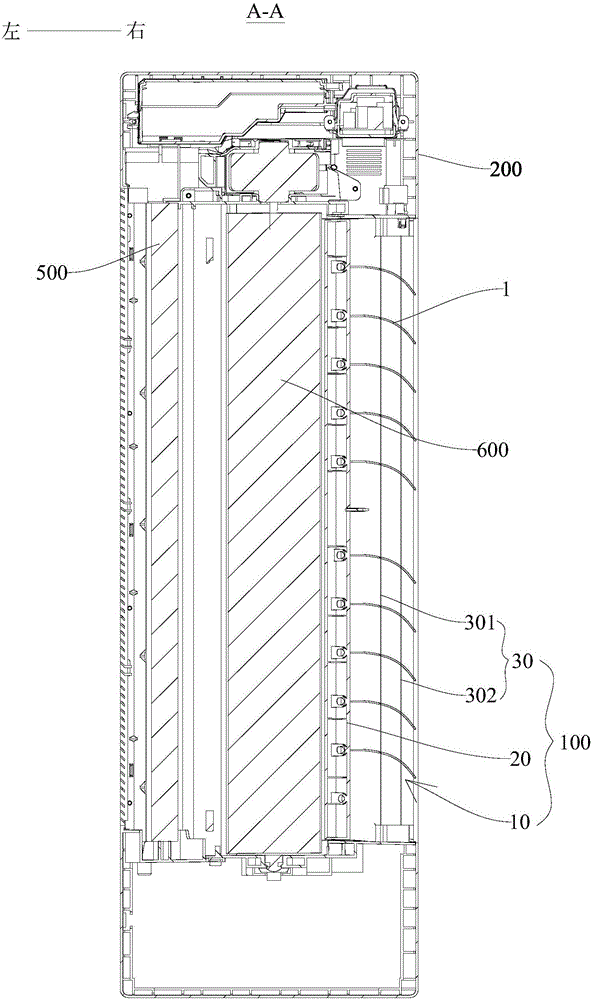

Air conditioner indoor unit and air guide assembly thereof

ActiveCN106765602AControllable deformationGuaranteed deformabilityLighting and heating apparatusEfficient regulation technologiesWaste management

The invention discloses an air conditioner indoor unit and an air guide assembly thereof. The air guide assembly of the air conditioner indoor unit includes an air outlet frame which is arranged in an air outlet of the air conditioner indoor unit; connection rods which are vertically and movably arranged in the air outlet of the air conditioner indoor unit; an air guide shutter which includes a plurality of air guide blades which are vertically arranged at intervals, wherein each air guide blade includes a first section, a second section, and a third section which are successively connected in an end-to-end manner, the hardness of the second section is less than that of the first section and the third section and can deform, a head end of each air guide blade is connected to the air outlet frame, clamping columns are arranged on each air guide blade, and the clamping columns are connected to the connection rods. The air guide assembly is large in air guide adjustment angle, is large in air feeding range, and can improve the use comfort.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

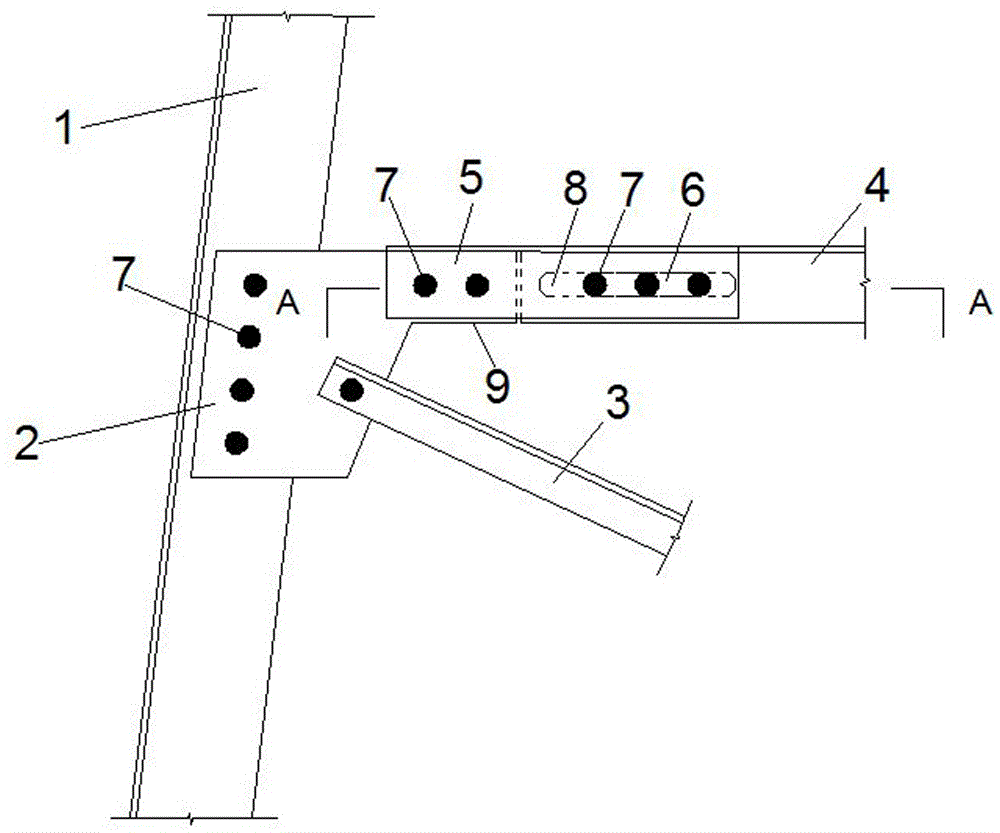

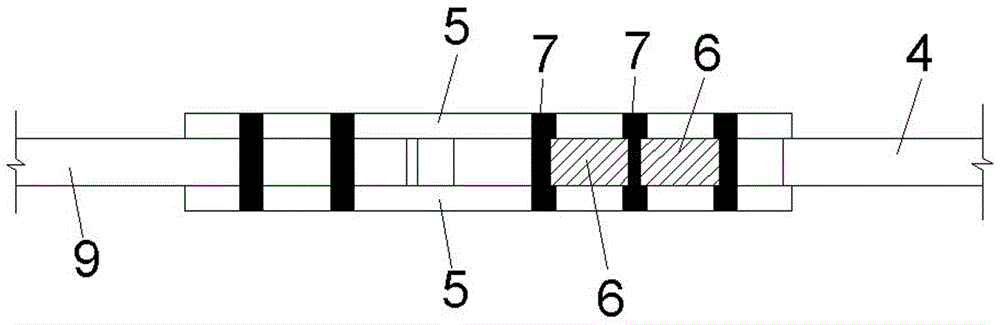

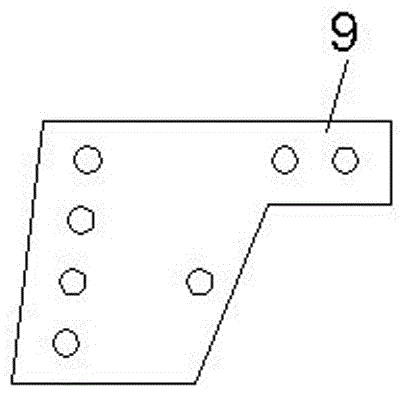

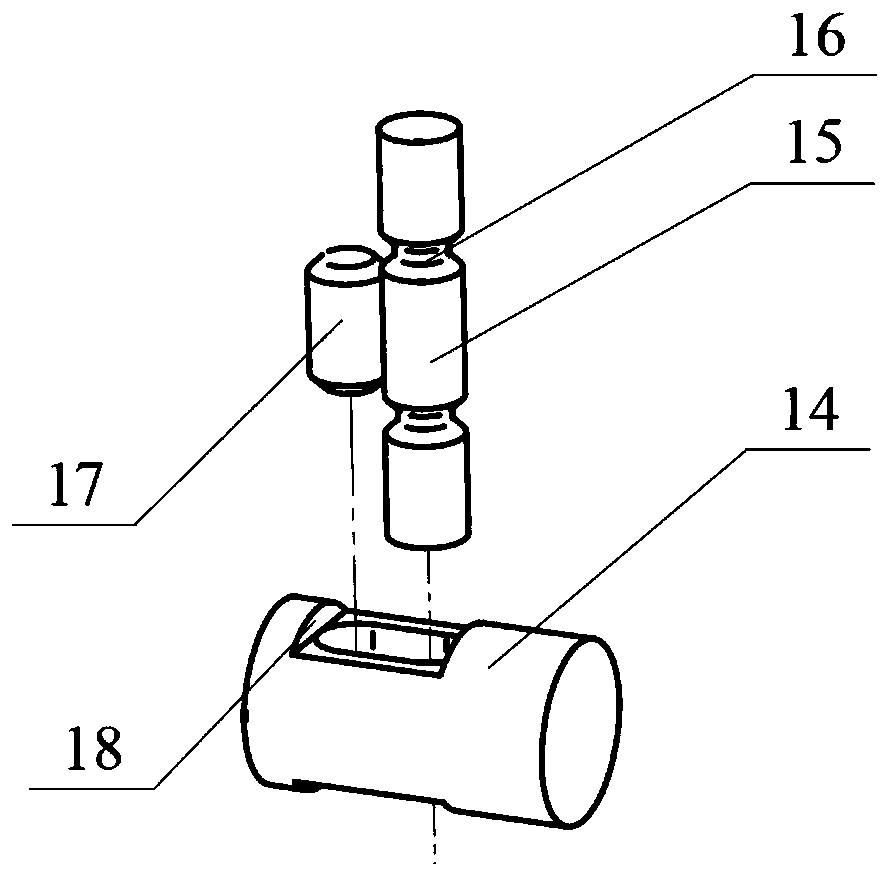

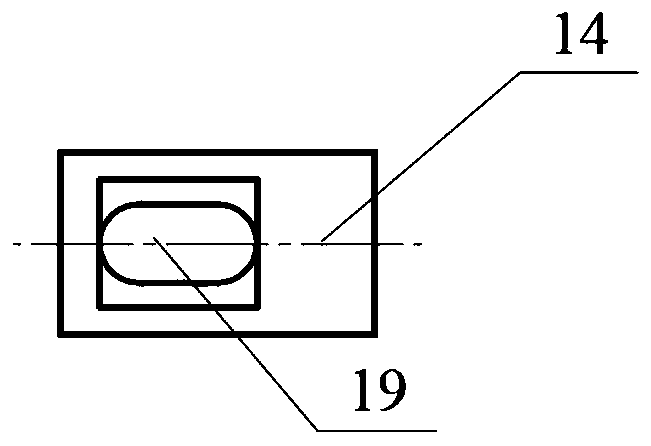

Slidably deforming node device for transmission tower in mining subsidence area and design method of such slidably deforming node device

ActiveCN106760876AReduce or eliminate stress concentrationsImprove stabilityDesign optimisation/simulationTowersTransmission towerAxial force

The invention discloses a slidably deforming node device for a transmission tower in a mining subsidence area and a design method of such slidably deforming node device. The slidably deforming node device is characterized in that a connecting arm extends out of the upper right of a node plate, an oblong hole slideway is arranged on the left portion of a slidable rod piece, the left portions of a pair of connecting rod pieces are positioned in front of and behind the connecting arm respectively and are connected through connecting bolts while the right portions thereof are positioned in front of and behind the left portion of the slidable rod piece respectively and are fixedly connected with connecting bolts passing through the oblong hole slideway, and a slider is arranged between each two adjacent connecting bolts in the oblong hole slideway. The design method includes establishing a finite element calculation model; determining a displacement mode and displacement of a tower pedestal; calculating a maximum axial force value of the slidable rod piece at a node position under various upper load conditions; obtaining a design value of maximum pressure borne by the slidable rod piece at the node position. The slidably deforming node device is capable of improving integral structure deformation capability. The design method is capable of designing anti-deformation structures meeting engineering practice requirements.

Owner:CHINA UNIV OF MINING & TECH

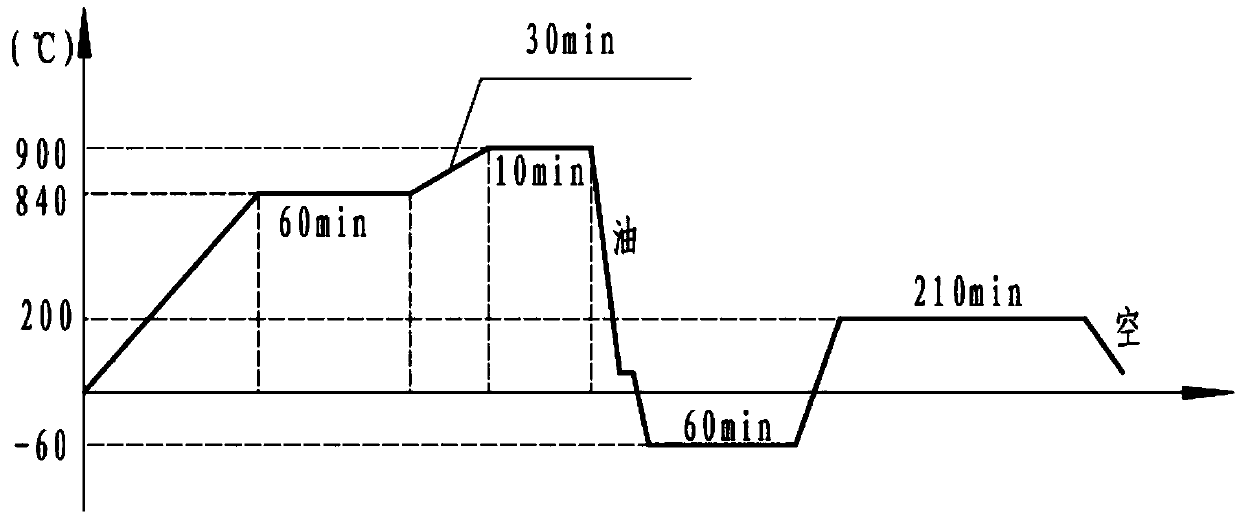

Method for improving surface strength of high-strength alloy transmission rod

ActiveCN105369016AGuaranteed deformabilityGuaranteed depthSolid state diffusion coatingCopper platingAlloy

The invention provides a method for improving the surface strength of a high-strength alloy transmission rod. The two ends of the transmission rod are provided with splines. The surfaces of the splines are to-be-carbonitrided faces. The method includes the steps that protection is performed in advance, a non-carbonitrided face of the outer surface of the transmission rod is plated with copper, an inner hole of the transmission rod is filled with stuffing, and the two ends of the inner hole are plugged through copper plugs; the transmission rod is hung and the transmission rod is perpendicularly clamped and hung in a thermal treatment furnace; carbonitriding treatment is performed; and after carbonitriding is finished, the high-temperature transmission rod is put in a cooling medium for quenching treatment. A copper plating method and a hole plugging method are adopted for carbonitriding treatment, it can be guaranteed that the material strength and tenacity of the non-carbonitrided face are enough, and the deformability of the transmission rod is guaranteed. It can be guaranteed that the transmission rod is prevented from being deformed greatly in the radial direction of the transmission rod when perpendicularly hung. A carbonitriding method is adopted, the depth of a hardened layer or the hardness of a core can be guaranteed, the surface strength of the splines at the two ends of the transmission rod is improved, high-temperature quenching is directly performed after carbonitriding is performed, secondary heating is not needed, and the deformation of the transmission rod is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Box type high-strength bamboo laminated wood beam and manufacturing method

ActiveCN105735104AReduce energy consumptionReduce pollutionWood working apparatusBridge structural detailsEngineeringEnergy consumption

The invention provides a box type high-strength bamboo laminated wood beam and a manufacturing method. The box type high-strength bamboo laminated wood beam structurally comprises a high-strength bamboo laminated wood top board, a high-strength bamboo laminated wood bottom board, high-strength bamboo laminated wood webs and low-density bamboo laminated wood anti-shearing bamboo pins. The high-strength bamboo laminated wood top board and the upper portions of the high-strength bamboo laminated wood webs are connected through clamping grooves A and the low-density bamboo laminated wood anti-shearing bamboo pins A. The high-strength bamboo laminated wood bottom board and the lower portions of the high-strength bamboo laminated wood webs are connected through clamping grooves B and the low-density bamboo laminated wood anti-shearing bamboo pins B. The box type high-strength bamboo laminated wood beam has the beneficial effects that the beam is suitable for a large-span bamboo structure, high in anti-torque rigidity and low in energy consumption and pollution; the height of the beam can be adjusted through the height of the webs according to the stress condition, standardized production is facilitated, the requirements for a fabricated structure and building diversity can be met, the clamping grooves and the bamboo pins are adopted for connection, the technology is simple, connection is reliable, and the quality is easy to control; and a box type section is adopted, the bearing capacity, the deformation capacity and the stability of the beam are improved, materials are saved, the dead weight is low, the manufacturing cost is reduced, and earthquake resistance and energy conservation are better achieved.

Owner:南京森工生物质材料研究院有限公司

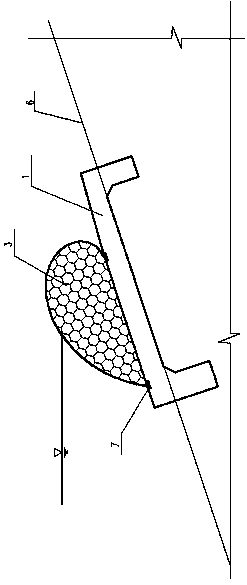

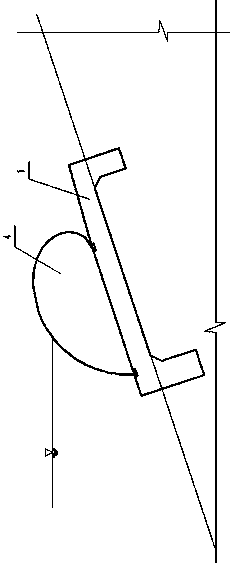

Honeycomb dam slope protection structure

ActiveCN108221841ARealize automatic sheddingEliminate damageCoastlines protectionHydraulic engineering apparatusHoneycombEngineering

The invention provides a honeycomb dam slope protection structure which comprises a bottom plate. The honeycomb dam slope protection structure has the advantages that the destructive effect of ice thrust, ice pullout, floating ice impact and the like generated by icing of a reservoir in winter on the upstream dam slope of a dam can be effectively reduced, a dam slope panel is effectively protected, an ice cover can automatically fall off, and the danger of manual ice drilling is avoided. The structure is long in service life and low in manufacturing cost and can be used for protecting cold region reservoir dam slopes and river channel bank slopes, and safety of the dam and the river channel bank slopes is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

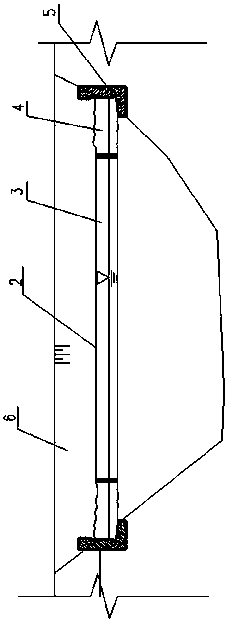

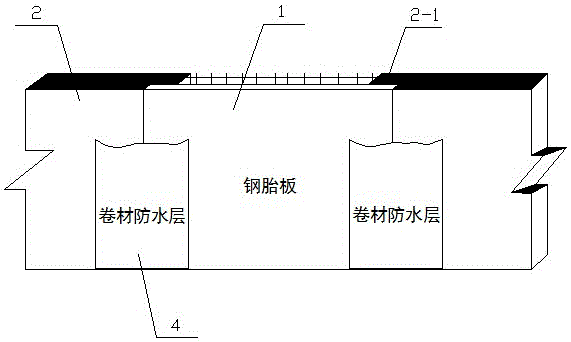

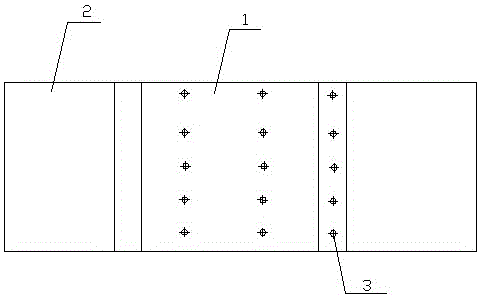

Advancing water stop steel bed mould composite structure on post-cast strip

InactiveCN106368334AGuaranteed deformabilityGood water stop effectBuilding constructionsReinforced concreteRebar

The invention discloses an advancing water stop steel bed mould composite structure on a post-cast strip and relates to the field of construction safety. The head water stop steel bed mould composite structure comprises a steel bed mould arranged on the outer side of the post-cast strip and reinforced concrete walls arranged on the two sides of the steel bed mould. The two ends, making contact with the steel bed mould, of the reinforced concrete walls are provided with steps matched with the steel bed mould in thickness. The two ends of the steel bed mould make contact with the steps correspondingly. The outer side face of the steel bed mould and the outer surfaces of the reinforced concrete walls are on the same plane. Three rows of T-shaped connection parts are arranged on the inner side face of the steel bed mould. Each row of T-shaped connection parts comprises a plurality of T-shaped connection part single bodies arranged perpendicularly from top to bottom. One row of T-shaped connection parts is arranged in the overlapping position of one end of the steel bed mould and the reinforced concrete wall on the opposite side and is welded to rebars of the reinforced concrete wall. Flexible waterproof layers are arranged on the joints of the outer side of the steel bed mould and the reinforced concrete walls. The advancing water stop steel bed mould composite structure is easy in material fetching, convenient to machine and good in water stop effect.

Owner:JIANGSU HONGSHENG CONSTR ENG GROUP

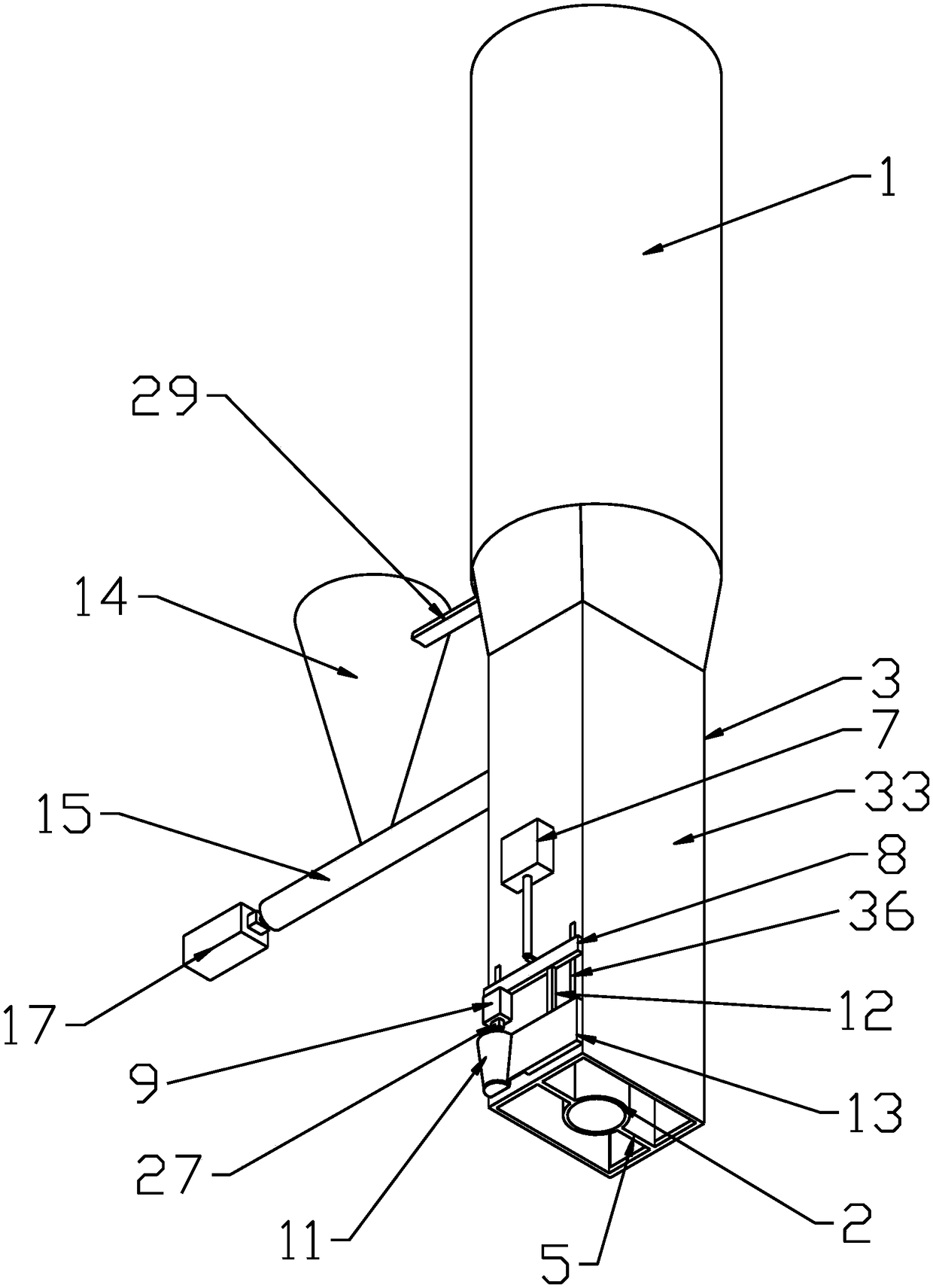

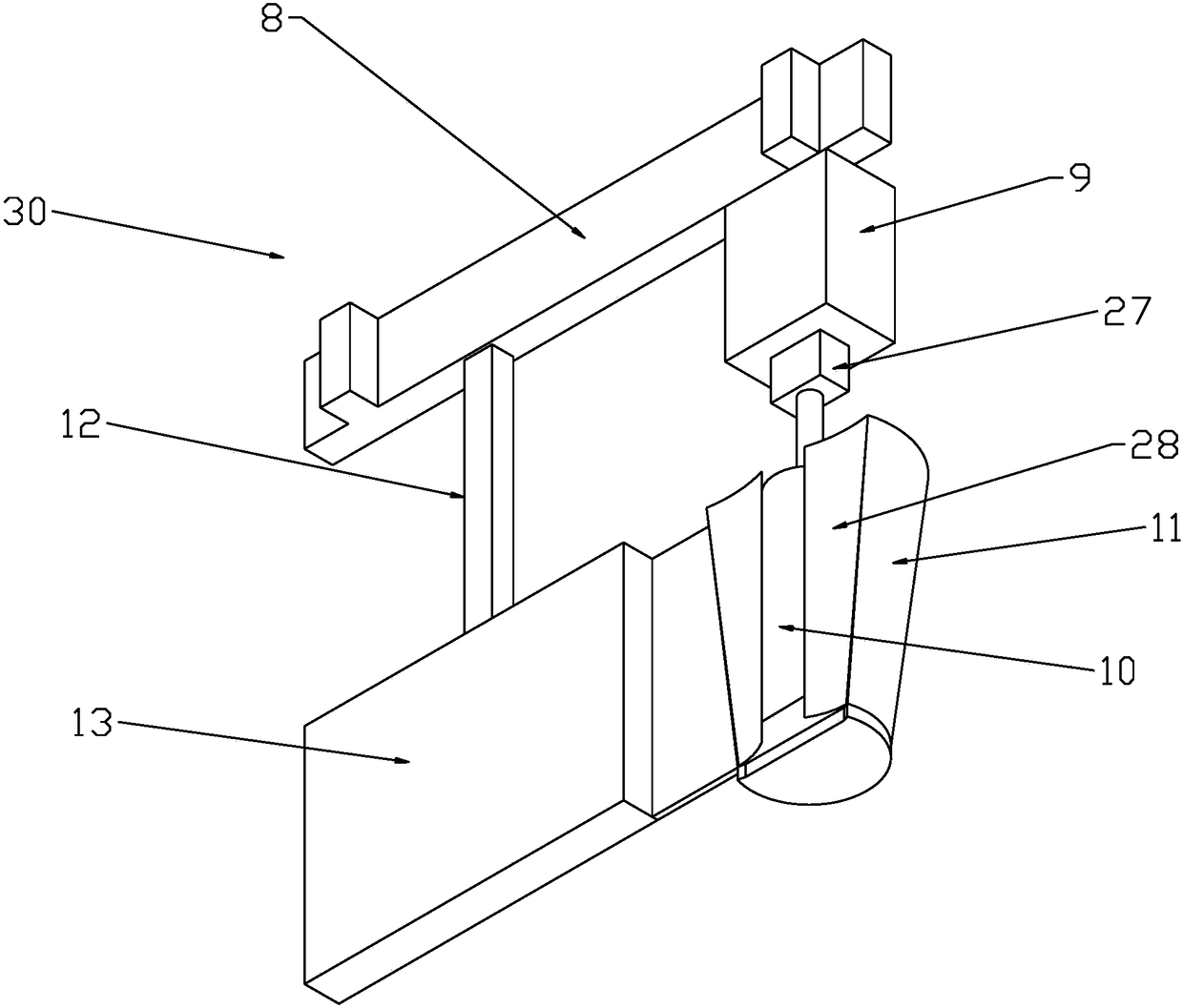

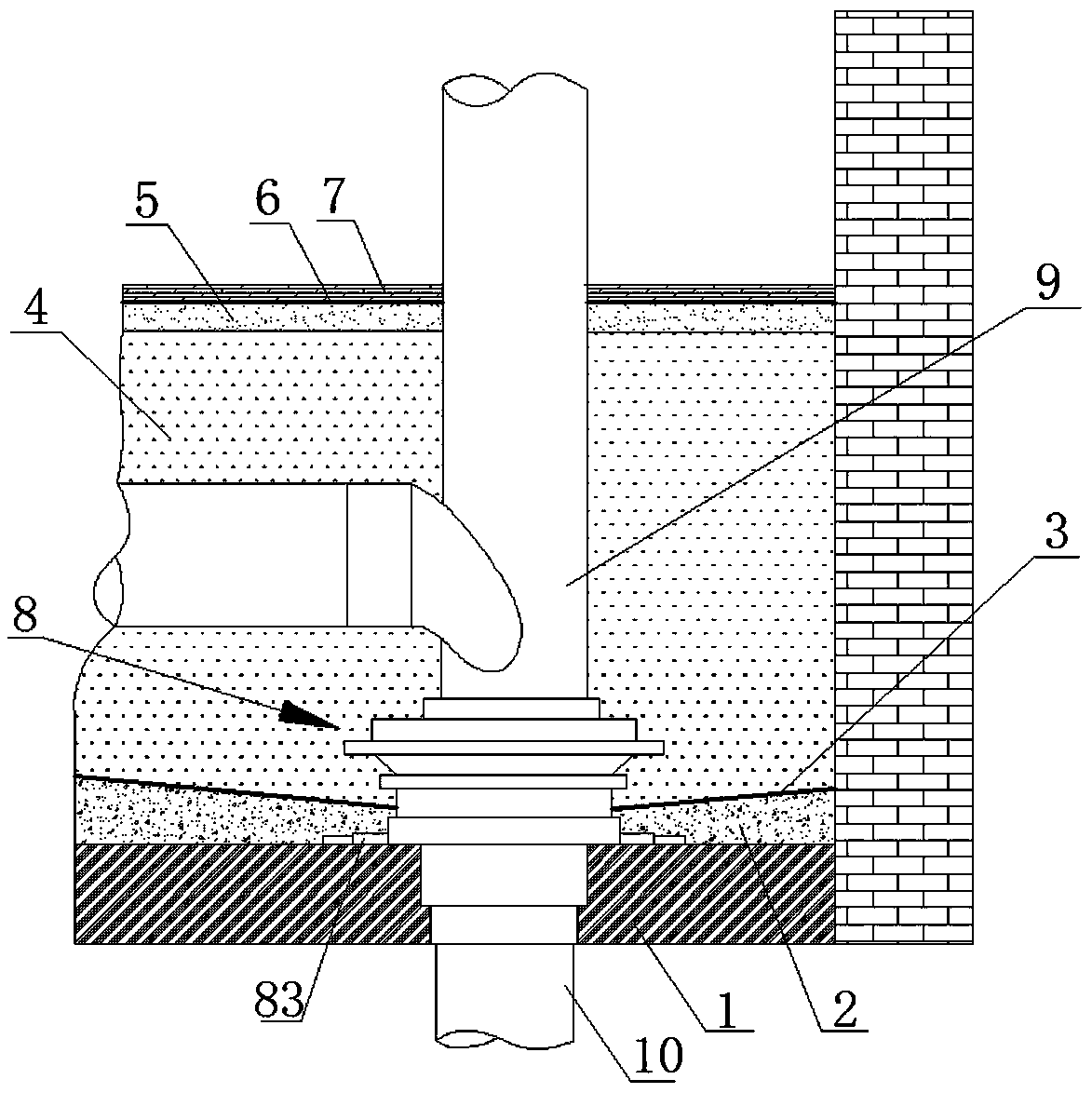

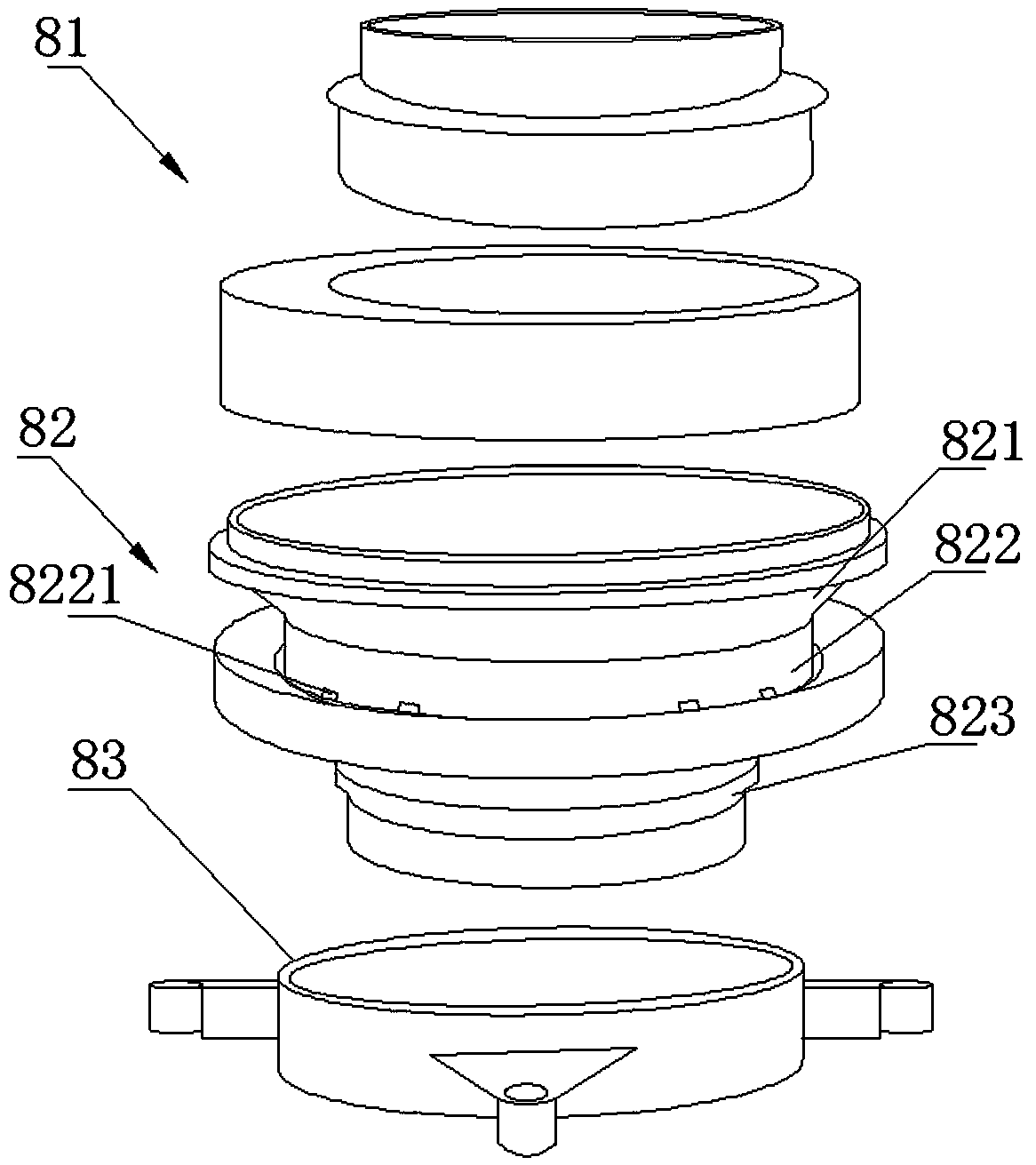

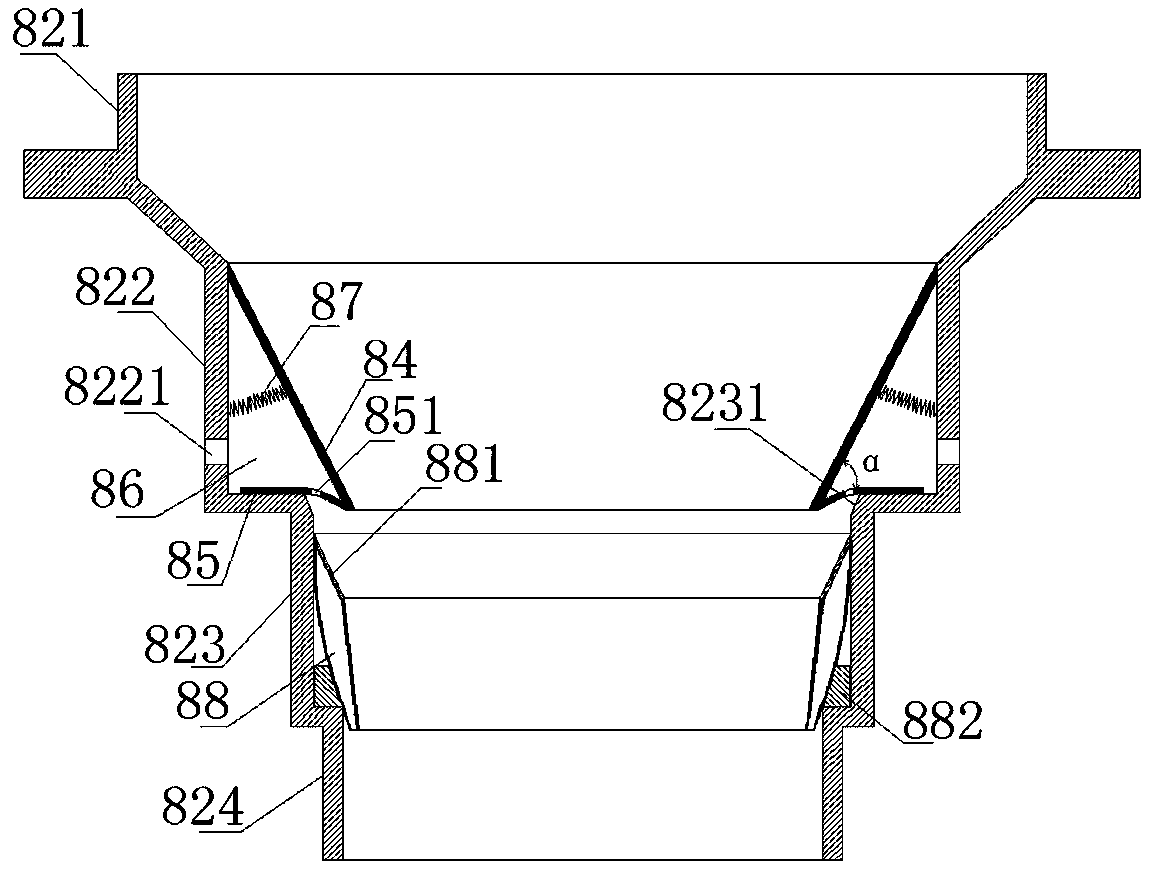

Toilet structure composed of vertical pipe embedding piece device and construction method of toilet structure

ActiveCN109537685AReduce squealingPrevent backflowSewerage structuresDomestic plumbingSurface layerWater flow

The invention relates to a toilet structure composed of a vertical pipe embedding piece device and a construction method of the toilet structure. The toilet structure comprises an accumulation water drainage device, an upper vertical pipe, a lower vertical pipe, a cast-in-situ floor, a lower leveling layer, a lower waterproof layer, a filling layer, an upper leveling layer, an upper waterproof layer and a decorative surface layer; the cast-in-situ floor, the lower leveling layer, the lower waterproof layer, the filling layer, the upper leveling layer, the upper waterproof layer and the decorative surface layer are sequentially arranged from bottom to top; the lower portion of the accumulation water drainage device is embedded in the cast-in-situ floor; the upper vertical pipe is inserted into the upper end of the accumulation water drainage device; the lower vertical pipe is inserted into the lower end of the accumulation water drainage device; the accumulation water drainage device comprises an eccentric adjustment piece and a main water passing body which are sleeved with each other from top to bottom. The toilet structure has good waterproof performance and water accumulation resistance, pipelines are arranged inside, the toilet structure is simple and attractive, the noise is low, one-time formation with the accumulation water drainage device can be achieved without additional sealing and secondary template support, mounting is convenient, the accumulation water drainage device can automatically adjust the diameter of a flow path according to the magnitude of water flow, singing generated by the running flow and air is reduced accordingly, and the noise is reduced.

Owner:福建建中建设科技有限责任公司

Thin-wall braking sleeve of direct drive rotary table and manufacturing method

InactiveCN103883647AProne to elastic deformationSolve deformation difficultiesBraking membersBrake actuating mechanismsThin walledHydraulic pressure

The invention relates to a thin-wall braking sleeve of a direct drive rotary table and a manufacturing method. A main body of the thin-wall braking sleeve of the direct drive rotary table is an annular cylinder, and the cross section of the annular cylinder is an oval ring. In the height direction of the oval ring, an external gap d is reserved between the outer edge of the oval ring and the inner wall of a case body, and an internal gap c is reserved between the inner edge of the oval ring and the outer wall of a motor rotor, wherein the external gap d is larger than the internal gap c and is filled with hydraulic oil. When the external gap d is filled with the hydraulic oil and the radial hydraulic pressure is generated, at least one action point on the inner wall surface of the annular cylinder is attached to the outer wall of the motor rotor under the effect of the hydraulic pressure in the circumferential direction of the oval ring, so that friction force is generated. On the premise of guaranteeing the strength and the abrasive resistance of the thin-wall braking sleeve, the thin-wall braking sleeve generates elastic deformation easily, and therefore braking of the direct drive rotary table is easy, safe and reliable, and oil leakage is avoided.

Owner:WUHAN POLYTECHNIC UNIVERSITY

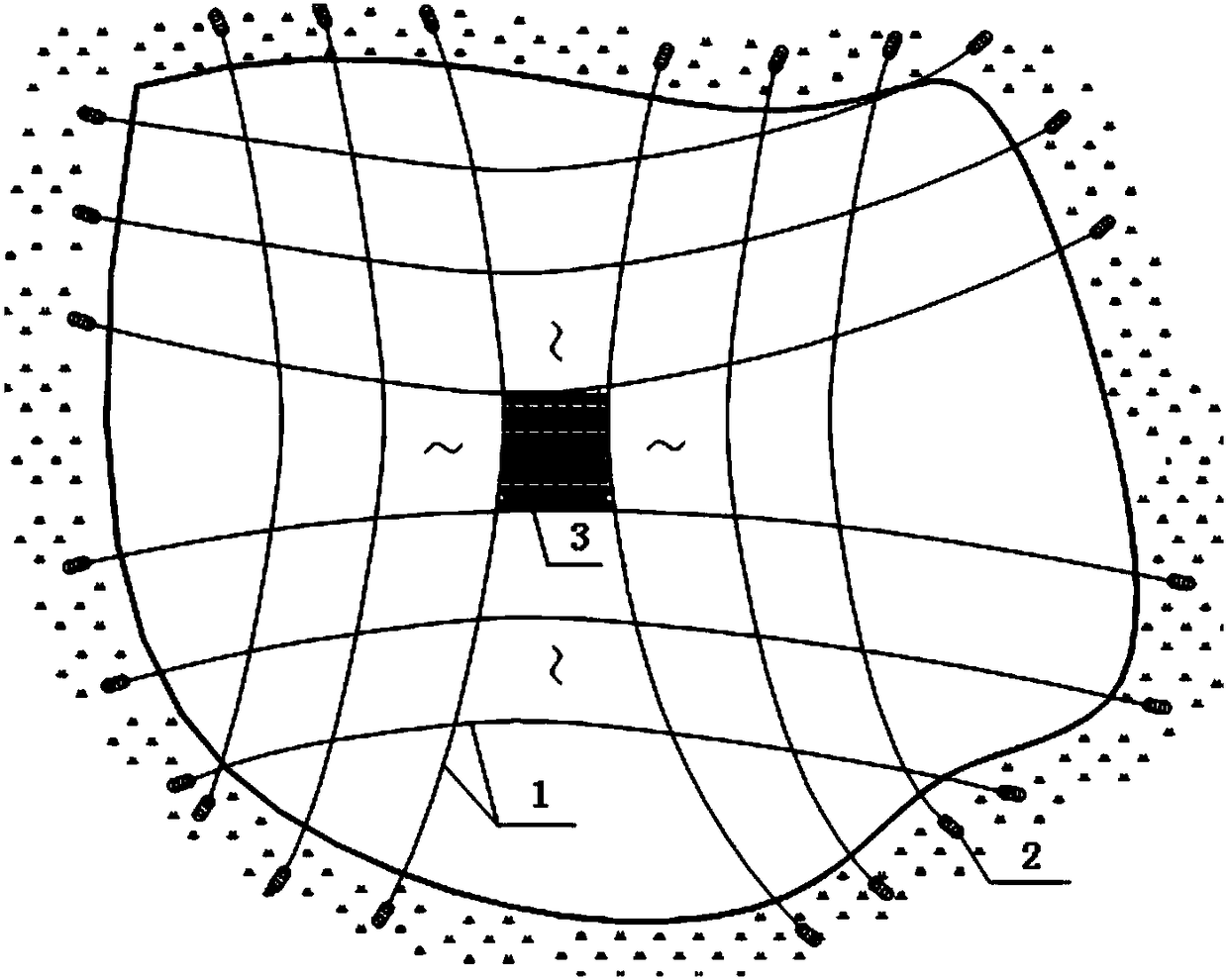

Mesh-supported floating photovoltaic power station

PendingCN109150069AGuaranteed deformabilityPrevent stack crush damagePhotovoltaic supportsWaterborne vesselsMarine engineeringPhotovoltaic power station

A mesh-supported floating photovoltaic power station is disclosed, a main network system comprises a main cable which is arranged across the water surface and is laterally and longitudinally staggered, each main cable is anchored to the shore at both ends by steel spiral piles, power generation units are arranged in each cell of the main network system, and each power generation unit comprises floating bodies arranged in rows and in columns, the floating bodies in each row are connected by transverse secondary cables, the floating bodies in each row are connected by longitudinal secondary cables, the two ends of each transverse secondary cable and the longitudinal secondary cables are fixedly connected with the main cables, and photovoltaic modules are fixed on each floating body. The power station adopts a ''big mesh sleeving small mesh'' structural system as a main support structure, bolts or pins between floating bodies are canceled, canceling underwater pile anchors and anchoring,and anchoring the whole system to steel spiral piles on the water bank can effectively prevent the floating bodies and photovoltaic modules from being stacked and squeezed, which is suitable for deepwater area environments such as reservoirs, large fish ponds and coal mining subsidence areas.

Owner:TIANJIN UNIV

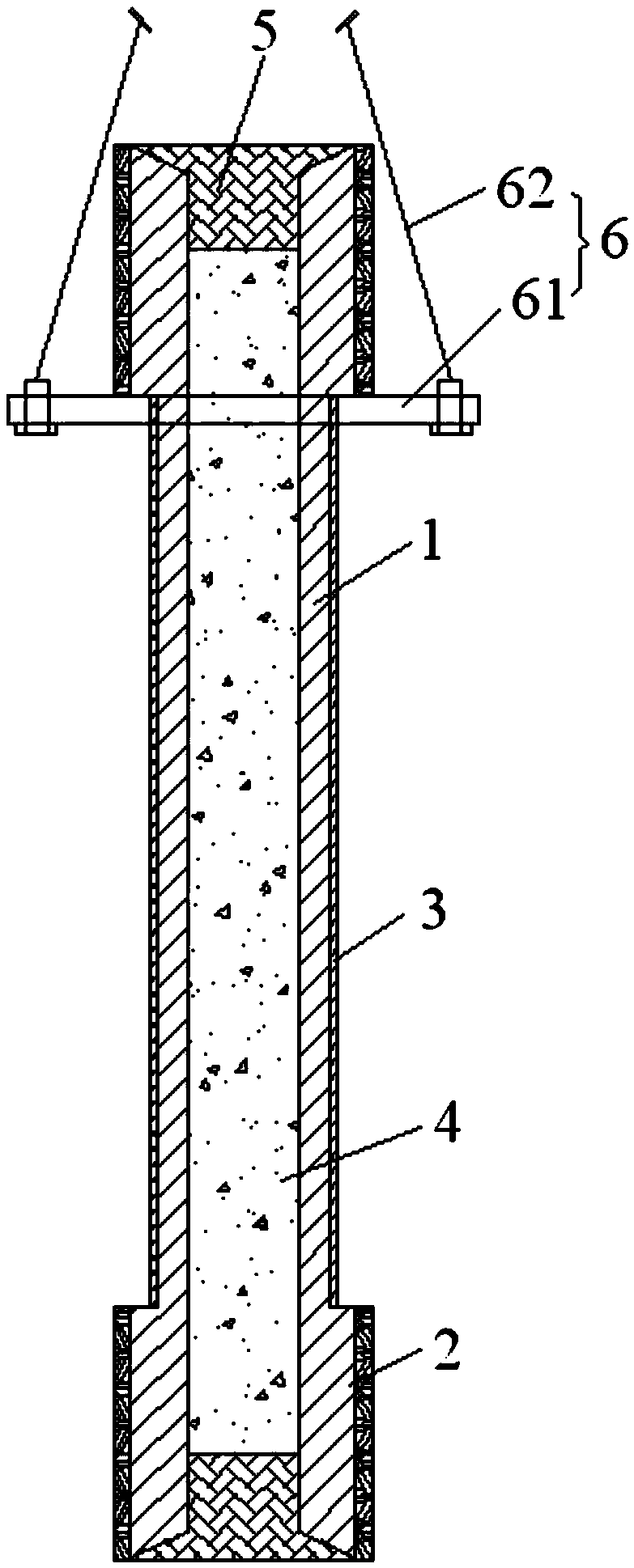

Novel combined pile foundation structure suitable for integral bridge and construction method thereof

PendingCN110847162AImprove the force deformation performanceSimple construction processBulkheads/pilesArchitectural engineeringAbutment

The invention relates to a novel combined pile foundation structure suitable for an integral bridge and a construction method thereof. Mainly aiming to solve the problems that the deformation capability of a traditional common concrete pile foundation cannot met the requirements of the integral bridge, the novel combined pile foundation structure is capable of meeting the requirements of the deformation capability of the integral bridge as well as ensuring the stress performance of the integral bridge. The novel combined pile foundation structure mainly comprises a cylindrical concrete pile body, wherein a reinforcement cage is arranged inside the concrete pile body, a mounting hole is formed in the middle of the top surface of the concrete pile body, a prefabricated protection cylinder isarranged inside the mounting hole, a steel bar is vertically arranged in the middle of the prefabricated protection cylinder, the upper end of the steel bar extends out of the mounting hole and is used for being inserted into an abutment, the lower end of the steel bar is inserted into the concrete pile body, and elastic materials fill the portion between the steel bar and the side wall of the prefabricated protection cylinder to ensure the deformation requirements. According to the novel combined pile foundation structure, the structural design is simple and reasonable, the prefabricated protection cylinder, the steel bar and the elastic materials are utilized to form a deformation assembly, so that the stress deformation performance of a pile foundation is obviously improved without reducing the bearing capacity of the integral bridge pile foundation.

Owner:FUZHOU UNIV

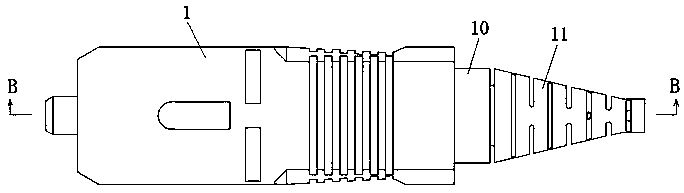

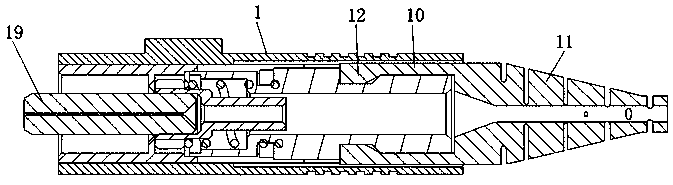

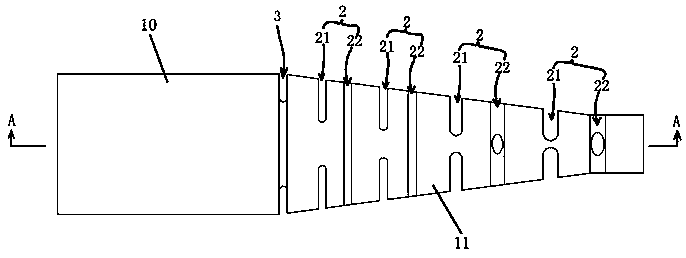

Tail jacket and connector using tail jacket

InactiveCN110174727AImprove deformation abilityConsistent deformabilityCoupling light guidesMechanical engineering

The invention provides a tail jacket and a connector using the tail jacket. The tail jacket comprises a jacket body, a connection section for connecting with a connector shell is arranged at a front end of the jacket body, a circumferentially closed deformation transition ring slot is arranged at a location, close to the connection section, on the tail section of the jacket body, and the deformation transition ring slot provides a deformation space for the lateral deformation of the tail section when a cable in the jacket body is suffered from the lateral tensile force. Due to the circumferential closing of the deformation transition ring slot, whether the cable is suffered from the lateral tensile force of any direction, the deformation space can be provided when the tail section of the jacket body is in lateral deformation along with the cable, and the deformation capacity consistency of the lateral deformation on a circumference direction is guaranteed.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Ship T-shaped profile welding deformation correcting method

InactiveCN112008273AGuaranteed deformabilitySimplify the corrective stepsWelding/cutting auxillary devicesAuxillary welding devicesCold airEngineering

The invention belongs to the field of shipbuilding, and particularly discloses a ship T-shaped profile welding deformation correcting method. The ship T-shaped profile welding deformation correcting method comprises the steps that a T-shaped profile panel is flatly placed on a correcting machining table, a laser heater is used for heating the welding position, a pushing mechanism pushes a push plate, the push plate and a standard vertical plate are kept in the state for clamping a T-shaped profile web, and cold air is used for cooling. According to the method, the T-shaped profile panel is kept in a straight state, the T-shaped profile web is corrected, and the correction steps are simplified; through assistance of the standard vertical plate and the push plate, the assembly welding position of the T-shaped profile panel and the T-shaped profile web is heated through the laser heater, the deformation effect of the end portion of the T-shaped profile web is guaranteed, and correction isfacilitated; the T-shaped profile web is restored to the vertical state by pushing of the push plate and is matched with the standard vertical plate to be clamped, so that the surface of the T-shapedprofile web is straightened and shaped conveniently; the cold air is used for cooling the assembly welding position at the bottom of the T-shaped profile web, the shaping effect after correction is guaranteed, and the correction efficiency is high.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Chamfering process in ship T profile production process

PendingCN111974852AGuaranteed deformation propertiesNot easy to reboundShaping toolsWaterborne vesselsPhysicsEngineering

The invention belongs to the field of ship manufacturing, and particularly discloses a chamfering process in the ship T profile production process. The chamfering process includes the steps that chamfering scale marks are marked on free sides of a T profile panel, the portions, except for the chamfering scale marks, of the T profile panel are heated through a laser heater, the heated portions arerolled and chamfered, the chamfered portions are cooled and shaped, and a T profile is formed through welding. Firstly, the chamfering scale marks are marked, the chamfered portions of the panel are locally heated in a laser heating manner, the deformation performance of the chamfered portions is guaranteed, and sufficient deformation during following rolling is facilitated; during rolling, the chamfering radian is limited through a guide circular shaft, and the forming precision of chamfering fillets is guaranteed; after rolling is completed, the rolled portions are cooled and shaped in a cold air conveying manner, and the rolled portions are conveniently kept in a chamfering state and are not prone to rebounding; and it is guaranteed that rolling and cooling links are immediately carriedout after heating is completed through the form that heating and side rolling are alternately carried out, heat dissipation is low, the deformation time is short, and the chamfering quality is guaranteed.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

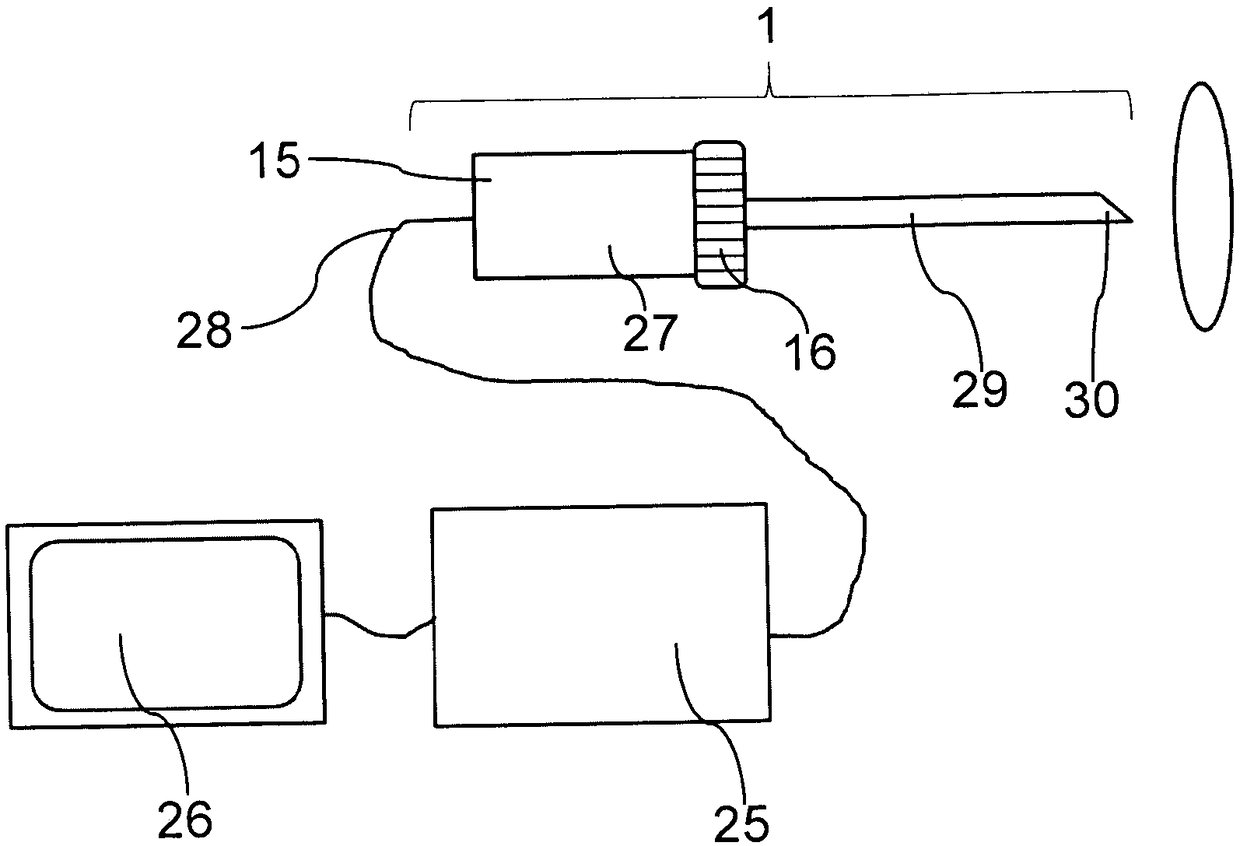

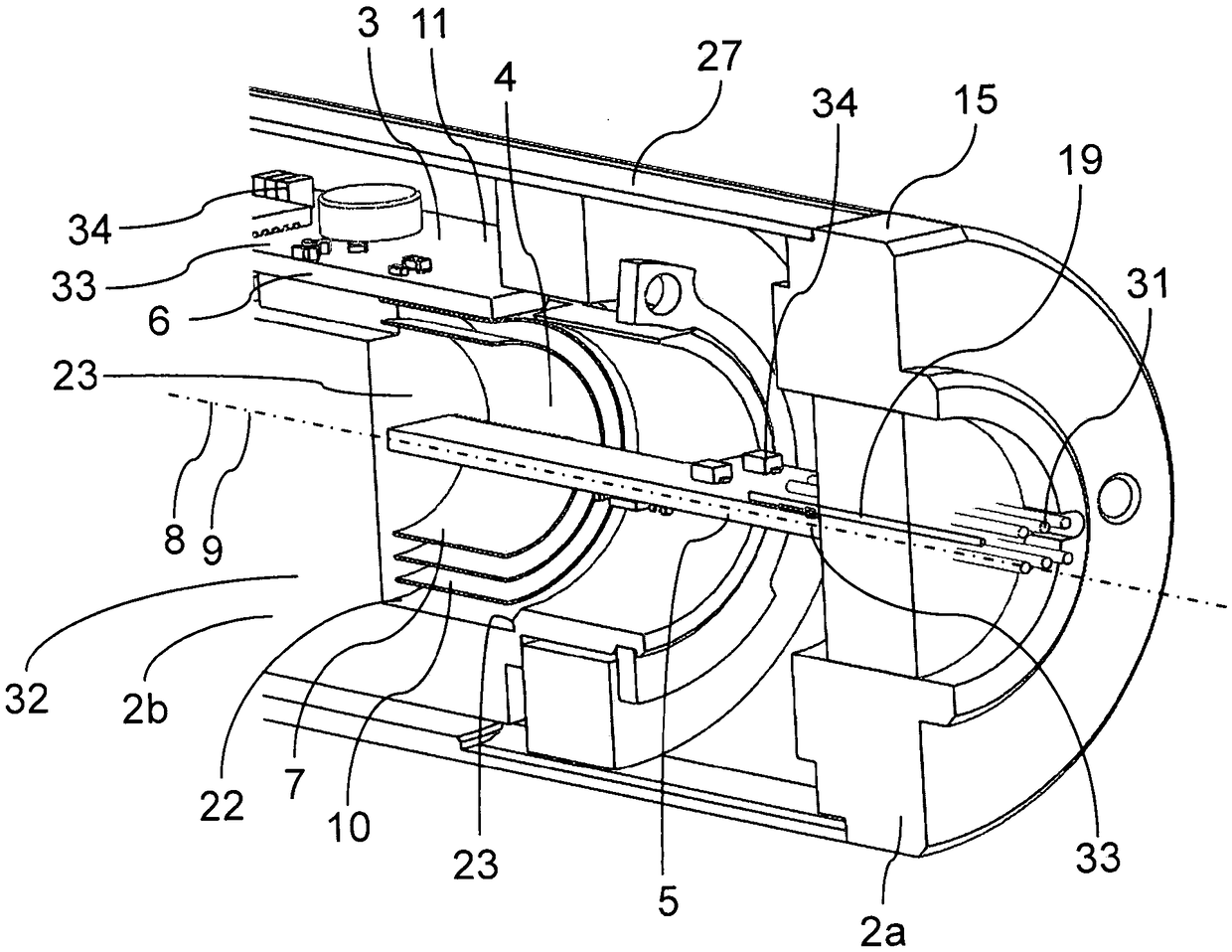

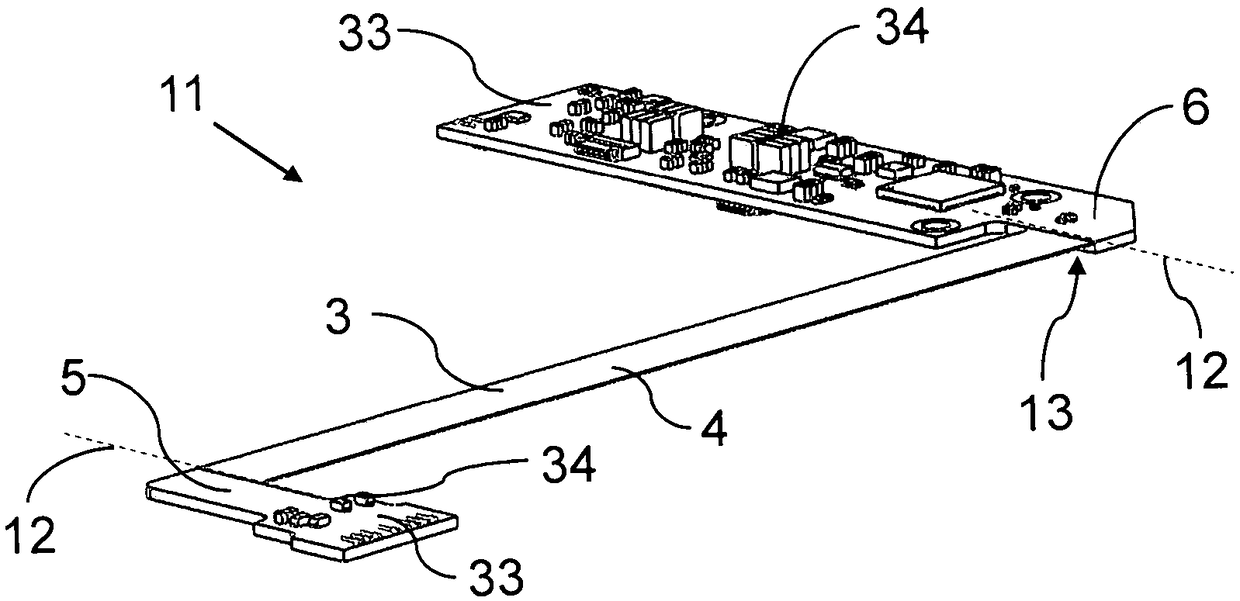

Endoscope having a rotatable electric connecting element

ActiveCN109419483AAchieve rotationShape stableCircuit bendability/stretchabilityPrinted circuit aspectsElectrical connectionEngineering

The invention relates to an endoscope comprising a rotatable electrical connecting element. A high-frequency transmission of data between functional units(2a,2b), which are mounted rotatably with respect to each other, of an endoscope(1), is permitted in which the functional units(2a,2b) can be electrically insulated from each other. For this, an electric connecting element which, in a central flexible portion, is rolled up transversely with respect to the direction of transmission and is fastened by its respective end portions to the functional units is provided. An uninterrupted electrical connection with consistent quality of the signal transmission can therefore be obtained even when the functional units are rotated in relation to each other. By the rolling up of the central portion(4)to form a winding(7), which is preferably configured in a self-supporting manner, a long term stable rotary degree of freedom is created in a very simple manner for the connecting element(3), with this degree of freedom permitting complex mechanical adjustment functions in the endoscope(1).

Owner:SCHOLLY FIBEROPTIC

A prefabricated shear wall structure of desert sand lightweight aggregate concrete

Owner:SHIHEZI UNIVERSITY

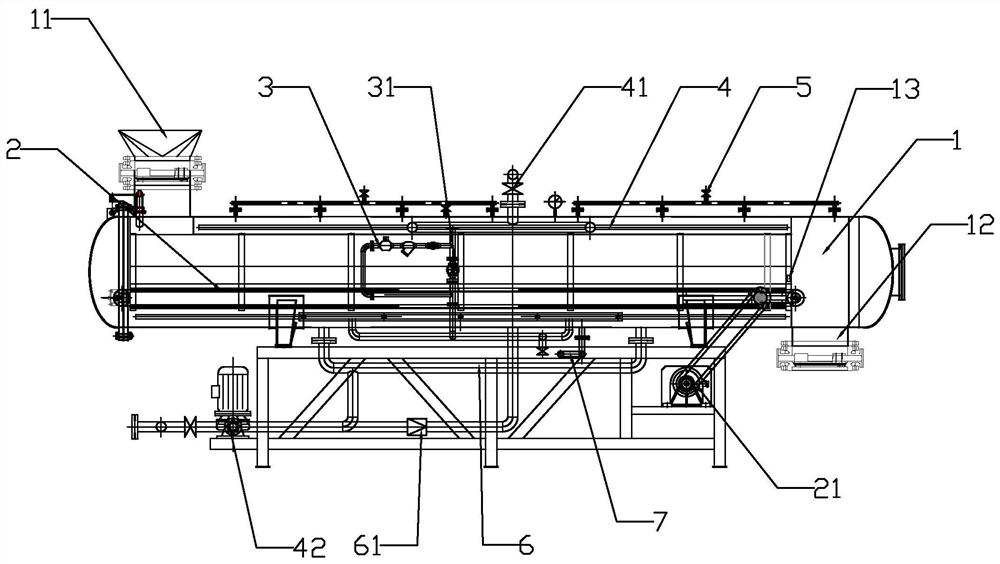

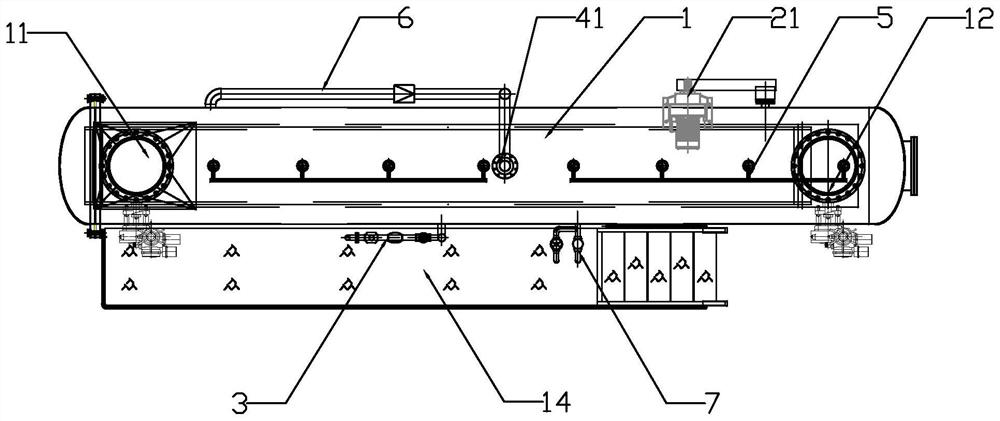

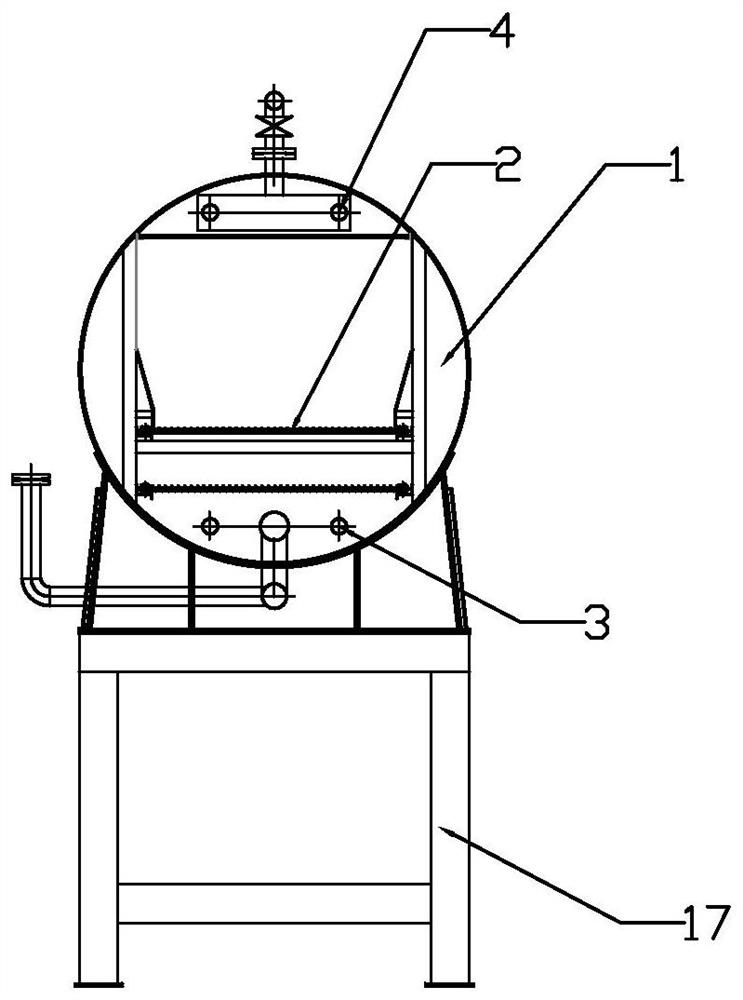

Automatic corn cob steamer

PendingCN111671035ARealize automatic controlHigh precision of speed regulationProgramme control in sequence/logic controllersSimultaneous control of multiple variablesAutomatic controlAgricultural engineering

The invention discloses an automatic corn cob steamer. A conveying belt is arranged in a pot body; a feeding opening is formed in the position, corresponding to the front end of the conveying belt, ofthe top of the pot body; a feeding executing mechanism is arranged on the feeding opening; a discharging opening is formed in the position, corresponding to the tail end of the conveying belt, of thebottom of the pot body; a discharging executing mechanism is arranged on the discharging opening; the automatic corn cob steamer further comprises a steam pipeline and a spraying pipeline; pressurized steam is led into the pot body through the steam pipeline; a steam valve group is arranged on the steam pipeline; a spraying valve group is arranged on the spraying pipeline; an air release valve group is arranged at the top of the pot body; the feeding executing mechanism, the discharging executing mechanism, the conveying belt, the steam valve group, the spraying valve group and the air release valve group are all controlled through a PLC; a temperature sensor is arranged in the pot body; and steam in the pot body is the pressurized steam. Pre-cooking is not needed, so that the steaming efficiency is high; and full-automatic control is achieved, so that the steaming effect is good, and the labor cost and the equipment cost are saved.

Owner:SHANGYU GUANFENG FOOD MACHINERY

Steel pipe and desert sand light aggregate concrete combination column

InactiveCN111827579AGuaranteed carrying capacityGuaranteed deformabilityStrutsCeramicwareSoil scienceMaterial supply

The invention discloses a steel pipe and desert sand light aggregate concrete combination column. The steel pipe and desert sand light aggregate concrete combination column comprises a steel pipe anddesert sand light aggregate concrete poured into the steel pipe. Preparation raw materials of the desert sand light aggregate concrete include desert sand. According to the steel pipe and desert sandlight aggregate concrete combination column, the bearing and deformation capacity of structural elements can be well guaranteed, and good heat insulating and heat resisting performance is achieved under the condition that the bearing requirements are met. The combination column is low in mass, materials are easy to draw, and the combination column has the accessory attributes of being simple in structure and convenient to transport and is especially suitable for remote towns with insufficient material supply, low human quality and deficient technical force in northwest regions. The desert sandlight aggregate concrete is restrained by the steel pipe, the hoop effect of the steel pipe is enhanced, the desert sand light aggregate concrete in the steel pipe is in a three-dimensional pressed state, the deformation of the desert sand light aggregate concrete is restrained, and the steel pipe and desert sand light aggregate concrete combination column has the beneficial effects of being convenient to construct, high in bearing force and good in anti-seismic performance and achieving energy saving and environmental friendliness.

Owner:FUZHOU UNIV

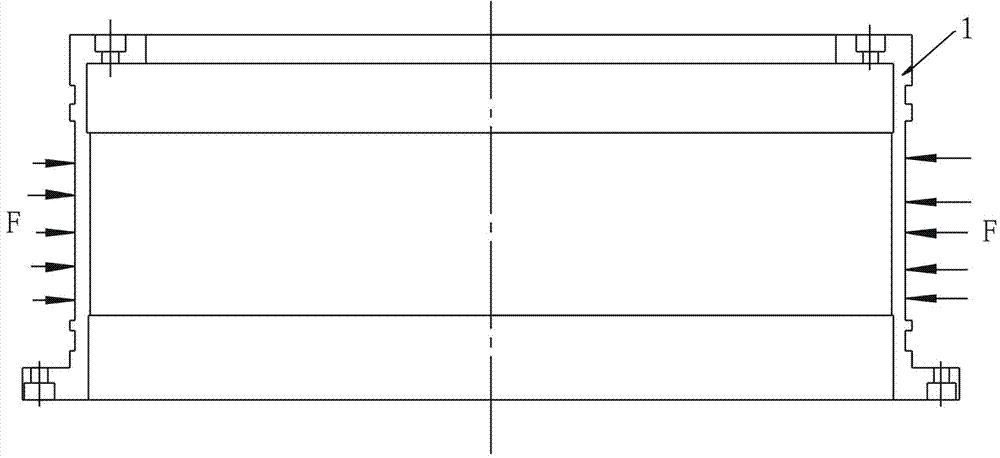

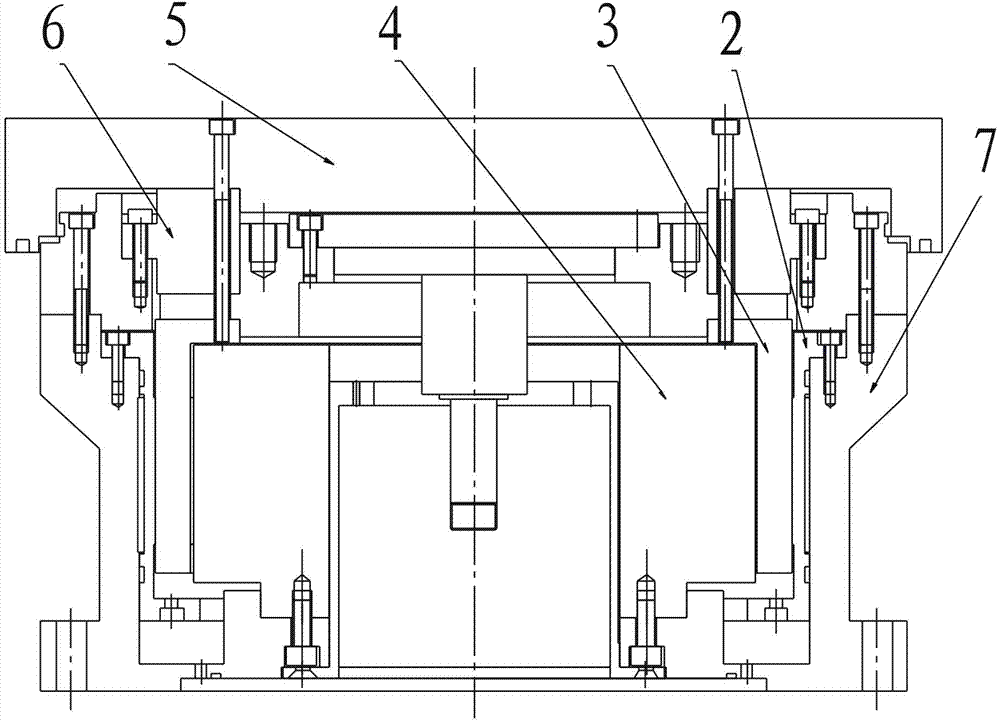

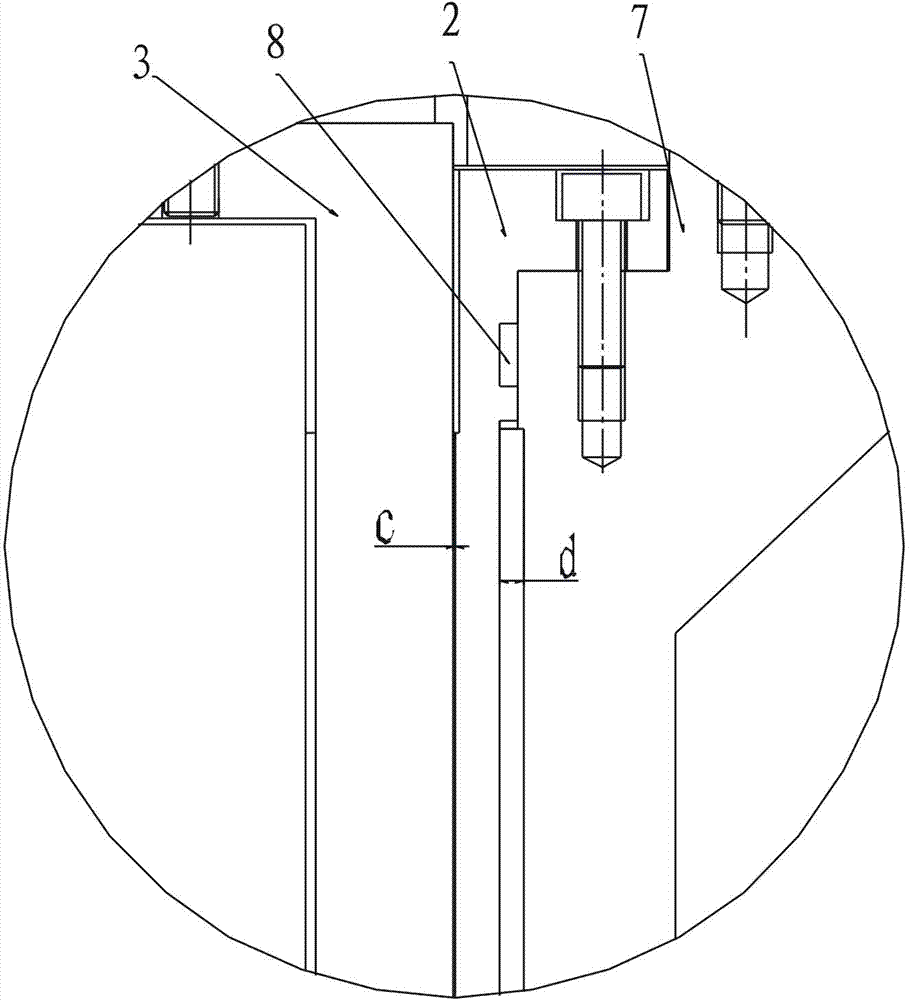

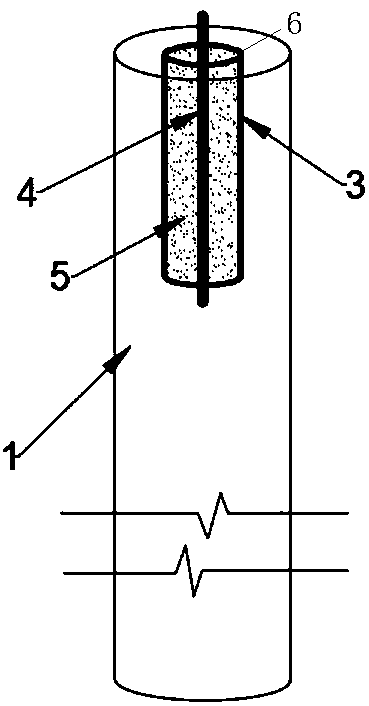

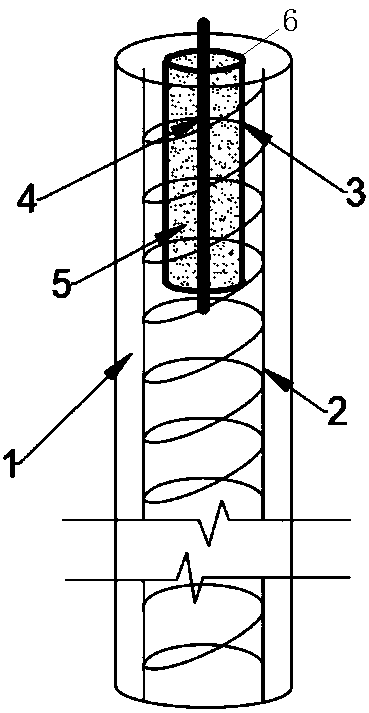

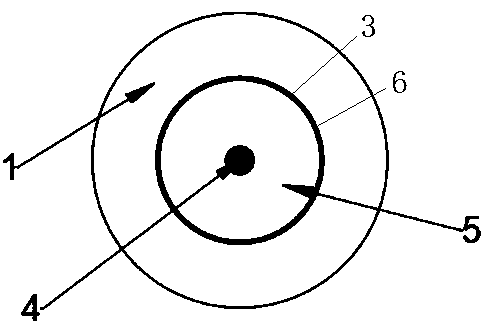

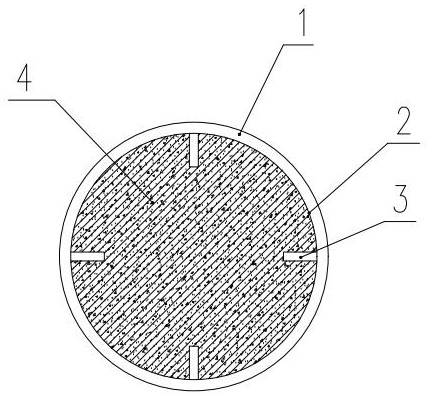

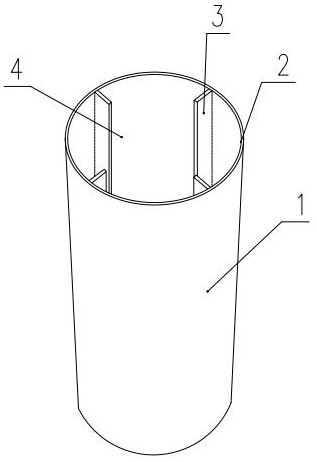

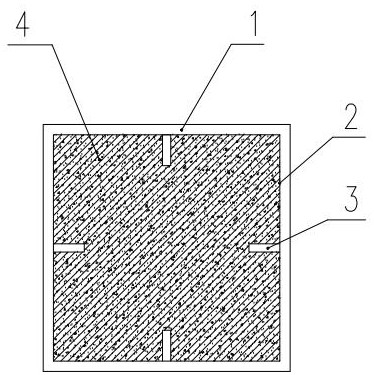

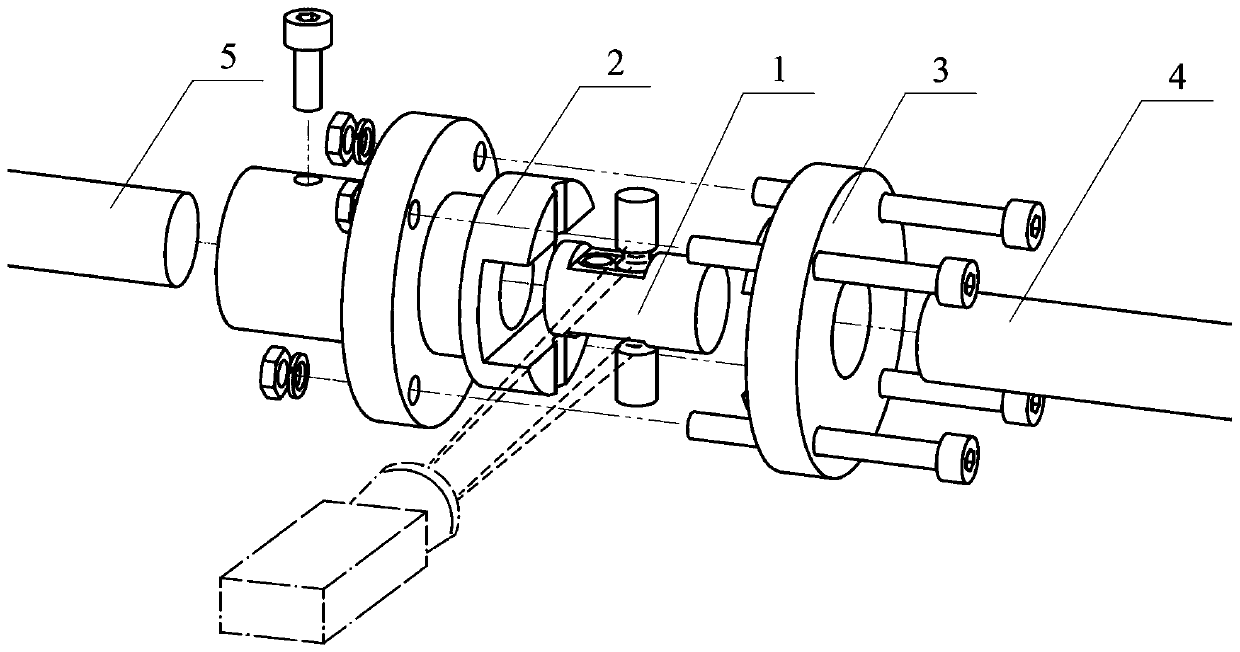

Device for realizing high strain rate pure shear of high plastic material

InactiveCN109839318AReduce negative impactSimple structureMaterial strength using single impulsive forceExperimental researchPlastic materials

The invention relates to the metal material dynamic mechanics experiment technology field and discloses a device for realizing high strain rate pure shear of a high plastic material. The device comprises a first component, a second component and a third component. The second component is installed on a transmission rod of a split Hopkinson Pressure Bar (SHPB) device. The third component and the second component are coaxially connected and are located on an incident bar of the SHPB device. The first component is clamped with the third component through the second component and is in contact with the incident bar. Experimental research of the high strain rate pure shear of the high plastic material can be realized, and a deformation process of a shearing area is shot by a high speed camera.The device is simple and reliable and is easy to implement.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com