Combination slit shear wall with replaceable energy dissipation steel plates

A shear wall and replacement technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of reduced bearing capacity and poor energy consumption capacity, so as to improve the consumption capacity, make up for the poor energy consumption capacity, and facilitate connection and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

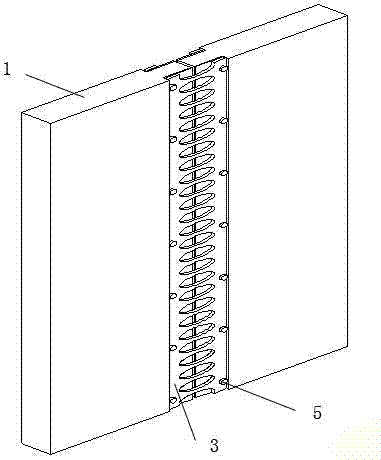

[0026] Such as figure 1 and 4 As shown, a replaceable energy-dissipating steel plate composite slotted shear wall is used to improve the energy dissipation and earthquake resistance of building structures, including shear wall 1, reinforced restraint steel plate 2, energy-dissipating steel plate 3 and threaded sleeve 4 .

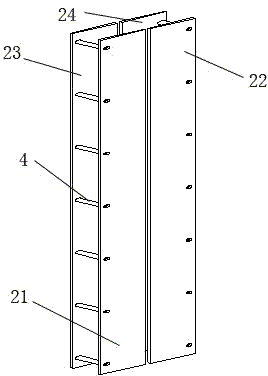

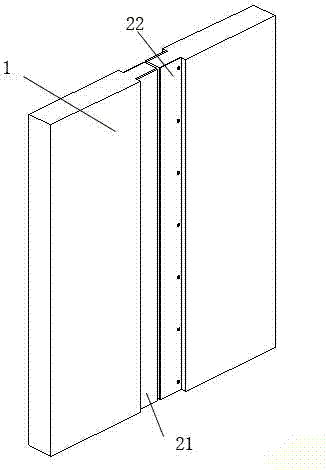

[0027] The shear wall 1 is vertically provided with through joints, and the reinforced restraint steel plates 2 are used to improve the rigidity and bearing capacity of the shear wall 1 and increase the replaceability, including the inner and outer two joints respectively arranged in the local area of the shear wall 1. The first reinforced constrained steel plate 21, the second reinforced constrained steel plate 22, the third reinforced constrained steel plate 23, and the fourth reinforced constrained steel plate 24 are respectively poured and connected with the shear walls 1 on both sides of the joint.

[0028] The energy-dissipating steel plate 3 is us...

Embodiment 2

[0035]The rest are the same as in Example 1, except that the local wall thickness of the shear wall 1 on both sides of the vertical joint is smaller than the thickness of the normal shear wall, and the difference in the thickness of the shear wall on one side is 25mm; There are eight steel plates, which are respectively connected to the shear walls on both sides of the joint and connected by pouring; the width of the joint is set to 22mm, and the joint is filled with a layer of cork material; the energy-dissipating steel plate is a soft steel plate with low yield , There are round holes on the soft steel plate.

Embodiment 3

[0037] The rest are the same as in Embodiment 1, except that the local wall thickness of the shear wall 1 on both sides of the vertical joint is smaller than the thickness of the normal shear wall, and the thickness difference of the shear wall on one side is 28mm; The width is set to 25mm, and the through seam is filled with a layer of viscoelastic material.

[0038] The beneficial effect of adopting the above technical scheme is: the composite slotted shear wall makes full use of the deformation on both sides of the vertical joints of the shear wall and the yield energy dissipation capacity of the energy dissipation steel plate to improve the energy dissipation capacity of the entire structure. At the same time, the rigidity and bearing capacity of the slotted shear wall are improved by arranging reinforced restraint steel plates on the inner and outer walls of the shear wall with vertical joints. Reinforced restraint steel plates are installed on the inner and outer sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com