Composite electrolyte and application thereof

A composite electrolyte and electrolyte technology, which is applied in the field of chemical power sources, can solve the problems that the electrical conductivity of all-solid-state batteries cannot meet the requirements, the electrical conductivity of all-solid-state electrolytes is unsatisfactory, and the coulombic efficiency of batteries is reduced, and the cycle and rate performance is not affected. Improve the energy density of the system and avoid side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

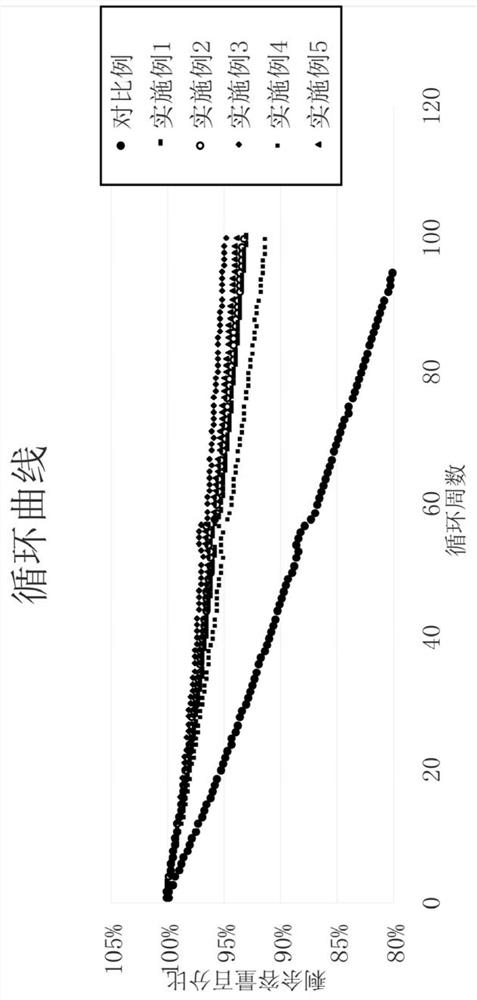

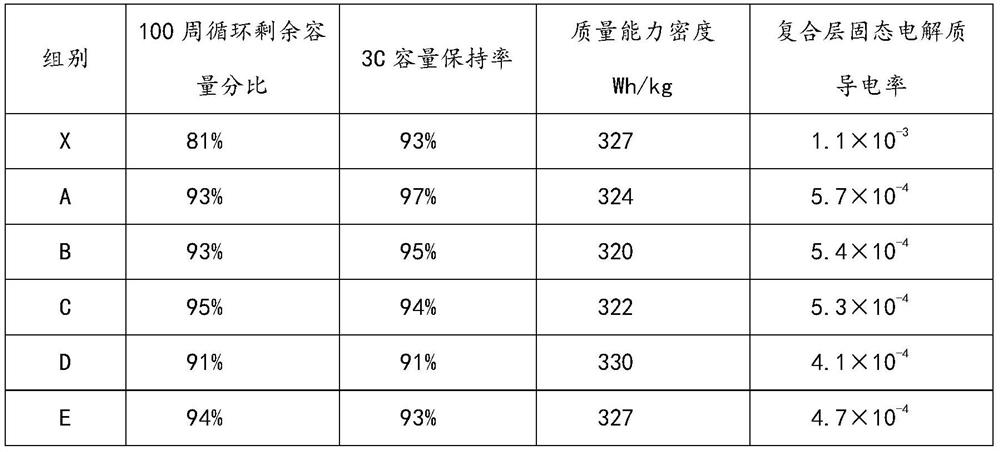

Examples

Embodiment 1

[0043] This embodiment discloses a composite electrolyte and a lithium ion battery using the composite electrolyte.

[0044] The composite electrolyte in this embodiment includes a gel electrolyte coated on the lithium negative electrode and a quasi-solid electrolyte coated on the positive electrode, the gel electrolyte and the quasi-solid electrolyte are in contact; electrolyte is adsorbed in the quasi-solid electrolyte;

[0045] The same Li between gel electrolyte and quasi-solid electrolyte 1.5 al 0.5 Ge 1.5 (PO 4 ) 3(abbreviated as LAGP).

[0046] The formulation of the adsorbed electrolyte in the quasi-solid electrolyte:

[0047] The solvent component of the electrolyte is 0.2mol / L fluorinated diether, EC:EMC=1:1, the additive amount is 0.1-0.3mol / L; the lithium salt is LiPF 6 , the addition amount is 1-1.5mol / L; the choice of electrolyte only affects the conductivity of the liquid system.

[0048] The mass fraction of each component in the gel electrolyte includes...

Embodiment 2

[0061] The main difference between this embodiment and embodiment 1 is:

[0062] Raw material ratio of the quasi-solid electrolyte: methyl methacrylate 60wt%, LAGP 10wt%, HMS 30wt%.

[0063] Polyethylene oxide is selected as the polymer matrix; ethylene carbonate is selected as the plasticizer; the raw material ratio of the gel electrolyte is: 80% polyethylene oxide, 15% LAGP, and 5% propylene carbonate.

[0064] The thickness of the quasi-solid electrolyte layer is 6um; the thickness of the gel electrolyte layer is 3um;

[0065] The batteries obtained in this example are designated as Group B.

Embodiment 3

[0067] The main difference between this embodiment and embodiment 1 is:

[0068] Raw material ratio of quasi-solid electrolyte: methyl methacrylate 70wt%, LAGP 20wt%, MCM-41 10wt%.

[0069] Polymethyl methacrylate is selected as the polymer matrix; ethyl methyl carbonate is selected as the plasticizer; the raw material ratio of the gel electrolyte is: 90% of polymethyl methacrylate, 6% of LAGP, and 4% of propylene carbonate.

[0070] The thickness of the quasi-solid electrolyte layer is 5um; the thickness of the gel electrolyte layer is 3um;

[0071] The batteries obtained in this example are designated as Group C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com