Advancing water stop steel bed mould composite structure on post-cast strip

A technology of combined structure and post-casting belt, applied in building construction, construction, etc., can solve problems such as infiltration and construction trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

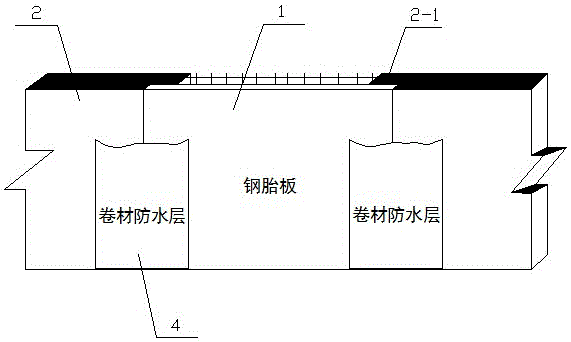

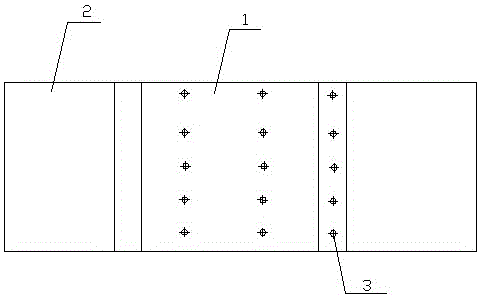

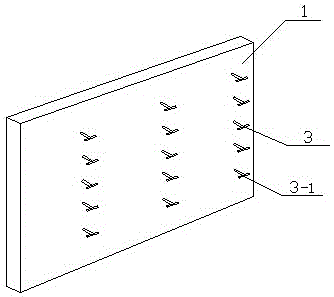

[0009] Such as figure 1 , 2 , 3, the present invention includes a steel tire board 1 arranged on the outside of the post-casting belt, a reinforced concrete wall 2 arranged on both sides of the steel tire board 1; The step 2-1 matching the thickness of the steel tire board 1, the two ends of the steel tire board 1 are respectively arranged in contact with the steps 2-1, and the outer surface of the steel tire board 1 is on the same level as the outer surface of the reinforced concrete wall 2; Three rows of "T"-shaped connectors 3 are arranged on the inner surface of the steel tire plate 1, and each row of "T"-shaped connectors 3 includes several "T"-shaped connectors 3-1 vertically arranged from top to bottom; One of the "T"-shaped connectors 3 is set at the overlap between one end of the steel tire board 1 and the reinforced concrete wall 2 on the opposite side and welded with the reinforcement of the reinforced concrete wall 2; A flexible waterproof layer 4 is set at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com