Endoscope having a rotatable electric connecting element

A technology for connecting components and endoscopes, applied in the field of endoscopes, can solve the problems of contact wear and interference, achieve stable shape and achieve repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

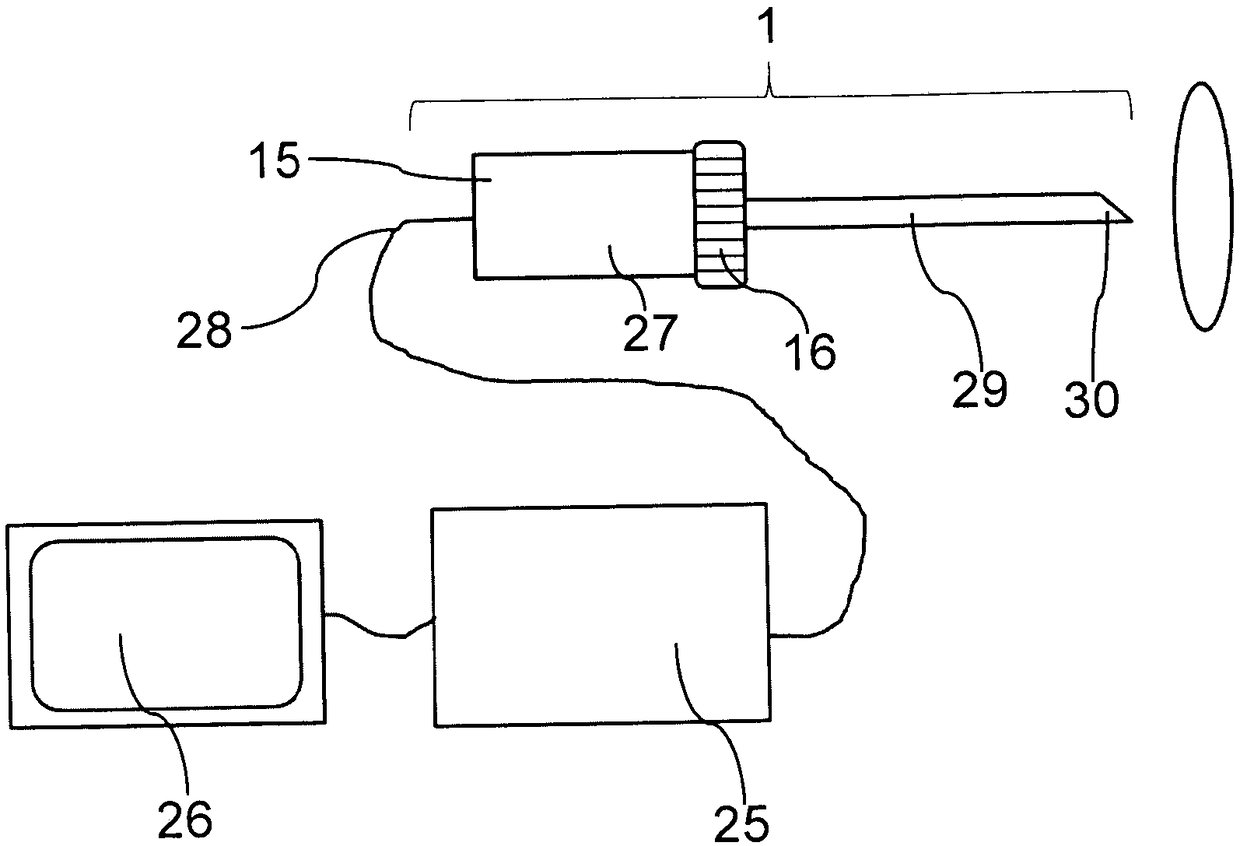

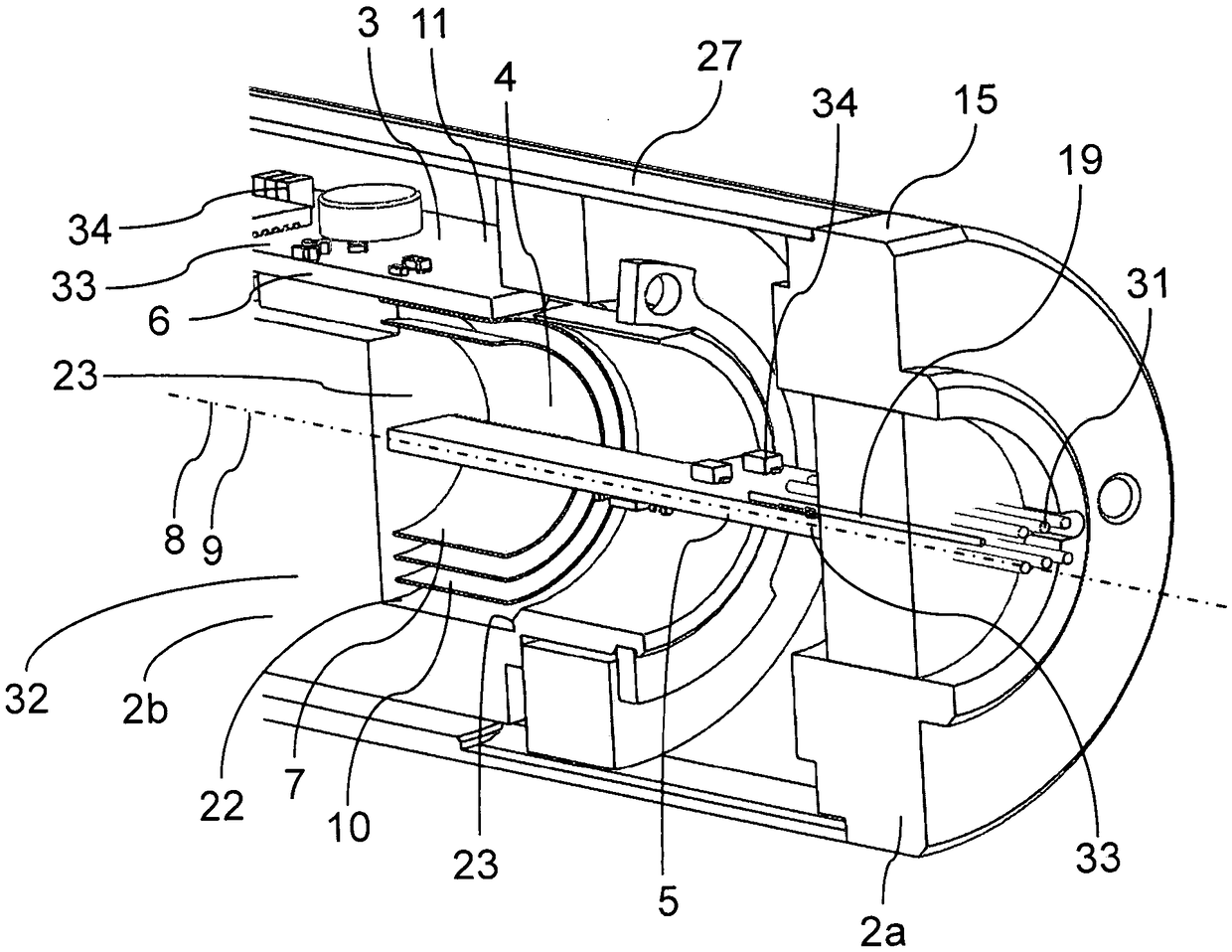

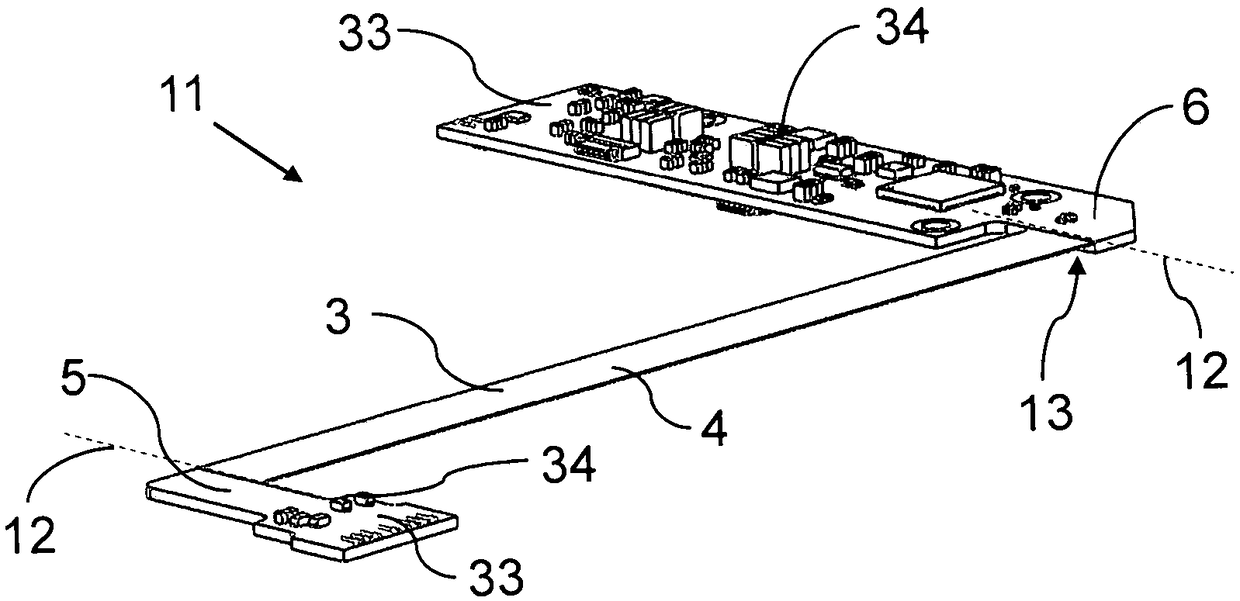

[0056] figure 1 An endoscope indicated by 1 as a whole is shown, which includes a handle 27, a rotating wheel 16 and an endoscope shaft 29. The image sensor is in the tip 30 of the endoscope, and the image sensor is figure 2 The cooling body indicated by 23 is connected. The cooling body 32 is rotatably supported with respect to the endoscope housing 15. By coupling the rotating wheel 16 with the cooling body 32 inside the endoscope 1, the image sensor can be rotated relative to the housing 15 and the endoscope rod 29 rigidly connected thereto. The rotating wheel 16 and the heat sink 32 thus form an external or internal coupling element.

[0057] In addition, the imaging optical system is located in the endoscope tip 30, and the optical system itself is connected to the endoscope shaft 29 and thereby the housing 15 so as not to rotate relative to one another. With the help of the camera cable 28, the video signal is transmitted from the image sensor of the endoscope 1 to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com