Patents

Literature

74results about How to "High precision of speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

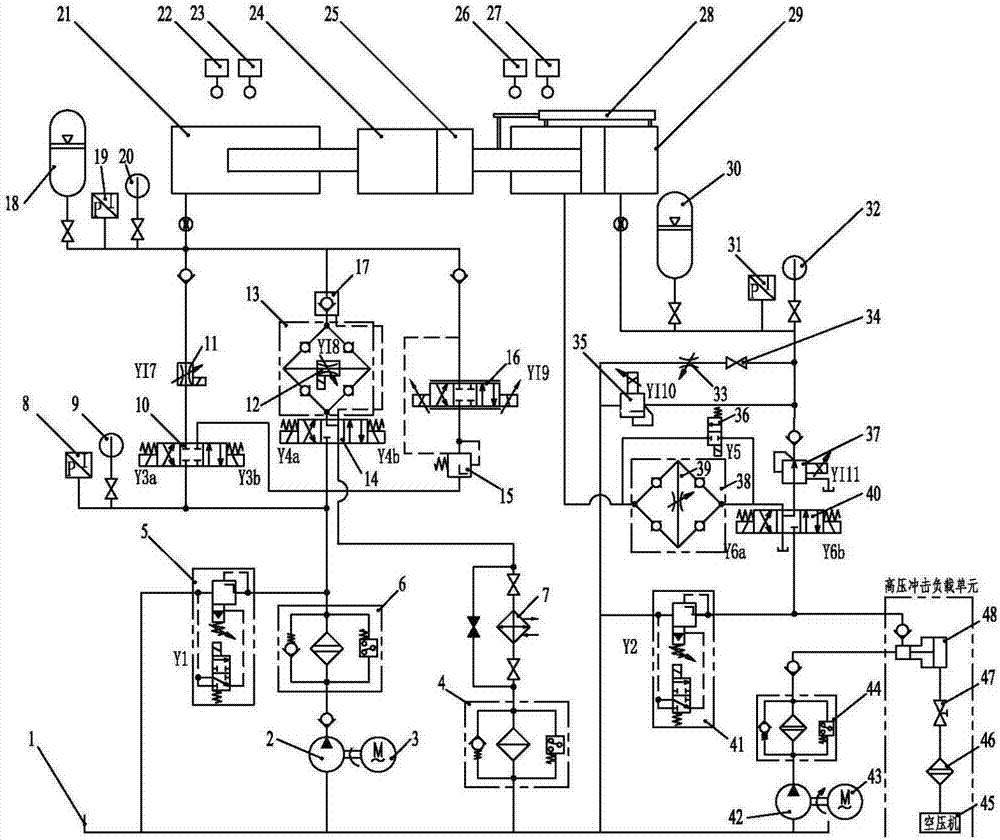

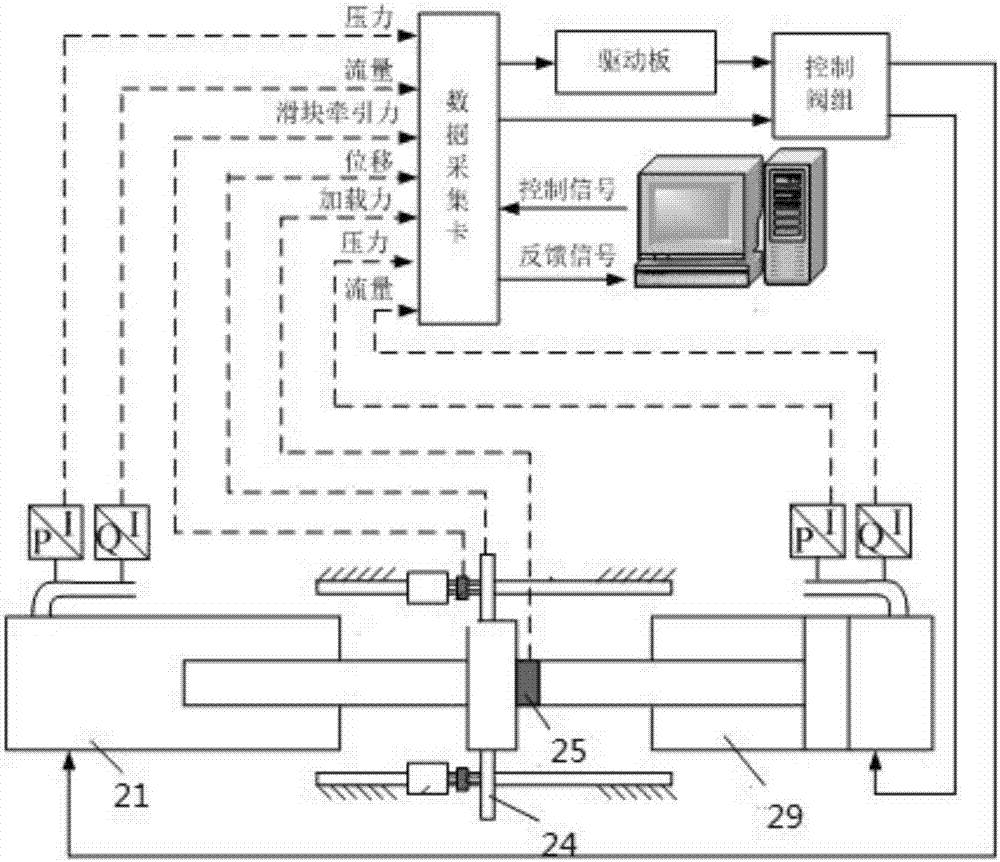

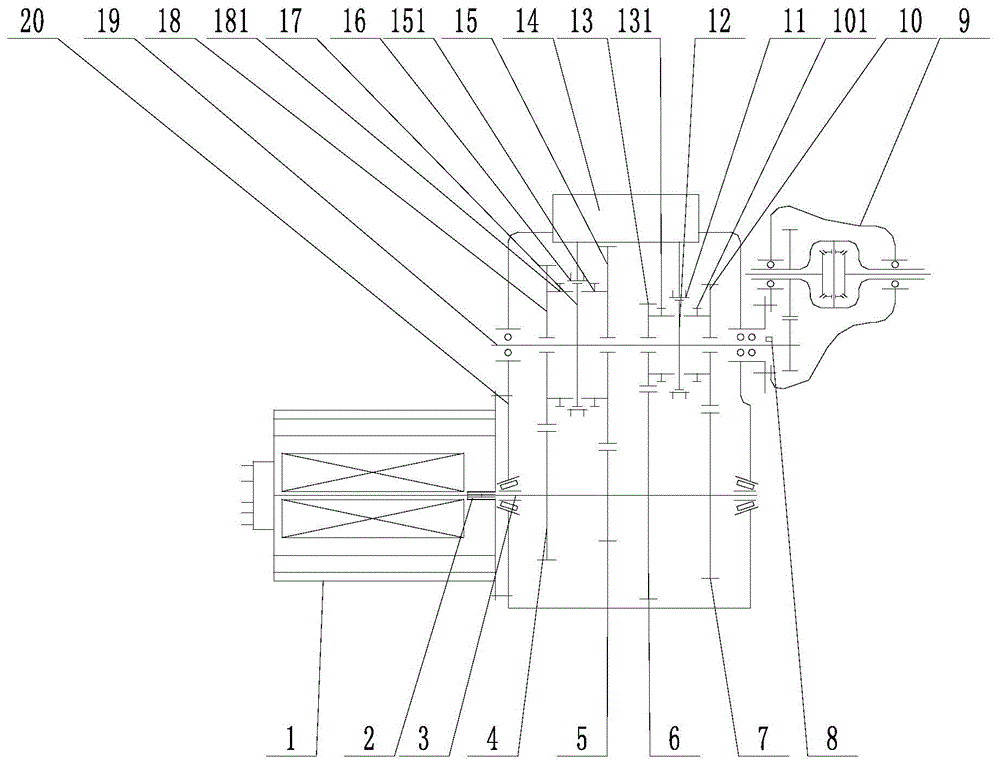

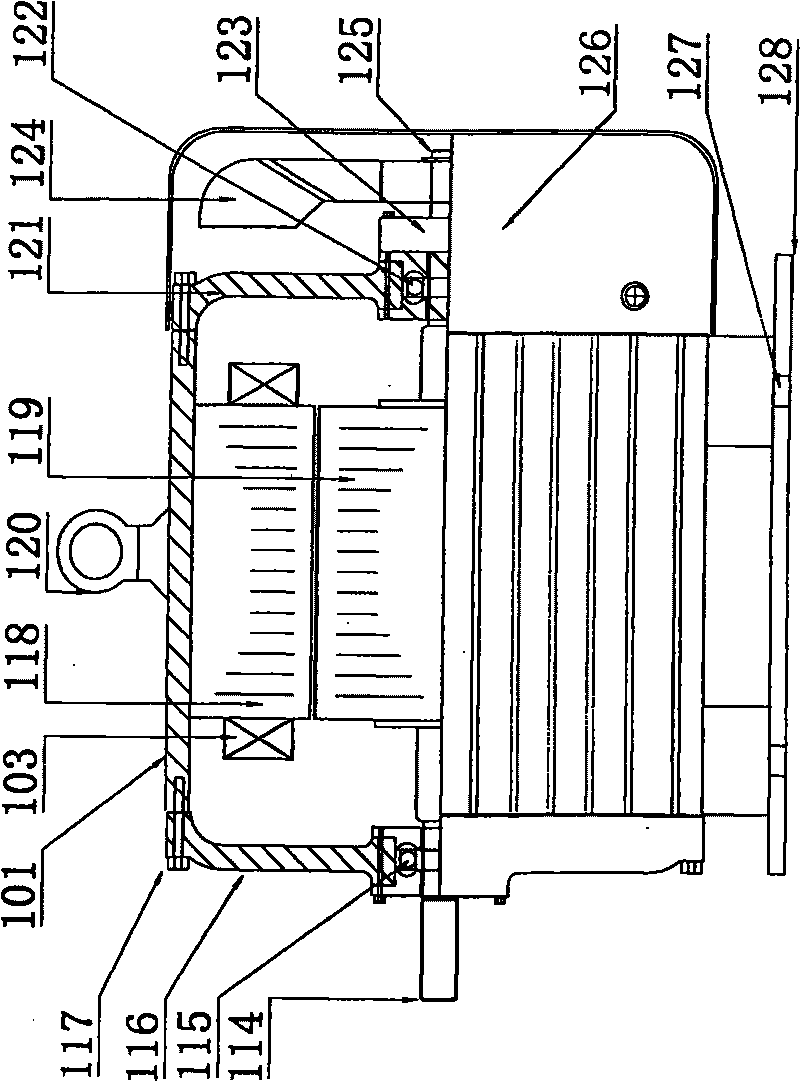

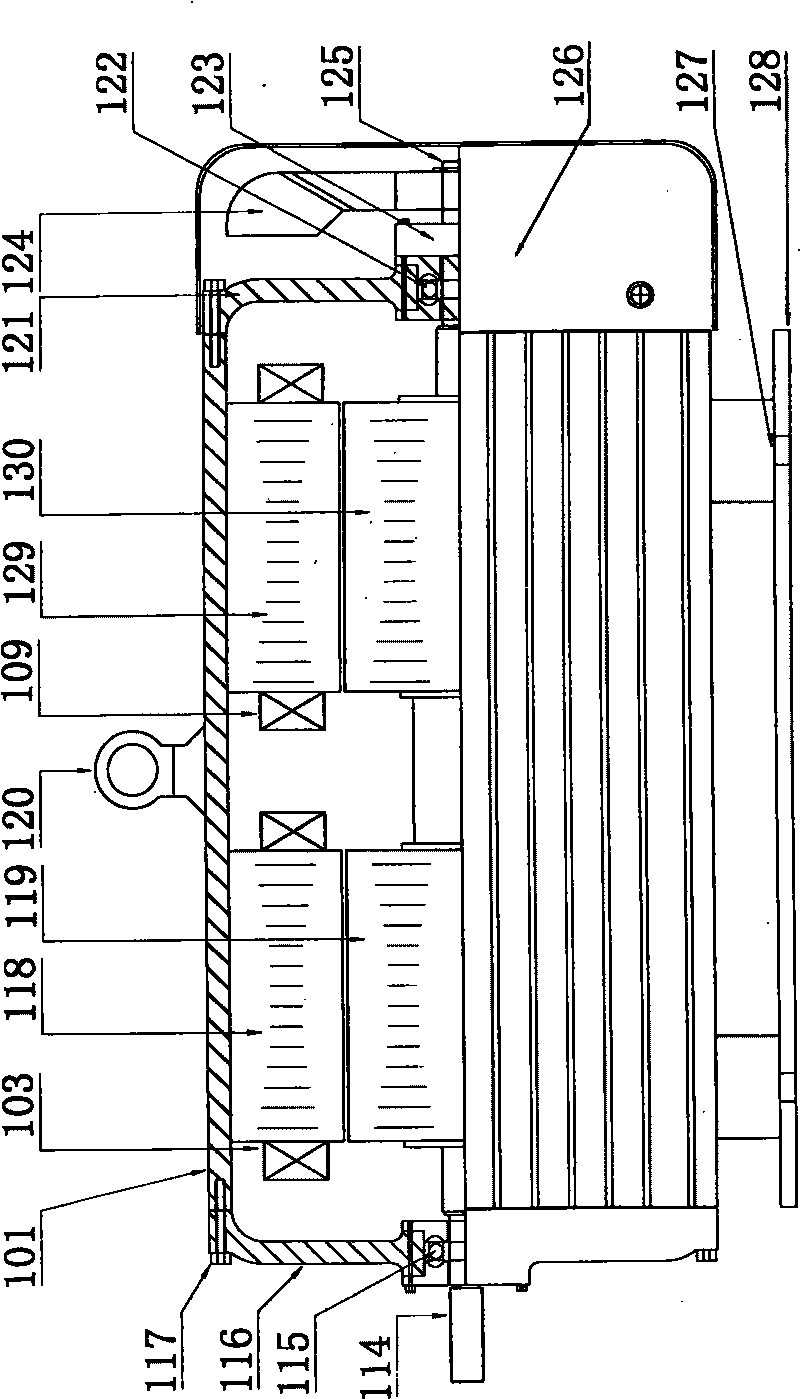

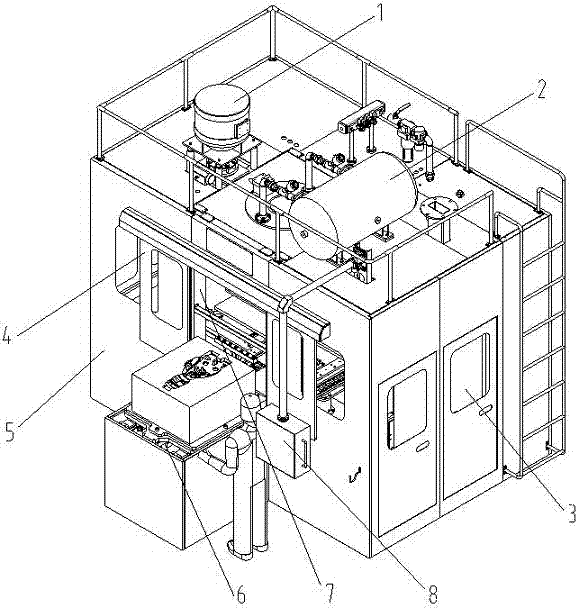

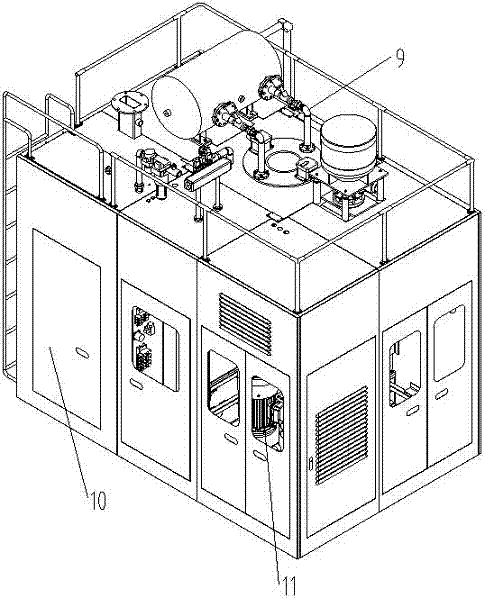

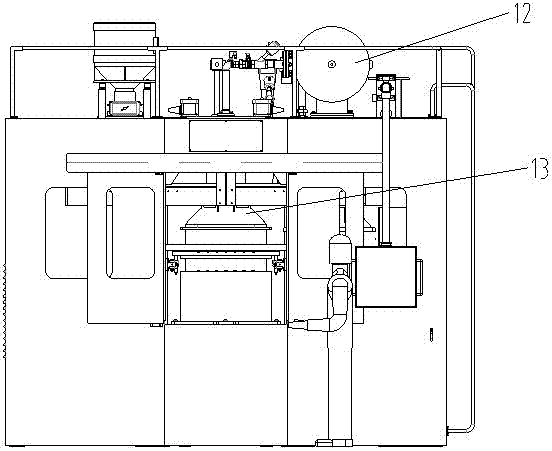

Comprehensive test platform for dynamic performance of hydraulic cylinder of engineering machine

ActiveCN107023536AImplement testWide speed rangeFluid-pressure actuator testingServomotor componentsHydraulic cylinderCombined test

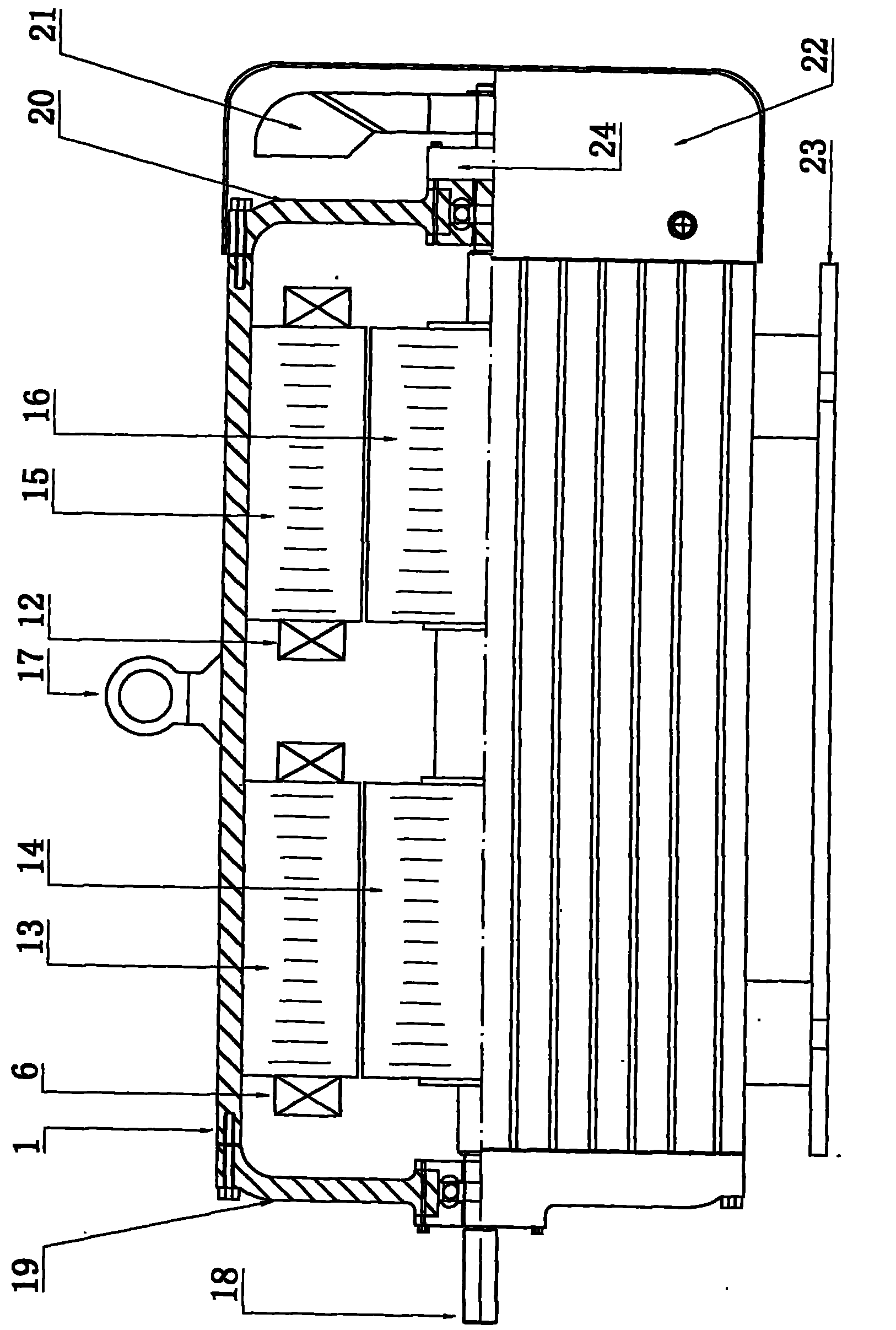

The invention discloses a comprehensive test platform for the dynamic performance of a hydraulic cylinder of an engineering machine. The comprehensive test platform for the dynamic performance of the hydraulic cylinder of the engineering machine comprises a test platform body, a hydraulic system and an electrical test control system. The hydraulic system comprises a drive system unit and a loading system unit. The drive system unit comprises a first hydraulic pump, a first filter and three liquid inlet valve banks. Oil outlets of the three liquid inlet valve banks are connected with an oil inlet of the tested hydraulic cylinder. The loading system unit supplies oil to a loading hydraulic cylinder. The electrical test control system controls all the valve banks of the hydraulic system according to feedback signals. According to the comprehensive test platform for the dynamic performance of the hydraulic cylinder of the engineering machine, a drive system, a loading system and a gas-liquid supercharging system which are independently arranged are used for meeting test and control needs under different loads and different working conditions; and the comprehensive test platform also utilizes the feedback signals to control the test process, when the oil pressure, the flow, the filter precision, the system temperature and other indexes are not at the normal level, the system gives out an alarm to remind people and stops, and therefore system operation reliability is guaranteed.

Owner:CENT SOUTH UNIV

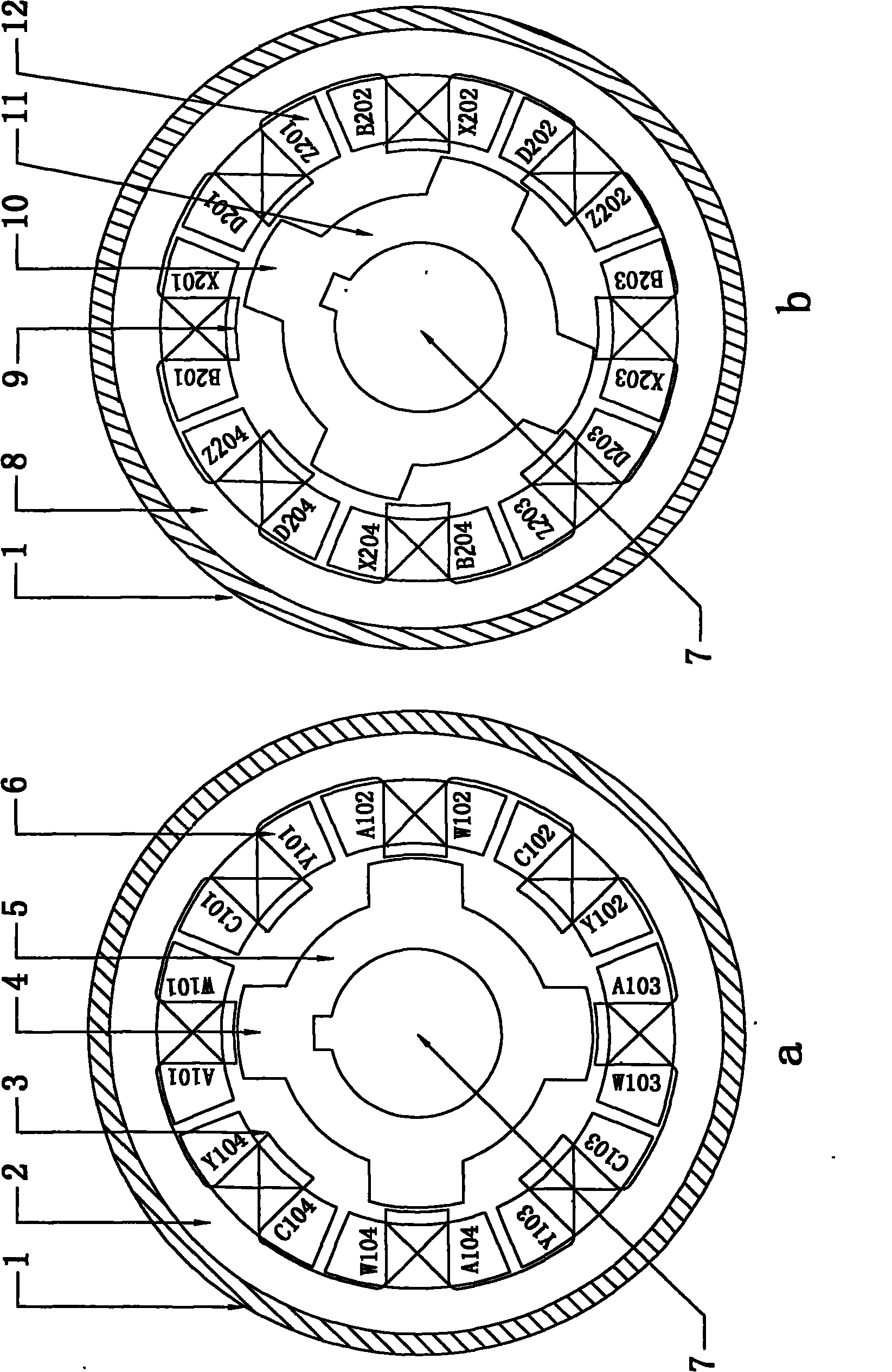

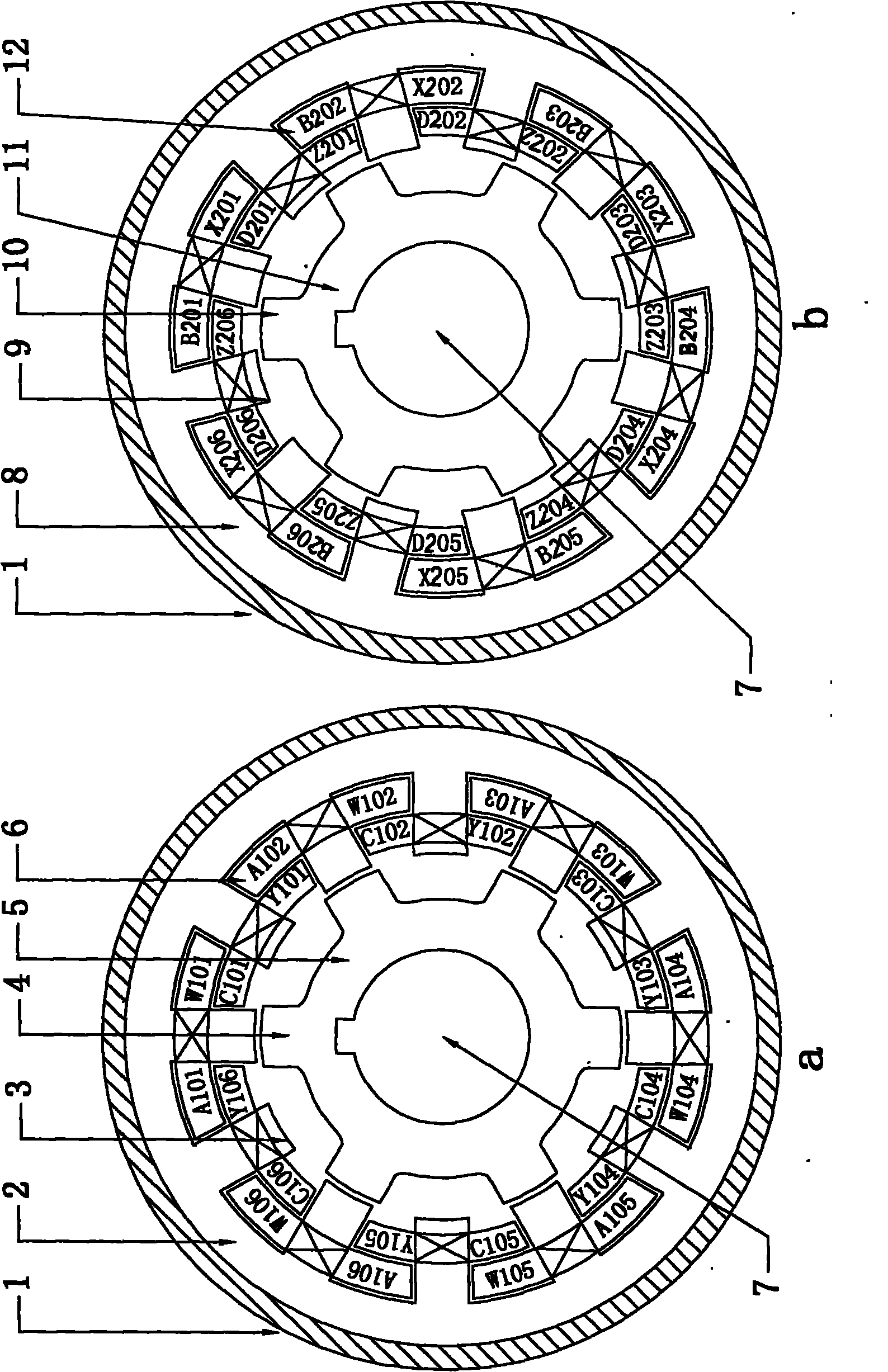

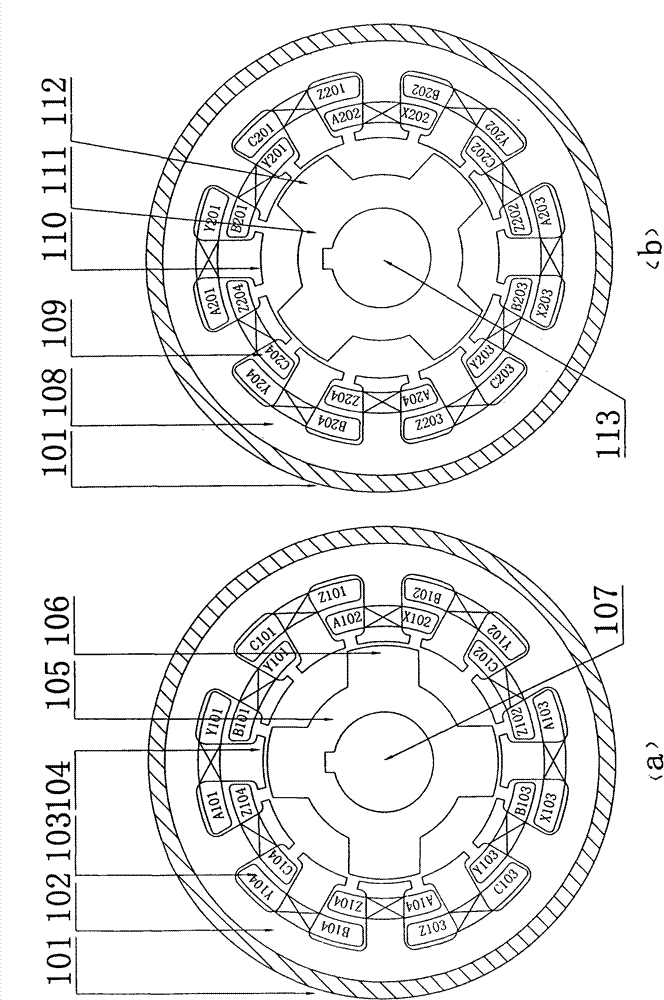

Double stator-rotor multiple-pole switching reluctance motor

InactiveCN102035319AIncrease the number of phasesDifficult to controlMagnetic circuit rotating partsMagnetic circuit stationary partsPole numberConductor Coil

The invention relates to a double stator-rotor multiple-pole switching reluctance motor. The motor comprises a stator and a rotor, which are laminated by silicon steel sheets and have double salient structures, wherein iron cores of the stator and the rotor consist of two sections respectively, lengths and diameters of the two sections of the iron core of the stator are the same as those of the iron core of the rotor; two sets of concentrated windings or layer windings are respectively arranged on teeth of the two sections of the stator; and armature windings on two teeth at the same phase position of each set of windings are connected in series or in parallel to form a phase. The motor is characterized in that: magnetic poles of the two sections of the stator are aligned, and the magnetic poles of the rotor are different from the stator by a 1 / 2 stator pole angle; or the two sections of the rotor are aligned, and the two sections of stators are different by a 1 / 2 stator pole angle. The pole number of the stator is twice of that of the rotor, and pole numbers of the stator and the rotor are an even number combination, so the motor solves the problem that a plurality of grooves and a plurality of poles cannot be manufactured in the traditional switched reluctance motor, and has the characteristics that: the cost is low, the efficiency is high and the motor is easy to control.

Owner:张世清

Automatic thickness control system and method of blown film

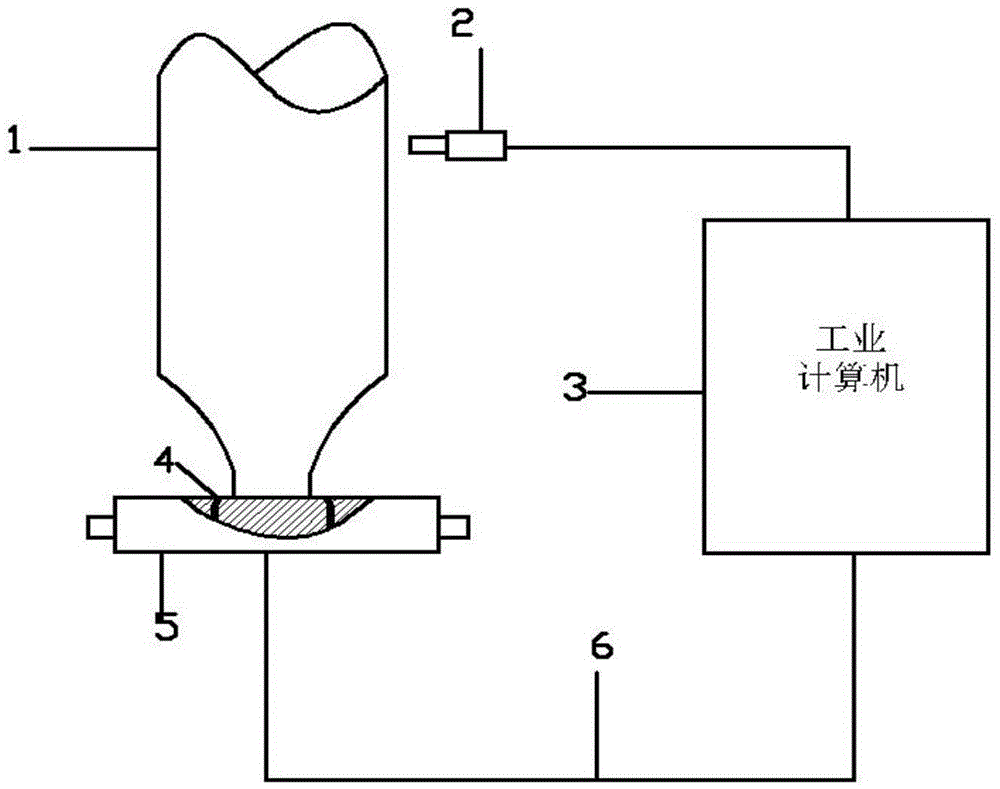

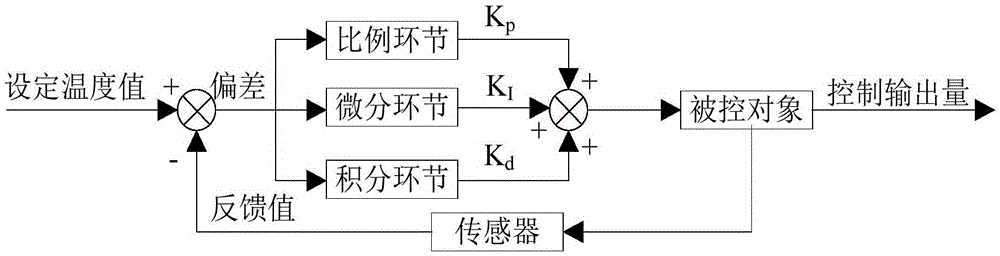

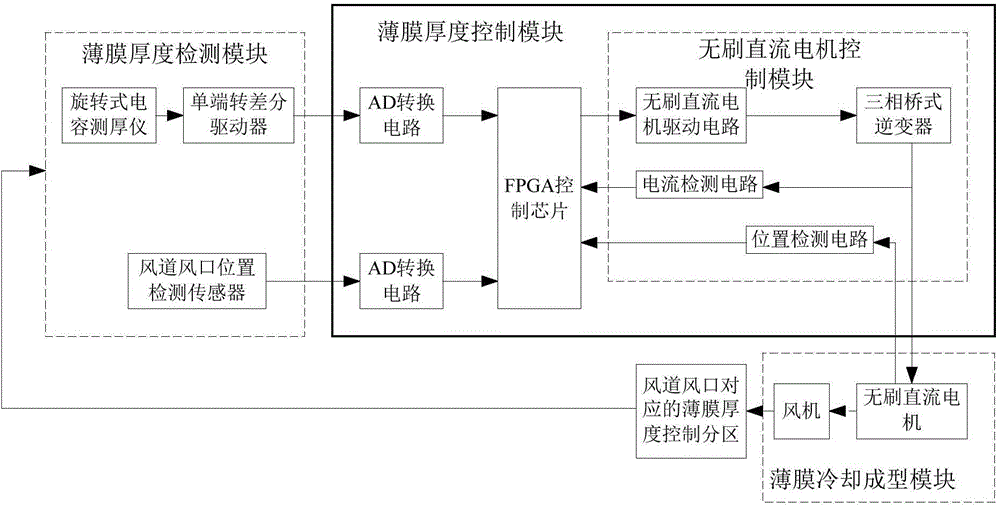

The invention discloses an automatic thickness control system and method of a blown film. The automatic thickness control system of the blown film comprises a film thickness detection module, a film thickness control module, a film cooling and forming mold with a plurality of brushless direct-current motors as well as a control panel. According to the invention, an FPGA (field programmable gate array) control chip of a programmable logic device is utilized to achieve a fuzzy control algorithm so as to obtain the speed control quantity of the brushless direct-current motors; by combining a double-closed-ring control algorithm for the brushless direct-current motors a control signal output by the FPGA control chip is changed and adjusted correspondingly when the thickness of the film is changed; the thickness uniformity of the films at different circumferential parts can be controlled by acquiring horizontal thicknesses of the films at controlled subzones and the positions of air flue openings corresponding to the films via transmission and decoupling control, so that the control requirement on horizontal thickness uniformity of the films can be met; the automatic thickness control system and method of the blown film are high in integrity, small in volume, good in robust performance, stable and reliable in operation, high in expansibility, high in control precision, low in accumulative error, and high in adaptability.

Owner:XI AN JIAOTONG UNIV

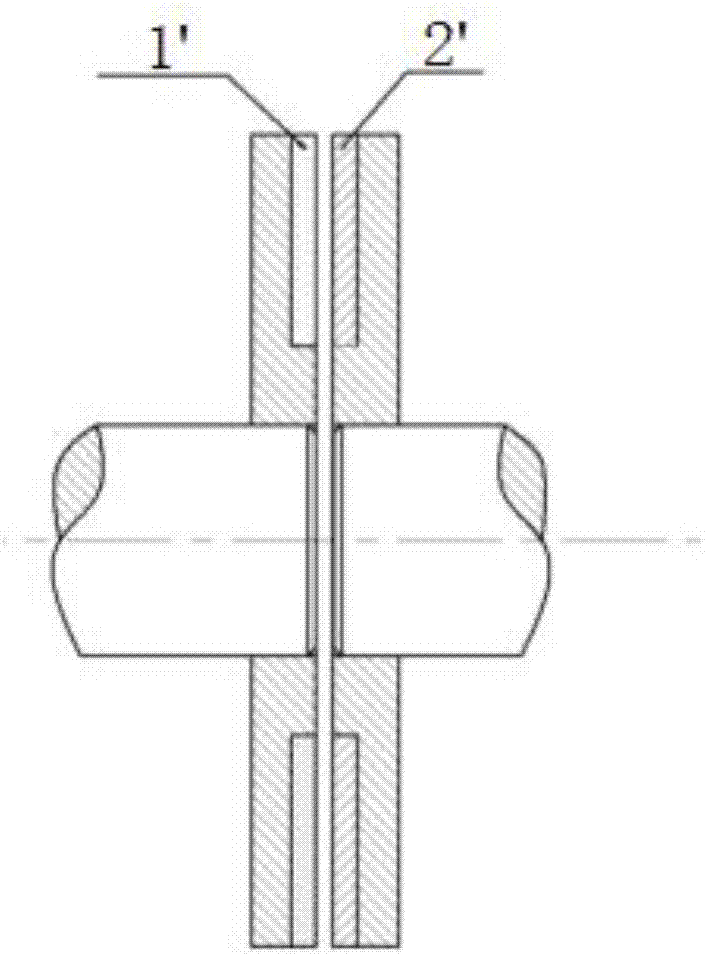

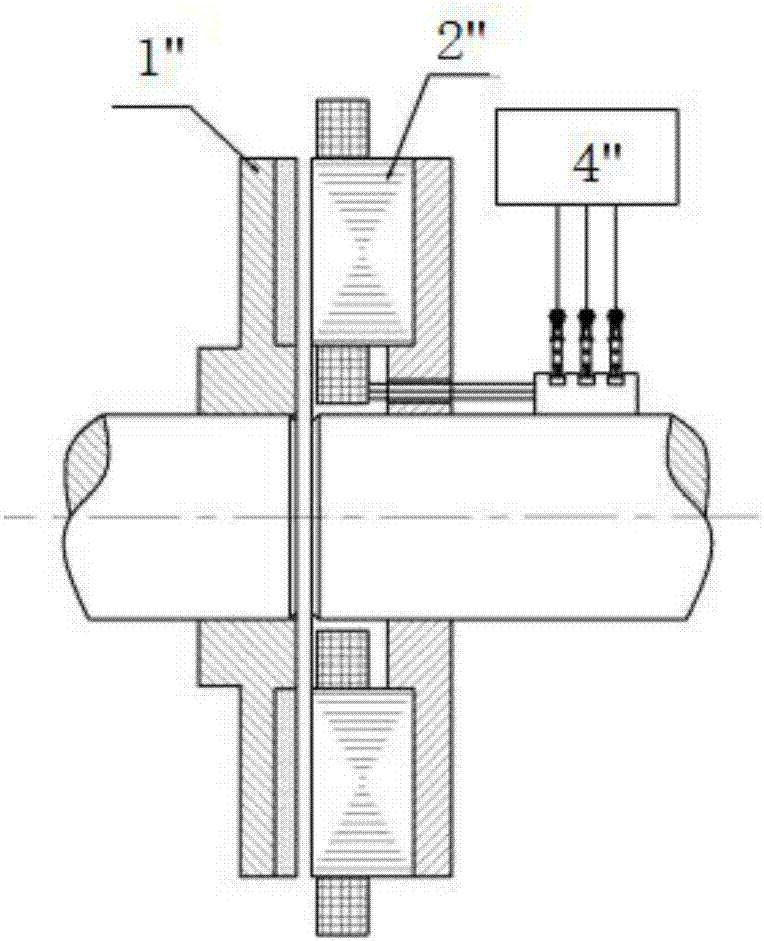

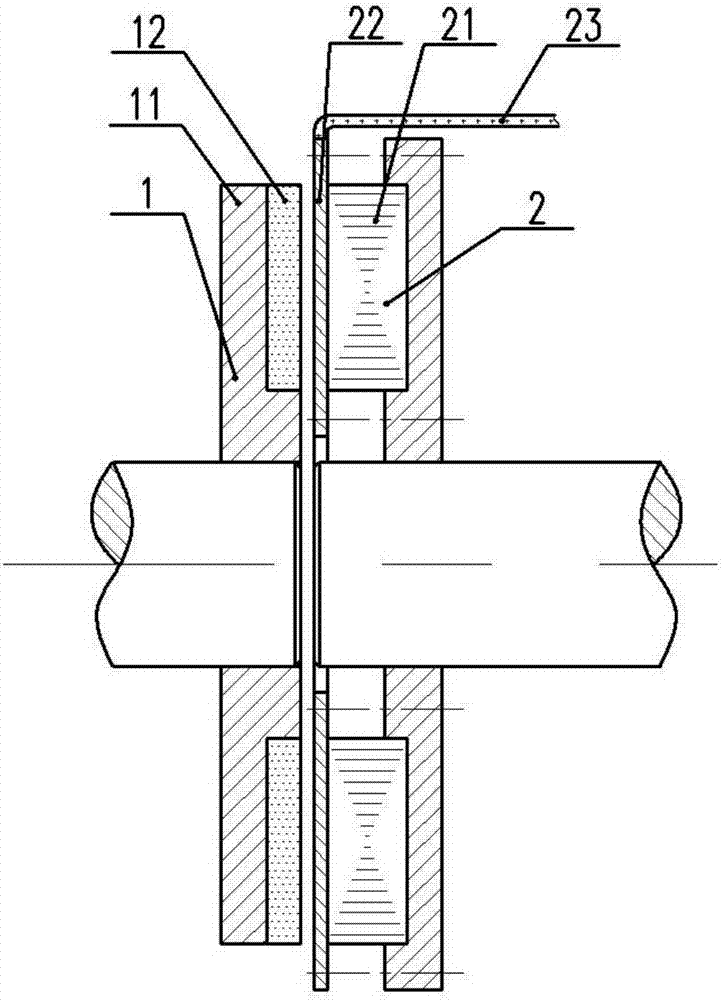

Speed-adjustable magnetic eddy current shaft coupling

InactiveCN103107675AIt is convenient to realize the increase and decrease requirementsSimple structureDynamo-electric gearsAsynchronous induction clutches/brakesElectrical conductorCoupling

The invention relates to a speed-adjustable magnetic eddy current coupling which comprises an input shaft connected with a motor and an output shaft connected with a load. A left conductor disk rotating synchronously with the input shaft is sleeved on the input shaft and can slide along the input shaft. The coupling further comprises a right conductor disk which is rotatably sleeved on the output shaft and can slide along the output shaft. A left magnetic disk and a right magnetic disk which are fixedly sleeved on the output shaft are arranged between the left conductor disk and the right conductor disk. A middle disk fixedly sleeved on the output shaft is connected between the left magnetic disk and the right magnetic disk. The left conductor disk, the left magnetic disc, the middle disk, the right magnetic disk and the right conductor disk are arranged in parallel. The left conductor disk, the middle disk and the right conductor disk rotate synchronously. The coupling further comprises an air gap regulating mechanism. The speed-adjustable magnetic eddy current coupling is stable, reliable and efficient, and is provided with the air gap regulating mechanism so as be capable of meeting requirements for increasing or reducing speed in working conditions.

Owner:ZHEJIANG UNIV

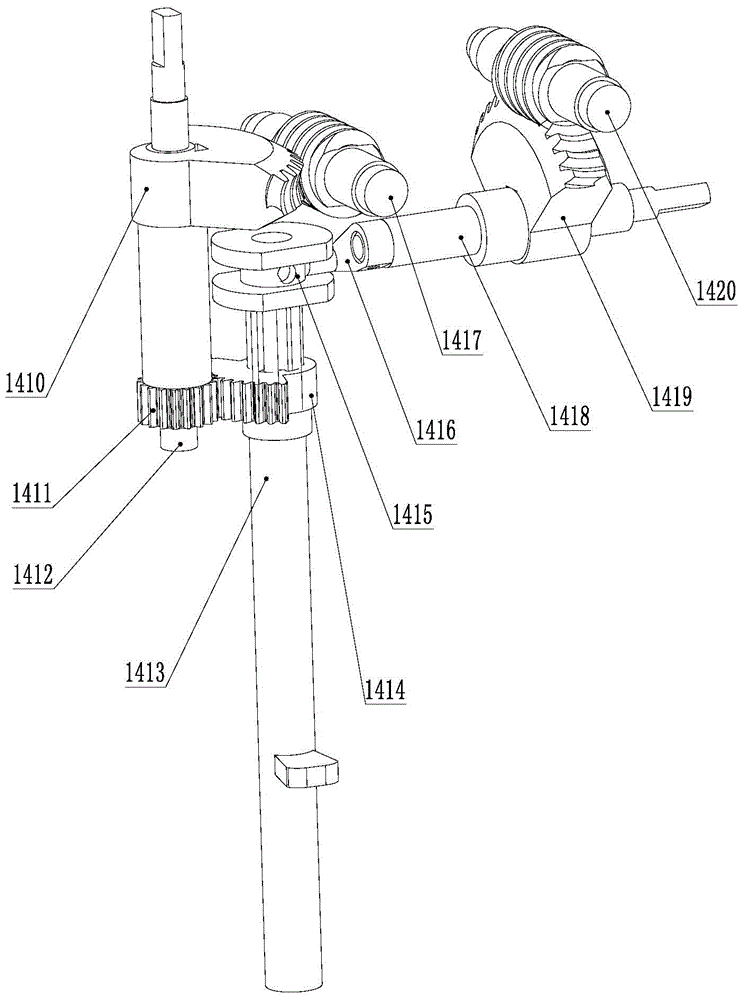

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448ASmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

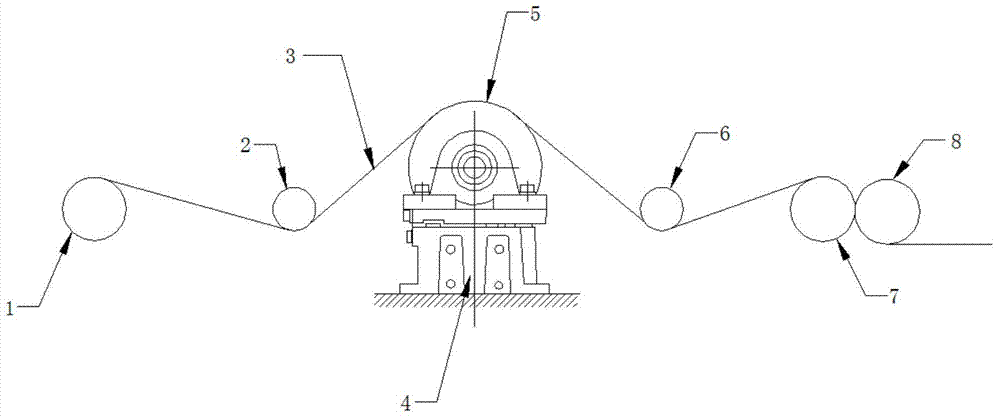

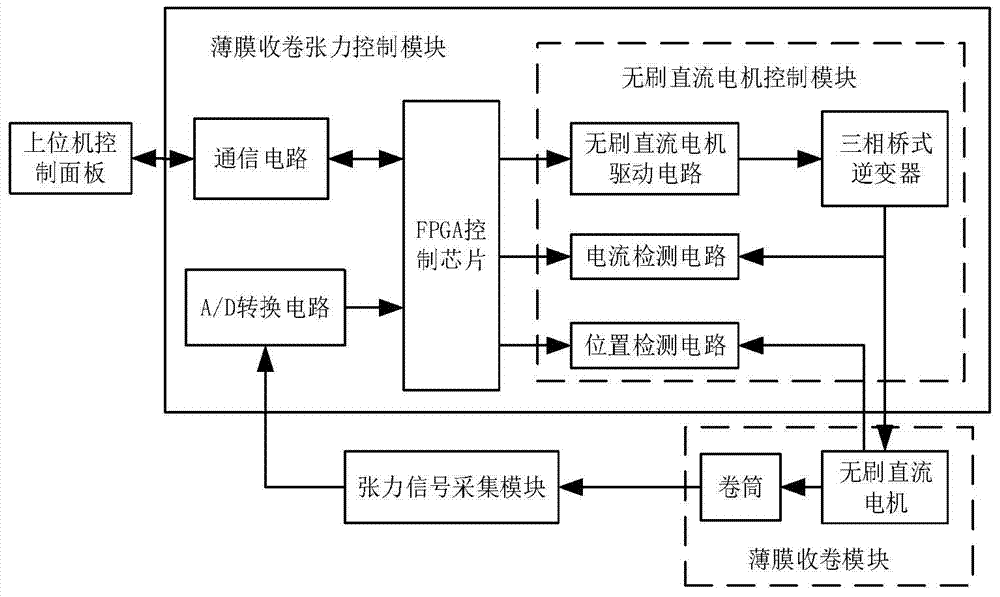

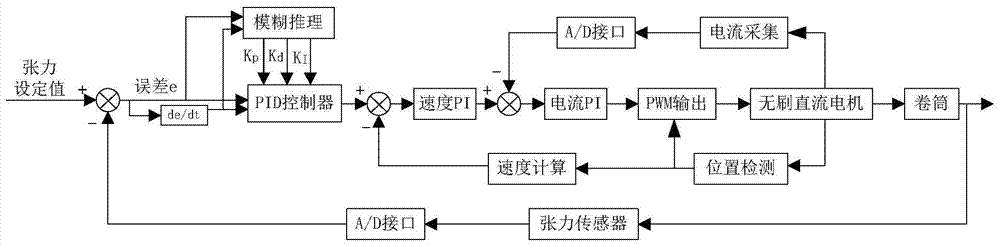

FPGA-based thin film rolling tension control system and method

InactiveCN104709748AImprove stabilityImprove parallel processing capabilitiesWebs handlingControl signalProgrammable logic device

The invention discloses an FPGA-based thin film rolling tension control system and method. The system comprises a tension signal collection module, a thin film rolling tension control module, a thin film rolling module and an upper computer operation panel. A programmable logic device FPGA controls a chip to achieve a fuzzy PID control algorithm, the speed controlled quantity of a brushless direct current motor is obtained, a double closed-loop control algorithm of the brushless direct current motor is combined, then signals are controlled to be correspondingly changed and adjusted when tension changes in the rolling process of a thin film, and constant control over the tension in the rolling process of the thin film can be achieved through real-time collection of tension of the thin film by utilization of the fuzzy PID control algorithm; the development cost is low, the integration level of the system is high, the steady state performance is good, the response speed is high, the control precision is high, and adaptability is high.

Owner:XI AN JIAOTONG UNIV

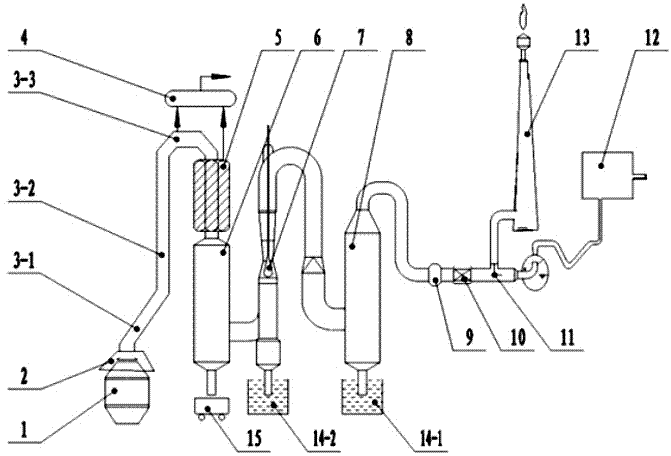

System and method for treating converter flue gas

InactiveCN102899444AEasy to controlEasy to operateIncreasing energy efficiencyManufacturing convertersEvaporative coolerDust control

The invention relates to an environmental-friendly device of an iron and steel enterprise and a dust removal method, that is to say, a system and a method for treating converter flue gas. The system comprises a furnace mouth nitrogen injection sealing petticoat pipe, a segmental evaporation cooling flue, a high-temperature heat pipe steam generator, a spray evaporation cooler, a long neck adjustable throat venturi tube, an impeller type composite dehydrator, a fan, an automatic continuous coal gas detector and a three-way switching valve, which are connected in sequence, wherein the three-way switching valve is connected with a gas chamber; or the three-way switching valve is communicated with a chimney. The method comprises the following steps of: forming a soft sealing screen between a furnace mouth and a petticoat pipe, after segmentally vaporizing and cooling the flue gas, and cooling in a high-temperature heat pipe; after carrying out spray evaporation, cooling and rough dust removal through a dry method, carrying out fine dust removal and cooling by a venturi tube through a wet method, dehydrating the flue gas, and entering into a coal gas recycling stage lastly. According to the invention, the wet method and the dry method are combined, waste heat recovery, coal gas recovery, sewage treatment and dust removal can be planned in a flue gas treatment and utilization system as a whole and the combination action of the device is fully exerted.

Owner:北京五一环保科技股份有限公司

Disc-type permanent magnetic coupling mechanism and devices using same

ActiveCN107248804ASolve fever problemSolve the problem of copper plate heatingPermanent-magnet clutches/brakesPermanent magnet rotorConstant power

The invention relates to a disc-type permanent magnetic coupling mechanism and devices using the same, including a disc-type permanent magnetic coupling speed regulator, a magnetic coupling speed regulation device running at constant power and a brushless doubly-fed coupling transmission device using the same. The mechanism comprises a permanent magnetic rotor and a conductor rotor, the conductor rotor comprises a conductor disc with a groove and a lead wire, induction current in the conductor disc flows in a set direction, and the current is guided to other device outside the conductor disc via the lead wire, so that the current is controlled or utilized. The current or current of the conductor rotor is controlled by a control unit, so that the disc-type permanent magnetic coupling speed regulator regulates the magnitude of the output torque to meet the requirement for rotating speed, and realizes a speed regulation function. The magnetic coupling speed regulation device running at constant power realizes constant power speed regulation operation. The brushless doubly-fed coupling transmission device reduces the radial size and the axial size and saves the installation space of equipment by combining a disc-type structure and an axial structure.

Owner:JIANGSU MAGNET VALLEY TECH

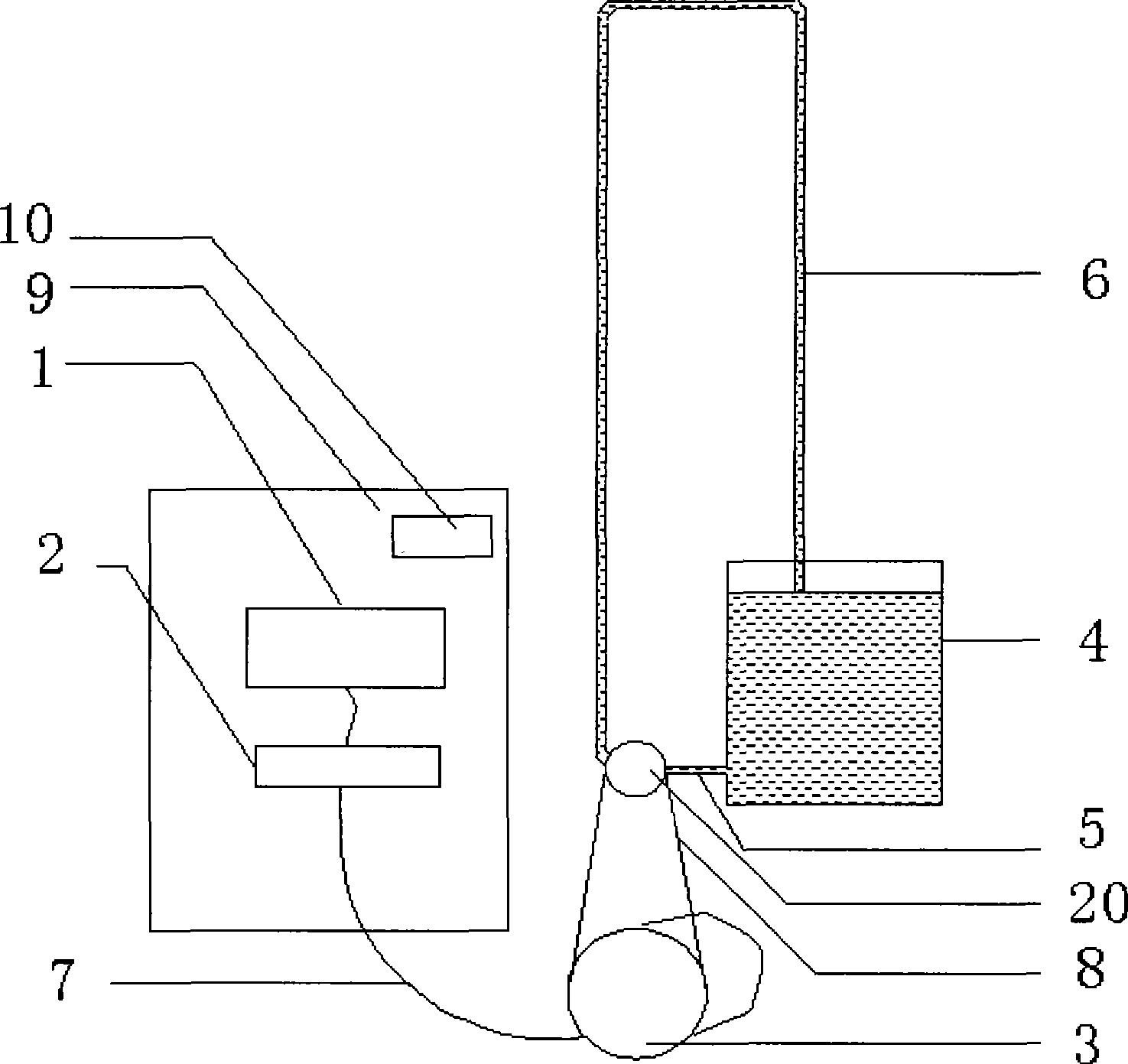

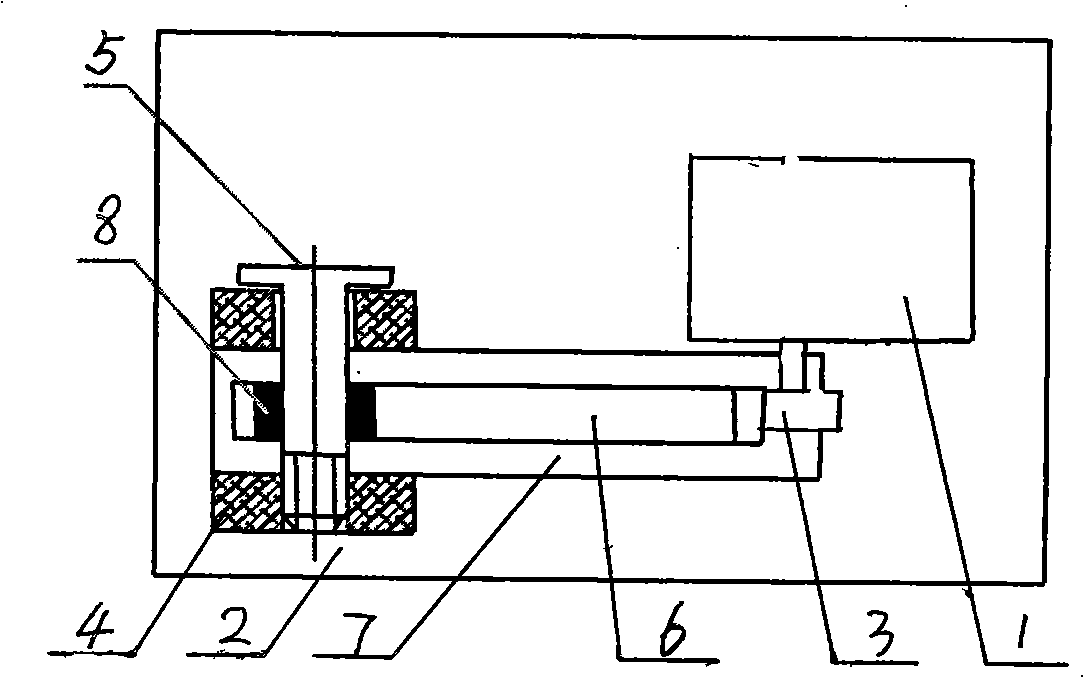

Water pump durability test-bed

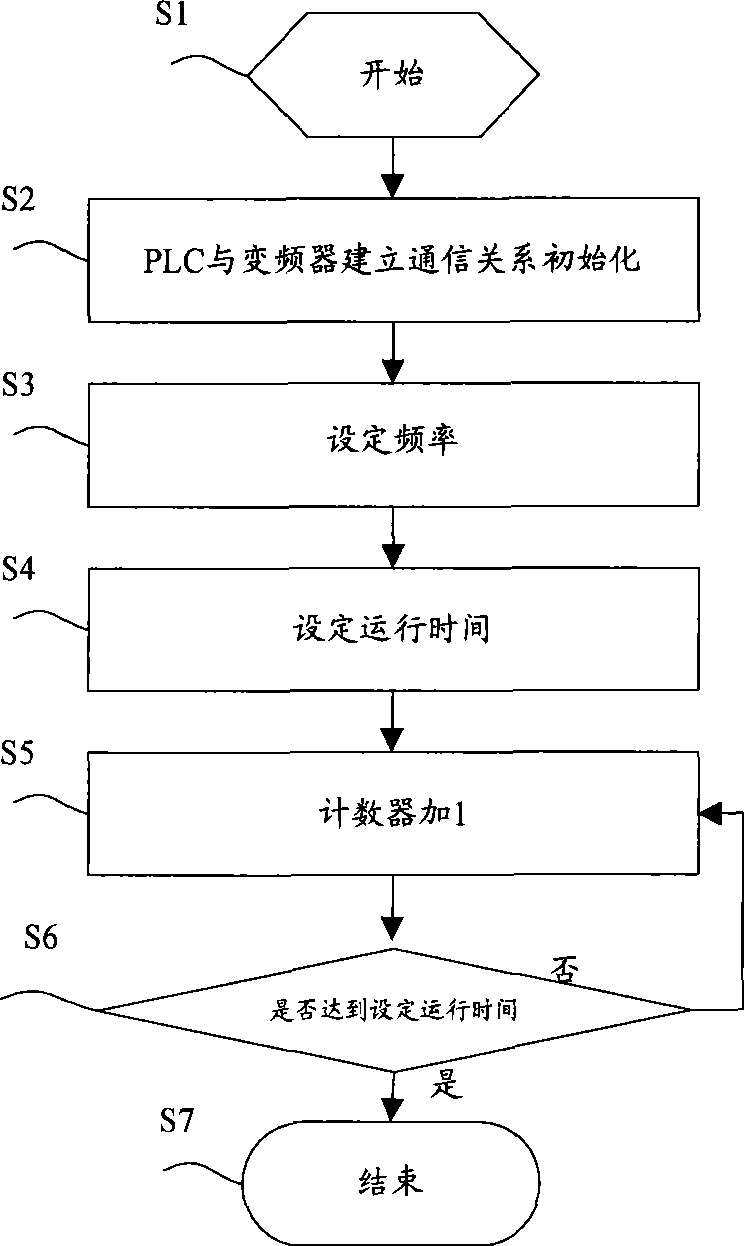

ActiveCN101469698AHigh precisionRealize automatic controlLiquid coolingPump testingFrequency changerAutomatic control

The present invention discloses a water pump durability test bench, which includes a programmable controller, a frequency transformator, a variable-frequency motor, a water tank, a first waterpipe, a second waterpipe, a workstation and a chucking appliance, wherein the chucking appliance fixes the water pump onto the workstation; the first waterpipe connects with a pump intake and the water tank outlet respectively; one end of the second waterpipe connects with outlet of the water pump and the other end inserted into the water tank; the programmable controller, the frequency transformator and the variable-frequency motor are connected in series through cables; the programmable controller sets frequency of the frequency transformator and start and stop time to control the frequency transformator outputs pressure frequency and drive the variable-frequency motor operate according to given rate of speed and drag the water pump operate. The water pump durability test bench of the invention has compact structure, low cost, high precision, automatic controllable test process, and suitable for small and medium-sized laboratories.

Owner:SHANGHAI HUAPU AUTOMOBILE CO LTD

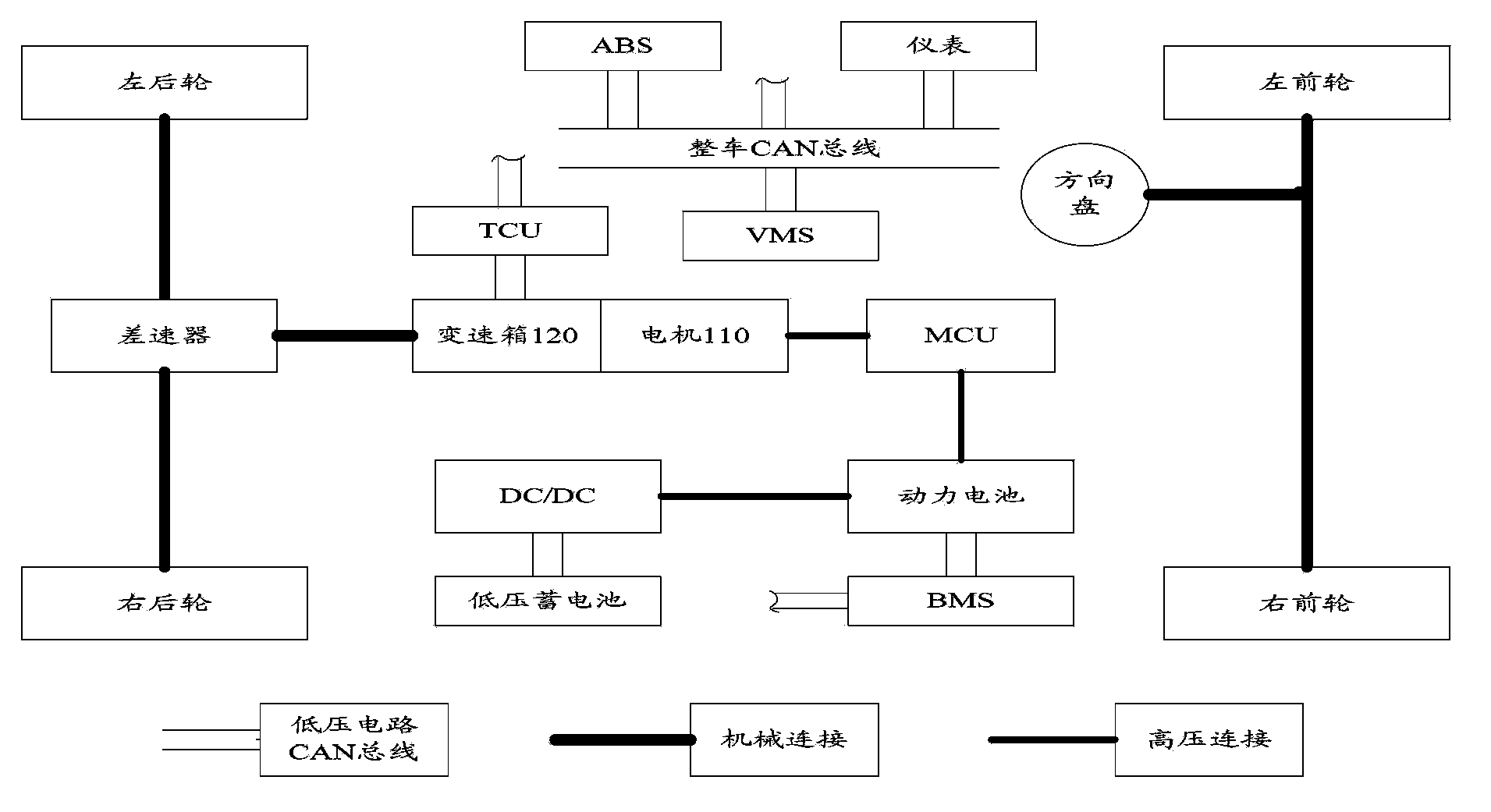

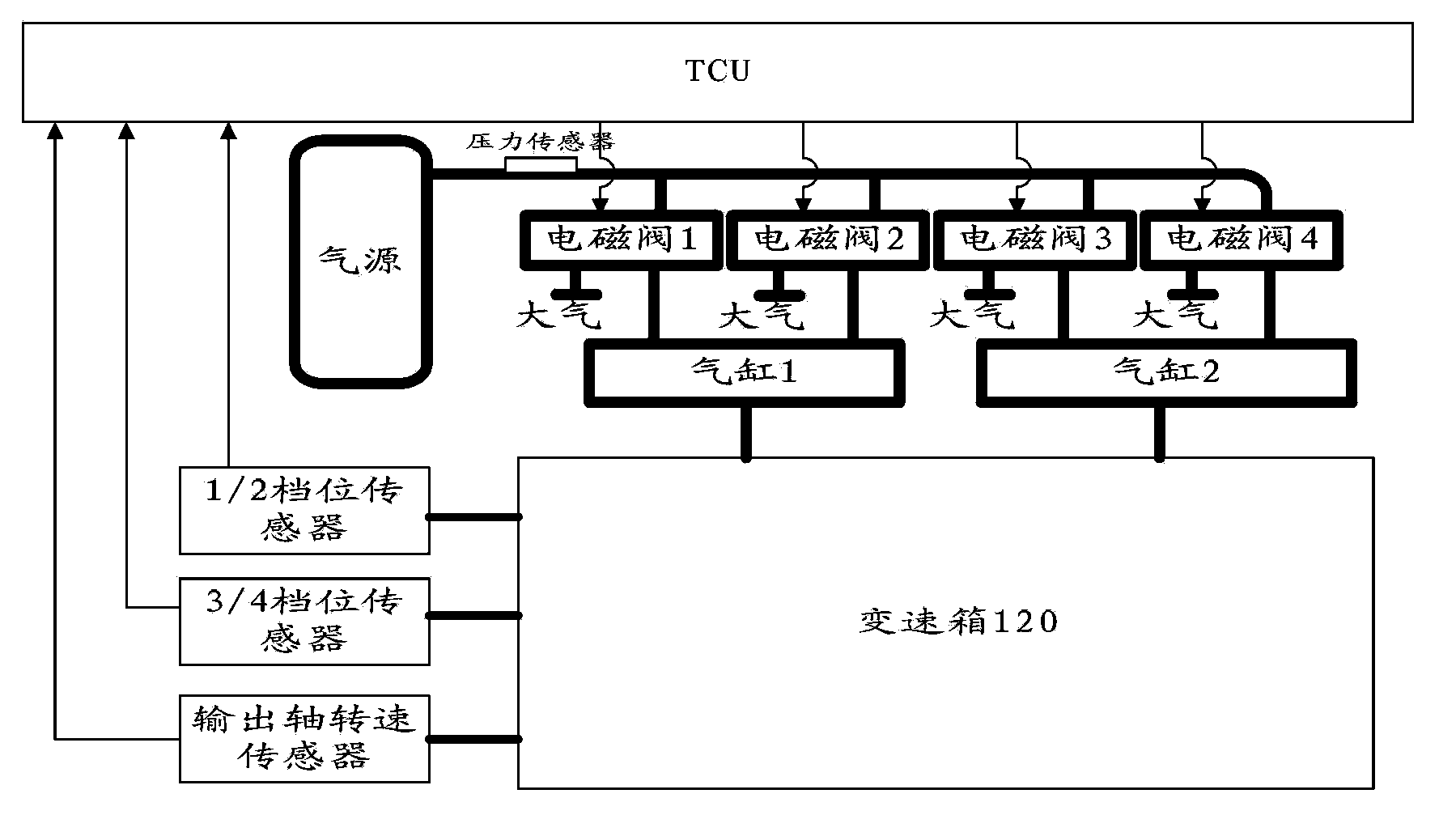

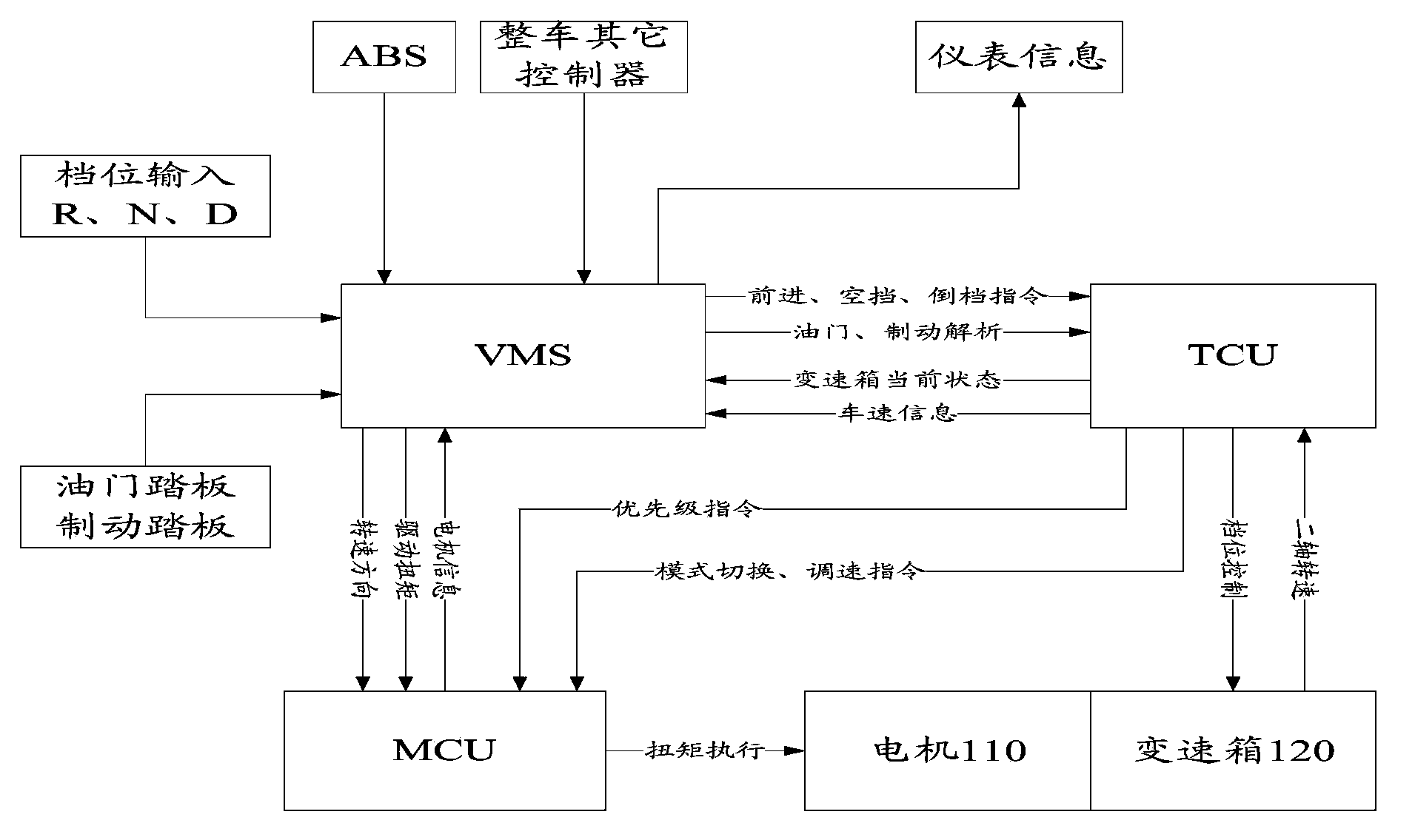

Electrical automobile control system and control method

ActiveCN103847534ASimple structureQuick responseSpeed controllerElectric/fluid circuitElectric machineAutomotive control systems

The invention provides an electrical automobile control system, which comprises a motor, a motor controller, a transmission, a transmission controller and an integral automobile controller, wherein the motor controller is connected with the motor, and is used for controlling the motor, the transmission is connected with the motor, the transmission controller is used for controlling the transmission and carrying out communication with the motor controller, and the integral automobile controller is respectively connected with the motor controller and the transmission controller, and is used for sending control commands to the motor controller and the transmission controller, and receiving feedback signals from the motor controller and the transmission controller. The control system provided by the embodiment of the invention has the advantages that the structure is simple, and the cost is low; the speed regulating precision of the transmission is high, and the response speed is high. The invention also provides a control method.

Owner:BEIQI FOTON MOTOR CO LTD

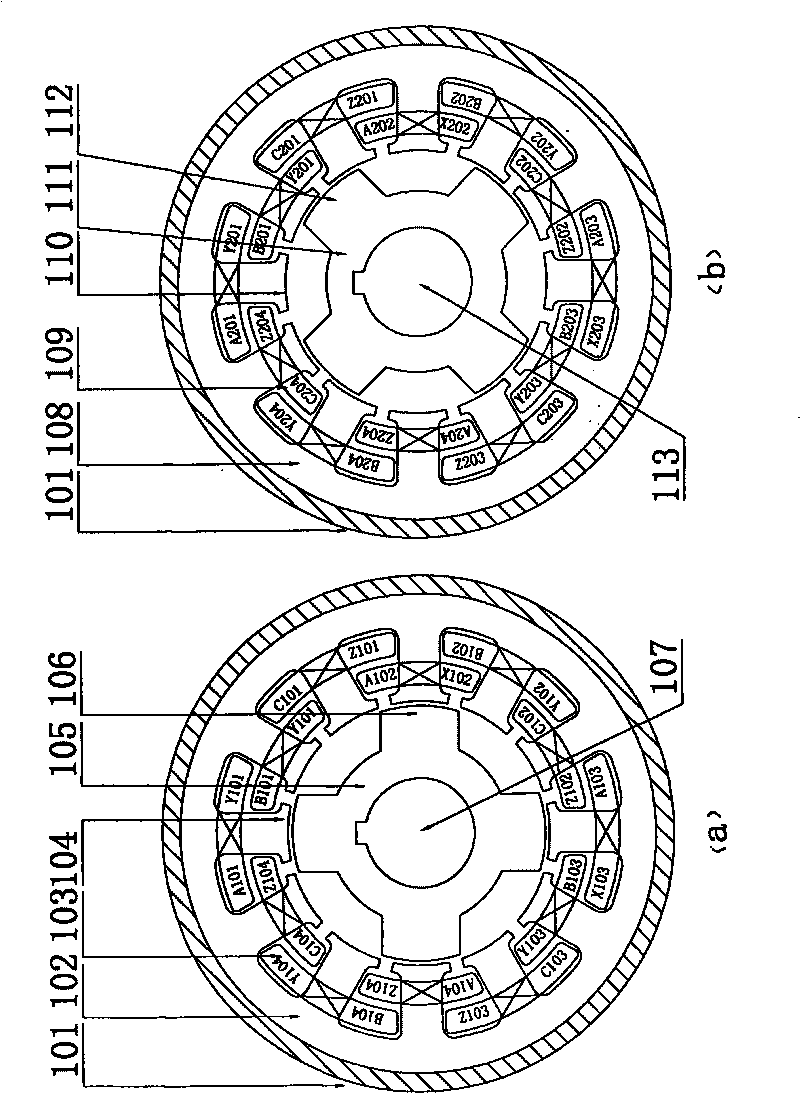

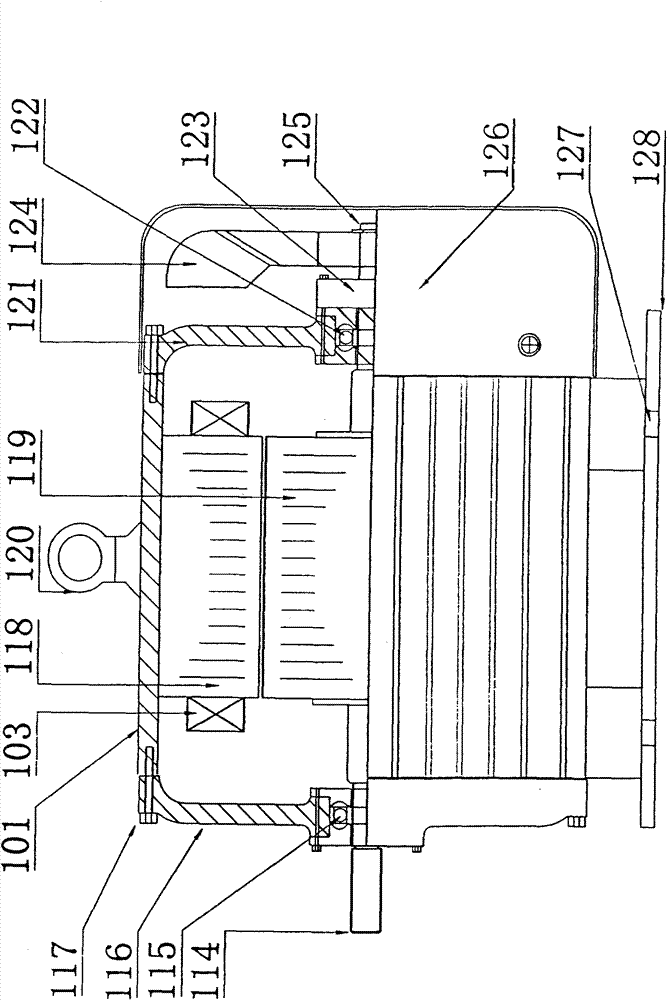

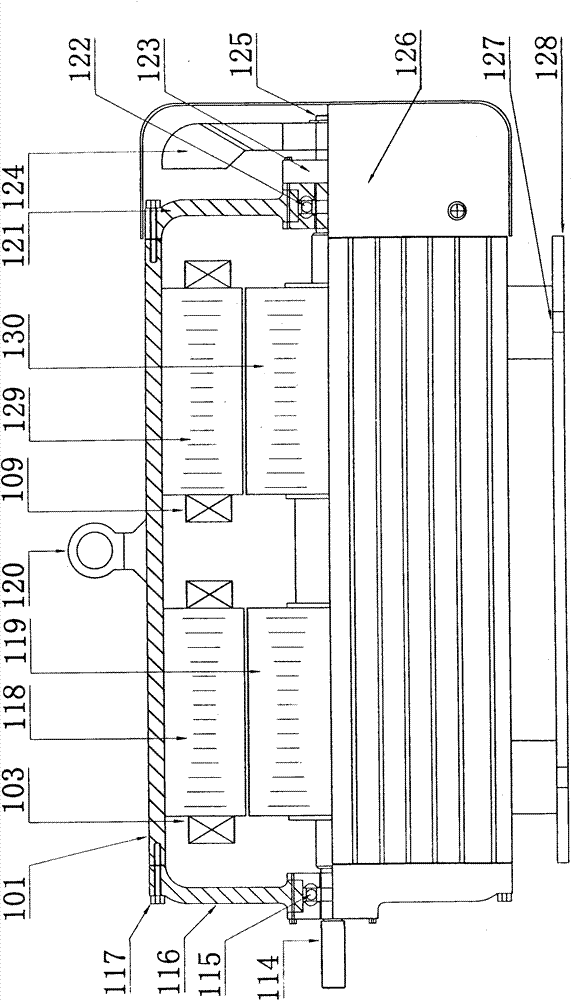

Three-phase single-section/double-section multiple-pole switching reluctance motor

InactiveCN101707428ABreak through the problem of not being able to manufacture multiple slots and multiple polesIncrease the areaMagnetic circuit stationary partsMagnetic polesReluctance motor

The invention relates to a three-phase single-section / double-section multiple-pole switching reluctance motor. A casing of the motor is arranged on a base, the middle part of the casing is provided with a hanging ring of the motor, a front end cover and a back end cover are respectively arranged at both ends of a rotating shaft, rotors are arranged between the front end cover and the back end cover, an air cover is arranged outside the back end cover, a fan is arranged in the air cover, and a sensor is arranged between the back end cover and the fan or between the back end cover and a second-section rotor; the motor comprises stators and the rotors with a structure of double convex poles, also comprises one section or two sections and can run by a single section or double sections; the iron cores of the stators and the rotors both comprise a single section or two sections, and the lengths and the diameters of the iron cores of the two sections of the stators and the rotors are equal; two sets of concentrated windings or sandwich windings are respectively arranged on two sections of stator teeth, and armature windings on two teeth of the same phase of each set of windings are connected in series or in parallel to form one phase; the magnetic poles of the two sections of stators are aligned, and the difference of the magnetic poles of the two sections of rotors is 1 / 2 of a rotorpolar distance angle; or, the magnetic poles of the two sections of rotors are aligned, and the difference of the magnetic poles of the two sections of stators is 1 / 2 of a stator polar distance angle; and the invention has the characteristics of high efficacy, high starting torque, easy control and low cost.

Owner:张世清

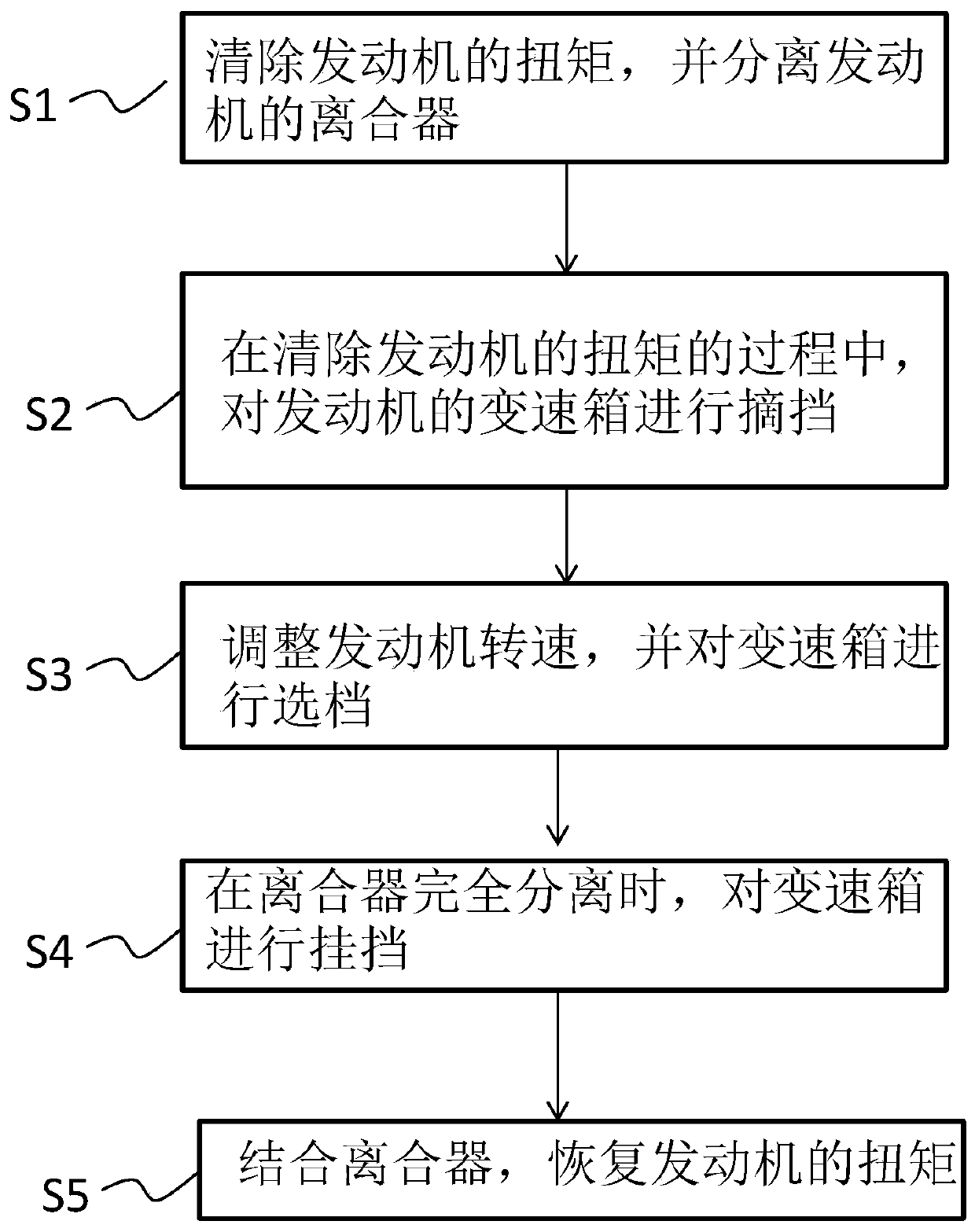

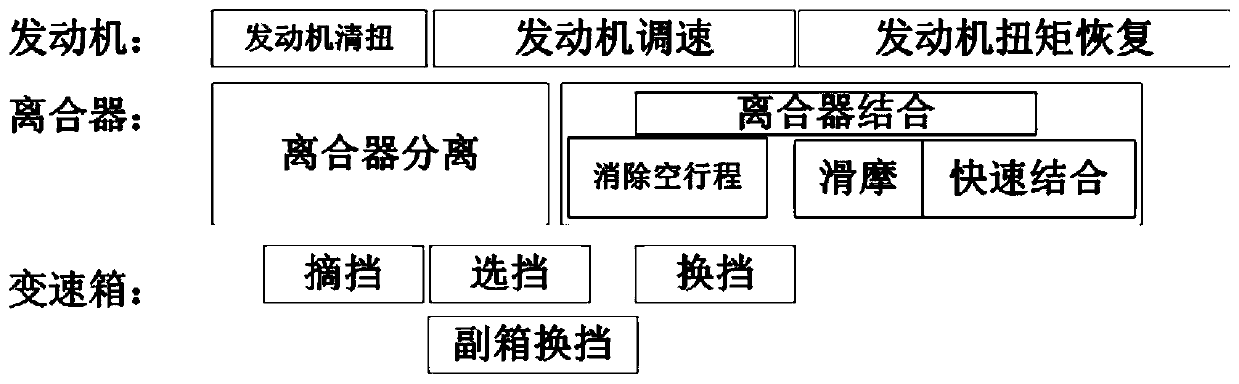

Gear shifting method used for AMT

The invention discloses a gear shifting method used for an AMT. The gear shifting method comprises the following steps that S1, the torque of an engine is cleared away, and a clutch of the engine is disengaged; S2, in the process of clearing away the torque of the engine, the transmission of the engine is subjected to idling; S3, the rotating speed of the engine is adjusted, and the transmission is subjected to gear selection; S4, when the clutch is completely disengaged, the transmission is subjected to gear engagement; and S5, the clutch is engaged, and the torque of the engine is restored.Compared with the prior art, the gear shifting method has the beneficial effects that when the clutch is disengaged and engaged, fine cooperation of the engine is not needed, and the control difficulty is reduced; idling and clutch engagement are started in advance, and therefore the total gear shifting time is shortened, and meanwhile the power failure time is also shortened; and due to the factthat torque clearing of the engine is finished in advance, more time is reserved for speed adjustment of the engine, the speed adjustment precision of the engine is higher, and gear shifting comfort is better.

Owner:WEICHAI POWER CO LTD

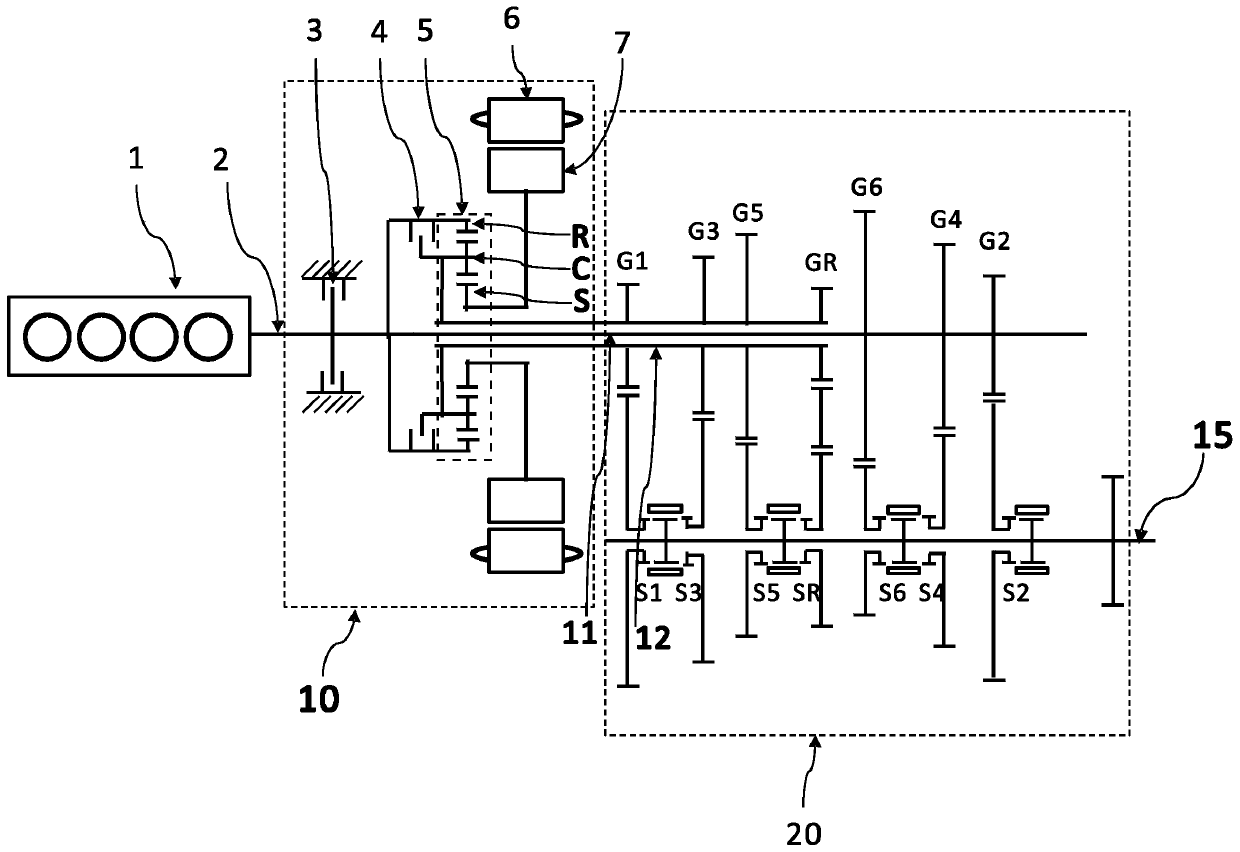

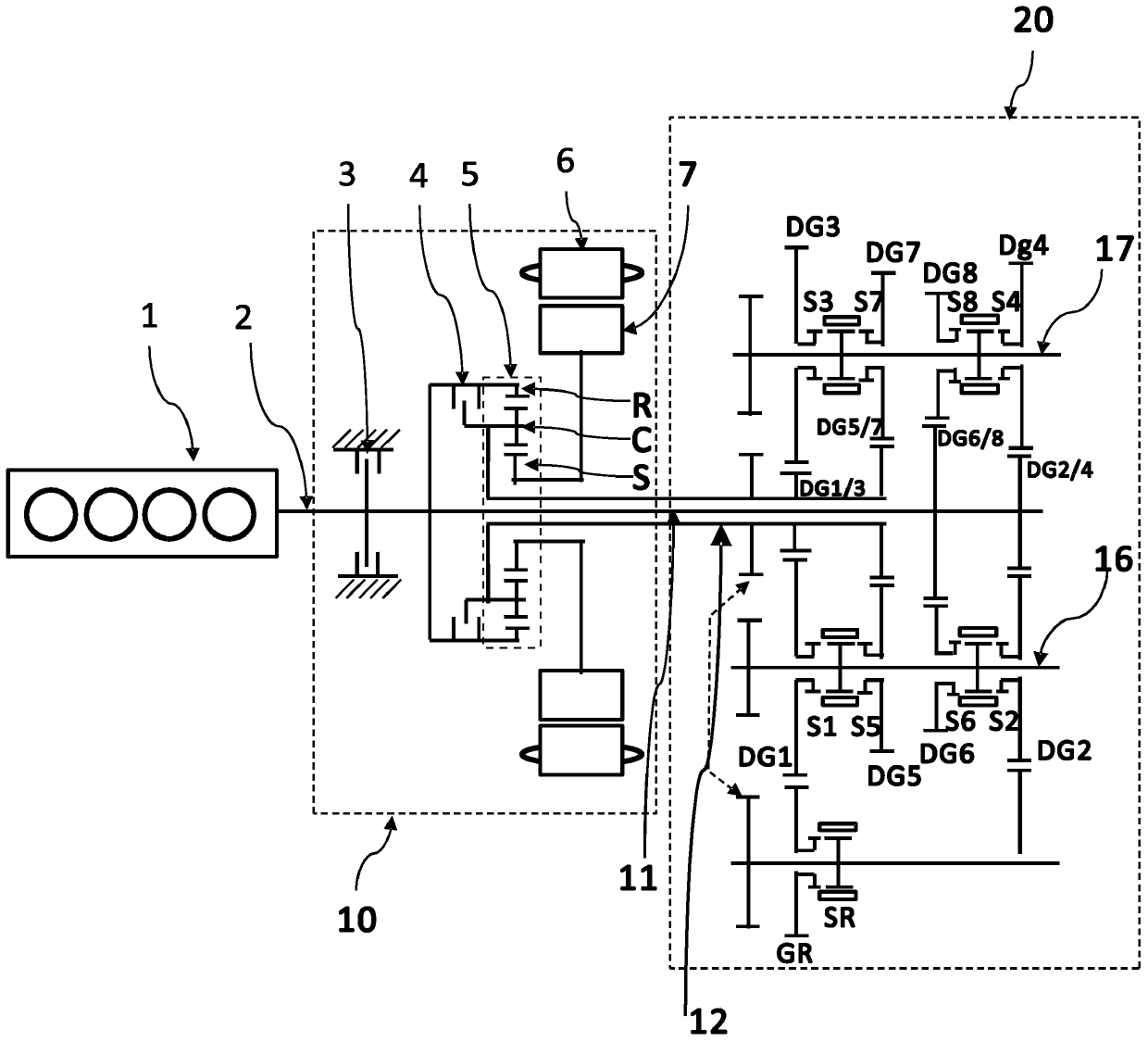

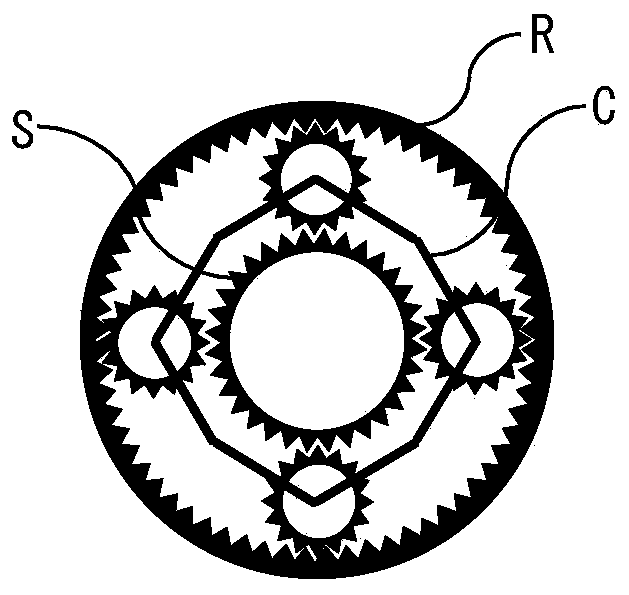

Vehicle hybrid power system and control method thereof

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

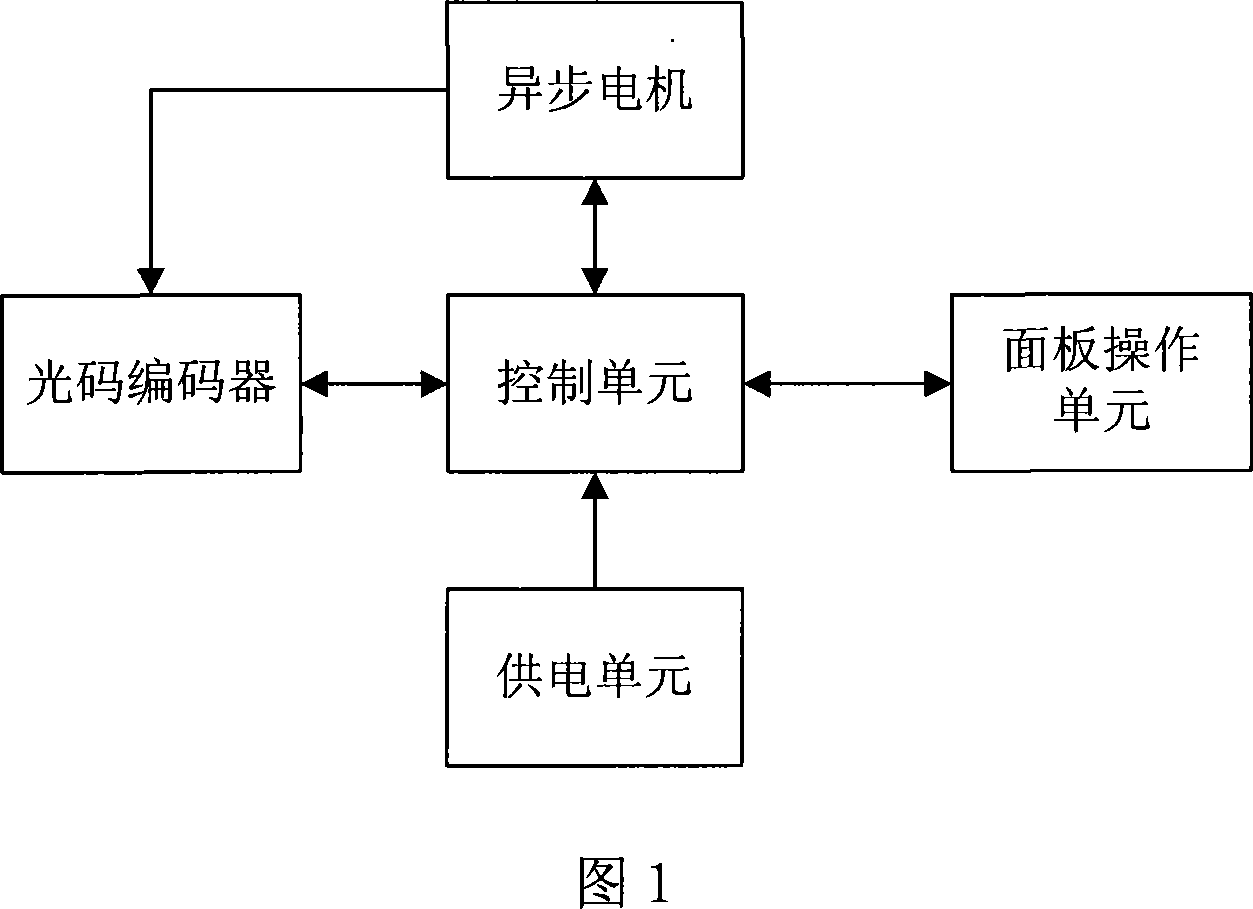

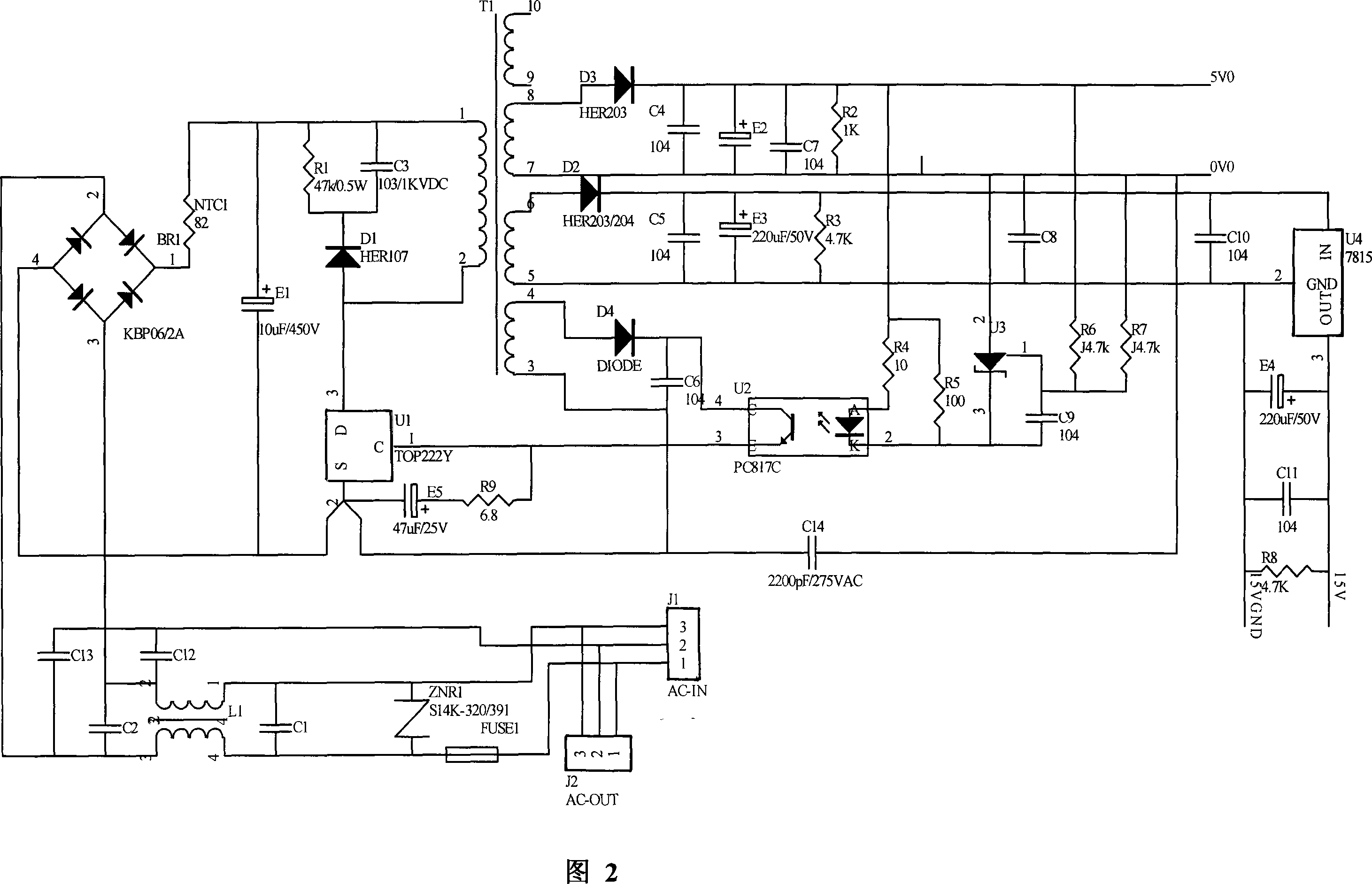

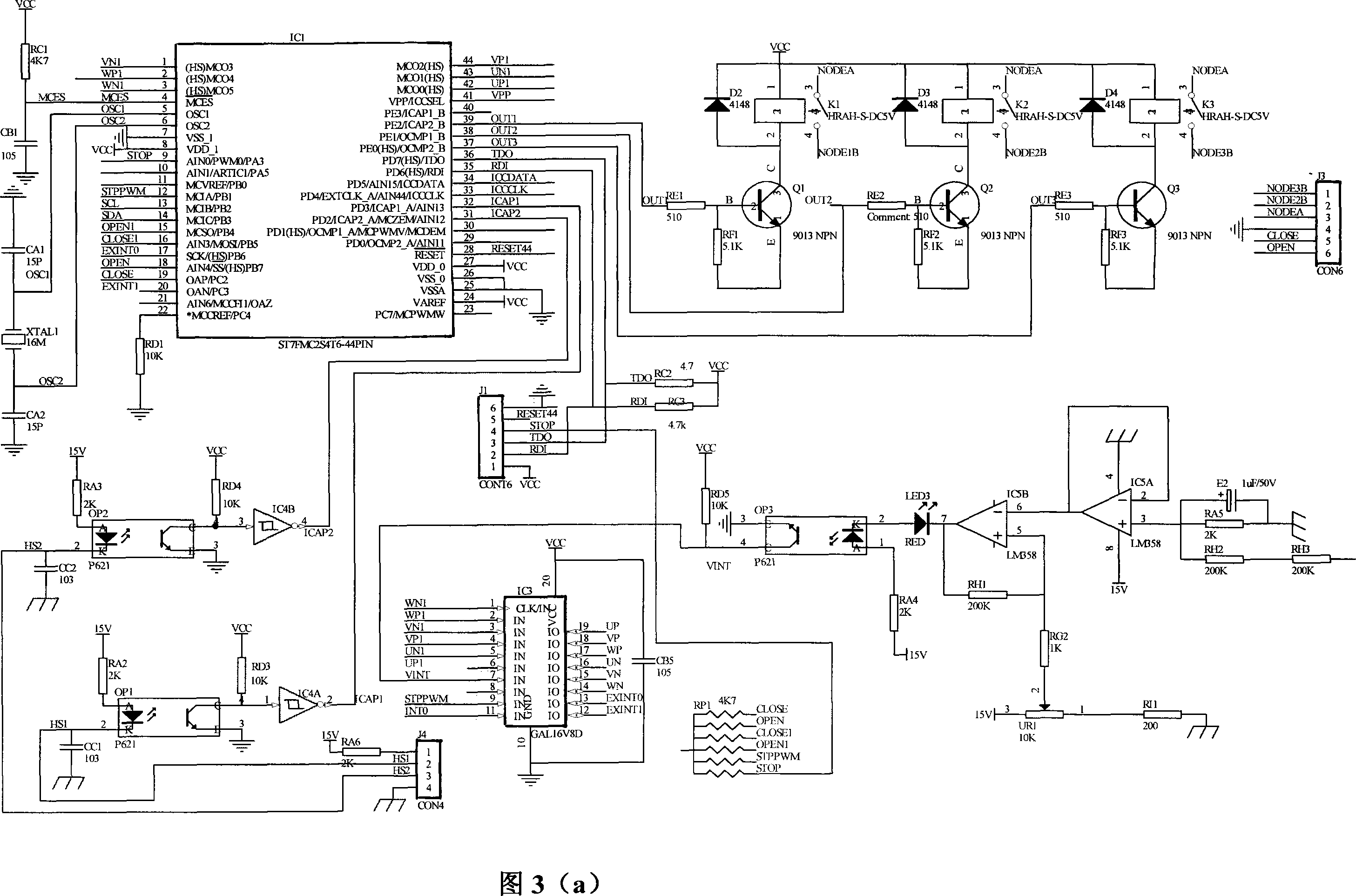

Intellective variable frequency controller dedicated to elevator door without limit switch

InactiveCN101092226AReduce dependenceHigh precision of speed regulationBuilding liftsEngineeringVariable frequency control

The invention is a special intelligent variable-frequency controller for elevator doors without limit switch, comprising power supply unit, control unit, panel operation unit, optical coder, and asynchronous machine, where the control unit is connected with the power supply unit, optical coder, panel operation unit and asynchronous machine, and the asynchronous machine is connected with the optical coder. And its advantages: high system intelligentization degree; safe and reliable; and convenient to install and debug.

Owner:边春元

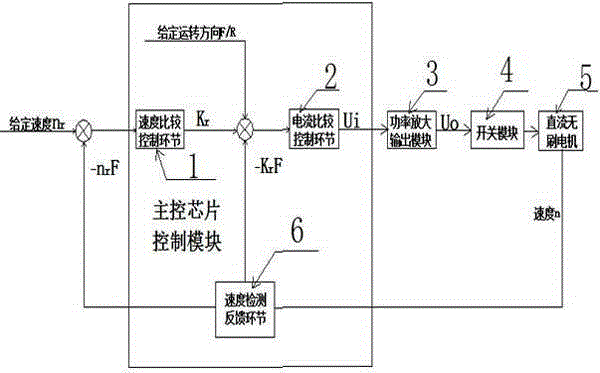

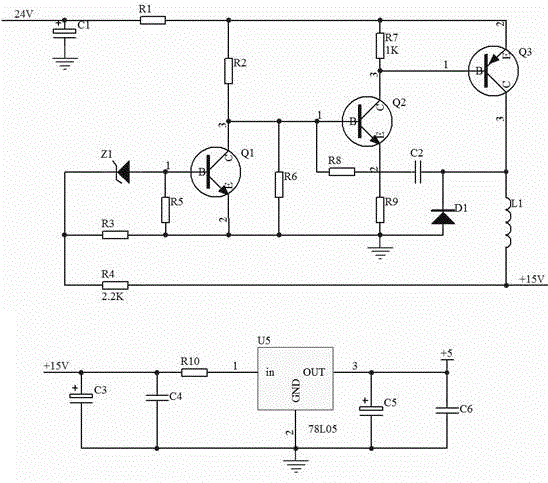

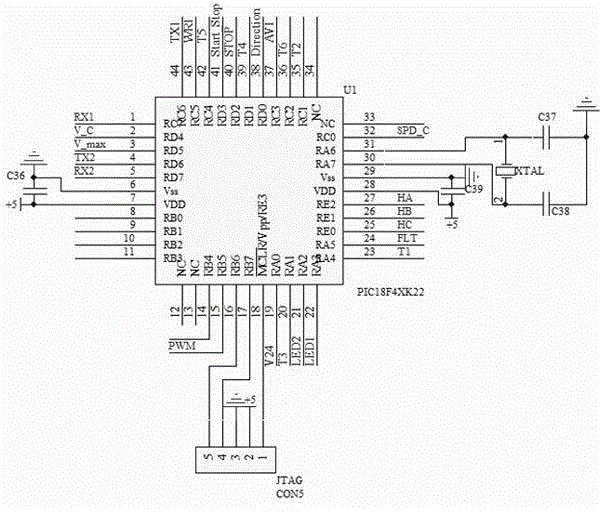

Brushless DC (Direct current) motor driver

InactiveCN104104283AReduced counter forceSolve the damageSingle motor speed/torque controlEmergency protective circuit arrangementsMicrocontrollerElectric machine

The invention discloses a brushless DC (Direct current) motor driver. The brushless DC motor driver structurally comprises a power supply changeover control module, a main control chip control module, a switch module and a power amplification output module, wherein the motor driver has three control modes below: rotating speed data are directly sent to a single-chip through 485 communication; rotating speed analogue input, that is to say, the input analogue signal is changed into a digital signal through A / D conversion, and then processed and changed into rotating speed data through the single-chip; rotating speed PWM ((Pulse Width Modulation) input, that is to say, an input PWM signal is sampled, and then changed into the rotating speed data based on a PWM duty ratio. The driver is simple in control method, high in speed adjusting precision and diversified in control mode, can export a negative current, can completely control the motor, can efficiently reduce system complexity, can reduce system cost and resource waste, and enables installation, debugging and after-sale to be simple.

Owner:江西方迪科技有限公司

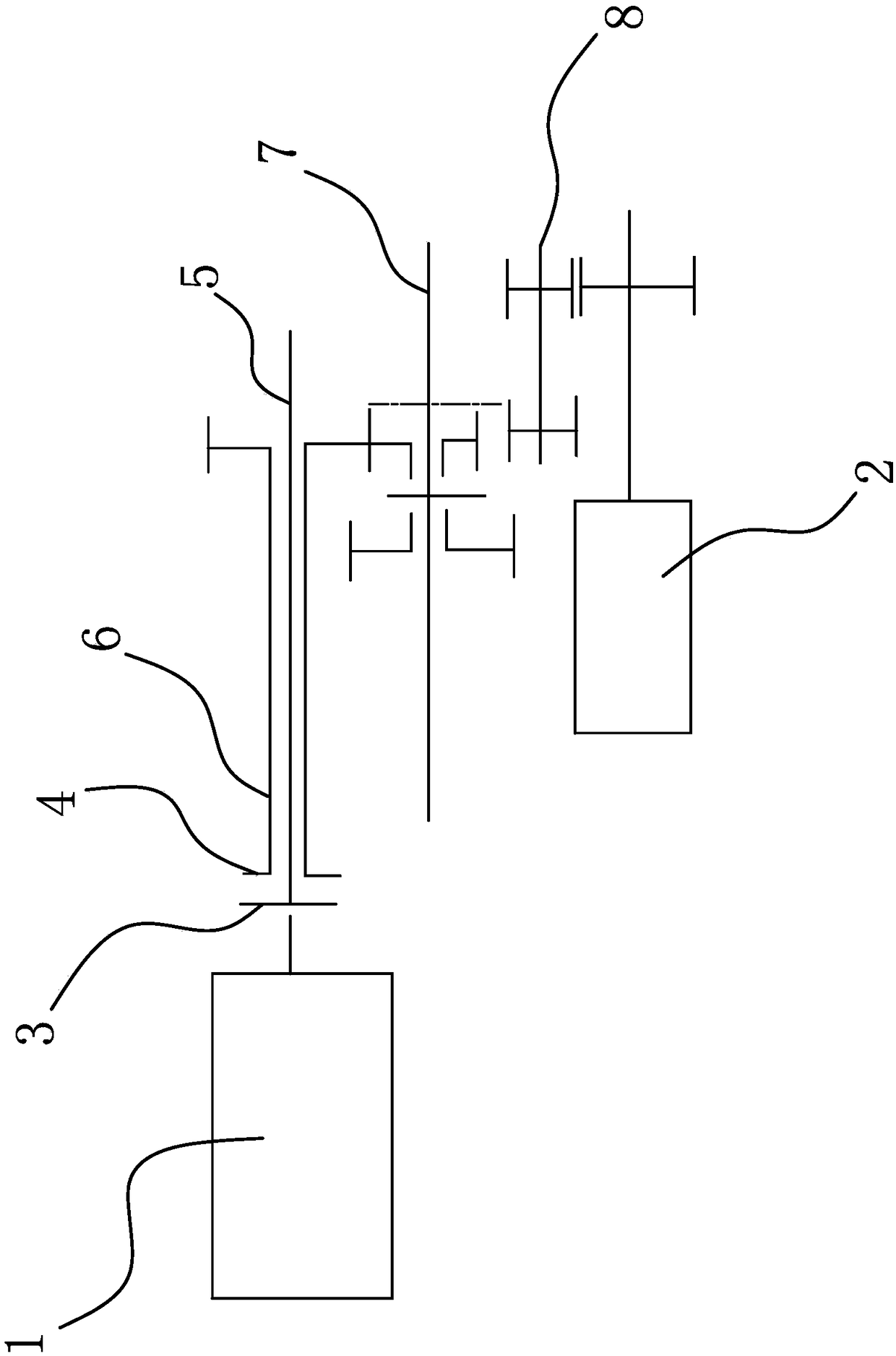

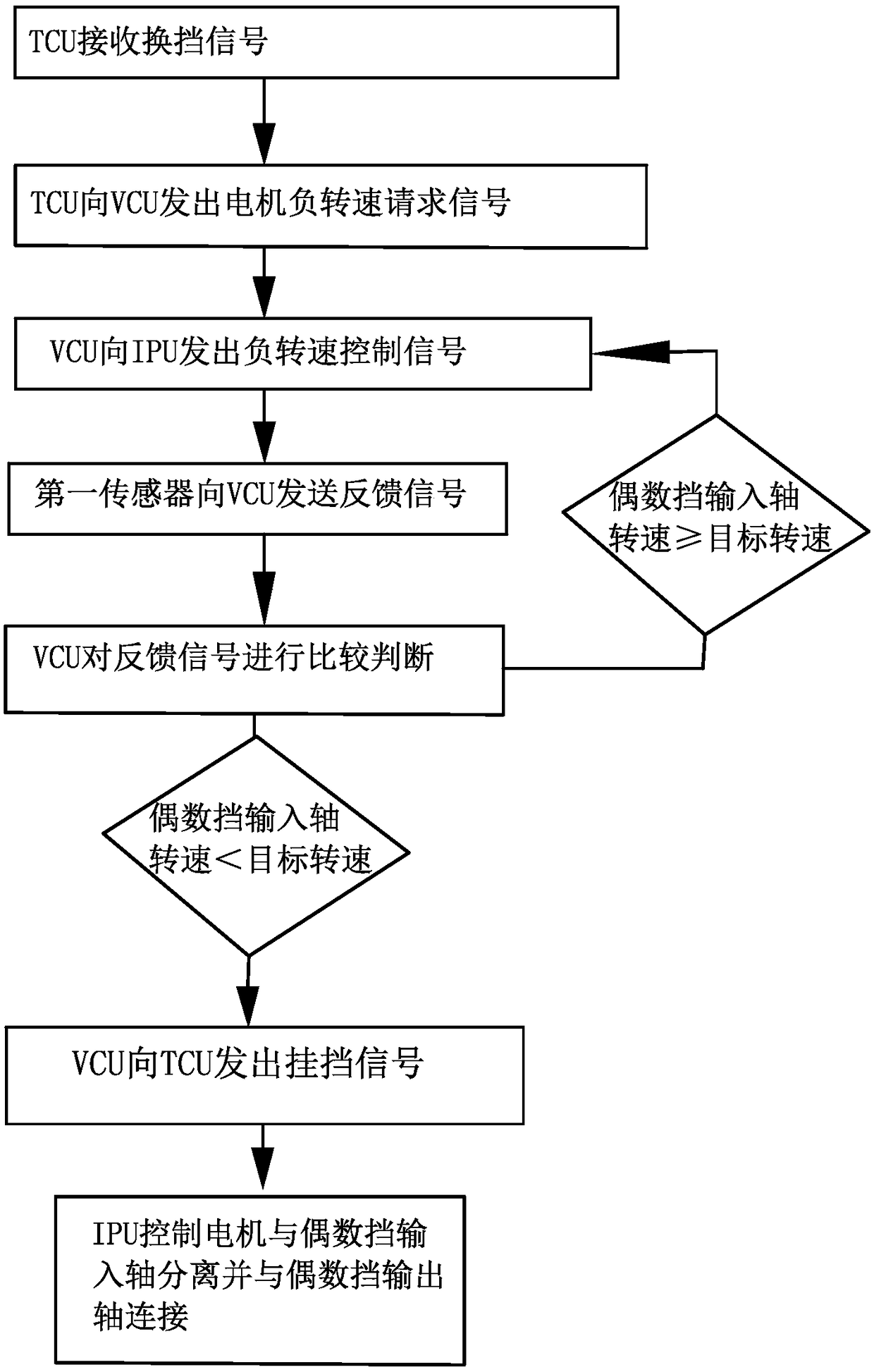

Static gear-shifting control system and method for hybrid electric vehicle

InactiveCN108583577AReduce speedReduce shockHybrid vehiclesGas pressure propulsion mountingControl systemControl signal

The invention provides a static gear-shifting control system and method for a hybrid electric vehicle, and belongs to the technical field of vehicles. The static gear-shifting control system solves the problem that an existing hybrid electric vehicle has larger impact when static gear-shifting is carried out. The static gear-shifting control system for the hybrid electric vehicle comprises a gear-shifting sensor and a first sensor, wherein the gear-shifting sensor is used for receiving gear-shifting signals and sending the gear-shifting signals to a TCU, and the first sensor is used for collecting rotating speed signals of a transmission pre-engaging-gear input shaft and sending the rotating speed signals to a VCU; the TCU sends motor negative rotation speed request signals to the VCU according to the gear-shifting signals, and the VCU sends motor negative rotation speed control signals for controlling the output of the motor and torque opposite to the rotation direction of the transmission pre-engaging-gear input shaft to reduce the rotation speed of the pre-engaging-gear input shaft to an IPU according to the motor negative rotation speed request signals; and the VCU stores the target rotational speed value of the pre-engaging-gear input shaft, when the rotation speed of the pre-engaging-gear rotation speed input shaft is less than the target speed value, and the VCU sends engaging-gear signals to the TCU. The static gear-shifting control system makes the impact smaller, the noise and vibration lower and the driving experience better when a gear is engaged.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

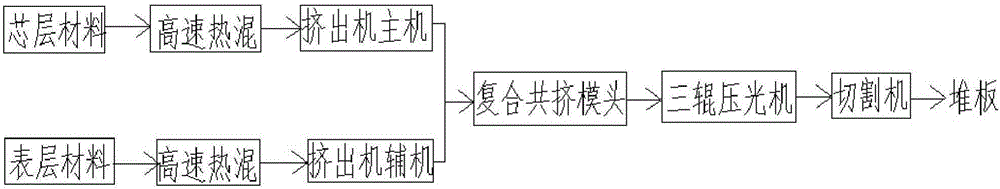

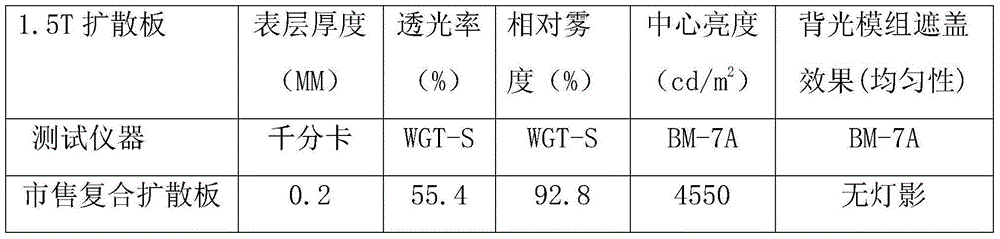

Production technology for composite co-extrusion PS diffuser plate

ActiveCN105175916AImprove optical performance indicatorsGuaranteed Diffusion EffectLuminescent compositionsSurface layerTransmittance

The invention relates to a production technology for a composite co-extrusion PS diffuser plate, and the technology mainly comprises steps of formula design, material mixing, extrusion, cutting, plate piling and the like. The material mixing step comprises high-speed hot mixing and sieving warehousing. The extrusion step employs a composite co-extrusion technology. A core-layer extruder is taken as a main machine, the main machine employs a screw with the diameter of 130 mm and the draw ratio of 38, and the main machine average rotation speed is 70 r / min. A surface-layer extruder is taken as an auxiliary machine, the auxiliary machine employs a screw with the diameter of 60 mm and the draw ratio of 33, and the auxiliary machine average rotation speed is 60 r / min. The main-machine material canister heating temperature is divided into seven stages, and the temperature is gradually raised. The auxiliary-machine material canister heating temperature is divided into five stages. Through formula design, equipment layout and technological parameter improvement, the diffuser plate is improved in light transmittance, relatively haze and center brightness, and the backlight module covering effect is good.

Owner:惠州市凯帝智光电科技有限公司

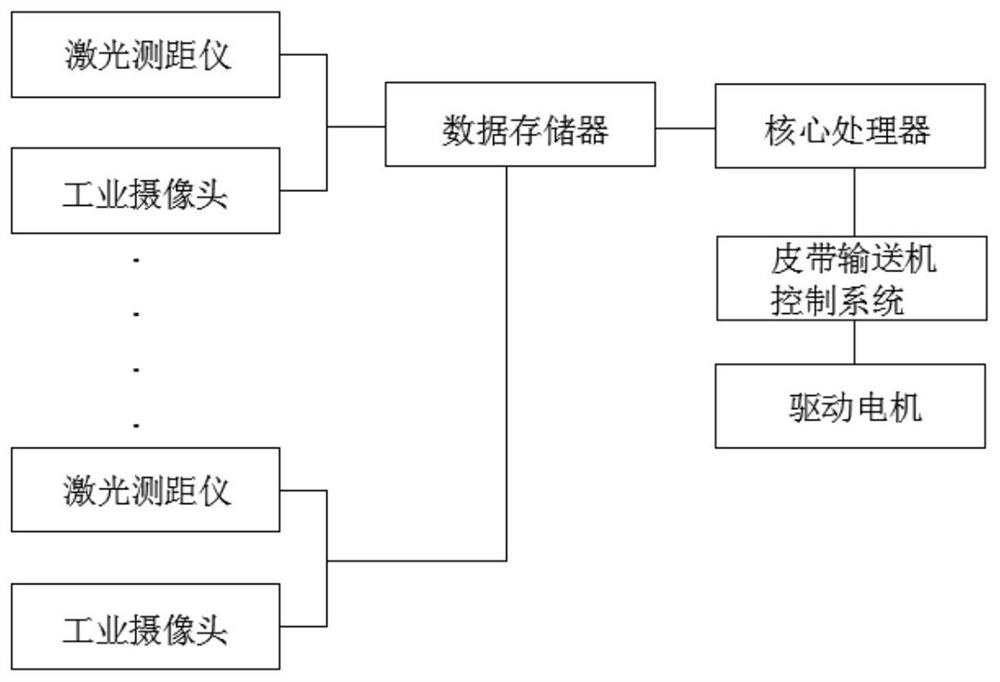

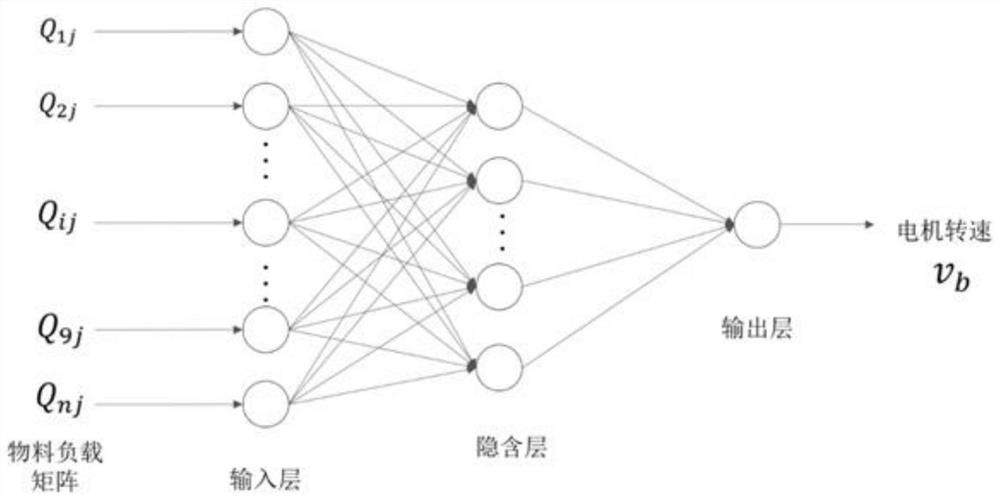

Intelligent speed regulation method for belt conveyor based on material monitoring

ActiveCN112793989AReduce energy consumptionReduce coal accumulationConveyorsControl devices for conveyorsElectric machineryAutomotive engineering

The invention discloses an intelligent speed regulation method for a belt conveyor based on material monitoring. The method comprises the steps that material loads at different positions of the belt conveyor and corresponding driving motor rotating speeds are obtained through manual teaching speed regulation and serve as training data to train an initial neural network, a neural network system with cognitive ability is obtained, and after training is completed, an intelligent speed regulation system is started; according to material information data collected by a material monitoring device in the actual operation process of the belt conveyor, material load capacity data of different positions of the belt conveyor are obtained through calculation of a core processor and are conveyed to a neural network with cognitive ability; the neural network system carries out prediction to obtain the current best rotating speed of a driving motor of the belt conveyor, and a belt conveyor control system carries out variable-frequency speed regulation on the driving motor. According to the method, the energy consumption of the belt conveyor motor can be effectively reduced, the accidents of coal accumulation can be reduced, the speed regulation range and precision are large, and the purposes of energy conservation, consumption reduction and safe production are achieved.

Owner:CHINA UNIV OF MINING & TECH +1

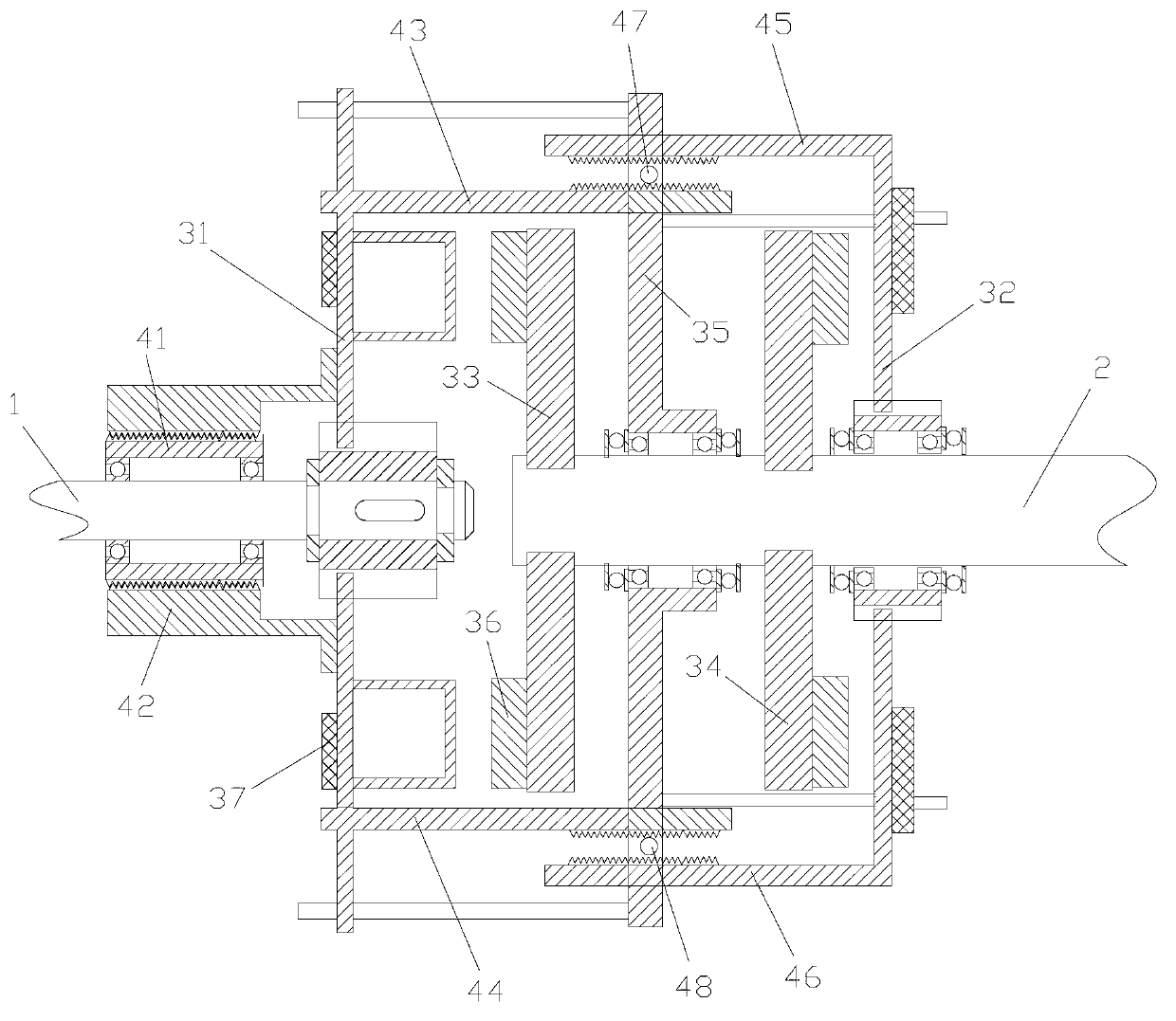

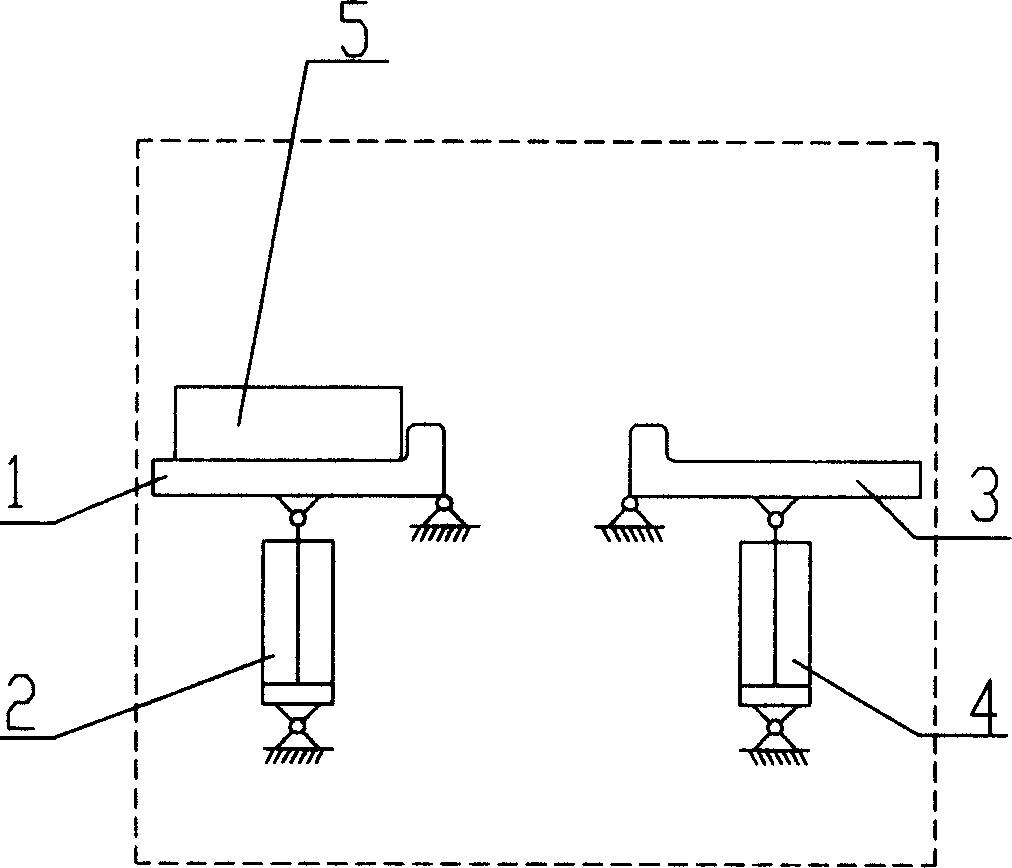

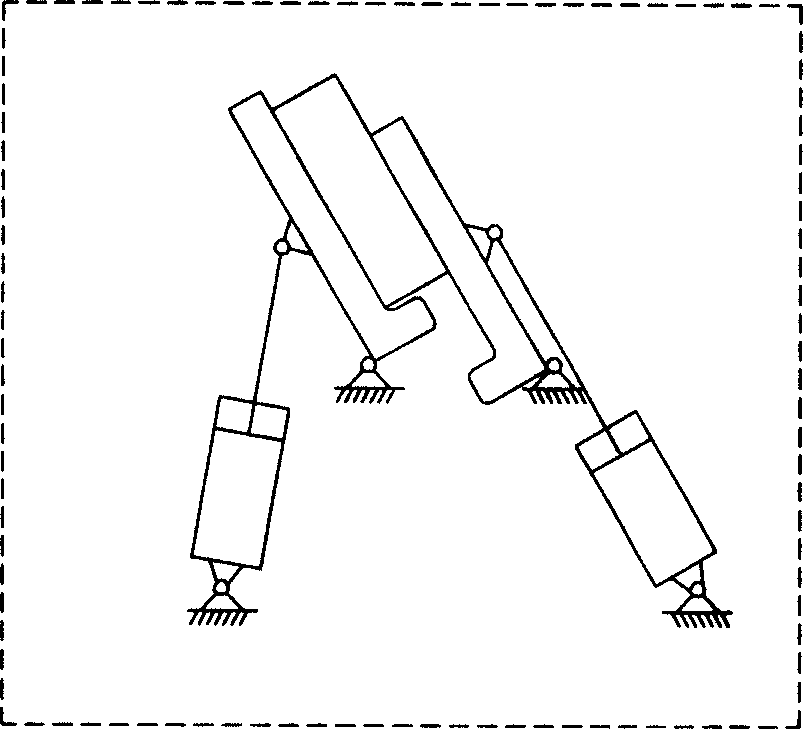

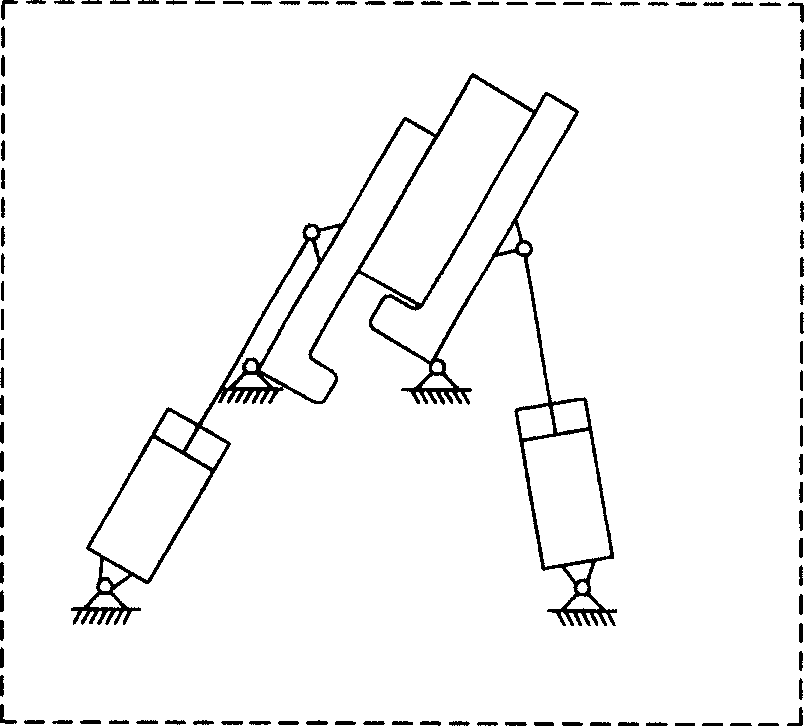

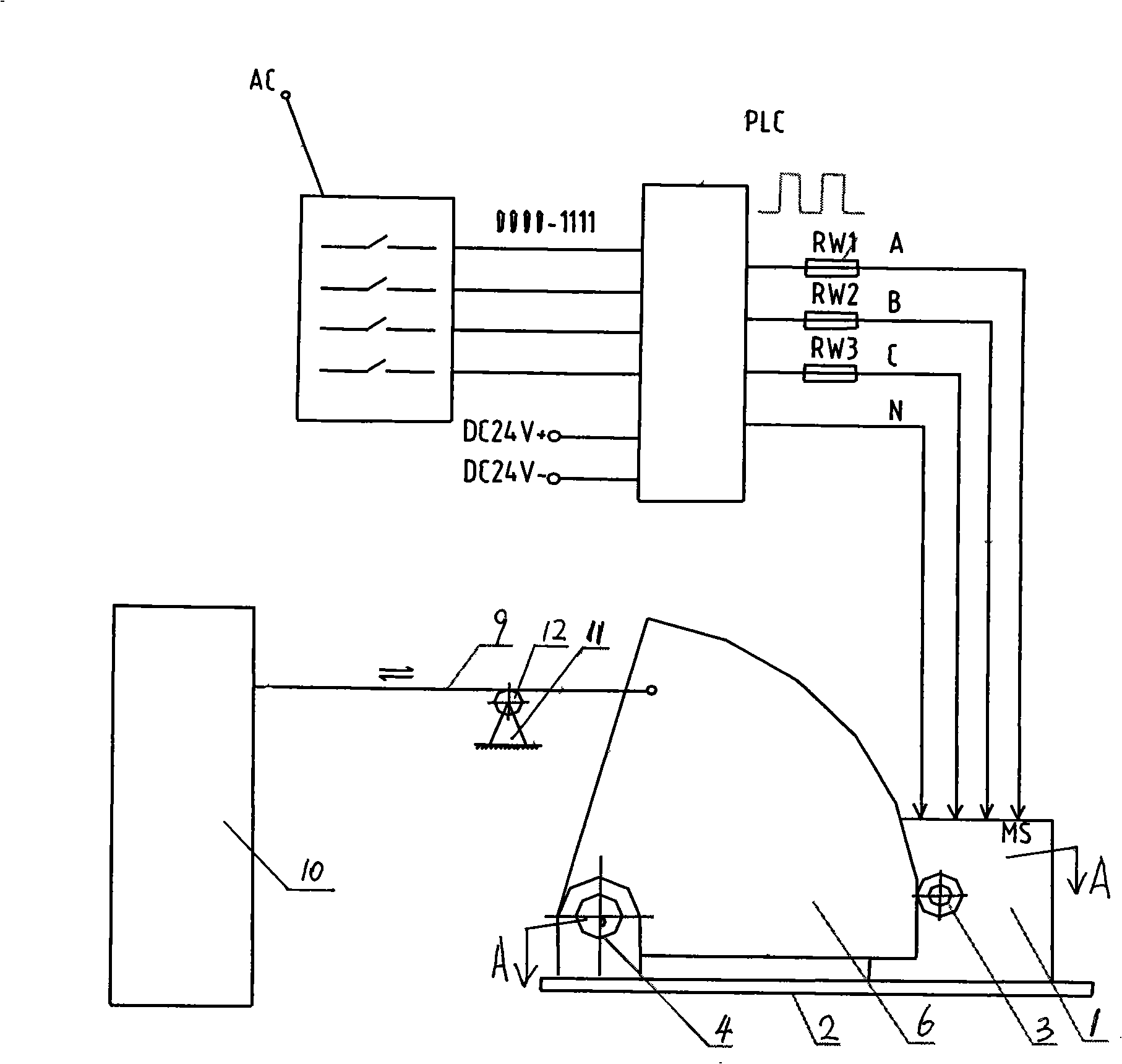

Compound controlling hydraulic system of blank turnover machine

InactiveCN1718303AHigh precision of speed regulationSynchronization can be adjustedWork manipulationSpeed regulator

A hydraulic system for the complex control of billet turning-over machine is composed of left arm unit and right arm unit. Each of left and right arm units is composed of 4 drive cylinders, 4 speed regulators for said drive cylinders, the first balance valve, proportional electromagnetic diverter valve, the second balance valve and overflow valve. Their connection scheme is also disclosed.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

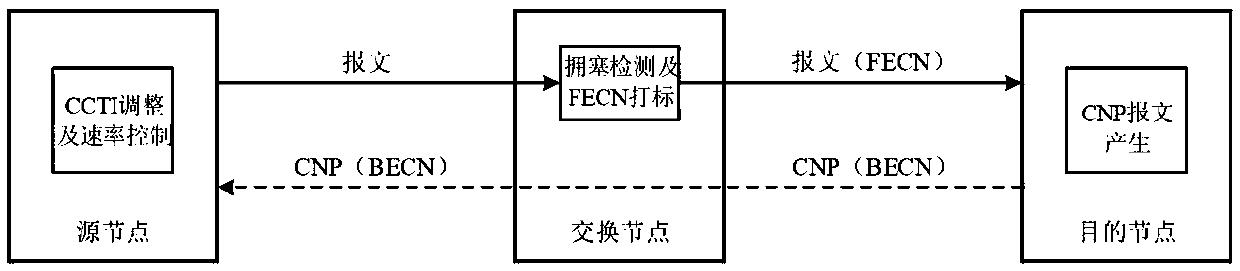

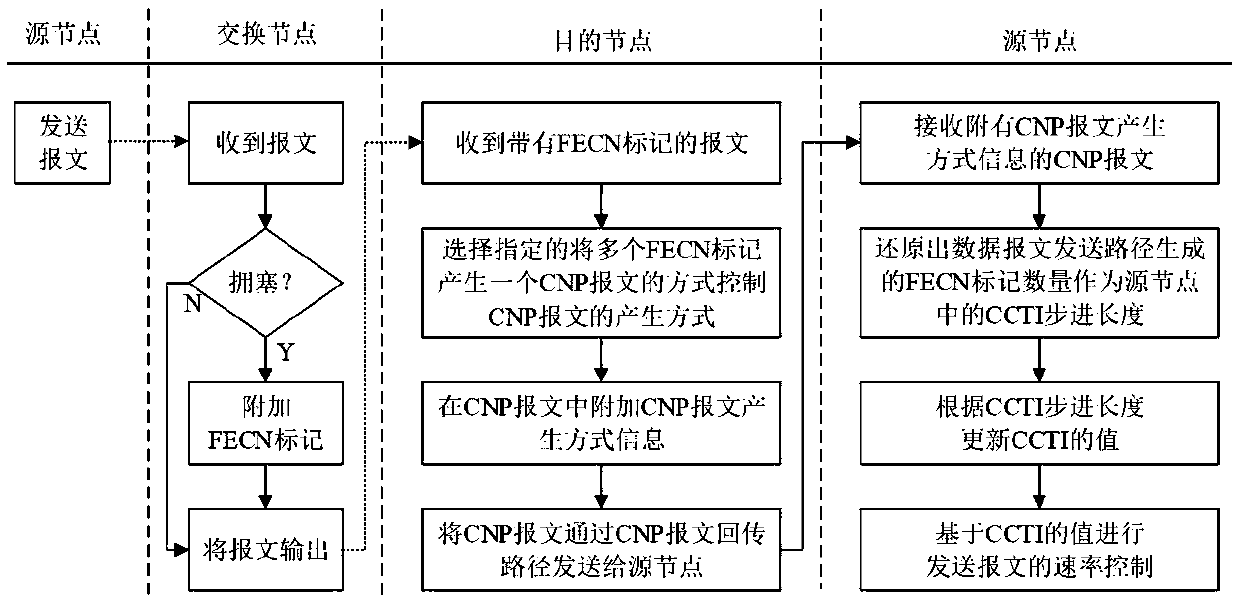

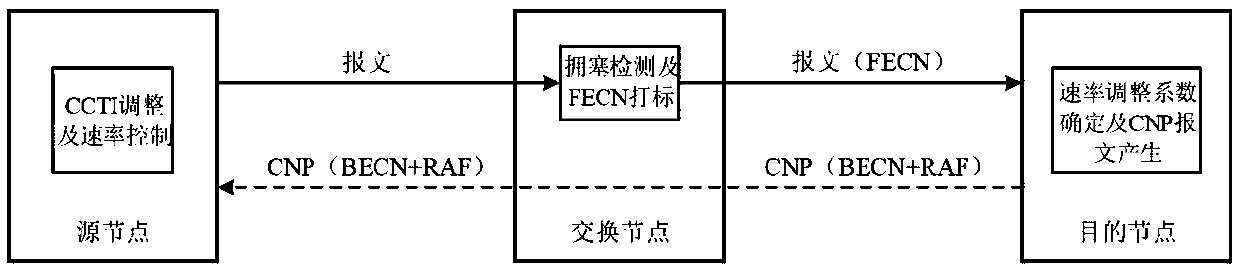

Low-overhead congestion control method in high-speed interconnection network

The invention discloses a low-overhead congestion control method in a high-speed interconnection network. According to the invention, when a destination node dynamically sends a CNP message, a specified mode of marking a plurality of FECNs to generate a CNP message is selected according to the congestion condition of a CNP message return path of the destination node to control the generation modeof the CNP message, and CNP message generation mode information is added to the CNP message; and thus, the source node restores the number of the FECN marks in the sending network path. According to the method, the number of the congestion notification messages can be dynamically adjusted according to the network state on the premise that the response speed and precision of congestion control arenot remarkably reduced, the overhead of an existing congestion control mechanism is remarkably reduced, a new congestion problem is avoided, and a good balance is achieved in the aspects of congestioncontrol overhead and precision. The method can be widely applied to the design of the switch chip, and has good popularization and application prospects.

Owner:NAT UNIV OF DEFENSE TECH

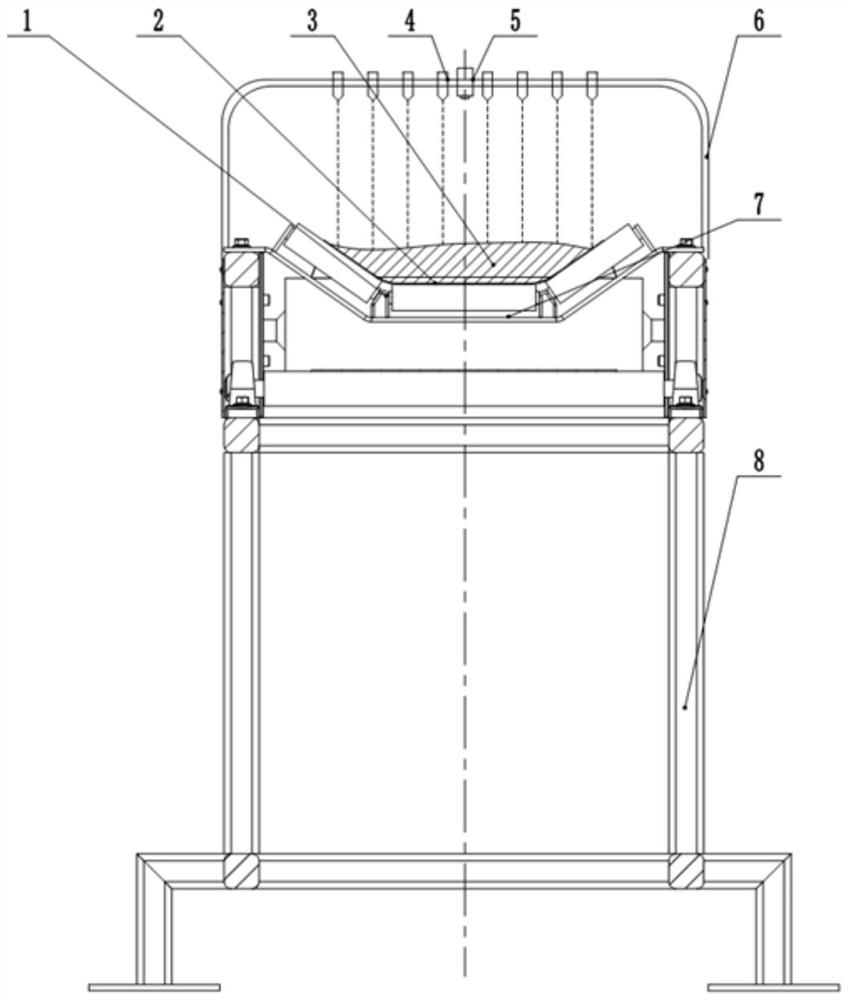

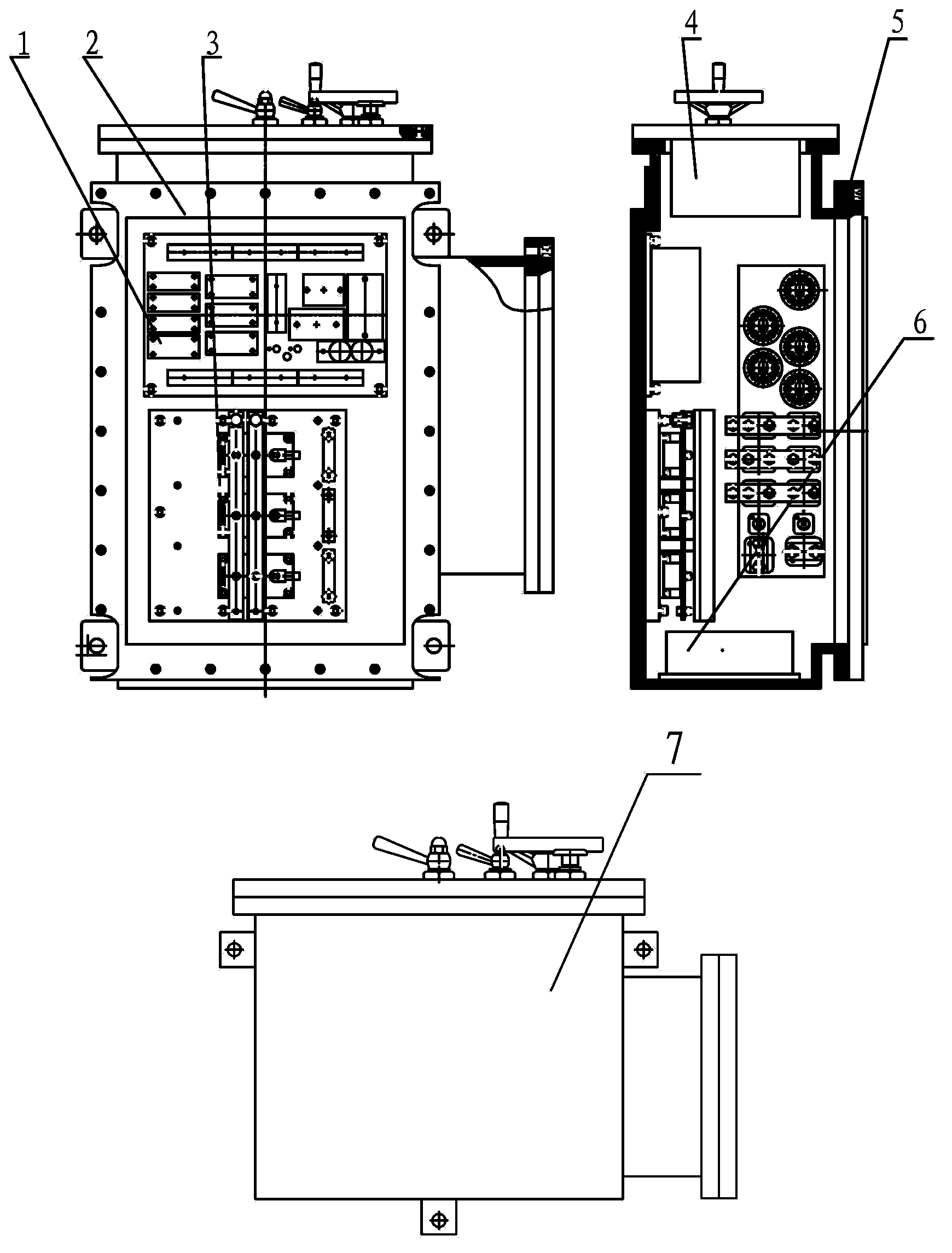

Cold-box core shooter

ActiveCN103170584ASmall footprintHigh precision of speed regulationMoulding machinesElectrical controlGas generator

The invention discloses a cold-box core shooter comprising a sand shooting mechanism, an electrical part, a base, a gas generator, a hydraulic system and an enclosing screen, wherein the electrical part, the base, the gas generator and the hydraulic system are located in the enclosing screen; an opening is arranged on the front side wall of the enclosing screen; a moving door is arranged at the opening; the sand shooting mechanism is located at the upper part of the base; the base comprises two air cushion moving guide rails, a lifting worktable and a moving worktable; the moving worktable is located above the lifting worktable; and the two air cushion moving guide rails are respectively located at two sides of the lower surface of the moving worktable. Through the way, the electrical control system, the hydraulic system and the gas generator are all placed in the enclosing screen, so that the cold-box core shooter is small in occupied area; a proportional valve is adopted in the hydraulic system to regulate speed, so that the cold-box core shooter is high in speed regulation accuracy; and the two air cushion moving guide rails are arranged below the moving worktable, so that the cold-box core shooter is good in wear resistance and guidance performance, stable and reliable in operation and high in motion accuracy.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

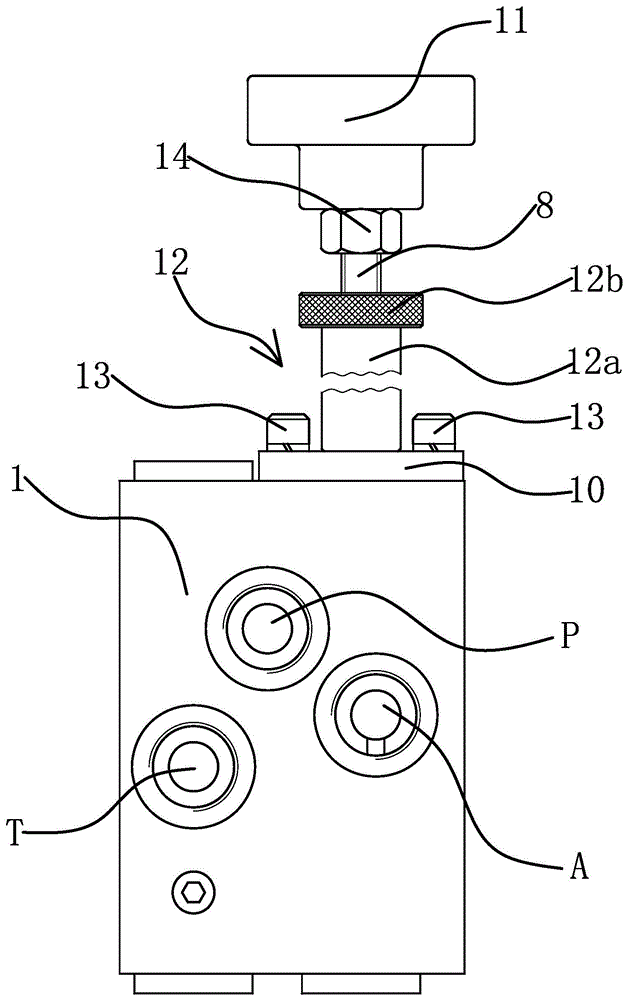

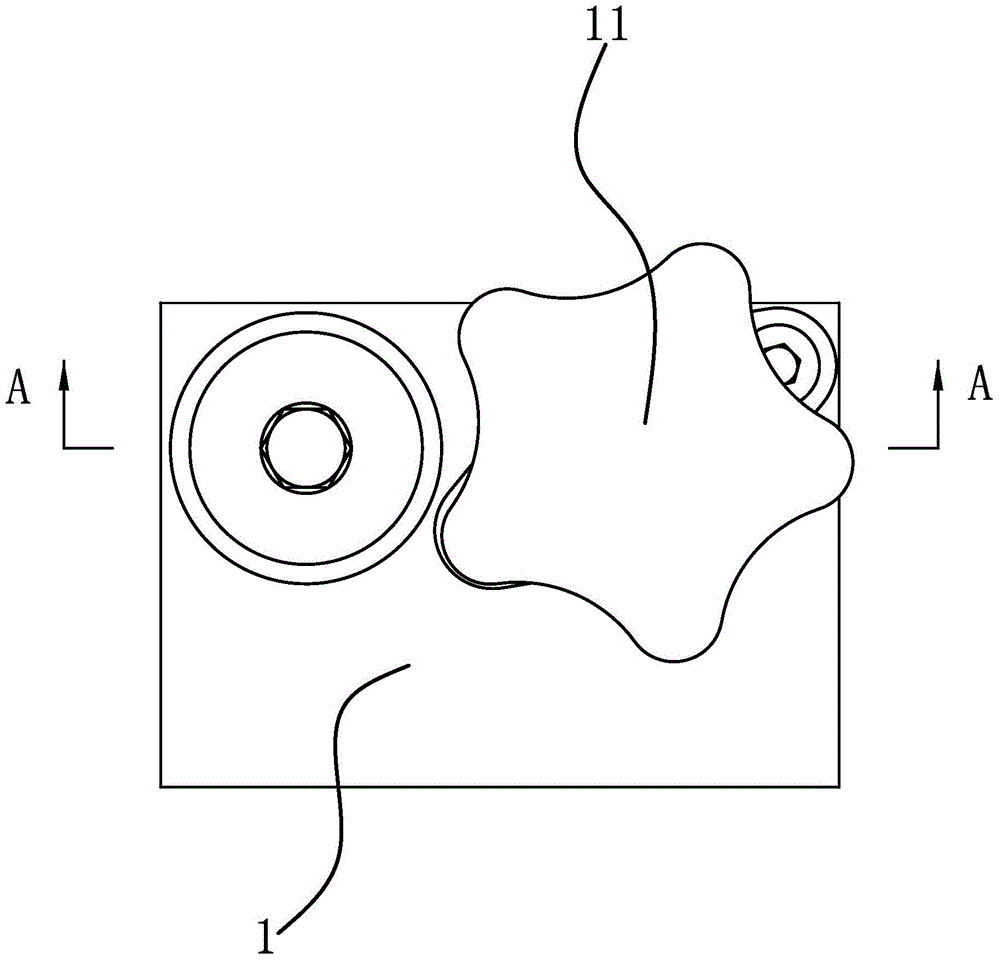

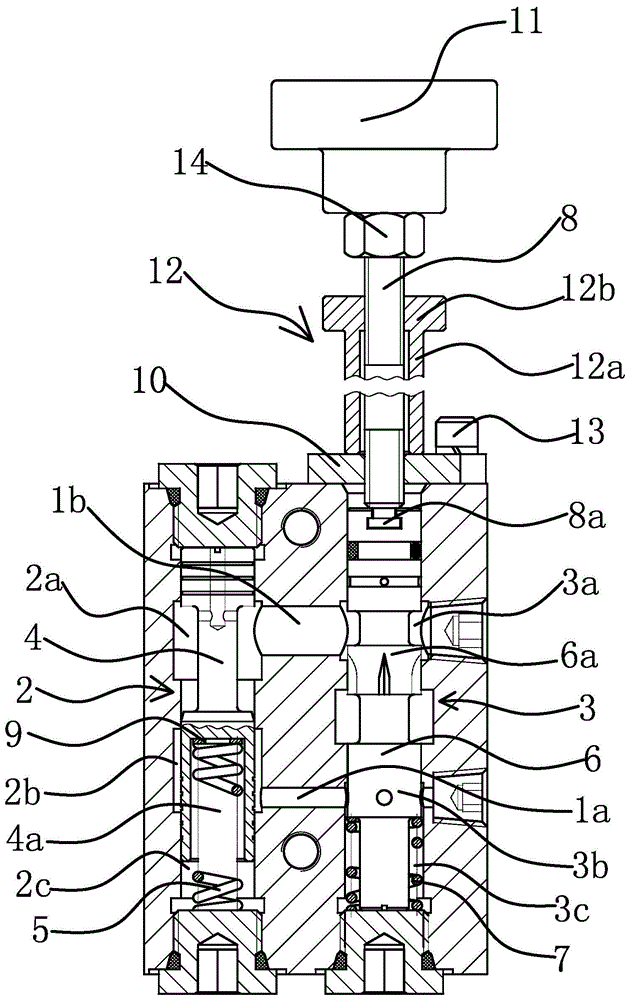

Hydraulic speed regulating valve

The invention provides a hydraulic speed regulating valve, and belongs to the technical field of hydraulic pressure. The hydraulic speed regulating valve solves the problems that an existing hydraulic speed regulating valve is large in energy consumption and serious in heat emission. The hydraulic speed regulating valve comprises a valve body in which a constant-difference overflow valve cavity and a throttling valve cavity are formed, the constant-difference overflow valve cavity is provided with an oil inlet valve cavity and an oil returning valve cavity, a constant-difference overflow valve element is arranged in the constant-difference overflow valve cavity, an overflow spring is further arranged between the constant-difference overflow valve element and the valve body, and the end, provided with the overflow spring, of the constant-difference overflow valve cavity is a feedback regulation valve cavity; a throttling segment is arranged in the throttling valve cavity, the portion, close to the throttling segment, of the throttling valve cavity is provided with a work valve cavity communicated with a work port, a throttling valve element is arranged in the throttling valve cavity, a throttling spring is arranged at one end of the throttling valve element, and the other end of the throttling valve element is provided with a speed regulating valve rod stretching out of the valve body; the oil inlet valve cavity is communicated with the throttling segment, and the work valve cavity is communicated with the feedback regulation valve cavity. Redundant hydraulic oil of the hydraulic speed regulating valve is directly conveyed back to an oil tank, and energy consumption and heat emission of the hydraulic speed regulating valve are reduced.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

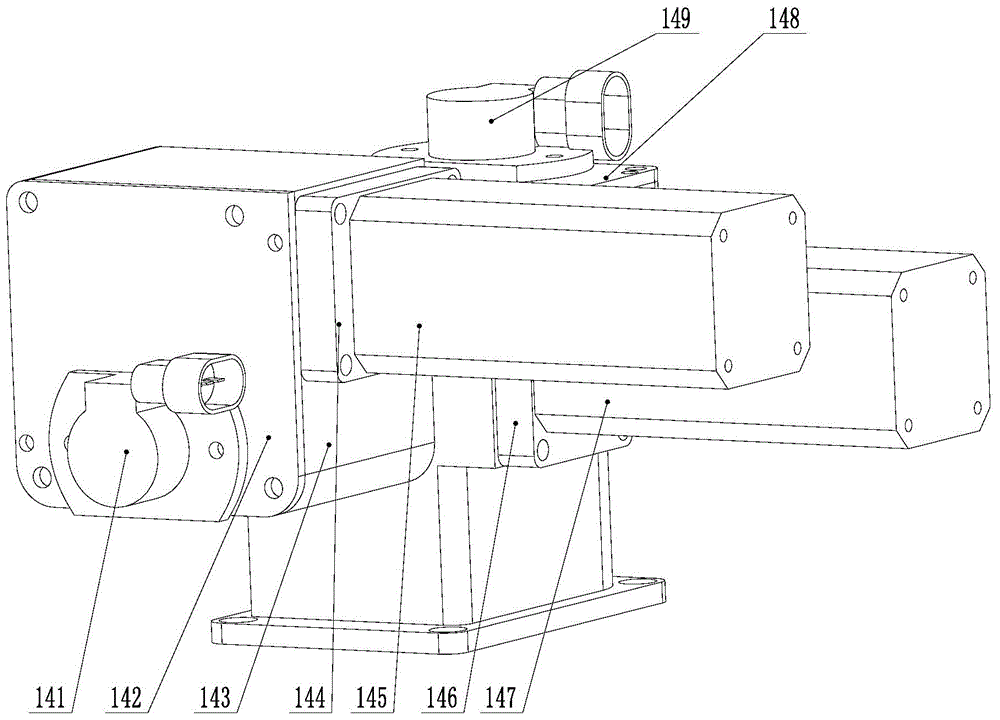

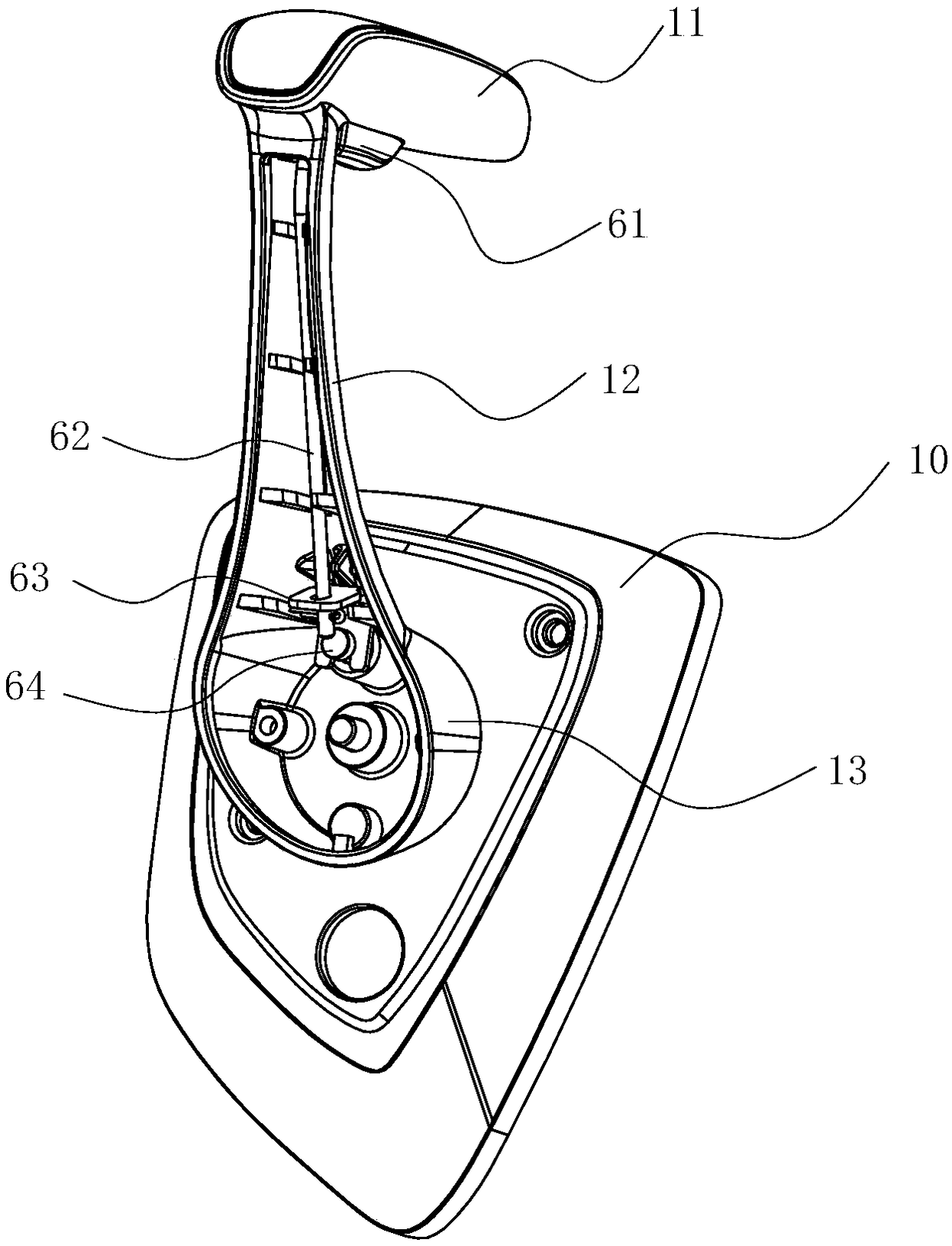

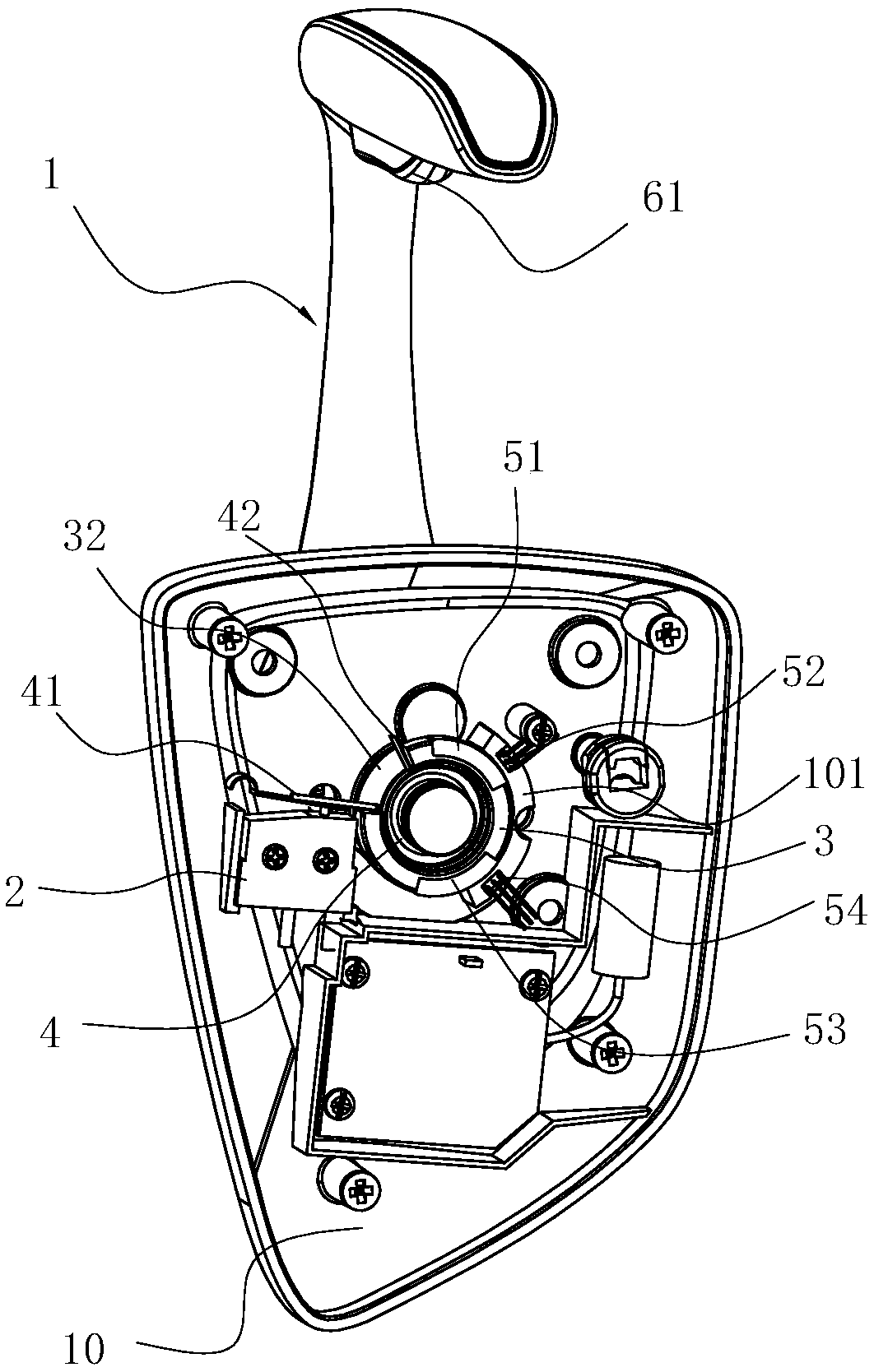

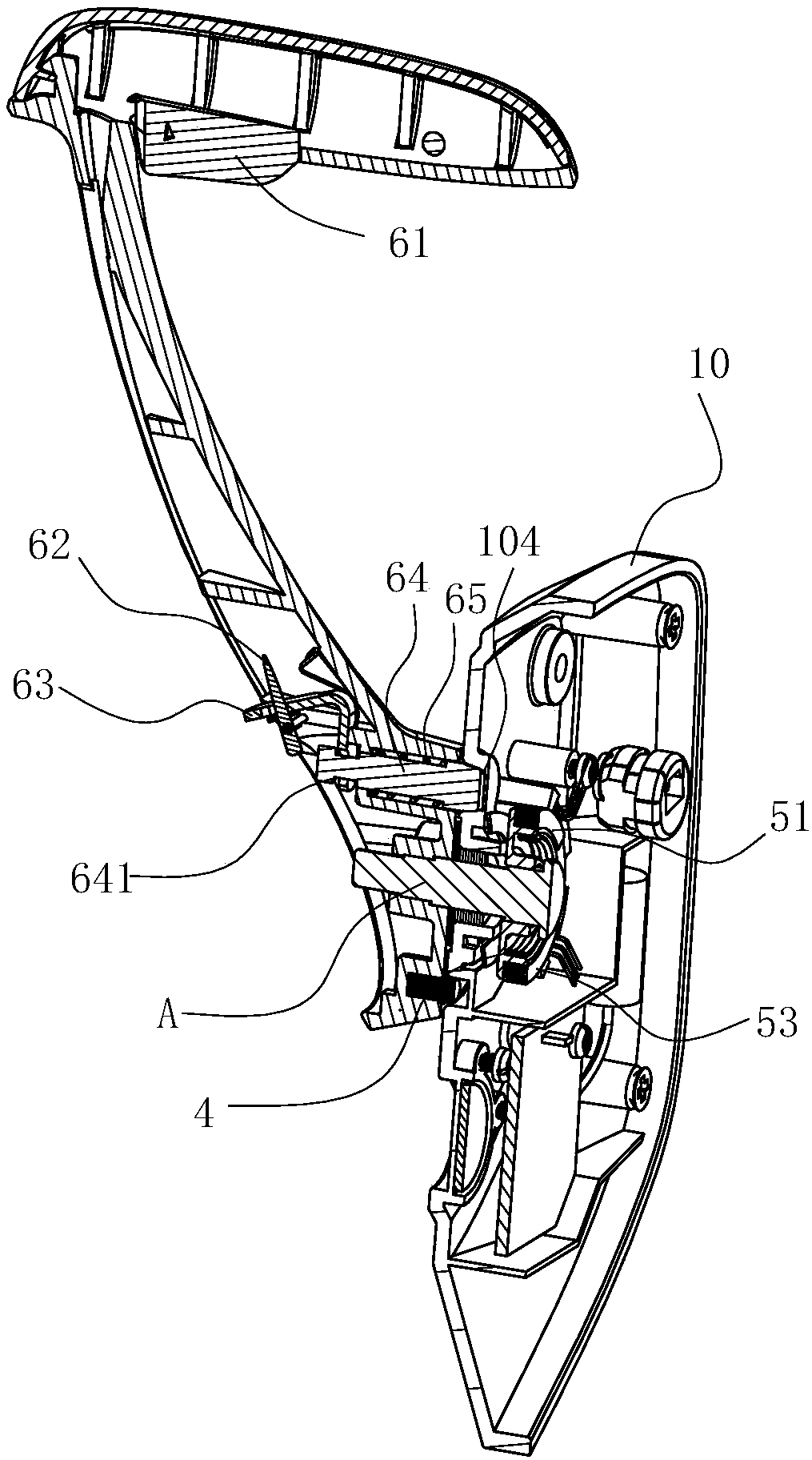

Operating device for marine propeller

PendingCN109484603AHigh precision of speed regulationImprove linearityPropulsion power plantsSteering initiationsPropellerEngineering

An operating device for a marine propeller comprises a casing, a speed control switch, a forward and reverse switching switch and a handle rotatably connected to the casing. The operating device for the marine propeller is characterized in that the forward and reverse switching switch is a microswitch with a pressing end, a turntable which is coaxially mounted with the handle to rotate with the handle is disposed in the casing, the turntable is provided with a groove for accommodating a torsional spring, and the side wall of the groove is provided with a limiting notch extending in the circumferential direction. When the handle is in an original state, the two ends of the torsional spring abut against two side walls of the limiting notch respectively, and one end of the torsional spring isfurther in touch with the pressing end of the microswitch. During use, flexible pressing is performed by utilizing the restoring force in the energy storage process of the torsional spring, so that in the rotating process, the handle completes microswitch motions to perform forward and reverse rotating signal switching, and can adjust the speed with the rotation. Particularly, a speed regulatingmode by the adoption of two magnetic strips and two Hall sensors is adopted, and the operating device has the advantages of high speed regulation precision, good linearity, small size and conveniencein installation.

Owner:NINGBO HAIBO GRP CO LTD

Speed governing control device of pulling wire type diesel

InactiveCN101328839AImprove reliabilityHigh precision of speed regulationEngine controllersMachines/enginesMotor shaftDiesel locomotive

The invention relates to a diesel engine speed regulation control field, in particular to a device for controlling speed regulation of a guyed diesel engine, which solves the problem that the diesel engine of the prior guyed speed regulator can not meet a use requirement of a traction engine. The control device comprises a mechanical transmission unit and an electric control unit, the mechanical transmission unit comprises a throttle stayguy of the diesel engine, a stepping motor that a pinion is fixed on the motor shaft and a fixed base plate, wherein the fixed base plate is fixed with a sector gear which is meshed with the pinion, one end of a stayguy is fixed with the sector gear, the right lower side of the sector gear arranged on the fixed base plate is provided with a rectangular through hole; and the electric control unit comprises an encoded driver controller and a logic controller, and the output ends of the logic controller are connected with incoming line ends of three-phase power of the stepping motor through current-limiting resistance. The device has the advantages of rational and concise structure, convenient operation and installation, high accuracy of speed regulation, strong adaptability and high cost performance, and can be widely applied to the fields of diesel locomotives, track cars and subway tractors with small power.

Owner:YONGJI XINSHISU ELECTRIC EQUIP

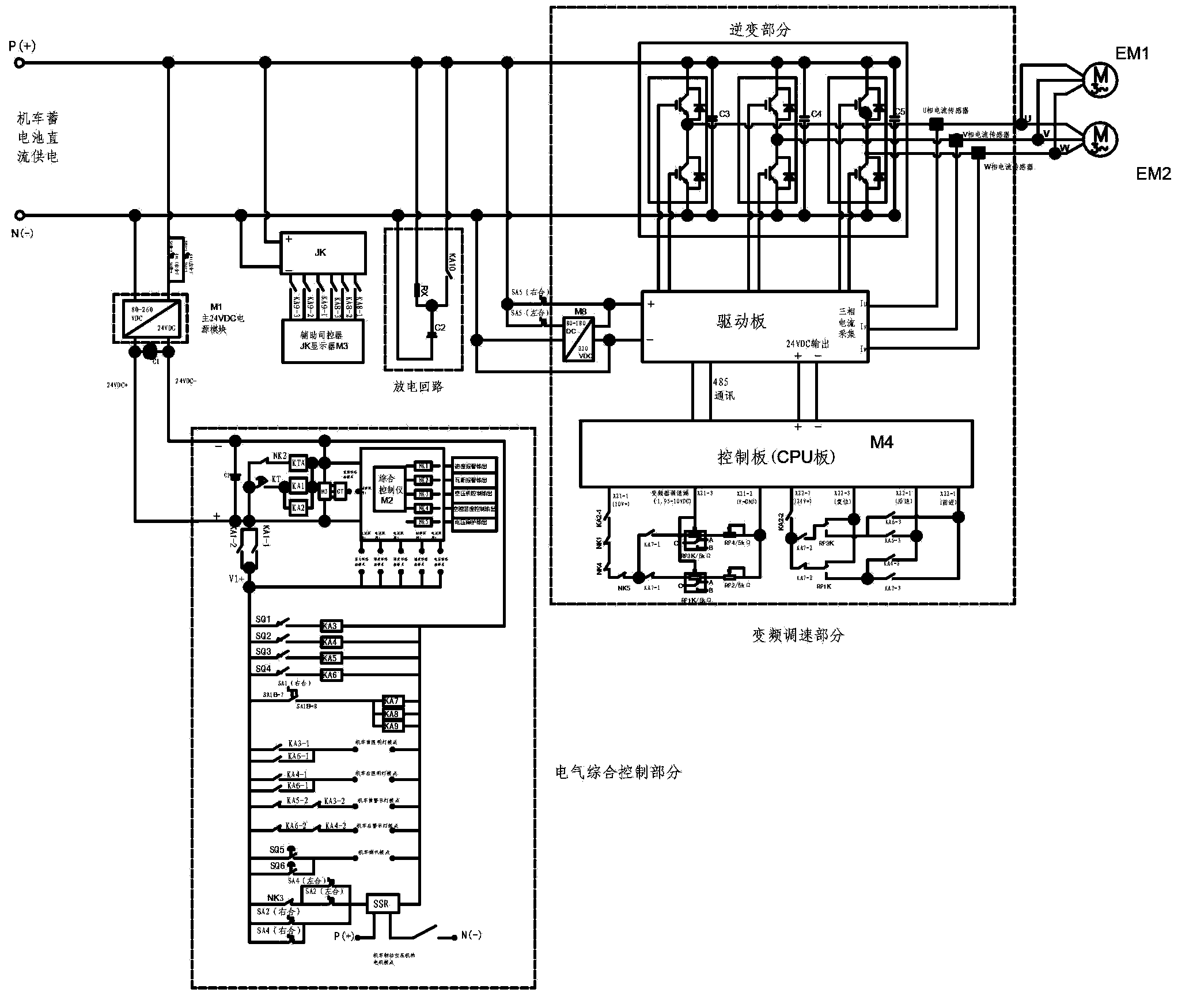

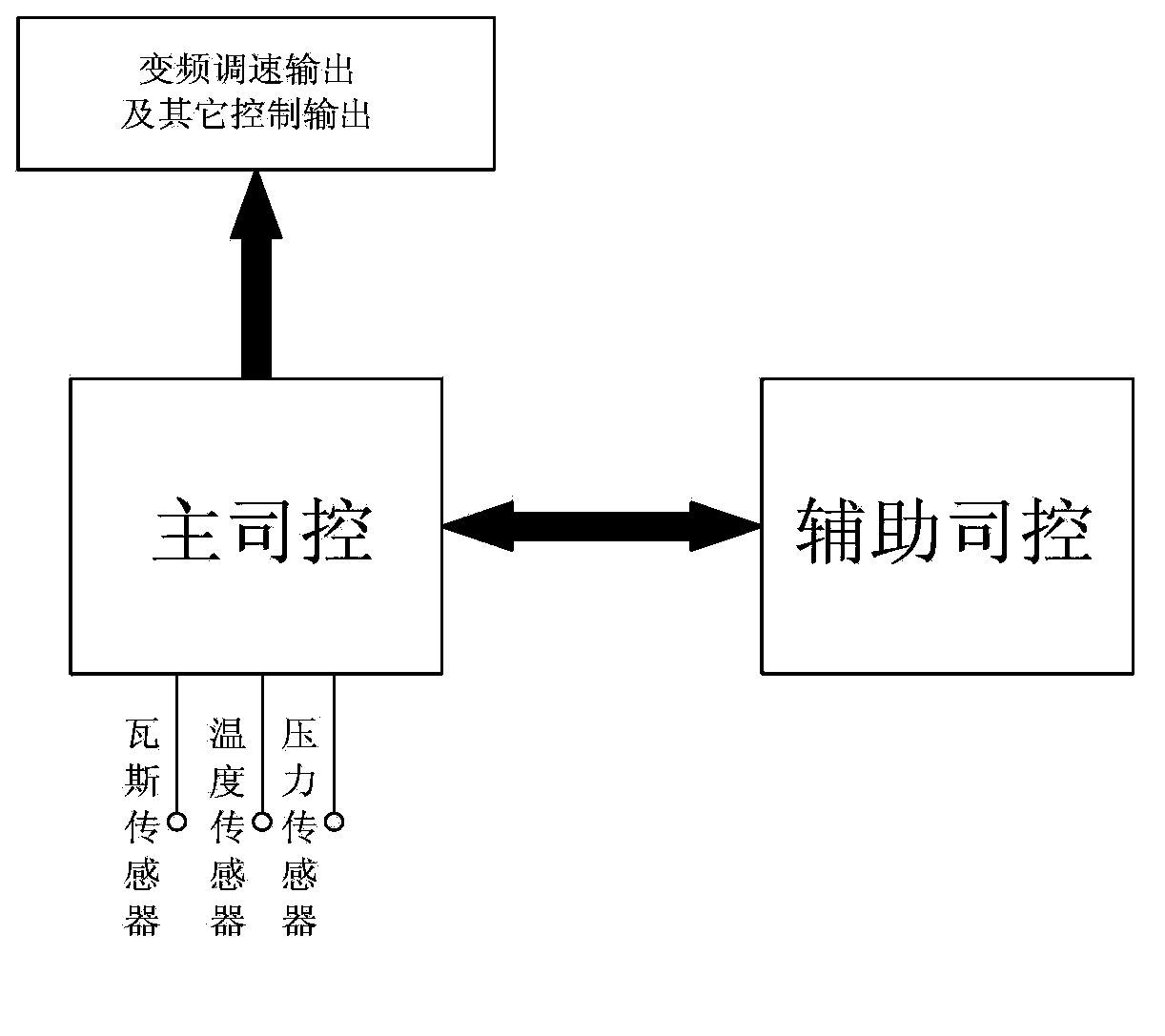

Frequency conversion, speed regulation and comprehensive electrical control system for electric locomotive

InactiveCN103569142APowerful heavy-duty startingAvoid stickingLocomotivesTemperature controlOperational system

The invention provides a frequency conversion, speed regulation and comprehensive electrical control system for an electric locomotive. The control system comprises a control electrical collection plate, a main cavity assembling member, a frequency conversion combiner, a driver controlled operating system assembly, a main cover plate assembling member, a power supply collection plate and an auxiliary driver controller. The control system is applicable to frequency conversion, speed regulation and comprehensive electrical control of an underground coal mine storage battery locomotive and comprises inverted frequency conversion and speed regulation, driver control, comprehensive monitoring of storage batteries, pressure and temperature control of air compressors, speed detection control, gas monitoring control and comprehensive control of locomotive lamps, loudspeakers and the like. The control system is small in volume, high in integration degree, safe and reliable, and simple to operate.

Owner:宜昌兆峰自动化仪表有限责任公司

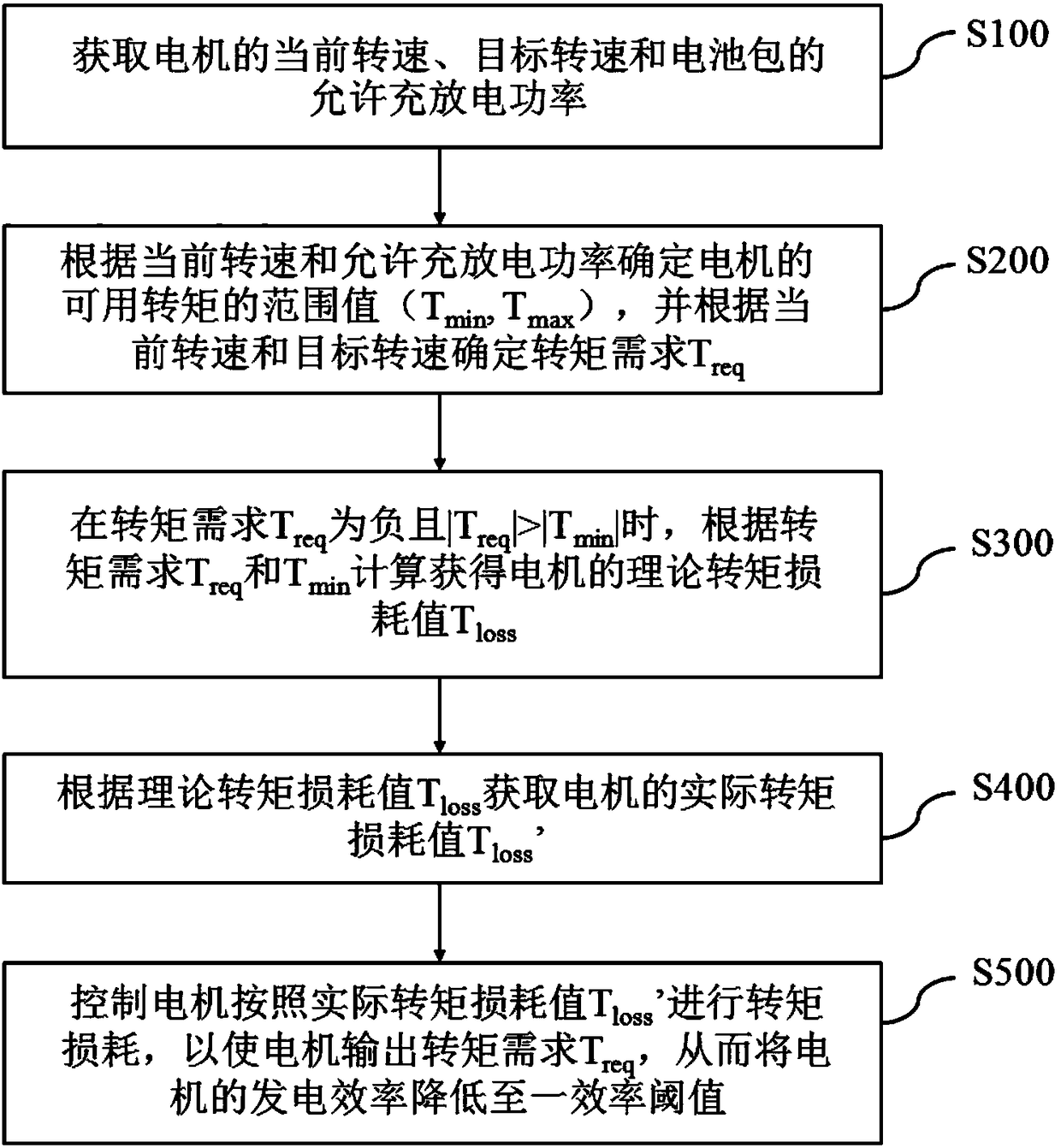

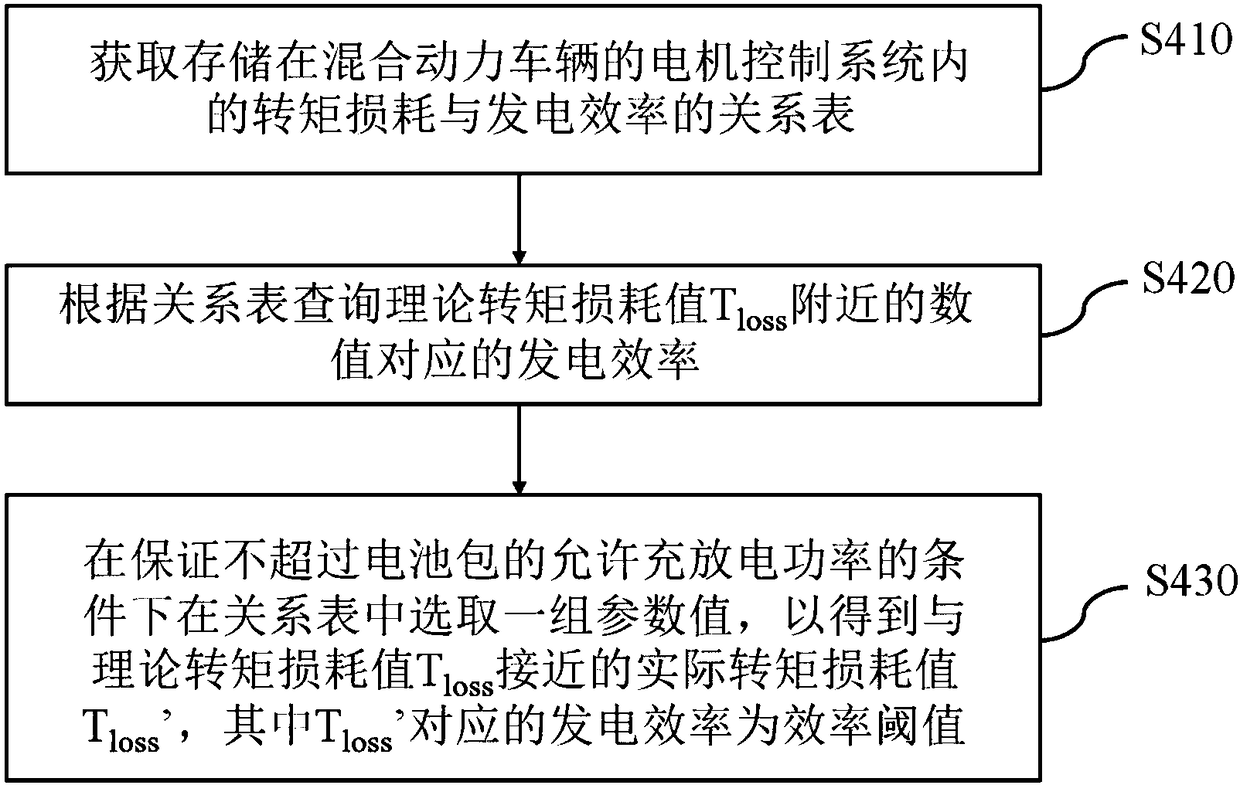

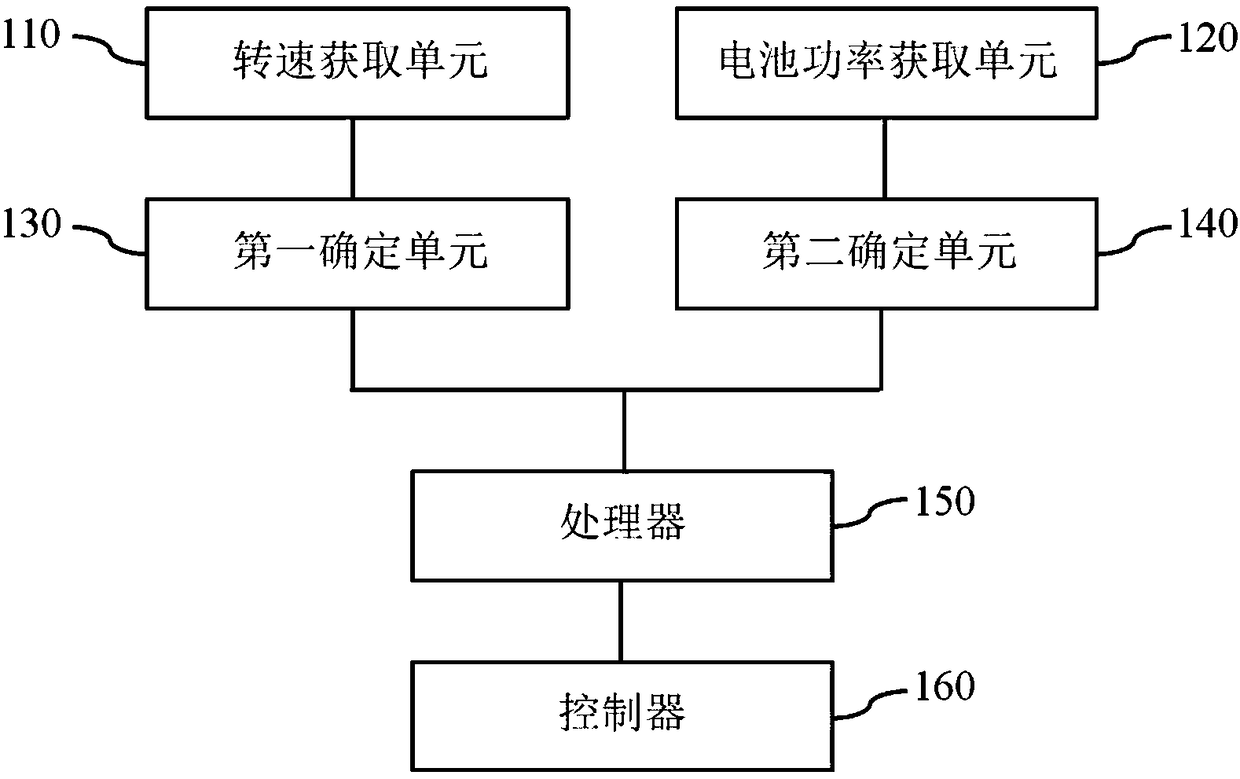

Motor electricity generation control method and system for hybrid power vehicle

ActiveCN108583560AImprove performanceReduce charging powerHybrid vehiclesElectric machineControl theory

The invention provides a motor electricity generation control method for a hybrid power vehicle. The motor electricity generation control method comprises the following steps that the current rotatingspeed and the target rotating speed of a motor, and the allowable charge and discharge power of a battery pack are obtained; the intervals (Tmin and Tmax) of available torque of the motor are determined according to the current rotating speed and the allowable charge and discharge power, and the torque requirement Treq is determined according to the current rotating speed and the target rotatingspeed; when the torque requirement Treq is negative and |Treq| is larger than |Tmin|, the theoretical torque loss value Tloss of the motor is calculated according to the torque requirement Treq and Tmin; the actual torque loss value Tloss' of the motor is obtained according to the theoretical torque loss value Tloss; and the motor is controlled to conduct torque loss according to the actual torqueloss value Tloss' in order to enable the motor to output the torque requirement Treq, and thus the electricity generation efficiency of the motor is reduced to an efficiency threshold value. According to the motor electricity generation control method, by reducing the charging power of the high-voltage end, under the condition that the battery allowable charging power is limited, it is guaranteedthat the motor outputs sufficient negative torque to complete speed adjusting within the specified time, and thus smooth gear shifting is achieved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

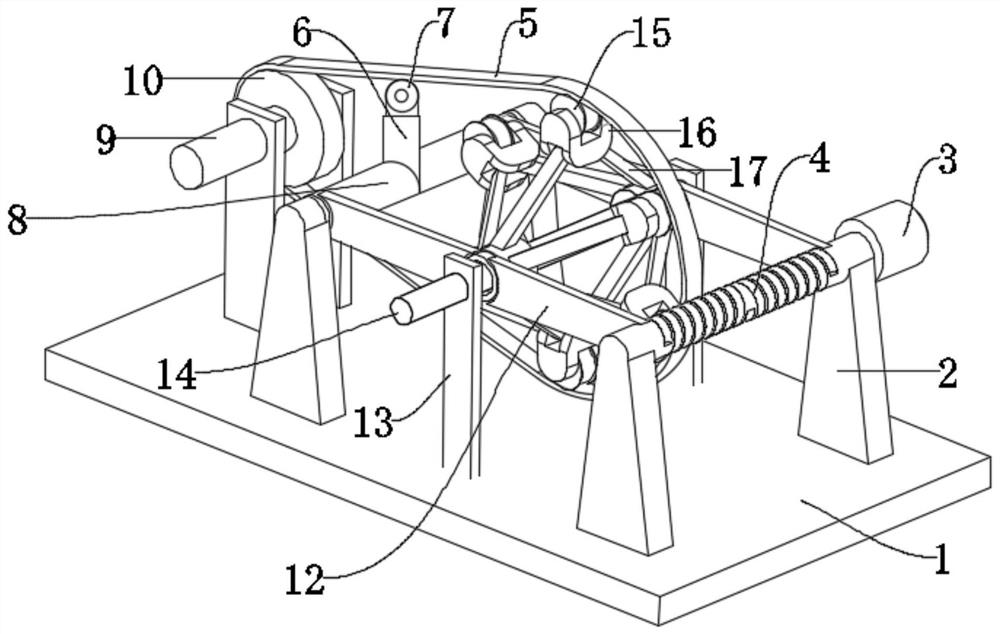

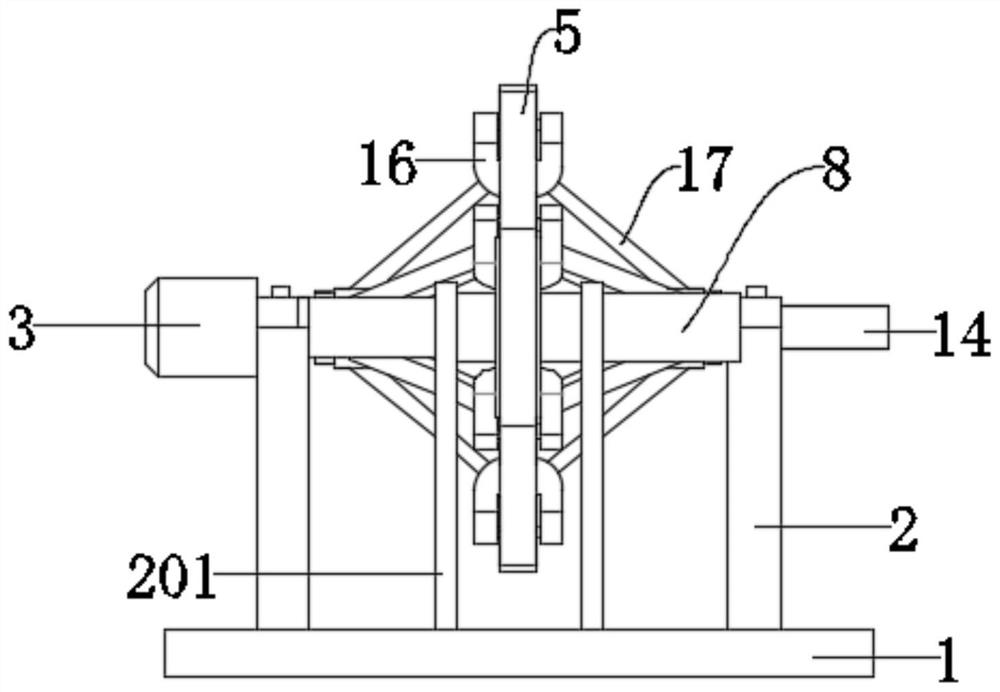

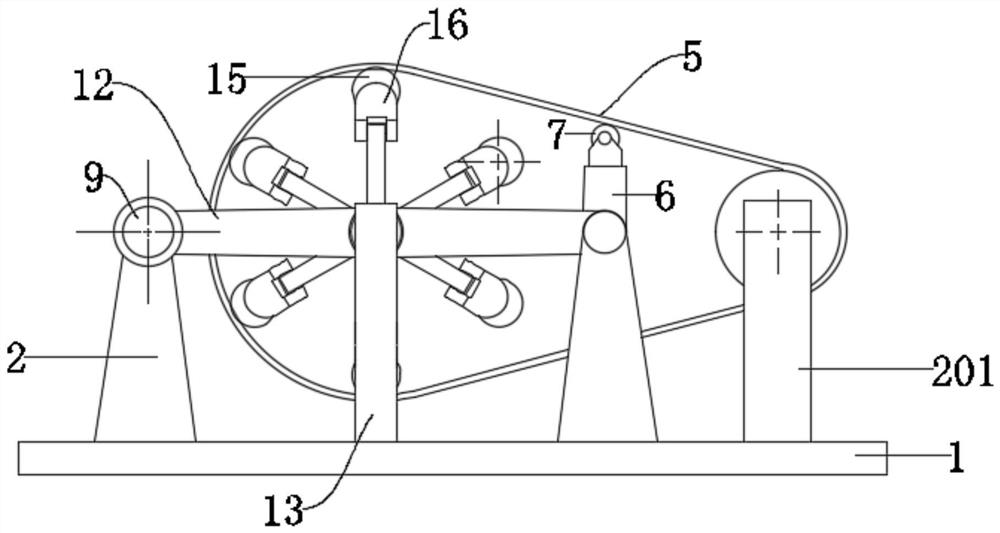

Easily adjustable speed change device

The invention discloses an easily adjustable speed change device. The easily adjustable speed change device comprises a baseplate, an input shaft and an output shaft, wherein a speed change adjustingcomponent is arranged between the input shaft and the output shaft; articulated sliding blocks are slidably arranged on a limiting rotating shaft and are matched with limiting grooves in a sliding manner; the two groups of articulated sliding blocks are symmetrically laid on the limiting rotating shaft; hanging loops are fixedly connected to the articulated sliding blocks; connecting rods are articulated on the hanging loops; the other ends of the connecting rods are articulated on articulated blocks; the connecting rods on the same side are articulated on the same articulated block; rotatingwheels are articulated on the tops of the articulated blocks; a driving belt is arranged on the rotating wheels in a tensioning manner; the other end of the driving belt is connected to the output shaft; and a driving device is arranged on the baseplate and is connected to the articulated sliding blocks. The easily adjustable speed change device has a simple structure and strong practicability; the articulated sliding blocks are driven to move, and the rotating radius of the rotating wheels changes, so that the transmission ratio between the output shaft and the input shaft changes, and the speed adjustment is further realized. The easily adjustable speed change device has high speed regulation accuracy and good application prospect.

Owner:常金丽

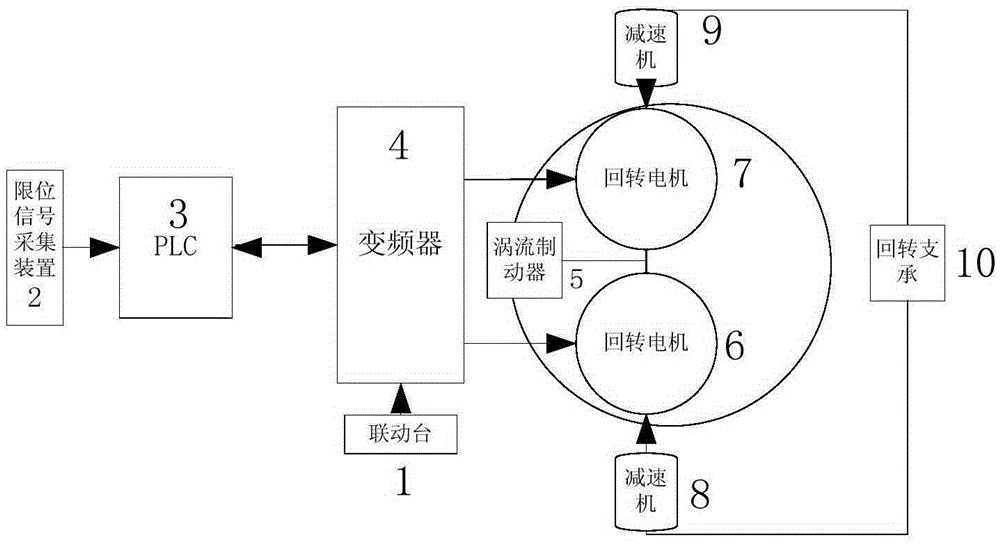

Variable-frequency-speed-adjusting control system and method of tower-crane rotating mechanism

InactiveCN105384095AImprove usageImprove operational safetyLoad-engaging elementsCranesFrequency changerControl system

The invention discloses a variable-frequency-speed-adjusting control system and method of a tower-crane rotating mechanism. The control system comprises a linkage table, a limiting signal collecting device, a PLC and a frequency converter, wherein the limiting signal collecting device and the frequency converter are connected with the PLC, the frequency converter is connected with the linkage table and rotating motors of the rotating mechanism, and a sequential control loop is formed by the linkage table, the frequency converter, the rotating motors of the rotating mechanism, speed reducers and a rotating bearing. Compared with the prior art, the variable-frequency-speed-adjusting control system and method have the advantages that as a current control step-less-speed-adjusting mode is adopted, the zero speed of the tower-crane rotating mechanism can be smoothly and stably increased to the maximum speed under controlling of a driver, the maximum speed of the tower-crane rotating mechanism can be also smoothly and stably decreased to the zero speed under controlling of the driver, and the whole work efficiency and the working stability of a tower crane are improved accordingly.

Owner:CAS OF CHENGDU INFORMATION TECH CO LTD

Three-phase single-section/double-section multiple-pole switching reluctance motor

InactiveCN101707428BBreak through the problem of not being able to manufacture multiple slots and multiple polesIncrease the areaMagnetic circuit stationary partsMagnetic polesThree-phase

The invention relates to a three-phase single-section / double-section multiple-pole switching reluctance motor. A casing of the motor is arranged on a base, the middle part of the casing is provided with a hanging ring of the motor, a front end cover and a back end cover are respectively arranged at both ends of a rotating shaft, rotors are arranged between the front end cover and the back end cover, an air cover is arranged outside the back end cover, a fan is arranged in the air cover, and a sensor is arranged between the back end cover and the fan or between the back end cover and a second-section rotor; the motor comprises stators and the rotors with a structure of double convex poles, also comprises one section or two sections and can run by a single section or double sections; the iron cores of the stators and the rotors both comprise a single section or two sections, and the lengths and the diameters of the iron cores of the two sections of the stators and the rotors are equal; two sets of concentrated windings or sandwich windings are respectively arranged on two sections of stator teeth, and armature windings on two teeth of the same phase of each set of windings are connected in series or in parallel to form one phase; the magnetic poles of the two sections of stators are aligned, and the difference of the magnetic poles of the two sections of rotors is 1 / 2 of a rotor polar distance angle; or, the magnetic poles of the two sections of rotors are aligned, and the difference of the magnetic poles of the two sections of stators is 1 / 2 of a stator polar distance angle; and the invention has the characteristics of high efficacy, high starting torque, easy control and low cost.

Owner:张世清

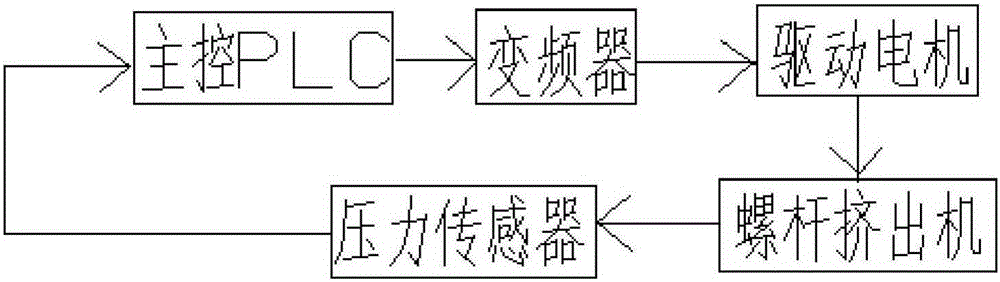

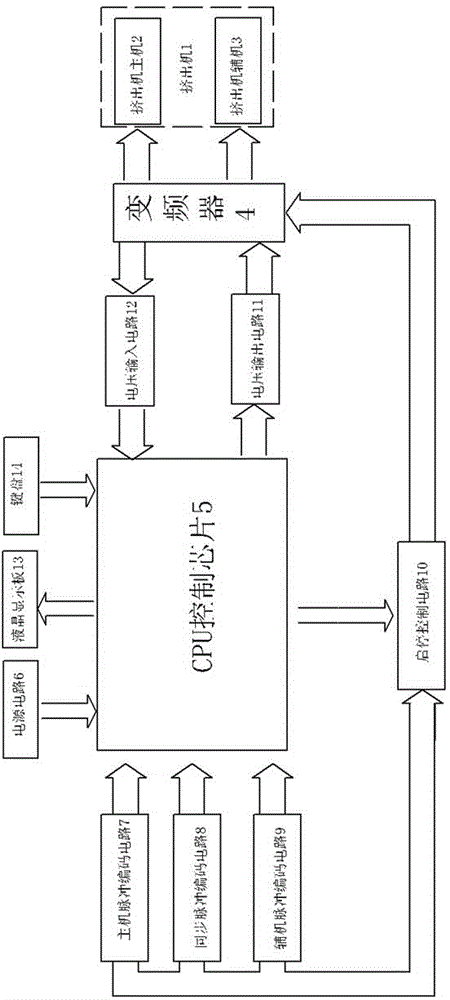

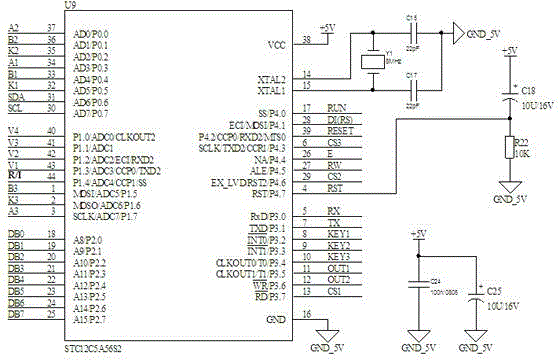

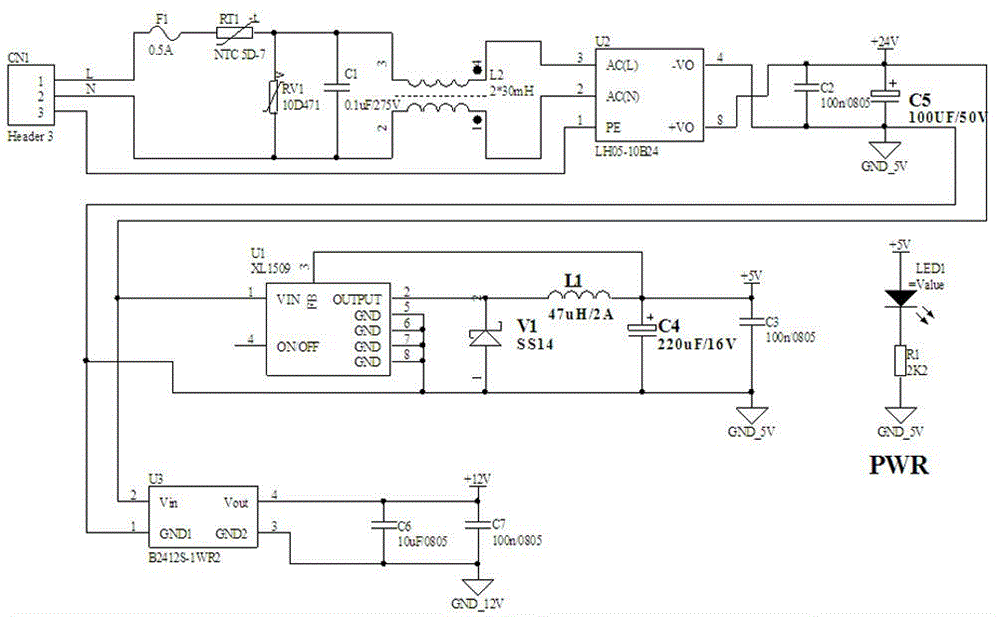

Extruding machine and controller thereof

ActiveCN104015339AAmplitude stableNo output noiseProgramme controlComputer controlFrequency changerStart stop

The invention provides an extruding machine and a controller thereof. The extruding machine and the controller have the advantages that the synchronous speed regulating harmony is good, the service life is long, the stability is good, the used discrete component is less, the fault point is less, and the maintenance is convenient. The extruding machine comprises an extruding machine body, a frequency converter and the controller for controlling the frequency converter to carry out speed regulation on the extruding machine; the controller comprises a CPU (central processing unit) control chip as well as a power circuit, a main engine pulse coding circuit, an auxiliary engine pulse coding circuit, a synchronization pulse coding circuit, a start-stop control circuit, a voltage output circuit, a voltage input circuit and external equipment which are connected with the CPU control chip in an electronic control manner.

Owner:WUXI BOYU PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com