Automatic thickness control system and method of blown film

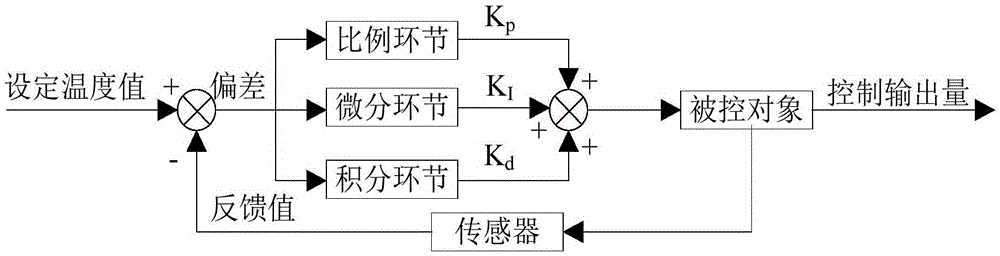

A technology of automatic thickness control and film thickness, which is applied to the automatic thickness control system and control field of blown film, which can solve the problems of inability to establish accurate mathematical models, inability to achieve automatic control, and difficulty in achieving high-precision control, and to speed up real-time system control. Speed, shorten the design cycle, simplify the effect of fuzzy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

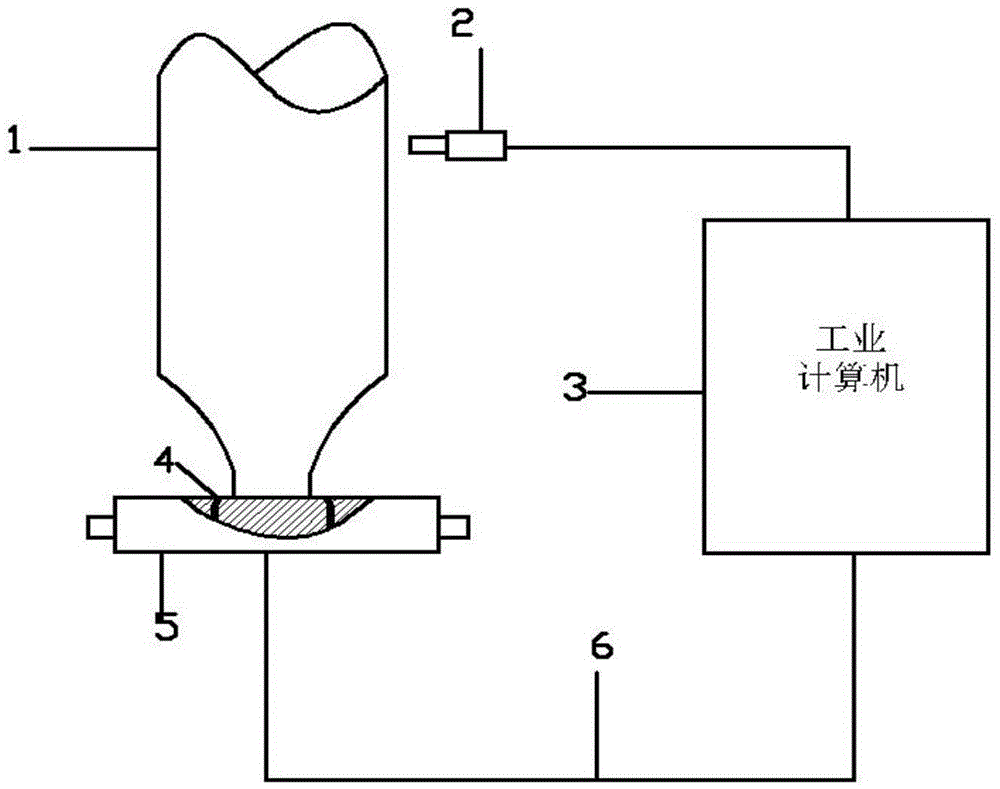

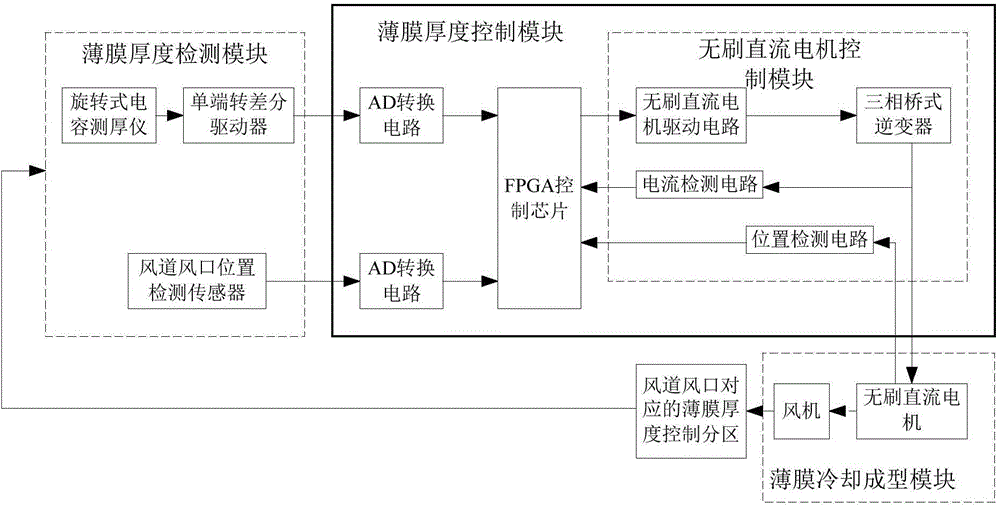

[0038] see Figure 3 to Figure 5 , the blown film automatic thickness control system of the present invention, comprises the film thickness detection module that is used to detect film circumference radial thickness and is used to detect the position of the corresponding air duct tuyere of each section of film circumference direction, has the film thickness control of FPGA control chip module, a film cooling forming module with several brushless DC motors, and a control panel for setting the initial value of the system and displaying working information; among them, the signal output terminal of the film thickness detection module and the signal input terminal of the film thickness control module The film thickness control module interacts with the film cooling forming module and the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com