Variable-frequency-speed-adjusting control system and method of tower-crane rotating mechanism

A slewing mechanism, frequency conversion speed regulation technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problem of unscientific and reasonable transmission scheme and control system, speed regulation performance affecting tower crane working stability, tower crane driver Emotional tension and other problems, to achieve the effect of easy process automation control, obvious power saving effect, and reduce the burden of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

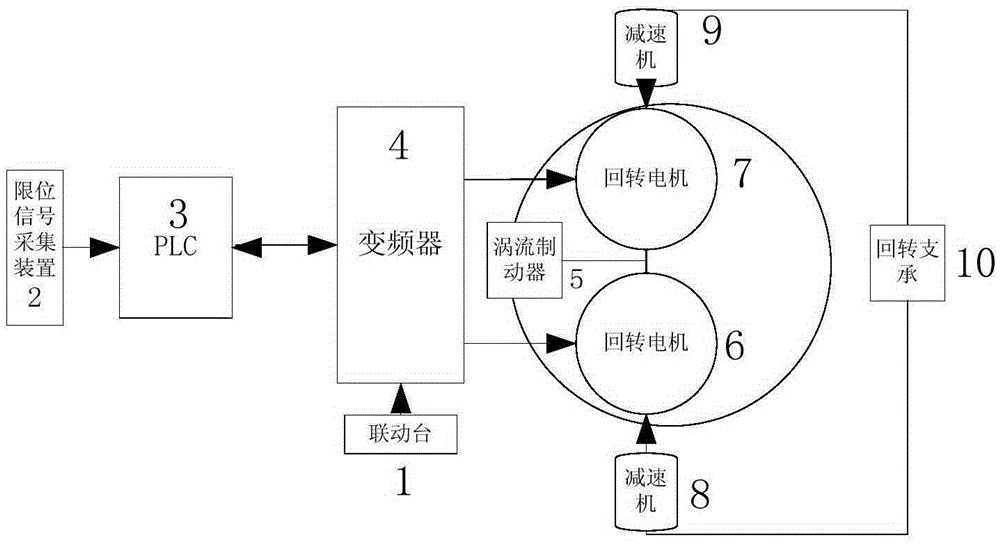

[0025] A frequency conversion speed regulation control system for the slewing mechanism of a tower crane, such as figure 1 As shown, it includes: linkage table 1, limit signal acquisition device 2, PLC controller 3, frequency converter 4, eddy current brake 5, rotary motor 6, rotary motor 7, reducer 8, reducer 9, slewing ring 10; typical The dual-motor configuration of which:

[0026] The limit signal acquisition device 2 and the frequency converter 4 are respectively connected with the PLC controller 3, and the linkage table 1, the frequency converter 4, the eddy current brake 5, the rotary motor 6, the rotary motor 7, the reducer 8, the reducer 9, and the slewing bearing 10 constitute A sequential control circuit; the rotary motor 6, the rotary motor 7, the reducer 8, the reducer 9, and the slewing bearing 10 are the slewing mechanism (dual motor drive plus eddy current braking).

[0027] The limit signal acquisition device 2 is a device used to collect the stroke of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com