Patents

Literature

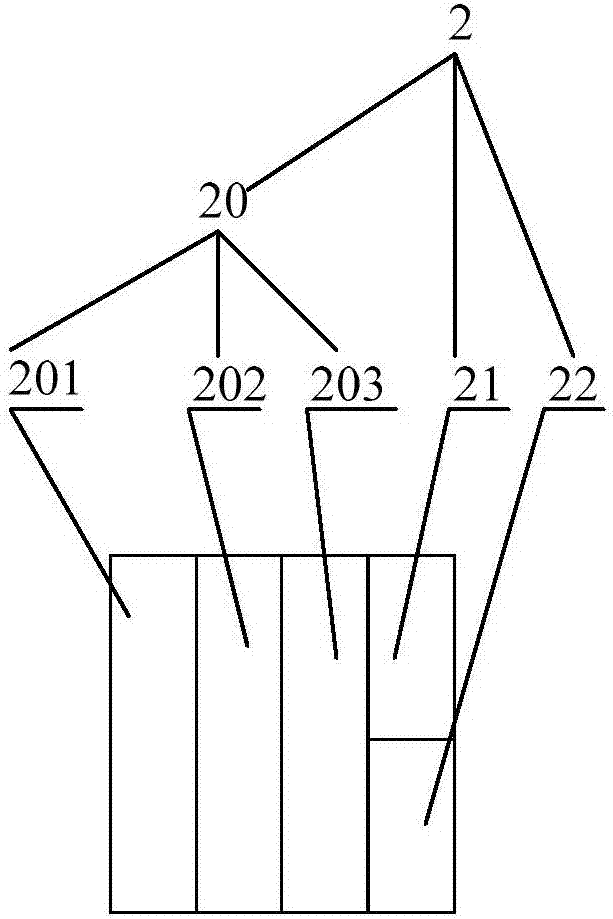

87results about How to "Reduce production pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power coal and sulfur concentrate sorting method and special device thereof

InactiveCN101455992AReduce entryReduce production pressureSievingReversed direction vortexSulfurVolumetric Mass Density

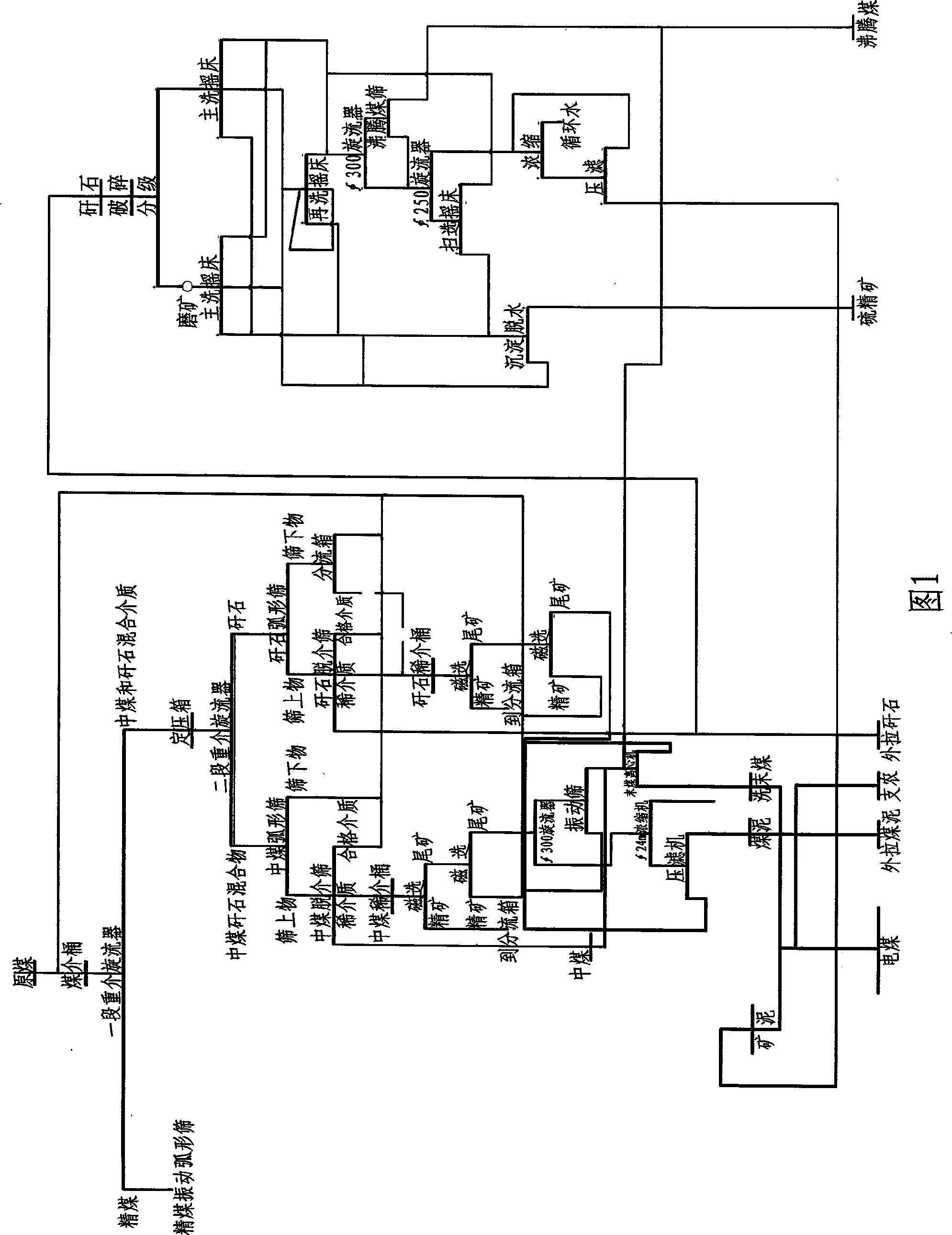

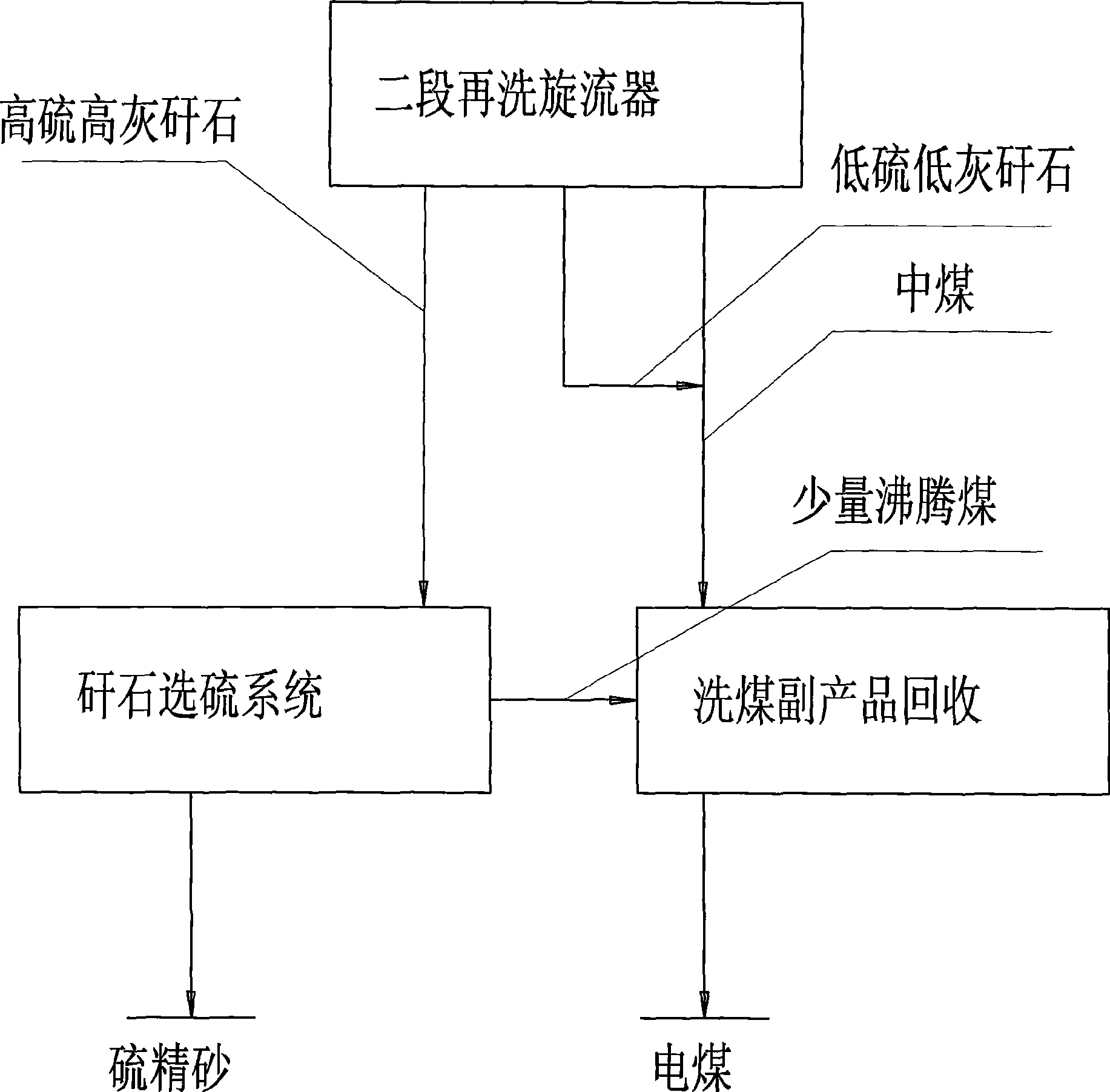

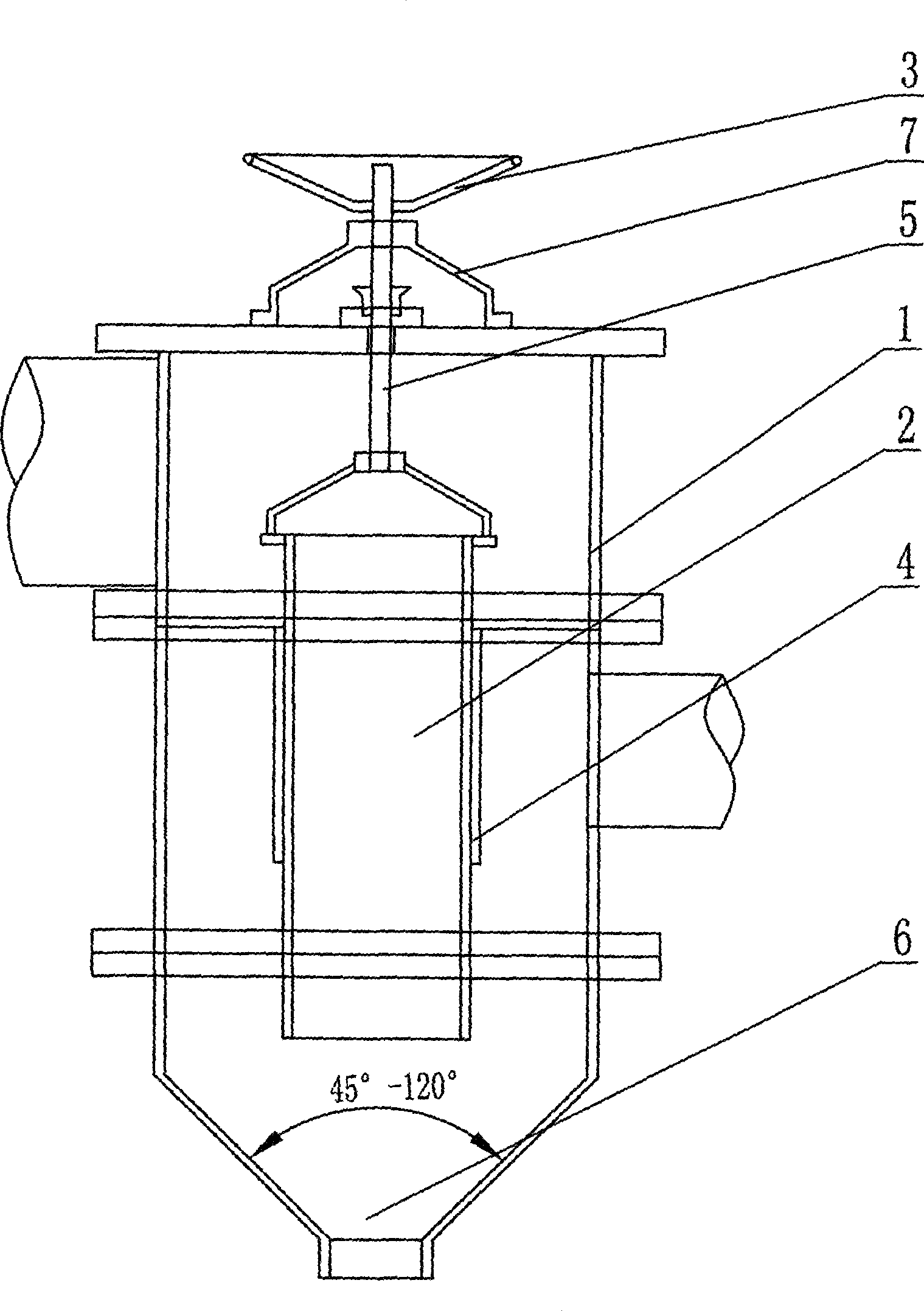

The invention discloses a method and a special device for separating thermal coal and sulfur concentrate. The method comprises: subjecting a mixture of raw coal and heavy medium suspension to the separation of a heavy medium cyclone, wherein a mixture of middlings and waste rocks separated by the heavy medium cyclone are placed into the heavy medium cyclone again to separate the middlings and the waste rocks. The process and the special device can separate middlings with a density of less than 1.8g / cm<3>, waste rocks with a density of less than 2.5g / cm<3> and waste rocks with a density with a density more than 2.5g / cm<3> at the same time, thereby preventing low-sulfur low-ash waste rocks from entering a sulfur separating system to a maximum degree and reducing the production pressure of the sulfur separating system.

Owner:重庆南桐矿业有限责任公司选煤厂

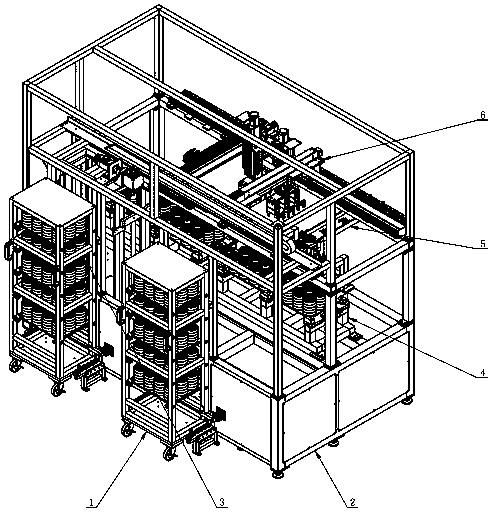

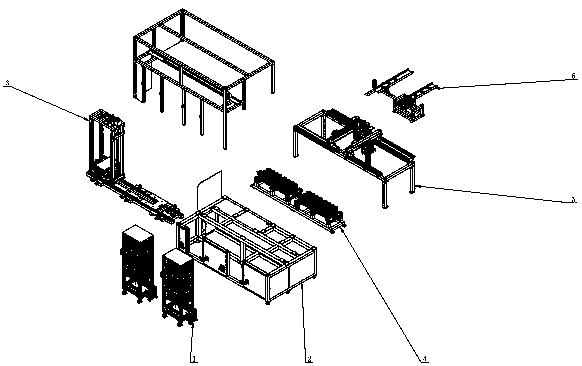

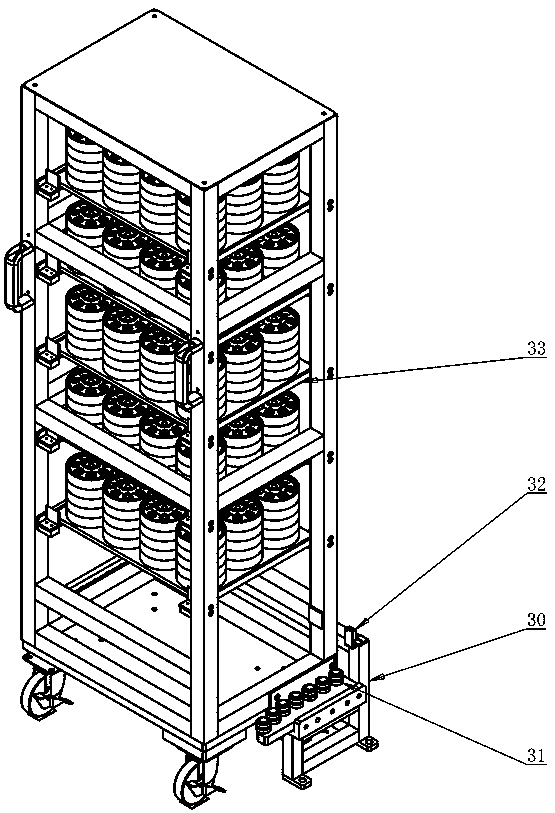

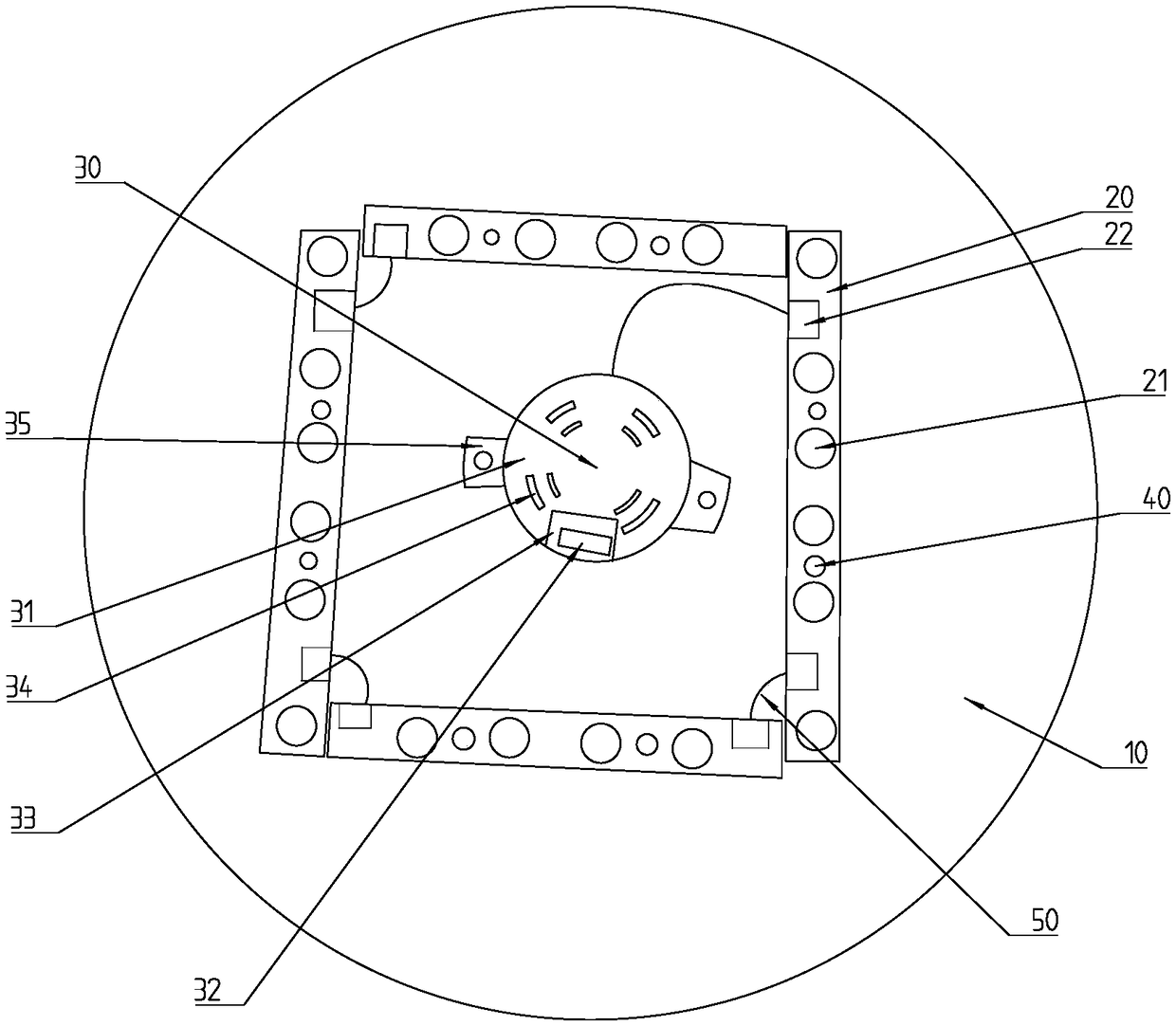

Automatic feeding and discharging robot unit for automatic machining equipment and method

ActiveCN110683314AHighlight substantiveSignificant technological progressControl devices for conveyorsControl engineeringConveyor belt

The invention relates to an automatic feeding and discharging robot unit for automatic machining equipment and method. The equipment comprises a equipment frame, cargo material trolleys, a tray servoassembly, a station tray rollway, a double-triaxial robot assembly, a feeding and discharging conveyor belt and a total controller, wherein the two cargo material trolleys are provided and connected to the front side of the equipment frame in a buckled, left-and-right side by side mode, the tray servo assembly is mounted in the front lower portion of the equipment frame, the station tray rollway is mounted in the middle of the equipment frame, the double-triaxial robot assembly is mounted in the rear upper portion of the equipment frame, the feeding and discharging conveyor belt is fixedly connected to the rear side of the equipment frame, and the total controller is electrically connected with and controls the tray servo assembly, the station tray rollway, the double-triaxial robot assembly and the feeding and discharging conveyor belt; a machining material is placed in a material tray, and is conveyed to the front of the equipment frame from the cargo material trolley on the left side, and after the cargo material trolleys are connected with the equipment frame in a buckled mode, the tray servo assembly brings and conveys the material to the feeding and discharging conveyor beltby the double-triaxial robot assembly through tray rollways; and machined finished products are reversely conveyed to the cargo material trolley on the right to complete feeding and discharging. According to the automatic feeding and discharging robot unit and the method, full automation of workshop production can be realized, and the production efficiency is improved.

Owner:SHANGHAI UNIV

Production method of austenitic stainless steel

InactiveCN101928804AHigh yieldAvoid the problem of high loss and low chromium yieldProcess efficiency improvementElectric furnaceNichromeSS - Stainless steel

The invention relates to a production method of austenitic stainless steel, which comprises the following steps of: a, mixing different low-grade nickel-chromium pig iron in an electric furnace, blowing, desiliconizing and decarbonizing to obtain a stainless steel mother liquor; preparing Cr to be about half of a finished product according to the content requirement of a stainless steel finished product, and properly preparing Ni in the stainless steel mother liquor in the electric furnace by using a grade high-carbon ferrochrome; b, adding the stainless steel mother liquor obtained in the step a to an AOD furnace, adding the high-carbon ferrochrome, laterally blasting air, oxidizing by using a gun and flowing out slag; c, adding metallurgical lime, high-carbon ferrochrome, ferronickel and waste steel to carry out primary decarbonization and secondary decarbonization, adjusting carbon content to the level required by the finished product; and e, finely adjusting components and adjusting temperature in an LF furnace to obtain the austenitic stainless steel. The invention has the advantages of low energy consumption, low cost and stable product quality.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

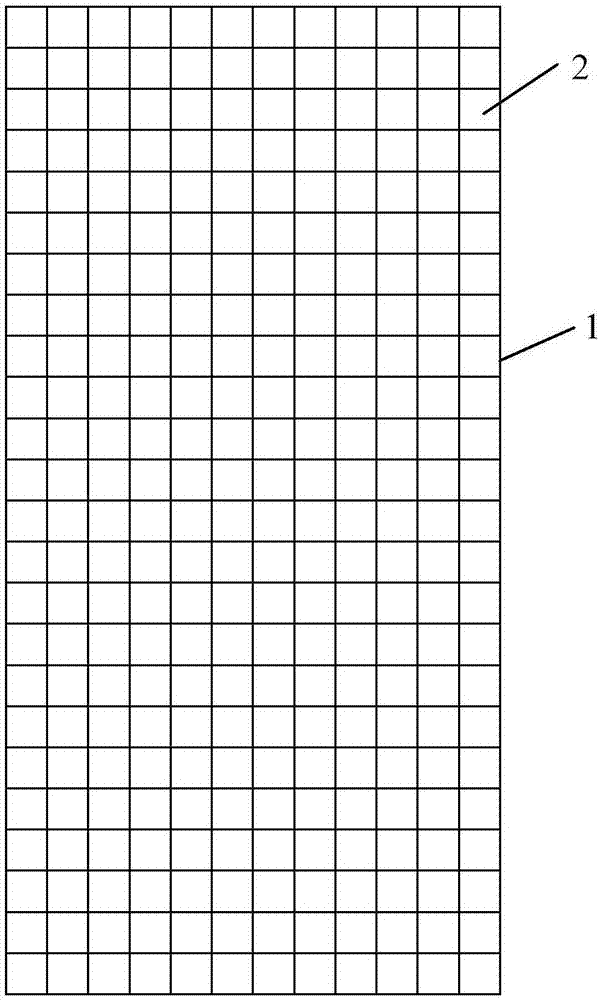

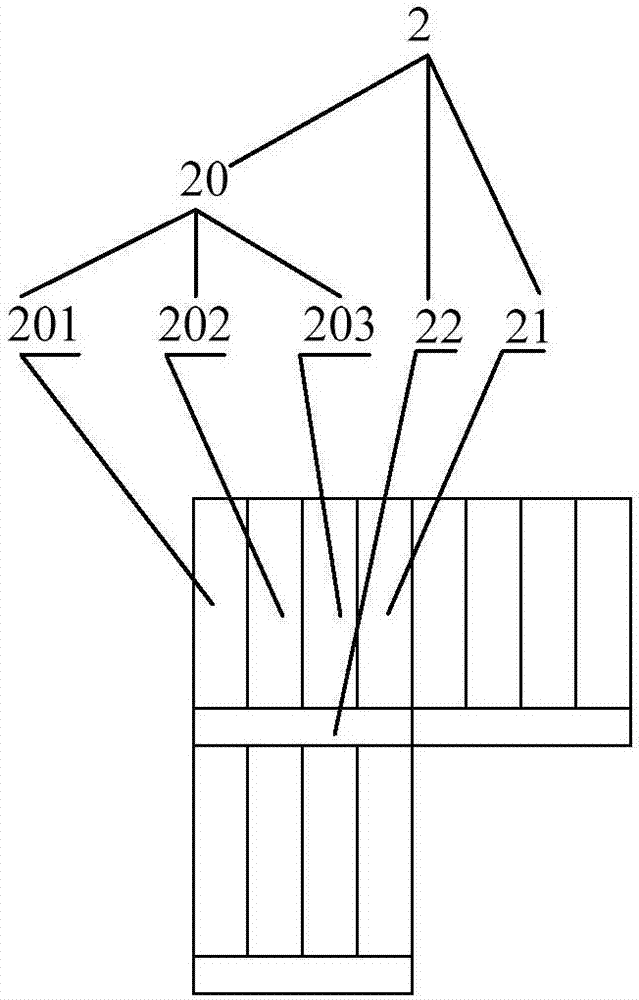

Array substrate, display module and electronic equipment

InactiveCN107145837AReduce production pressureReduce the difficulty of structural designAcquiring/recognising eyesPrint image acquisitionOptoelectronicsIris recognition

The invention relates to the technical field of electronics, and discloses an array substrate, a display module and electronic equipment. The array substrate comprises a substrate body and first basic points which are in matrix arrangement on the substrate body; the first basic points comprise M display pixels, M infrared sensing units and N infrared light emitting units which are arranged together, wherein M and N are both positive integers, and M is greater than or equal to N; and the substrate body also has signal circuits of the display pixels, the infrared light emitting units and the infrared sensing units. According to the embodiments, by integrating the infrared light emitting units, the infrared sensing units and the display pixels of the display apparatus together, the structural design difficulty of the electronic equipment can be lowered and open pores can be reduced; in addition, the infrared sensing units can be used for fingerprint identification as well as iris identification, so that multifunction is realized and cost can be lowered; and meanwhile, the fingerprint identification function is realized in a display region, so that fingerprint identification flexibility is improved, and convenience in use of a user can be achieved.

Owner:SHANGHAI YUDE TECH CO LTD

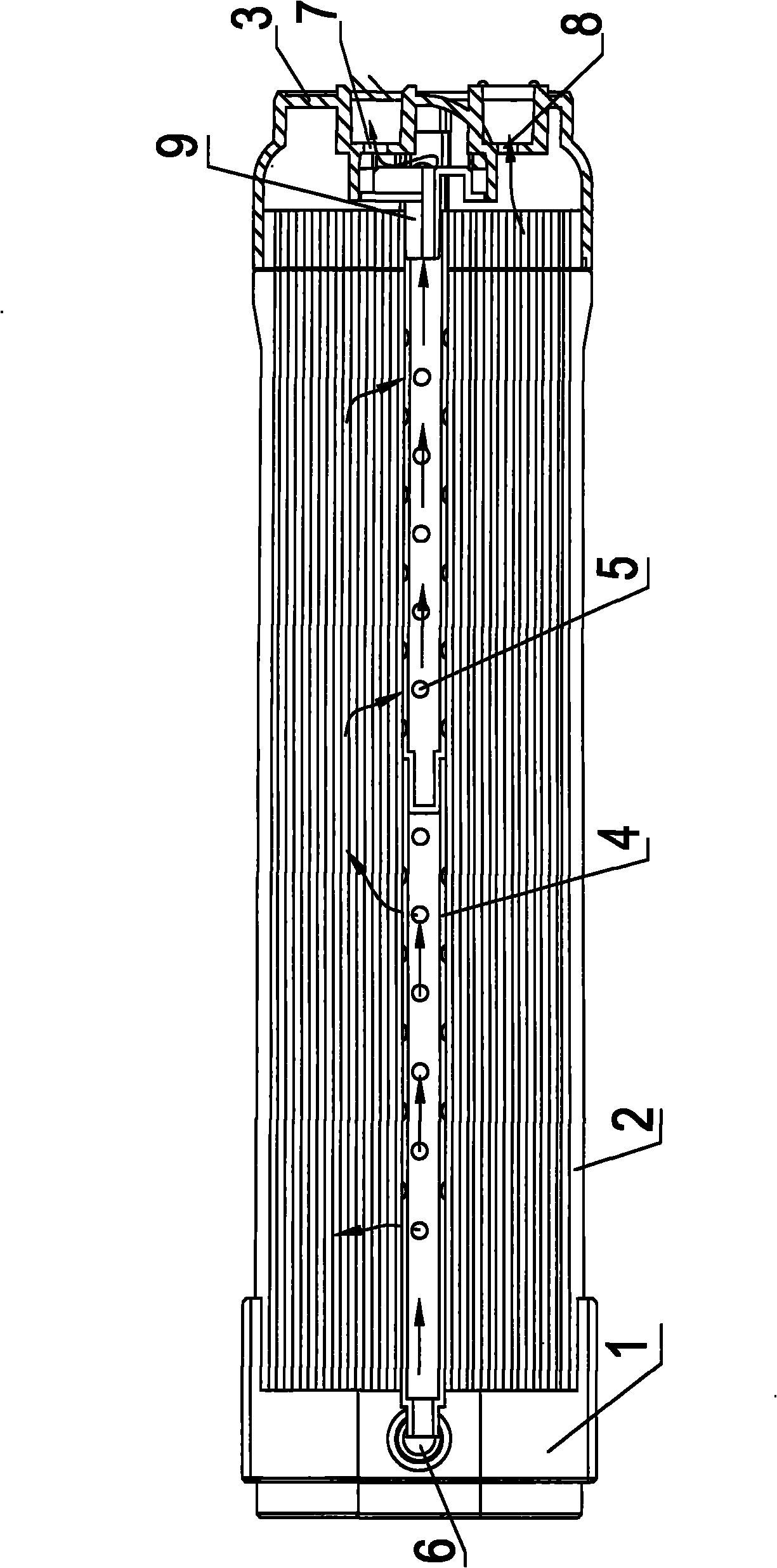

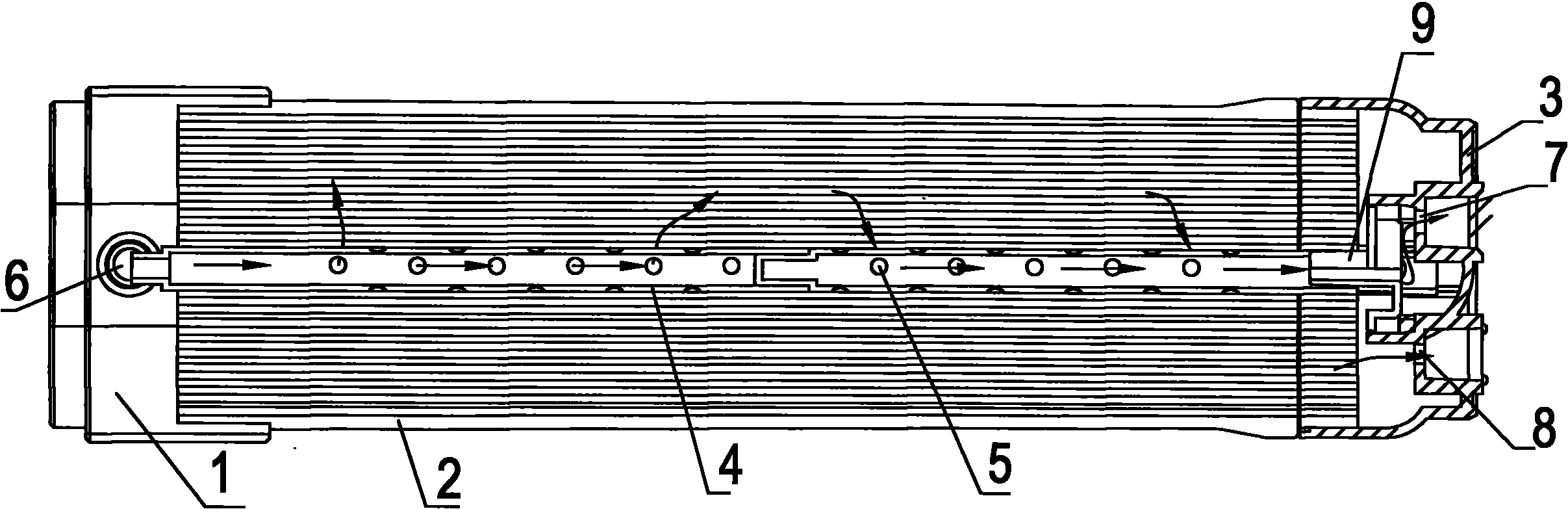

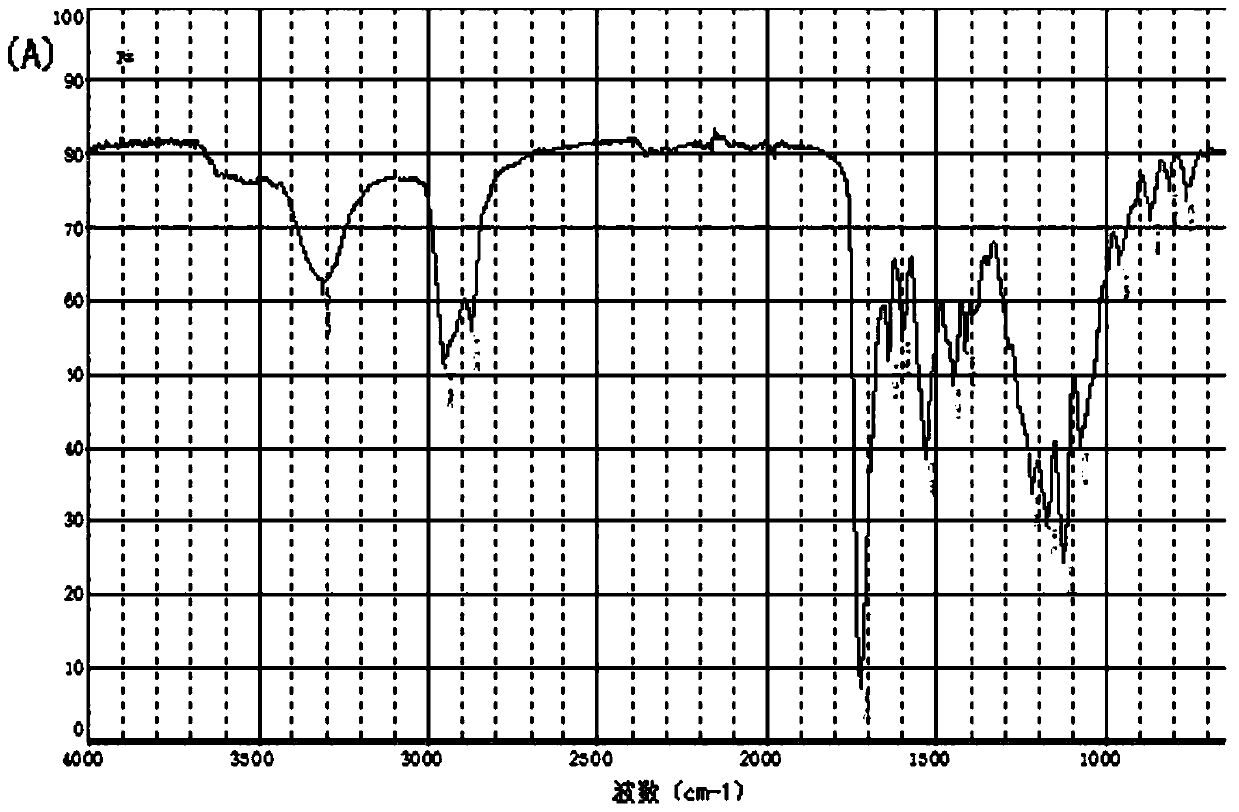

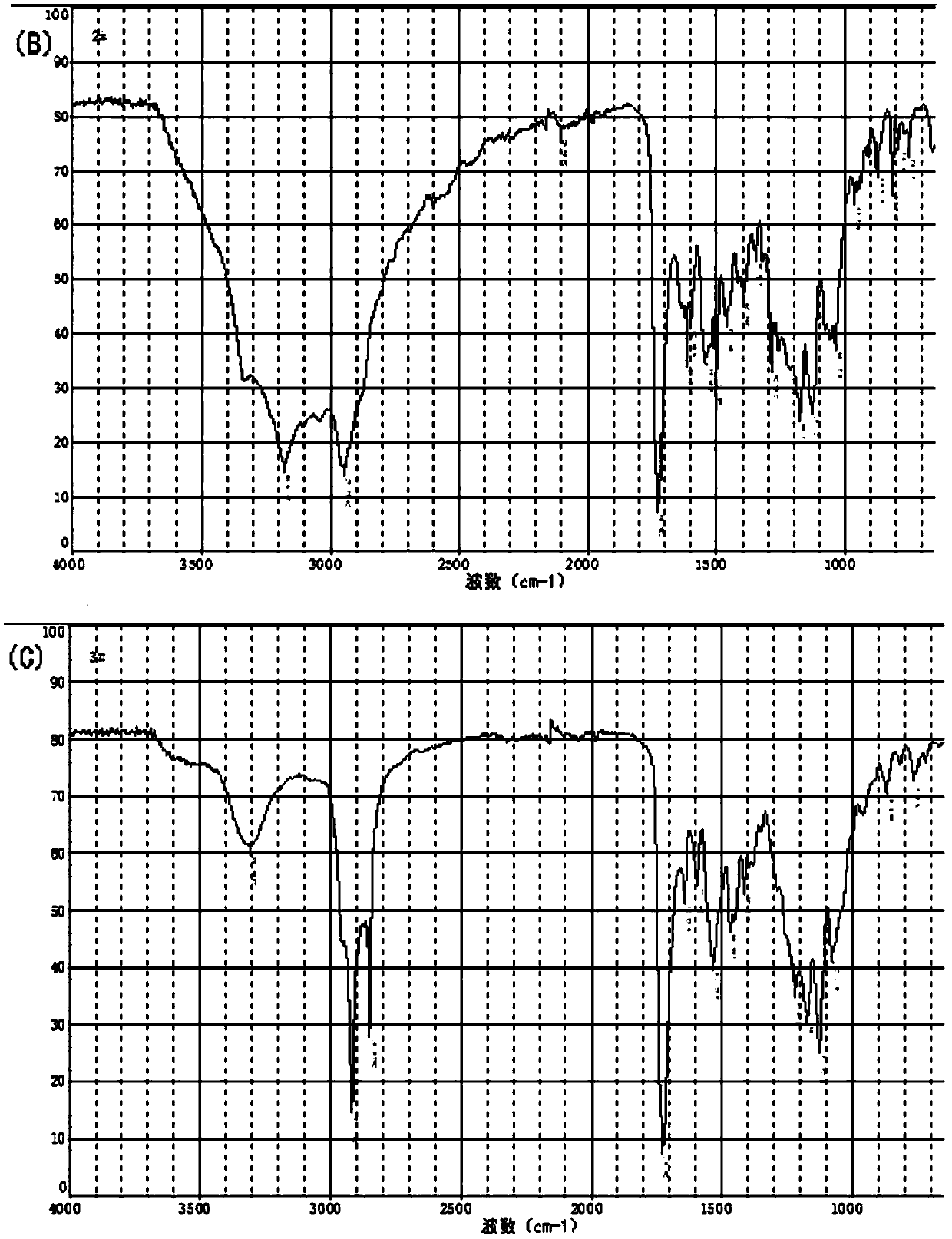

Method for manufacturing nano-filtration membrane filter

InactiveCN102049196AShorten production timeReduce in quantitySemi-permeable membranesHollow fibreFiber bundle

The invention discloses a method for manufacturing a nano-filtration membrane filter, which comprises the following steps of: 1, arranging a plurality of hollow fiber nano-filtration membranes in parallel to form a hollow fiber bundle, sealing the water outlet end of the hollow fiber bundle by using ultraviolet glue so that the ends of the hollow fiber nano-filtration membranes are filled with the ultraviolet glue, and then scattering the water outlet end of the hollow fiber bundle so that the plurality of hollow fiber nano-filtration membranes are mutually separated; 2, irradiating the water outlet end of the hollow fiber bundle by using ultraviolet rays so that the ultraviolet glue is cured; 3, wrapping the hollow fiber bundle by using a water permeable film, filling a central pipe in the center of the hollow fiber bundle, coiling the hollow fiber bundle to be cylindrical and filling the coiled hollow fiber bundle into a shell of a nano-filtration membrane assembly; 4, sealing the water outlet end and the water inlet end of the hollow fiber bundle by using sealant so that the hollow fiber bundle is hermetically combined with the shell; and 5, cropping the water outlet end of the nano-filtration membrane assembly so that the water outlet ends of the hollow fiber nano-filtration membranes are conducted.

Owner:苏州优水纳滤膜技术有限公司

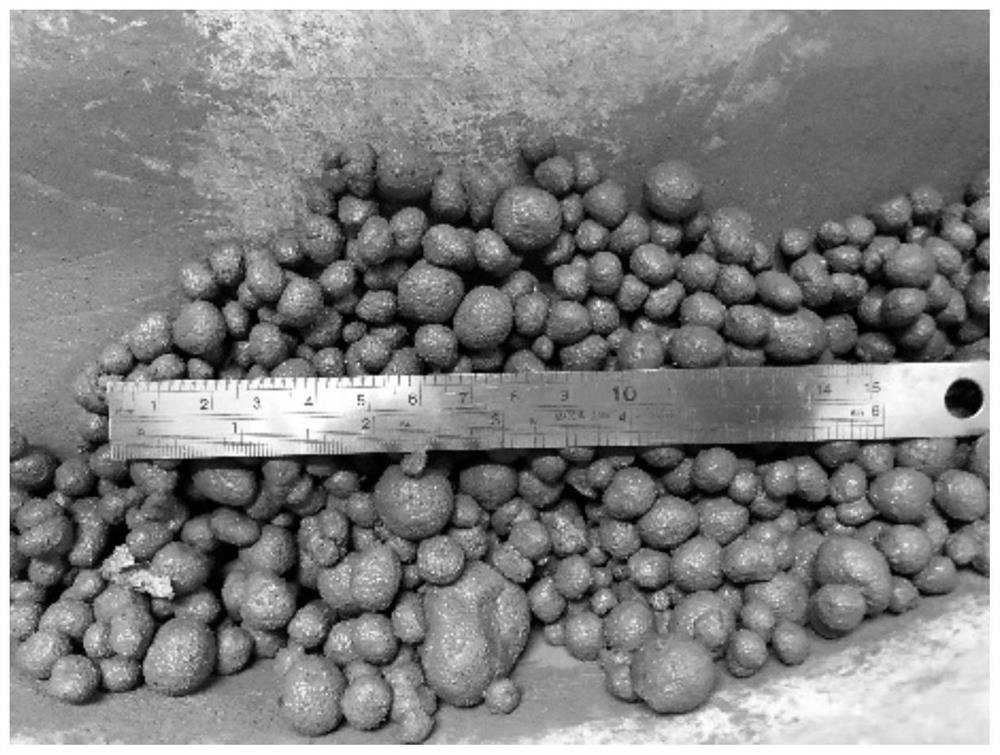

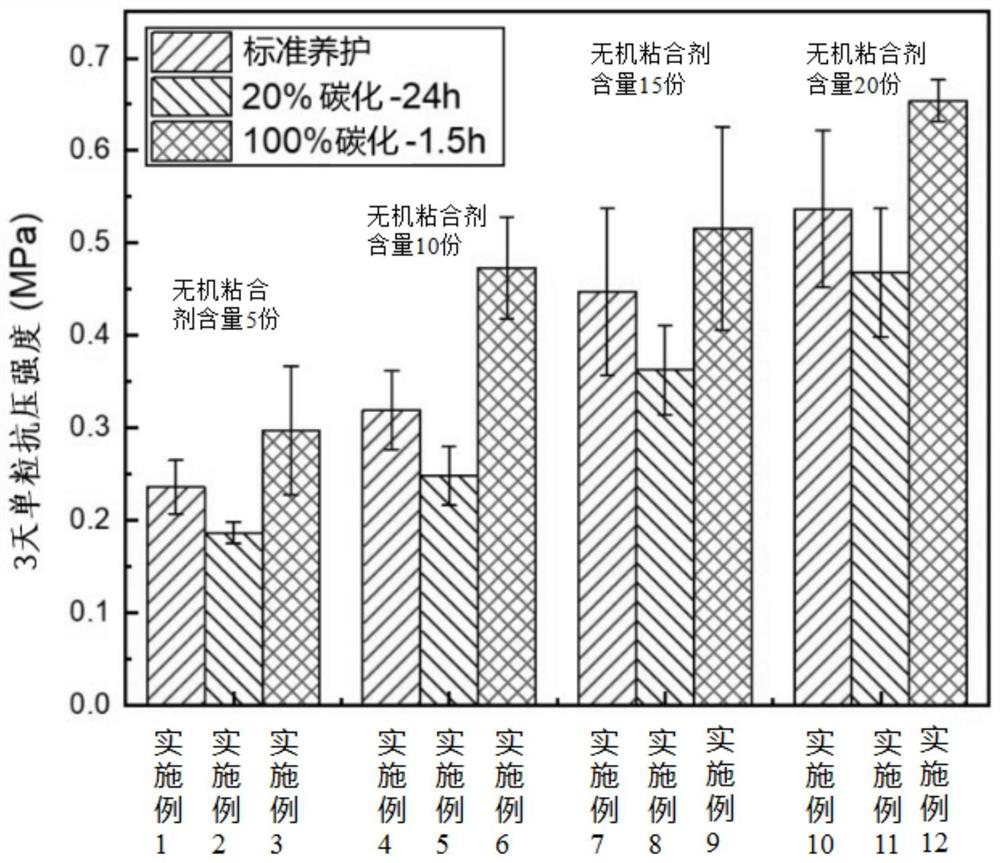

Preparation method of sludge-based artificial building aggregate

InactiveCN112194394AReduce moisture contentReduce production pressureSolid waste managementSludgeAdhesive

The invention provides a preparation method of sludge-based artificial building aggregate, which comprises the steps of providing sludge, and pretreating the sludge to obtain dry sludge powder; mixingthe dried sludge powder with an inorganic binder, a mineral admixture and an excitant according to a part ratio of (50-90): (5-20): (1-30): (0.5-5) to obtain a first mixture; and mixing and granulating the first mixture and water to obtain the artificial building aggregate. According to the method, the sludge serves as a main component, the inorganic adhesive is used for crosslinking and curing harmful components, it is guaranteed that the artificial building aggregate has enough mechanical strength and excellent properties, the sludge can be recycled on a large scale through the method, andon the other hand, the artificial building aggregate can replace natural aggregate to be exploited and is widely applied to engineering such as buildings.

Owner:SHENZHEN UNIV

Fracturing process in oil and water well by means of biological enzyme preparation

InactiveCN1766283AImprove work efficiencyDoesn't take into account the reverse dischargeFluid removalWater wetFracturing fluid

The invention discloses an oil field oil-water well fracturing craft method of biological enzyme agent, which is characterized by the following: building the mixed biological enzyme agent and water or biological acid or antisludging agent or liquid nitrogen as fracturing fluid; forcing the fracturing fluid into the oil well or water well through the fracturing vehicle; pressing the fracturing fluid into the crack; opening the well after 72 hours. The biological enzyme agent penetrates the hole throat then enters into the microscopic hole gap, which attaches the rock surface and denudes the raw oil to improve the earth penetration factor. The method improves the water wet effect and washes the spalling oil film, which improves the recovery factor of raw oil.

Owner:SUNCOO PETROLEUM TECH

Removal method for calcium and strontium impurity irons in rare earth feed liquid

InactiveCN108796247AEfficient separationProcess stabilityProcess efficiency improvementRare-earth elementEnvironmental resistance

The invention provides a removal method for calcium and strontium impurity irons in a rare earth feed liquid. The removal method comprises the following steps: kalifying and performing a reaction; performing an ageing reaction; performing centrifuge dripping; and performing high-temperature calcining. The rare earth feed liquid is a lanthanum chloride, cerium chloride or lanthanum cerium chloridefeed liquid containing calcium chloride and strontium chloride, wherein the concentration of lanthanum chloride, cerium chloride or lanthanum cerium chloride are 100 g / L-150 g / L, and the sum of concentrations of calcium oxide and strontium oxide is 0.5 g / L-15 g / L. By controlling the conditions such as reaction temperature, stirring time, pH value and settling time in a reaction process of sodium carbonate and a rare earth chloride solution, rare earth elements in the feed liquid are settled fully, and meanwhile, calcium and strontium ions are left in the solution, so that rare earth and calcium and strontium impurities are separated efficiently; and the removal method is stable in process and economical and environment-friendly.

Owner:中稀(寿光)资源科技有限公司

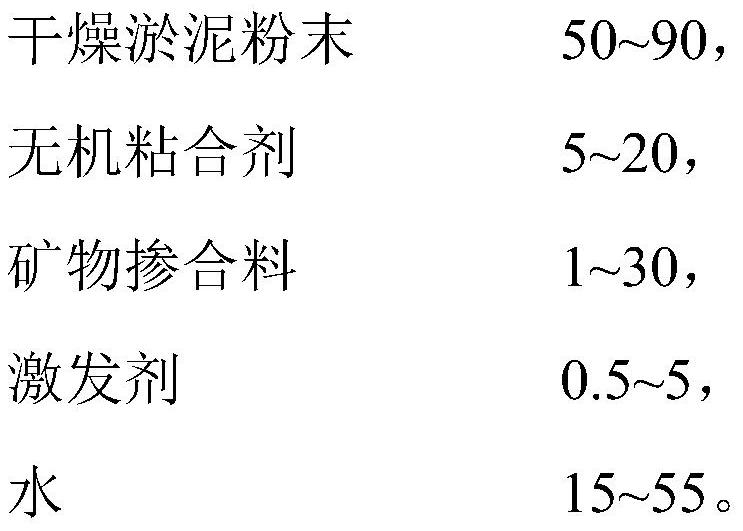

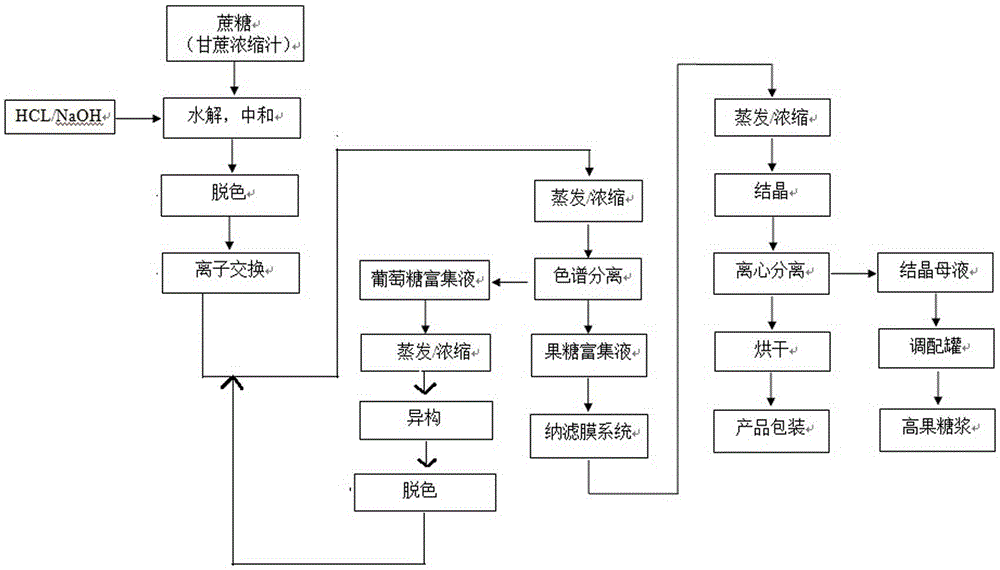

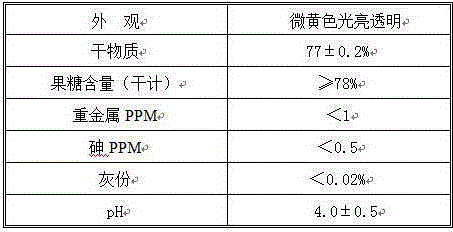

Method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material

PendingCN105331751AIncrease fructose contentIncreased spawn chanceFructose productionInvert sugar productionBiotechnologyHigh-fructose corn syrup

A method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material is disclosed. The technological process of the method comprises the following steps: performing cane juice squeezing concentration, preparing high fructose corn syrup, refining high fructose corn syrup, separating refined high fructose corn syrup, crystallizing fructose and recovering a glucose solution. In the method, the equipment and technological parameters of all procedures are comprehensively optimizes and reasonable matched, the method is suitable for industrialized production demand, equipment investment and production cost are substantially reduced, the once yield of the industrialized produced crystallized fructose product is up to 50%, the technology content of fructose production is improved, and the situation that fructose market severely depends on imported high-quality medicinal fructose and technology equipment thereof is solved.

Owner:姜蓉生

Application of modified polyurethane sponge in repair of non-aqueous organic-phase liquid contaminated soil and repair method of non-aqueous organic-phase liquid contaminated soil

InactiveCN109848192AAvoid secondary pollutionTo achieve the effect of repeated useContaminated soil reclamationAdsorption effectSURFACTANT BLEND

The invention discloses an application of modified polyurethane sponge in repair of non-aqueous organic-phase liquid contaminated soil and a repair method of the non-aqueous organic-phase liquid contaminated soil. The modified polyurethane sponge can be repeatedly used, adsorbed substances can be recycled only through physical extrusion, and elasticity and adsorption capacity of the sponge can berecovered, so that an effect of reutilization is achieved. Meanwhile, the modified polyurethane sponge is a biodegradable material, and secondary pollution to the soil is avoided. The modified polyurethane sponge provided by the invention has super-strong hydrophobicity, can selectively adsorb a non-aqueous organic-phase and repel water phase, and has a notable adsorption effect on non-aqueous organic-phase liquid in the soil, and the preparation method is simple and is easy to implement. The preparation method of the modified polyurethane sponge is simple, and the raw materials are easy to obtain. The modified polyurethane sponge provided by the invention is matched with a surfactant for use, so that a better removal effect is achieved on the non-aqueous organic-phase liquid in the soil,the repairing time is shorter, and repairing efficiency is higher.

Owner:SOUTH CHINA NORMAL UNIVERSITY

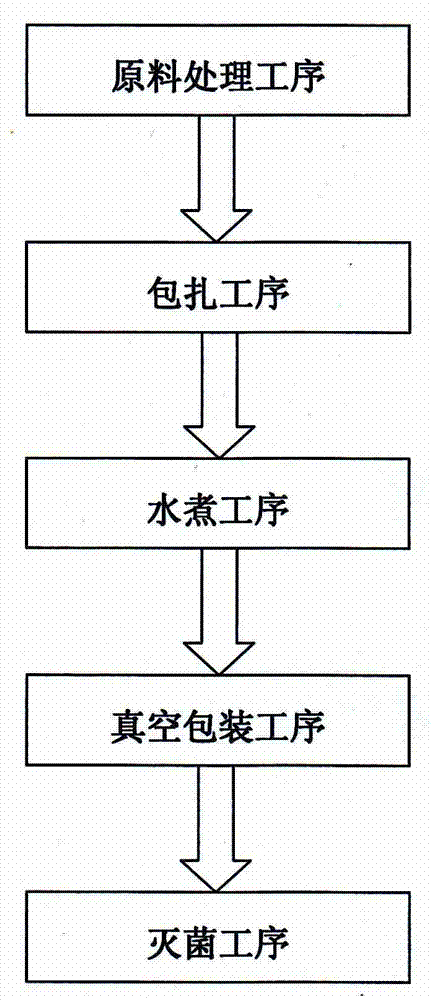

Preparing method of microwave traditional Chinese rice-pudding

The invention relates to a preparing method of a microwave traditional Chinese rice-pudding. Currently, the existing preparing method of the microwave traditional Chinese rice-pudding does not have a simple process and can not be used for preparing the traditional Chinese rice-pudding with a comfortable mouth feel, a special flavor and capacity of being directly heated by microwaves. The preparing method comprises the following steps of: a raw material treating procedure, a binding procedure, a water boiling procedure, a vacuum packaging procedure and a sterilizing procedure; for the raw material treating procedure: finished-product stuffing is prepared through using a chequer-shaped indocalamus leaf treating step, a sticky rice treating process and a stuffing treating step; an uncooked traditional Chinese rice-pudding is prepared in the binding procedure; for the water boiling procedure: the uncooked traditional Chinese rice-pudding is boiled for 30-35 minutes and is braised for 30-35 minutes to prepare the cooked traditional Chinese rice-pudding; a vacuum packaged traditional Chinese rice-pudding is prepared by using the vacuum packaging procedure; and the microwave traditional Chinese rice-pudding is prepared by using the sterilizing procedure. The preparing method of the microwave traditional Chinese rice-pudding is simple in process; and the manufactured traditional Chinese rice-pudding has a comfortable mouth feel, a special flavor anda high nutritive value, and can be directly heated by the microwaves.

Owner:ZHEJIANG QINGLIAN FOOD

A kind of production method of austenitic stainless steel

InactiveCN102268593AHigh yieldIncrease productivityProcess efficiency improvementNichromeFerrochrome

The invention relates to a production method of austenitic stainless steel, which comprises the following steps of: a, mixing different low-grade nickel-chromium pig iron in an electric furnace, blowing, desiliconizing and decarbonizing to obtain a stainless steel mother liquor; preparing Cr to be about half of a finished product according to the content requirement of a stainless steel finished product, and properly preparing Ni in the stainless steel mother liquor in the electric furnace by using a grade high-carbon ferrochrome; b, adding the stainless steel mother liquor obtained in the step a to an AOD furnace, adding the high-carbon ferrochrome, laterally blasting air, oxidizing by using a gun and flowing out slag; c, adding metallurgical lime, high-carbon ferrochrome, ferronickel and waste steel to carry out primary decarbonization and secondary decarbonization, adjusting carbon content to the level required by the finished product; and e, finely adjusting components and adjusting temperature in an LF furnace to obtain the austenitic stainless steel. The invention has the advantages of low energy consumption, low cost and stable product quality.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

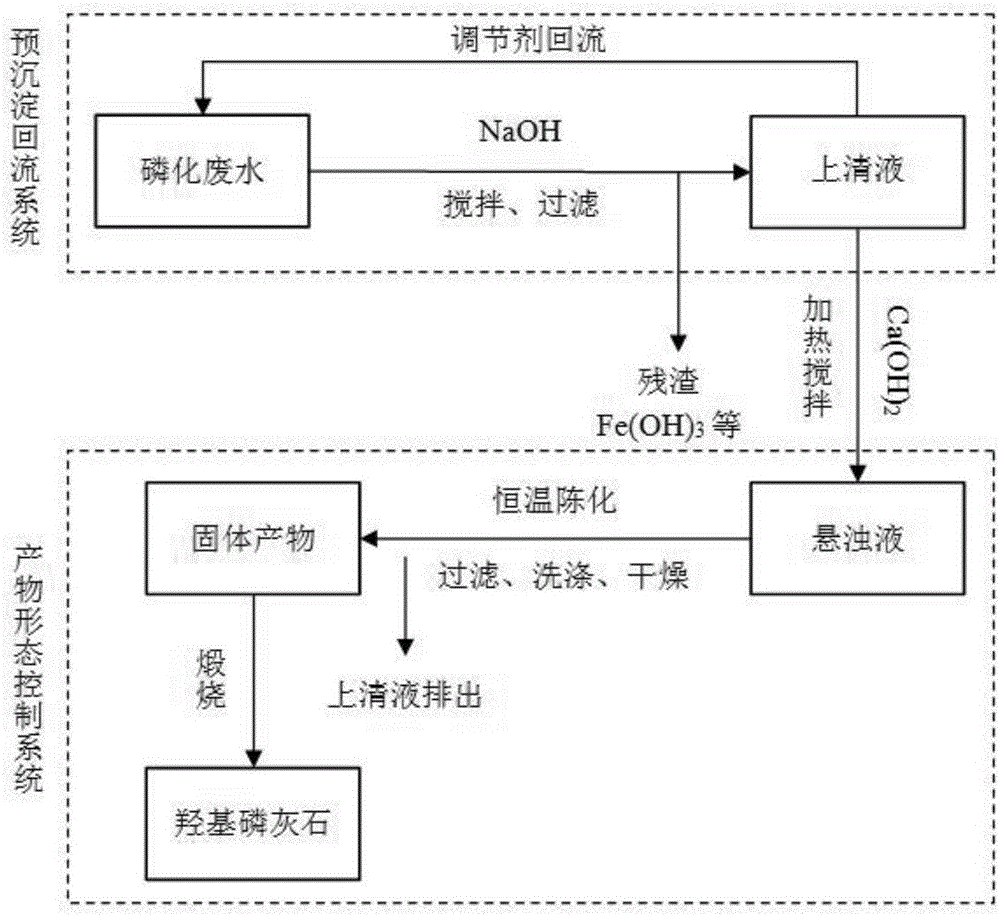

Technological method for preparing hydroxyapatite by using phosphating waste water as raw material

InactiveCN106586994AAvoid interferenceGuaranteed purityWater/sewage treatment by flocculation/precipitationPhosphorus compoundsHigh concentrationEmission standard

The invention relates to a technological method for preparing hydroxyapatite by using phosphating waste water as a raw material. Aiming at high concentration phosphating waste water, the method is used for disposing the high concentration phosphating waste water with NaOH as a regulator and Ca(OH)2 as a precipitant, and preparing hydroxyapatite at the same time. Fractional precipitation and a product morphology control method are adopted to ensure the purity of the hydroxyapatite and improve the quality of the hydroxyapatite. Simple in process and operation, the method can not only remove most PO4<3-> and heavy metal ions in phosphating waste water to make effluent quality up to an emission standard but also recycle the by-products, so that the method has good economic benefits and application prospects.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

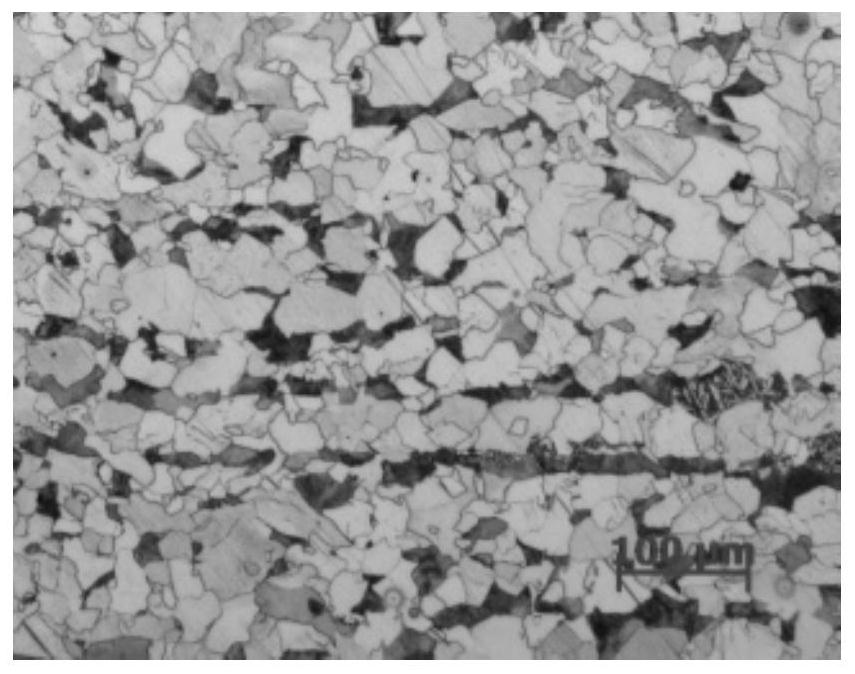

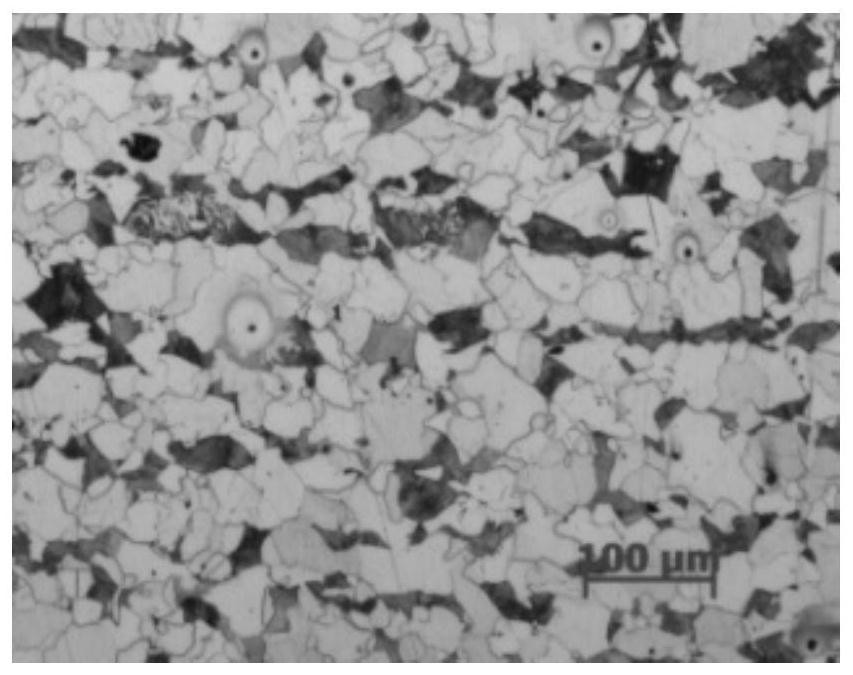

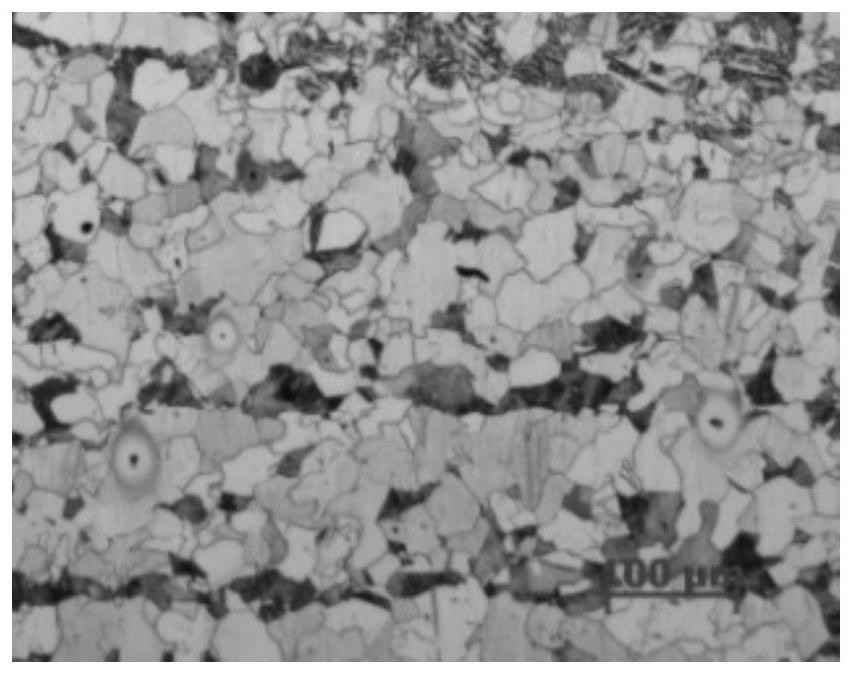

100 mm-120 mm Q460D extra-thick high-strength steel and preparation method thereof

ActiveCN113249641AReduce production pressureImprove efficiencyFurnace typesHeat treatment furnacesChemical compositionDehydrogenation

The invention relates to 100 mm-120 mm Q460D extra-thick high-strength steel which comprises the following chemical components including, by mass, 0.10% to 0.13% of C, 0.30% to 0.50% of Si, 1.40% to 1.60% of Mn, less than or equal to 0.0070% of P, less than or equal to 0.0020% of S, 0.020% to 0.050% of Nb, 0.008% to 0.020% of Ti, 0.020% to 0.040% of Al, 0.10% to 0.20% of Cu, 0.10% to 0.20% of Cr, 0.10% to 0.20% of Ni and the balance Fe and inevitable impurity elements. The production process flow comprises the following steps of converter smelting, LF refining, RH vacuum degassing, Ca treatment, continuous casting, casting blank dehydrogenation treatment, heating, normalizing rolling, air cooling, steel plate stacking and slow cooling and unstacking. The yield strength of a steel plate ranges from 430 MPa to 470 MPa, the tensile strength ranges from 550 MPa to 570 MPa, the ductility is larger than or equal to 20%, and the Charpy impact energy at the 1 / 4 position and the 1 / 2 position of the thickness of -20 DEG C is larger than or equal to 200 J. The flaw detection result meets the ASTM A 578C level requirement, and the surface of the steel plate has no defect.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

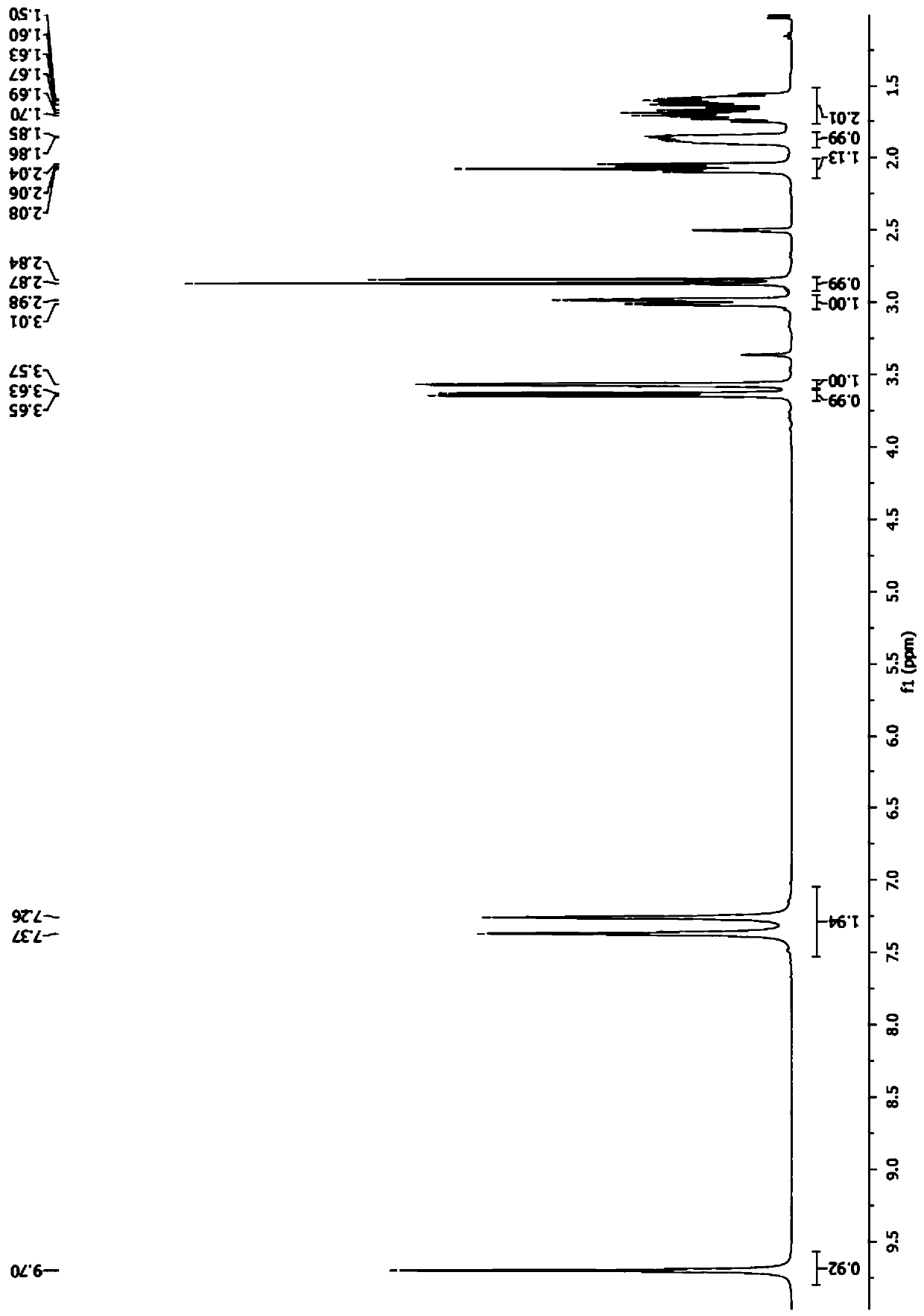

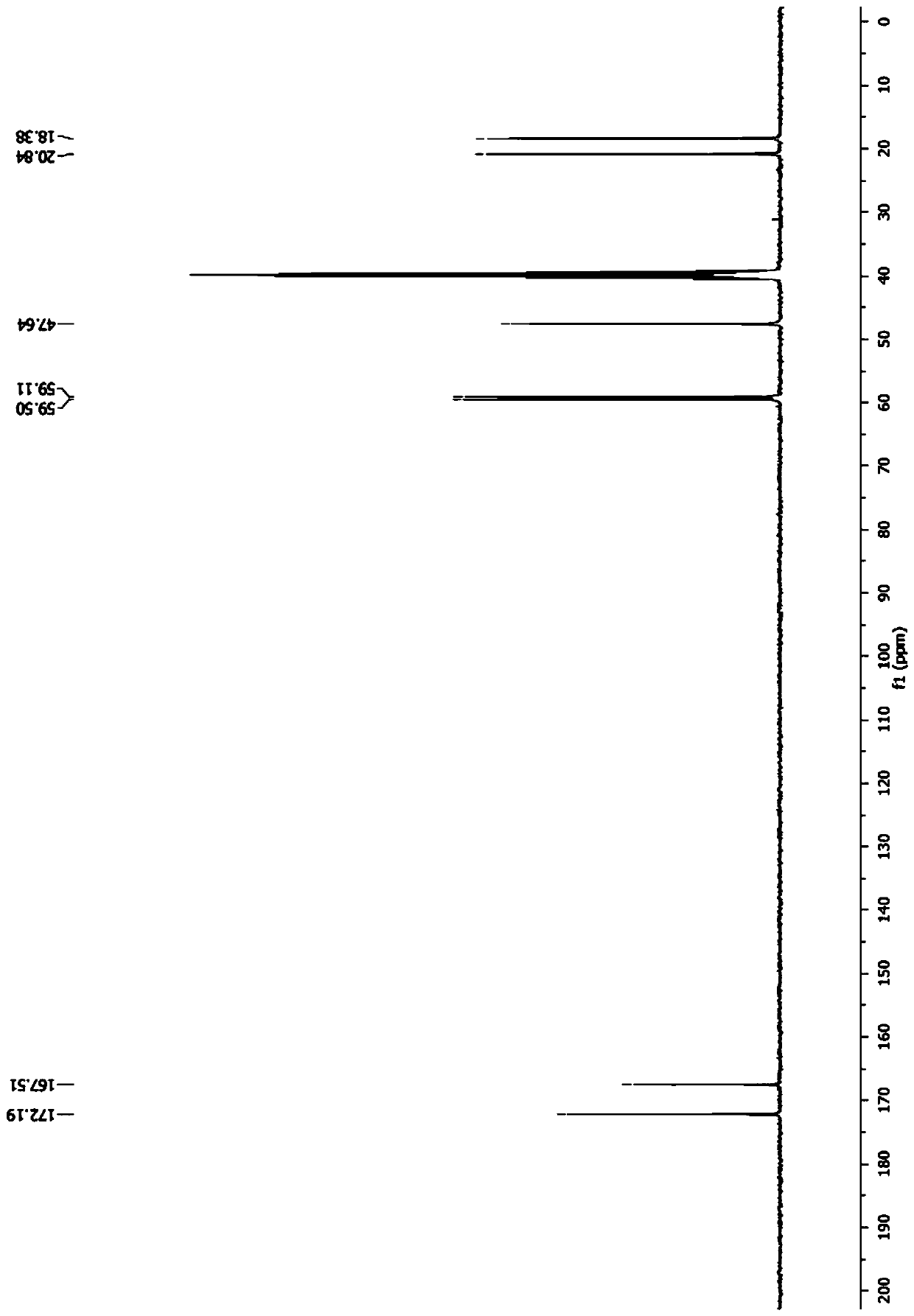

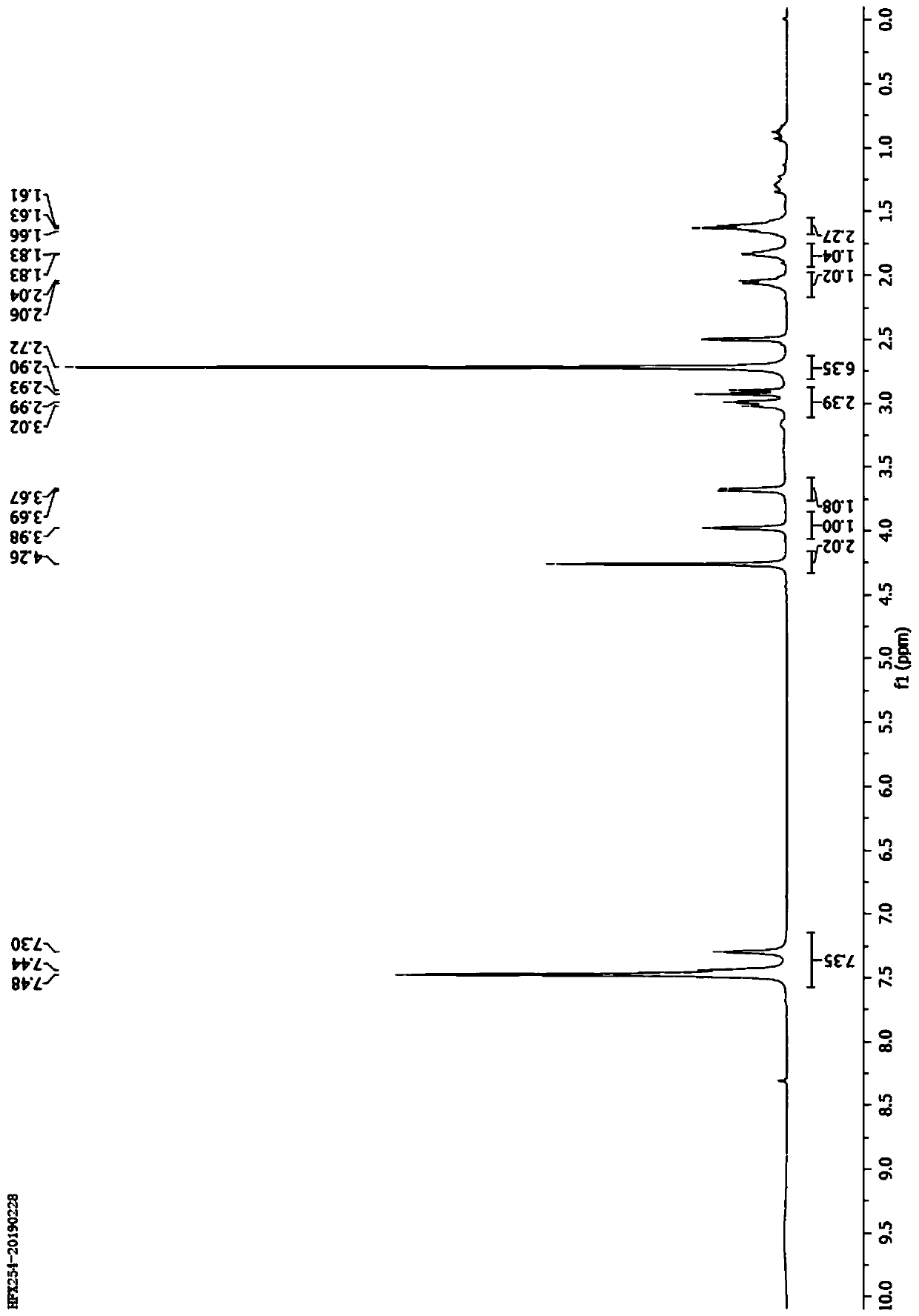

Avibactam intermediate, and preparation method and application of avibactam intermediate

ActiveCN110078728APost-processing is simpleReduce production pressureOrganic chemistryBenzylaminePhotochemistry

The invention discloses an avibactam intermediate, and a preparation method of the avibactam intermediate. The preparation method comprises the steps of allowing a compound II to react with a sulfonation reagent in the presence of an alkaline agent and then react with the alkaline agent to form the avibactam intermediate, wherein the alkaline agent is trialkylamine, pyridine, alkylpyridine, N-alkylpiperidine, dialkyl phenylamine or dialkyl benzylamine; alkyl in trialkyl amine is C5-8 alkyl; alkyl in alkyl pyridine in C1-4 alkyl; alkyl in N-alkylpiperidine is C1-4 alkyl; alkyl in dialkyl phenylamine is C1-4 alkyl; and alkyl in dialkyl benzylamine is C1-4 alkyl. Compared with the traditional method, the method adopts the alkaline agent with appropriate alkalinity to substitute the traditional alkaline agent; the alkaline agent can react with the compound II in a step directly with the sulfonation reagent; the post-treatment is simple; and the method is more suitable for industrial mass production.

Owner:JIANGXI FUSHINE PHARMA CO LTD

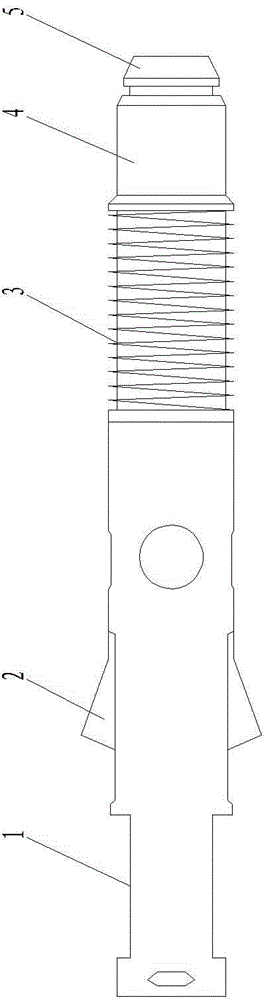

Underground oil and gas nozzle

InactiveCN102913188AReduce production pressureReduced minimum unloading flowWell/borehole valve arrangementsSealing/packingCarrying capacityDischarge rate

The invention provides an underground oil and gas nozzle and relates to a high-pressure oil and gas well throttling device working under the ground. The underground oil and gas nozzle comprises a hollow cylindrical main body; an oil nozzle is formed at one end of the main body and is a hollow cone; and lock blocks are also obliquely arranged on the main body. The underground oil and gas nozzle has the benefits that the production pressure is reduced, the wellhead temperature is improved, the generation conditions of hydrates are damaged, and the hydrates can be effectively prevented; and in addition, the minimum discharge rate of a wellhead of a gas well is reduced, and the liquid-carrying capacity of the gas well self is enhanced, so that the production of the gas well with lower liquid yield tends to be more stable.

Owner:SHAANXI QIYUAN TECH DEV

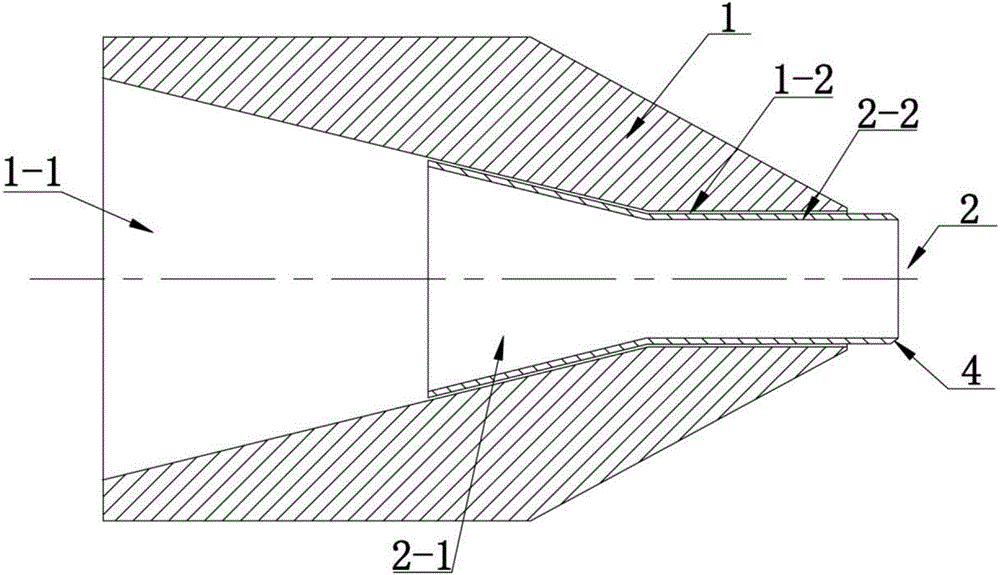

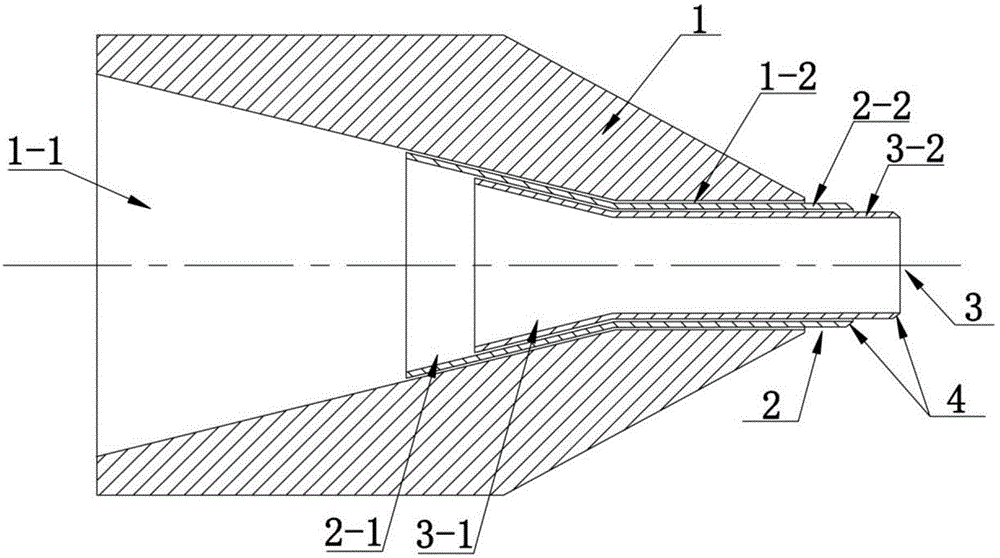

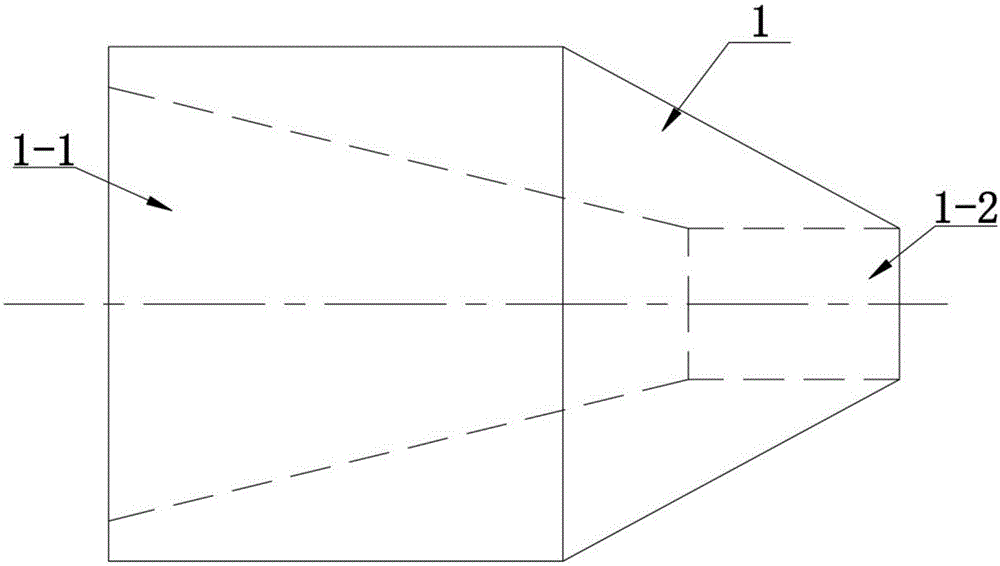

Catenary-chain type cross-linked cable production die and production method

ActiveCN104900346AReduce product quality riskArrive successfullyCable/conductor manufactureCross-linkElectrical conductor

The invention discloses a catenary-chain type cross-linked cable production die and a production method, and belongs to the technical field of wire and cable manufacturing. The die comprises a basic die body, and the interior of the basic die body is provided with a wire-bearing circular hole and an incoming wire tapered hole. The die also comprises a first inner die body and a second inner die body, wherein the inner die bodies are in an integrated structure. The first inner die body is disposed in the basic die body in a sleeved manner, and the second inner die body is disposed in the first inner die body in a sleeve manner. One end of the first inner die body and one end of the second inner die body are respectively provided with a first incoming wire hole and a second incoming wire hole, and the other ends of the first and second inner die bodies are respectively provided with a first bushing and a second bushing. The conical degree of the first incoming wire hole is consistent with the conical degree of the incoming wire tapered hole. The conical degree of the second incoming wire hole is consistent with the conical degree of the first incoming wire hole. The production method needs to produce different types of cable conductors, and enables the corresponding first inner die body to be inserted into the basic die body or enables the second inner die body to be inserted into the first inner die body. The die and method are quick and convenient in die replacement, improve the production efficiency, and achieve the continuous production of adjacent types of conductors.

Owner:YANTAI CABLE FACTORY

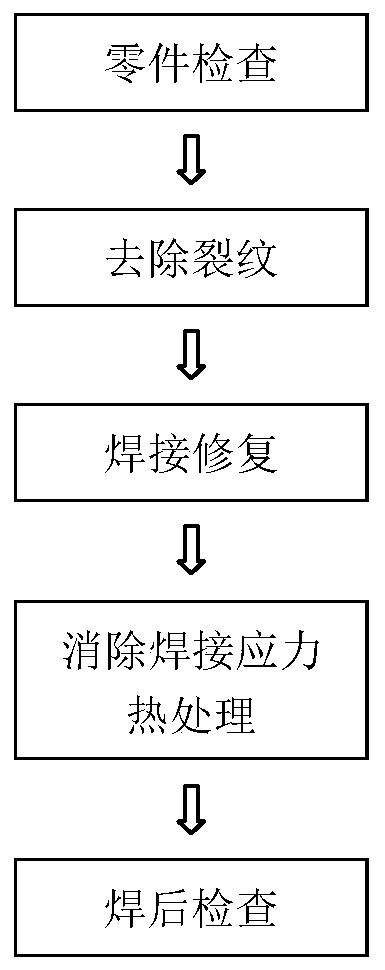

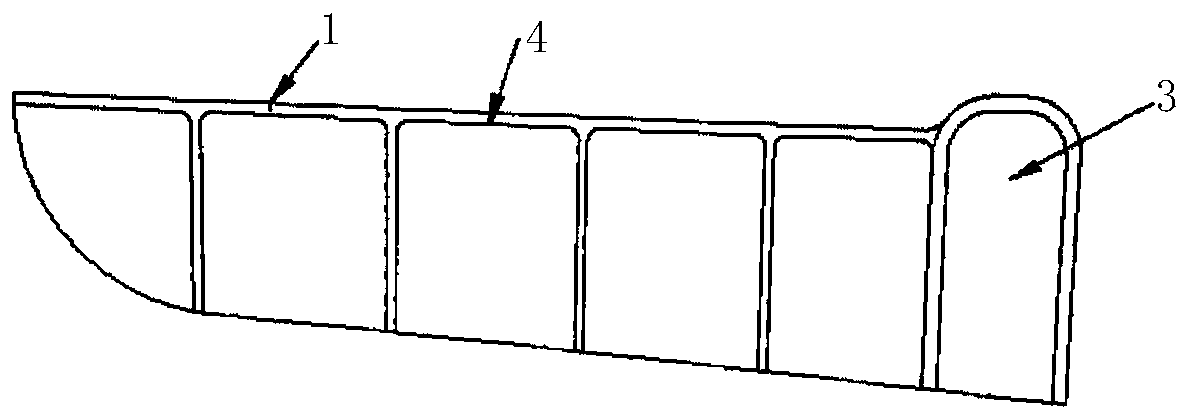

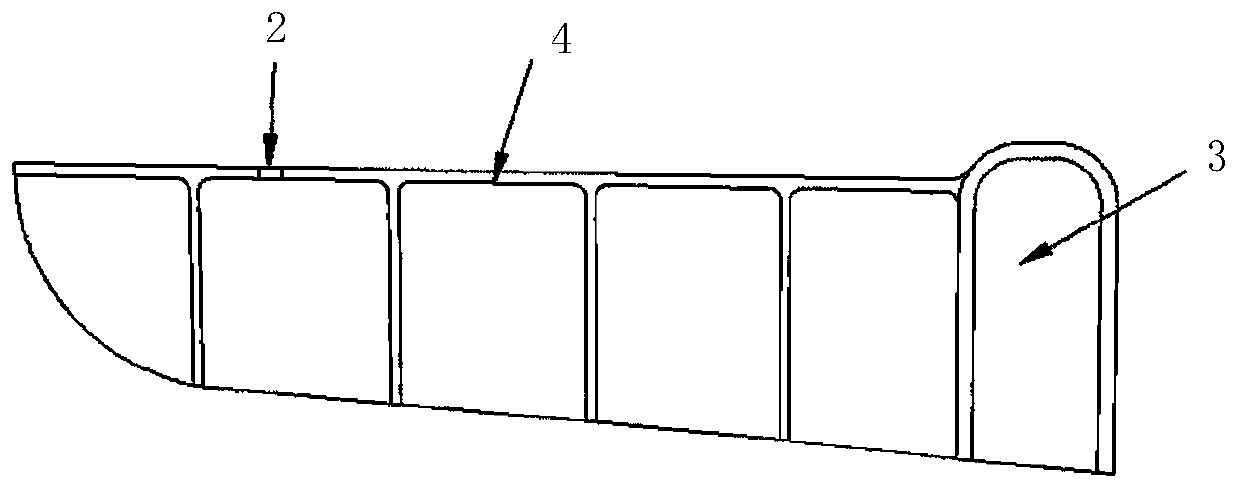

Aero-engine rib plate type part repairing method

InactiveCN110977323ASolve the problem of repair rateReduce production pressureAircraft componentsShielding gas supply/evacuation devicesWeld seamPerformance recovery

The invention discloses an aero-engine rib plate type part repairing method, and belongs to the technical field of aero-engine part performance recovery. The aero-engine rib plate type part repairingmethod comprises the following steps: S1, part inspection is conducted, specifically, fluorescence inspection is conducted on rib plate type parts with cracks, and the positions and the lengths of thecracks are determined; S2, cracks are removed and polished, a through groove with the width ranging from 1 mm to 1.5 mm is polished in the length direction of the cracks, grooves are formed in the two sides of the through groove in the length direction, and oxides on the surfaces of the grooves and the peripheral surfaces of the grooves are removed; S3, welding repair is conducted, and direct-current fast-frequency pulse welding is adopted; S4, heat treatment for eliminating welding stress is conducted; and S5, post-welding inspection is conducted, specifically, fluorescence inspection and X-ray inspection are conducted on each weld joint. The aero-engine rib plate type part repairing method is effective, reliable, high in operability, stable in welding parameter and simple in process, and the problem of crack repairing of aero-engine rib plate type parts can be effectively solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

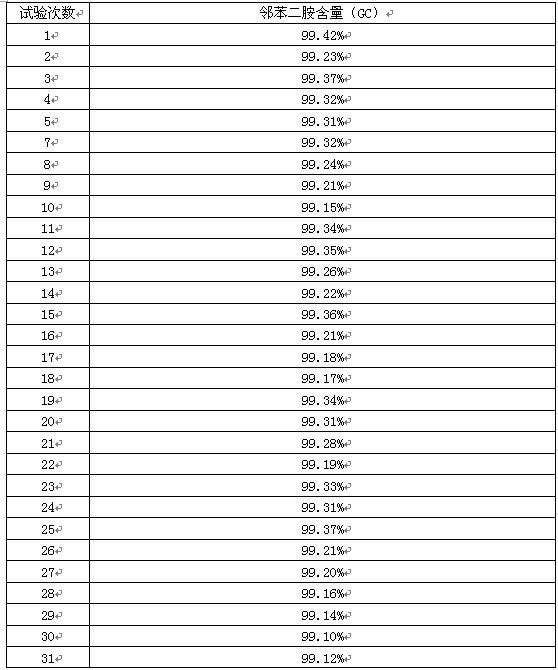

O-phenylenediamine preparation process by means of hydrogenization with nano nickel serving as catalyst

InactiveCN102633654ASolve the problem of a large amount of organic wastewater produced by reductionReduce corrosionOrganic compound preparationAmino compound preparationChemical industryOrtho-nitroaniline

The invention discloses an o-phenylenediamine preparation process by means of hydrogenization with nano nickel serving as a catalyst. The o-phenylenediamine is prepared by means of reduction process with ortho-nitroaniline serving as a raw material and alcohol serving as solvent. The process is characterized in that nano nickel and hydrogen which serve as catalysts are added during reaction, the hydrogen pressure ranges from 0.5MPa to 1.5MPa, the reaction temperature is below 30-80 DEG C, and the o-phenylenediamine is obtained by rectification after reduction for 0.5-10h. By means of the nano nickel catalyst with the patent application number being 201110059900.X and made by Jiangsu Kangheng chemical industry Co.,Ltd, the problem of a great quantity of organic waste water generated in reduction of iron powder or sodium sulfide in the traditional art is solved. The hydrogenization process avoids concentrated acid and concentrated base which are used in the traditional art, so that equipment corrosion is greatly reduced, pollution is reduced, and approximate zero pollution is achieved. Further, product yield and quality are improved, equipment production efficiency is improved, and energy consumption is greatly reduced.

Owner:JIANGSU KANGHENG CHEM

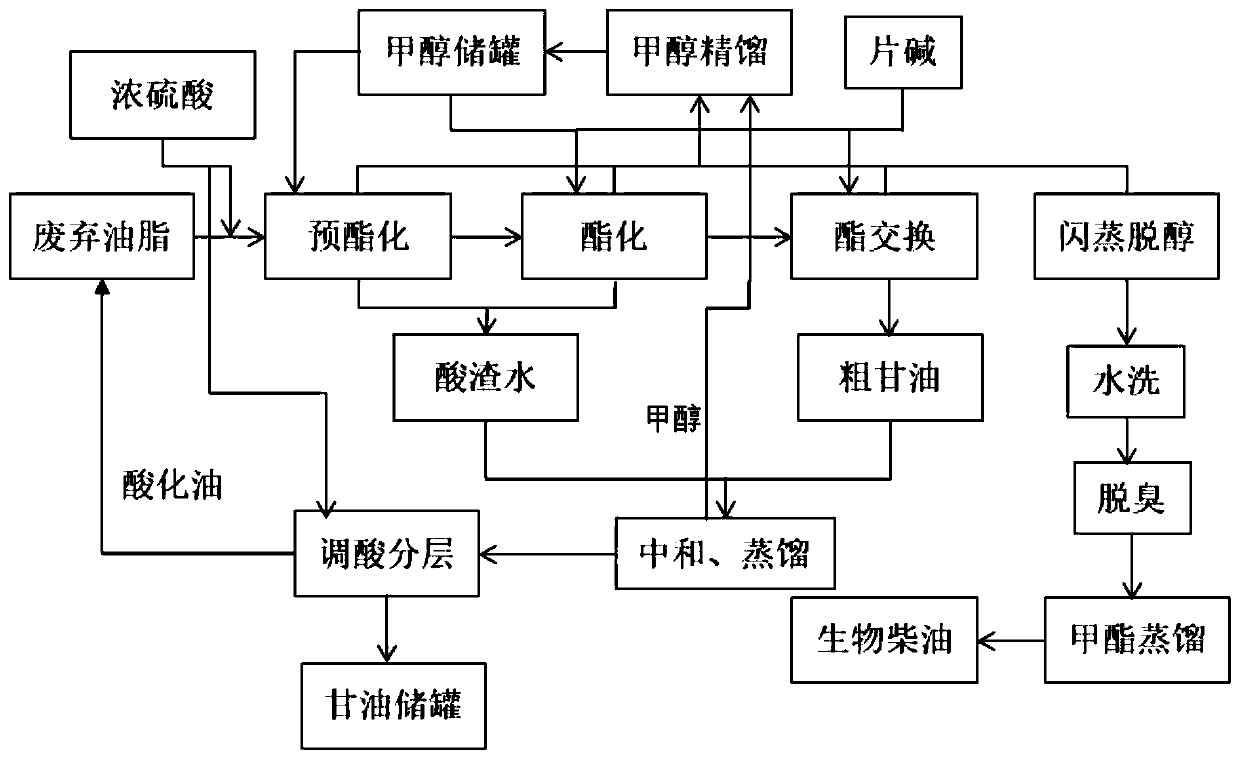

Green production process of biodiesel

ActiveCN111019720AEfficient removalReduce production pressureFatty acid esterificationFatty acids production/refiningOil and greaseBiodiesel

The invention discloses a green production process of biodiesel. The green production process comprises the following steps: (1) pre-esterification; (2) an esterification reaction; (3) an ester exchange reaction; (4) flash evaporation for dealcoholization; (5) washing; (6) deodorizing; and (7) distilling: conveying acid sludge water and crude glycerol into a neutralization kettle for a neutralization reaction, evaporating out methanol after the neutralization reaction is completed, feeding evaporated methanol into a methanol rectifying tower, adding concentrated sulfuric acid to adjust a pH value of a neutralized product having undergone methanol removal to 6-6.5, carrying out standing for layering, allowing glycerin at a lower layer to enter a glycerin storage tank, and allowing acidifiedoil at an upper layer to enter a waste oil storage tank and to be reused as a raw material. According to the method, impurities in the raw materials can be effectively removed, the production pressure of a subsequent process is reduced, product quality is improved, acid the sludge water and saponified grease can be recycled, and environmental protection pressure and production cost are reduced.

Owner:浙江卓尚环保能源有限公司

Method for efficiently using converter precipitator dust

InactiveCN106282475AReduce the phosphorus content in the furnacePromote rapid slaggingManufacturing convertersProcess efficiency improvementSlagLiquid surfaces

The invention discloses a method for efficiently using converter precipitator dust, belongs to the technical field of converter steel making methods, and is used for efficient reuse of the precipitator dust. The method is characterized in that the precipitator dust is added along with a chute in the process of extracting vanadium to discharge from semisteel; when the vanadium is extracted to discharge from the semisteel by 1 / 5, a secondary dust removing valve is opened; the chute rotates to add the precipitator dust by one time or two times; after the precipitator dust is added, the precipitator dust is accelerated to melt through front-back movement; the dust removing valve is recovered to a normal state; and after the semisteel is discharged, the iron mixing for converter steel making is prepared. The precipitator dust totally covers the liquid surface of the semisteel to achieve the effect of inhibiting the smoke discharge; the pecipitator dust is molten in a semisteel ladle to form slag to improve the difficulties of making steel slag by the semisteel; and the problems of non-ignition of a converter and explosion venting of an electric field in direct returning of the precipitator dust along with waste steel are solved. The method is an initiate in converter steel making, solves the problem, of capability of effectively using the precipitator dust, not thoroughly solved for a long time, and has the advantages of short flow, high metal yield and low cost.

Owner:HEBEI IRON AND STEEL

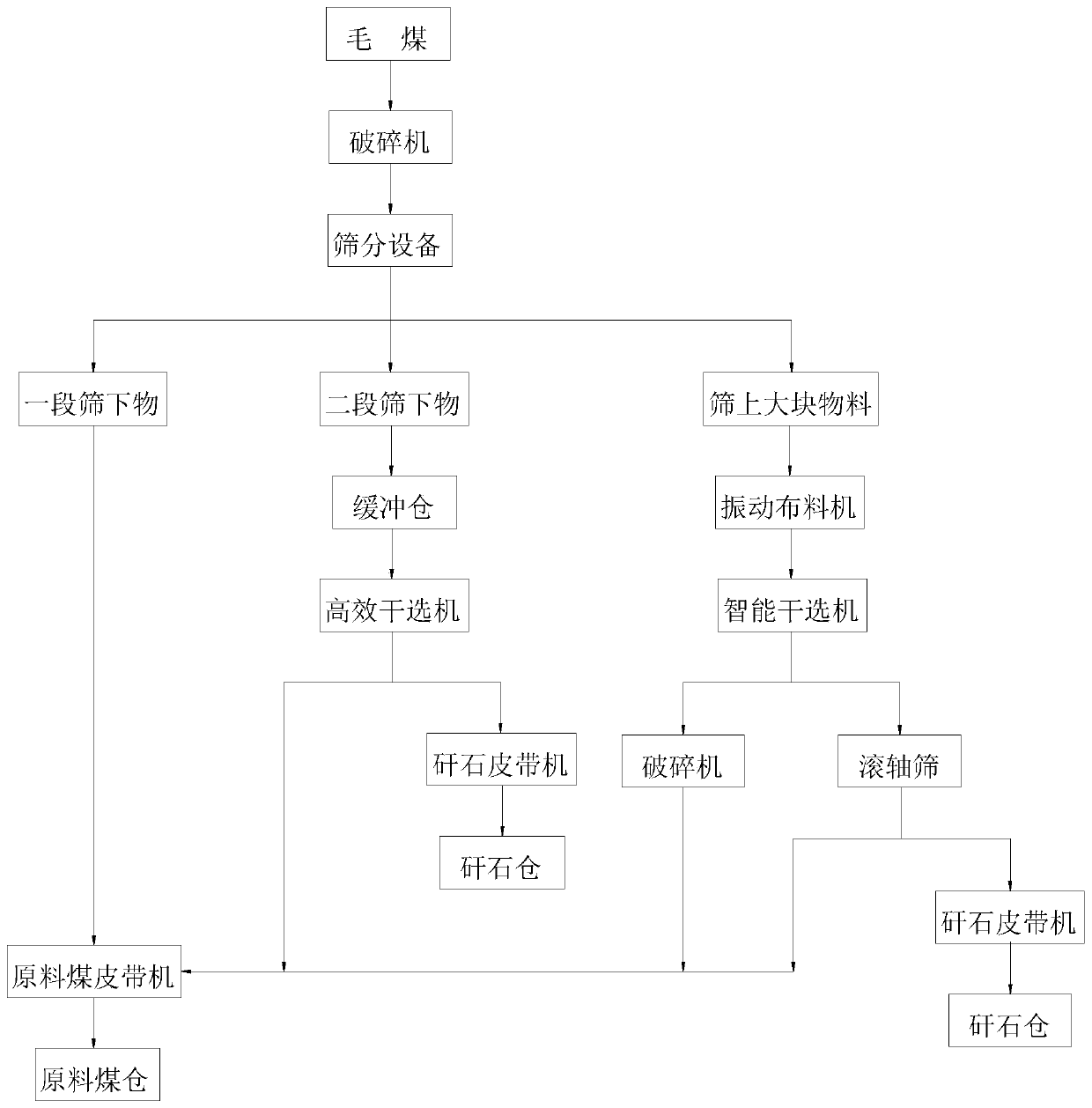

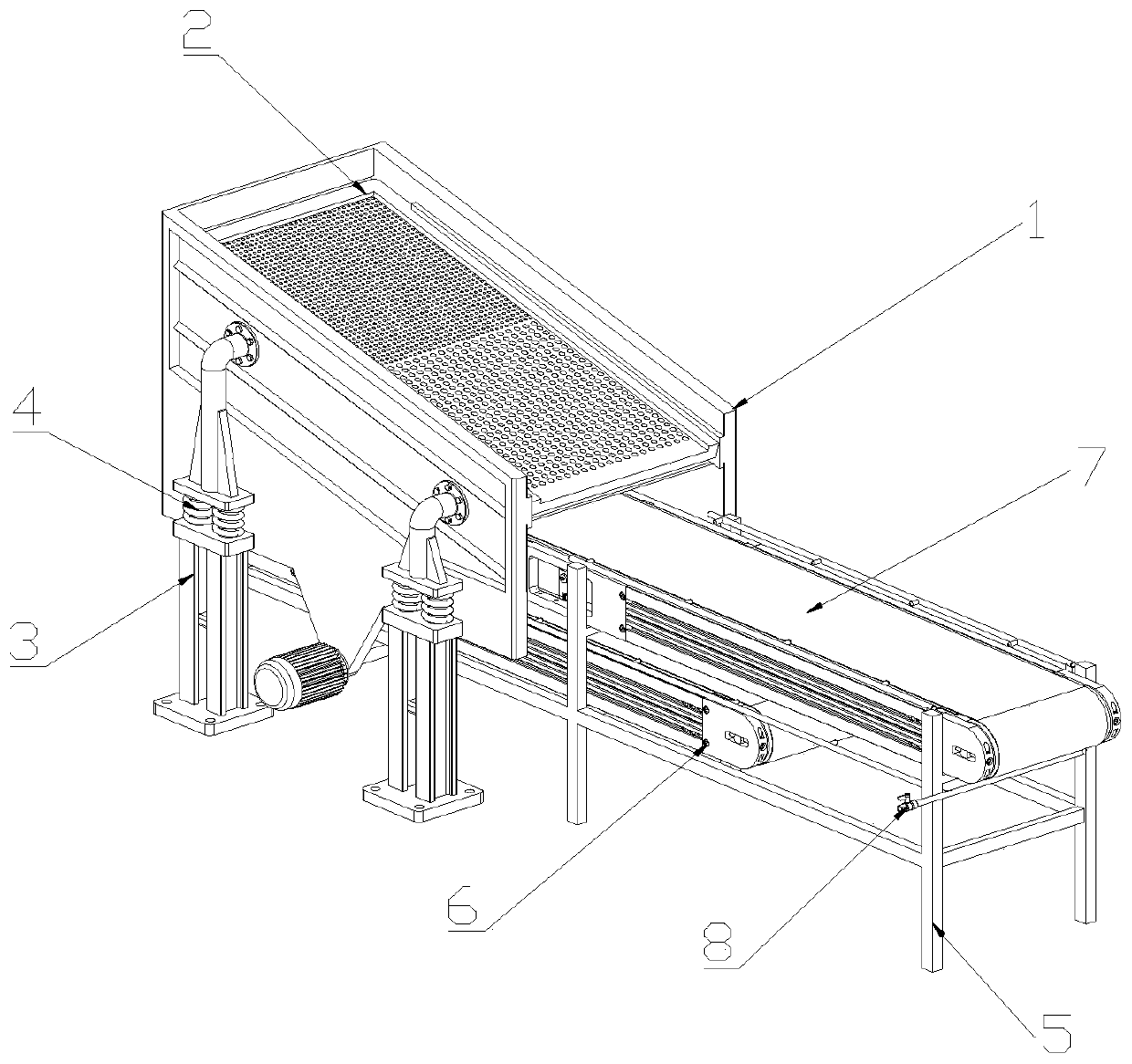

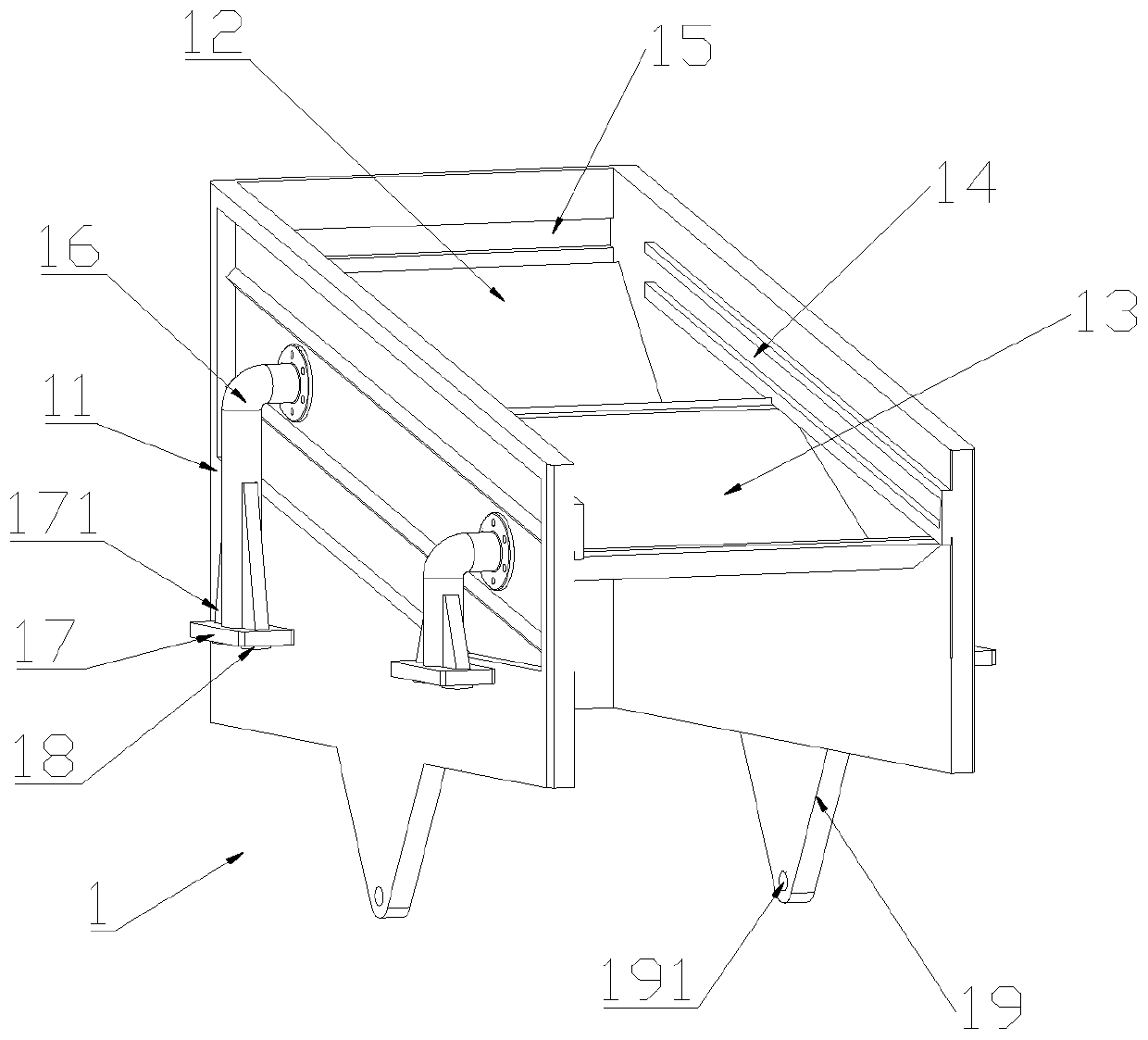

Gangue pre-discharging process for selecting coking coal as raw coal and screening device thereof

ActiveCN111298940AReduce production pressureSave on shippingSolid separationGrain treatmentsMining engineeringProcess engineering

The invention discloses a gangue pre-discharging process for selecting coking coal as raw coal and a screening device thereof. The gangue pre-discharging process comprises the processes of crushing, screening grading, separating and discharging gangue, performing screen underflow treatment and performing gangue discharging on second-stage screen underflow; the screening device comprises a first supporting frame; a polyurethane screen body is arranged on the first supporting frame; supporting feet which are distributed in arrays are arranged below the first supporting frame; elastic pieces which are distributed symmetrically are arranged on the supporting feet; a second supporting frame is arranged below the first supporting frame; and a first belt conveyor and a second belt conveyor are arranged on the second supporting frame. According to the gangue discharging process disclosed by the invention, the ash content of the raw coal of a mine is reduced; part gangue is discharged; the production pressure of a coal preparation plant for the coking coal is lightened; the transportation expense and the expense for re-screening are reduced; the screening device is skillfully provided withtwo stages of different screen holes, so that materials with three grain grades are graded by single equipment; the plant layout height is reduced; the investment in infrastructure is reduced; and a process flow is simplified.

Owner:ANHUI UNIV OF SCI & TECH

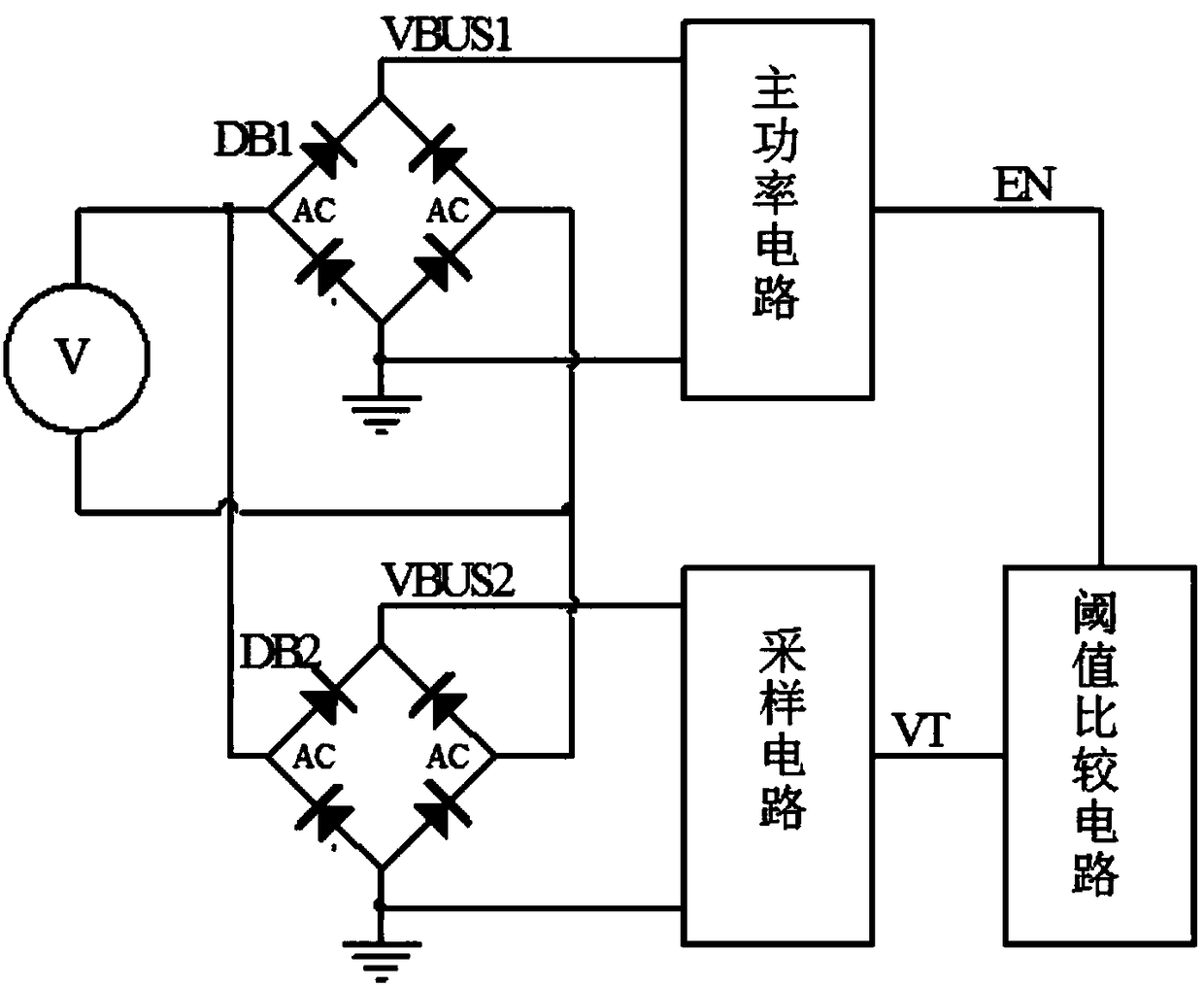

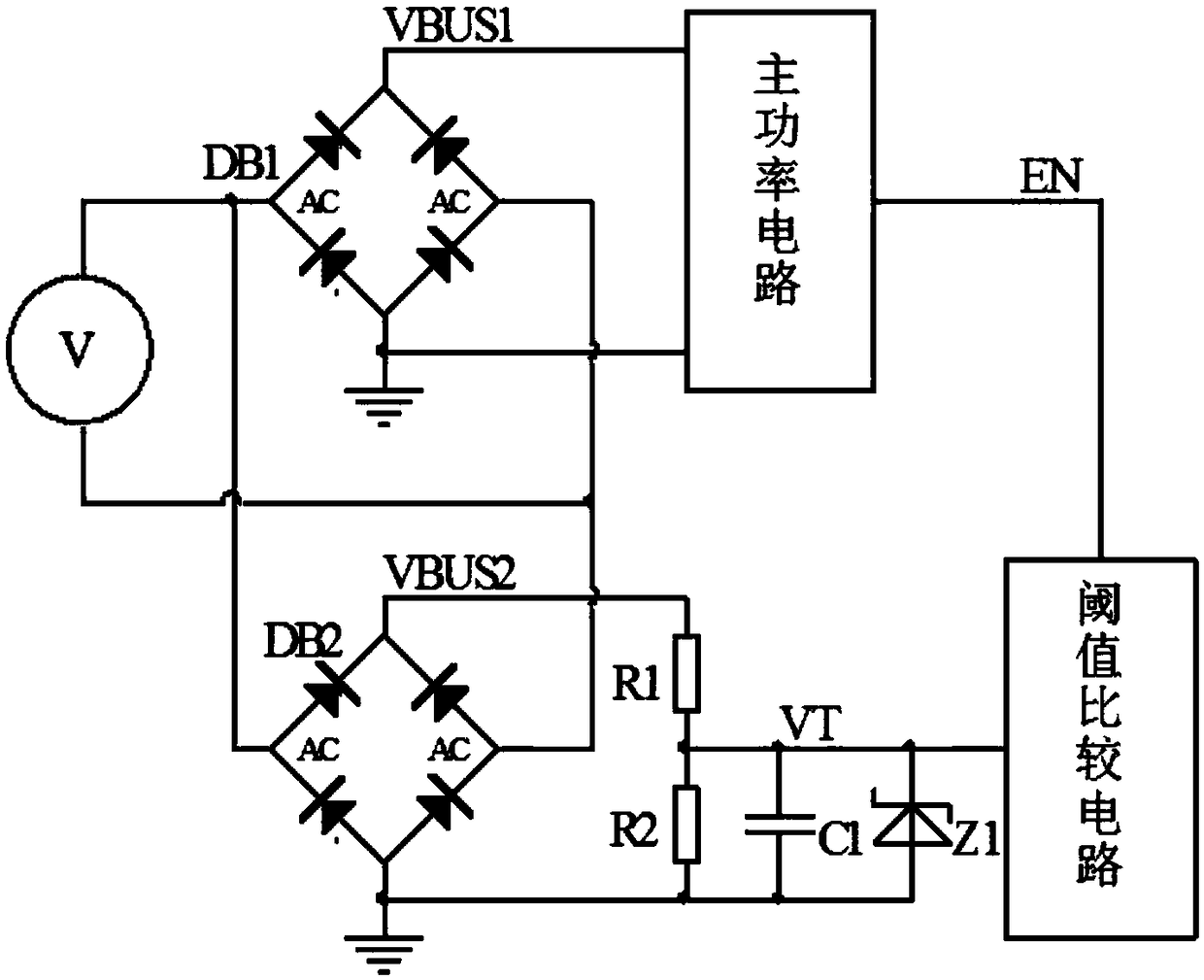

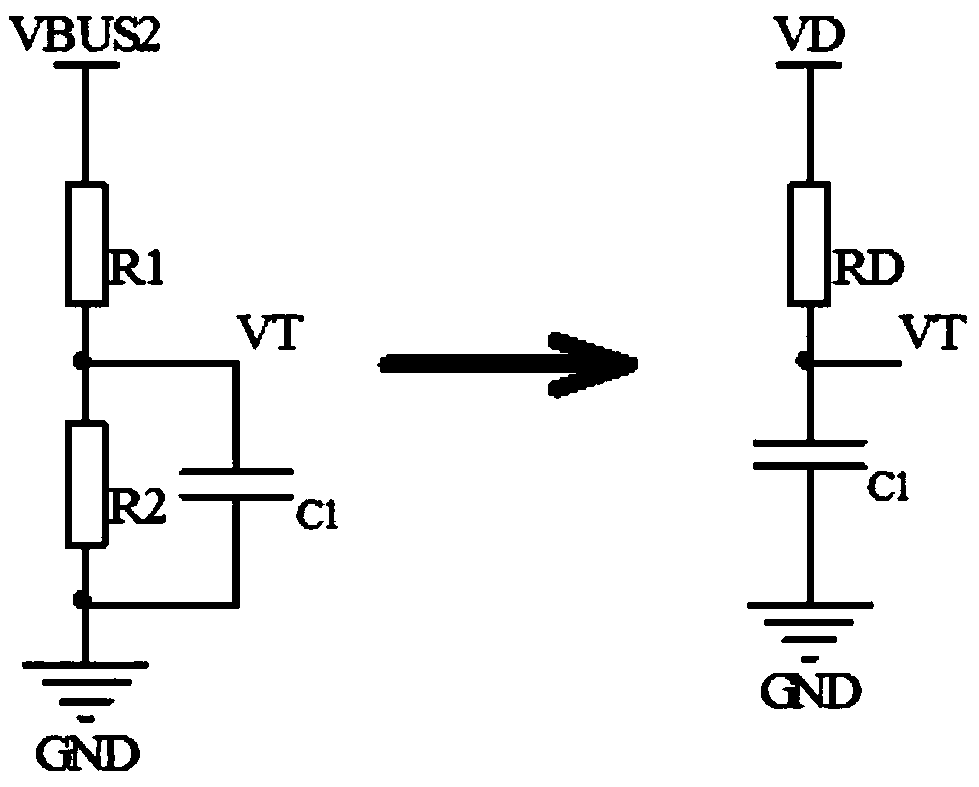

Contactor power saver detecting circuit

PendingCN108387810AAchieve universalReduce production pressureElectric connection testingRelaysEngineeringPeak value

The invention discloses a contactor power saver detecting circuit. On the basis of the existing contactor power saver circuit composed of a rectifier bridge and a main power circuit, a rectifier circuit, a sampling circuit and a threshold comparison circuit are additionally provided. The threshold comparison circuit is internally provided with a reference 1 and a reference 2. When the peak voltageof an output signal of the sampling circuit is greater than the reference 1, the main power circuit is controlled to work, and a contactor is closed; when the peak voltage of the output signal of thesampling circuit is less than the reference 2, the main power control circuit is switched off, and the contactor is released; it is required that the peak voltage of the output signal of the samplingcircuit when input voltage is AC is equal to the peak voltage of the output signal of the sampling circuit when the input voltage is DC, so that a voltage point that triggers action of the contact isenabled to be the same. Therefore, the object that attracting and releasing voltage points of the wide-input-voltage contactor are consistent under AC / DC input voltages is achieved, and the circuit is simple and easy to use, thereby finally realizing the universality of the AC / DC contactor power saver product, and reducing the production and inventory pressure of the manufacturer.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

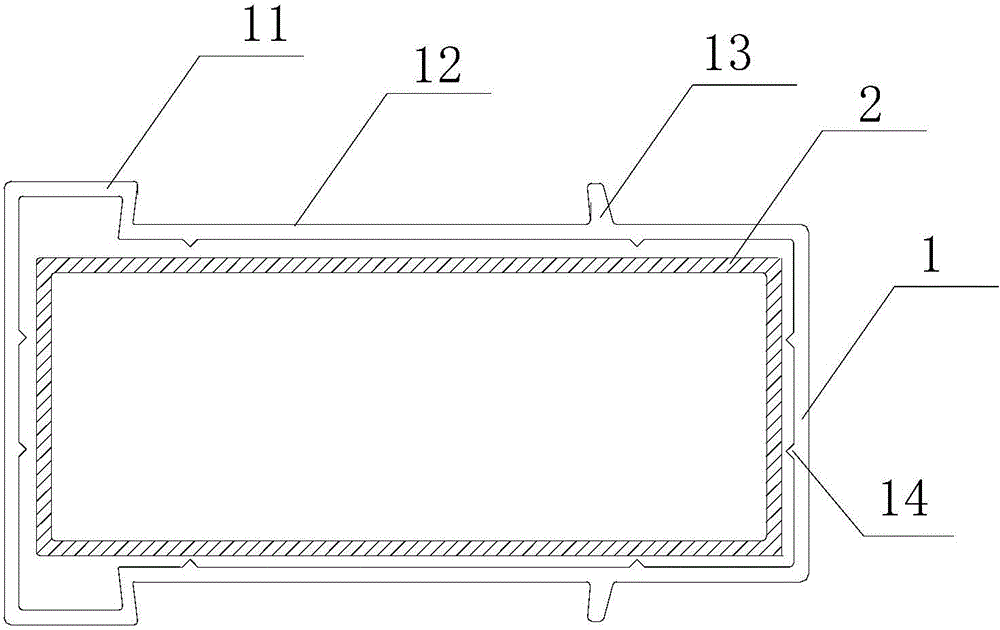

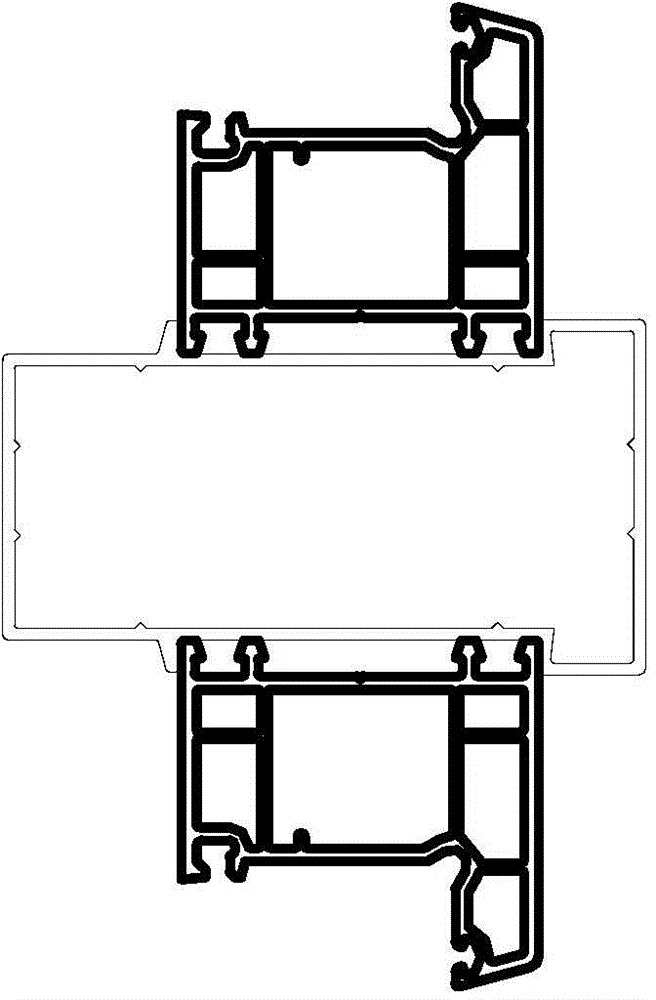

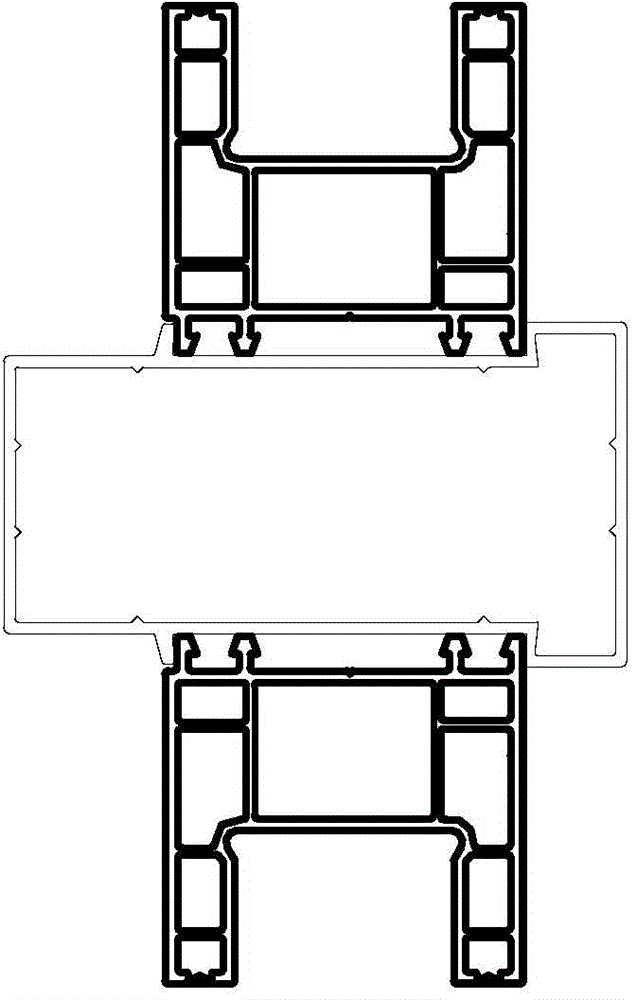

Universal spliced tube for plastics doors and windows and profiles using spliced tube

The invention discloses a universal spliced tube for plastics doors and windows and profiles using the spliced tube. The spliced tube comprises a plastic frame and a steel liner positioned in the plastic frame, wherein the section of the plastic frame comprises a spliced claw and a frame body which are integrally shaped; the spliced claw is higher than the frame body; the section of the plastic frame is integrally T-shaped; raised fixture blocks are respectively arranged at two sides of the frame body. The plastic frame and the profiles are consistent in material, large in pressure bearing, and difficult to deform. The inner chamber steel liner adopts the common square tubes on the market; the steel liner does not need special customization and processing. The spliced claw and fixture blocks of the spliced tube can be excellently matched with 60 side hung, 60 push-and-pull, 80 push-and-pull and 90 push-and-pull door and window series.

Owner:安徽科苑门窗工程有限公司

Medium smelting cohesion primary directional solidification process applied to purifying polycrystalline silicon

InactiveCN103553049AReduce manufacturing costAvoid wastingChemical industrySilicon compoundsSlagMetal impurities

The invention belongs to the field of polycrystalline silicone purification, and in particular relates to a medium smelting cohesion primary directional solidification process applied to purifying polycrystalline silicon. The process comprises medium smelting which comprises the steps of reacting a to-be-purified silicon block with a slag remover to remove boron impurity in the silicon, the process is characterized in that a silicon solution is placed in a primary directional solidification device under atmospheric condition after the medium smelting is finished, the metal impurity in the silicon solution is gathered at the top to remove by adopting a manner of water-cooling and pulling an ingot at the bottom. The primary directional solidification process has the advantages of being short in period, high in production efficiency, simple in process, saving in energy and low in cost.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

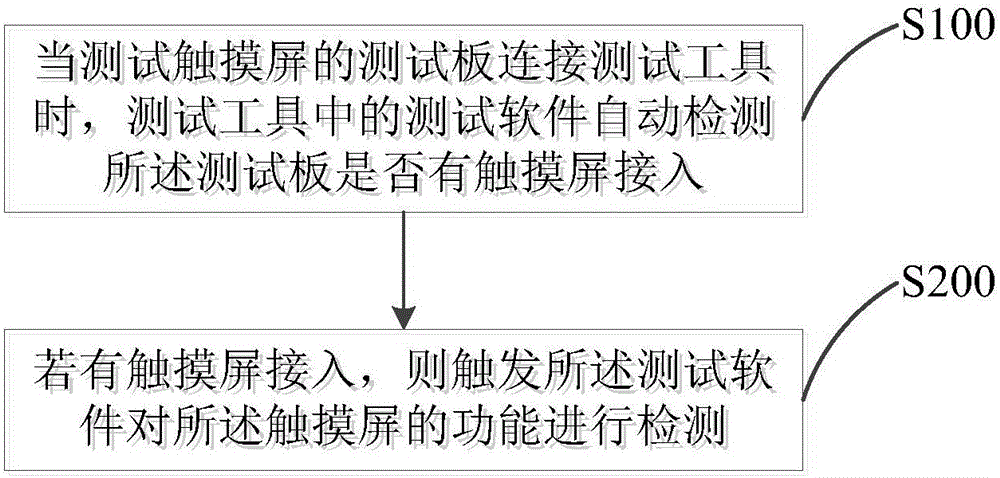

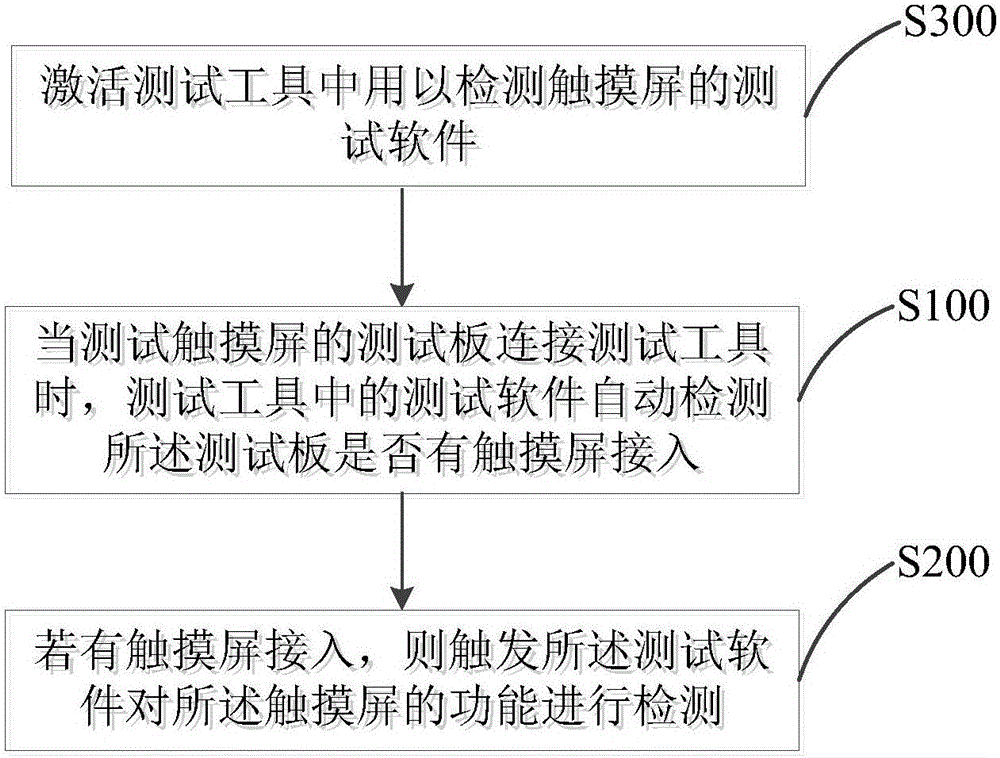

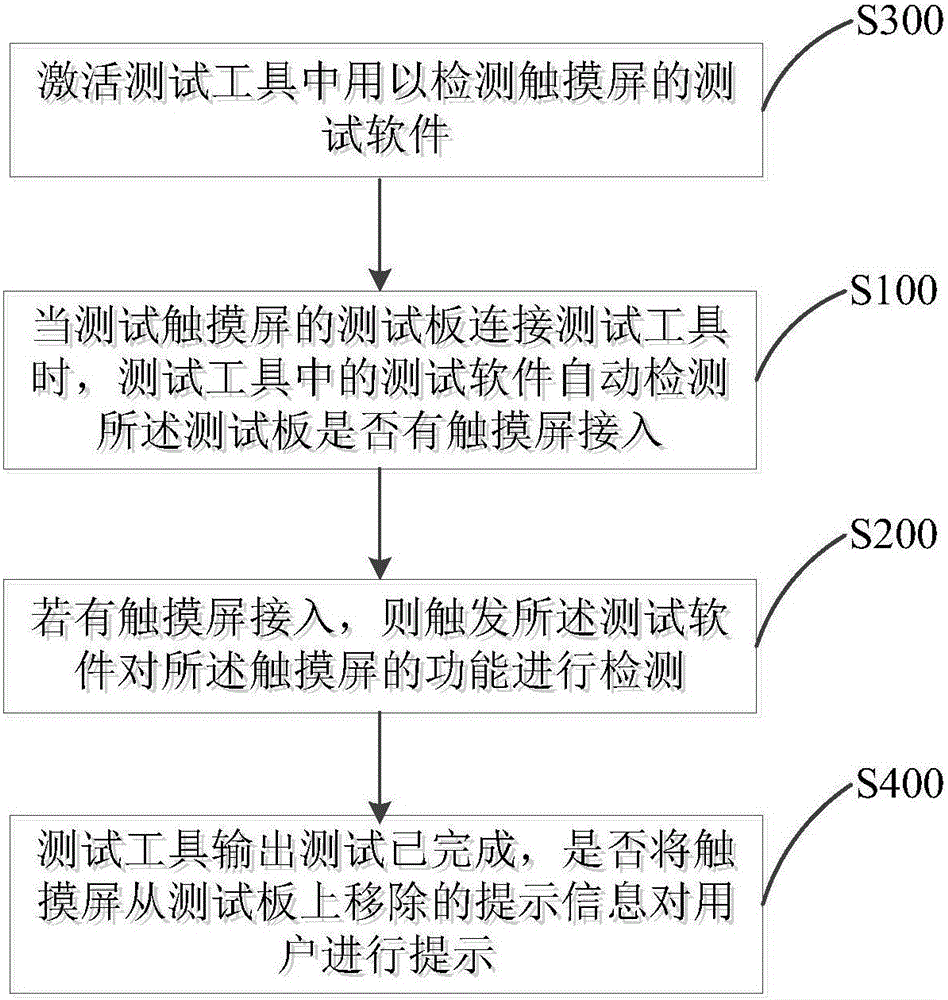

Touch screen automatic test method and touch screen automatic test system

InactiveCN106249092AAvoid connection statePrevent omission of recordsElectrical testingAutomatic test equipmentComputer science

The invention provides a touch screen automatic testing method and system, and relates to the technical field of touch screen testing. Wherein, the automatic testing method comprises: when the test board of test touch screen is connected with test tool, the test software in test tool automatically detects whether described test board has touch screen access; If there is touch screen access, then trigger described test software to all The function of the touch screen is tested. The invention avoids the operator from manually confirming the connection state of the touch screen through the mouse, improves the production efficiency, effectively prevents personnel from missing records on the touch screen, and eases the pressure on production capacity when multiple touch screens are detected.

Owner:SHENZHEN JUNDA OPTOELECTRONICS

Novel LED lamp comprising lamp shell

InactiveCN108458263AReduce production pressureReduce lamp costPlanar light sourcesElectric circuit arrangementsLamp shellLed driver

The invention discloses a novel LED lamp comprising a lamp shell. The lamp shell is internally and fixedly connected with an LED driver and LED lamp bar plates. The LED lamp bar plates are of a multi-segment structure. The LED lamp bar plates are connected in an end-to-end manner to form a round or a rectangle or are arranged side by side. The LED lamp bar plates can surround the outer side of theLED driver. The head and the tail of each LED lamp bar plate are both provided with connection joints, the connection joints can be rapidly connected with a power line so that the multiple LED lamp bar plates can form a current loop to be lightened. The LED driver comprises a shell and a drive circuit contained in the shell. The shell is provided with a notch. The drive circuit is provided with apower source and a grounding wiring terminal. The power source and the grounding wiring terminal can be exposed through the notch. The LED lamp bar plates are designed in a multi-segment combinationmanner and can be spliced and assembled according to different LED lamp shells to adapt to various lamp shells, an enterprise does not need to design the LED lamp bar plates to correspond to the lampshells one by one, the production pressure is reduced for the enterprise, and meanwhile, the lamp cost is reduced.

Owner:海宁福得电器有限公司

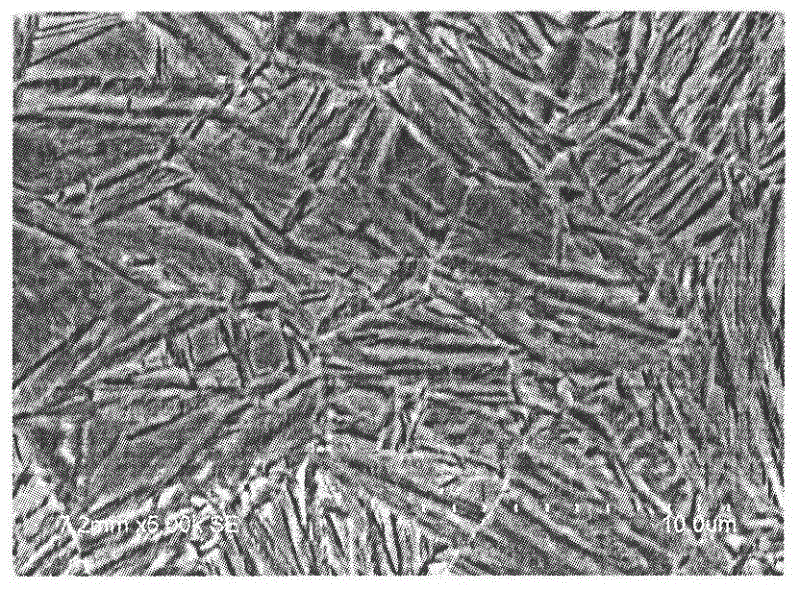

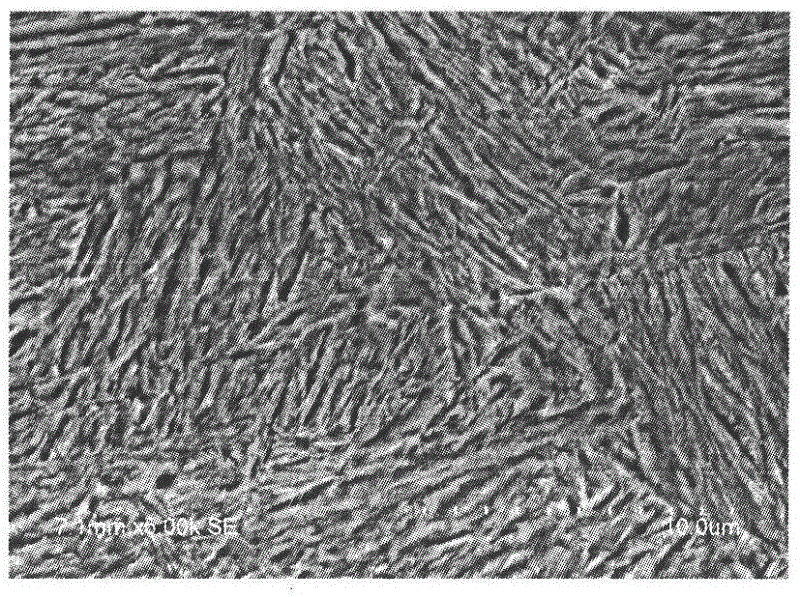

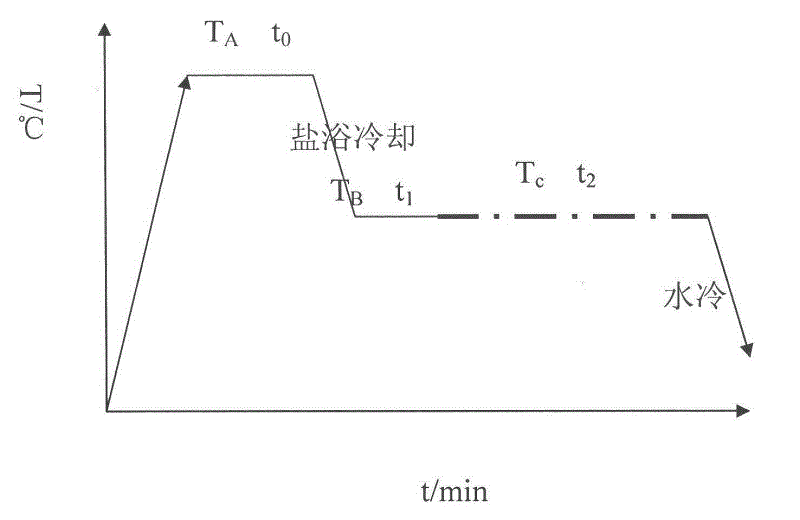

Si-containing medium carbon steel and thermal treatment method for Si-containing medium carbon steel to obtain high strength and elasticity

Owner:SHOUGANG CORPORATION

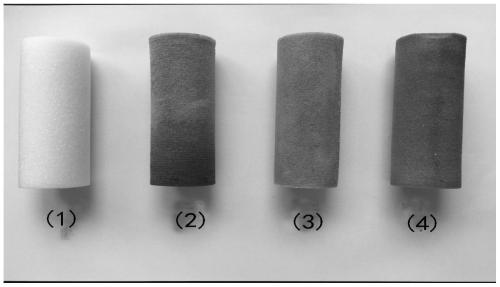

A kind of dyeing method of denim fabric

The invention discloses a dying method of jeans fabric which relates to a pre-spinning dying process of the fiber materials of jeans fabric. The dying process comprises the steps of pretreating, dying and post-treating steps. The fiber materials of the jeans fabric is the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15%. The method provided by the invention is the dying process of the fiber materials for the jeans fabric manufacturing which uses the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15% as the fiber materials. The materials undergo the fiber dying process and spinning process and the like to become the jeans fabric. The method is helpful to solve the problems of low yielding rate and non-fulfillment of environment protection requirements which at present is prevailing in the prior art of jeans fabrics manufacturing process. The method can be widely applied and promoted.

Owner:YIBIN SPARK NEW FIBER CO LTD

Jeans fabric and dying method thereof

The invention discloses a dying method of jeans fabric which relates to a pre-spinning dying process of the fiber materials of jeans fabric. The dying process comprises the steps of pretreating, dying and post-treating steps. The fiber materials of the jeans fabric is the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15%. The method provided by the invention is the dying process of the fiber materials for the jeans fabric manufacturing which uses the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15% as the fiber materials. The materials undergo the fiber dying process and spinning process and the like to become the jeans fabric. The method is helpful to solve the problems of low yielding rate and non-fulfillment of environment protection requirements which at present is prevailing in the prior art of jeans fabrics manufacturing process. The method can be widely applied and promoted.

Owner:YIBIN SPARK NEW FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com