Automatic feeding and discharging robot unit for automatic machining equipment and method

A technology for automatic loading and unloading and processing equipment, applied in the field of robots, can solve the problems of limiting the production capacity of production equipment, high labor intensity of operators, and high error rate of manual loading and unloading, achieving automatic operation, saving manpower and material resources, and ensuring universality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

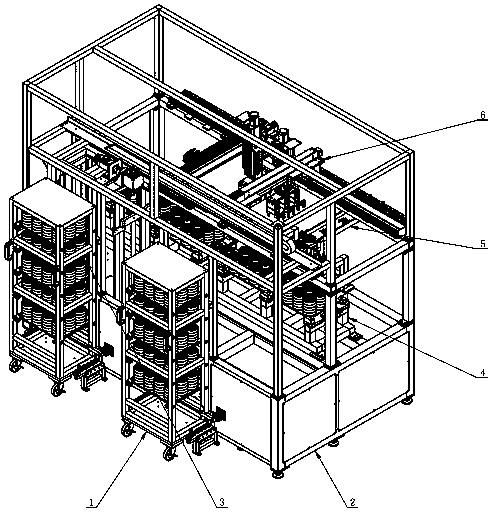

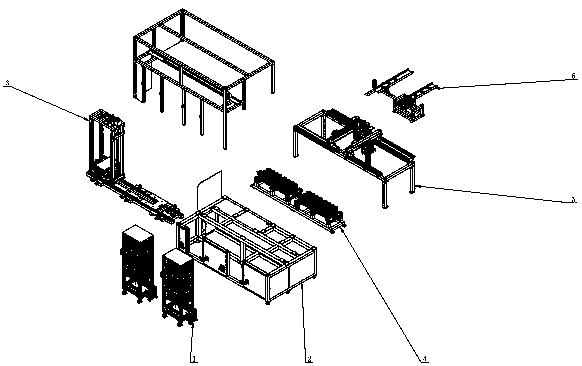

[0041] see Figure 1-10 , the automatic loading and unloading robot unit used for automatic processing equipment, including equipment frame 2, material trolley 1, pallet servo component 3, station pallet raceway 4, dual three-axis robot component 5, loading and unloading conveyor belt 6 and the general control device7.

[0042] It is characterized in that there are two cargo trolleys, which are side by side and detachably fastened on the front side of the equipment frame 2; the tray servo assembly 3 is installed in the front lower part of the equipment frame 2; the station tray raceway 4 is installed in the middle of the equipment frame 2; the double-three-axis robot assembly 5 is installed in the rear upper part of the equipment frame 2; the loading and unloading conveyor belt 6 is fixedly connected to the rear side of the equipment frame 2; Connect and control the material trolley 1, the pallet servo component 3, the station pallet raceway 4, the dual-three-axis robot compo...

Embodiment 2

[0045] see Figure 1-10 , an automatic loading and unloading robot unit for automatic processing equipment, including a material trolley 1, an equipment frame 2, a pallet servo assembly 3, a station pallet raceway 4, a double-three-axis robot assembly 5, and a loading and unloading conveyor belt 6.

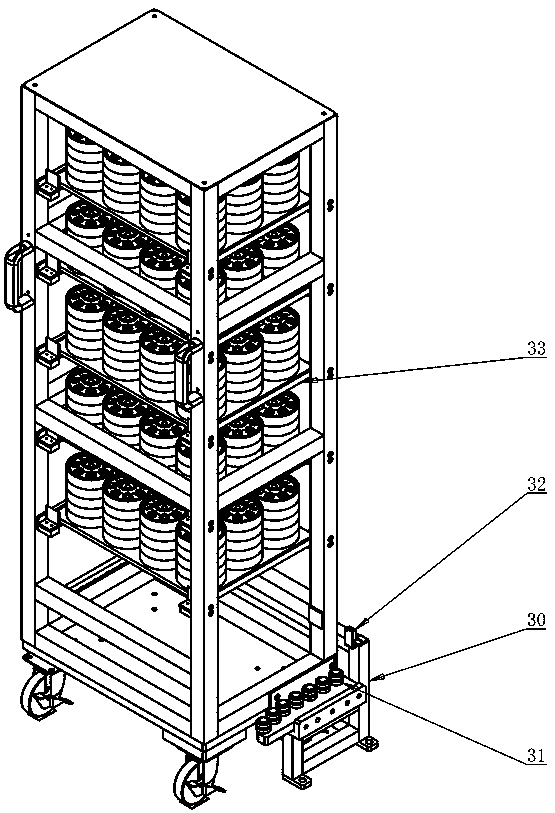

[0046] It is characterized in that the cargo trolley 1 is placed at the front of the equipment, and is used to hold cargo pallets and transport OEM products. A wheel centering mechanism 30 is arranged under the cargo trolley 1, and the wheel The centering mechanism 30 is connected to the equipment frame 2, the front bottom beam of the equipment frame 2 is connected to the pallet servo assembly 3, the bottom of the station pallet raceway 4 is connected to the bottom beam of the equipment frame 2, and the double The bottom of the three-axis robot assembly 5 is connected to the rear column of the equipment frame 2, and the loading and unloading conveyor belt 6 is connected to the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com