Method for manufacturing nano-filtration membrane filter

A manufacturing method and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as low production efficiency, long binder coagulation time, damage to hollow fiber membranes, etc. The effect of initial potting time, shortening production time, and relieving production pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

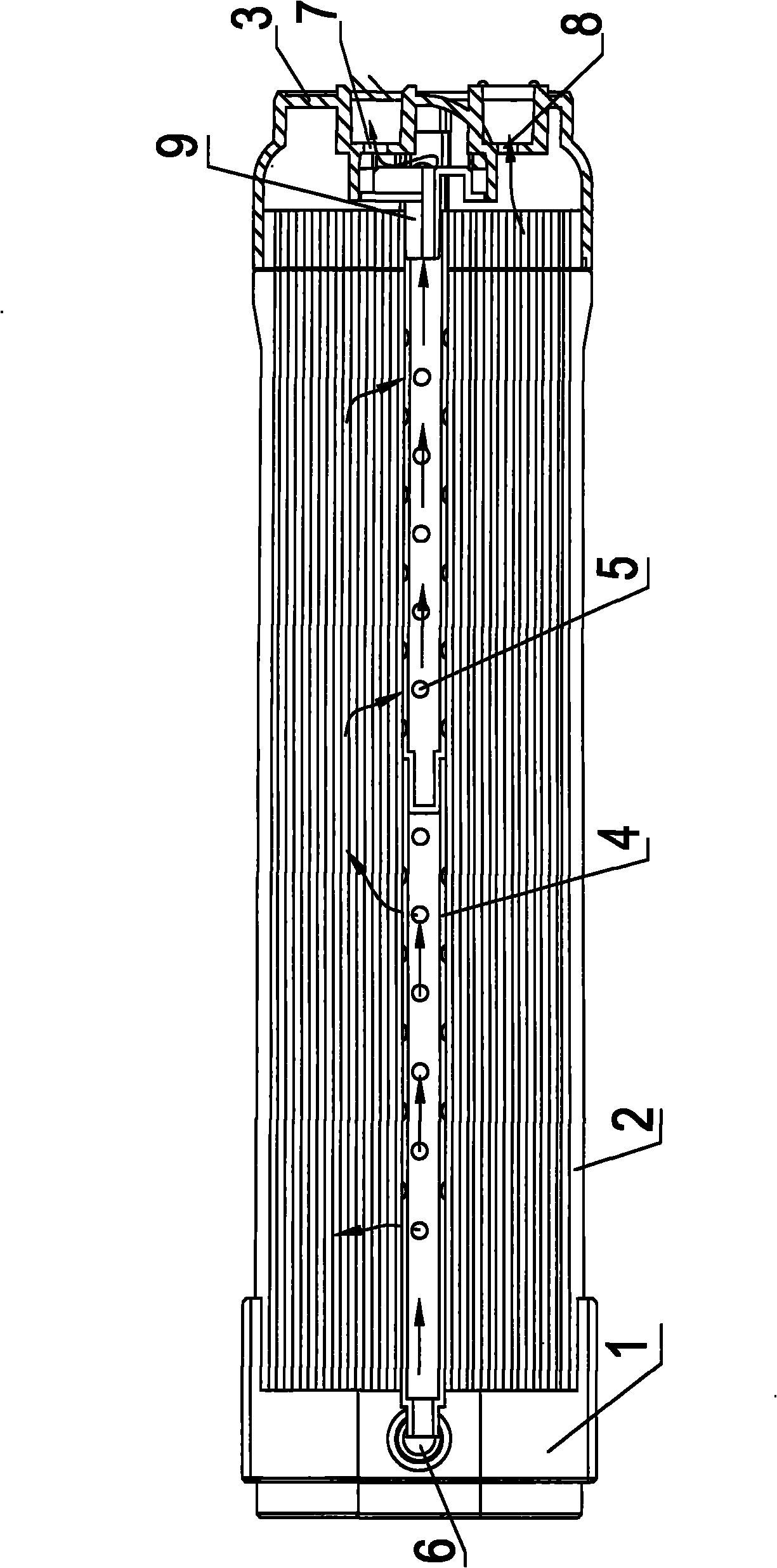

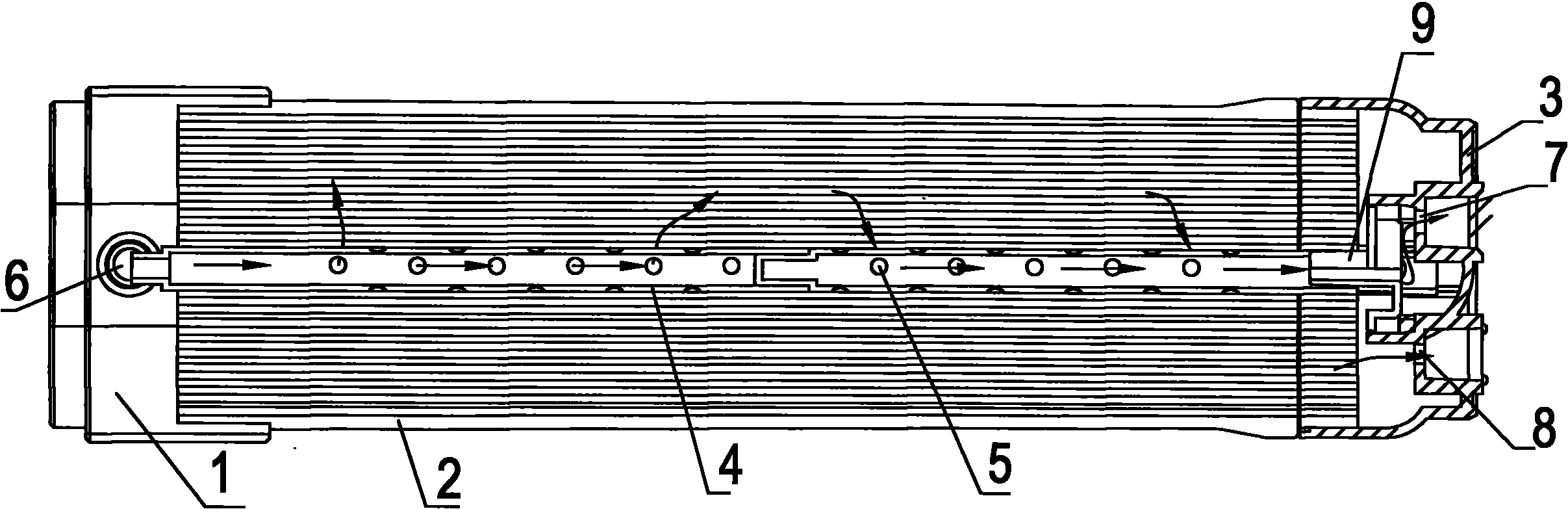

[0016] A method for making a nanofiltration membrane filter, wherein the nanofiltration membrane uses cellulose triacetate as the membrane material, and the specific steps include:

[0017] The first step: a plurality of hollow fiber nanofiltration membranes are arranged in parallel to form a hollow fiber bundle, and the water outlet end of the hollow fiber bundle is potted with ultraviolet glue, so that each hollow fiber nanofiltration membrane is located at the end of the water outlet side. All parts are filled with the above-mentioned ultraviolet glue, and the letter "D" is used to indicate the length of the ultraviolet glue potting in the hollow fiber nanofiltration membrane; because the gaps between multiple hollow fiber nanofiltration membranes will also be filled during the glue filling process. In order not to affect the sealant in the second glue filling process into the gap between the hollow fiber nanofiltration membranes, the water outlet ends of the hollow fiber bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com