Gangue pre-discharging process for selecting coking coal as raw coal and screening device thereof

A technology for coking coal and raw materials, which is applied in the field of pre-discharging process of coking coal into raw coal and its screening device, which can solve the problems of increasing the process of coal slime water treatment, affecting the separation accuracy of the process, and coal with gangue, so as to save more time Sorting costs, reducing infrastructure investment, and reducing the effect of layout height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

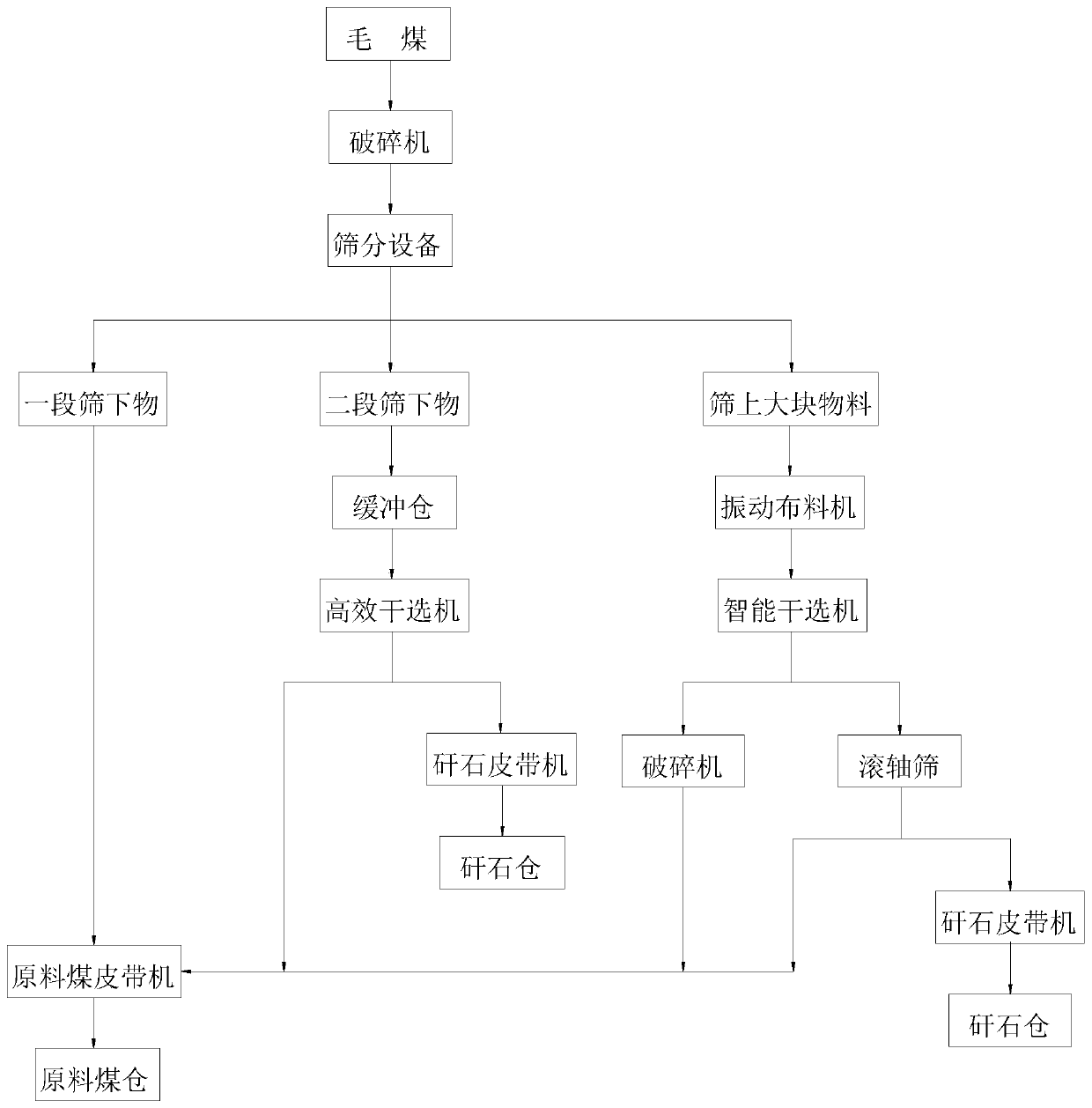

[0044] A process of pre-discharging gangue for selected raw material coal of coking coal. The pre-discharging process includes: crushing, screening and grading, separation and discharge of gangue, treatment of under-screen objects and second-stage under-screen object discharge, such as figure 1 Shown, the concrete steps of described technology are as follows:

[0045] S1: Broken

[0046] The raw coal mined in the mine is transported by the lifting equipment into the double-toothed roller crusher of the ground production system, and the output particle size of the double-toothed stick crusher is 100mm.

[0047] S2: Screening and classification

[0048] The crushed raw coal enters the screening and grading equipment, and the screening and grading equipment performs segmental screening. The size of the first-stage sieve hole is 4.5mm, and the second-stage sieve size is 25mm. The raw coal is crushed and classified to obtain a 0-4.5mm first-stage sieve The material under the 4.5-...

Embodiment 2

[0057] A process of pre-discharging gangue for selected raw material coal of coking coal. The pre-discharging process includes: crushing, screening and grading, separation and discharge of gangue, treatment of under-screen objects and second-stage under-screen object discharge, such as figure 1 Shown, the concrete steps of described technology are as follows:

[0058] S1: Broken

[0059] The raw coal mined in the mine is transported by the lifting equipment into the double-toothed roller crusher of the ground production system, and the output particle size of the double-toothed stick crusher is 150mm.

[0060] S2: Screening and classification

[0061] The crushed raw coal enters the screening and grading equipment, and the screening and grading equipment performs sectional screening. The size of the sieve hole of the first stage is 6mm, and the size of the sieve hole of the second stage is 30mm. , 6-30mm secondary sieve material and 30-150mm sieve material.

[0062] S3: Sep...

Embodiment 3

[0070] A process of pre-discharging gangue for selected raw material coal of coking coal. The pre-discharging process includes: crushing, screening and grading, separation and discharge of gangue, treatment of under-screen objects and second-stage under-screen object discharge, such as figure 1 Shown, the concrete steps of described technology are as follows:

[0071] S1: Broken

[0072] The raw coal mined in the mine is transported by the lifting equipment into the double-toothed roller crusher of the ground production system, and the output particle size of the double-toothed stick crusher is 200mm.

[0073] S2: Screening and classification

[0074] The crushed raw coal enters the screening and grading equipment, and the screening and grading equipment carries out segmental screening. The size of the first-stage sieve hole is 13mm, and the second-stage sieve size is 40mm. After the raw coal is crushed and classified, the 0-13mm first-stage under-sieve material , 13-40mm se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com