Si-containing medium carbon steel and thermal treatment method for Si-containing medium carbon steel to obtain high strength and elasticity

A heat treatment method and high plasticity technology, which is applied in the field of medium carbon steel, can solve the problems of no heat treatment process reports, etc., and achieve the effects of process stability, process optimization, and good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

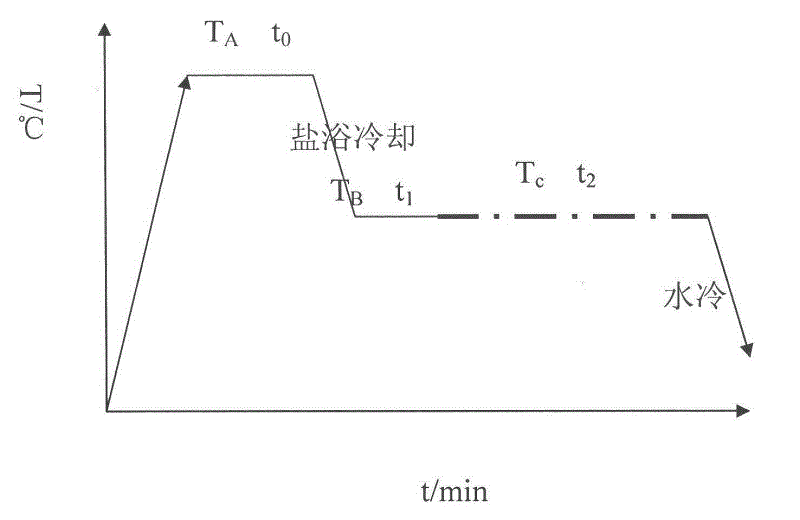

[0029] The heat treatment process is completed in three steps:

[0030] The first step, austenitizing treatment, is to heat the material to 850°C for 20 minutes in a conventional resistance furnace under air conditions, so that the material can obtain a uniform austenite structure.

[0031] The second step, salt bath treatment after austenitization, is to quickly cool the material from 850°C to the lower bainite transformation temperature range, and keep it warm for 40 seconds to obtain uniform supercooled austenite.

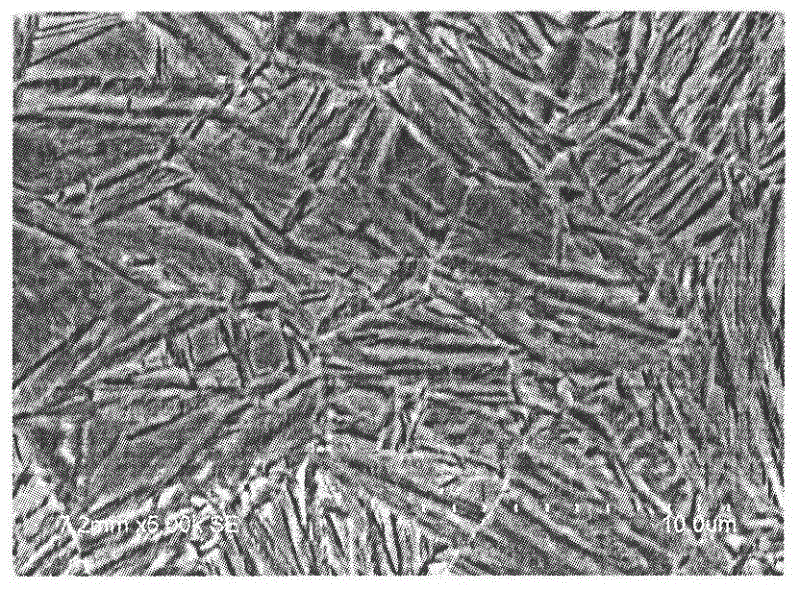

[0032] The third step is the transformation of lower bainite and stabilized austenite. The material cooled in the salt bath is placed in an air holding furnace at 300°C for 5 minutes, and the transformation of lower bainite and the stabilization of austenite (such as figure 1 and Figure 7 ), and then water-cooled to room temperature, the strength reaches about 1600Mpa, and the elongation is 10.8% ( Figure 4 ), the area shrinkage rate reaches 45% ( Figure 6...

Embodiment 2

[0035] The heat treatment process is completed in three steps:

[0036] The first step, austenitizing treatment, is to heat the material to 900°C for 10 minutes in a conventional resistance furnace under air conditions, so that the material can obtain a uniform austenite structure.

[0037] The second step, salt bath treatment after austenitization, is to quickly cool the material from 850°C to the lower bainite transformation temperature range, and keep it warm for 60 seconds to obtain uniform supercooled austenite.

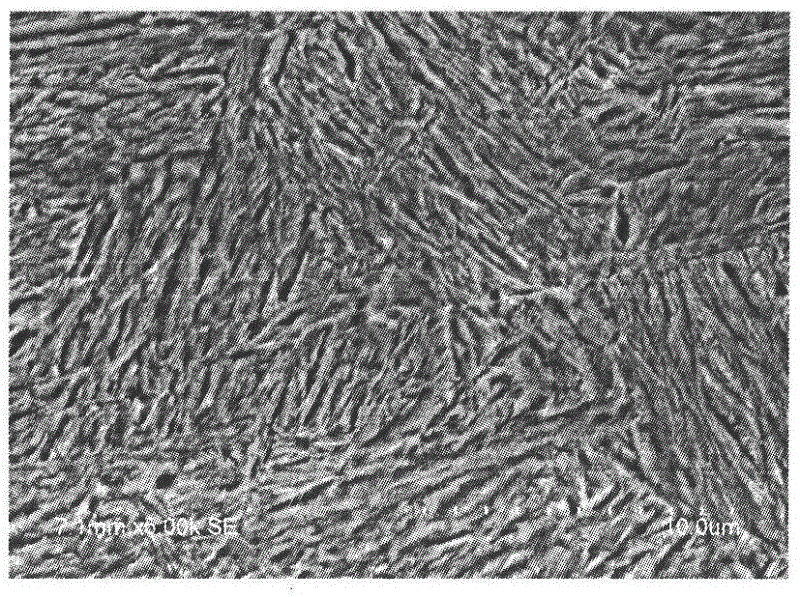

[0038] The third step is the transformation of lower bainite and stabilized austenite. The material cooled in the salt bath is placed in an air holding furnace at 250°C for 20 minutes, and the transformation of lower bainite and stabilization of austenite occurs ( figure 2 ), and then water-cooled to room temperature, the strength reaches about 1700Mpa, and the elongation is 10.5% ( Figure 4 ), the area shrinkage rate reaches 37%.

[0039] The three steps me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com