O-phenylenediamine preparation process by means of hydrogenization with nano nickel serving as catalyst

The technology of o-phenylenediamine and catalyst is applied in the field of preparation of o-phenylenediamine, which can solve the problems of long production cycle, poor product quality, large amount of waste water, etc., and achieve the effects of reducing corrosion, reducing energy consumption and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

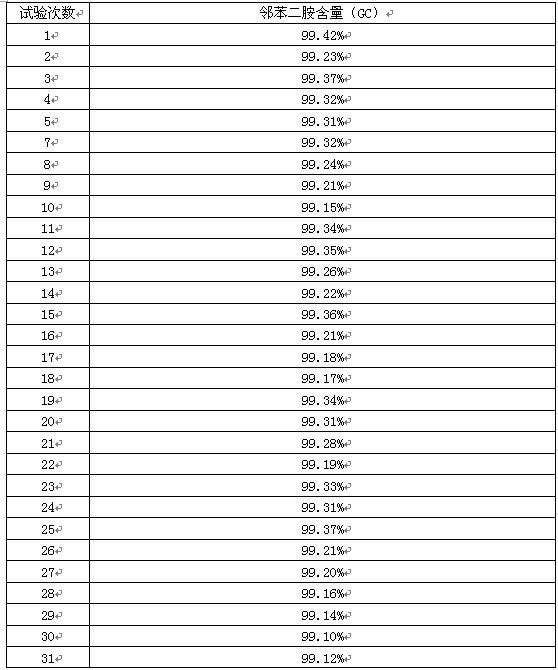

Examples

Embodiment 1

[0017] Add 150 g of o-nitroaniline and 300 g of methanol into the autoclave, add 4.5 g of nano-nickel catalyst at the same time, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, ventilate 3 times, and adjust the pressure of the autoclave to 1.0 MPa, stir and heat up to 35-45°C to react, so that the pressure does not change (about 1h), take a sample, and the result of gas chromatography analysis shows that the content of o-phenylenediamine is 99.20%, (HPLC coupling compound 0.45%)

[0018] Comparative test:

[0019] Add 150 g of o-nitroaniline and 300 g of methanol into the autoclave, and add 7.5 g of ordinary Ni catalyst at the same time, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, change the air for 3 times, and adjust the pressure of the autoclave to 2.0 MPa, stir and heat up to 60-70°C to react, so that the pressure does not change (about 2-3h), take a sample, and the result of gas chromatography analysis sh...

Embodiment 2

[0021] Add 500 g of o-nitroaniline and 1,000 g of methanol into the autoclave, and add 15 g of nano-nickel catalyst at the same time, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, ventilate 3 times, and adjust the pressure of the autoclave to 1.0 MPa , stir and heat up to 35-45°C to react, so that the pressure does not change (about 1h), take a sample, and the result of gas chromatography analysis shows that the content of o-phenylenediamine is 99.18% (HPLC coupling compound 0.43%), after the reaction solution is filtered, the solvent is recovered, and then Rectification obtained 370g of white o-phenylenediamine, GC detection 99.9%, yield 94.5%

[0022] Comparative test:

[0023] Add 500 g of o-nitroaniline and 1000 g of methanol into the autoclave, and add 25 g of ordinary Ni catalyst at the same time, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, change the air for 3 times, and adjust the pressure of the aut...

Embodiment 3

[0025] Add 1,000 g of o-nitroaniline and 2,000 g of methanol into the autoclave, and at the same time add 30 g of nano-nickel catalyst, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, ventilate 3 times, and adjust the pressure of the autoclave to 1.0 MPa , stir and heat up to 35-45°C to react, so that the pressure does not change (about 1h), take a sample, and the result of gas chromatography analysis is that the content of o-phenylenediamine is 99.28% (HPLC coupling compound 0.40%), after the reaction solution is filtered, the solvent is recovered, and then Rectification obtained 745g of white o-phenylenediamine, GC detection 99.9%, yield 95.2%

[0026] Comparative test:

[0027] Add 1000 g of o-nitroaniline and 2000 g of methanol into the autoclave, and add 50 g of ordinary Ni catalyst at the same time, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, change the air for 3 times, and adjust the pressure of the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com