Patents

Literature

54 results about "Hydrogen valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogen valve is a special type of valve that is used for hydrogen at very low temperatures or high pressures in hydrogen storage or for example hydrogen vehicles.

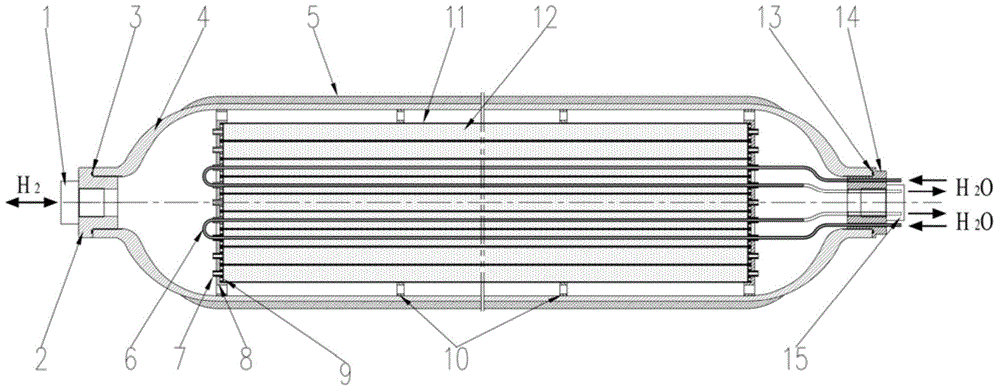

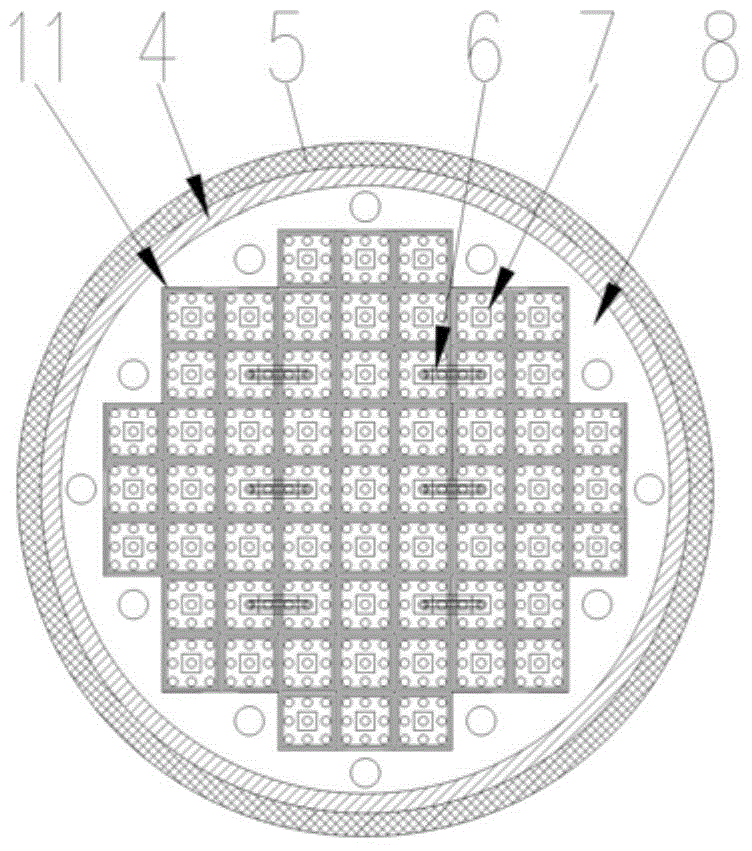

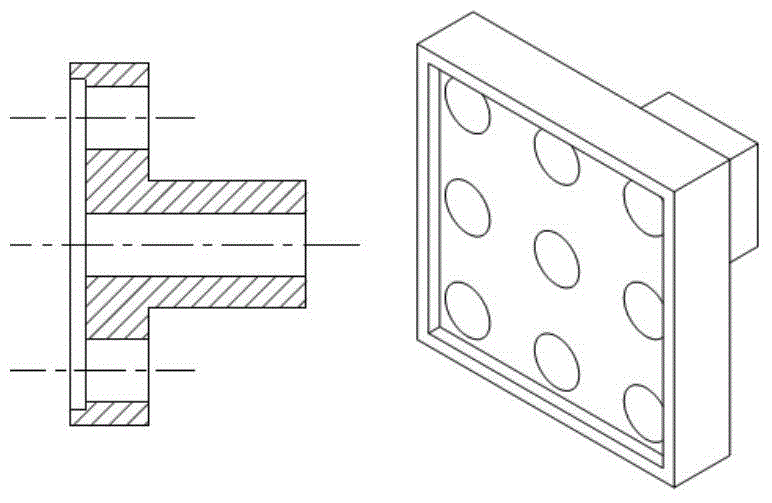

Solid-state high-pressure mixing hydrogen storage tank

ActiveCN105715943ASimple structureEasy to processContainer filling methodsPressure vesselsHydrogen valveSolid mass

The invention belongs to a hydrogen storage technology of the hydrogen energy field, and especially relates to a solid-state high-pressure mixing hydrogen storage tank based on solid hydrogen storage and high-pressure hydrogen storage. A main body of the solid-state high-pressure mixing hydrogen storage tank is a metal liner, and a fiber wound reinforced layer is wound and laid on the outer surface of the metal liner; the metal liner is internally provided with a plurality of close-contact metal square pipes which are fixed by a plurality of supporting rings; both ends of each metal square pipe are respectively welded with supporting and positioning stoppers, each supporting and positioning stopper is provided with a through hole and is provided with a filter sheet, and the metal square pipes are internally filled with hydrogen storage materials; both ends of the metal liner are each provided with an end plug, the end plug at one side is provided with a hydrogen valve, and the end plug at the other side is supplied for a plurality of heat exchange pipes to pass through; main bodies of the heat exchange pipes are uniformly distributed in an array formed by the metal square pipes. The metal hydride hydrogen storage device has the advantages of simple structure, easy fabrication and processing, and the nominal working pressure is not less than 35 MPa, and the hydrogen storage capacity is improved by 50% or more compared with that of a pure high-pressure hydrogen storage tank with the same specification.

Owner:GRIMAT ENG INST CO LTD

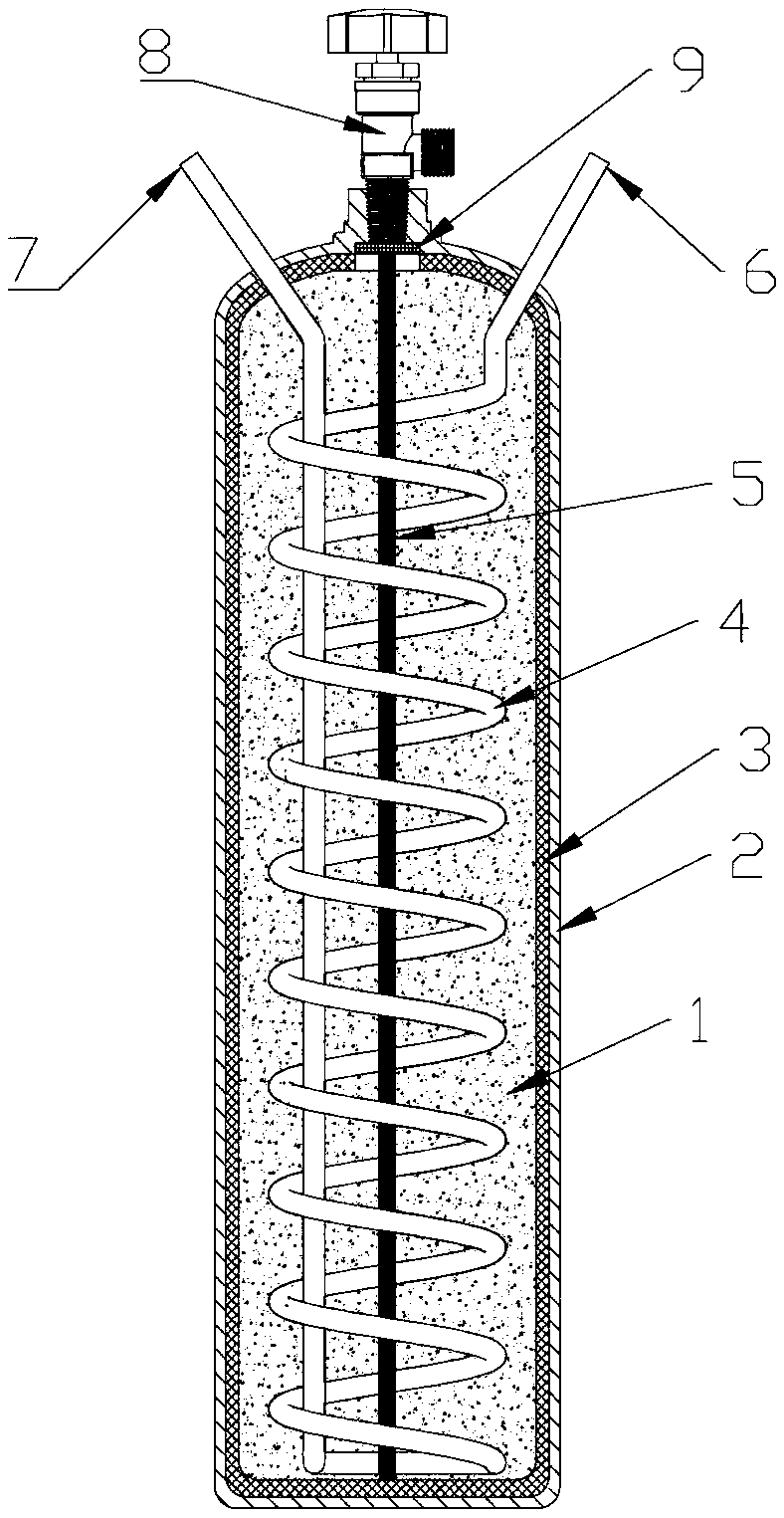

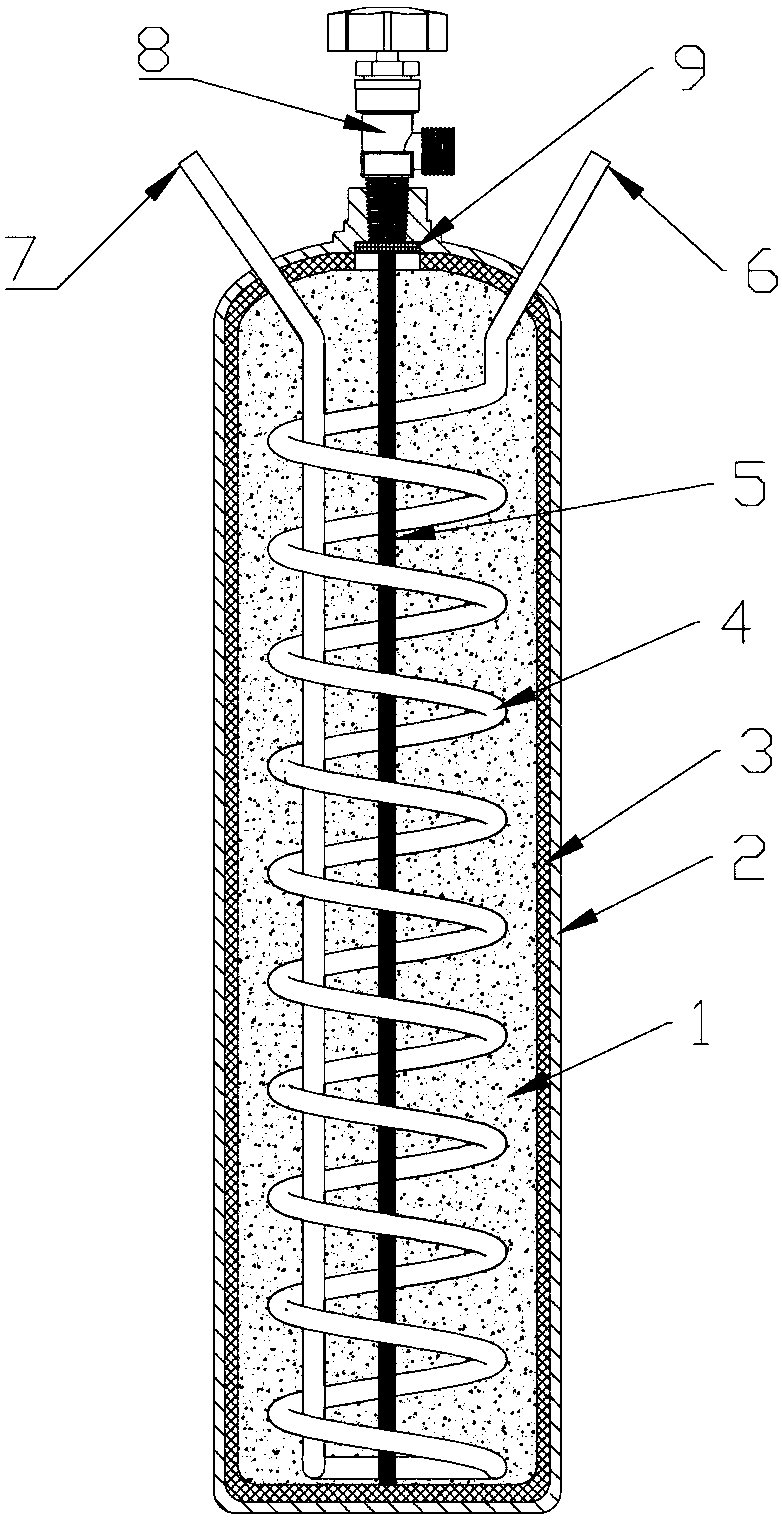

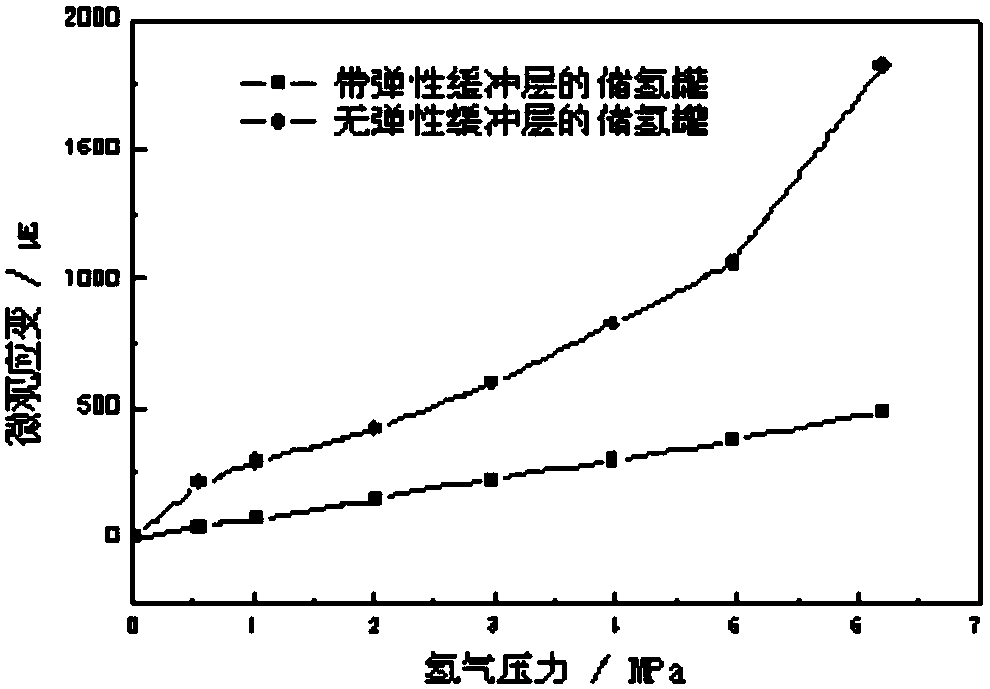

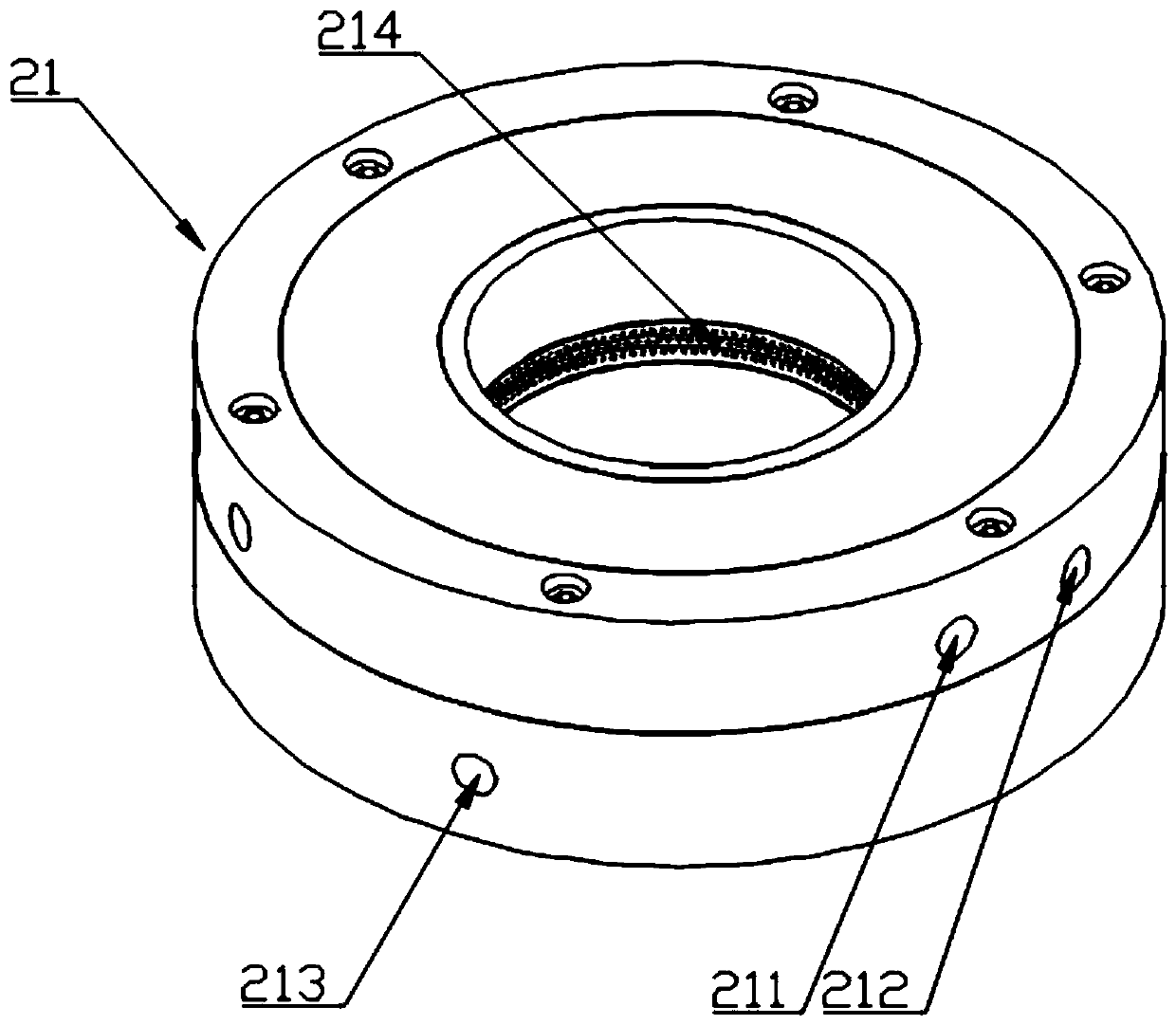

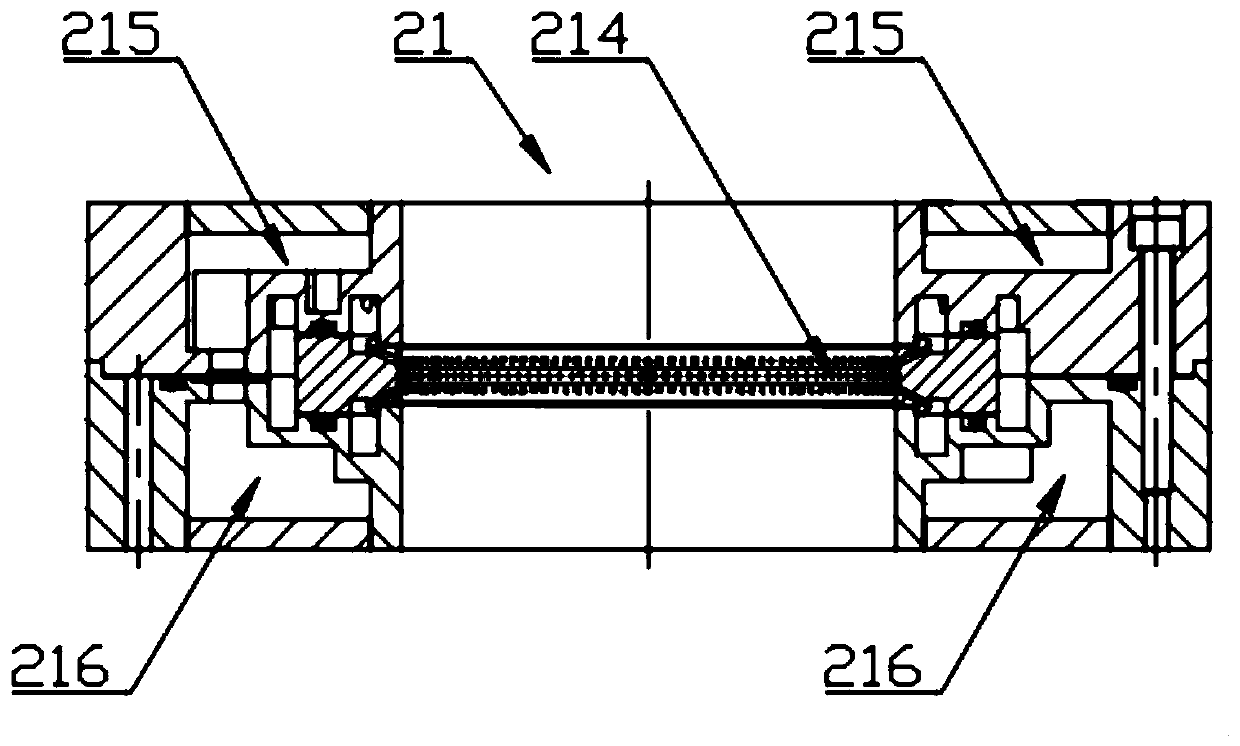

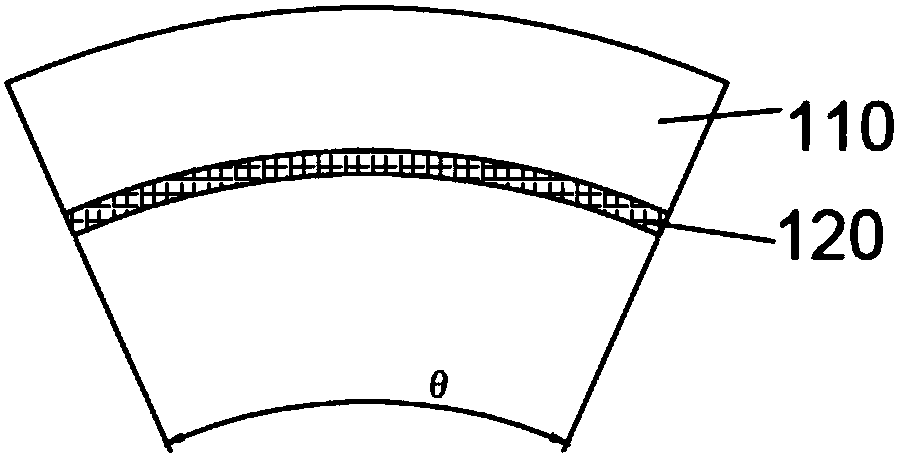

Hydrogen-absorption low-strain metal hydride hydrogen storage tank

ActiveCN105371105ASimple structureEasy to implementContainer filling methodsFixed capacity gas holdersHydrogen valveHydrogen absorption

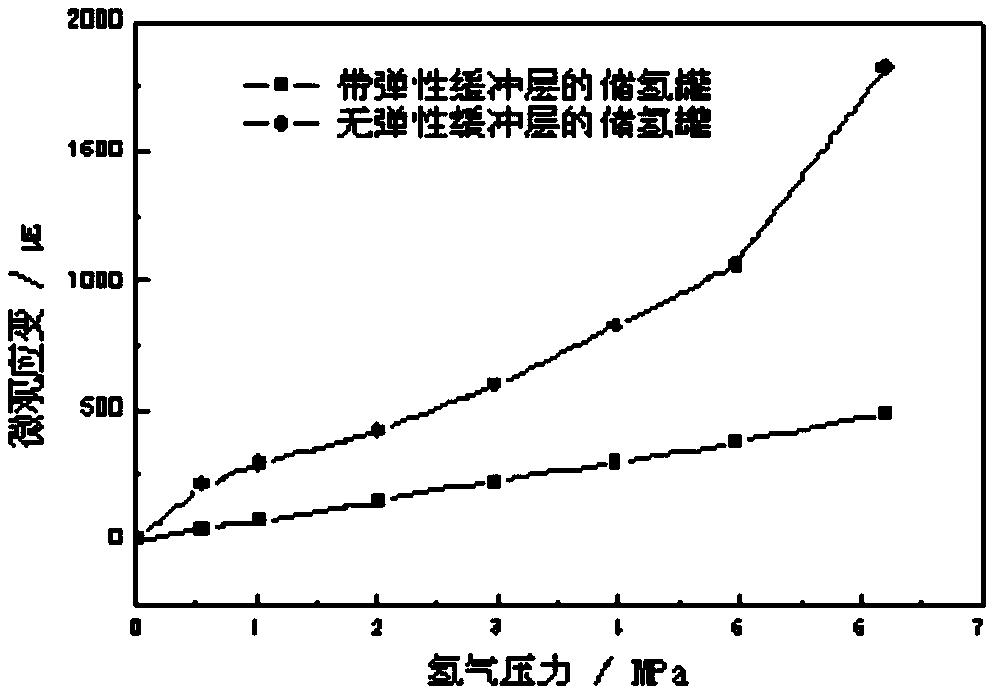

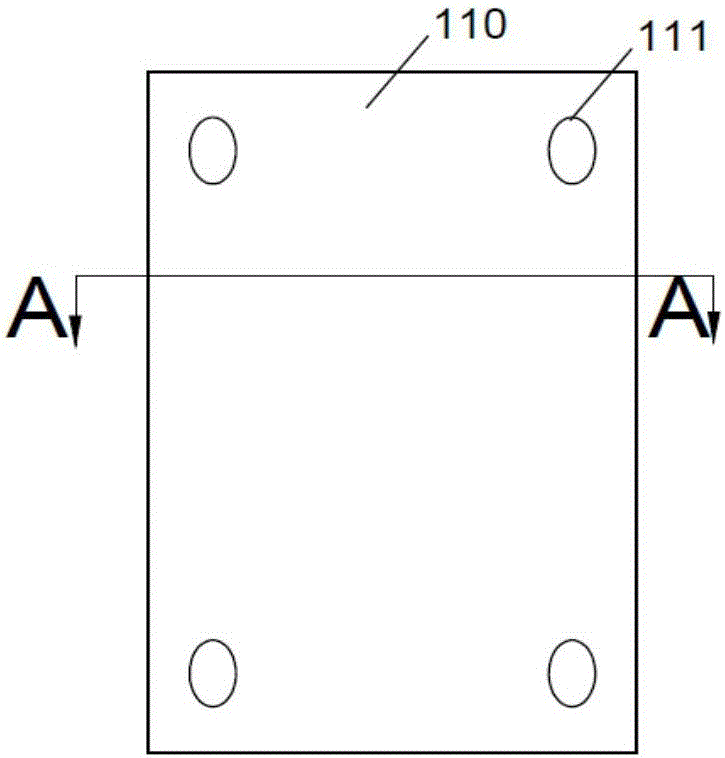

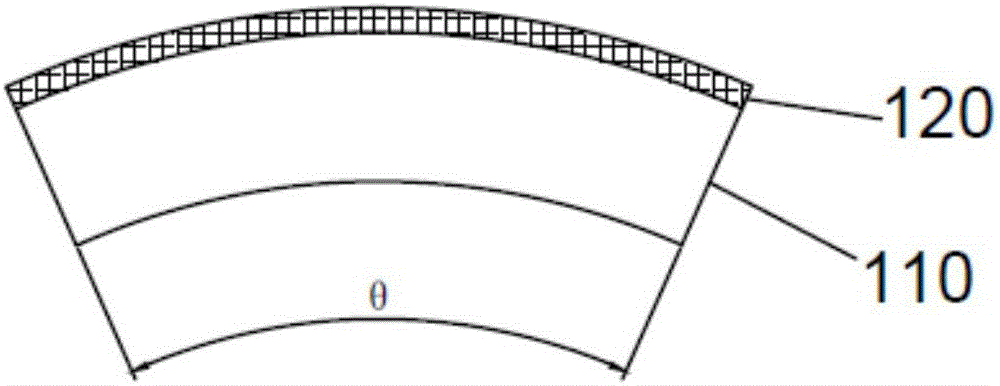

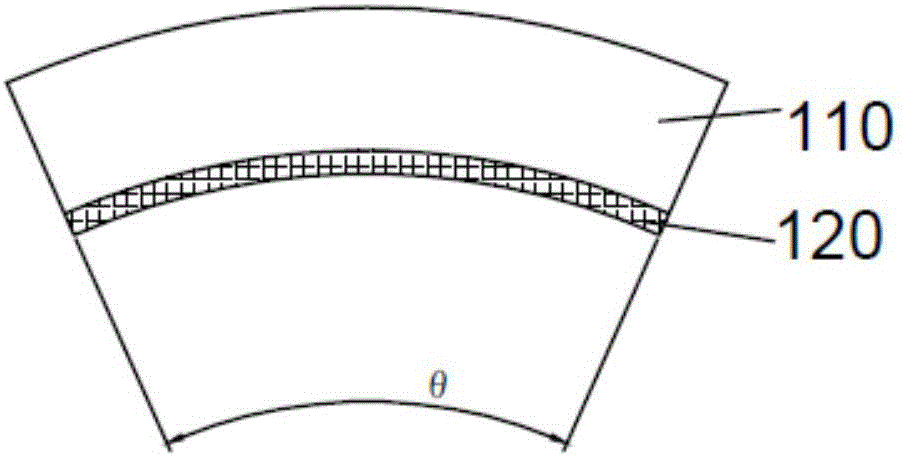

The invention belongs to the hydrogen storage technology in the hydrogen energy field and particularly relates to a hydrogen-absorption low-strain metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a tank body, a metal hydride hydrogen storage alloy bed body and an elastic buffer layer. The elastic buffer layer is arranged between the tank body and the metal hydride hydrogen storage alloy bed body. A heat exchange pipe is communicated with the interior of the metal hydride hydrogen storage alloy bed body and used for guiding heat generated in the hydrogen absorption and release processes of the metal hydride hydrogen storage alloy bed body out. A hydrogen valve is installed on an outlet of the tank body and meanwhile a hydrogen filter is welded to the outlet end of the tank body. The hydrogen-absorption low-strain metal hydride hydrogen storage tank is simple in structure and easy to obtain, the destructive effect on the tank body due to the fact that the metal hydride hydrogen storage alloy bed body expands after absorbing hydrogen can be relieved effectively, and the use safety of the hydrogen storage tank is improved.

Owner:GRIMAT ENG INST CO LTD

Hydrogen valve with function of removing leaked hydrogen

ActiveCN106402475AEfficient Hydrogen Oxidation EliminationEfficient dischargeSpindle sealingsGas treatmentHydrogen valveEngineering

The invention discloses a hydrogen valve with a function of removing leaked hydrogen. The valve comprises a valve body, a valve rod, padding and a padding gland. A plurality of first grooves are symmetrically formed in the outer wall of the padding gland in the circumferential direction, a plurality of second grooves are correspondingly formed in the inner wall of the padding gland in the circumferential direction, and the first grooves and the second grooves are internally provided with hydrogen absorbing reactors. The hydrogen absorbing rectors are provided with Pd / Pt-Al2O3 catalyst coatings and located in an opening in the upper end of the padding, and the catalyst coatings are exposed in the grooves. An iron, chromium and aluminum metal plate is coated with the hydrophobic Pd / Pt-Al2O3 catalyst coatings and installed in the grooves formed in the inner wall face and the outer wall face of the padding gland, and efficient hydrogen oxidation removing is achieved at the normal temperature. Meanwhile, by means of the character of the Pd / Pt-Al2O3 catalyst coatings, effective draining of reaction product water is achieved, and stability of the catalysts is guaranteed. The valve has the beneficial effects of being simple and safe in structure and capable of efficiently removing leaked hydrogen.

Owner:EAST CHINA UNIV OF SCI & TECH

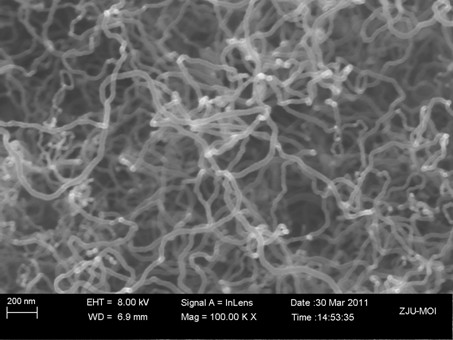

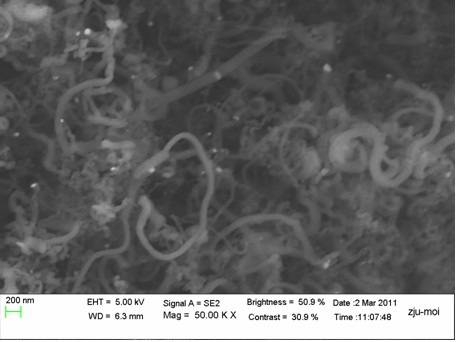

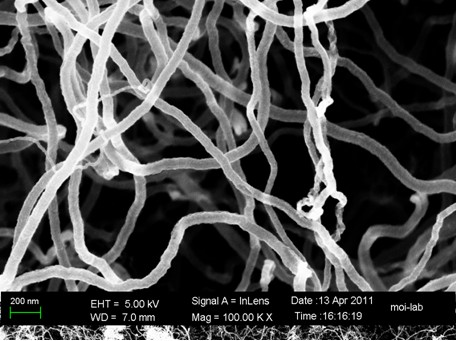

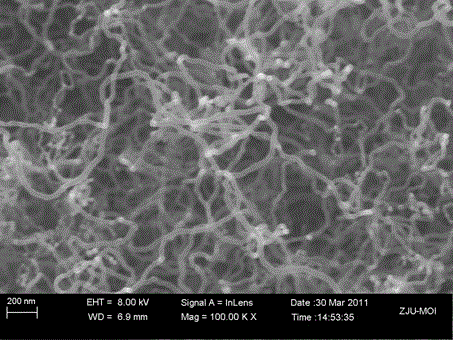

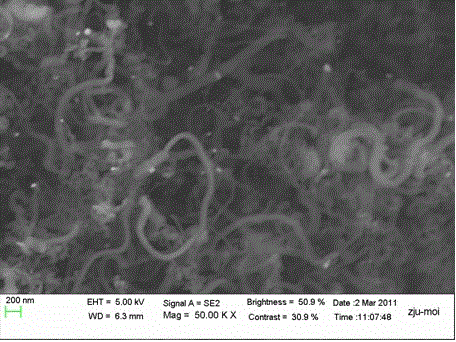

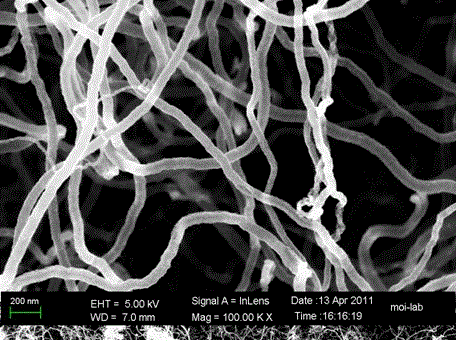

Preparation method for synthesizing carbon nanotubes in quantity and with low cost

InactiveCN102161481ASimple preparation processReduce energy consumptionNanotechnologyChemical platingCarbon nanotube

The invention discloses a preparation method for synthesizing carbon nanotubes in quantity and with low cost. The method comprises the following steps of: plating and coating nano-grade metal catalysts such as iron, cobalt, molybdenum and the like on foamed nickel by a chemical plating process; placing the foamed nickel plated with the catalysts into a quartz boat; heating the foamed nickel plated with the catalysts by using the common horizontal resistance furnace; introducing nitrogen with flow of 200 ml / min to remove air from a quartz tube; when the temperature reaches 650 DEG C, introducing hydrogen with flow of 50 ml / min to reduce the metal catalysts for 10 minutes; when the temperature reaches 690 to 720 DEG C, introducing acetylene gas with flow of 50 to 100 ml / min, wherein the hydrogen flow can be set to be 25 to 100 ml / min; closing an acetylene valve and a hydrogen valve after the reaction is performed for 30 minutes; introducing nitrogen with the flow of 20 ml / min; when the temperature is reduced to 300 DEG C, closing a nitrogen valve; and after the hearth is cooled to room temperature, taking out the quartz boat, wherein black products are found to be generated on the foamed nickel and are the carbon nanotubes according to electron microscope and Raman spectrum detection. By the method, the preparation process is simple; energy consumption is small; cost is low; time is saved; and preparation conditions are easy to implement.

Owner:ZHEJIANG UNIV

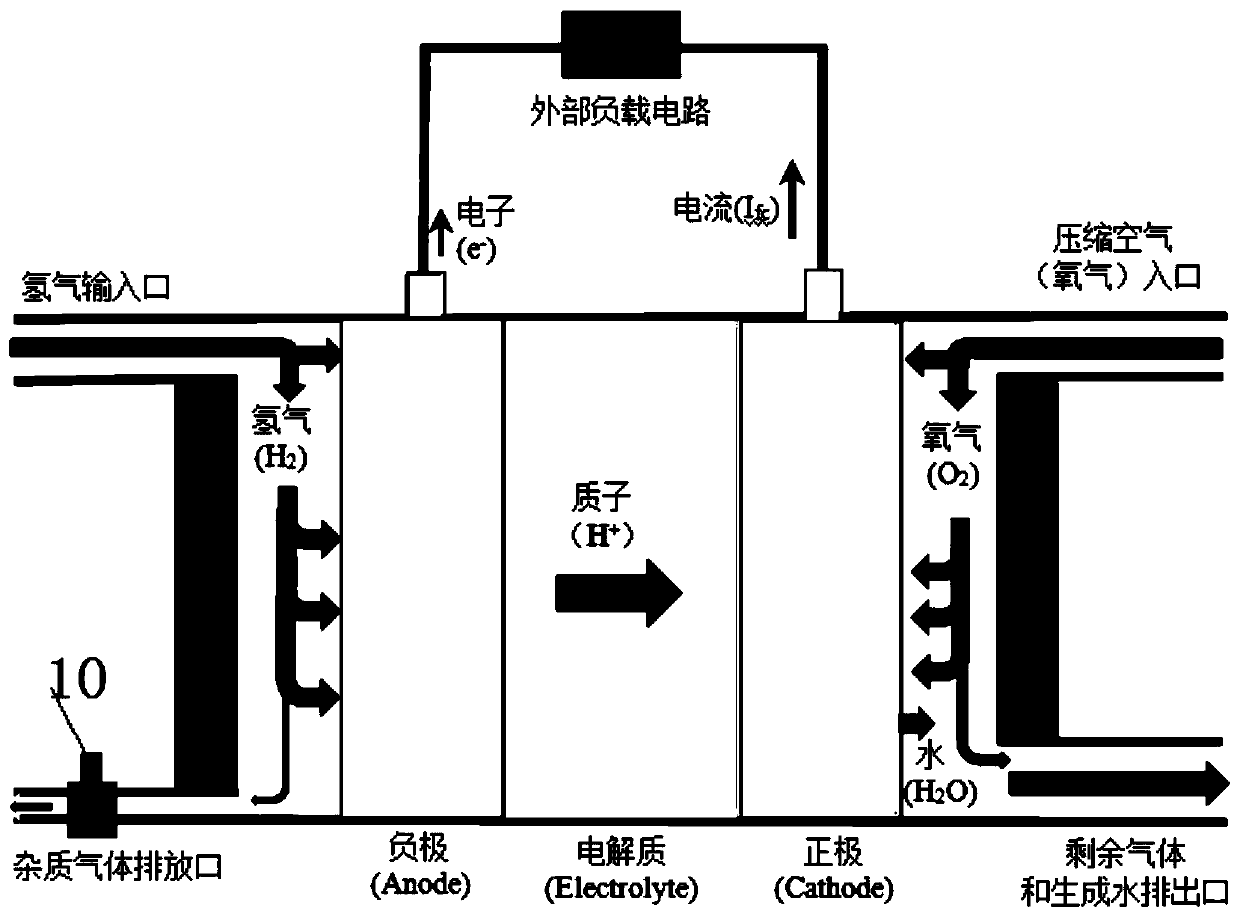

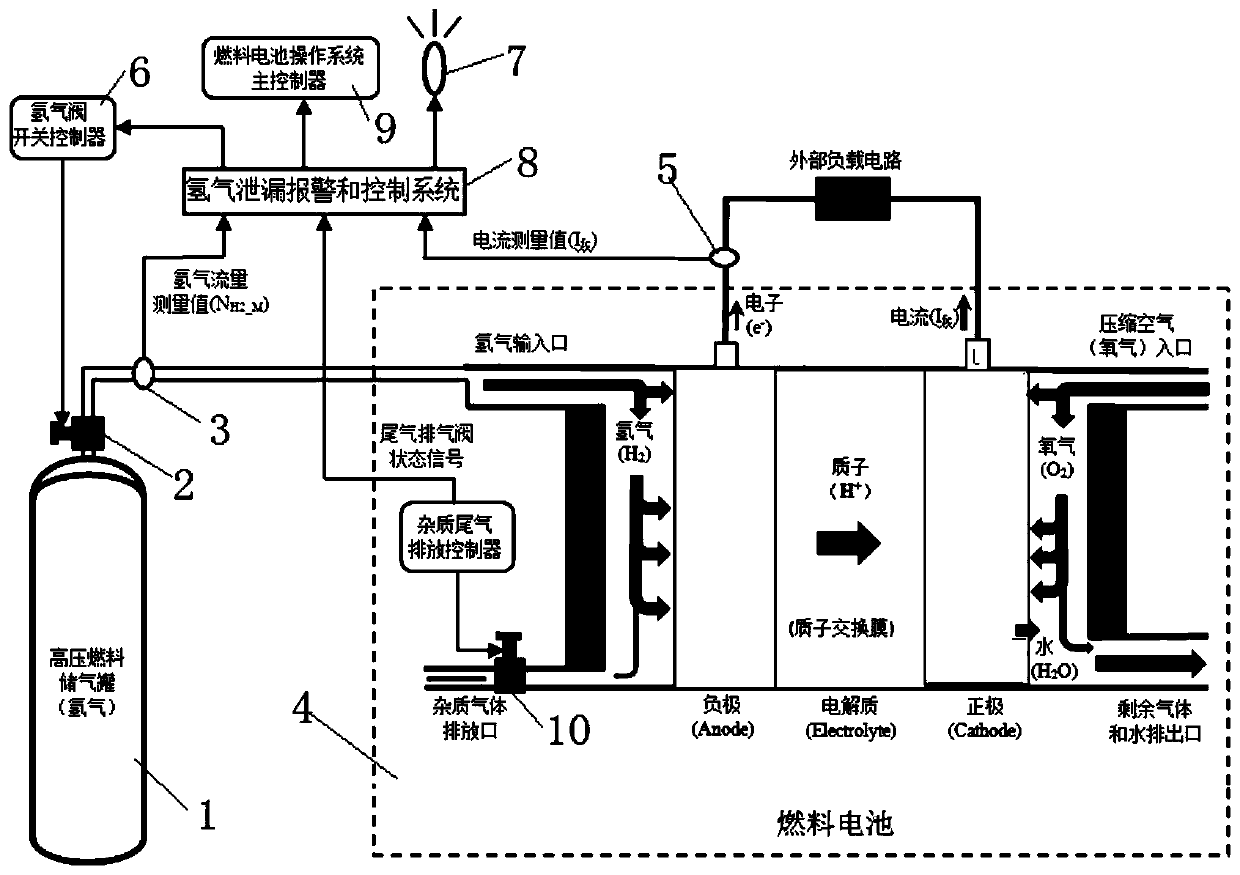

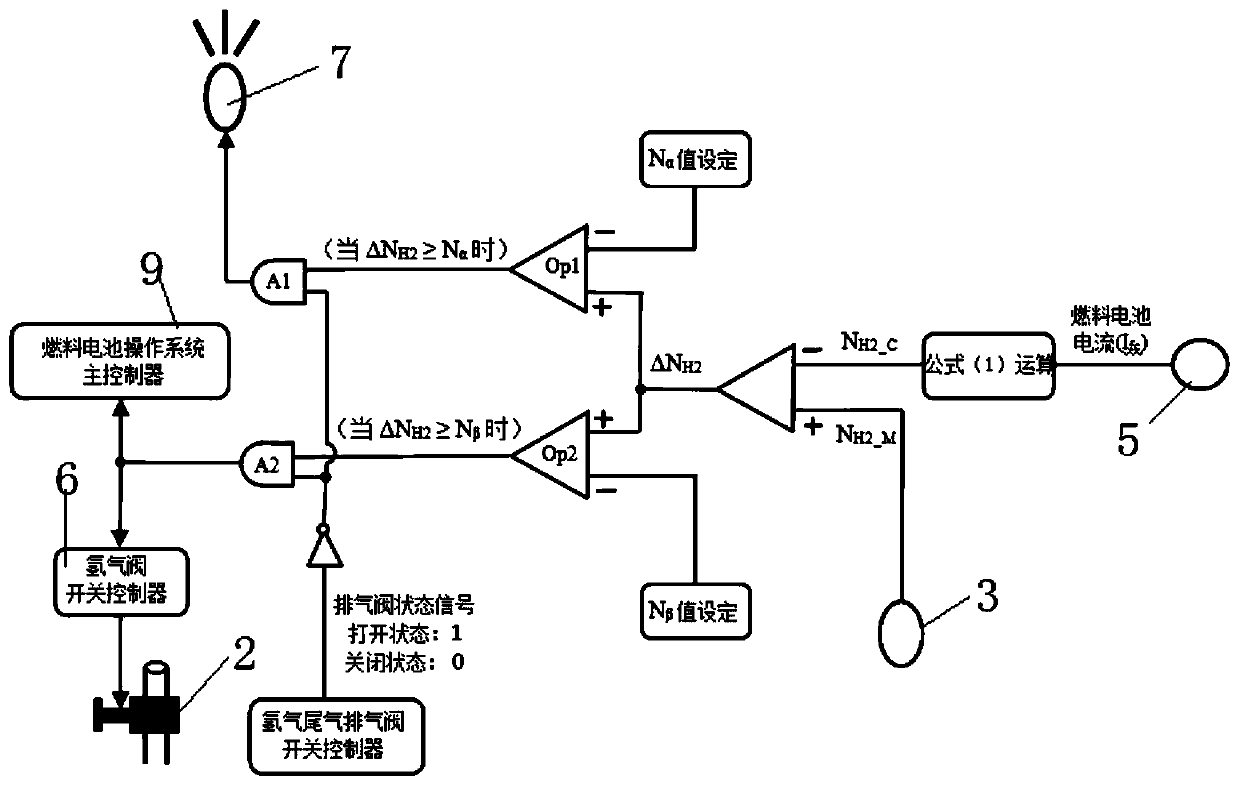

Gas fuel leakage automatic detection and safety alarm system in fuel cell system

ActiveCN111584904AAccurate detectionImprove performanceMeasurement of fluid loss/gain rateElectrical testingHydrogen valveMeasuring output

The invention discloses a gas fuel leakage automatic detection and safety alarm system in a fuel cell system. The gas fuel leakage automatic detection and safety alarm system comprises a hydrogen flowmeter, an ampere meter, a numerical analysis and operation part, a logic judgment and control part, a hydrogen leakage alarm and a hydrogen valve switch controller. According to the invention, the output current of a fuel cell stack is measured in real time, and the measured output current is converted into the reaction amount of the corresponding fuel gas according to the corresponding chemicalreaction principle of the fuel cell. Meanwhile, the gas supply flow of a fuel gas storage tank is also measured in real time, and then whether fuel gas leakage exists in the whole system or not is judged by comparing the actually measured consumption of the fuel gas with the gas reaction amount participating in the corresponding chemical reaction. Therefore, the system is simple, accurate and reliable to operate.

Owner:张智好

Method for producing 2,5-dichloroaniline without anti-dechlorinating agent

ActiveCN103467308AReduce generationHigh yieldOrganic compound preparationAmino compound preparationHydrogen valveDistillation

The invention provides a method for producing 2,5-dichloroaniline without an anti-dechlorinating agent. The method is characterized by comprising the following steps of: adding 2,5-dichloronitrobenzene and a catalyst into a high-pressure kettle, sealing, opening a hydrogen valve, and introducing hydrogen into the high-pressure kettle; stirring, heating and pressurizing, setting the reaction rotating speed to be 700 revolutions / minute, controlling the reaction temperature to be 110-120 DEG C and the reaction pressure to be 1.1-1.2MPa, and reacting until hydrogen cannot be absorbed; closing the hydrogen valve, cooling, opening the high-pressure kettle, and discharging; filtering, adding into a rectifying still for distillation to obtain 2,5-dichloroaniline after the distillation is finished. A sample is collected, and gas chromatography results indicate that the purity of 2,5-dichloroaniline is 99.85 percent, and dechlorination rate is 0.006 percent. The anti-dechlorinating agent is not needed to be extra added, so that the best anti-dechlorination effect can be achieved. The method is easy to operate, short in production cycle and small in environmental pollution, and can reduce generation of side products, so that the product yield can be effectively increased, cost can be reduced, and benefit can be increased. Therefore, the method is suitable for industrial production.

Owner:HULUDAO TIANQI SHENGYE CHEM

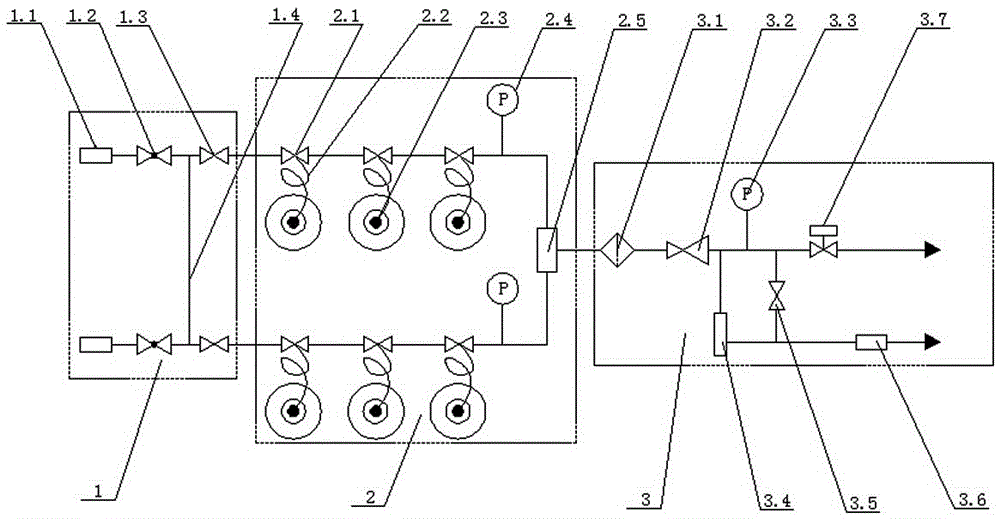

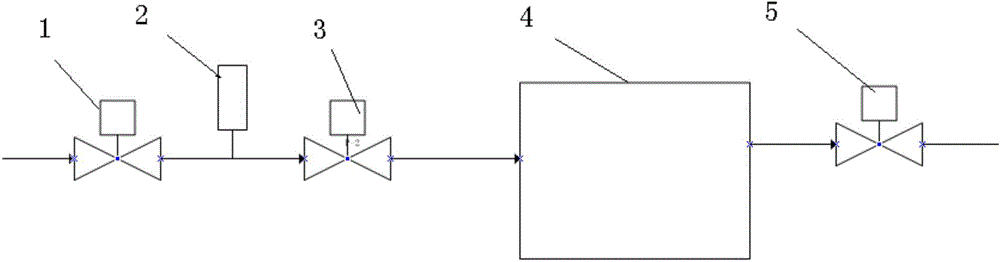

Filling-type gas supply confluence system of fuel cell

ActiveCN106252689AEasy to adjust the output volumeSimple structureReactant parameters controlFlame arresterGas cylinder

The invention discloses a filling-type gas supply confluence system of a fuel cell. The system consists of a gas filling unit, a gas bottle confluence switching unit and a safety unit which are successively connected with one another. The gas filling unit is a double-circuit pipeline parallel structure, and each circuit is serially connected with an outer interface, a ball valve and a stop valve. The gas bottle confluence switching unit is also a double-circuit pipeline parallel structure, each circuit is serially connected with two to five hydrogen valves, each hydrogen valve is connected with a hydrogen bottle by virtue of a corrugated pipe, and the last hydrogen valves in the two circuits are respectively connected with two ends of a distribution valve and uniformly output high-pressure hydrogen. The safety unit is provided with a low-pressure hydrogen output passage formed by a filter, a decompressor and an electromagnetic valve, and for a safety reason, the passage is provided with a discharging passage consisting of a safety valve, a bypass valve and a flame arrester. Two circuits of pipelines are used for alternately supplying the gas, the idle pipeline is convenient for replacing the hydrogen bottle or on-site filling the hydrogen, and since the hydrogen is supplemented in time, the fuel cell can supply power continuously.

Owner:SHUANGDENG GRP

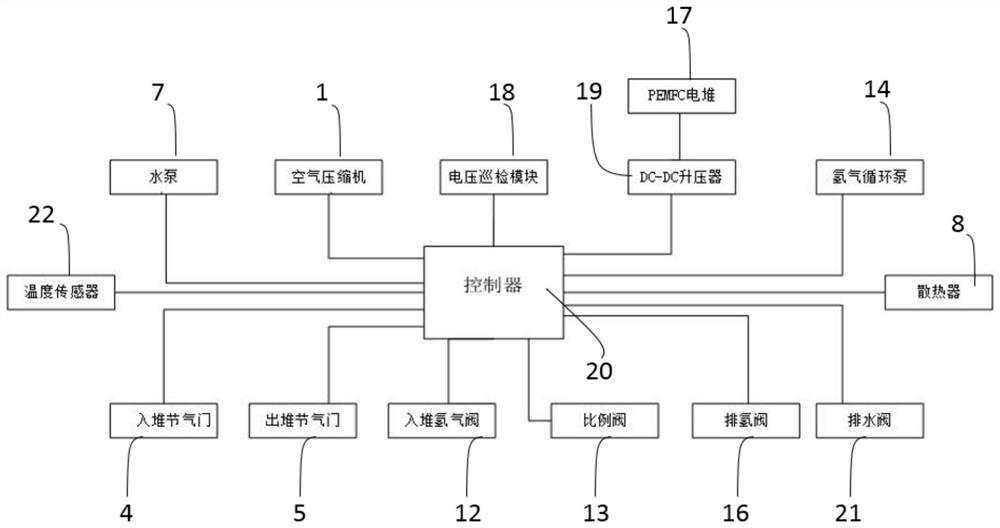

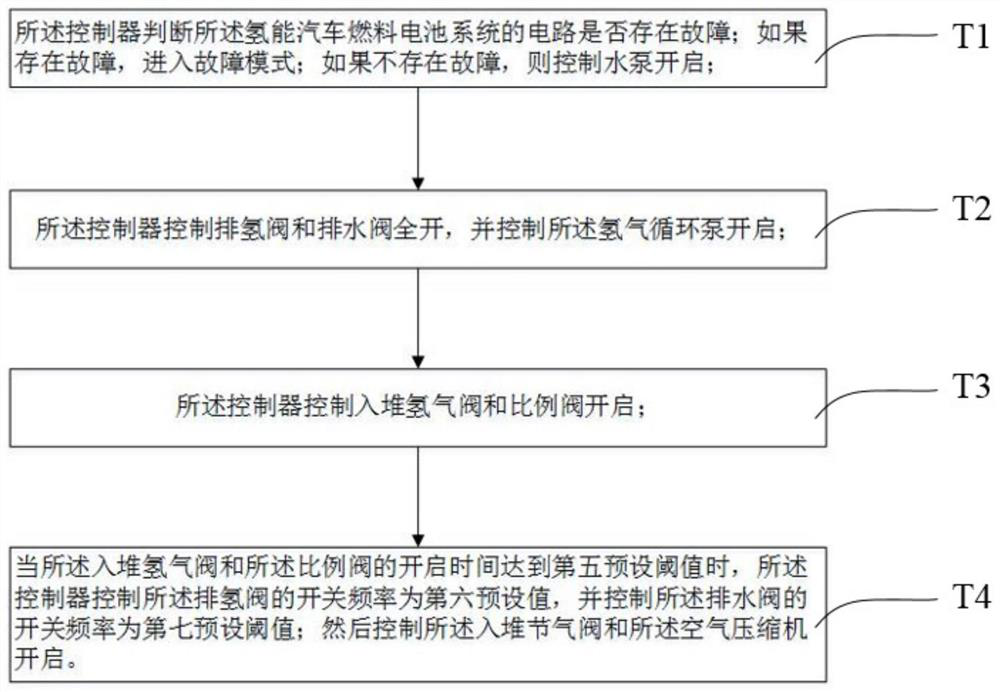

Hydrogen energy automobile fuel cell system and control method thereof

PendingCN112563536AReduce performanceAffect consistencyReactant parameters controlHydrogen valveAutomotive fuel

The invention provides a hydrogen energy automobile fuel cell system, and relates to the technical field of fuel cell systems. The fuel cell system comprises an electric pile, an air compressor, a pile outlet throttle valve, a hydrogen cylinder, a voltage inspection module and a controller. An air inlet, an air outlet, a hydrogen inlet, a hydrogen outlet, a hydrogen discharging valve and a water discharging valve are arranged on the galvanic pile; the pile outlet throttle valve is communicated with the air outlet; the air compressor is communicated with the galvanic pile through the air inlet;an in-pile throttle valve is arranged between the air compressor and the air inlet; the hydrogen cylinder is communicated with the galvanic pile through the hydrogen inlet; an in-pile hydrogen valveis arranged between the hydrogen cylinder and the hydrogen inlet; the in-pile hydrogen valve is respectively communicated with the hydrogen cylinder and the hydrogen inlet; the controller is electrically connected with the air compressor, the pipe inlet throttle valve, the pipe outlet throttle valve, the in-pile hydrogen valve and the voltage inspection module. The invention further provides a control method of the hydrogen energy automobile fuel cell system. And attenuation of the performance of the galvanic pile can be effectively slowed down.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

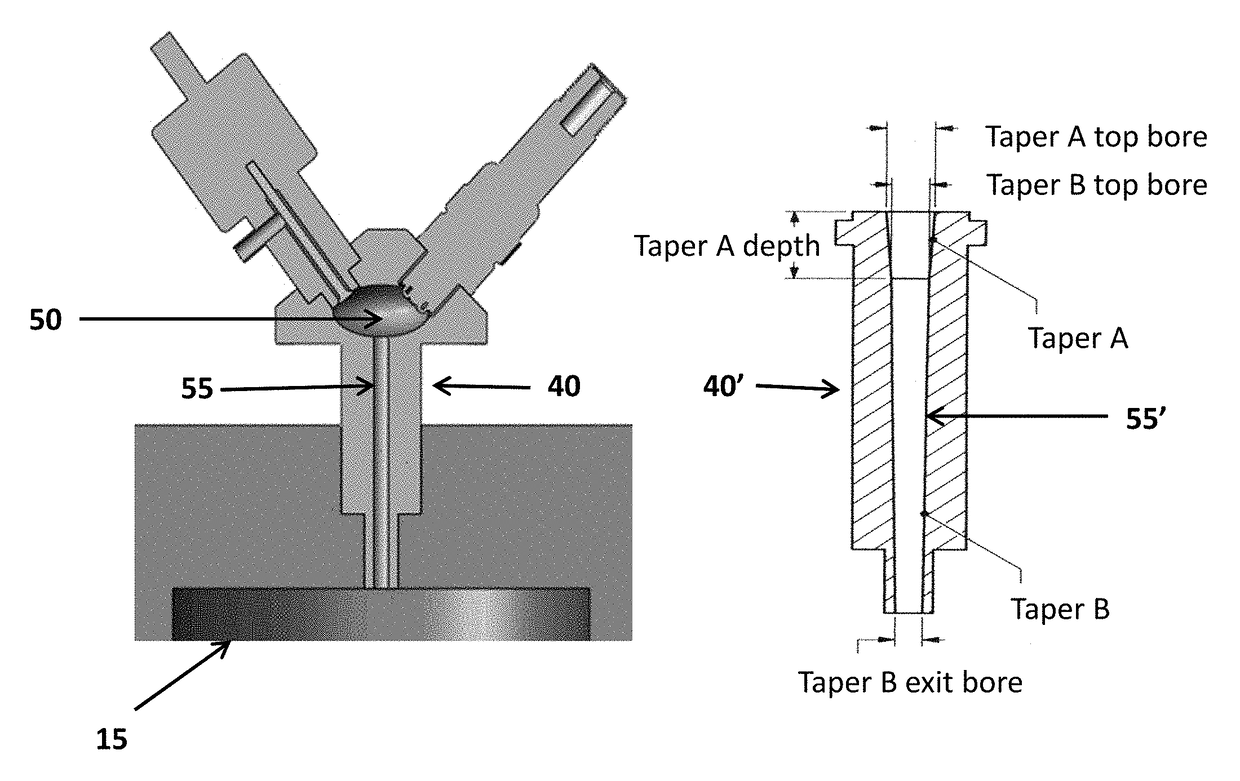

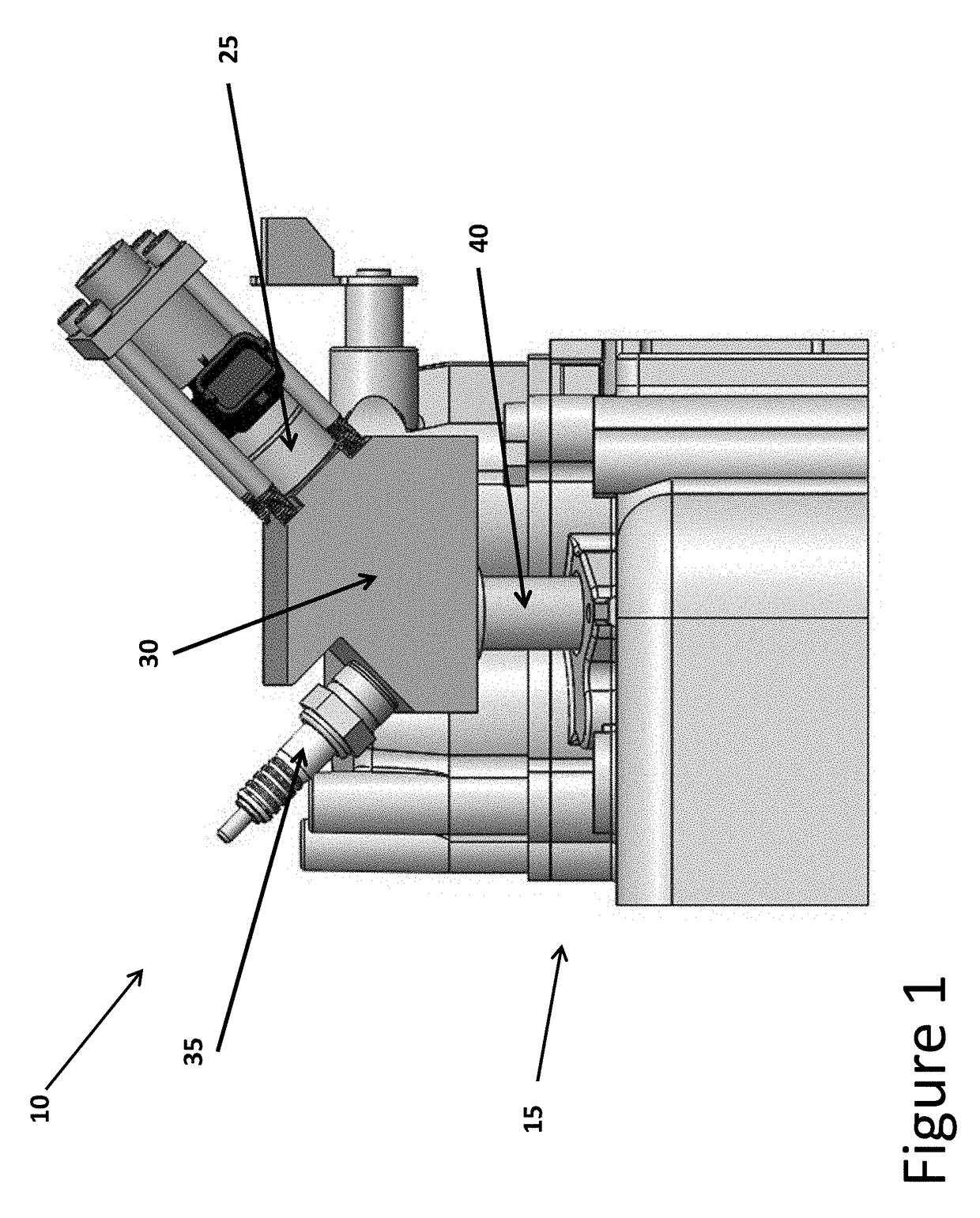

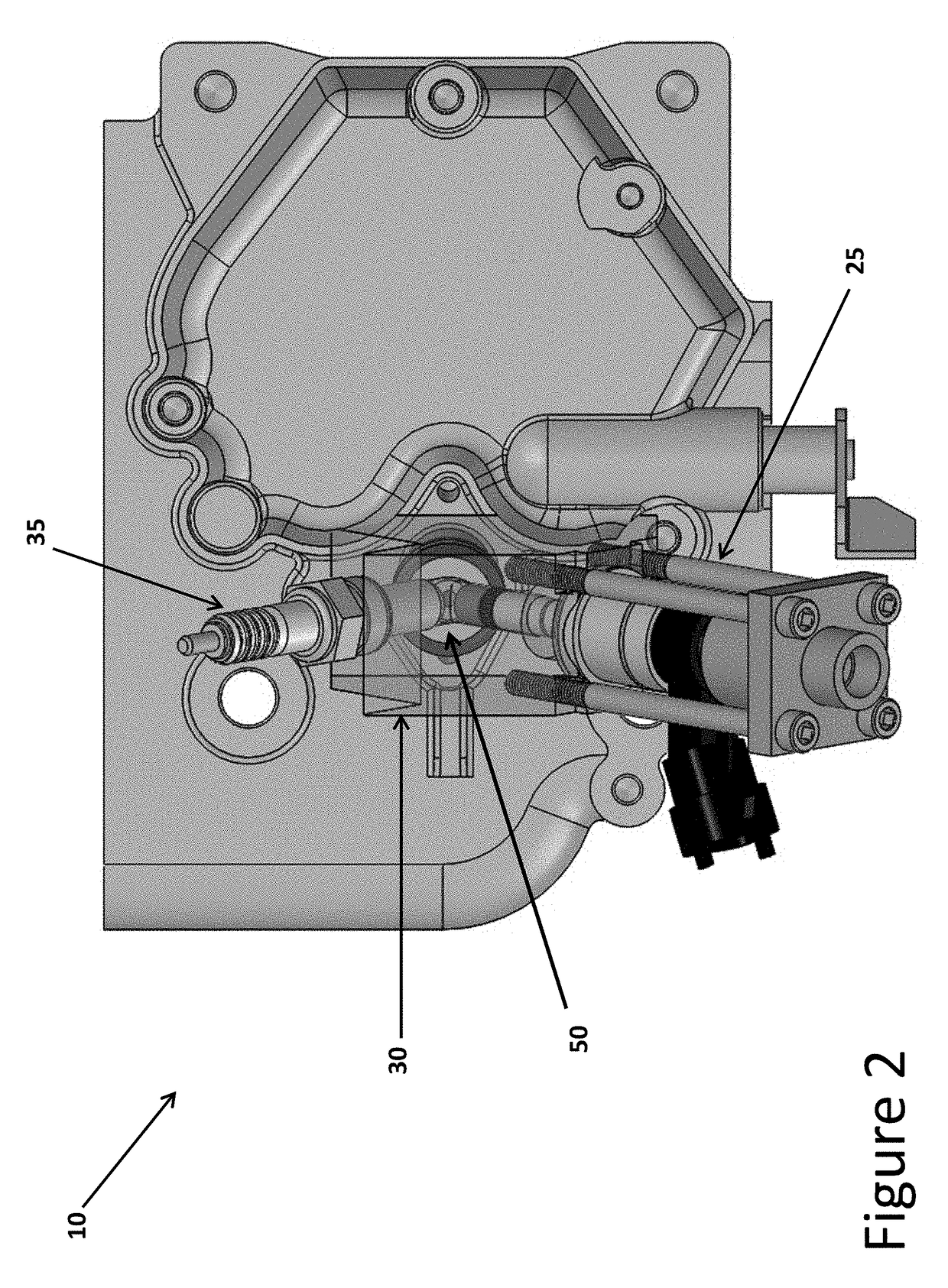

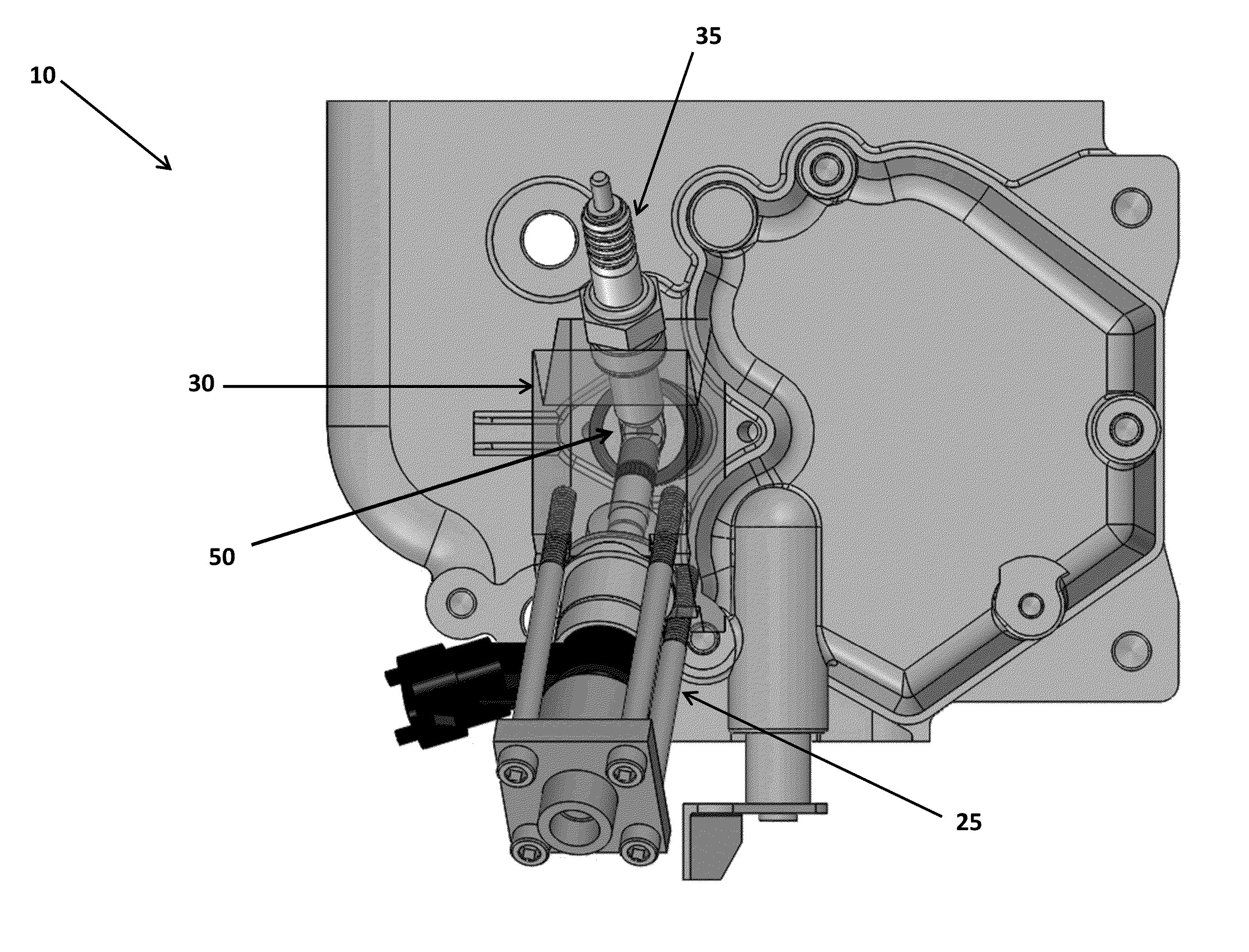

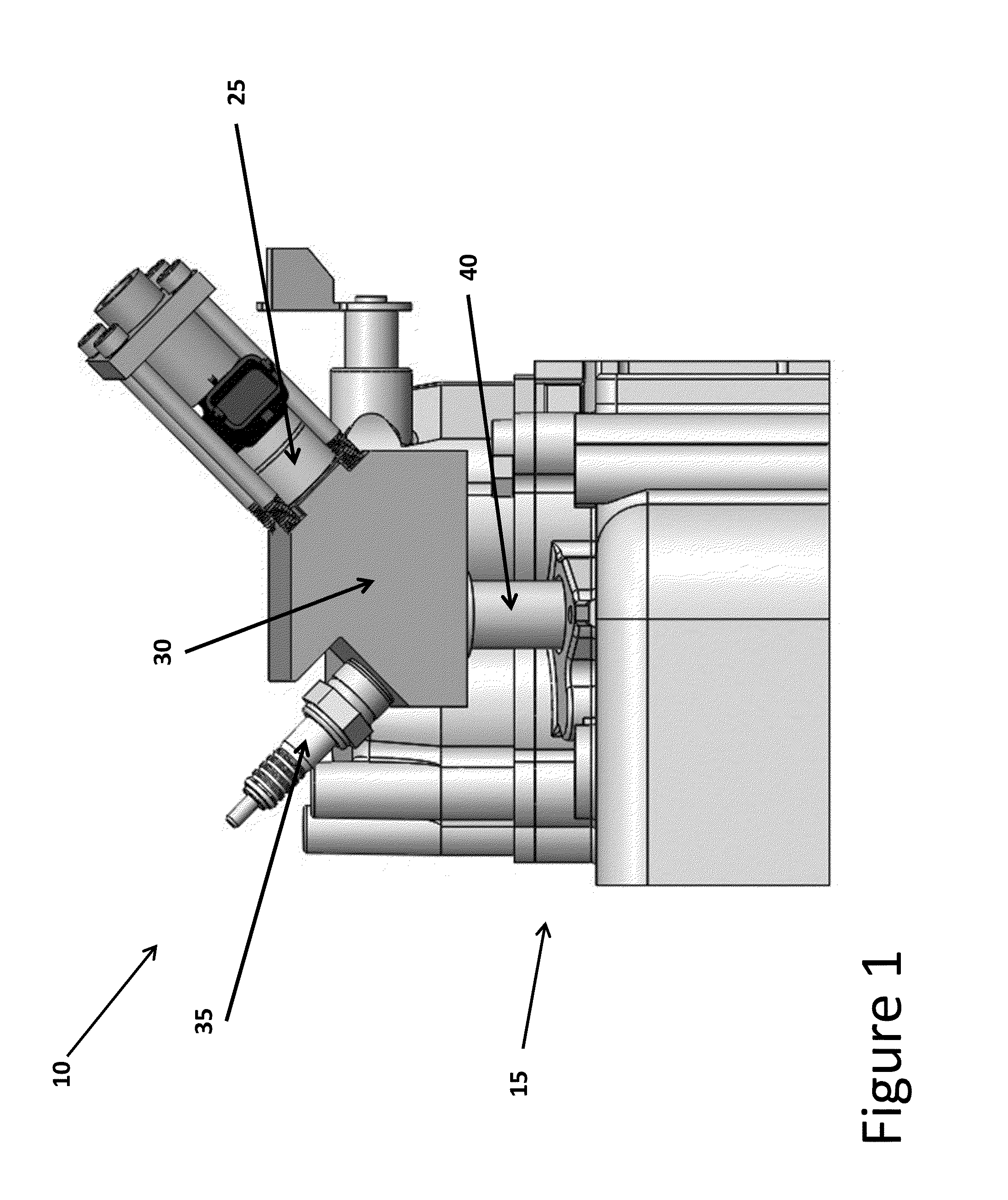

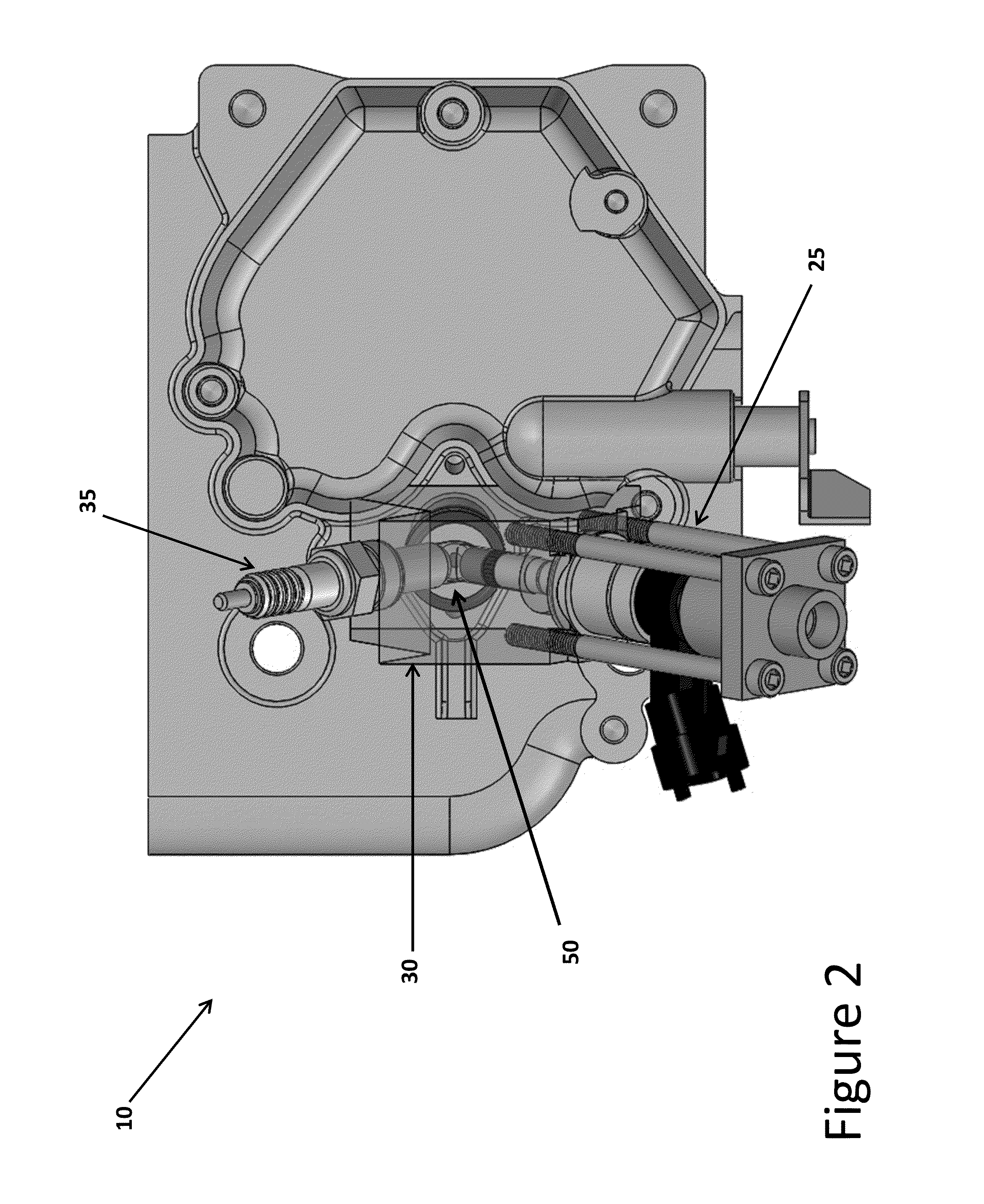

Ignition system for low grade synthesis gas at high compression

InactiveUS9739193B2Internal combustion piston enginesGasification processes detailsHydrogen concentrationHydrogen valve

An igniter system for a reciprocating piston internal combustion engine having one or more cylinders including at least one igniter per cylinder is disclosed. The igniter system can comprise: a combustion chamber connected to a main cylinder of the engine by a restricted diameter bore, wherein a lean burn fuel mixture is introduced into the combustion chamber by the normal compression stroke of the engine; a hydrogen valve that injects a hydrogen rich gas into the combustion chamber forming a mixture of hydrogen and air having a hydrogen concentration above the stoichiometric ratio for hydrogen and air in the combustion chamber; and a spark ignition source that injects hot unburned hydrogen into the main cylinder, thereby initiating ignition.

Owner:V GRID ENERGY SYST INC

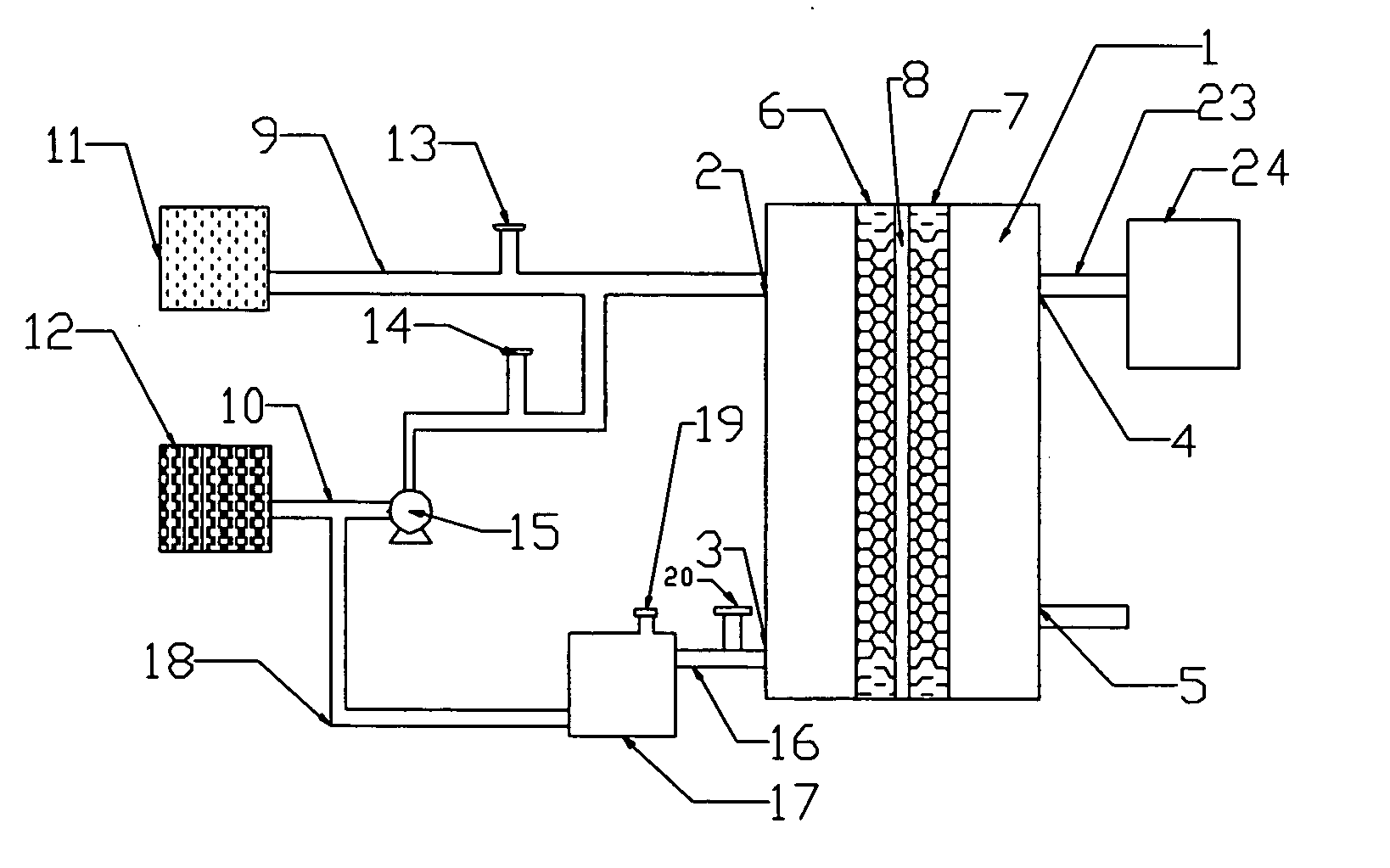

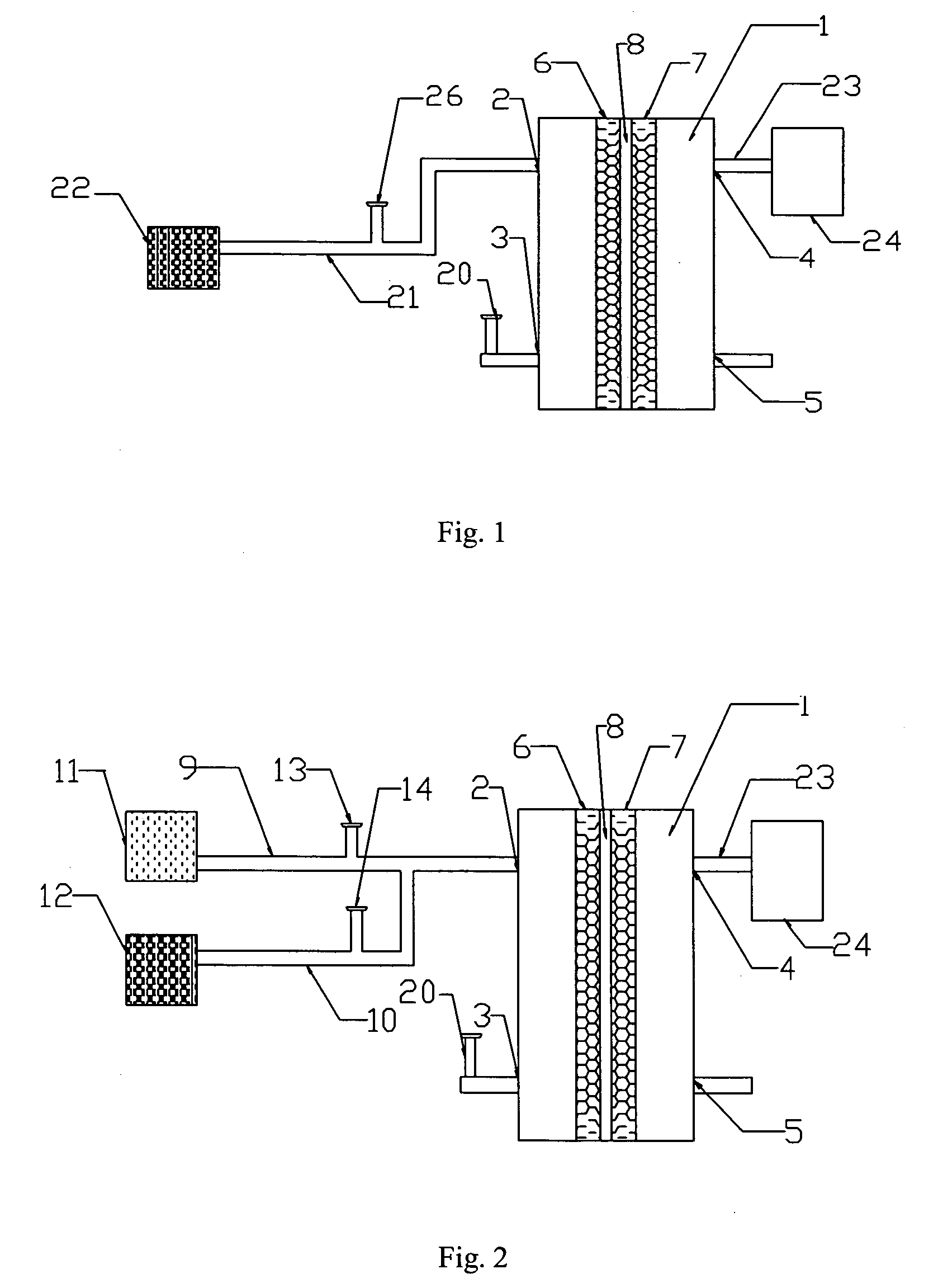

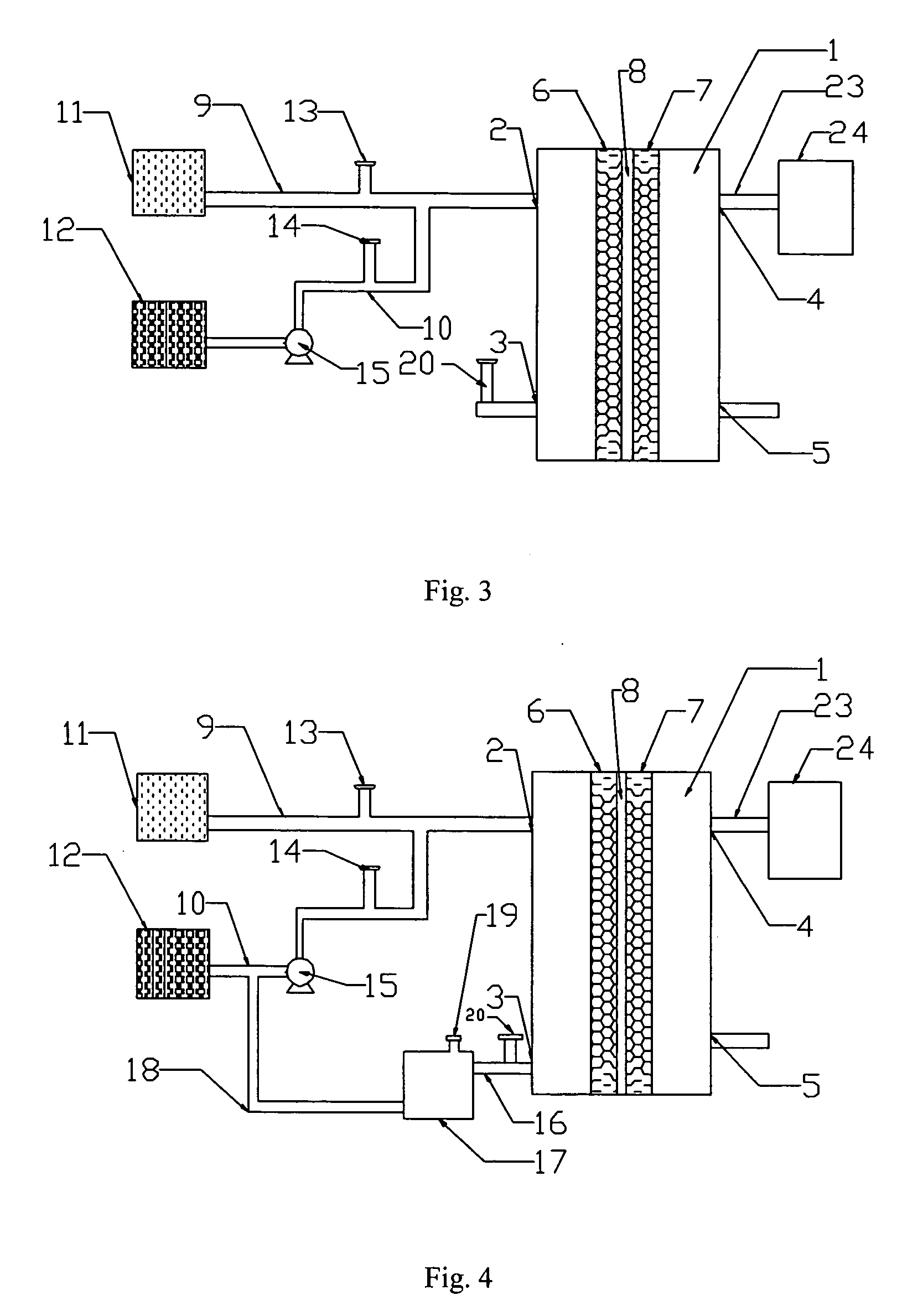

Type of fuel cell battery

ActiveUS20060147766A1Small cell areaSmall sizeReactant parameters controlFinal product manufactureHydrogen valveEngineering

A fuel cell battery, comprising a chamber unit (1), an anode entrance (2) connected to the chamber unit (1), an anode exit (3), a cathode entrance (4) and a cathode exit (5). The anode entrance (2) is connected to a hydrogen source (11) and an organic fuel source (12) respectively through a hydrogen duct (9) and an organic fuel duct (10). Duct (9) and duct (10) are respectively installed with a hydrogen valve (13) and an organic fuel valve (14). An exit valve (20) is installed at the anode exit. This fuel cell battery combines the advantages provided by hydrogen fuel and organic fuel. The fuel cell battery can meet the dual requirements of operating on both high and low power. The fuel cell battery's design leads to low manufacturing costs, a simple structure, and easy implementation.

Owner:BYD CO LTD

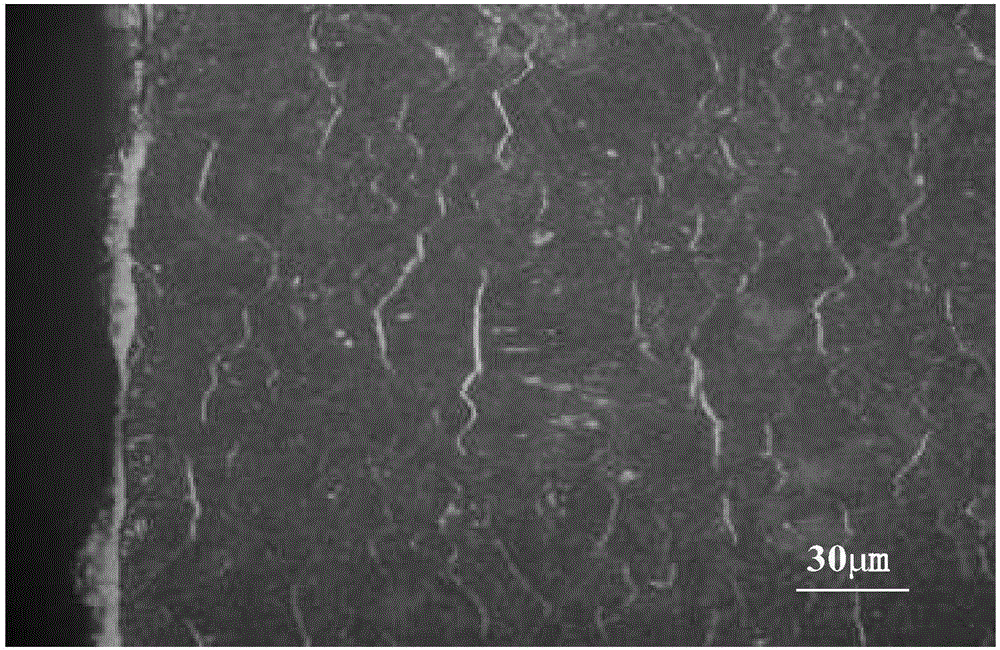

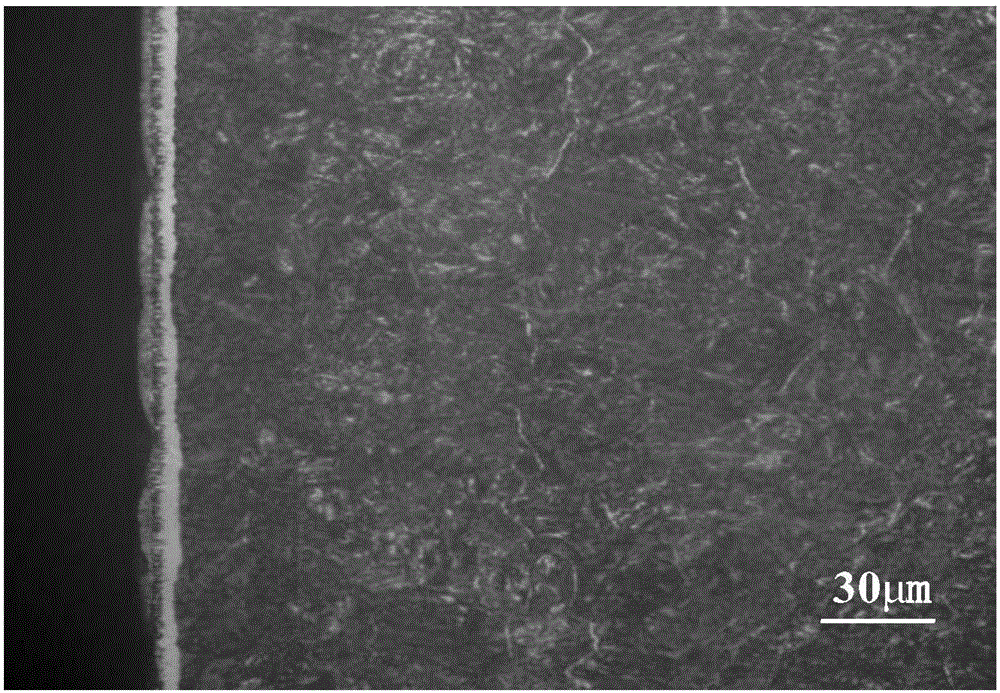

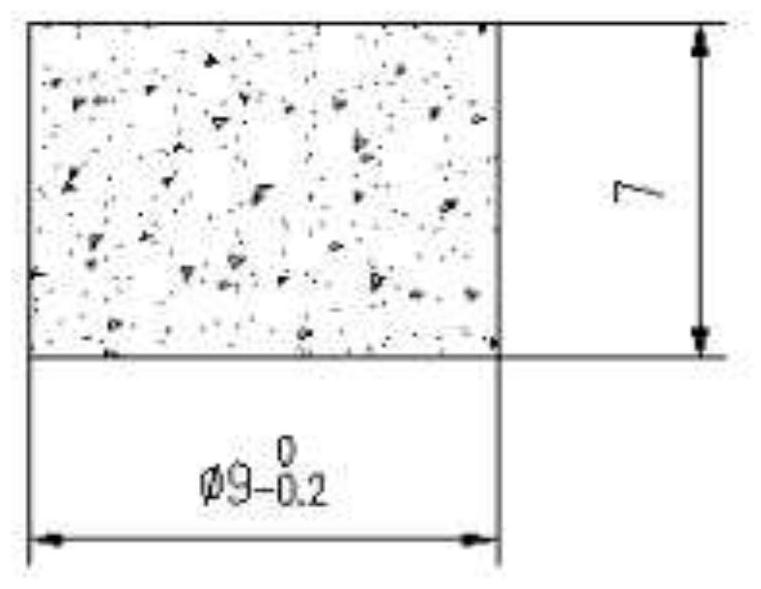

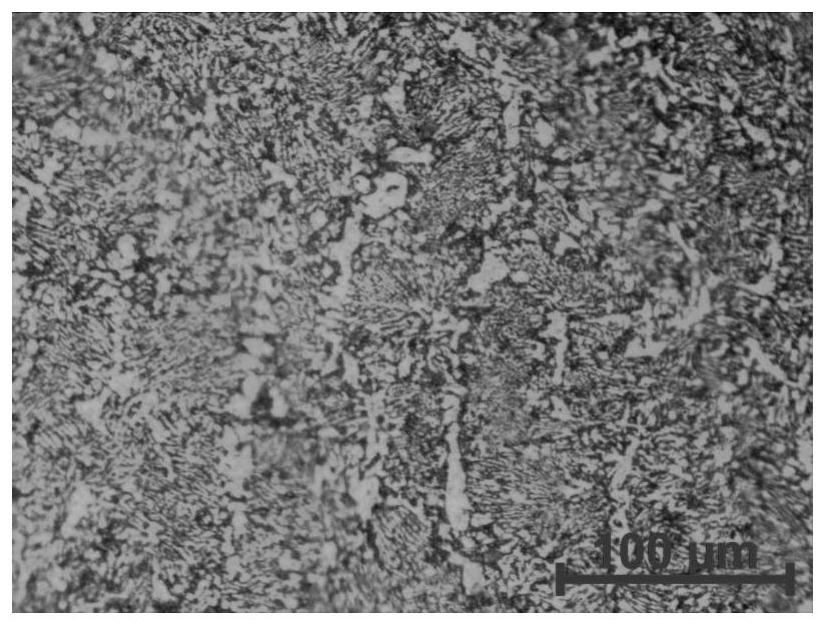

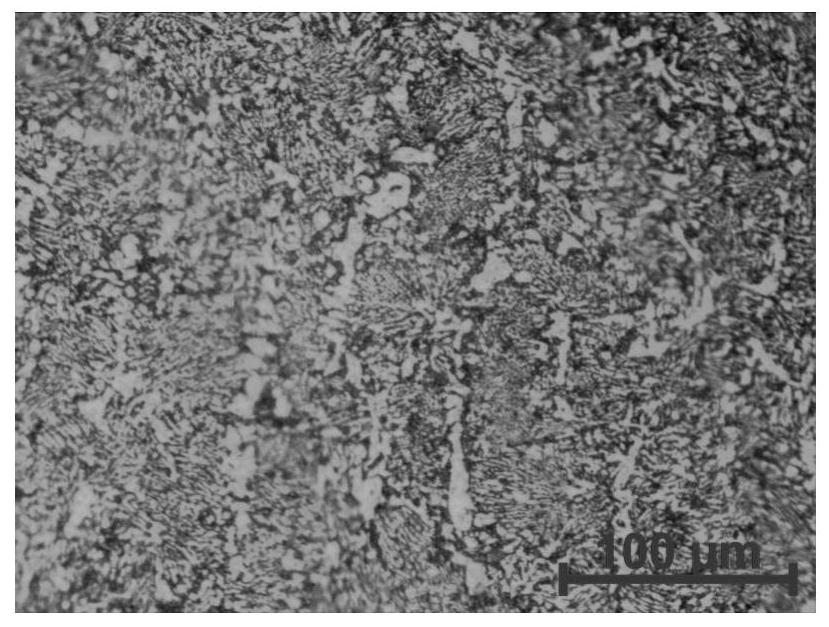

Ion nitriding method for efficiently controlling formation of vein-like nitride on surface layer of 38CrMoAl mold

InactiveCN106591771AMany defectsIncrease surface free energySolid state diffusion coatingConcentration gradientNitrogen gas

The invention relates to an ion nitriding method for efficiently controlling formation of vein-like nitride on the surface layer of a 38CrMoAl mold. The ion nitriding method comprises the steps that the 38CrMoAl mold is put into an ion nitriding furnace, hydrogen is injected, ion sputtering is conducted, and nitrogen continues to be injected; after the temperature is raised to the oxidizing temperature, nitrogen and hydrogen valves are closed, and air is injected; an air valve is closed, the nitrogen and hydrogen valves are opened, and ion nitriding is conducted; and after the temperature is lowered to the room temperature, a sample is taken out. The ion nitriding method has the beneficial effects that an oxidation treating process is additionally conducted before ion nitriding, the nitrogen content of the surface of a workpiece is increased remarkably, the nitrogen concentration gradient of the material surface is increased, diffusing of nitrogen atoms to a substrate is accelerated, no vein-like or net-like nitride exists in a nitride layer, and the surface abrasion resistance and the contact fatigue strength are improved significantly.

Owner:CHANGZHOU UNIV

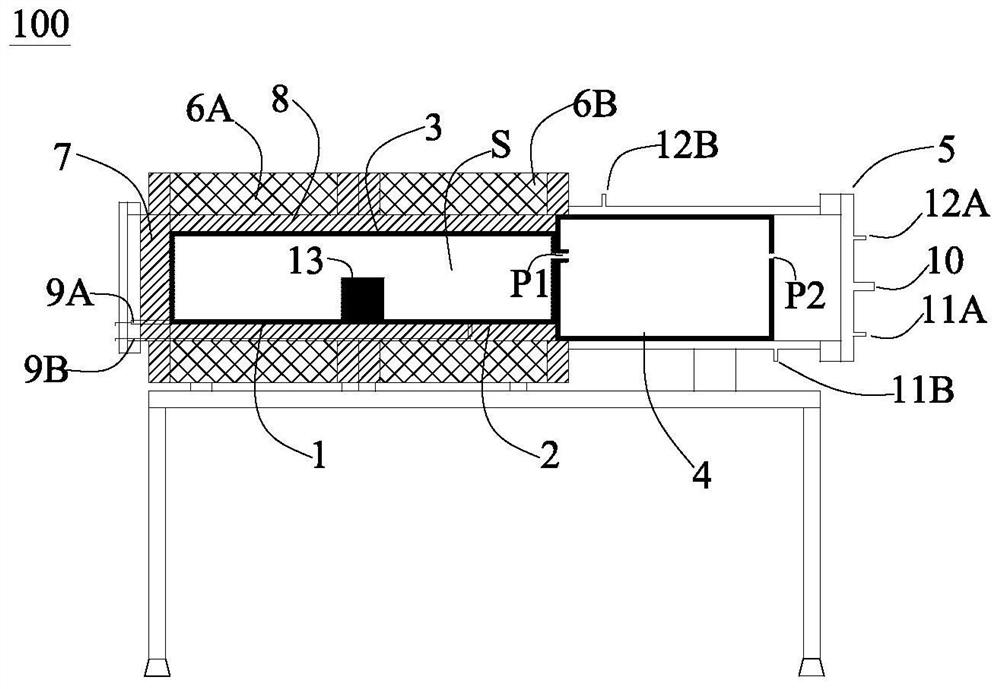

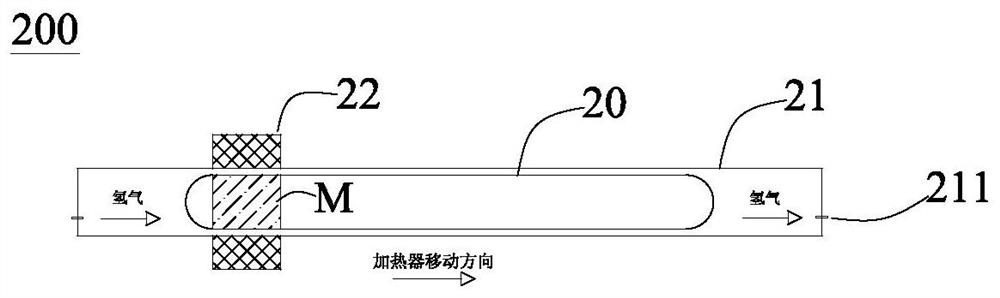

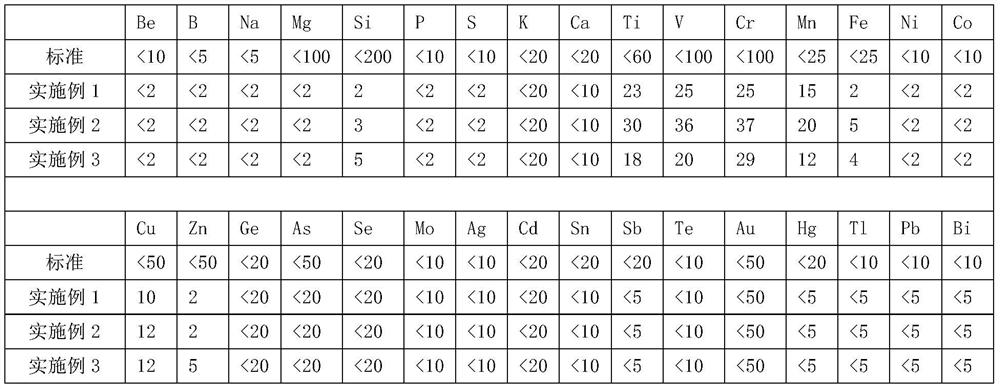

Preparation method of ultra-high-purity aluminum

ActiveCN113416854APrevent oxidationMeet the requirements of impurity contentProcess efficiency improvementHydrogen valveZone melting

Owner:广东先导微电子科技有限公司

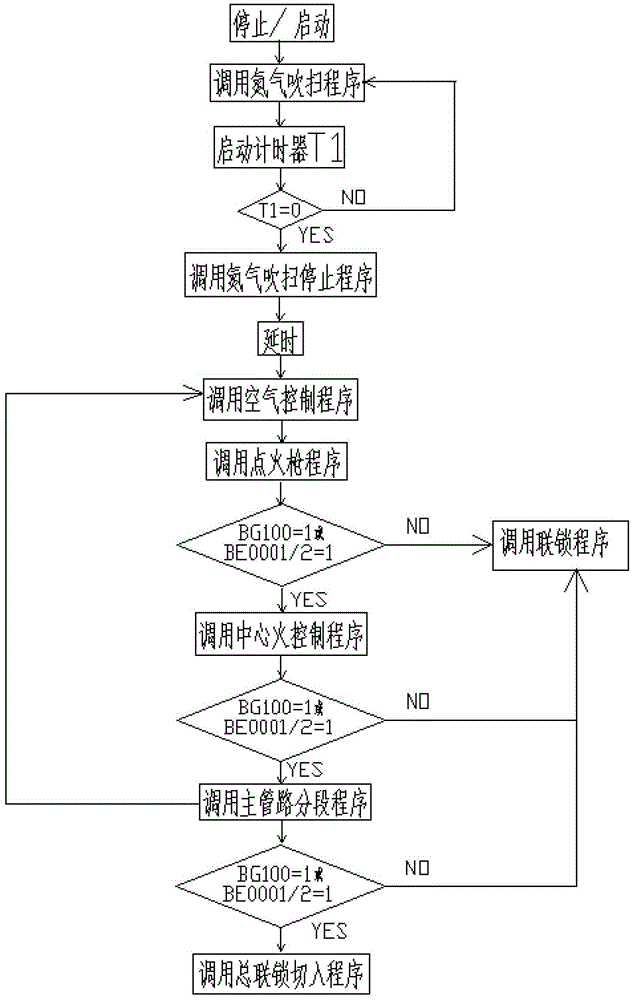

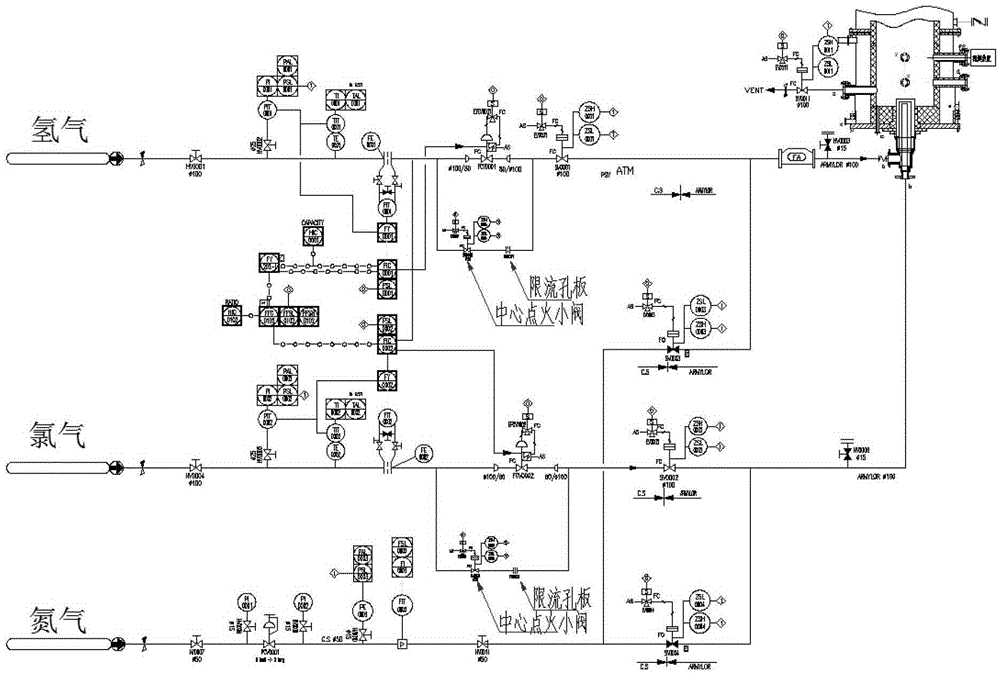

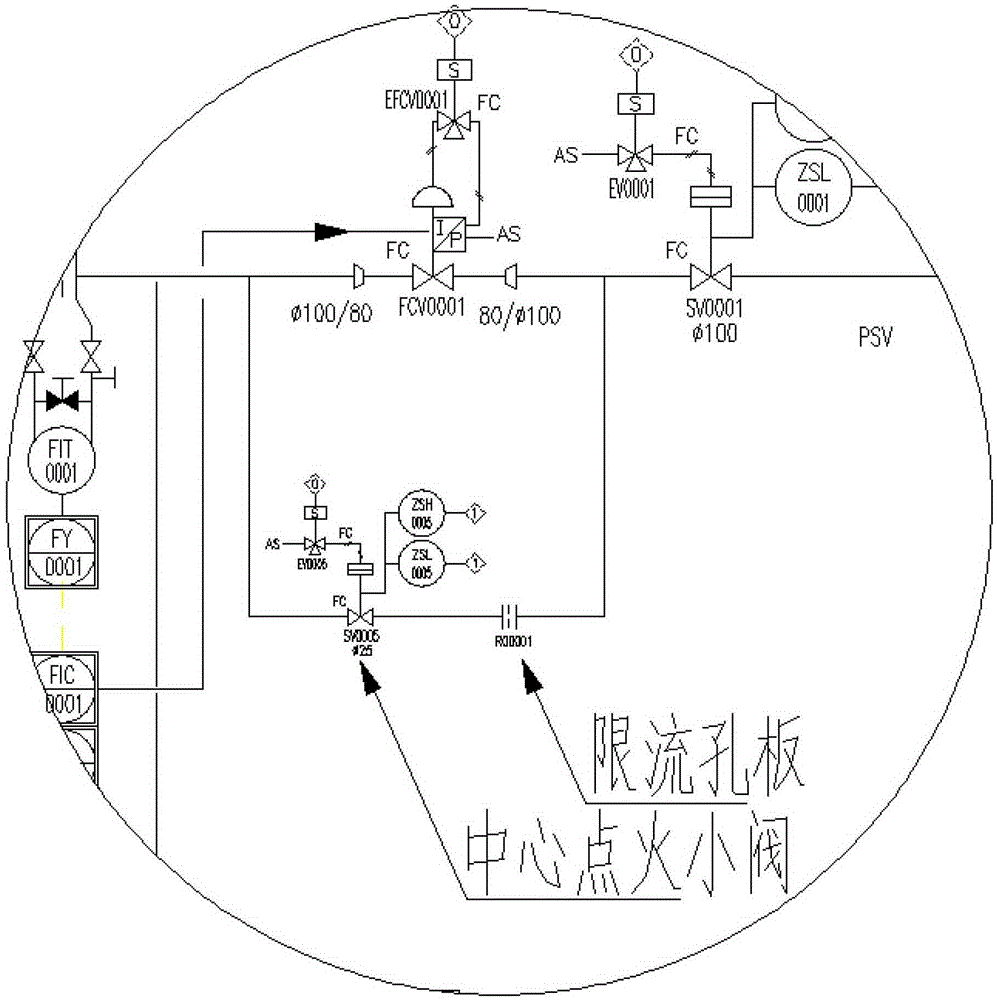

Negative pressure and positive pressure automatic ignition method of hydrogen chloride synthesis furnace

ActiveCN103420339BSave human effortHigh degree of automationChlorine/hydrogen-chlorideHydrogen valveUltraviolet

Owner:SHANGHAI TIANSAN AUTOMATIC CONTROL

Hydrogen pressure control system and method for fuel battery backup power supply system

ActiveCN104064787AAvoid failureEliminate distractionsFinal product manufactureFuel cell controlHydrogen valveExhaust valve

The invention relates to a hydrogen pressure control system and a method for a fuel battery backup power supply system. The hydrogen pressure control system comprises a main hydrogen valve, a hydrogen feeding valve and a hydrogen exhaust valve, wherein the main hydrogen valve, the hydrogen feeding valve and the hydrogen exhaust valve are connected in sequence through pipelines; a hydrogen feeding pressure sensor is also arranged on the pipeline between the main hydrogen valve and the hydrogen feeding valve; an electric pile is also connected to the pipeline between the hydrogen feeding valve and the hydrogen exhaust valve; the hydrogen feeding pressure sensor is also connected with a single-chip microcomputer for cyclically detecting a hydrogen feeding pressure output signal; the main hydrogen valve, the hydrogen feeding valve and the hydrogen exhaust valve are connected with the single-chip microcomputer and are controlled to be switched on and switched off through the single-chip microcomputer. When the output signal of the hydrogen feeding pressure sensor is lower than a set value, the hydrogen pressure control system effectively eliminates interference caused by a negative pressure phenomenon of a hydrogen pipeline, and can accurately judge whether the hydrogen feeding pressure sensor has a zero-point drifting problem and effectively avoid the phenomenon that the system reports a failure of the hydrogen feeding pressure sensor by mistake, so that the diagnosis accuracy of the system is improved, and the reliability of the system during standby is guaranteed.

Owner:KUSN FUERSAI ENERGY

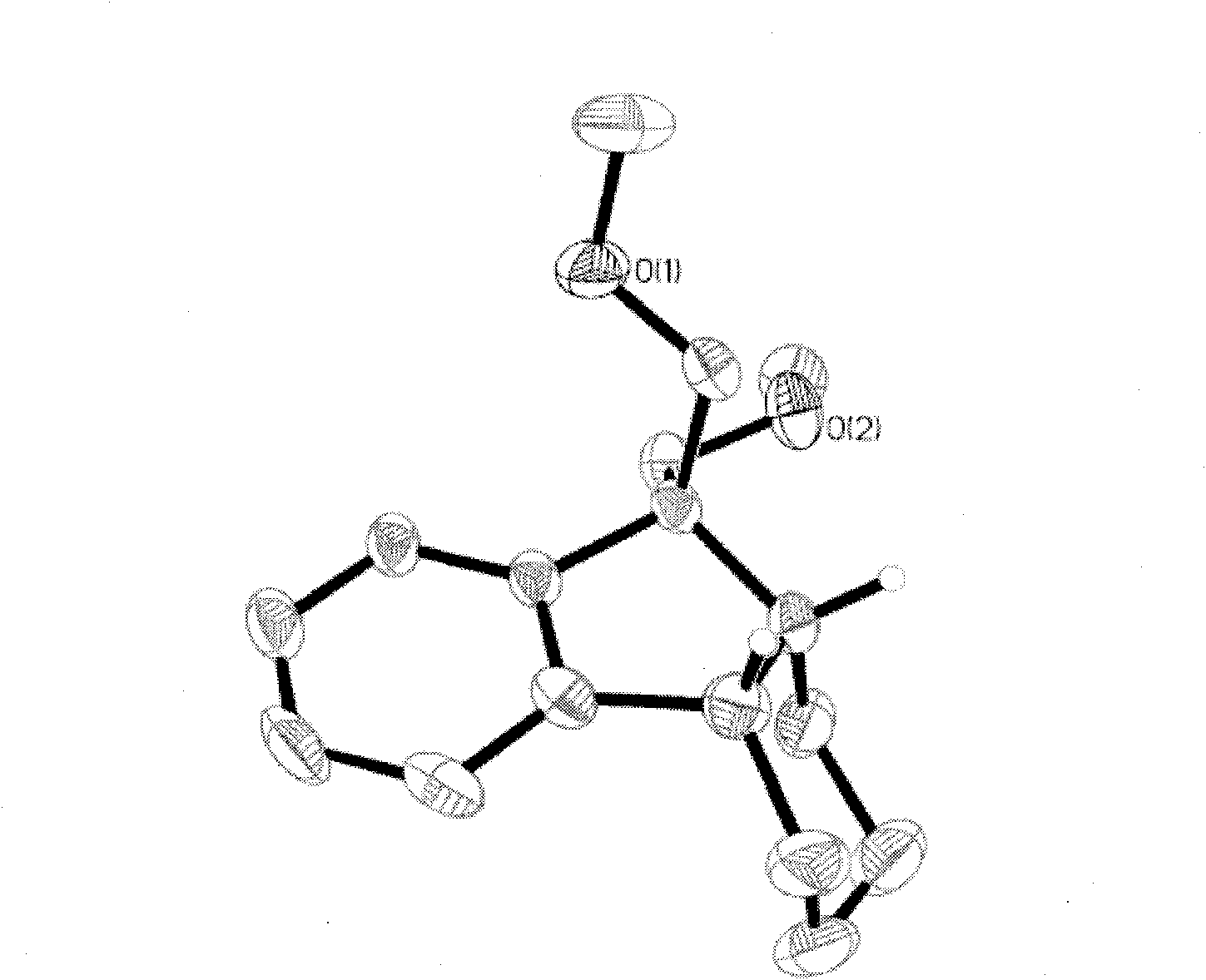

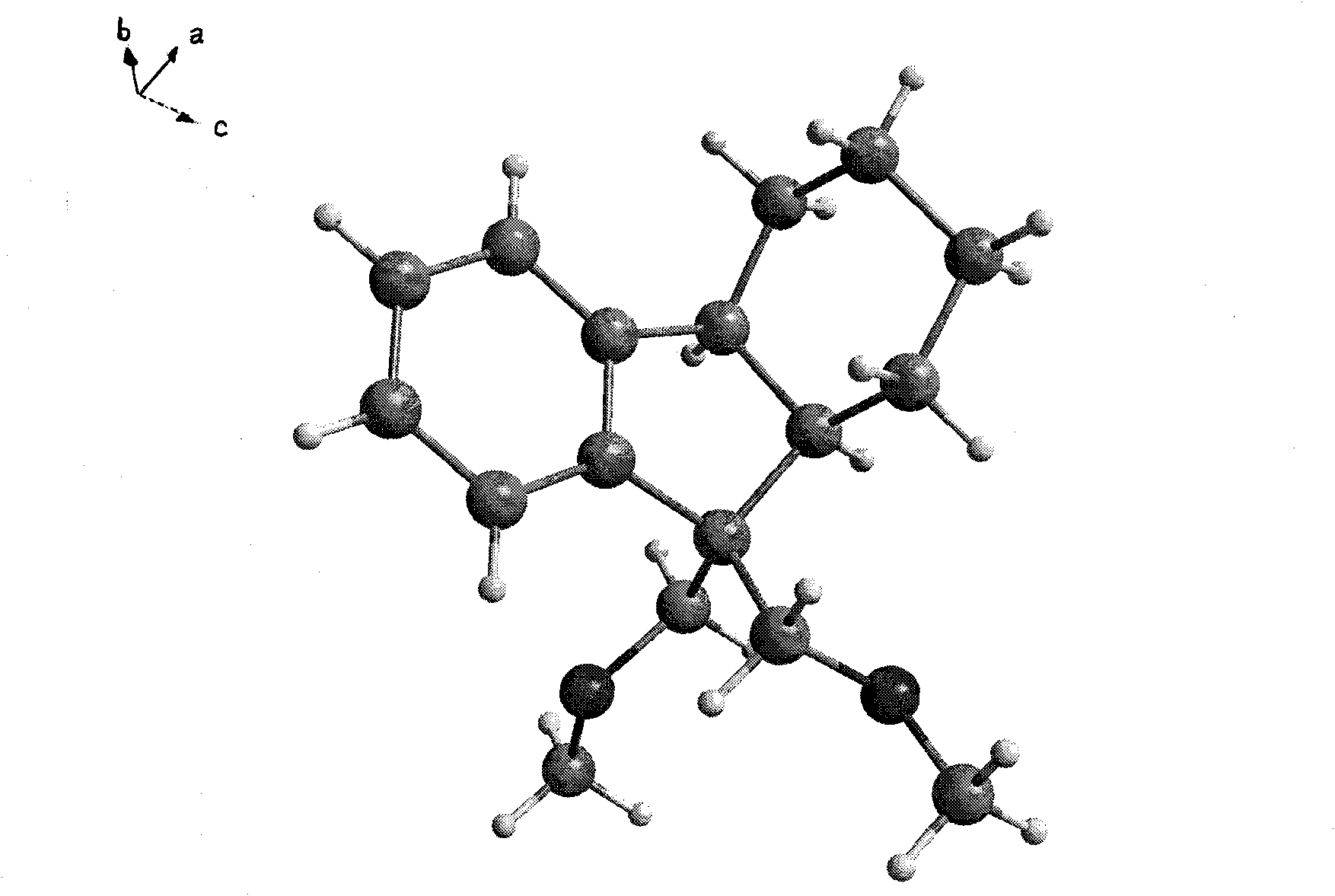

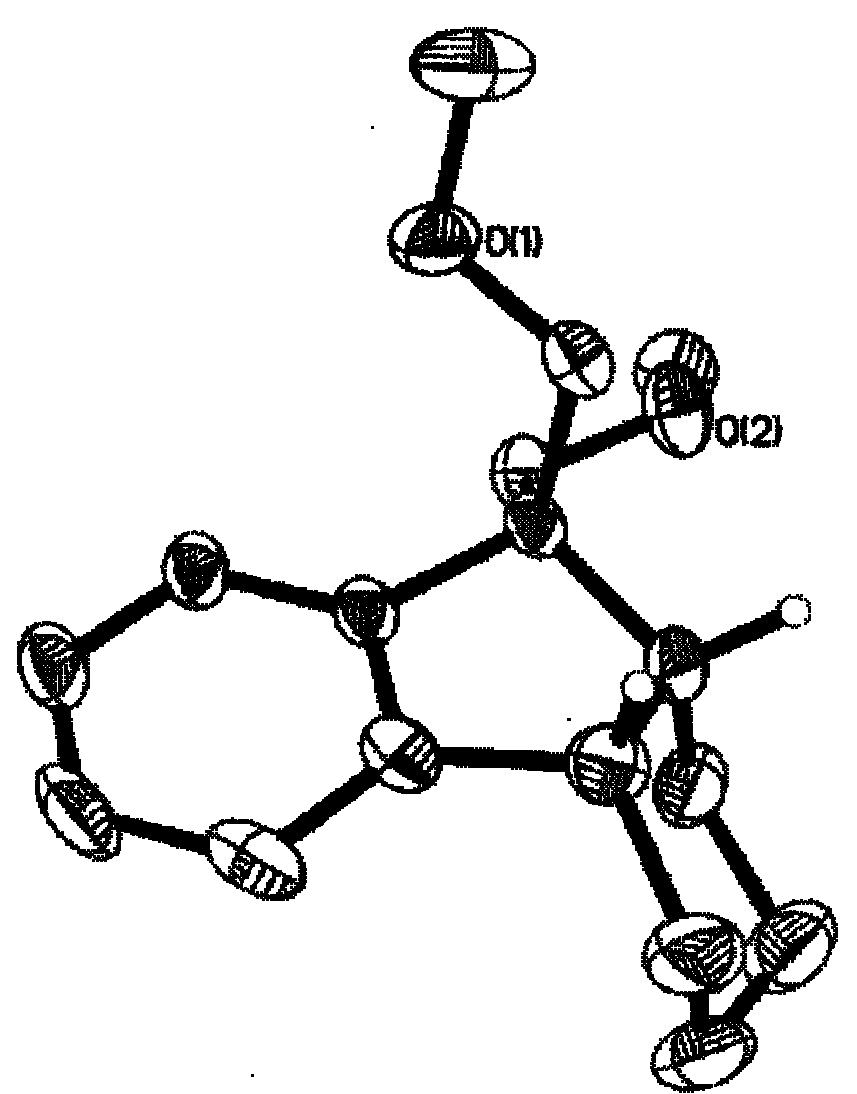

Method for selective catalytic hydrogenation for 9,9-bi(methoxymethylated) fluorine (BMMF)

InactiveCN101955419AHigh stereoselectivityEasy to operateOrganic chemistryOrganic compound preparationHydrogen valveNickel catalyst

The invention relates to a method for selective catalytic hydrogenation for 9,9-bi(methoxymethylated) fluorine (BMMF), which comprises the following steps: adding BMMF, solvent and a modified skeleton nickel catalyst in an autoclave, wherein the mass ratio of the solvent to the BMMF is 1:1-10:1, the dosage of the modified skeleton nickel catalyst is 1-20wt% of that of the BMMF; replacing air after closing the autoclave; then introducing a certain amount of hydrogen; putting the autoclave into oil bath, and heating slowly to the reaction temperature, wherein the reaction temperature is 100-250DEG C; and adjusting a hydrogen valve so as to enable the system pressure to be 0.5-4.0MPa and keeping for 0.5-5h, wherein the selectivity of cis-H6BMMF can be up to 98%. The method has the characteristics of simple operation, good repeatability, high product stereoselectivity and the like.

Owner:DALIAN UNIV OF TECH

Ignition system for low grade synthesis gas at high compression

InactiveUS20150020764A1High thermal efficiencyInternal combustion piston enginesGasification processes detailsHydrogen concentrationHydrogen valve

An igniter system for a reciprocating piston internal combustion engine having one or more cylinders including at least one igniter per cylinder is disclosed. The igniter system can comprise: a combustion chamber connected to a main cylinder of the engine by a restricted diameter bore, wherein a lean burn fuel mixture is introduced into the combustion chamber by the normal compression stroke of the engine; a hydrogen valve that injects a hydrogen rich gas into the combustion chamber forming a mixture of hydrogen and air having a hydrogen concentration above the stoichiometric ratio for hydrogen and air in the combustion chamber; and a spark ignition source that injects hot unburned hydrogen into the main cylinder, thereby initiating ignition.

Owner:V GRID ENERGY SYST INC

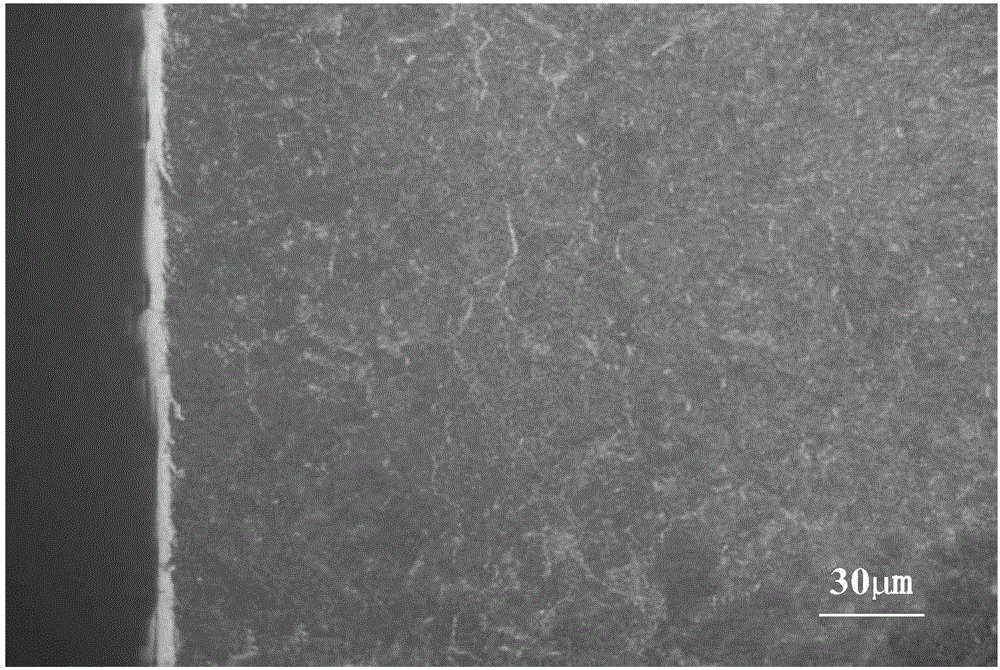

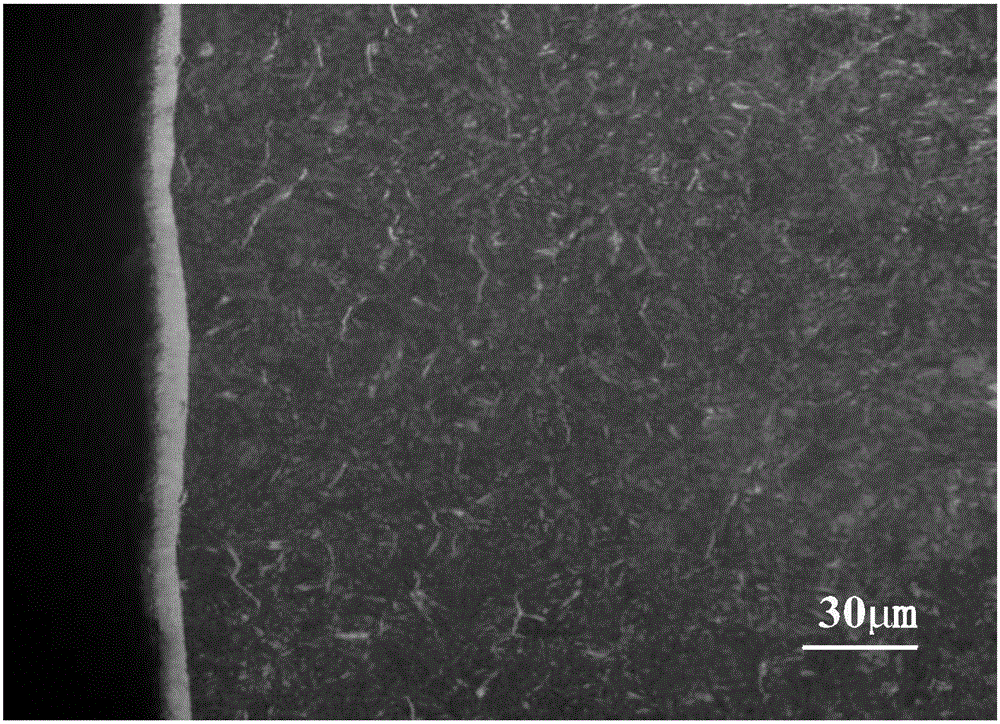

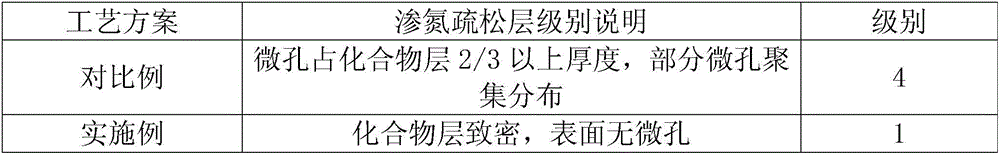

Nitridation loosening layer heat treatment method capable of controlling ion nitriding formation effectively

InactiveCN106637064AHigh nitrogen contentHigh surface hardnessSolid state diffusion coatingHydrogen valveFree energies

The invention relates to a nitridation loosening layer heat treatment method capable of controlling ion nitriding formation effectively. The nitridation loosening layer heat treatment method capable of controlling ion nitriding formation effectively comprises the following steps: placing a 42CrMo gear in an ion nitriding furnace, feeding hydrogen to carry out ion sputtering, and continuing feeding nitrogen; after the temperature rises to an oxidizing temperature, closing a nitrogen valve and a hydrogen valve, and feeding air; closing an air valve, opening the nitrogen valve and the hydrogen valve, and carrying out ion nitriding; and after cooling to the room temperature, taking out a sample. The nitridation loosening layer heat treatment method capable of controlling ion nitriding formation effectively has the beneficial effects that an oxidizing treatment process is added before ion nitridation, a compact oxidizing layer is generated on the surface of a material, the surface free energy is increased, loosening is eliminated, the surface hardness and the wear resistance of 42CrMo and the grade accuracy of workpieces of 42CrMo are improved, and nitridation loosening grade is increased to be grade 1 from the original grade 4; the method is simple to operate; a pre-oxidizing medium is air; moreover, the oxidizing temperature is low; and consumption of energy is reduced.

Owner:CHANGZHOU UNIV

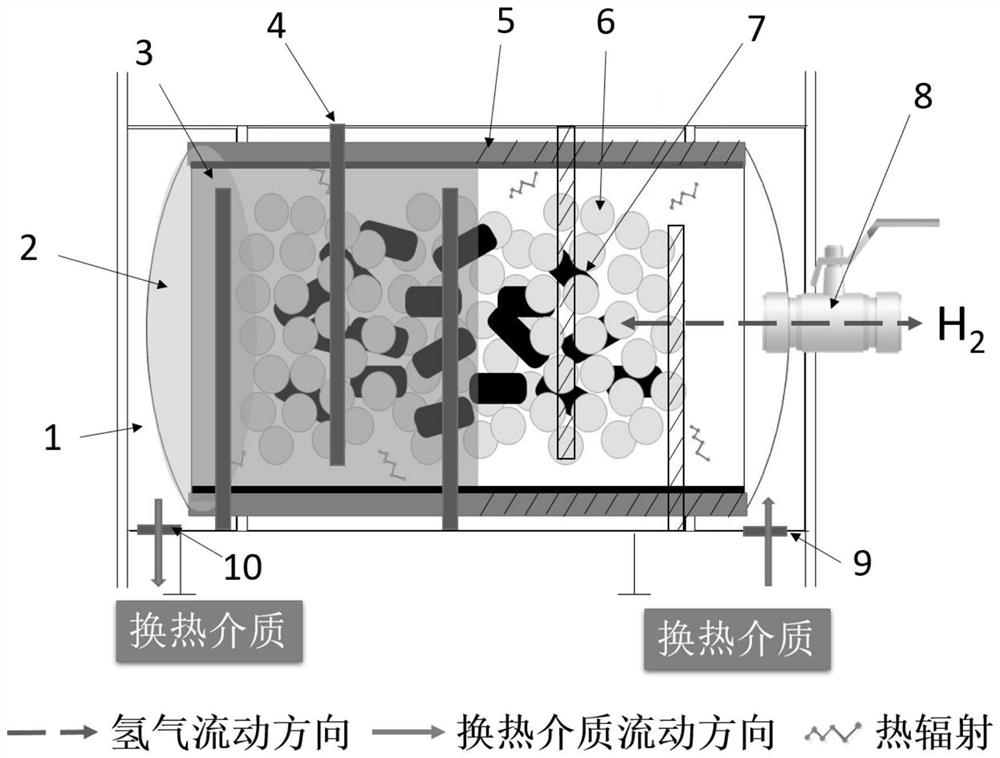

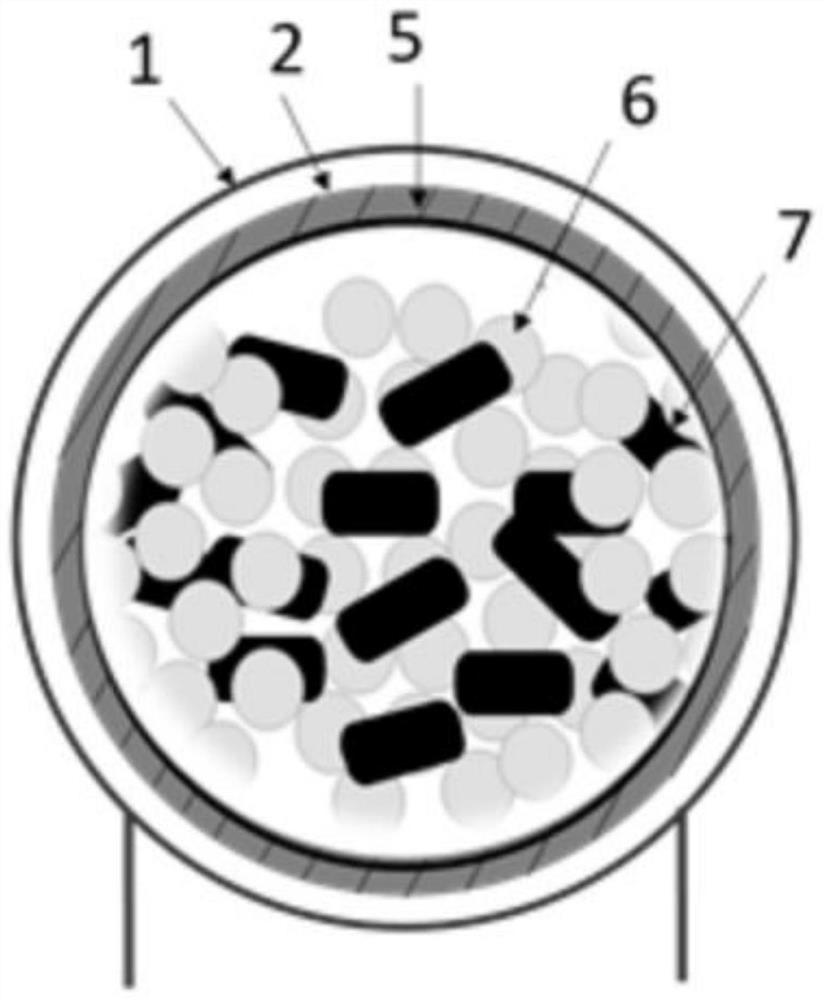

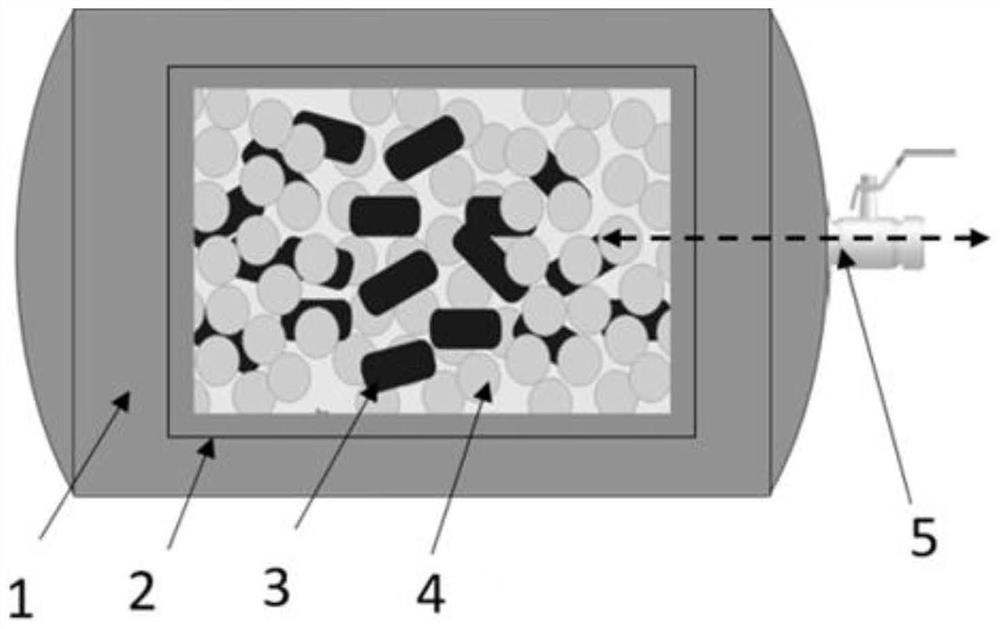

Hydride heat storage system for dissipating heat by thermal radiation and application

InactiveCN112113452AComprehensive contactReduce lossesSolar heating energySolar heat storageHydrogen valveMetallic hydrogen

The invention relates to a hydride heat storage system for dissipating heat by thermal radiation. The system comprises a heat exchange tank and a heat storage reactor mounted in the heat exchange tank. The heat exchange tank is separately provided with a flow inlet and a flow outlet where a heat exchange medium comes in and goes out, and the flow inlet and the flow outlet communicate; a hydrogen valve where hydrogen circulates is arranged between the heat exchange tank and the heat storage reactor; and a thermal radiation coating is arranged on the inner wall of the heat storage reactor, and ametal hydride and thermal radiation enhanced particles mixed with each other are placed in the heat storage reactor. Heat in the heat storage reactor is mainly transferred by thermal radiation between the thermal radiation coating and the thermal radiation enhanced particles. By adopting the technical scheme, the hydride heat storage system is simple in structure and economical and practical, andthe heat exchange performance and the heat storage efficiency of the system are improved.

Owner:GUANGDONG INST OF RARE METALS

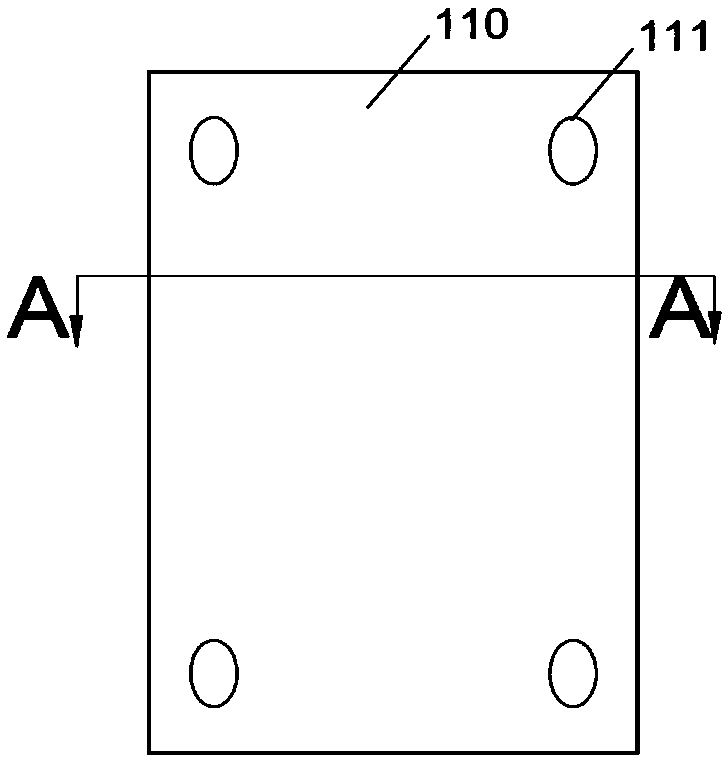

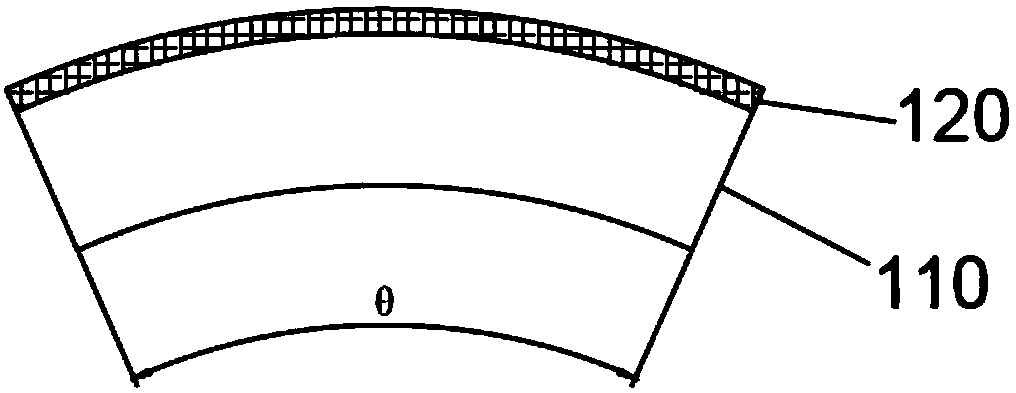

A hydrogen-absorbing low-strain metal hydride hydrogen storage tank

ActiveCN105371105BSimple structureEasy to implementContainer filling methodsFixed capacity gas holdersHydrogen valveHydrogen absorption

The invention belongs to the hydrogen storage technology in the hydrogen energy field and particularly relates to a hydrogen-absorption low-strain metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a tank body, a metal hydride hydrogen storage alloy bed body and an elastic buffer layer. The elastic buffer layer is arranged between the tank body and the metal hydride hydrogen storage alloy bed body. A heat exchange pipe is communicated with the interior of the metal hydride hydrogen storage alloy bed body and used for guiding heat generated in the hydrogen absorption and release processes of the metal hydride hydrogen storage alloy bed body out. A hydrogen valve is installed on an outlet of the tank body and meanwhile a hydrogen filter is welded to the outlet end of the tank body. The hydrogen-absorption low-strain metal hydride hydrogen storage tank is simple in structure and easy to obtain, the destructive effect on the tank body due to the fact that the metal hydride hydrogen storage alloy bed body expands after absorbing hydrogen can be relieved effectively, and the use safety of the hydrogen storage tank is improved.

Owner:GRIMAT ENG INST CO LTD

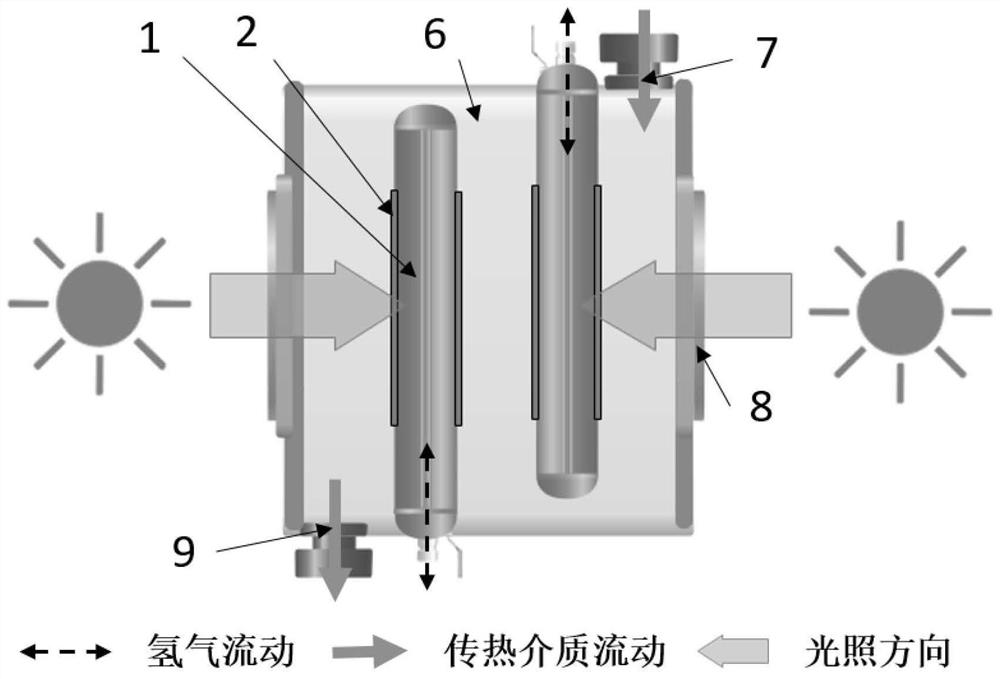

Hydride heat storage system and method adopting direct illumination heating

InactiveCN112344572AFully contactedPlay the role of diversionSolar heating energySolar heat storageHydrogen valveDirect illumination

The invention relates to a hydride heat storage system adopting direct illumination heating. The system comprises a heat exchange tank, wherein a first light-transmitting module allowing sunlight to pass through is arranged on the side face of the heat exchange tank, and the heat exchange tank is provided with a flow inlet and a flow outlet allowing a heat exchange medium to come in and go out. Aplurality of heat storage reactors playing a baffling role are alternately arranged on the upper inner wall surface and the lower inner wall surface of the heat exchange tank correspondingly, each heat storage reactor is provided with a hydrogen valve connected with an external hydrogen storage container, and second light-transmitting modules matched with the first light-transmitting module are arranged on the side surfaces of the heat storage reactors (1). When the system is installed, metal hydride and heat radiation reinforced particles which are arranged in a mutually mixed mode are placedin the plurality of heat storage reactors. By the adoption of the technical scheme, efficient heat storage of the metal hydride heat storage system is achieved; and meanwhile, the structure is simple, economical and practical.

Owner:GUANGDONG INST OF RARE METALS

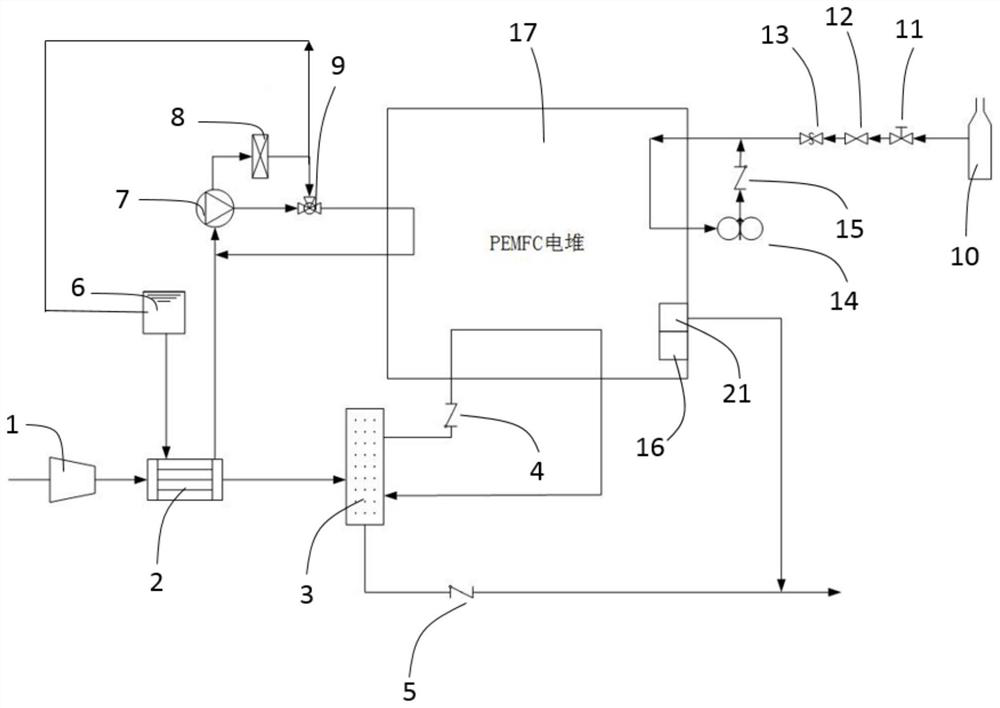

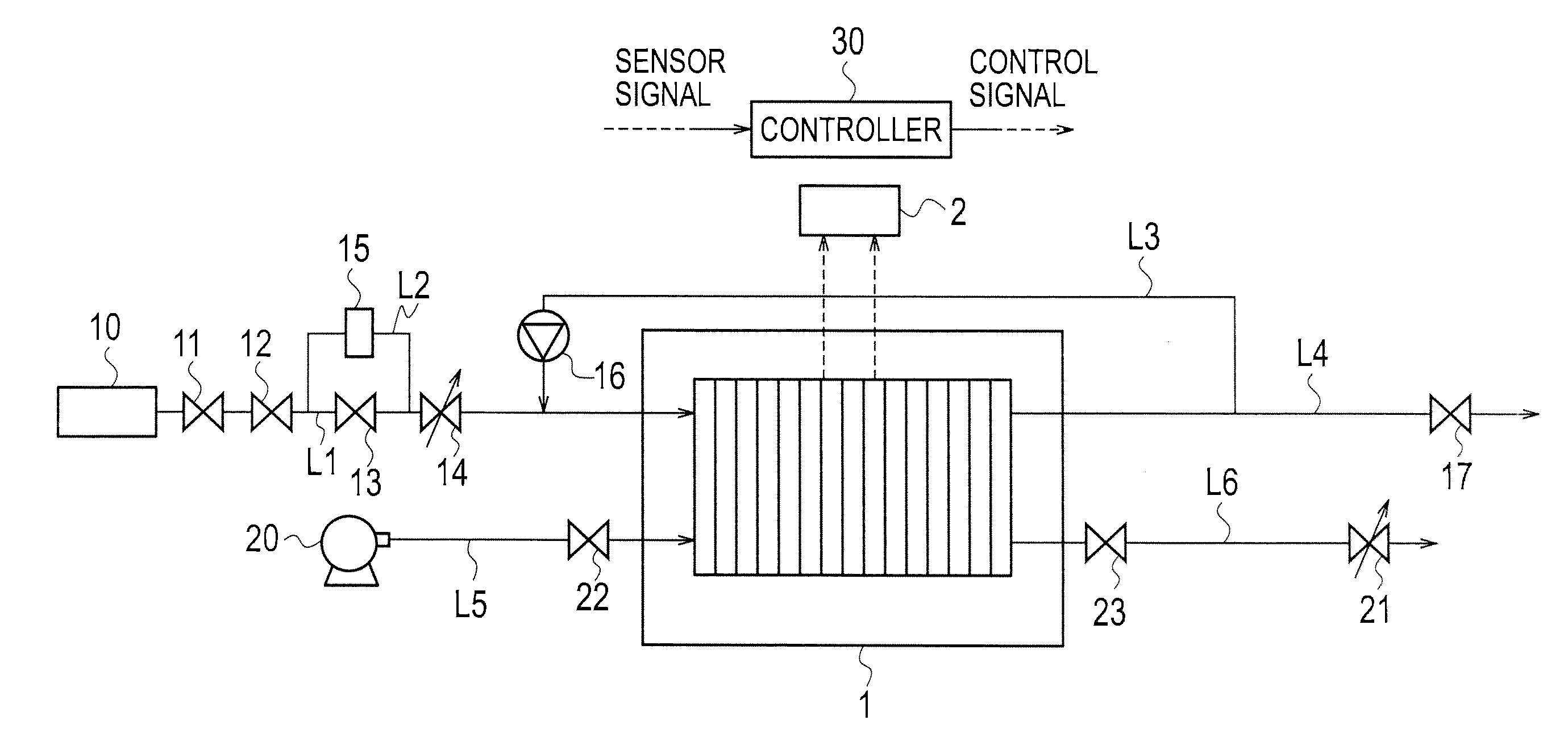

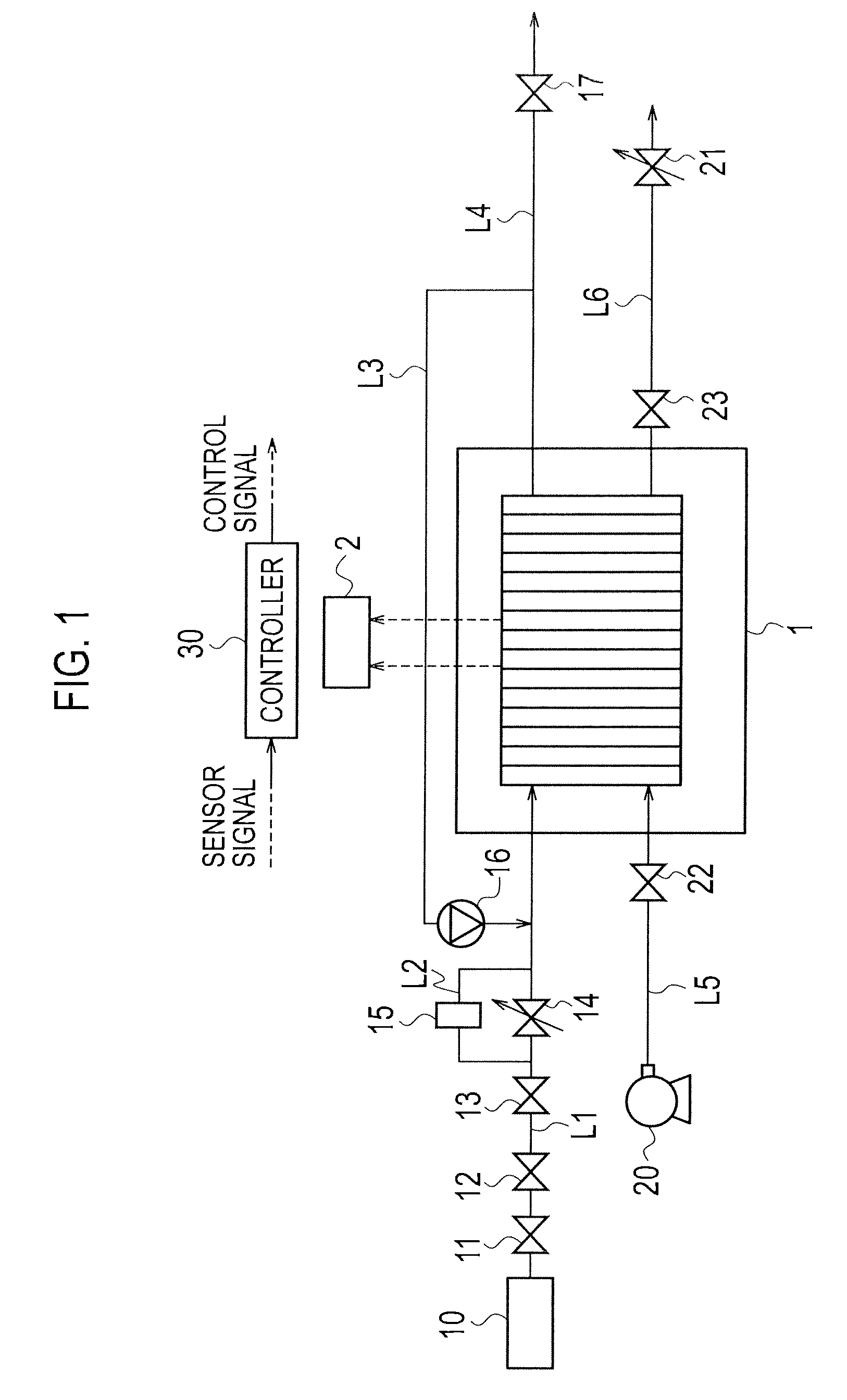

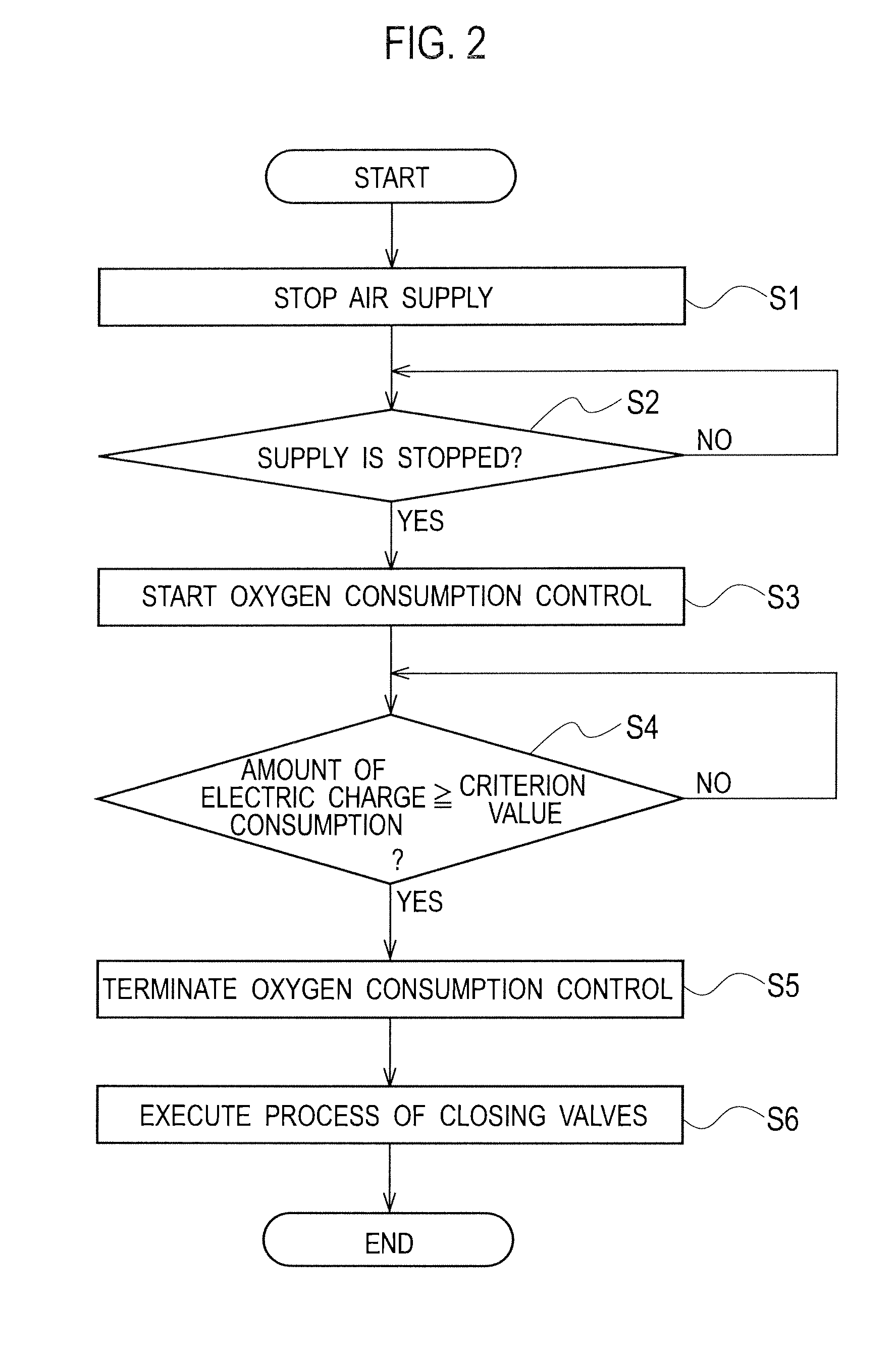

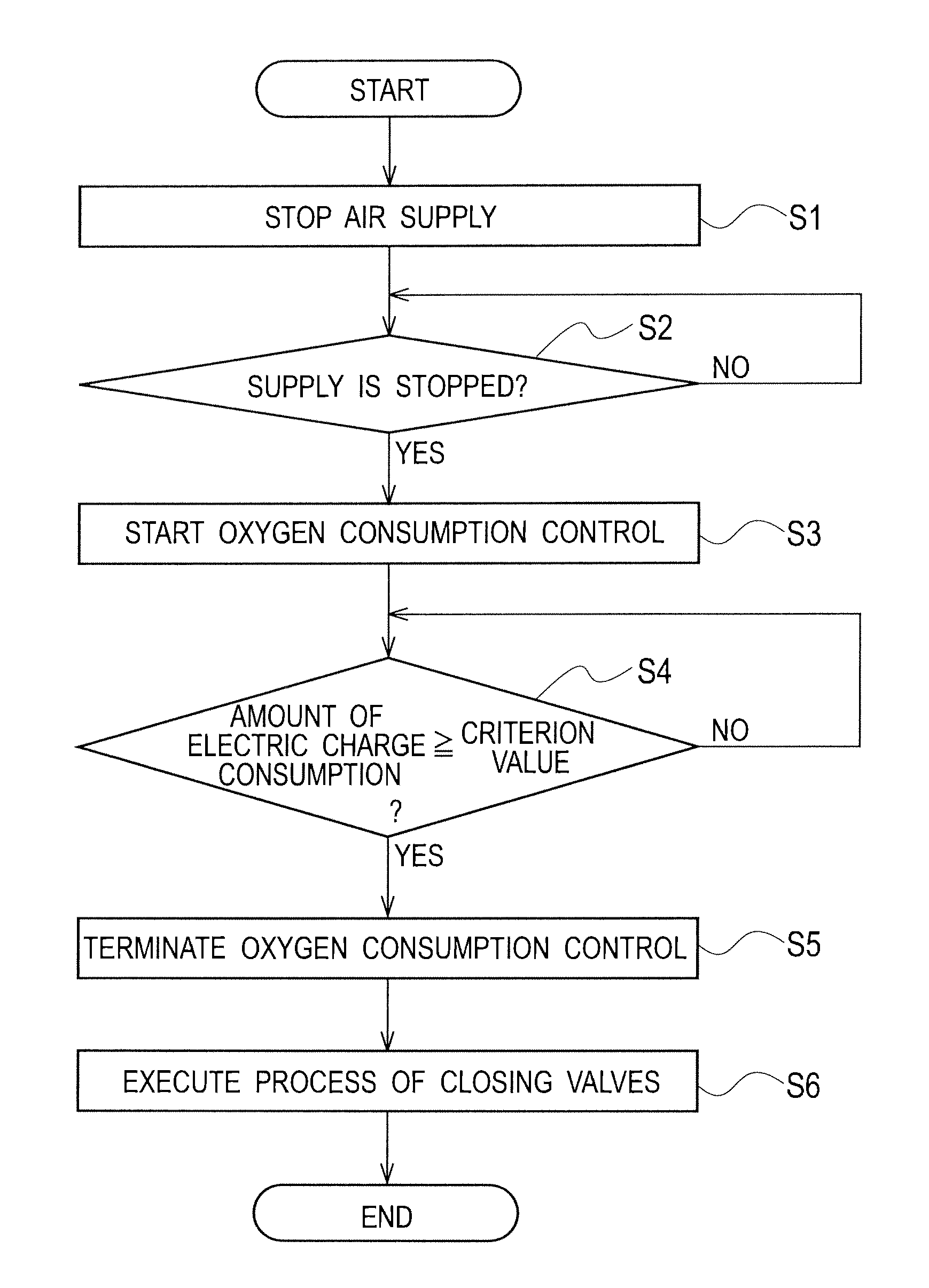

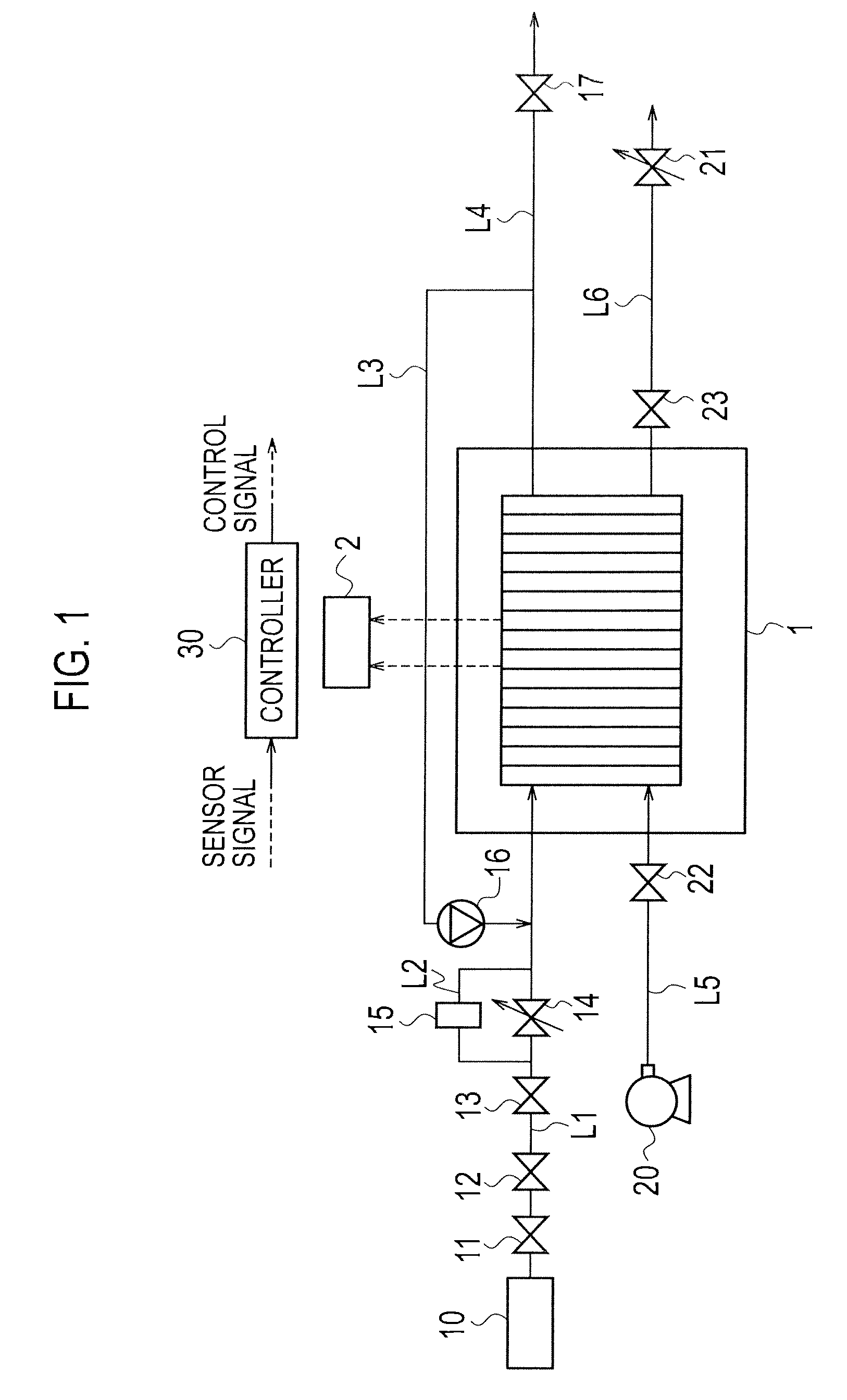

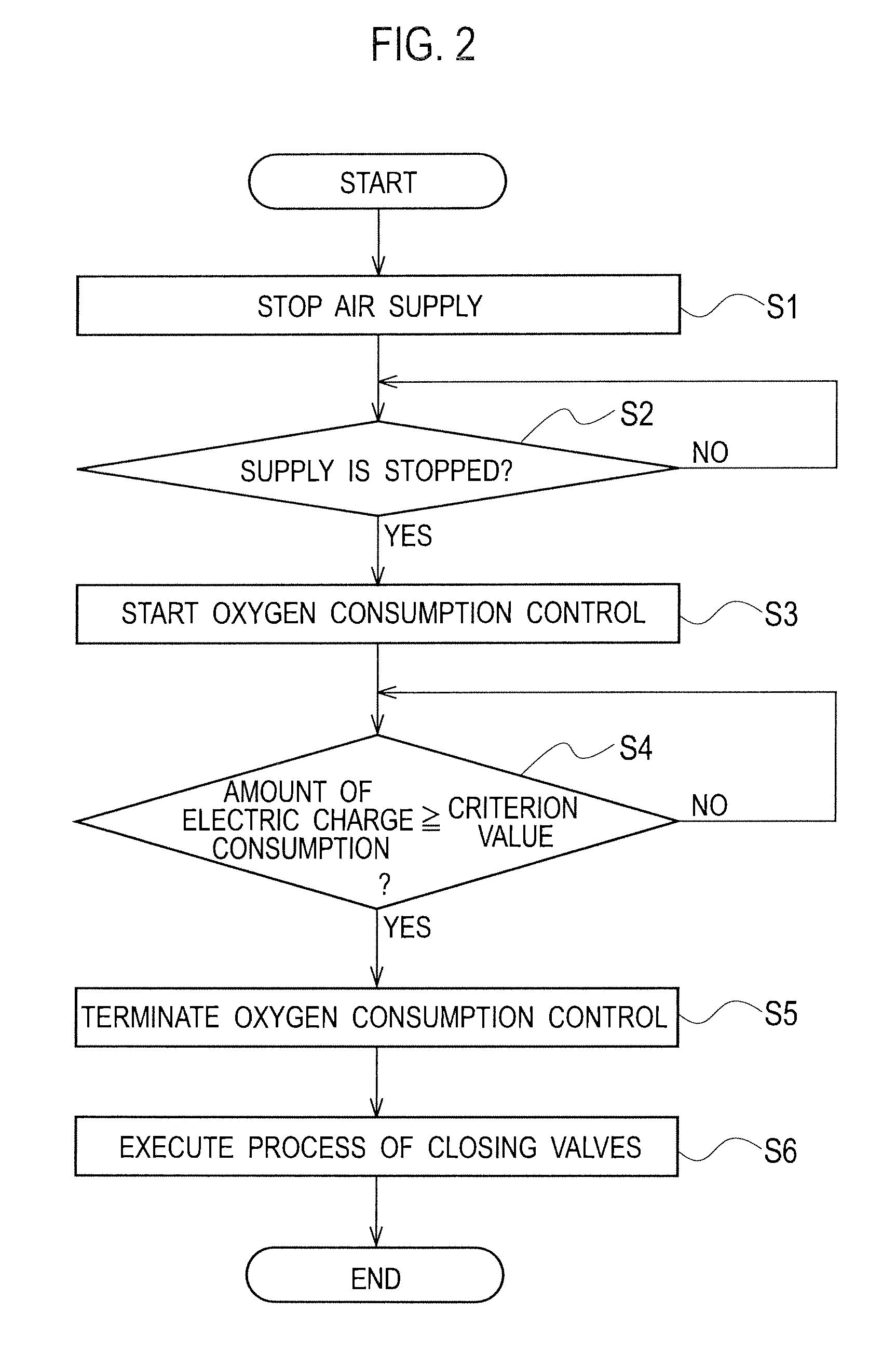

Fuel cell system and method of controlling fuel cell system

ActiveUS20110159390A1Inhibit deteriorationDelay problemFuel cell auxillariesHydrogen valveHydrogen pressure

Deterioration at the start-up and deterioration during the leaving period are suppressed in a good balance. As a system shutdown process, a controller (30) causes consumption of the air (oxygen) present in an oxidant electrode of a fuel cell stack (1) (oxygen consumption control). Further, after the termination of the oxygen consumption control, the controller (30) performs control to set a medium pressure hydrogen valve (13) and a hydrogen pressure adjustment valve (14) in a closed state. The controller (30) thereby causes hydrogen to be held in a passage located between the medium pressure hydrogen valve (13) and the hydrogen pressure adjustment valve (14). During a system shutdown period, a predetermined amount of hydrogen (medium pressure hydrogen) held in the hydrogen supply passage (L1) at a position between the medium pressure hydrogen valve (13) and the hydrogen pressure adjustment valve (14) can be supplied to the fuel electrode of the fuel cell stack (1) through a bypass passage (L2).

Owner:NISSAN MOTOR CO LTD

Preparation method for synthesizing carbon nanotubes in quantity and with low cost

InactiveCN102161481BSimple preparation processReduce energy consumptionNanotechnologyChemical platingCarbon nanotube

The invention discloses a preparation method for synthesizing carbon nanotubes in quantity and with low cost. The method comprises the following steps of: plating and coating nano-grade metal catalysts such as iron, cobalt, molybdenum and the like on foamed nickel by a chemical plating process; placing the foamed nickel plated with the catalysts into a quartz boat; heating the foamed nickel plated with the catalysts by using the common horizontal resistance furnace; introducing nitrogen with flow of 200 ml / min to remove air from a quartz tube; when the temperature reaches 650 DEG C, introducing hydrogen with flow of 50 ml / min to reduce the metal catalysts for 10 minutes; when the temperature reaches 690 to 720 DEG C, introducing acetylene gas with flow of 50 to 100 ml / min, wherein the hydrogen flow can be set to be 25 to 100 ml / min; closing an acetylene valve and a hydrogen valve after the reaction is performed for 30 minutes; introducing nitrogen with the flow of 20 ml / min; when the temperature is reduced to 300 DEG C, closing a nitrogen valve; and after the hearth is cooled to room temperature, taking out the quartz boat, wherein black products are found to be generated on the foamed nickel and are the carbon nanotubes according to electron microscope and Raman spectrum detection. By the method, the preparation process is simple; energy consumption is small; cost is low; time is saved; and preparation conditions are easy to implement.

Owner:ZHEJIANG UNIV

Fuel cell system and method of controlling fuel cell system

ActiveUS8765315B2Deterioration at start-up can be suppressedInhibit deteriorationFuel cell auxillariesHydrogen valveHydrogen pressure

Deterioration at the start-up and deterioration during the leaving period are suppressed in a good balance. As a system shutdown process, a controller (30) causes consumption of the air (oxygen) present in an oxidant electrode of a fuel cell stack (1) (oxygen consumption control). Further, after the termination of the oxygen consumption control, the controller (30) performs control to set a medium pressure hydrogen valve (13) and a hydrogen pressure adjustment valve (14) in a closed state. The controller (30) thereby causes hydrogen to be held in a passage located between the medium pressure hydrogen valve (13) and the hydrogen pressure adjustment valve (14). During a system shutdown period, a predetermined amount of hydrogen (medium pressure hydrogen) held in the hydrogen supply passage (L1) at a position between the medium pressure hydrogen valve (13) and the hydrogen pressure adjustment valve (14) can be supplied to the fuel electrode of the fuel cell stack (1) through a bypass passage (L2).

Owner:NISSAN MOTOR CO LTD

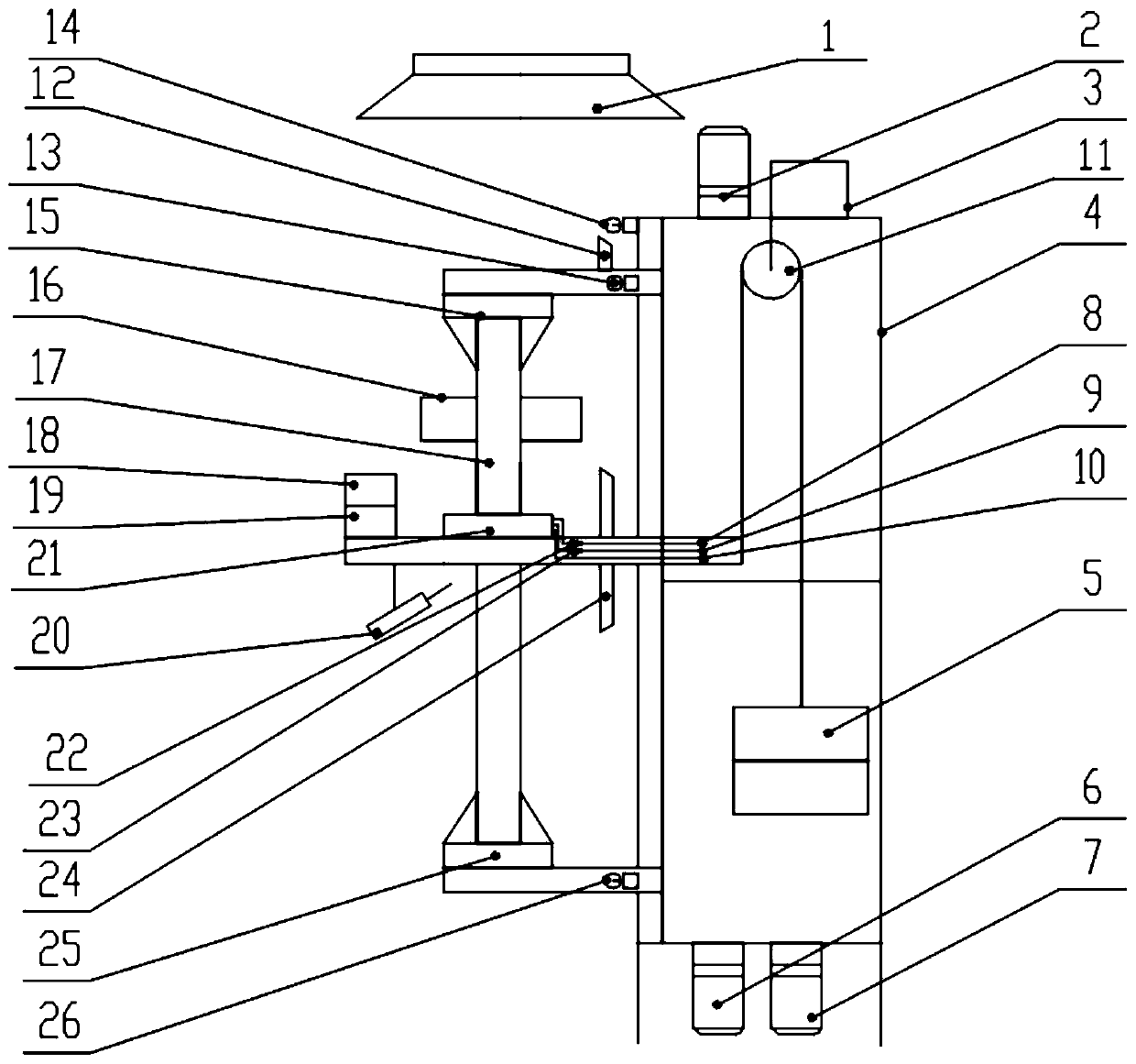

Combustion type optical fiber preform stretching apparatus and control method thereof

InactiveCN110668692AAchieve integrated controlAbundant stockGlass making apparatusHydrogen valveEngineering

The invention discloses a combustion type optical fiber preform stretching apparatus and a control method thereof, and belongs to the technical field of optical fiber preform production apparatuses. The apparatus comprises: a tower main body, wherein the tower main body comprises a tower, an upper chuck device, a lower chuck device and an annular blowtorch, the annular blowtorch is mounted in themiddle position of a pair of vertical guide rails on the front surface of the tower through a blowtorch lifting device, and an igniter is arranged beside the annular blowtorch; an ignition cabinet, wherein a hydrogen supply pipeline and an oxygen supply pipeline which are connected with the annular blowtorch are arranged in the ignition cabinet, the hydrogen supply pipeline is provided with a hydrogen flow meter and a hydrogen valve assembly, and the oxygen supply pipeline is provided with an oxygen flow meter and an oxygen valve assembly; and a control cabinet, wherein a PLC and a control panel are arranged in the control cabinet, and the control panel is in communication connection with the PLC. The apparatus has the advantages of high automation degree, good stability, suitableness forlarge-scale production, and facilitation of later apparatus maintenance and product upgrading due to large stock and convenient purchasing of the PLC on the market.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

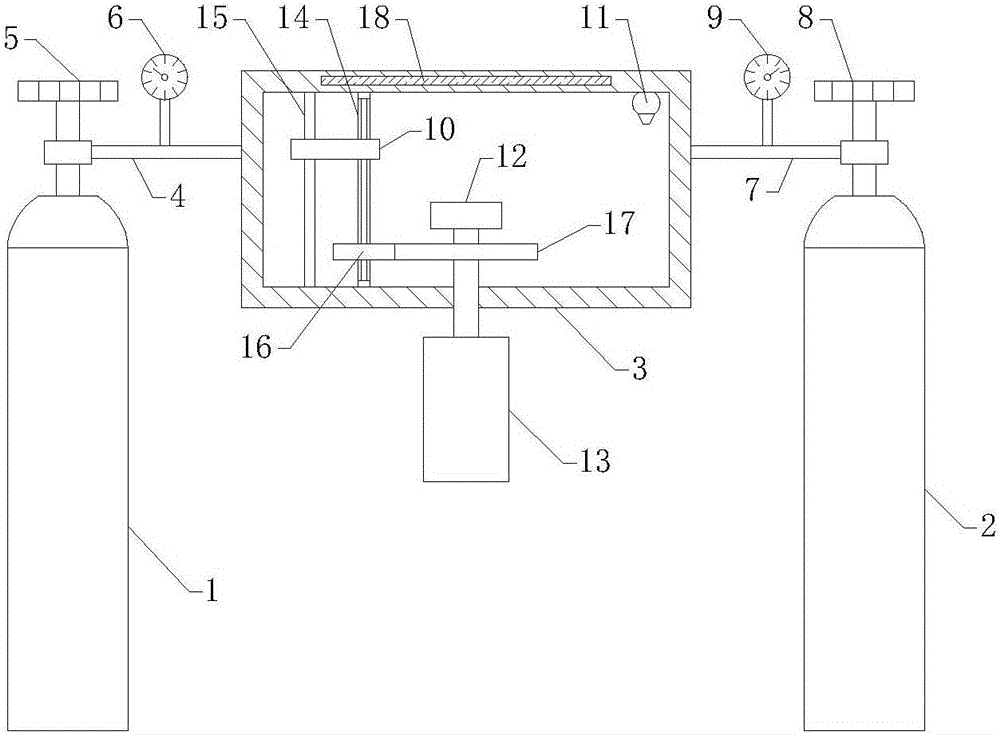

Mechanical part surface burr removing device

ActiveCN106678867AImprove removal efficiencyRemove completelyElectric spark ignitersHydrogen valveMechanical components

The invention discloses a mechanical part surface burr removing device which comprises an oxygen bottle, a hydrogen bottle and a sealing chamber. The oxygen bottle communicates with the sealing chamber through an oxygen pipe. The oxygen pipe is provided with an oxygen valve and an oxygen flow meter. The hydrogen bottle communicates with the sealing chamber through a hydrogen pipe. The hydrogen pipe is provided with a hydrogen valve and a hydrogen flow meter. A magnet and a sparking plug are arranged in the sealing chamber. The mechanical part surface burr removing device of the structure has the beneficial effects of being high in burr removing efficiency, removing burrs completely, and being small in damage to a part base body.

Owner:SHANDONG TANGONG HYDRAULIC PARTS MFG

Method for preparing p-chloroaniline without adding organic solvent

ActiveCN103497112AImprove poisonReduce manufacturing costOrganic compound preparationAmino compound preparationEnvironmental resistanceP-chloroaniline

The invention discloses a method for preparing p-chloroaniline without adding an organic solvent. The method is characterized by comprising the following steps: adding p-nitrochlorobenzene, a catalyst and an assistant in a high pressure kettle, sealing the high pressure kettle, opening a hydrogen valve to introduce hydrogen into the high pressure kettle, and meanwhile, stirring, heating and boosting, setting the reaction speed at 700 rpm, controlling the reaction temperature within 110-120 DEG C, controlling the reaction pressure within 1.1-1.2 MPa, reacting until no hydrogen is absorbed, closing the hydrogen valve, cooling, opening the high pressure kettle, discharging, filtering, adding the product into a rectifying kettle for distilling, and distilling to obtain the p-chloroaniline. A sample is taken, and a gas chromatography analysis result shows that the purity of the p-chloroaniline is 99.85%. The method disclosed by the invention has the advantages of simple operation, short production period, small environmental pollution, favorable environmental protection and low energy consumption, and is capable of recycling resources, reducing equipment investment and lowering the cost, and suitable for industrial production.

Owner:HULUDAO TIANQI SHENGYE CHEM

Tin-lead alloy and preparation process thereof

Owner:HANGZHOU CHUNJIANG VALVE

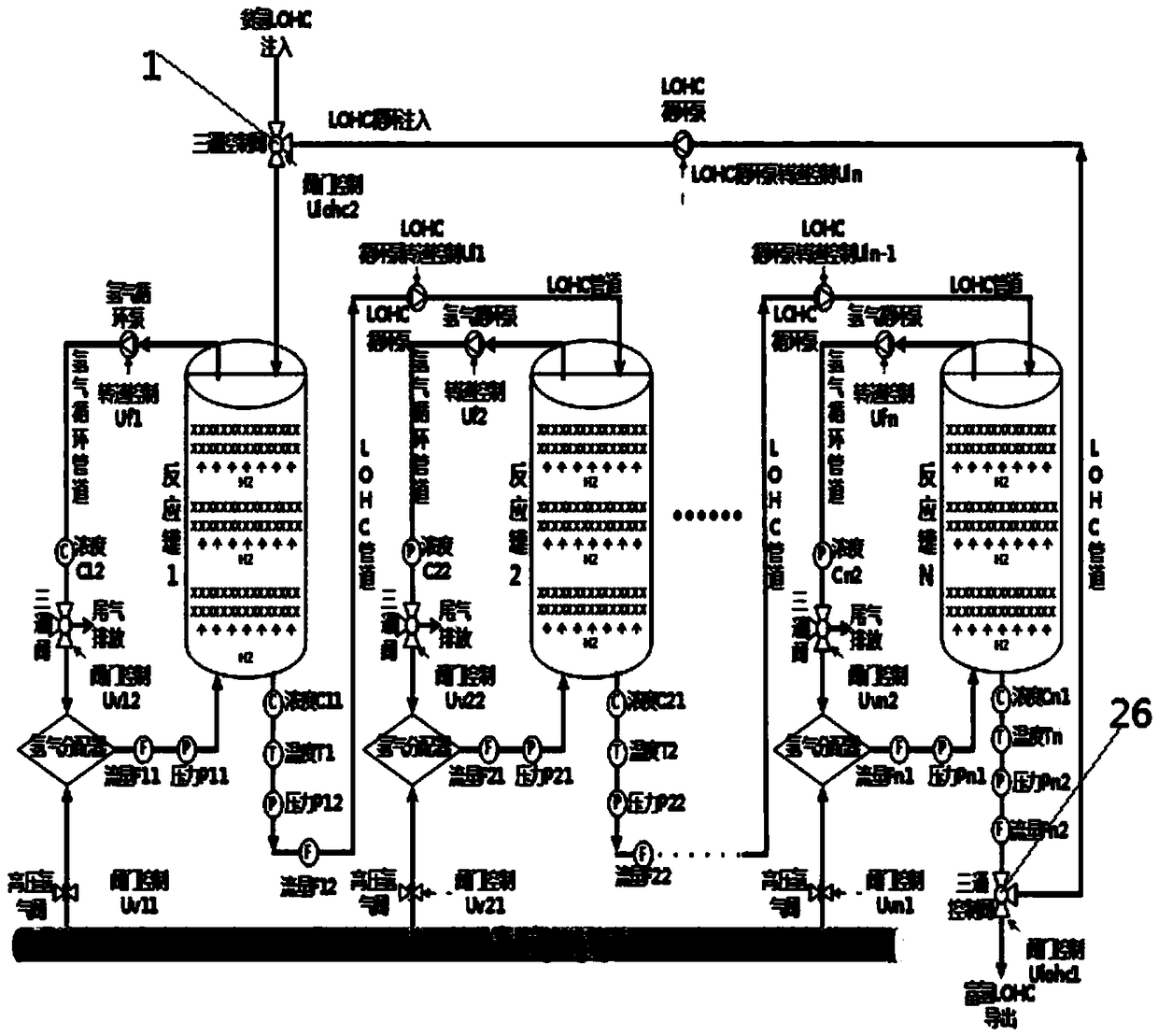

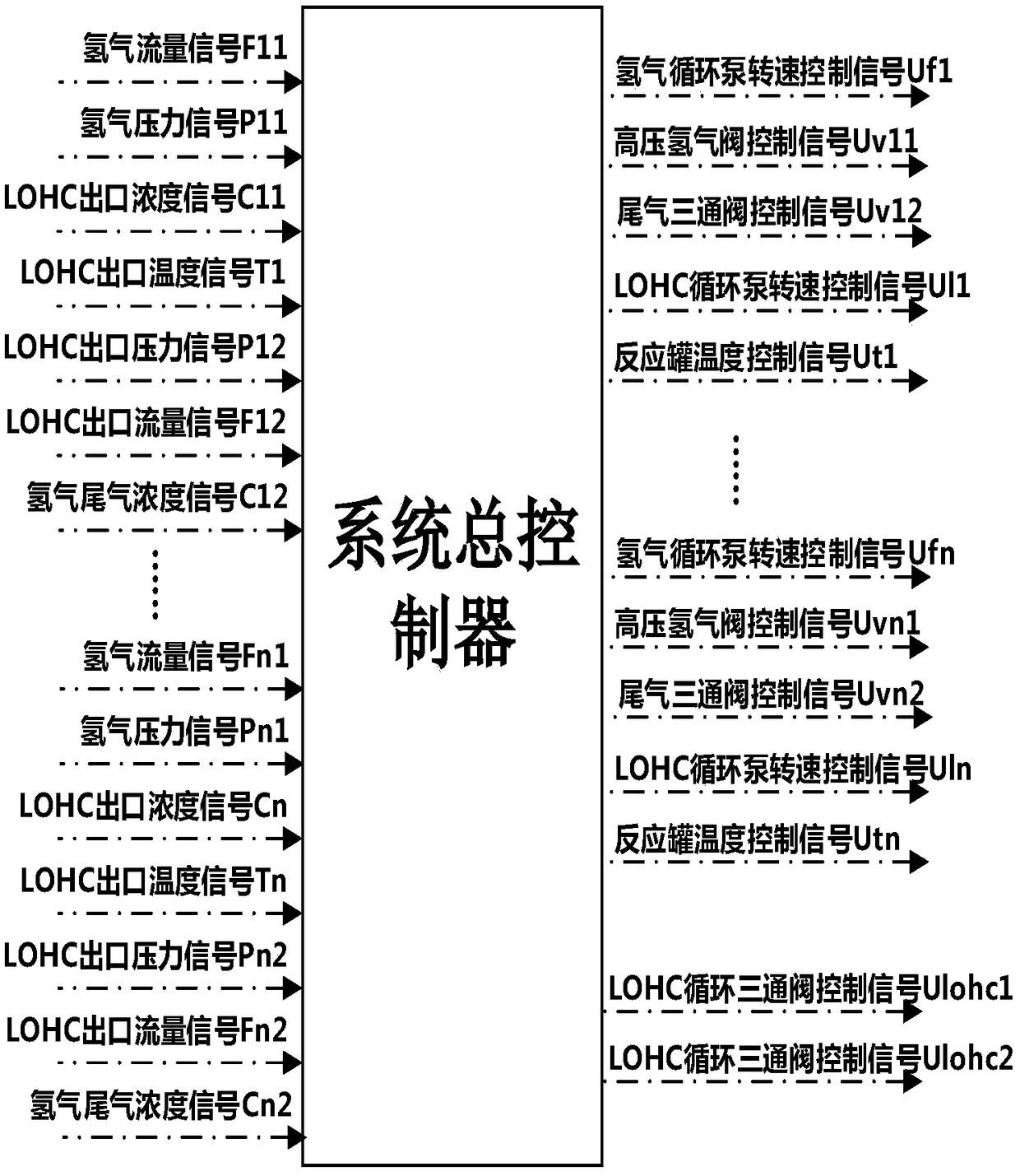

Cascading liquid state organic hydrogen storage system and control method

ActiveCN109179315AShorten hydrogenation timeImprove hydrogenation efficiencyHydrogenSimultaneous control of multiple variablesHydrogen concentrationHydrogen pressure

The invention discloses a cascading liquid state organic hydrogen storage system and a control method. The system is formed by N (N is more than 2) reaction tanks through cascading of a pipeline, wherein three-way valves A are connected to the tops of the reaction tanks; a hydrogen circulating pump, a hydrogen concentration sensor, a three-way valve, a hydrogen distributor, a hydrogen flow sensorand a hydrogen pressure sensor are connected between the top and bottom of each reaction tank; a high-pressure hydrogen pipeline is connected to the hydrogen distributor through a high-pressure hydrogen valve; an LOHC concentration sensor, an LOHC temperature sensor, an LOHC pressure sensor, an LOHC flow sensor and an LOHC circulating pump are connected between the bottom of the front reaction tank to the top of the rear reaction tank from the first reaction tank; and the LOHC concentration sensor, the LOHC temperature sensor, the LOHC pressure sensor, the LOHC flow sensor, the three-way valveB and the LOHC circulating pump are connected between the bottom of the reaction tank N and the three-way valve A. The cascading liquid state organic hydrogen storage system is high in hydrogen storage efficiency and low in energy consumption.

Owner:瀚锐氢能科技集团有限公司

Hydrogen Valve with Leaked Hydrogen Removal

ActiveCN106402475BEfficient Hydrogen Oxidation EliminationEfficient dischargeSpindle sealingsGas treatmentHydrogen valveEngineering

The invention discloses a hydrogen valve with a function of removing leaked hydrogen. The valve comprises a valve body, a valve rod, padding and a padding gland. A plurality of first grooves are symmetrically formed in the outer wall of the padding gland in the circumferential direction, a plurality of second grooves are correspondingly formed in the inner wall of the padding gland in the circumferential direction, and the first grooves and the second grooves are internally provided with hydrogen absorbing reactors. The hydrogen absorbing rectors are provided with Pd / Pt-Al2O3 catalyst coatings and located in an opening in the upper end of the padding, and the catalyst coatings are exposed in the grooves. An iron, chromium and aluminum metal plate is coated with the hydrophobic Pd / Pt-Al2O3 catalyst coatings and installed in the grooves formed in the inner wall face and the outer wall face of the padding gland, and efficient hydrogen oxidation removing is achieved at the normal temperature. Meanwhile, by means of the character of the Pd / Pt-Al2O3 catalyst coatings, effective draining of reaction product water is achieved, and stability of the catalysts is guaranteed. The valve has the beneficial effects of being simple and safe in structure and capable of efficiently removing leaked hydrogen.

Owner:EAST CHINA UNIV OF SCI & TECH

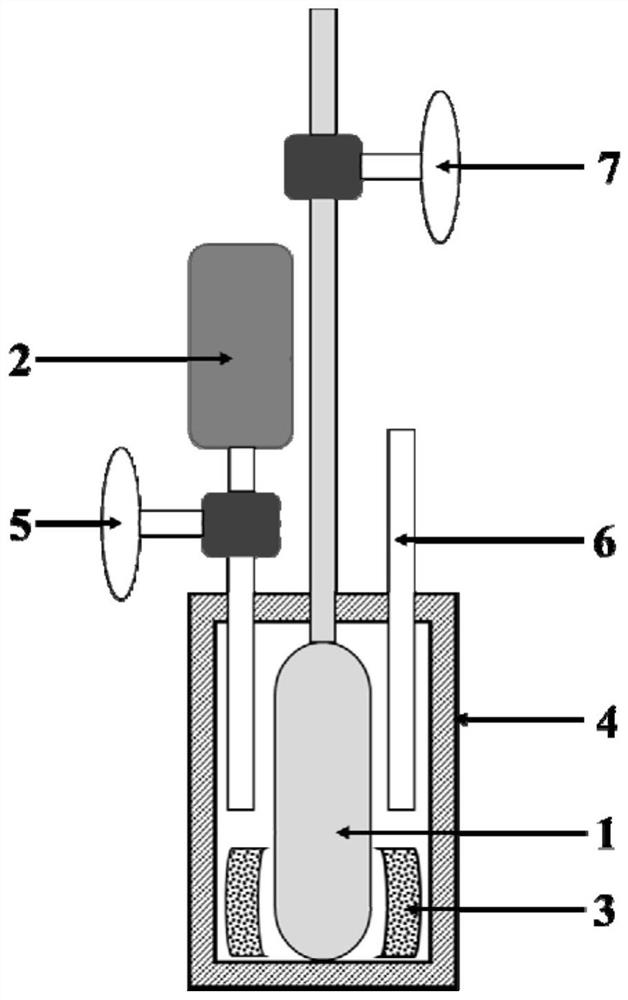

Self-heating type rapid hydrogen supply device

InactiveCN113464839APromote productionQuick releaseVessel mounting detailsVessel geometry/arrangement/sizeHydrogen valveWater storage

The invention provides a self-heating type rapid hydrogen supply device. The self-heating type rapid hydrogen supply device specifically structurally comprises a hydrogen storage tank, a water storage tank, a heating bag, a heat preservation shell, a water tank valve, a thermometer and a hydrogen valve, wherein the hydrogen storage tank is located in the middle position of the heat preservation shell, the periphery of the tank body of the hydrogen storage tank clings to the heating bag, the water storage tank is arranged above the heat preservation shell, a water tank valve between the water storage tank and the heat preservation shell controls the opening and closing of water, the thermometer is adjacent to the heating bag, and the hydrogen storage tank is externally connected to the hydrogen valve to control opening and closing of hydrogen. The self-heating type rapid hydrogen supply device has the advantages of rapid heating, simple operation, reusability, no environmental pollution and the like.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com