Preparation method of ultra-high-purity aluminum

A pure aluminum, ultra-high technology, applied in the field of ultra-high-purity aluminum preparation, can solve the problems that the product is difficult to meet the 6.5N standard, it is difficult to effectively remove metal impurities, and the graphite boat cannot be reused, so as to shorten the purification time and improve the purification efficiency. The effect is remarkable and the effect of preventing material oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of ultra-high-purity aluminum according to the present disclosure includes steps:

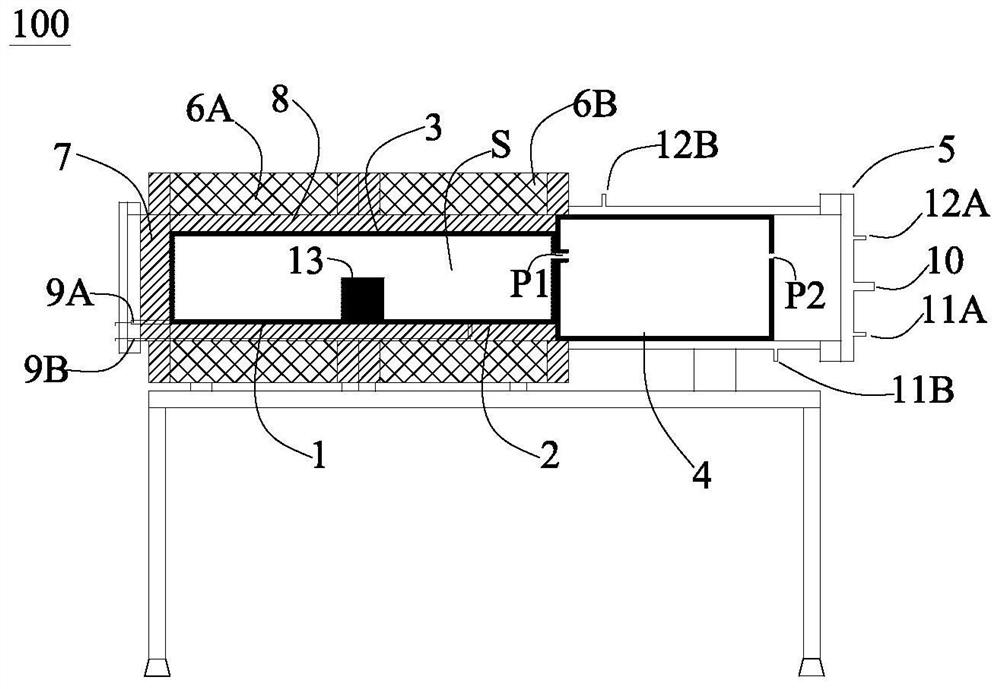

[0059]Step 1, put the 5N raw material aluminum ingot into the graphite boat raw material tank 1, the graphite boat raw material tank 1 is adjacent to the graphite boat product tank 2, spaced from each other and communicated above, cover the graphite cover 3 so that the graphite cover 3 and the graphite boat raw material Groove 1 and graphite boat product groove 2 form the cavity S that is all closed except that the side of graphite boat product groove 2 far away from graphite boat raw material groove 1 has communication port P1, and graphite cover 3, graphite boat raw material groove 1 , Graphite boat product tank 2 is packed into vacuum distillation furnace together with raw material aluminum ingot, then loads into the dust collection tank 4 that has vacuum port (P2) so that the inner cavity of dust collection tank 4 communicates with communication port P1, and cov...

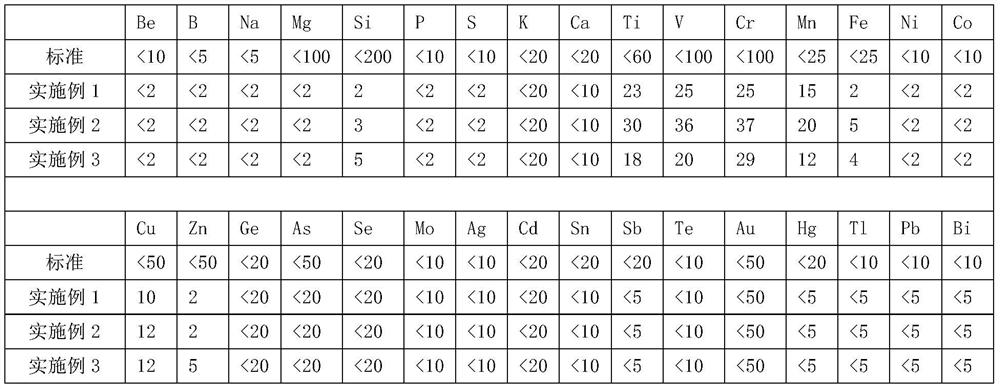

Embodiment 1

[0091] Ultrahigh-purity aluminum was prepared as follows.

[0092] Step 1: Put the 5N raw material aluminum ingot into the raw material tank 1 of the graphite boat. The raw material tank 1 of the graphite boat is adjacent to the product tank 2 of the graphite boat, separated from each other and communicated above. Cover the graphite cover 3 so that the graphite cover 3 and the raw material of the graphite boat Groove 1 and graphite boat product groove 2 form the cavity S except that there is communication port P1 on the side far away from graphite boat raw material groove 1 of graphite boat product groove 2, graphite cover 3, graphite boat raw material groove 1, graphite boat product groove 2 Put the raw material aluminum ingot into the vacuum distillation furnace, and then put it into the dust collection tank 4 with the vacuum port P2 so that the inner cavity of the dust collection tank 4 is connected with the communication port P1, cover the furnace cover 5, and the external ...

Embodiment 2

[0103] The operation steps are the same as in Example 1, the difference is that

[0104] In step 1, the temperature of the first zone corresponding to graphite boat raw material tank 1 is 1300°C, the temperature of the second zone corresponding to graphite boat product tank 2 is controlled at 700°C, the distillation time is 12h, and the aluminum in graphite boat product tank 2 The yield is 71%;

[0105] In step five, the length of the other glassy carbon boat or boron nitride boat 20 is 72cm;

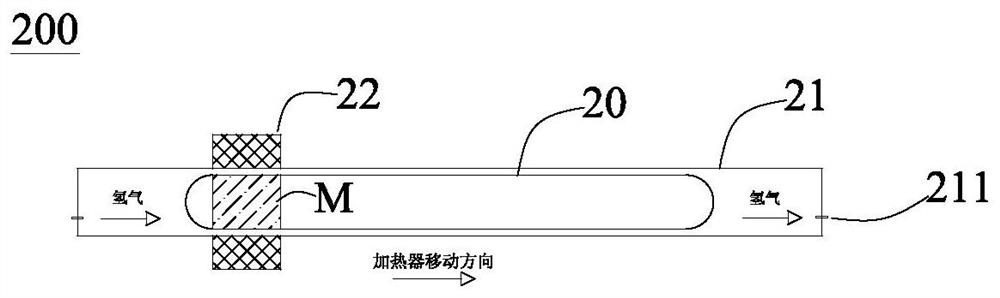

[0106] In step seven, the operating speed of the heater 22 is 25 mm / h and the length of the melting zone M formed after the aluminum ingot is melted is maintained at 8 cm;

[0107] In step 8, repeat the regional operation 10 times in total;

[0108] In step nine, remove 15cm from the head and tail of the aluminum ingot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com