Hydrogen Valve with Leaked Hydrogen Removal

A technology of hydrogen and valves, applied in the direction of valve devices, valve details, gas treatment, etc., can solve the problems of gas removal, no leakage of hydrogen valve packing, complex system, etc., to achieve efficient removal, efficient hydrogen oxidation elimination, safety and The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, a hydrogen valve with leaking hydrogen removal function, such as Figure 1-8 As shown, it includes: a valve body 6, packing 7, packing gland 5, valve stem 4 and a hydrogen absorption reactor arranged on the packing gland 5, wherein the valve body 6 is provided with an opening, and the valve stem 4 is arranged on the In the above opening, the bottom of the valve stem is connected with the valve core to control the on-off state of the valve, the upper end of the valve stem is drawn out from the opening, and the space between the lower end of the valve stem and the inner wall of the opening is filled with filler 7 to play the role of the valve. The leading end of the stem is airtightly connected with the inside of the valve to prevent hydrogen leakage in the valve; the packing gland 5 is set in a cylindrical structure and is sleeved on the valve stem 4. Specifically, the packing gland 5 shaft A through hole 53 is opened in the center, the valve stem passes th...

Embodiment 2

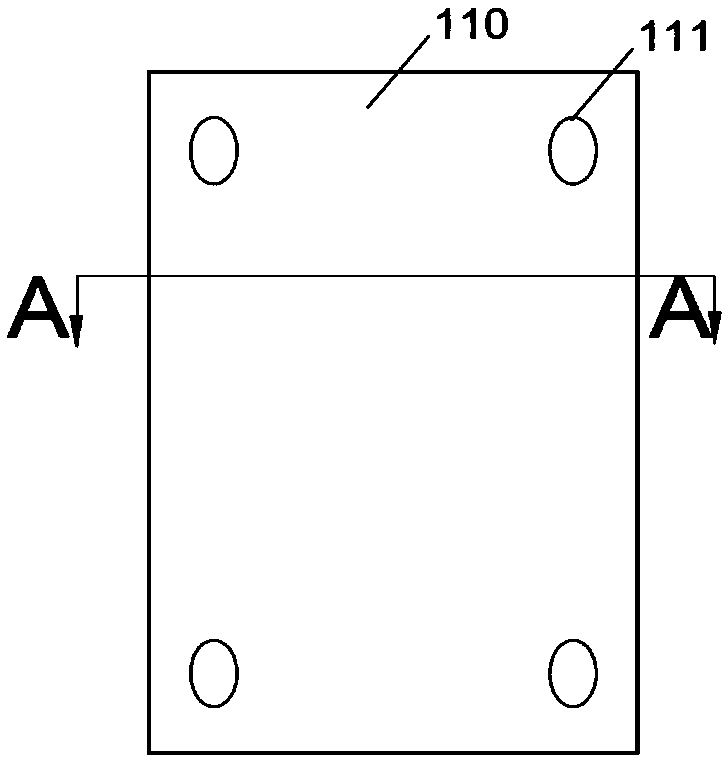

[0045] Embodiment 2, the upper end of the packing gland is provided with a protrusion, and the upper end of the packing gland is fixed on the valve body 6 at the upper end of the opening through the first bolt 1, and the upper end of the first bolt 1 is connected to the protrusion through a nut 8. The metal plate of the hydrogen absorption reactor is provided with several threaded holes 111 for installation, and the inner wall of the groove is provided with threaded holes, and the hydrogen absorption reactor is fixed in the groove by the second bolt 3, The hydrogen absorption reactor does not protrude from the groove. The packing gland and the opening of the valve body are in clearance fit, and the difference between the outer diameter of the packing gland and the inner diameter of the opening is 0.5 mm to 1 mm, and the outer hydrogen absorption reactor is exposed in this gap; the packing gland and the valve stem are in clearance fit, The difference between the inner diameter ...

Embodiment 3

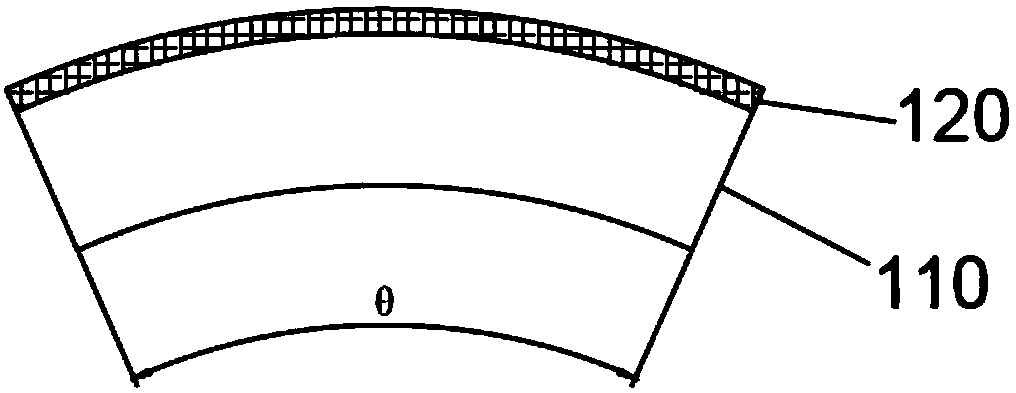

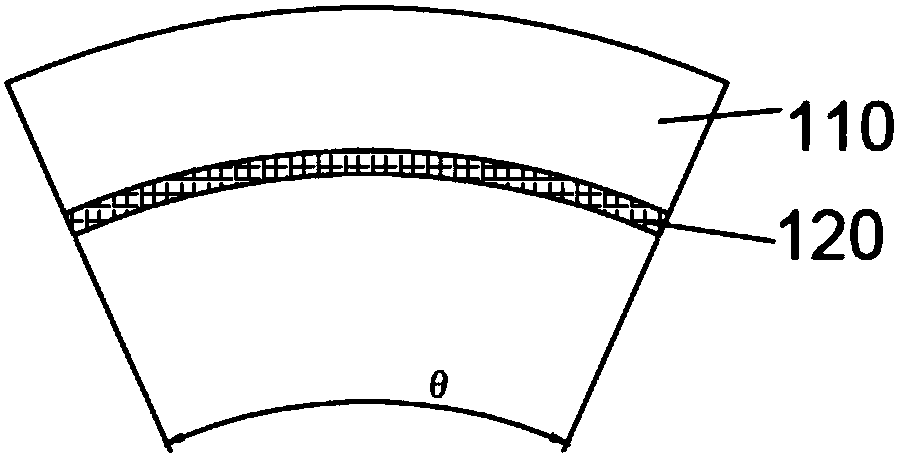

[0046] Embodiment three, such as Figure 1-3 As shown, the hydrogen absorption reactor specifically includes a metal plate 110 and a catalyst coating 120 coated on the surface of the metal plate, wherein the thickness of the metal plate is 0.4mm, and the metal plate is made of a sandblasted iron-chromium-aluminum metal plate , the aluminum content is 5wt%; Catalyst coating 120, it is evenly coated on the surface of described metal plate, and described catalyst coating is made of hydrophobic Pd / Pt-Al 2 o 3 made, coated with Pd / Pt-Al 2 o 3 Hydrophobic catalyst-coated iron-chromium-aluminum metal plates form a hydrogen absorption reactor. The catalyst coating can catalyze the removal of hydrogen leaked from the valve packing at room temperature. The activity is specific, to achieve continuous and stable removal of leaked hydrogen, and to improve the safety of hydrogen valves. In this embodiment, for the convenience of installation, the metal plate is set as a circular arc pan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com