Mechanical part surface burr removing device

A technology of burr removal and mechanical parts, which is applied in the direction of combustion ignition, combustion method, and ignition using electric spark, etc., can solve the problems of incomplete burr removal, cost a lot of time and cost, reduce bright band, etc., and achieve burr removal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

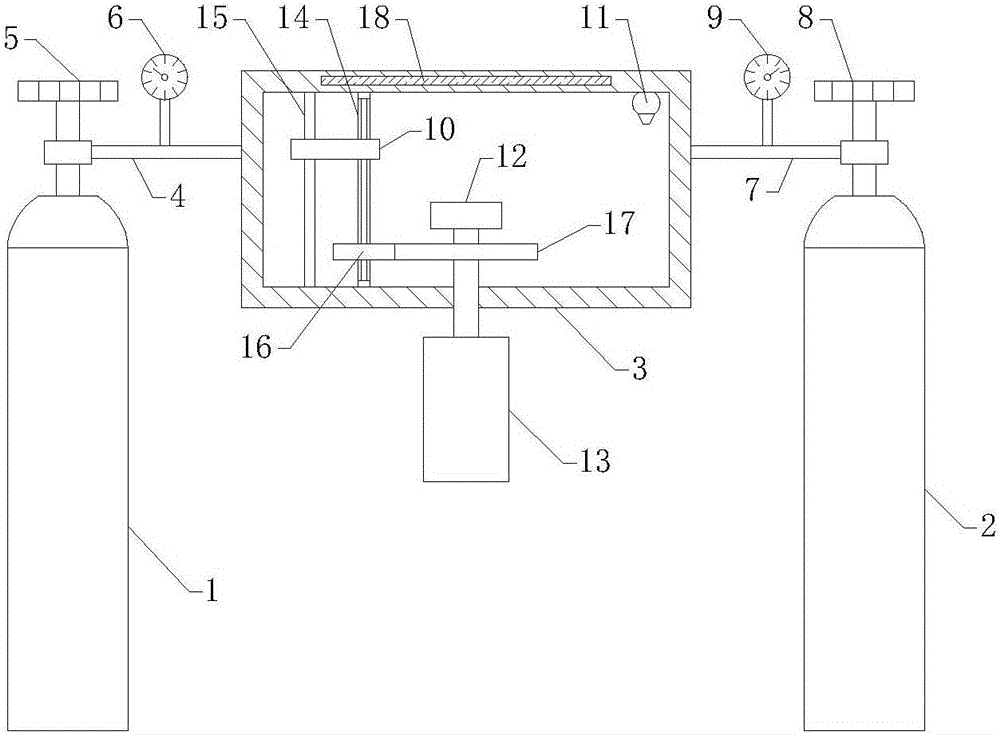

[0011] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: a device for removing burrs on the surface of mechanical parts, including an oxygen cylinder 1, a hydrogen cylinder 2 and a sealed chamber 3. The oxygen cylinder communicates with the sealed chamber through an oxygen tube 4, and the oxygen tube is provided with an oxygen valve 5 and an oxygen valve. A flow meter 6, the hydrogen bottle communicates with the sealed chamber through a hydrogen pipe 7, a hydrogen valve 8 and a hydrogen flow meter 9 are arranged on the hydrogen pipe, and a magnet 10 and a spark plug 11 are arranged in the sealed chamber. When deburring the parts, put the parts in the sealed room, open the oxygen valve and the hydrogen valve respectively to feed oxygen and hydrogen into the sealed room, so that the molar weight ratio of hydrogen and oxygen mixed gas in the sealed room is 0.5-1:1; After the spark plug is ignited, the mixed gas ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com