Filling-type gas supply confluence system of fuel cell

A fuel cell, mounted technology, applied in fuel cells, fuel cell additives, electrical components, etc., can solve the problem of poor safety in replacing hydrogen cylinders, and achieve the effects of uninterrupted power supply, easy logistics, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

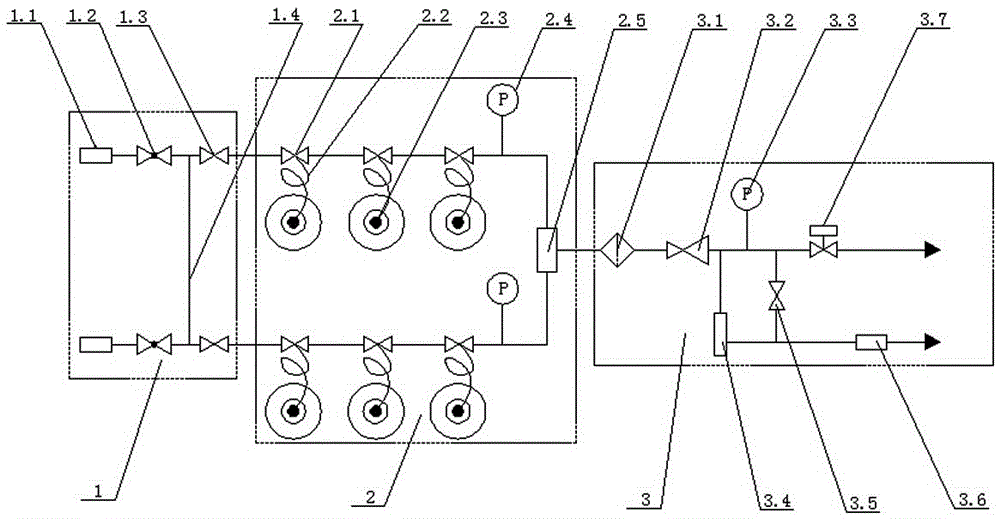

[0015] figure 1 The fuel cell refillable gas supply confluence system shown is composed of a gas filling unit 1 , a gas cylinder confluence switching unit 2 and a safety unit 3 connected in sequence. The gas filling unit 1 is located at the front of the system, and is an interface for connecting external supplementary hydrogen. The gas filling unit 1 is a two-way pipeline structure arranged side by side, and each line is sequentially connected in series with an external interface 1.1, a ball valve 1.2 and a stop valve 1.3. The ball valve 1.2 and the stop valve 1.3 in the double pipeline are connected in parallel through the pipeline 1.4 to form a valve-controlled intercommunication loop. With this loop, the following hydrogen supplementary working conditions can be easily achieved. The first working condition is that one way is open, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com