Patents

Literature

36results about How to "Prevent splashing around" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

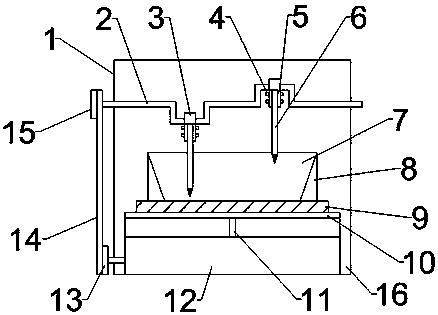

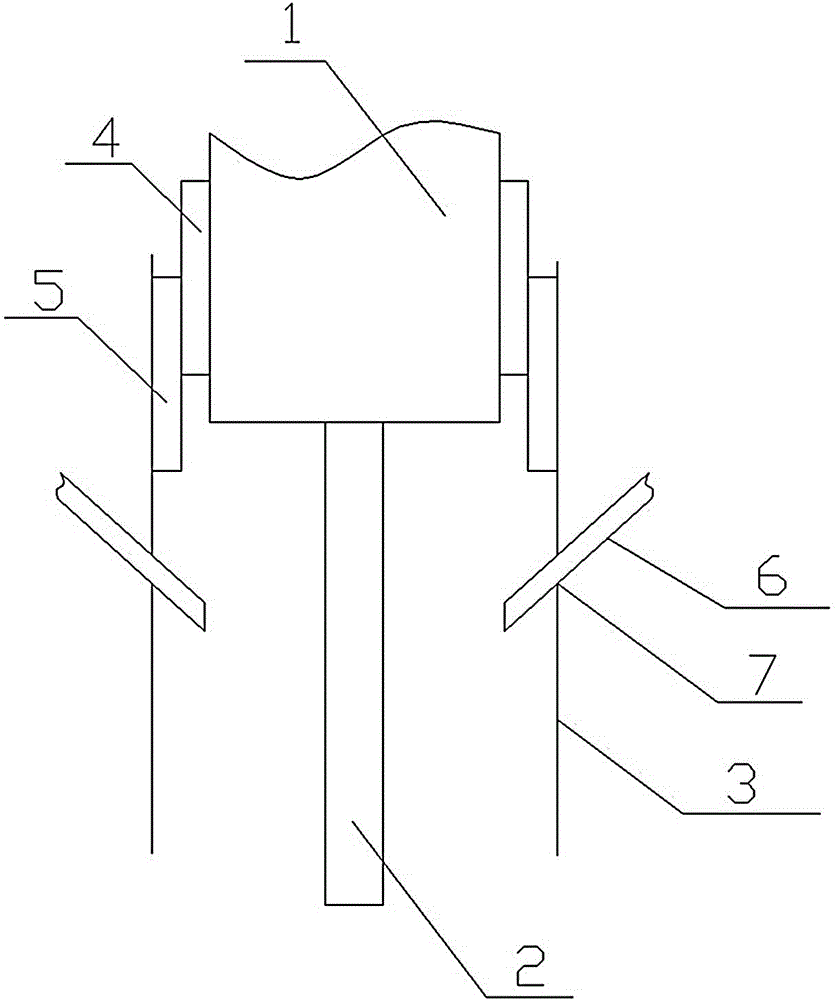

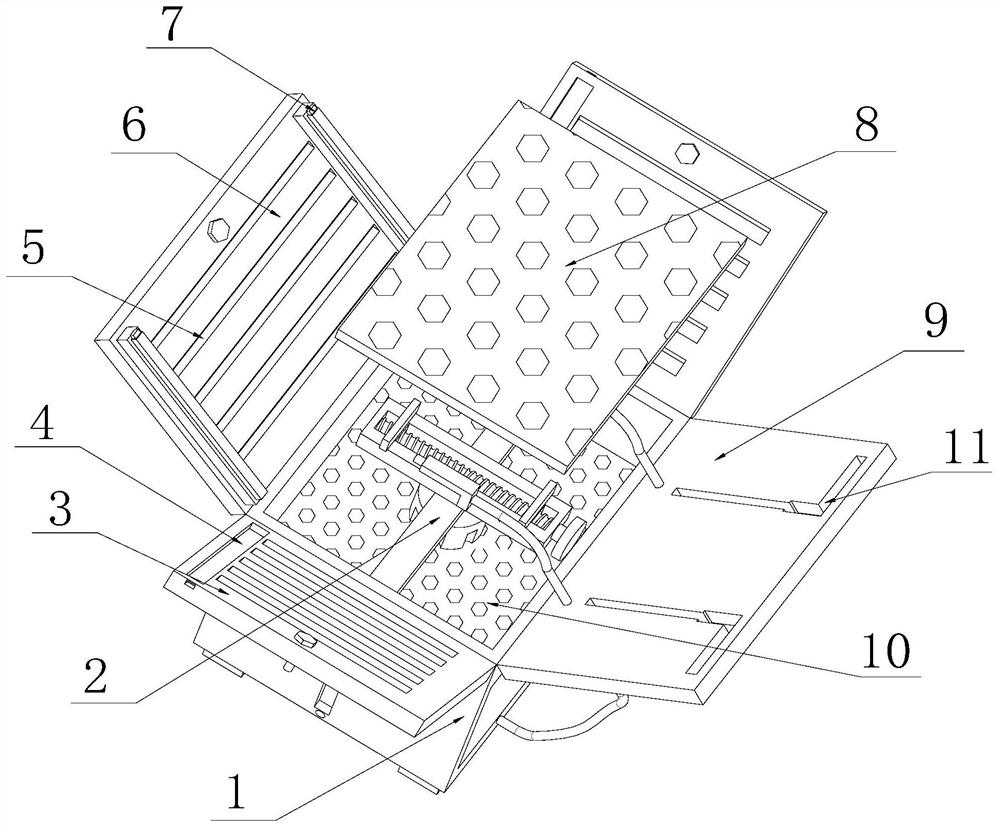

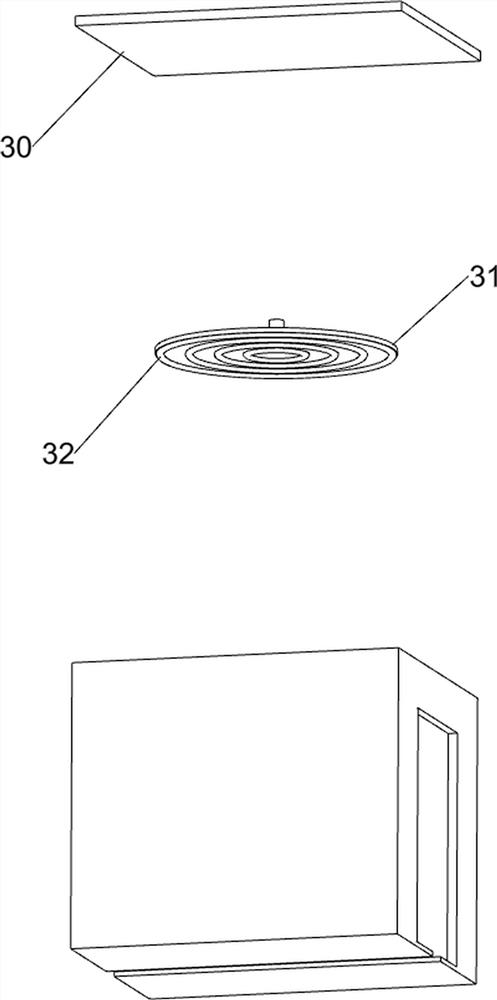

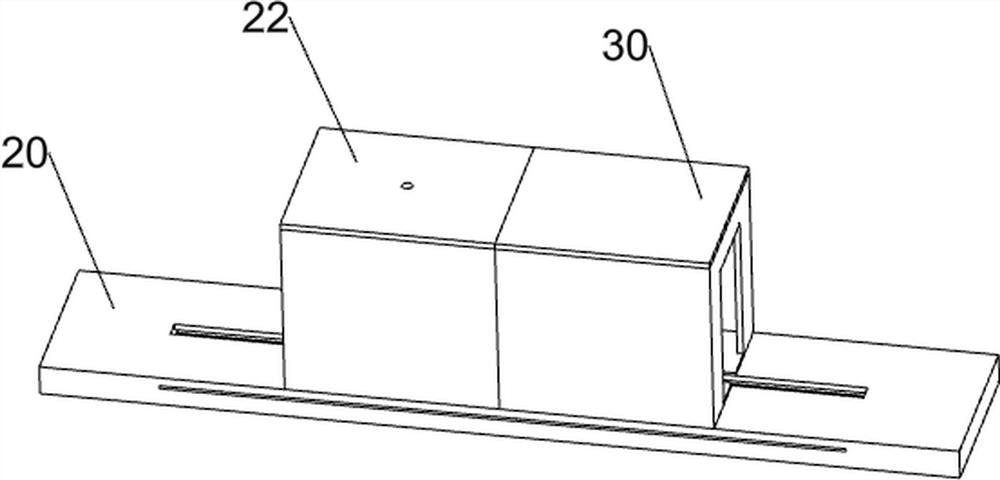

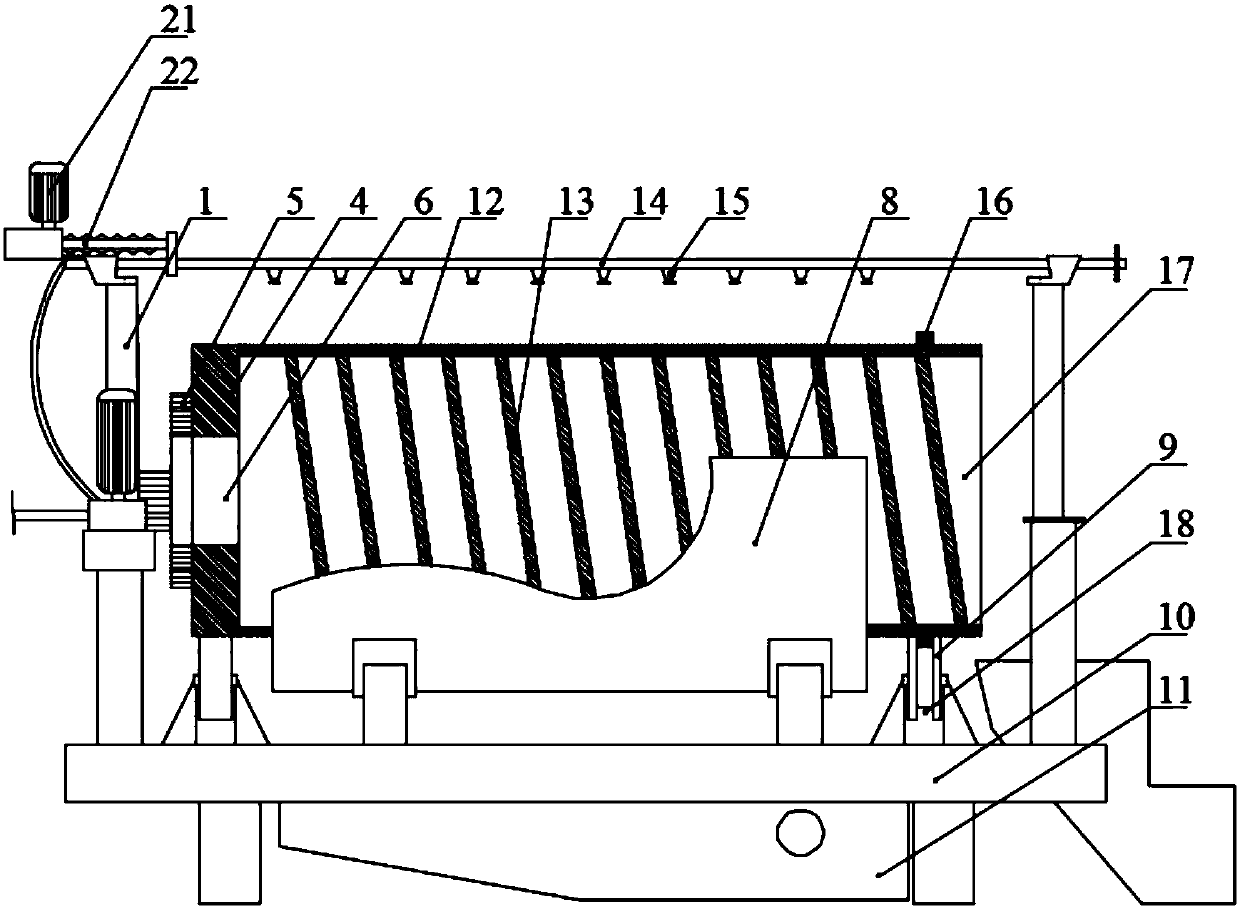

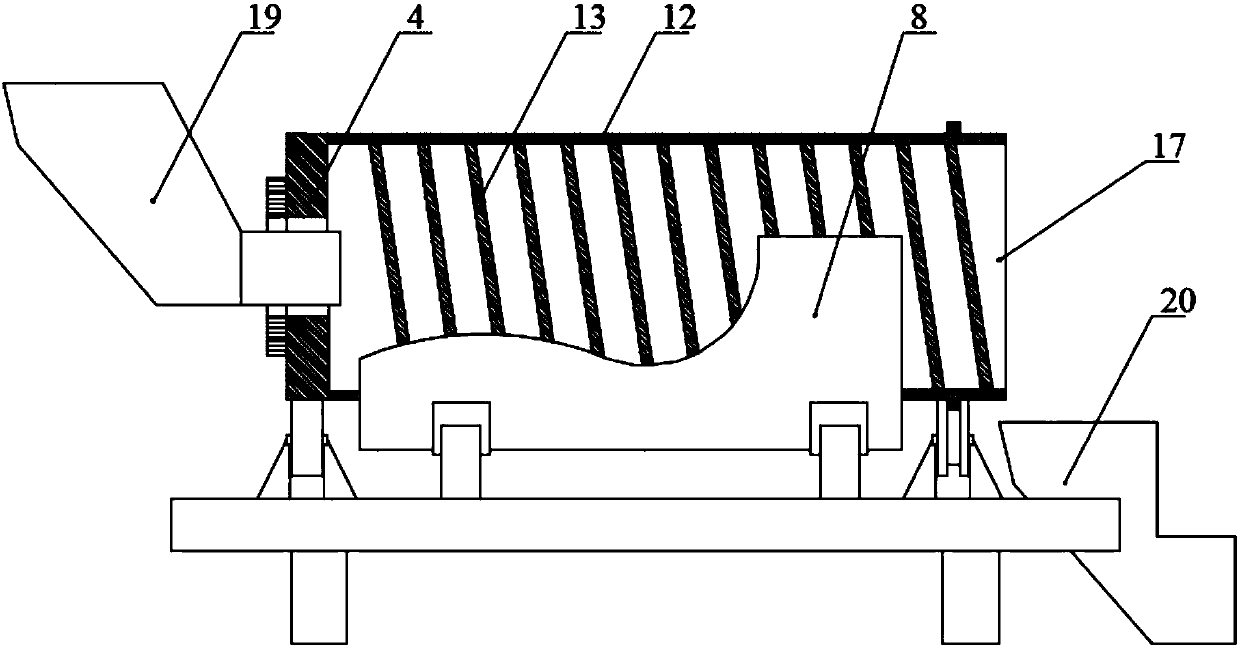

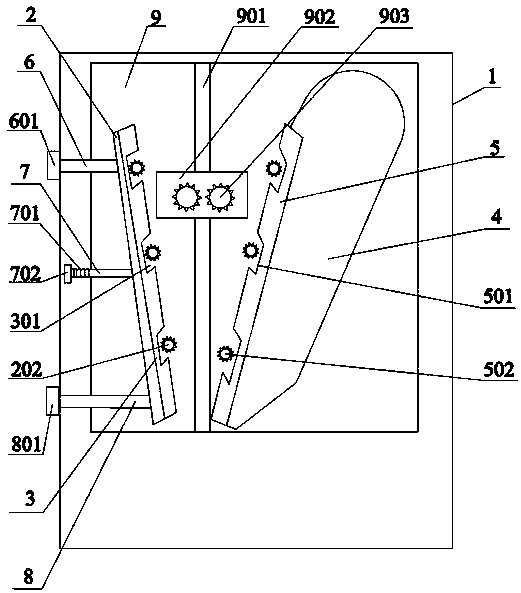

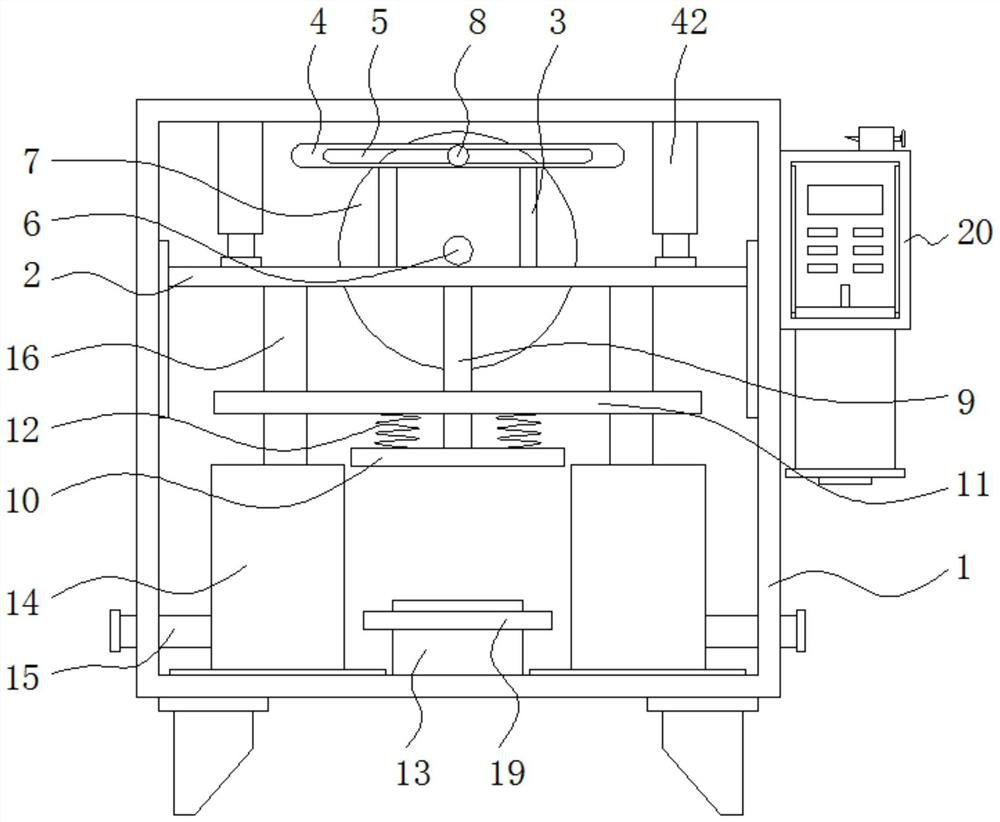

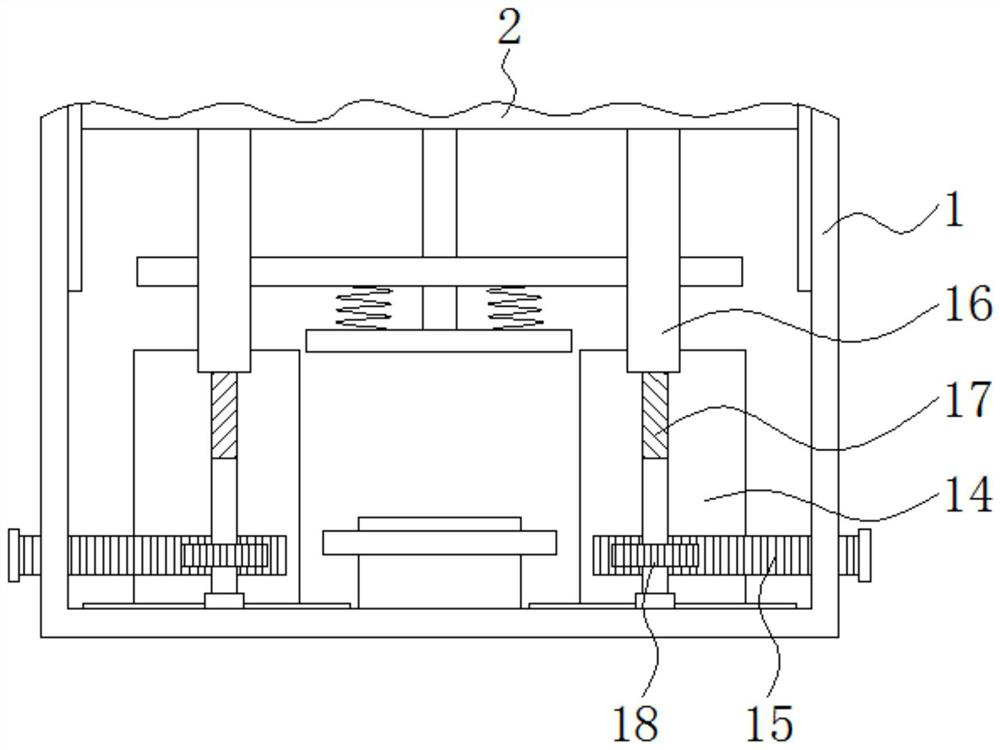

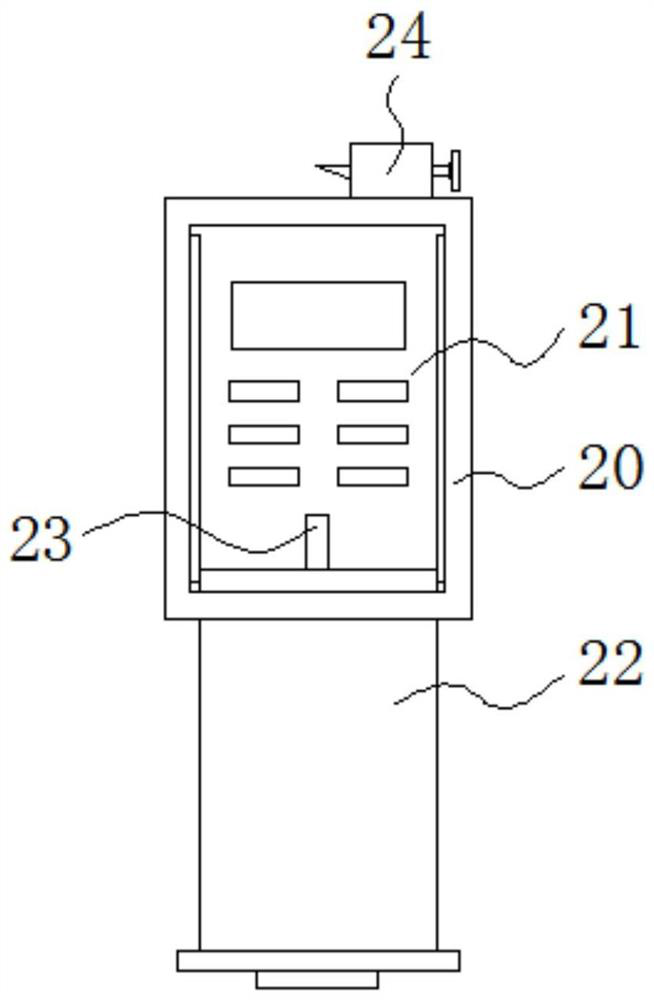

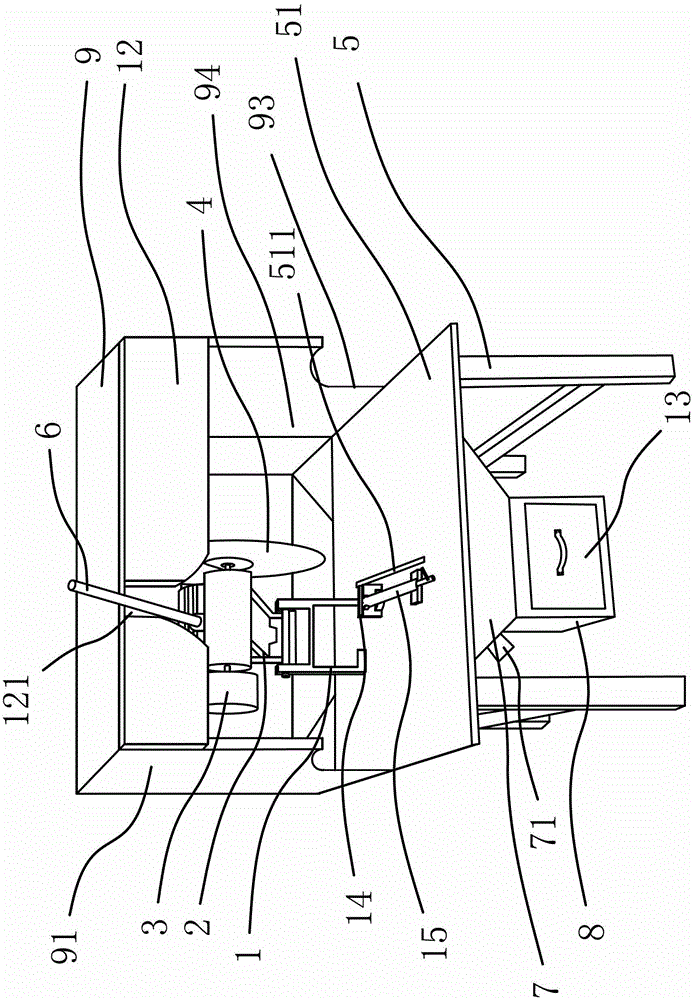

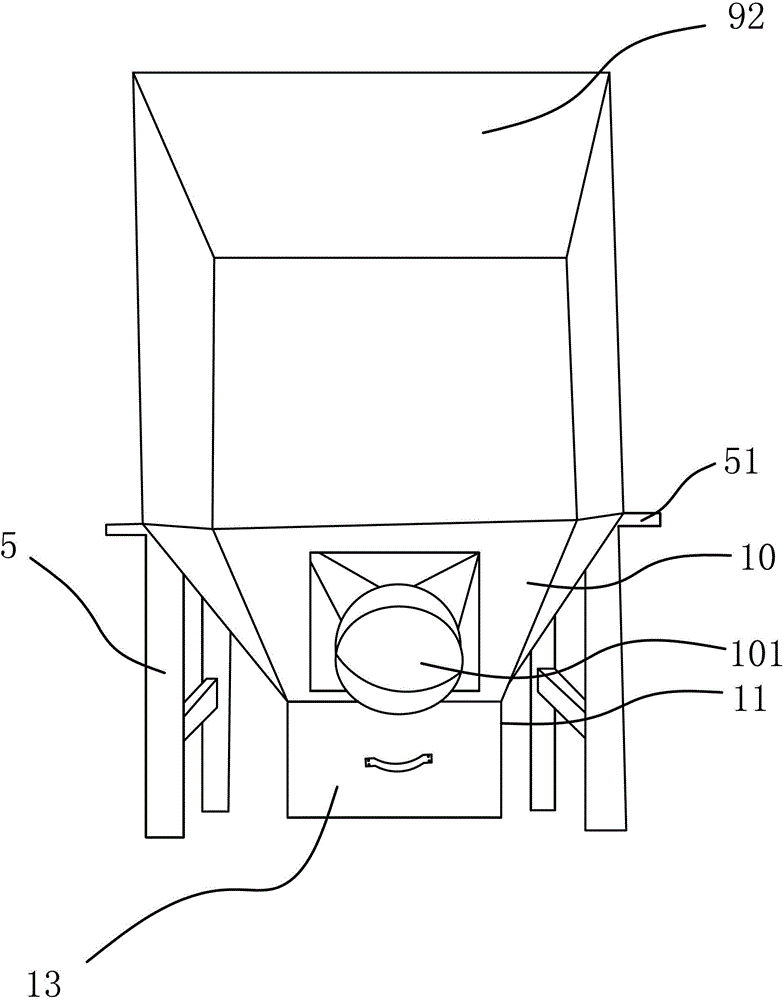

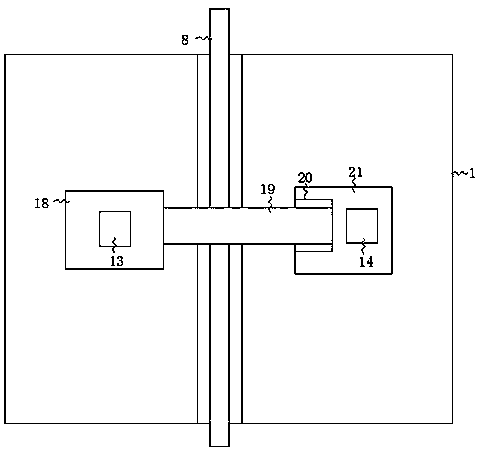

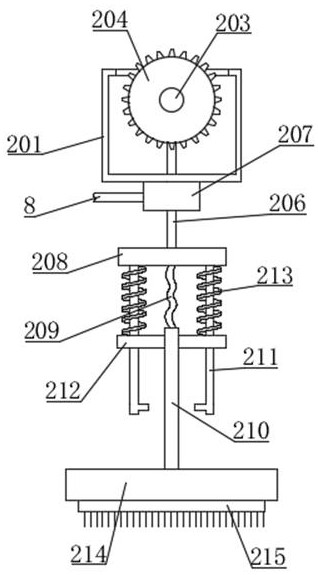

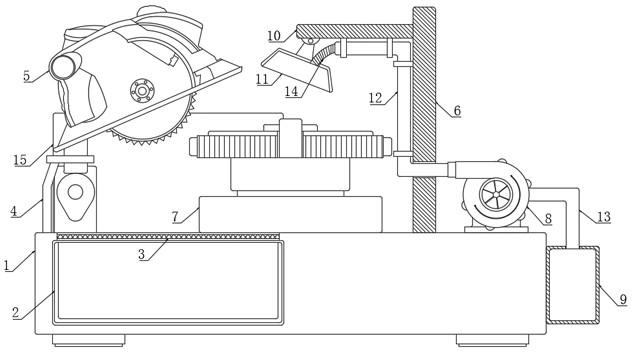

Automatic filling chopping machine

InactiveCN108283208APrevent splashing aroundReduce manual labor intensityMeat processingGrain treatmentsBlock effectEngineering

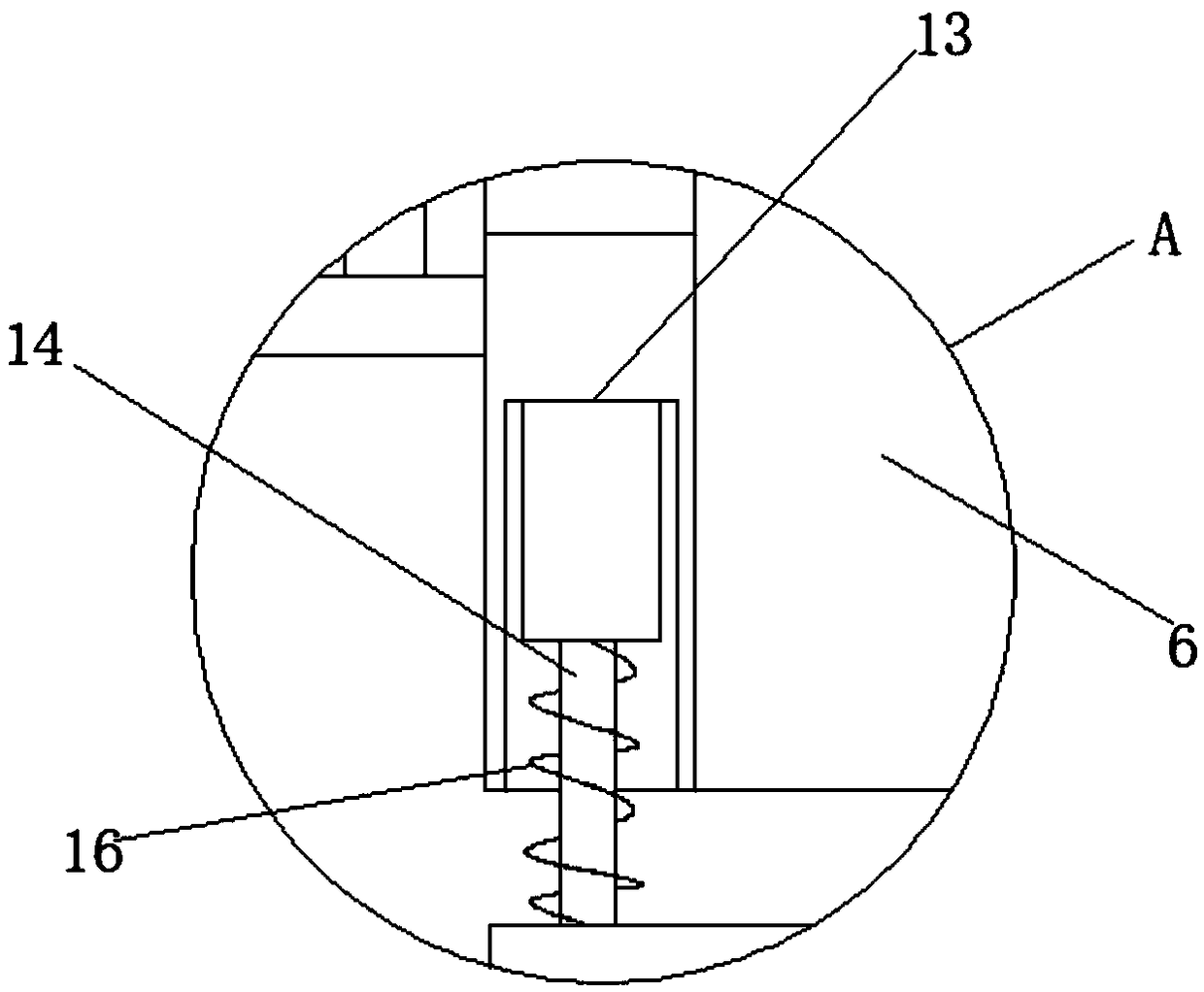

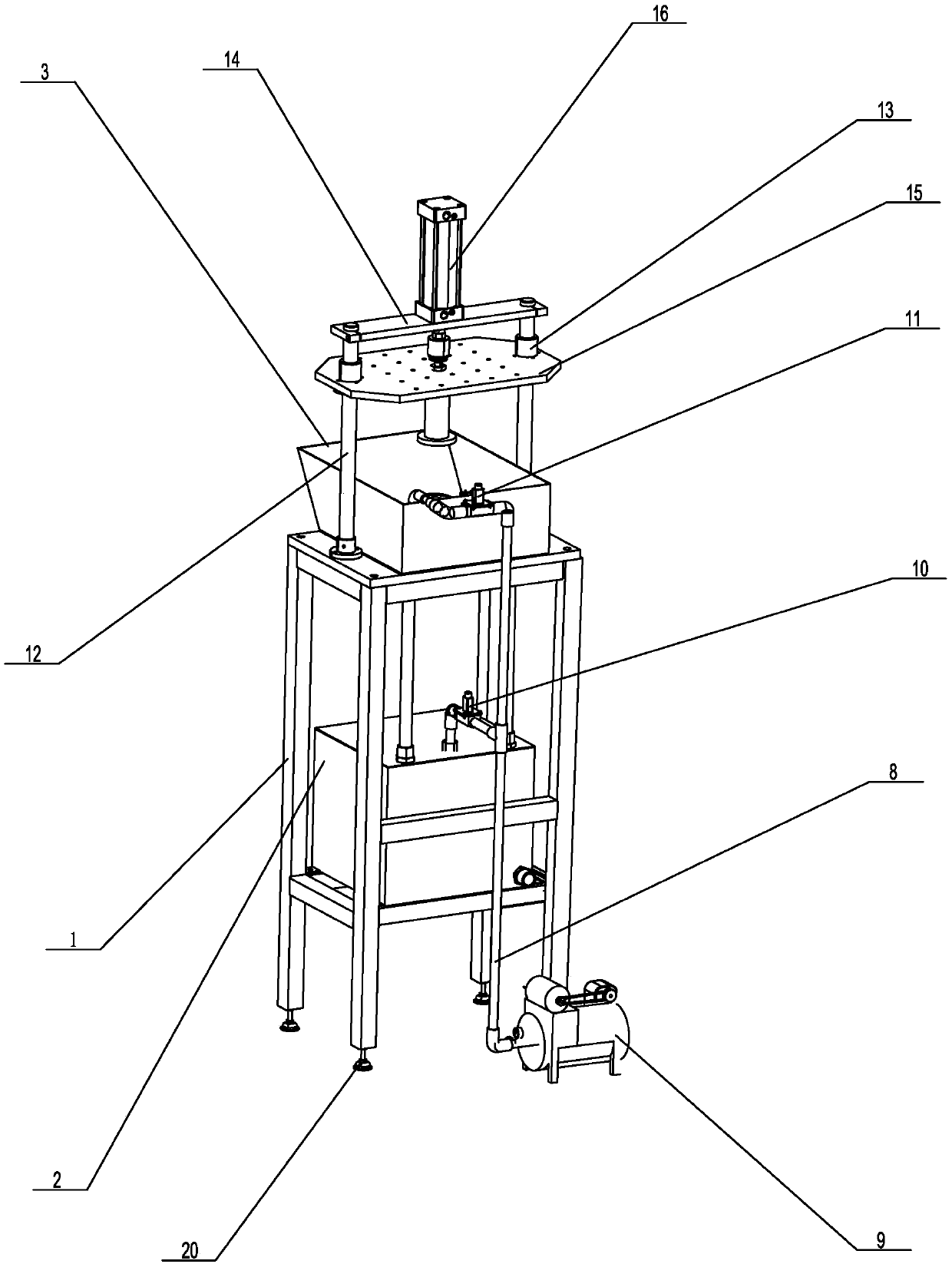

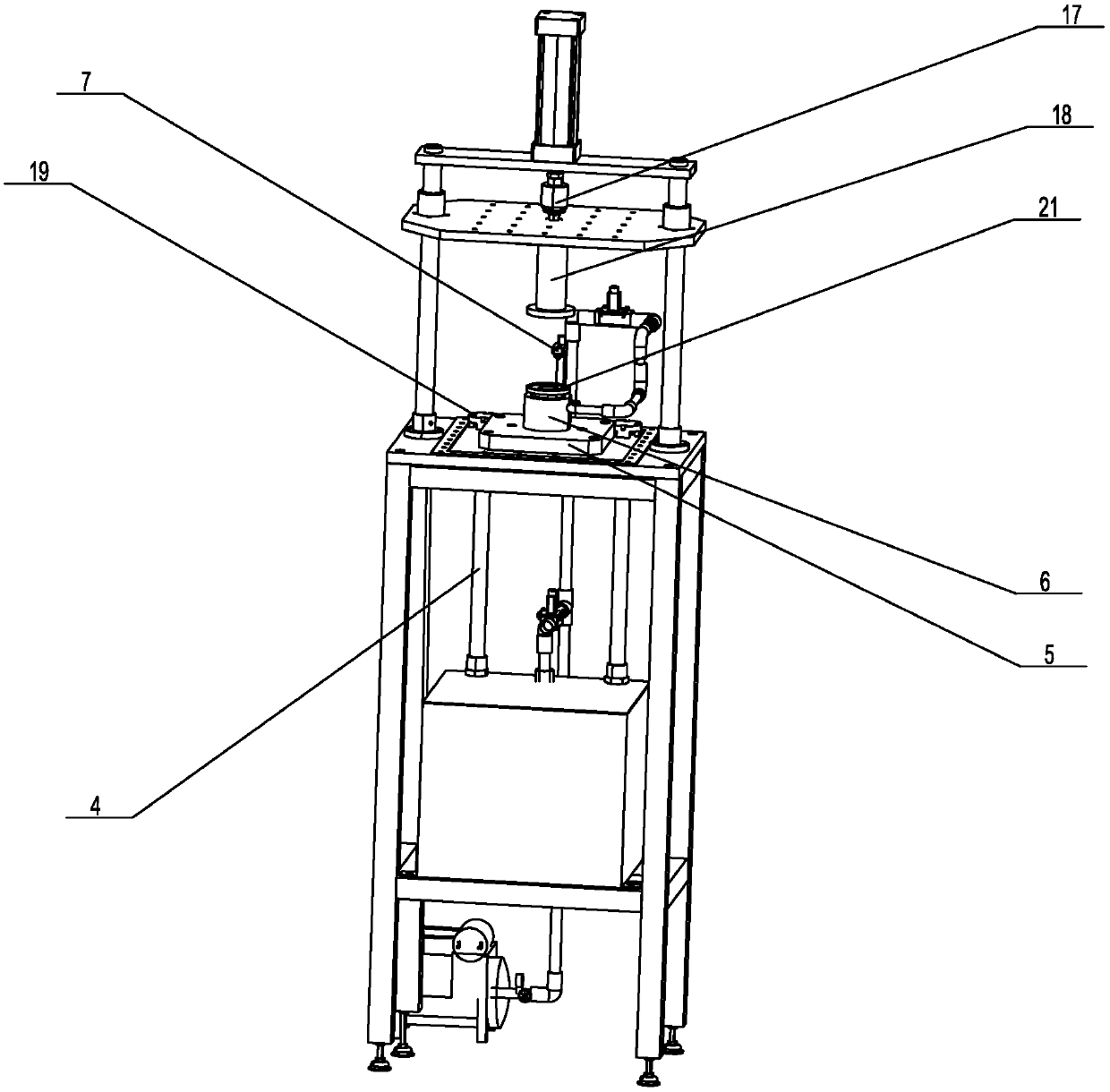

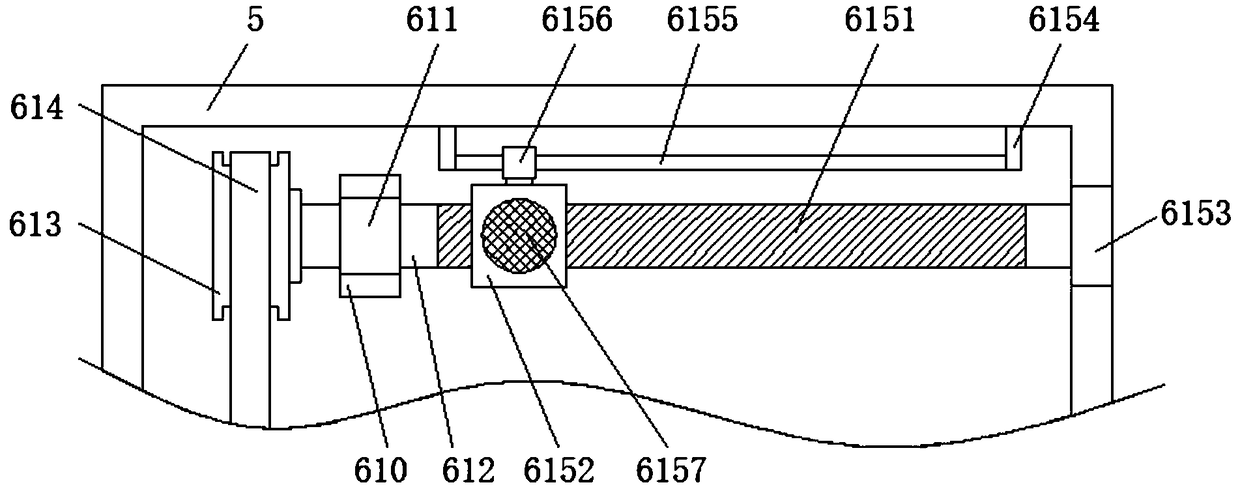

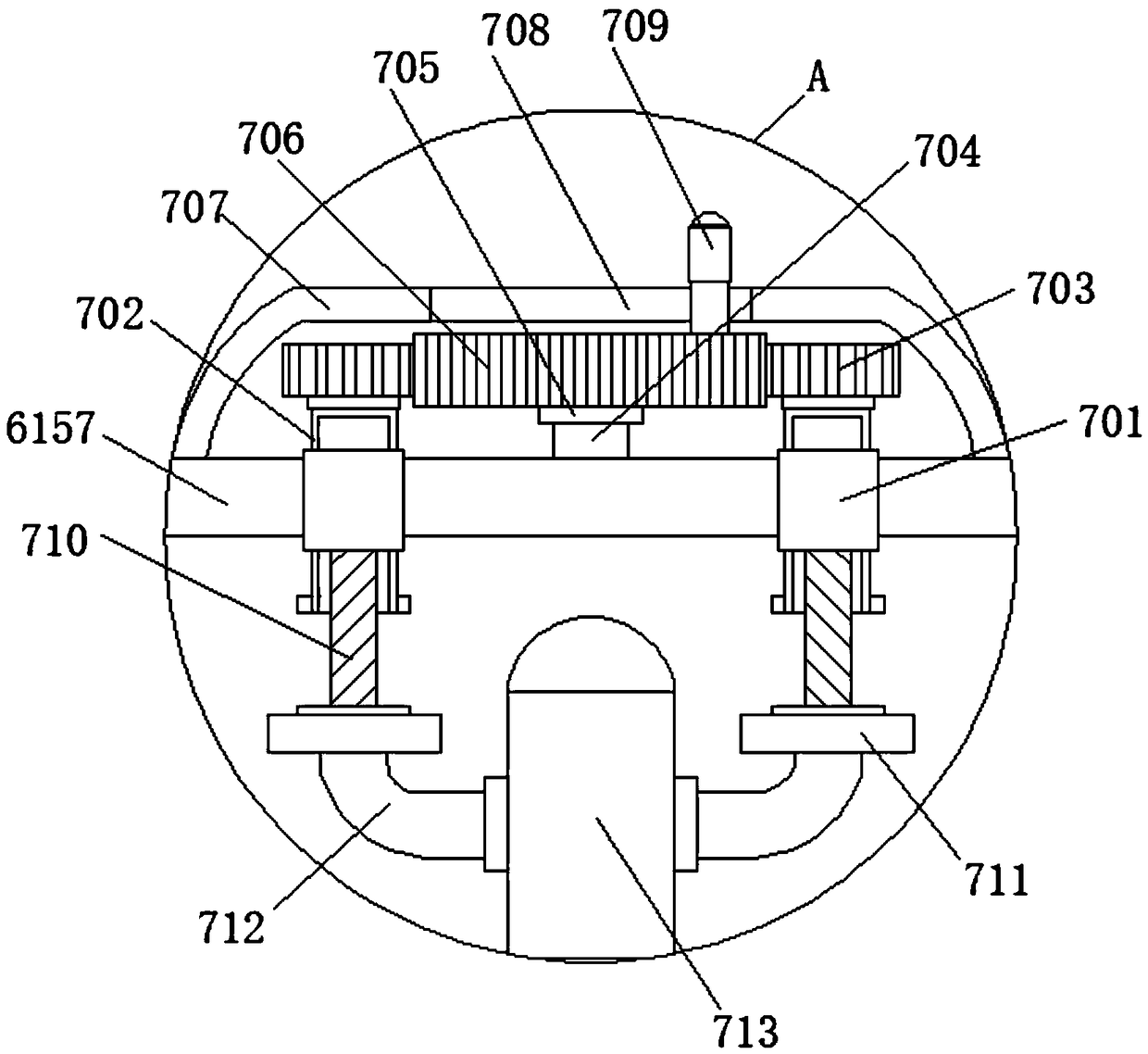

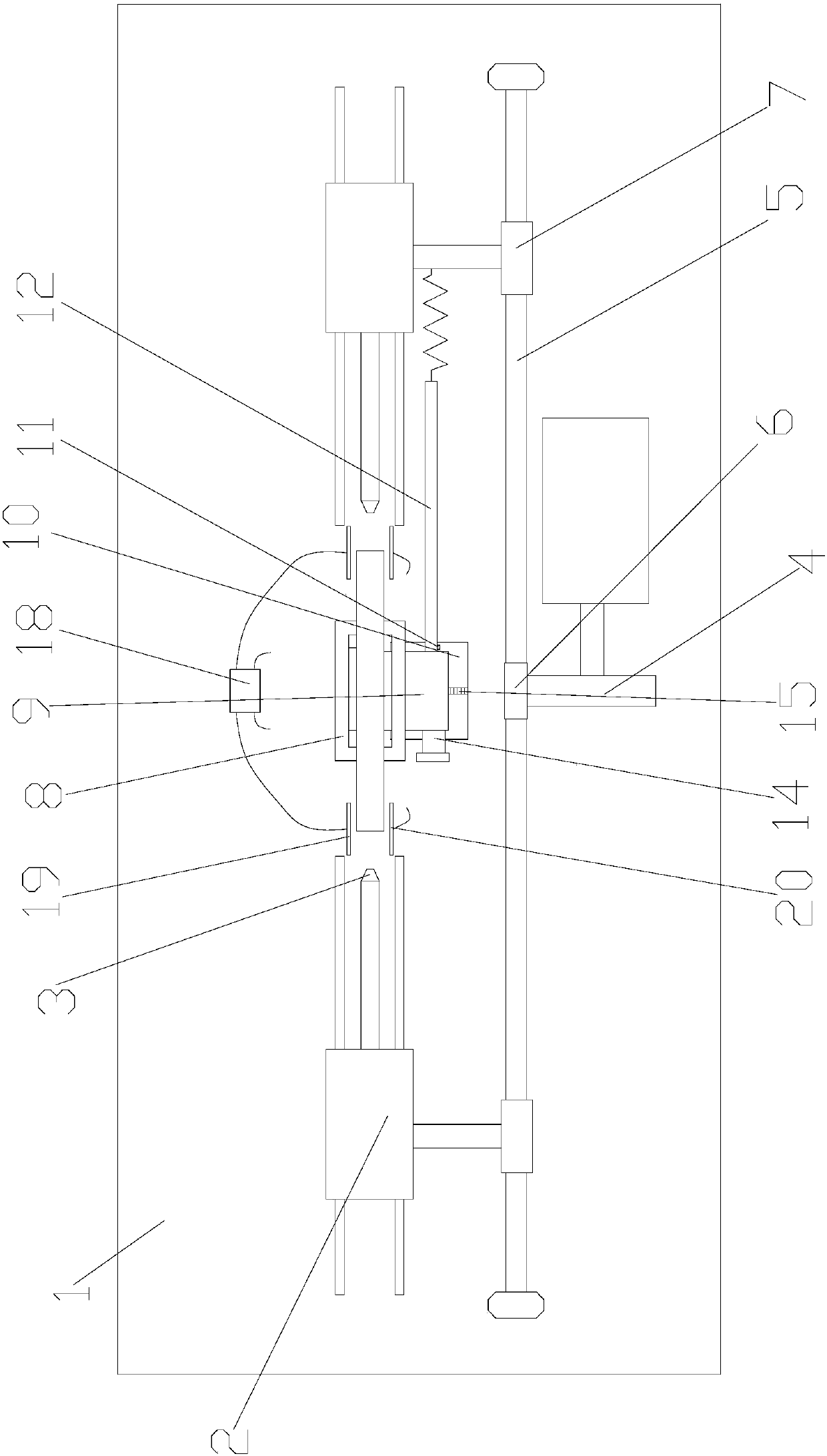

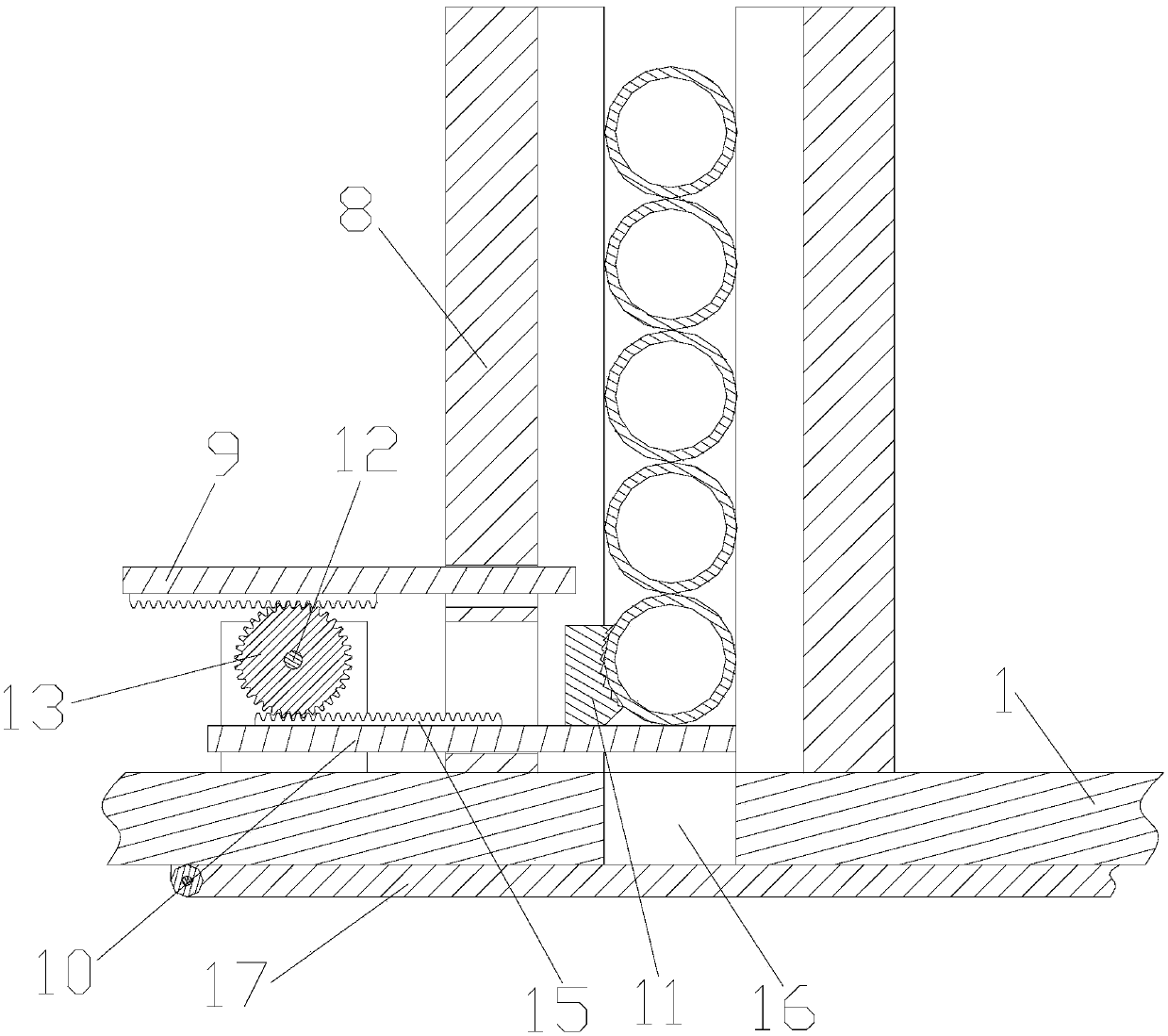

The invention relates to an automatic filling chopping machine, and belongs to the technical field of food processing. The automatic filling chopping machine is realized through a method comprising the following steps of firstly, loading fillings on a chopping plate; assembling a surrounding plate and spray proof slopes; placing the assembled surrounding plate and the assembled spray proof slopeson a rotating disk; and performing plugging and turning on a motor to uniformly chop the loaded fillings. Through the adoption of the automatic filling chopping machine disclosed by the invention, passive stirring and passive overturning are realized; in the process of chopping operation, the fillings naturally move to the periphery of the chopping plate; under the blocking effect of the surrounding plate and the spray proof slopes arranged outside the chopping plate, stirring and overturning are performed, so that splashed fillings can be effectively sheltered, the situation that the fillingsare splashed everywhere is avoided, the alternate continuous reciprocating chopping of a left chopping knife and a right chopping knife and the rotating filling mixing of the chopping plate are realized, and manual operation is replaced to automatically complete the operations of filling chopping and filling overturning. According to the automatic filling chopping machine disclosed by the invention, automatic filling chopping can be completed according to the requirements of people; the manner of the automatic filling chopping machine, namely the manner of simulating manual filling chopping is adopted, so that the primary juice and the primary odor of meat and vegetables are maintained; and complex operation of manual filling chopping is replaced, so that time is saved, people can conveniently enjoy dainty; and after entering the market, the automatic filling chopping machine can have good social benefits and good market prospects.

Owner:赵建平

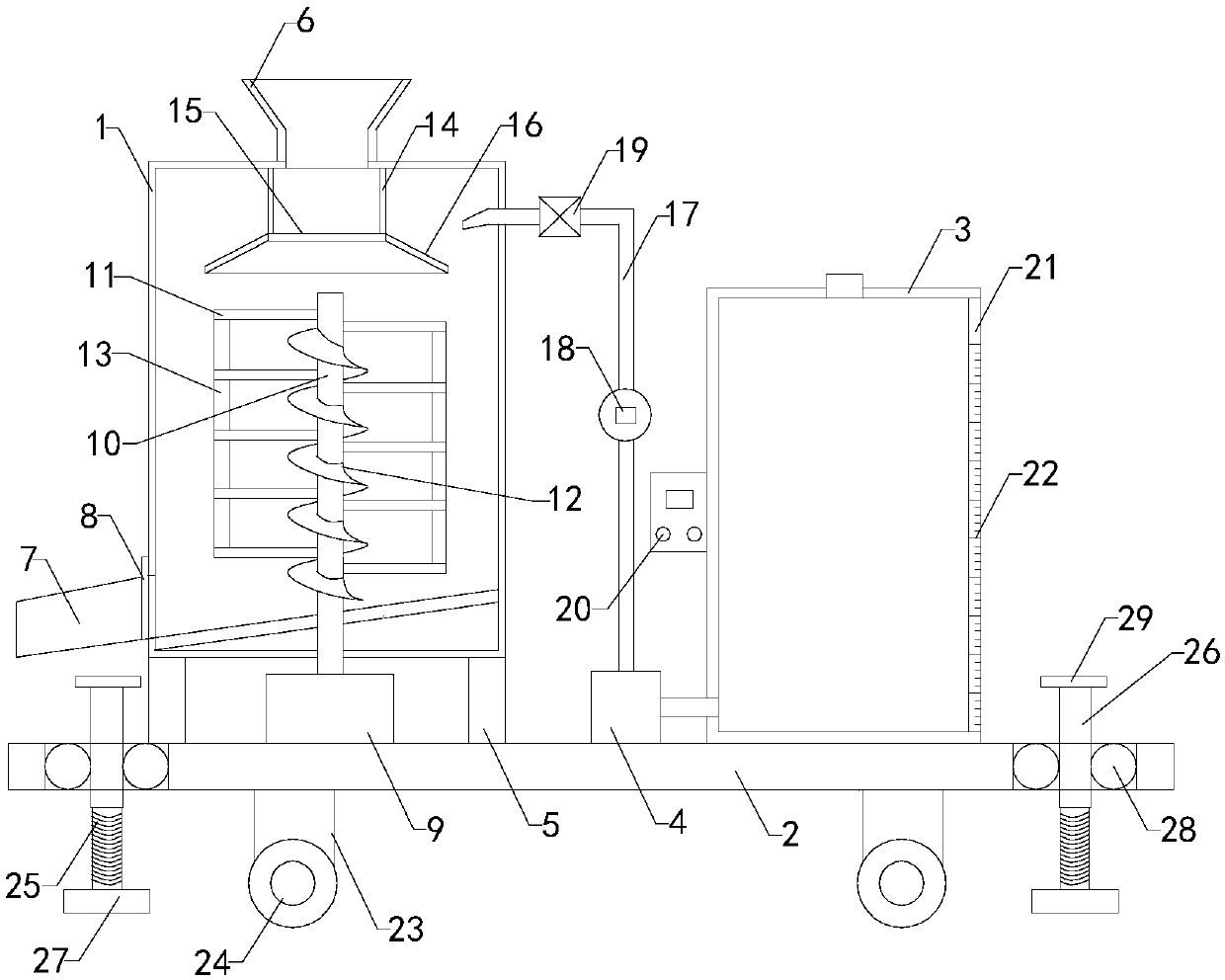

Concrete mixing device

InactiveCN107856181AImprove the mixing effectAvoid damageCement mixing apparatusSolenoid valveDrive shaft

The present invention relates to the technical field of building construction attachments, in particular to a concrete mixing device, which can improve the mixing effect of concrete, thereby improving the mixing efficiency; and can prevent cement and sand and gravel from causing damage to the mixing blade; The water volume is controlled to improve the use effect of the concrete mixture; it includes a mixing tank, a base, a water tank and a water pump. The bottom of the mixing tank is provided with a pillar, the inside of the mixing tank is provided with a working chamber, and the top of the mixing tank is connected with a feeding hopper. There is a discharge pipe at the bottom of the left end of the mixing tank, and a baffle is provided at the discharge pipe, a motor is provided at the top of the base, a transmission shaft is provided at the top output end of the motor, and a horizontal stirring blade and a spiral stirring blade are arranged on the transmission shaft. , vertical stirring blades are arranged between the horizontal stirring blades, and four sets of connecting rods, connecting plates, four sets of deflectors, connecting pipes, flow meters, solenoid valves and controllers are also included.

Owner:盐城市恒纬物流有限公司

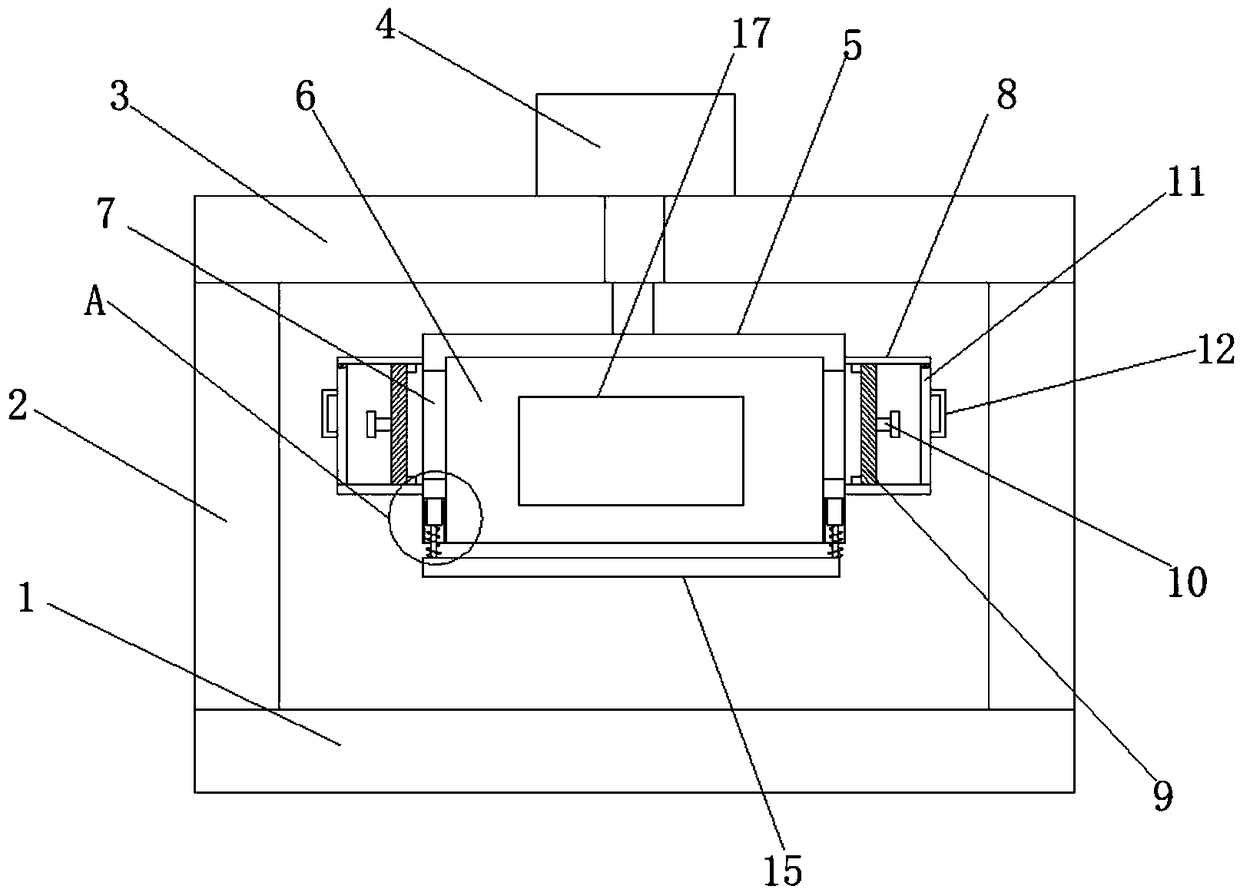

Machining chip removing method

ActiveCN108857504APrevent splashing aroundEasy to cleanWork clamping meansPositioning apparatusMagnetMachining process

The invention discloses a machining chip removing method. According to the machining chip removing method, a machining cutter is installed inside a first groove (6), a workpiece is placed on the surface of a first supporting plate (1), an air cylinder (4) is started and pushes a fixing plate (5), the fixing plate (5) drives a pressing plate 15 to squeeze the workpiece, along with downward movementof the fixing plate (5), the cutter machines the workpiece, a part of metal chips generated in the machining process enters collection boxes (8) via first through holes (7) and are attracted on the surfaces of magnets (9), the remaining metal chips remain inside the first groove (6), baffles (11) are opened finally, push plates (10) are pulled, the push plates (10) drive the magnets (9) to move out of the collection boxes (8), and the metal chips on the surfaces of the magnets (9) are collected. By the adoption of the machining chip removing method, the metal chips generated in the machiningprocess can be rapidly collected, the metal chips can be prevented from splashing all around, and people can conveniently clean the metal chips.

Owner:CHUZHOU KEXIN MECHANICAL TECH

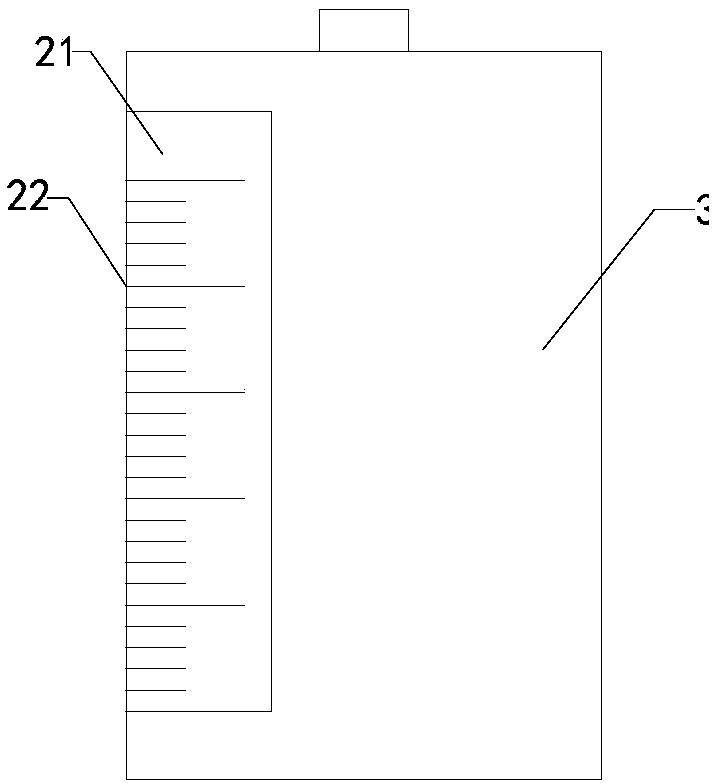

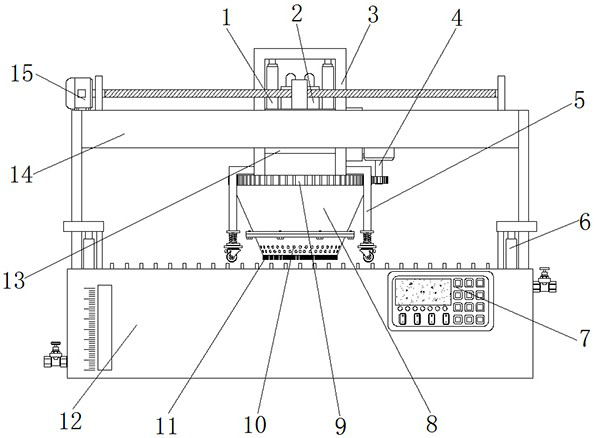

Welding seam detection device based on low-pressure leak hunting

PendingCN107727321AEasy to detectDetection is simple and fastDetection of fluid at leakage pointHydraulic cylinderWater storage tank

The invention provides a welding seam detection device based on low-pressure leak hunting. The welding seam detection device comprises a detection support, a water storage tank and a water detection tank, a connection water pipe is connected between the water storage tank and the water detection tank, and a supporting base support and a workpiece supporting base are arranged in the water detectiontank in sequence; a liquid level sensor is further arranged in the water detection tank, the water storage tank and the workpiece supporting base are both connected with an air compressor through airpipes, and a first electromagnetic valve and a second electromagnetic valve are arranged among the water storage tank, the water detection tank and the air compressor respectively; two vertical guiderails are arranged above the detection support, a hydraulic cylinder is arranged at the tops of the two vertical guide rails, and a vertical extruding column is connected with the hydraulic cylinderthrough a connector. By using the low-pressure leak hunting principle, the welding seam detection device can conveniently and constantly detect welding seams of workpieces, is simple in structure andconvenient to operate, can rapidly and conveniently detect welding seam defects, is suitable for being operated by all types of workers, and is high in detection efficiency, high in practicability andworthy of popularization and application.

Owner:QINZHOU UNIV

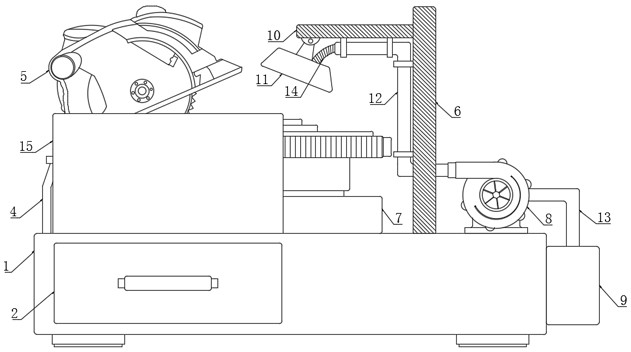

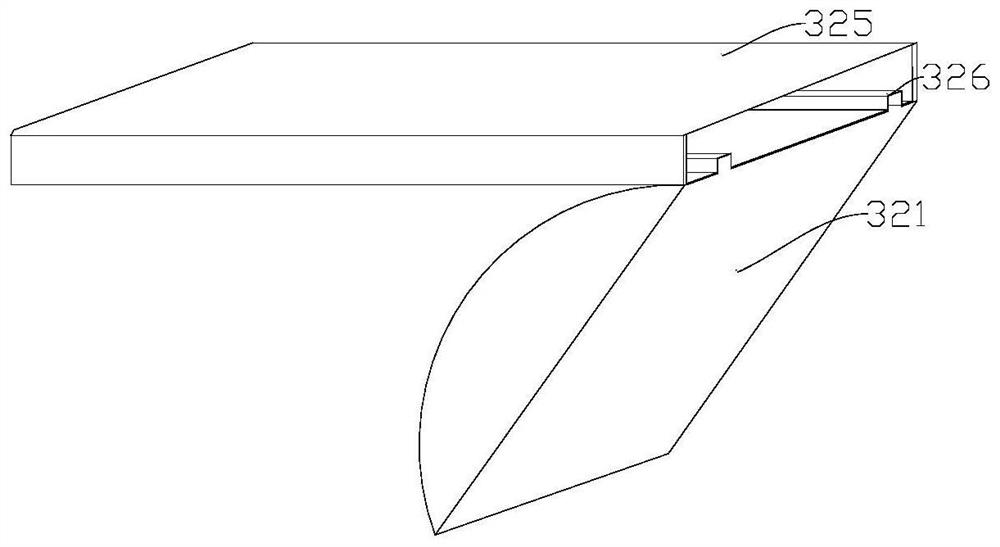

Debris blocking structure of cutting machine tool

InactiveCN106799640APrevent splashing aroundAvoid processing environmental pollutionMaintainance and safety accessoriesBroomEngineering

The invention discloses a debris blocking structure of a cutting machine tool. The debris blocking structure of the cutting machine tool comprises a worktable; a blocking cover is installed on the worktable, an opening for workpiece entering and existing is formed in the side edge of the blocking cover, an cavity is formed in the blocking cover, an annular collecting groove is formed in the bottom of the cavity, and the side edge of the collecting groove is connected with the side wall of the worktable; a telescopic arm movably penetrates through the top of the blocking cover and is installed above the worktable, and a cutting wheel is rotatably installed at the tail end of the telescopic arm; the air suction end of the draught fan is connected with the collecting groove; and a filtering net is installed on the collecting groove, and a gap is reserved between the filtering net and the bottom of the collection groove. During cutting, generated debris slides downwards along the inner wall of the metal debris till falling into the annular collecting groove; after cutting is completed, the collecting groove can be cleaned through simple tools such as a broom, meanwhile, the metal debris accumulated in the collection groove can be centrally recycled, and consequently secondary utilization can be achieved.

Owner:重庆市木越机械制造有限公司

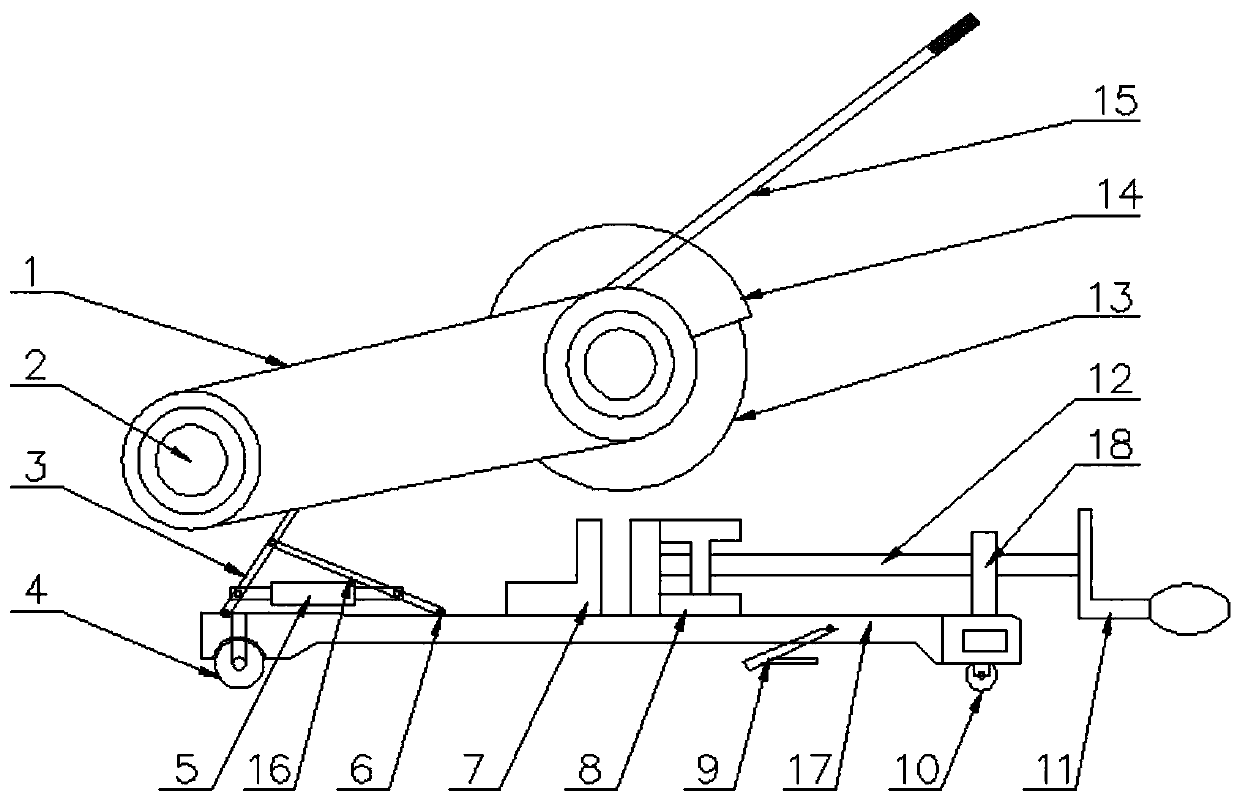

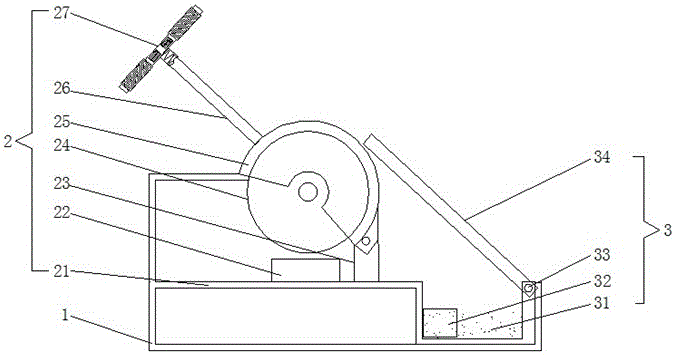

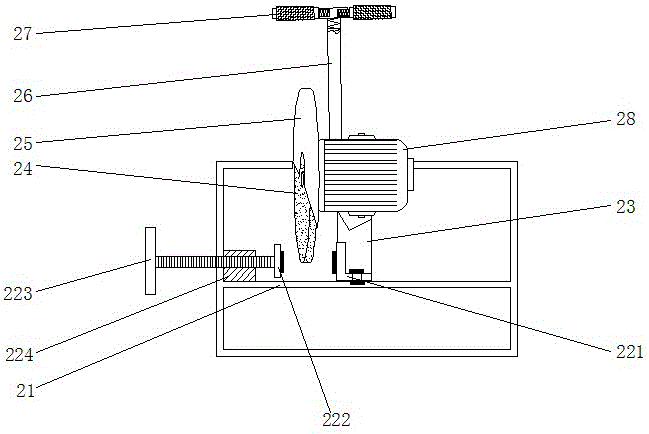

Movable steel bar cutter

InactiveCN107716805AEasy to movePrevent splashing aroundGrinding machinesGrinding/polishing safety devicesRebarDrive motor

The invention discloses a movable steel bar cutting machine, which includes a base, a cutting wheel, an operating rod and a motor, the motor is fixed on a transmission box, and the other end of the transmission box is fixed with the cutting wheel and the operating rod. The transmission box is hinged to the left end of the base through the first bracket below one end of the motor, the fixed column is vertically arranged and one end is fixedly connected to the bottom of the box body, and the bottom end of the fixed column is connected to the running wheel by rotation. Both ends of one side of the fixed column are fixed with fixed blocks, and the two fixed blocks are rotated and connected with a rotating plate, and the rotating plate is fixedly connected with an engaging nail. There are engaging holes matching the nails, and a base bracket is provided on the left side of the universal wheel. This movable steel bar cutting machine can be placed at will, and has a simple structure and is easy to operate.

Owner:盐城来拾集装箱有限公司

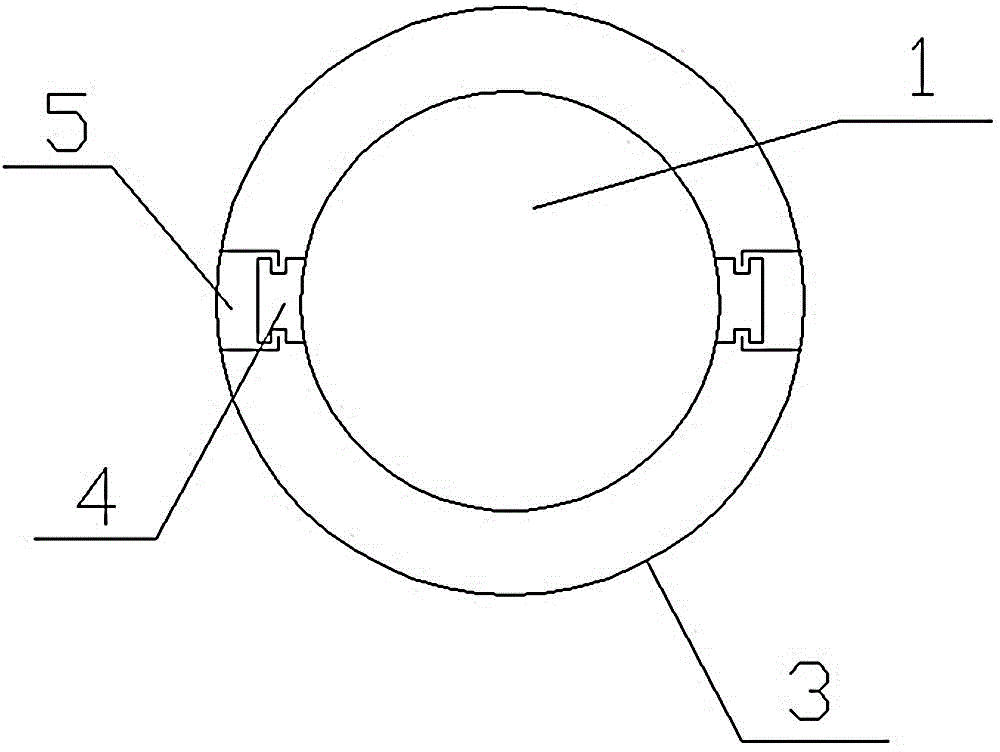

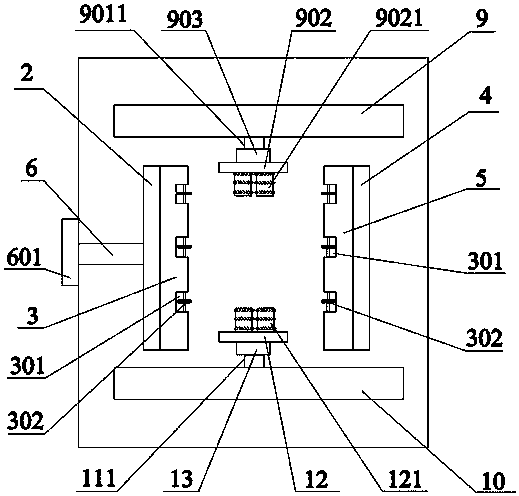

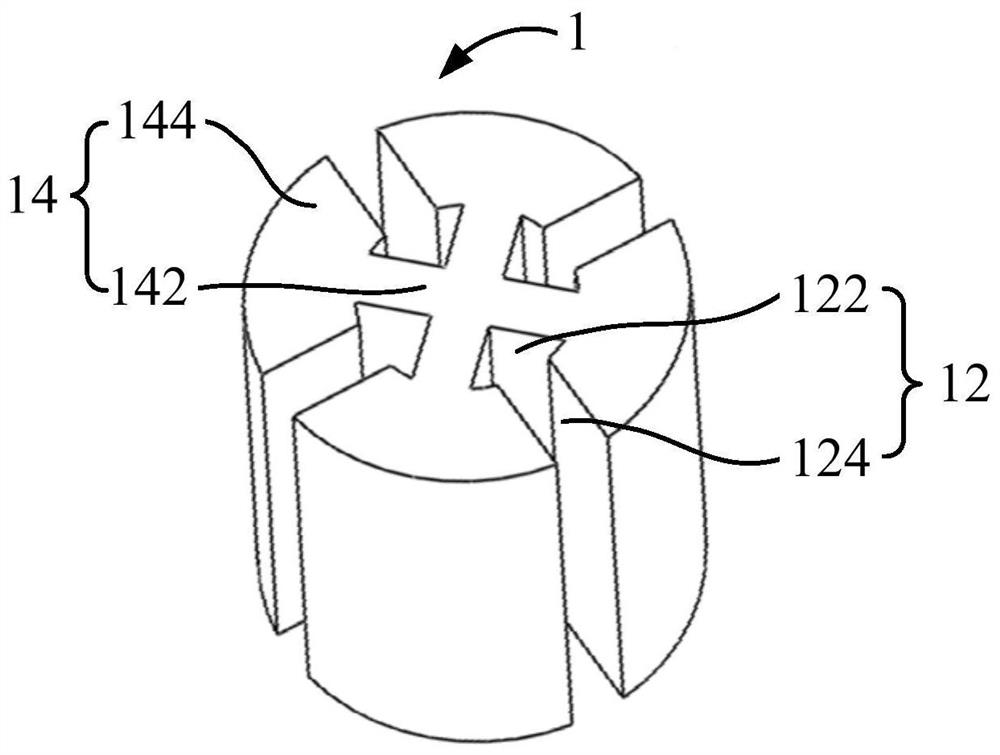

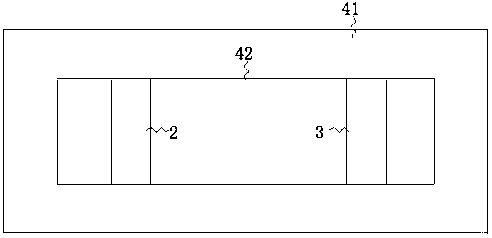

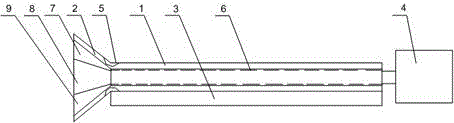

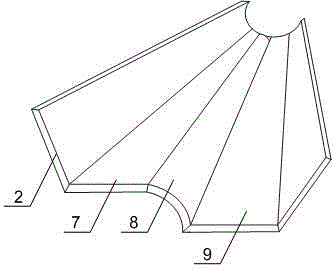

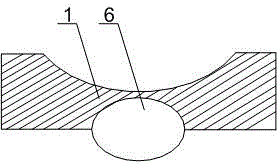

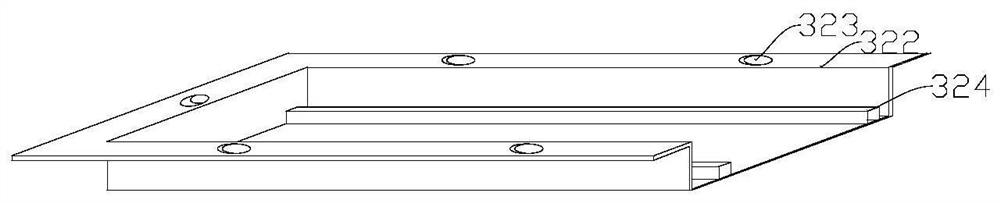

Device for preventing cooling water of CNC (computer numerical control) grinding head from splashing outside

InactiveCN104669119APrevent splashing aroundAvoid pollutionGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses a device for preventing cooling water of a CNC (computer numerical control) grinding head from splashing outside. The CNC grinding head (2) is vertically arranged on the bottom of a CNC main shaft (1); the device comprises a protective cover (3), wherein the inner diameter of the protective cover (3) is larger than the outer diameter of the CNC main shaft (1); slide slots (5) and slide blocks (4) which are in sliding fit are arranged on the inner wall of the protective cover (3) and the outer wall of the CNC main shaft (1) respectively, so that the protective cover (3) can vertically move up and down along the CNC main shaft (1); through holes (7) which are matched with cooling water tubes (6) areformed in the side wall of the protective cover (3); rebounded water obtained by flushing the cooling water onto the grinding head is blocked by the protective cover and flows into a CNC machine table along the inner wall of the protective cover, so that the cooling water is effectively prevented from splashing in all directions, and thus, pollution to the ground of a manufacturing shop is avoided, and the waste of resources is also avoided; meanwhile, the protective cover can vertically move up and down along the CNC main shaft to conveniently mount and replace the CNC grinding head.

Owner:凯盛科技股份有限公司 +1

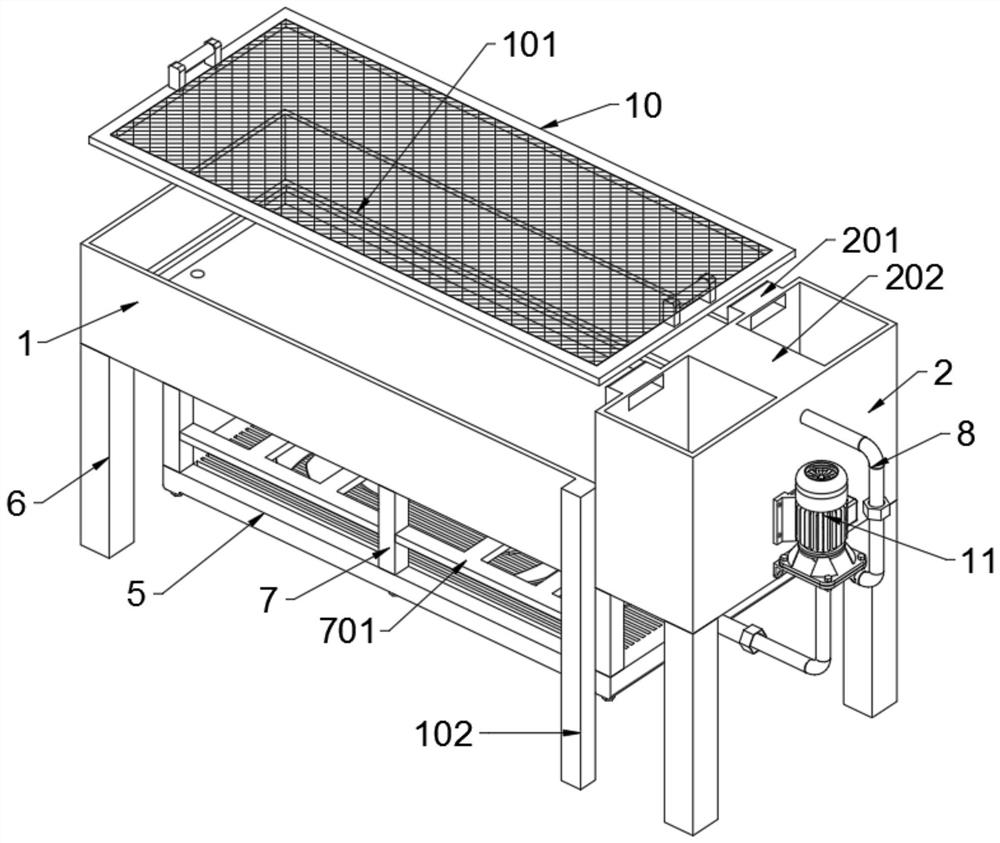

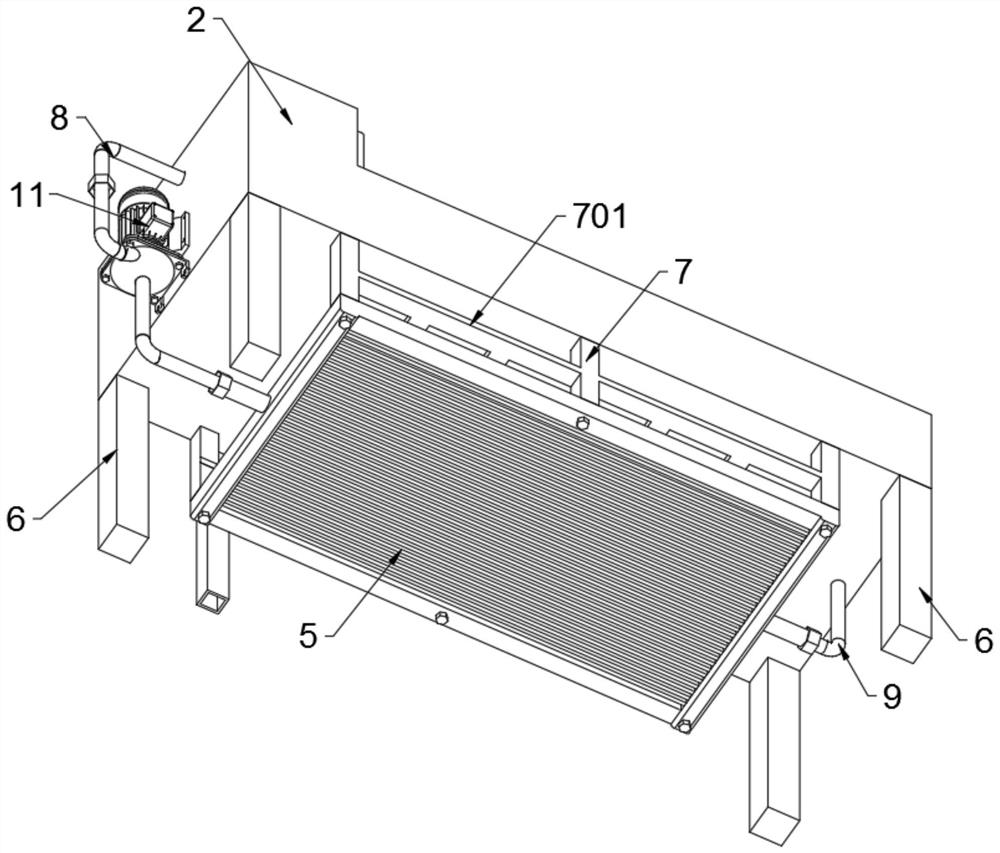

Household appliance cleaning machine with disinfection function and use method thereof

ActiveCN113953247APrevent splashing aroundReduce workloadCleaning using liquidsHeatWorking environmentEnvironmental engineering

The invention relates to the technical field of household appliance cleaning machines, in particular to a household appliance cleaning machine with a disinfection function, which comprises a cleaning shell, wherein first baffles are hinged to the tops of the outer walls of the two sides of the cleaning shell, a second baffle is hinged to the top of the outer wall of one end of the cleaning shell, shielding mechanisms are arranged on the two sides of the outer wall of the top of the second baffle, a sealing plate is hinged to the top of the outer wall of the other end of the cleaning shell, and a cleaning mechanism is arranged in the cleaning shell. According to the household appliance cleaning machine with the disinfection function, the shielding mechanisms are arranged, fixing rods on fixing shells are pulled out, the fixing rods are fixed into fixing grooves in the first baffles, arc-shaped sliding blocks on fixing springs are used for fixing the fixing rods to the first baffles, so that gaps between the first baffles and the second baffle are protected through pulled-out folding water shielding curtains, and when a spray gun is used for cleaning and disinfecting small household appliances and parts, cleaning liquid and water are prevented from splashing everywhere during cleaning, and the workload of cleaning the working environment in the later period is reduced.

Owner:广东顺德蓝导电器科技有限公司

Lens cleaning and drying device

ActiveCN112691975APrevent splashing aroundThe location of the movement is preciseDrying machines with local agitationDrying machines with materials at restOphthalmologyBiomedical engineering

The invention relates to a drying device, in particular to a lens cleaning and drying device. The invention provides a lens cleaning and drying device capable of cleaning and drying a lens and collecting and filtering a cleaning agent. The lens cleaning and drying device comprises a base, wherein a cleaning mechanism is arranged on the base; and a drying mechanism which is arranged on the cleaning mechanism. According to the invention, the lens is placed through the cleaning mechanism, and then the lens is dried under the cooperation of the drying mechanism; by arranging the flushing mechanism, automatic flushing of the lens is achieved, a sliding block can block the cleaning agent in the flushing mechanism, and then the cleaning agent is prevented from splashing everywhere.

Owner:江西超联光电科技有限公司

Grinding wheel type metal cutter

InactiveCN106737078APrevent splashing aroundAvoid accidental cutsGrinding machinesGrinding/polishing safety devicesType metalScrap

The invention discloses a grinding wheel type metal cutter, comprising a basic outer shell, wherein the bottom parts of left and right sides of the inner cavity of the basic outer shell are respectively provided with a cutting device and a collecting device; the cutting device comprises a cutting platform, and the upper surface of the cutting platform is provided with a clamp; the outside of the clamp is fixedly connected with a supporting pillar, and the supporting pillar is moveably connected with a protecting shell at the top part through a nut; the collecting device comprises a condensing pond, wherein one side of the condensing pond is fixedly connected with the cutting platform, and the other side thereof is connected with a moving baffle through a nut. Through the basic outer shell, the protecting shell and the moving baffle, the working space of the grinding wheel type metal cutter is completely sealed; through the cooperation of the condensing pond and the moving baffle in the collecting device, the spluttered hot scrap irons directly enter the condensing pond and finally absorbed by a permanent magnet block through cooling of the condensing fluid, thereby reaching the effects of cooling and collecting scrap irons.

Owner:WUXI CAIYUN MACHINERY & EQUIP

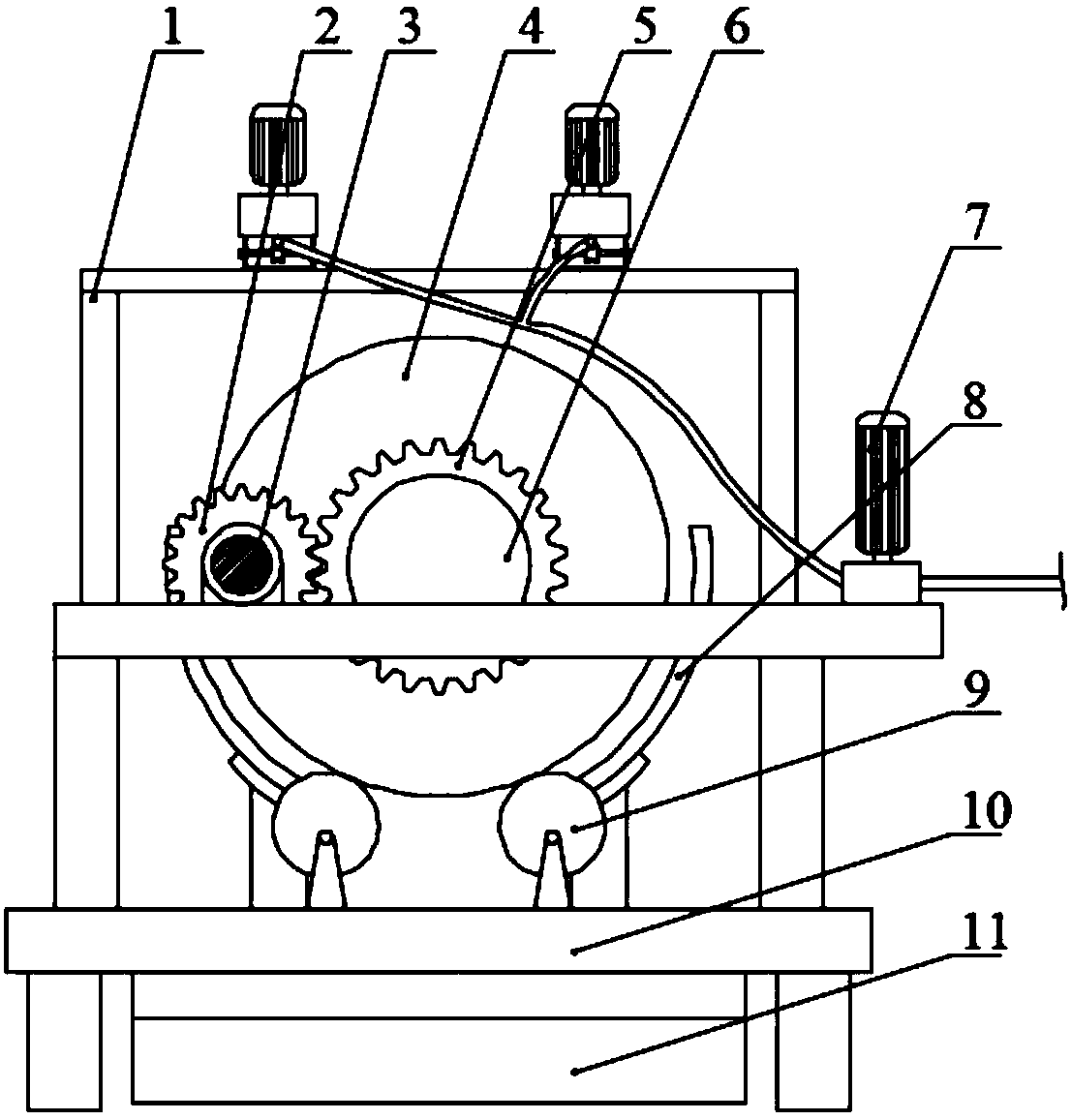

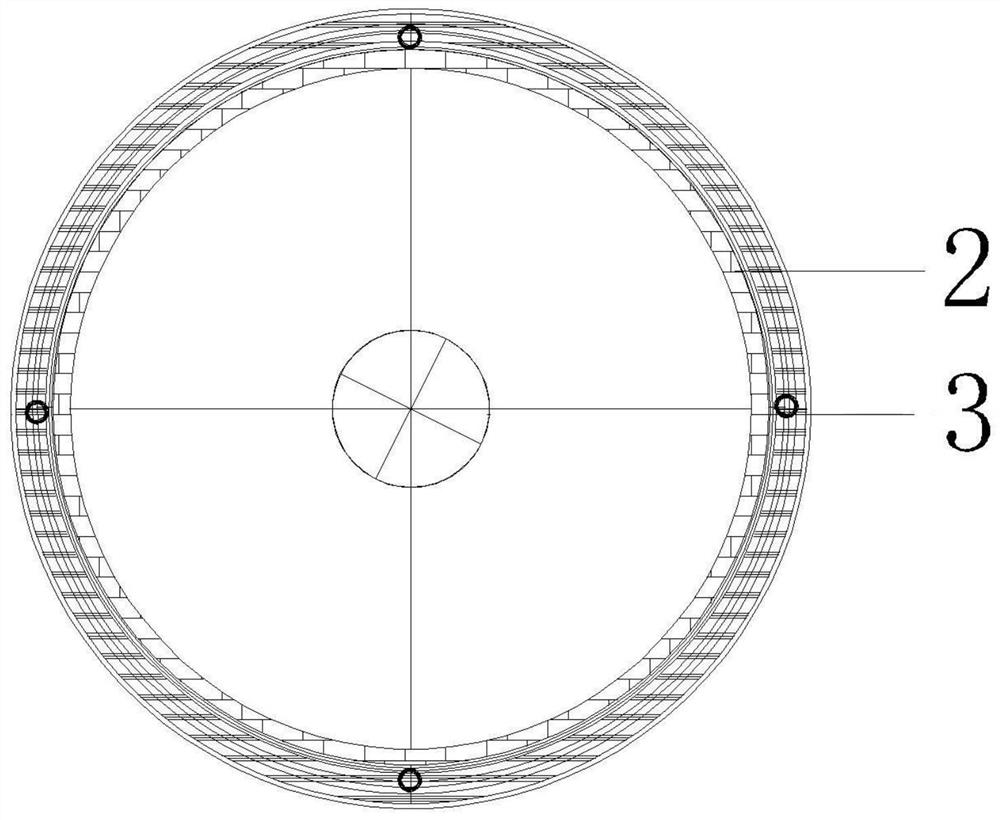

Centrifugal cleaning device for perilla leaves

InactiveCN109985843APrevent splashing aroundRealize fully automatic high efficiencyCleaning using liquidsPower unitEngineering

The invention relates to a centrifugal cleaning device of perilla leaves. The centrifugal cleaning device comprises a base and a machine frame, wherein the machine frame is fixedly installed on the upper part of the base; a cleaning unit is rotatably installed on the base; the cleaning unit comprises a rotary table and a filter screen roller, wherein the rotary table is coaxially and fixedly installed at one end of the filter screen roller, and a spiral feeding ring is further manufactured in the filter screen roller; a plurality of spray brackets are fixedly installed at the top of the machine frame, a supporting pulley is rotatably arranged in each of the spray brackets, a spray rod is slidably supported on each of the supporting pulleys, and a plurality of high-pressure spray heads arearranged on the spray rods; cam motors are fixedly installed on the spray brackets at one ends of the spray rods, fixing blocks are installed at the output ends of the cam motors, and the fixing blocks are fixedly connected with the spray rods; and the machine frame is provided with a power unit which provides rotating power for the rotary table. The centrifugal cleaning device uses the centrifugal principle to clean the perilla leaves, and meanwhile, the spray rods can spray the filter screen roller in a full-coverage mode; and the entire cleaning process can be further completed without theneed for operators, and thus manpower is greatly saved.

Owner:天津圣鑫源农产品有限公司

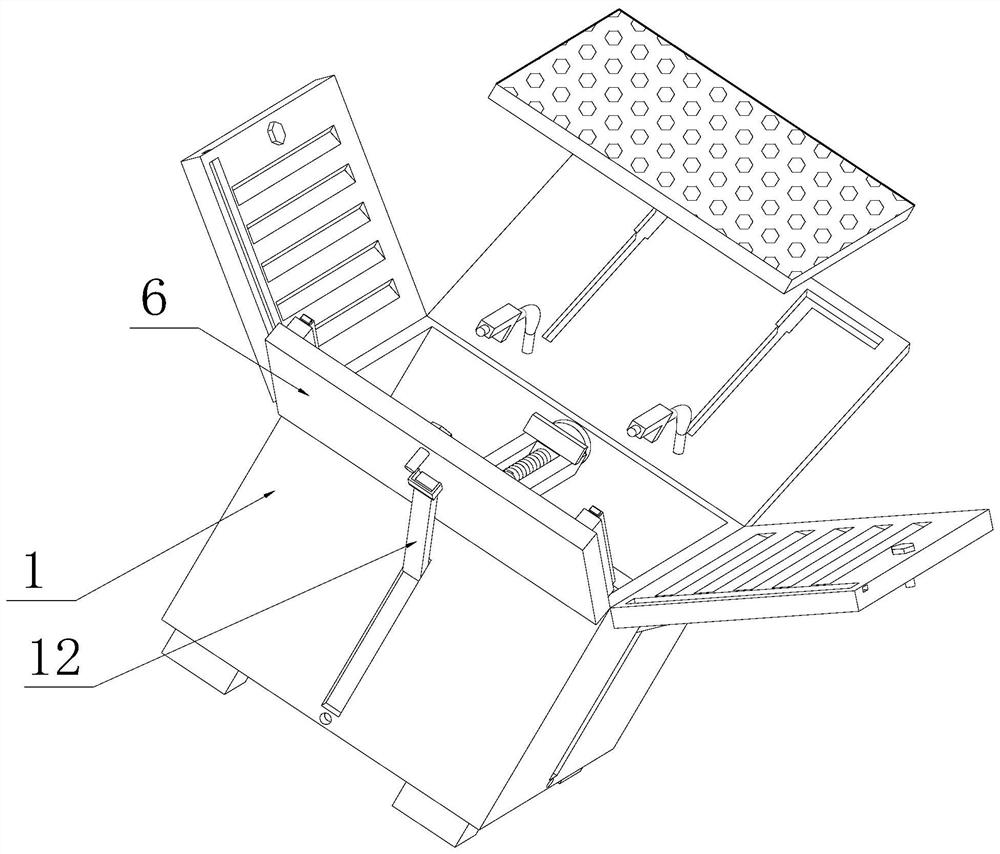

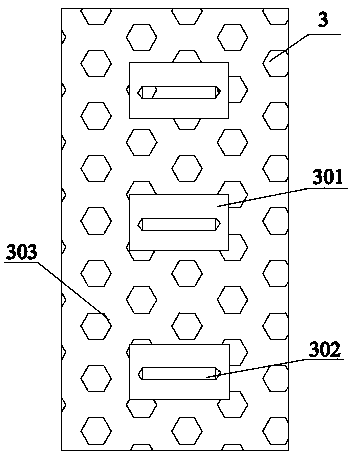

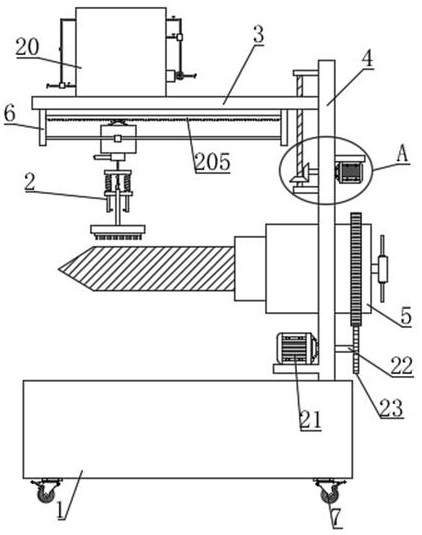

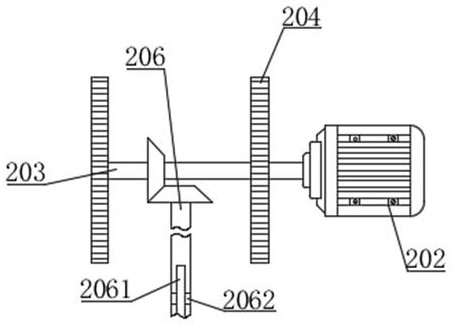

Mashed garlic manufacturing device subjected to deformation and transverse grinding based on pressure

ActiveCN108814241APrevent splashing aroundImprove production efficiencyStrainersManufacturing efficiencyEngineering

The invention relates to the technical field of mashed garlic machining, in particular to a mashed garlic manufacturing device subjected to deformation and transverse grinding based on pressure. The device solves the technical problems that existing marshes garlic manufacturing is not convenient and the efficiency is not ideal. In order to solve the technical problems, the mashed garlic manufacturing device subjected to deformation and transverse grinding based on pressure comprises a base, a supporting base is fixedly connected to the top of the base, a through hole is formed in the front face of the supporting base, a top plate is fixedly connected to the top of the supporting base, and the top of the top plate is fixedly connected with a U-shaped machine body. A power execution mechanism drives a pressure deformation mechanism to continue to move left and right transversely, garlic cloves inside a garlic clove containing mechanism are ground, smashed garlic cloves and garlic juice are effectively prevented from being splashed, the mashed garlic manufacturing efficiency is improved, time and labor force are saved, the mashed garlic quality is enhanced, and manufactured mashed garlic can be conveniently taken out.

Owner:绍兴市侨陆智能科技有限公司

Electrostatic chip collecting type tapping device

PendingCN107855615APrevent splashing aroundImprove tapping efficiencyThread cutting machinesMaintainance and safety accessoriesEngineeringTransformer

The invention discloses an electrostatic chip collecting type tapping device. The tapping device comprises a workbench, wherein a bidirectional tapping mechanism and an electrostatic collecting mechanism are arranged on the workbench; the bidirectional tapping mechanism comprises two tapping machines, and the tapping machines comprise tapping screws, and an corresponding elastic triggering switchis arranged at the end of every two tapping rods where the two tapping rods close to each other; the electrostatic collecting mechanism comprises electrostatic chip collecting areas where a high-voltage rectifying transformer are in cooperation with each tapping machine, the electrostatic chip collecting areas comprise discharging polar plates and chip collecting plates, the discharging polar plates and the chip collecting plates are connected with positive pole and negative pole of the high-voltage rectifying transformer correspondingly; and a feeding mechanism comprises a storage chamber, the storage chamber comprises two guide walls which are oppositely arranged at intervals, an intermittent material supply part is arranged on one of the guide walls, the material supply part is used fordriving one tapping machine as power through a transmission part. Compared with the prior art, the electrostatic chip collecting type tapping device has the advantages that working environment of workers is improved, and tapping efficiency and quality are improved.

Owner:重庆卡沃尔工业有限公司

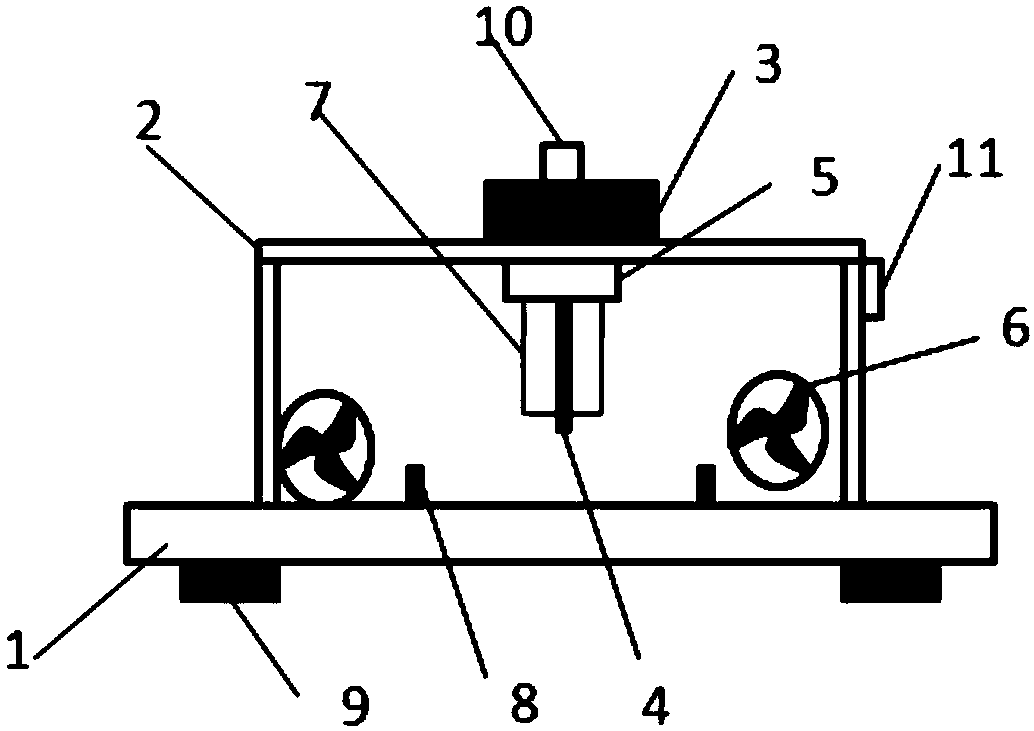

Cutting dust removal purification device

InactiveCN109926863APrevent splashing aroundPrevent splashMaintainance and safety accessoriesExhaust gasEngineering

The invention provides a cutting dust removal purification device. The cutting dust removal purification device comprises a bearing table (1), a cutting machine support (2), a cutting motor (3), a cutting head (4), a cutting head control device (5) and two exhaust fans (6). The cutting machine support (2) is fixedly welded to the middle of the bearing table (1). The cutting motor is placed on theupper side of the cutting machine support (2). The cutting head control device (5) is located on the lower side of the cutting machine support (2). The exhaust fans (6) are fixed to the two sides of the cutting machine support (2). By adoption of the cutting dust removal purification device, powder cut off can be collected in time, and the phenomenon that the powder flies everywhere to pollute theworking environment is prevented.

Owner:XINCHANG XIANGYUN MACHINERY

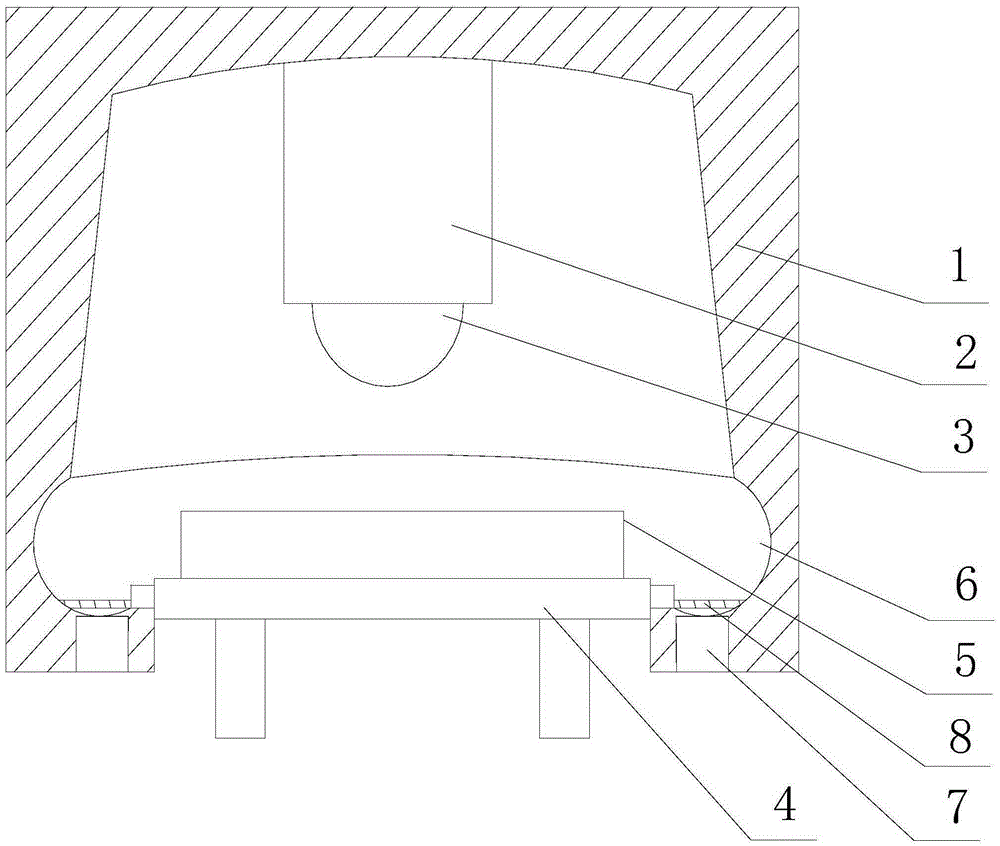

Enhanced jaw plate used for jaw crusher

PendingCN108246390AImprove crushing efficiencyPrevent splashing aroundGrain treatmentsPlastic recyclingReciprocating motionCrusher

The invention provides an enhanced jaw plate used for a jaw crusher. The jaw plate comprises a fixed jaw plate and a movable jaw plate for carrying out a reciprocating motion relative to the fixed jawplate; a first auxiliary plate for preventing materials from sputtering is arranged on one side of the fixed jaw plate and one side of the movable jaw plate, a second auxiliary plate for preventing materials from sputtering is arranged on the other side of the fixed jaw plate and the other side of the movable jaw plate, and a material crushing passage is enclosed by the fixed jaw plate, the movable jaw plate, the first auxiliary plate and the second auxiliary plate; a push rod I, a supporting rod and a push rod II are arranged on one side, away from the movable jaw plate, of the fixed jaw plate in sequence from top to bottom; a crushing plate I is arranged on one side, close to the movable jaw plate, of the fixed jaw plate; a crushing plate II is arranged on one side, close to the fixed jaw plate, of the movable jaw plate; an auxiliary crushing mechanism I is arranged on one side, close to the material crushing passage, of the first auxiliary plate, and an auxiliary crushing mechanismII is arranged on one side, close to the material crushing passage, of the second auxiliary plate. According to the jaw plate, slipping of materials between the fixed jaw plate and the movable jaw plate can be reduced, and the crushing efficiency of the materials is improved effectively.

Owner:洛阳博林智能装备有限公司

Anti-caking performance testing device based on fertilizer anti-caking agent production

PendingCN112730087APrevent splashing aroundAvoid pollutionMaterial strength using tensile/compressive forcesAgricultural scienceAgricultural engineering

The invention provides an anti-caking performance testing device based on fertilizer anti-caking agent production. The anti-caking performance testing device based on fertilizer anti-caking agent production comprises: a shell; and a sliding plate, wherein the two sides of the sliding plate are slidably connected to the two sides of the inner wall of the shell correspondingly, first connecting rods are fixedly connected to the two sides of the top of the sliding plate correspondingly, a moving plate is fixedly connected between the top ends of the two first connecting rods, a sliding groove is formed in the moving plate, the front face of the shell is rotationally connected with a first rotating rod, and the outer surface of the first rotating rod is fixedly connected with a circular plate. According to the anti-caking performance testing device based on fertilizer anti-caking agent production, through cooperative use of the protection frame and the cover plate, protection can be conducted when a fertilizer to be detected is detected, the situation that the fertilizer is exploded by pressure and splashes around is prevented, the working environment is prevented from being polluted, and potential safety hazards are reduced.

Owner:ANHUI FURUIXUE CHEM SCI & TECH INC

Environmental protection grinding wheel cutting machine

ActiveCN102873624BPrevent splashing aroundPrevent floating spreadGrinding machinesMaterial removal/additionElectric machineryPulp and paper industry

Owner:陈美青

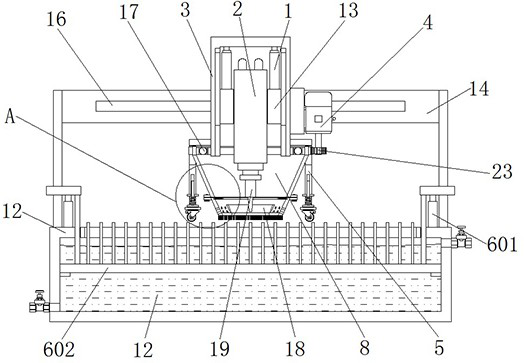

Automatic water jet cutting machine for automobile sheet metal

ActiveCN114523420APrevent splashing aroundAvoid wastingBlast gunsCleaning using toolsStructural engineeringMotronic

The invention discloses an automatic automobile metal plate water jet cutting machine which comprises a collecting bin, U-shaped frames are symmetrically mounted at the two ends of the top of the collecting bin, a mounting base is arranged on the inner sides of the two U-shaped frames jointly, cutting equipment is mounted in the mounting base, a nozzle is arranged at the bottom end of the cutting equipment, and a water inlet is formed in the bottom end of the nozzle. And electric telescopic rods are symmetrically mounted in the middle positions of the two sides of the top of the mounting seat. An electric telescopic rod is controlled to be shortened, a U-shaped plate is driven to descend, a funnel bin completely covers a nozzle, when an automobile metal plate is cut, a servo motor is controlled to rotate, the funnel bin is forced to rotate slowly, when a water column sprayed out of the nozzle cuts the metal plate, part of splashed water can be completely blocked by the rotating funnel bin, and therefore the cutting efficiency of the automobile metal plate is improved. And centrifugal force generated by rotation enables cutting water gathered on the inner side of the annular groove to be automatically and rapidly discharged into the external environment from the drainage hole, and the situation that water splashes all around in the metal plate cutting process of the water jet cutting machine is completely avoided.

Owner:CHENGDU UNIV

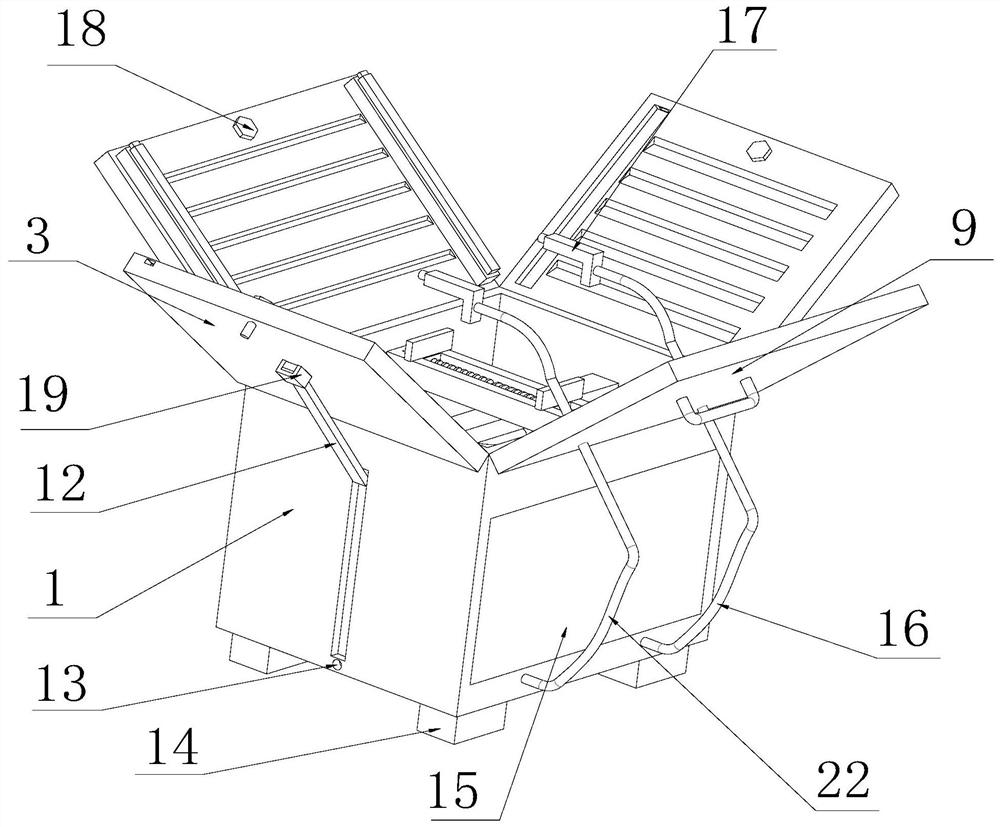

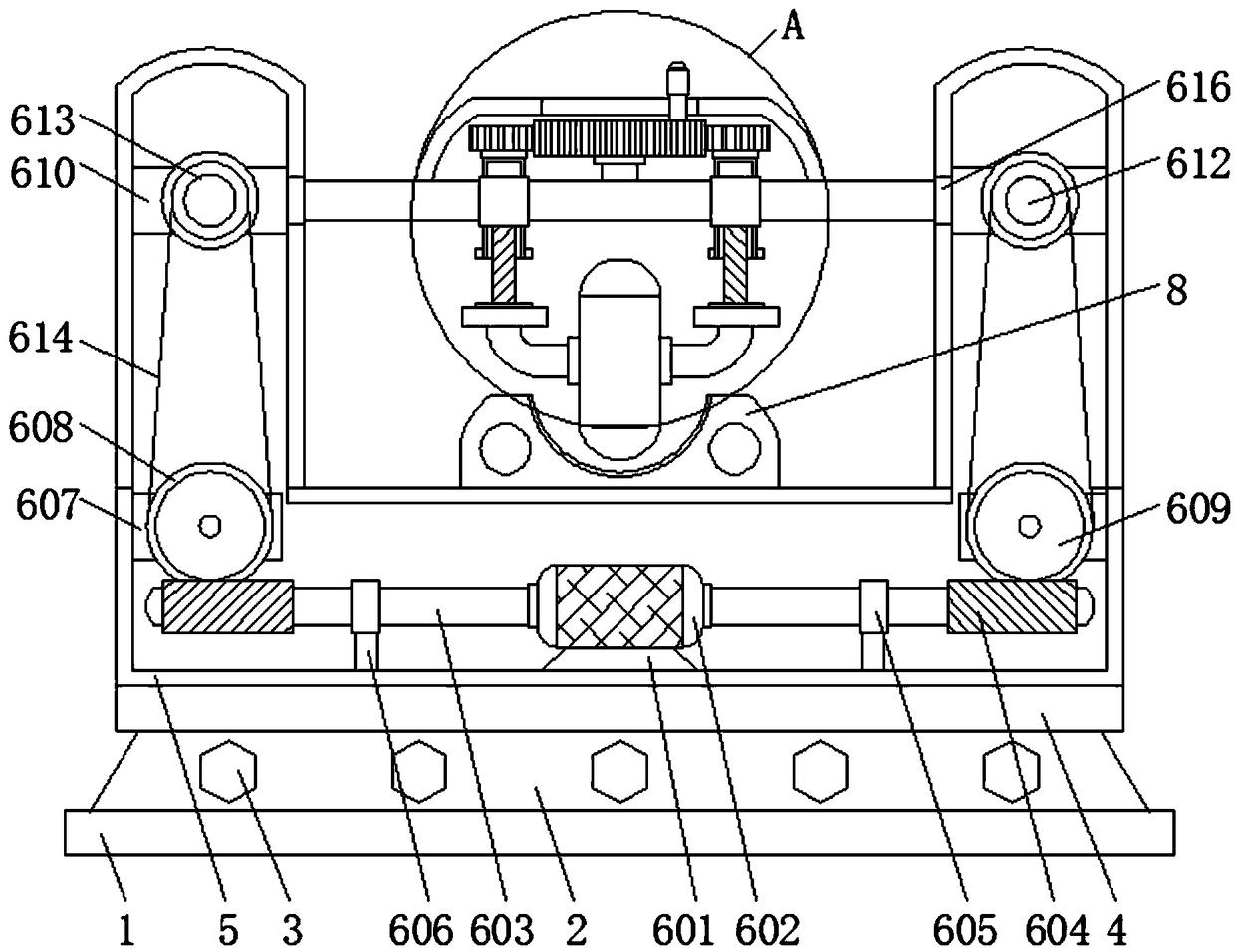

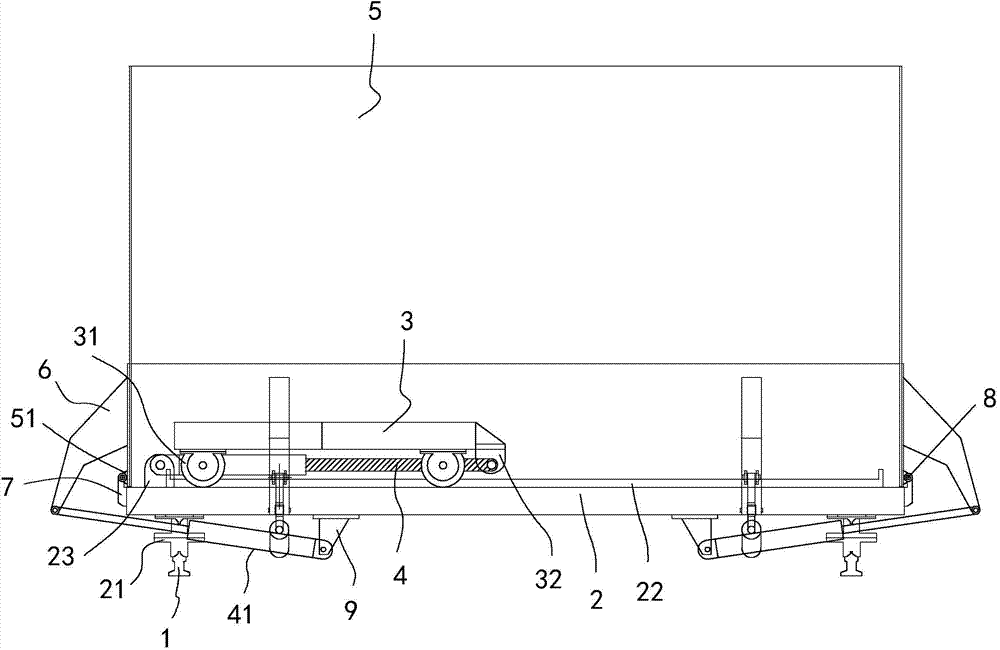

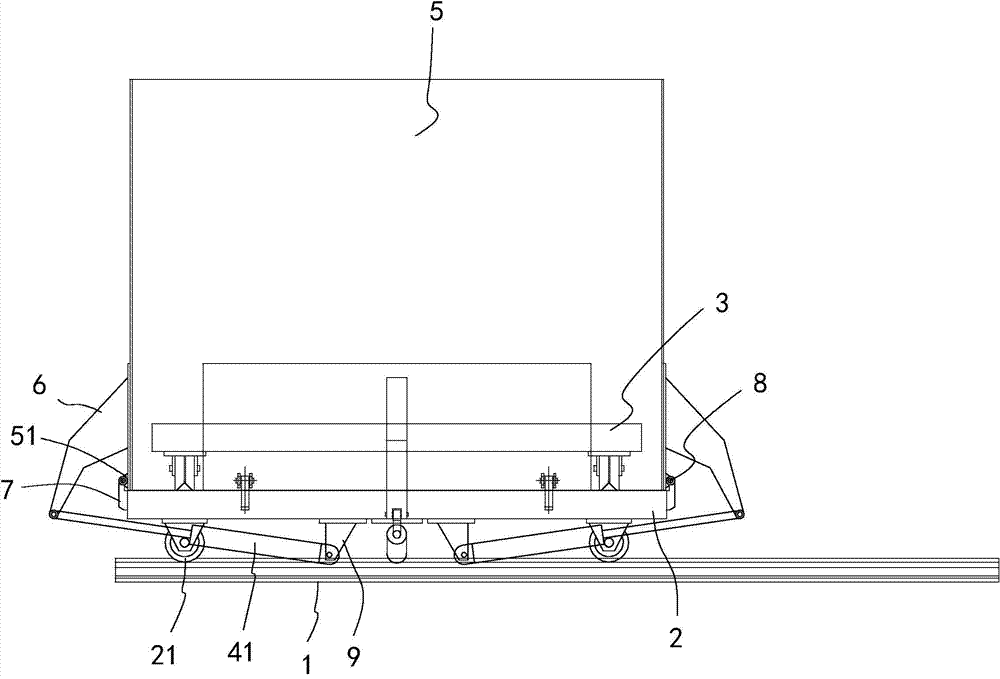

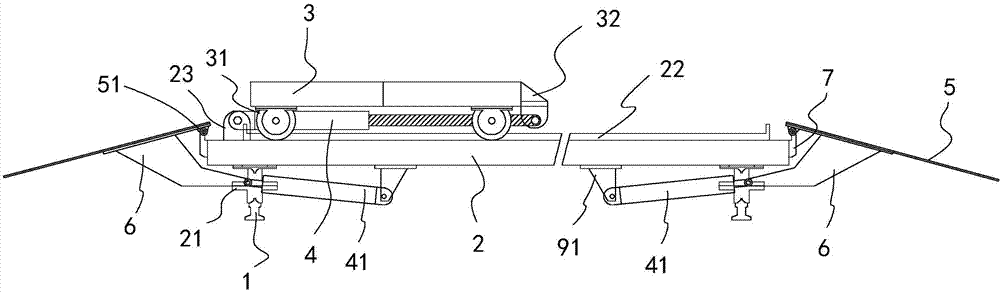

Hydraulic feeding and fragmentation mine car of stone sawing machine

ActiveCN104118062AWon't swingReduce energy consumptionStone-like material working toolsAutomotive engineering

The invention provides a hydraulic feeding and fragmentation mine car of a stone sawing machine. The hydraulic feeding and fragmentation mine car is high in use safety performance and capable of greatly improving stone cutting work efficiency. The hydraulic feeding and fragmentation mine car comprises two transverse guide rails, a lower car body, an upper car body, four plate push oil cylinders, four coamings and four swing arms, the lower car body is arranged on the two transverse guide rails in a transverse sliding mode, the upper car body is arranged on a longitudinal guide rail of the lower car body in a longitudinal sliding mode, a front transmission support is arranged at one end of the lower car body, an oil cylinder is further arranged between the lower car body and the upper car body, a cylinder body of the oil cylinder is fixedly connected with a transmission support, a rear transmission support is arranged at the position, corresponding to the transmission support, of the end, away from the transmission support, of the upper car body, a piston rod of the oil cylinder is connected with the rear transmission support of the upper car body, the coamings can be opened and closed and are arranged on the side edge around the lower car body, the height of each coaming is larger than that of the upper car body, hinge seats are respectively arranged on the peripheral side of the lower car body, hinge buckles are arranged on the lower portions of the coamings respectively, and the hinge buckles and the corresponding hinge seats are rotatably hinged together through pin shafts respectively.

Owner:晋江鹏盛机械有限公司

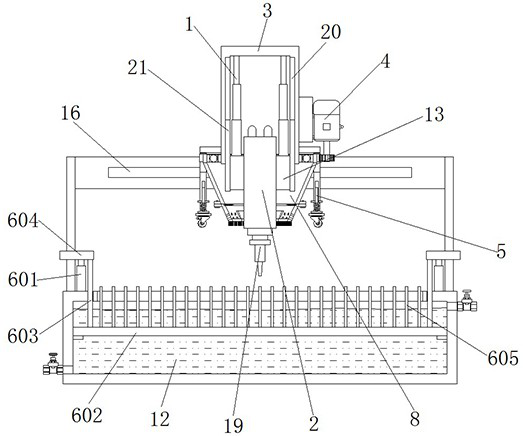

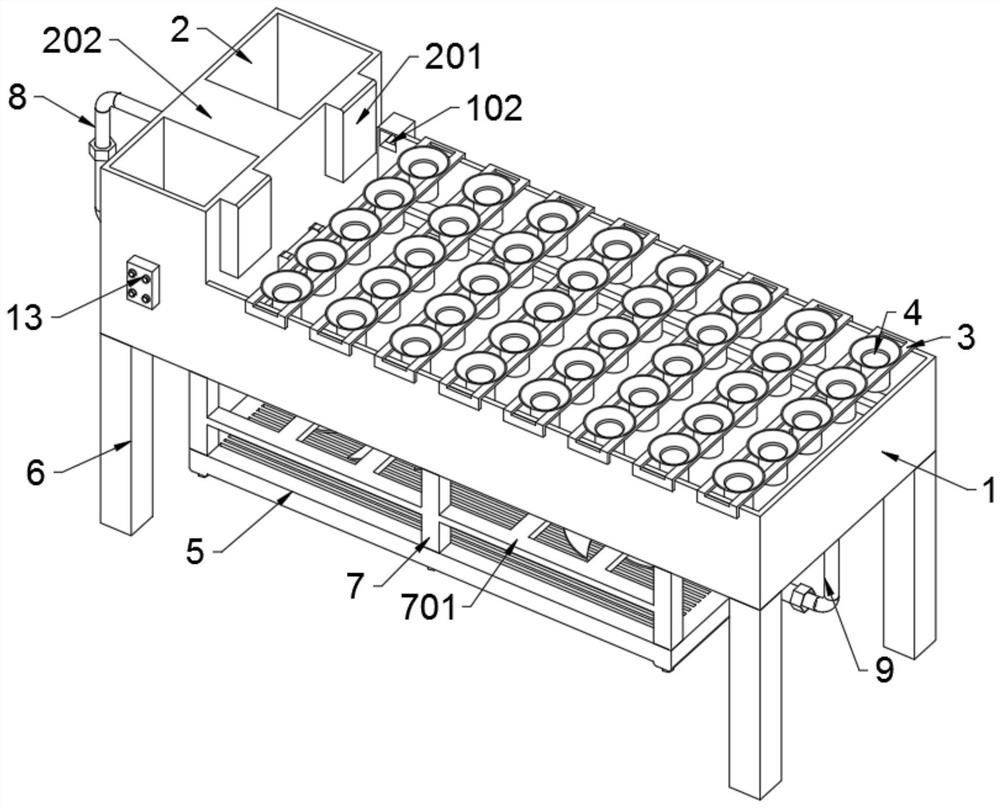

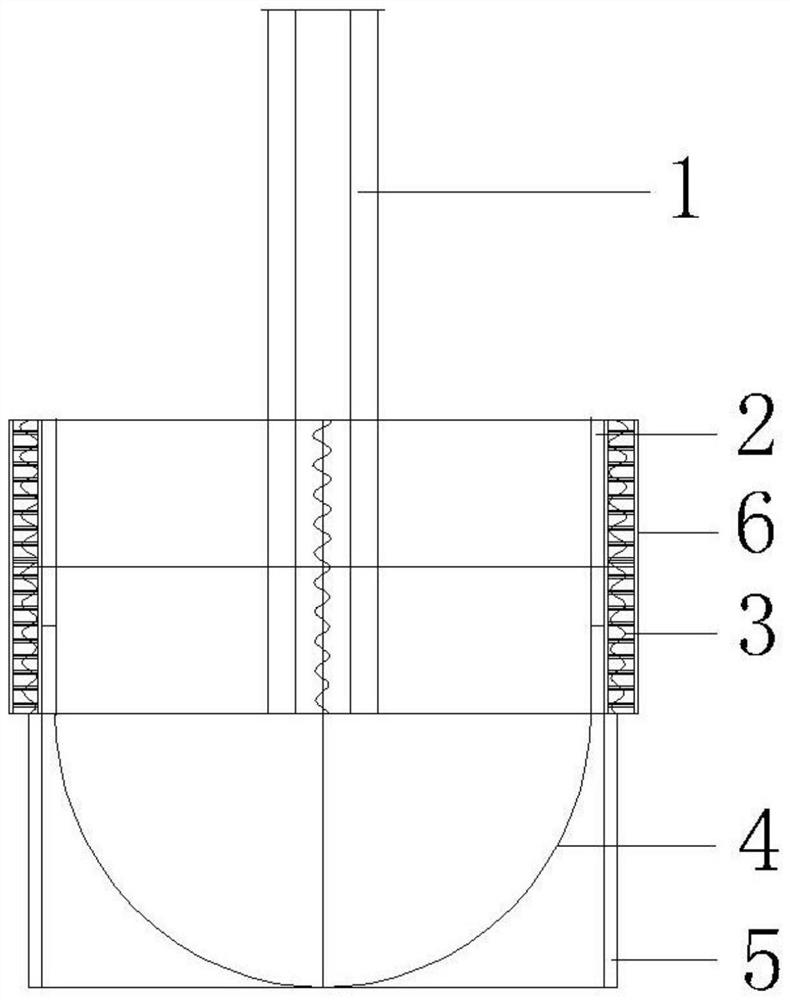

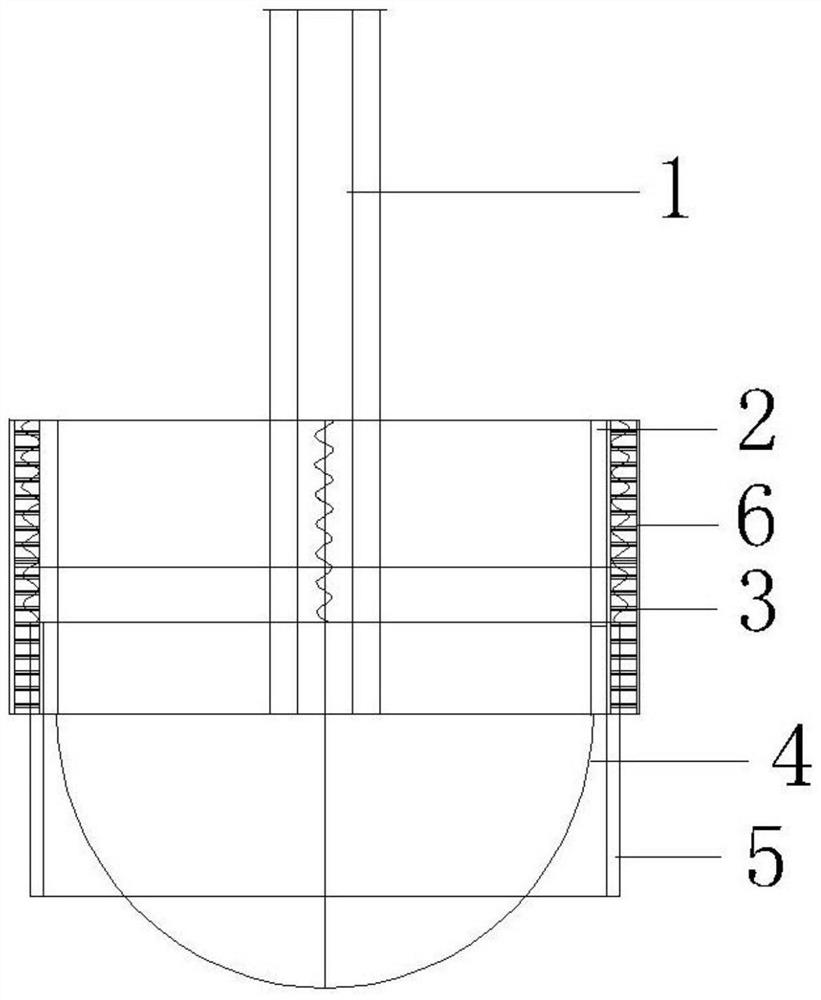

A cooling water device for making wax models

ActiveCN110976759BImprove cooling effectPrevent splashing aroundDomestic cooling apparatusLighting and heating apparatusThermodynamicsWater leakage

The invention provides a cooling water device for making wax molds, which includes an overflow pipe, an ice box, an overflow pipe, a water inlet tank, a fan and a control panel box. The cold water tank body is arranged in a rectangular shape as a whole, and an ice cube is welded on its left end box, and the left and right ends of the bottom of the cold water tank body are symmetrically supported by four supporting legs; the tail section of the water suction pipe is bent to the left, and its through-welding is hung on the right side of the bottom plate of the cold water tank body; There are multiple leaking grooves running through the leaking plate at equal distances; a water pump is locked and fixed in the middle position of the outer wall on the left side of the ice box, and the mold frame of the present invention is set, and the mold frame is the carrier of the wax film cylinder. , it can support and place the wax film cylinder so that it is immersed in the cooling water inside the cold water tank body to implement cooling of the wax liquid inside the wax film cylinder.

Owner:宁海凯汇日用品有限公司

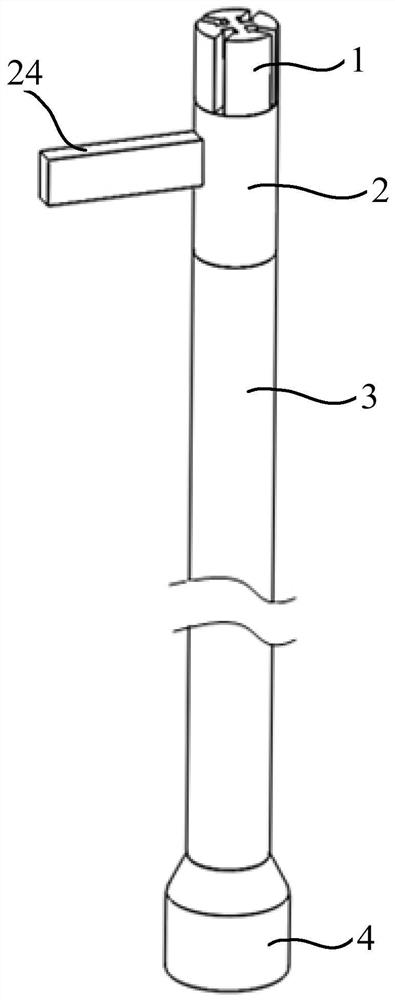

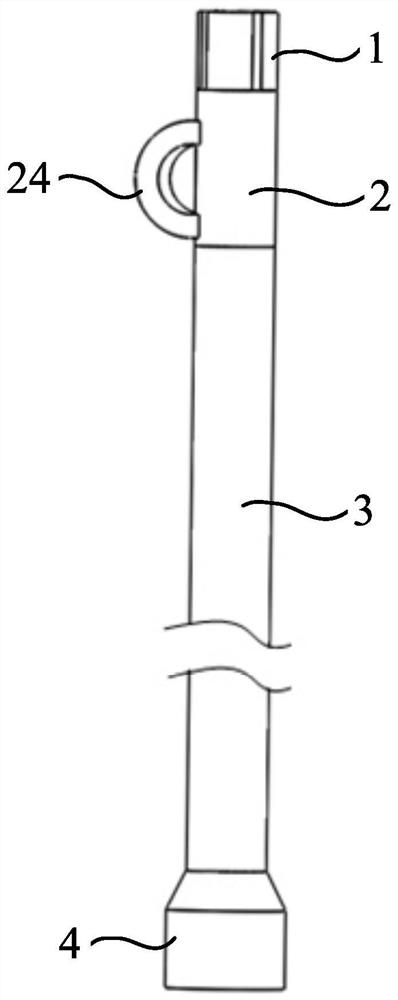

Splash-proof cake beating hammer

InactiveCN112716019APrevent splashing aroundPrevent splashFood shapingMixing/kneading with vertically-mounted toolsStructural engineeringMechanical engineering

Owner:永康市新生王工贸有限公司

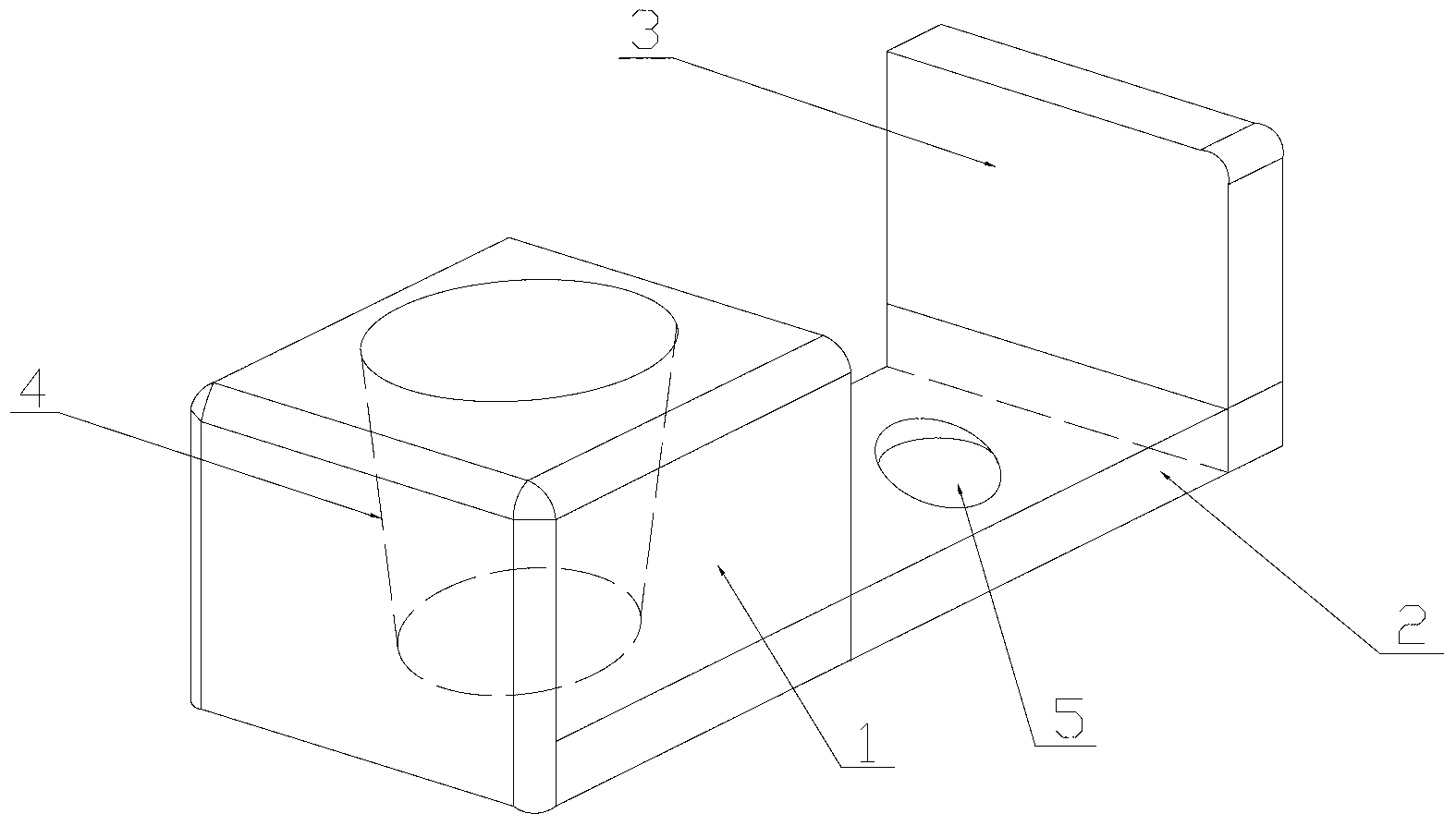

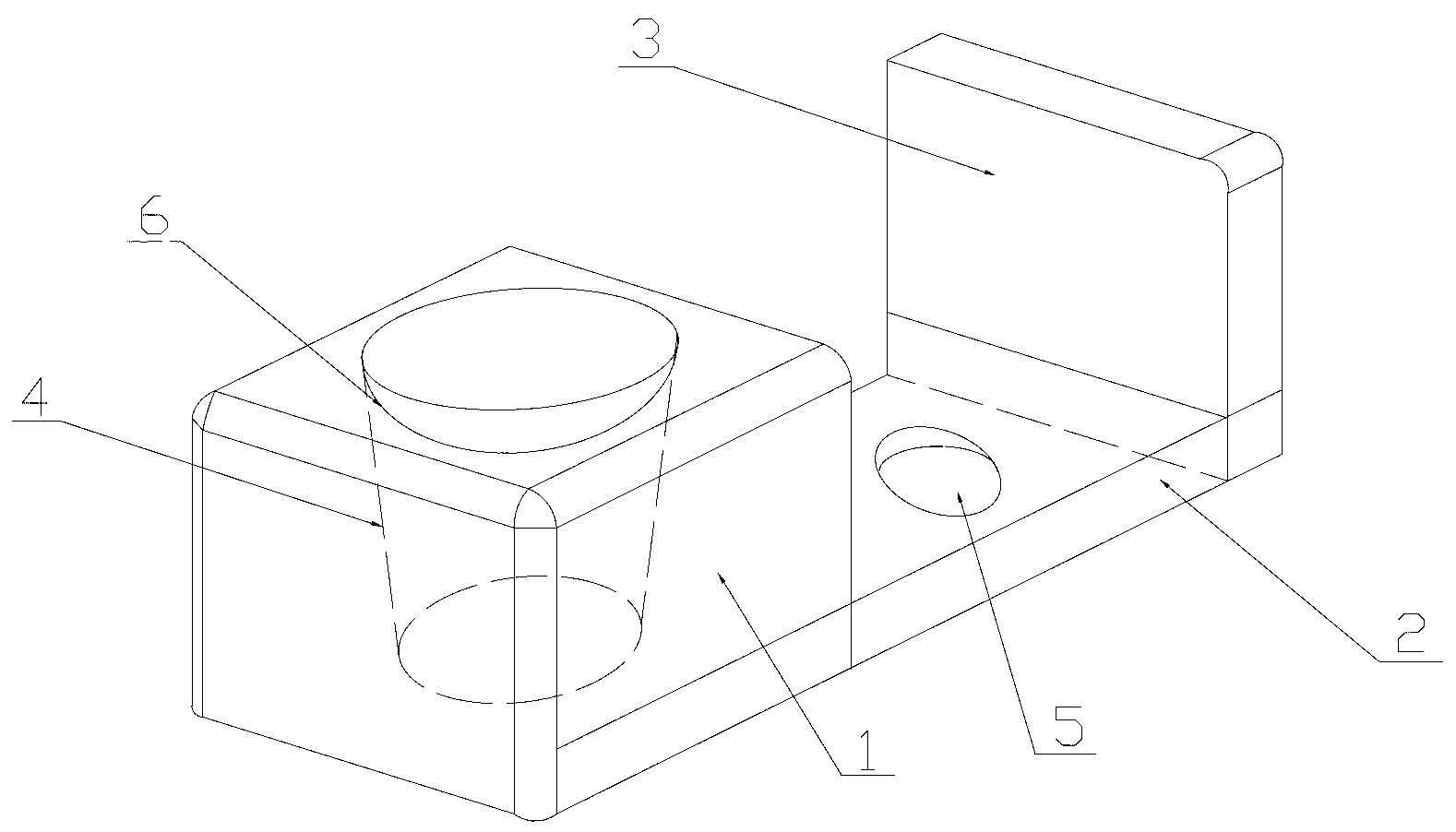

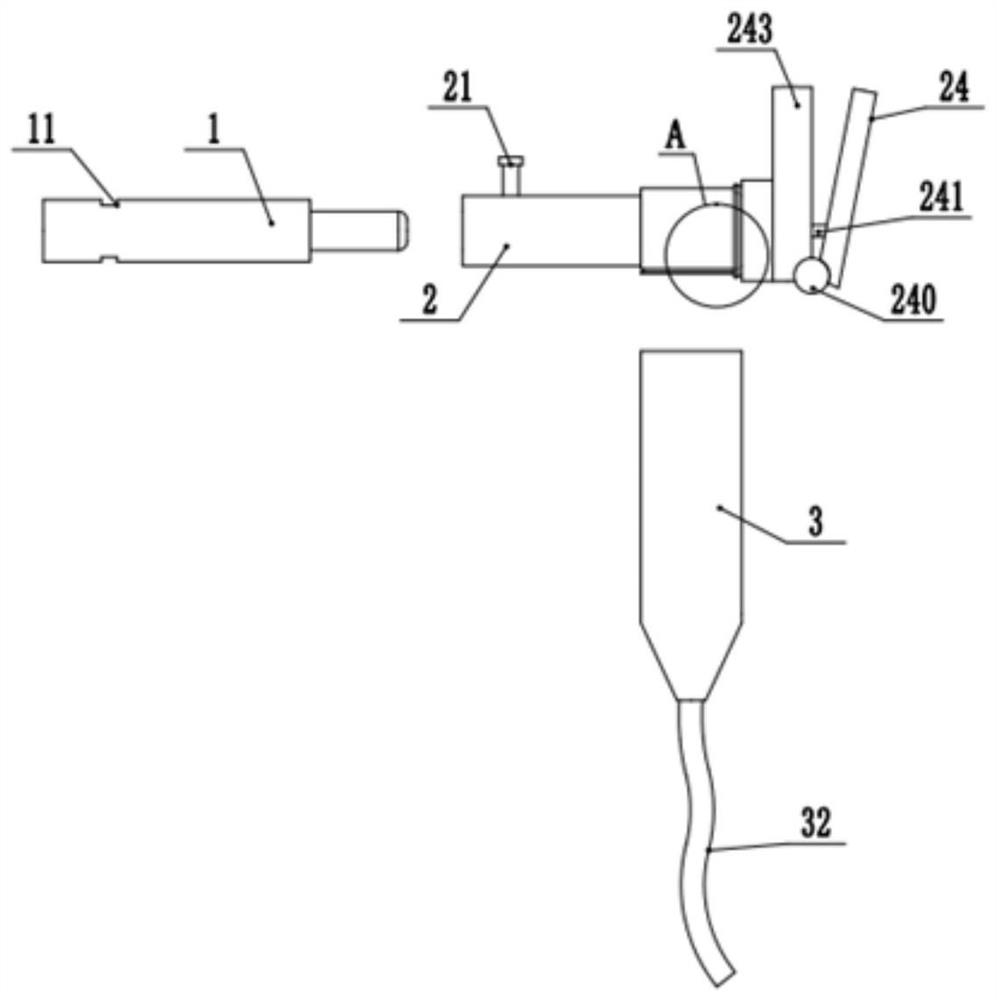

Automotive headlamp cleaner nozzle

The invention relates to an automotive headlamp cleaner nozzle comprising a mounting seat and a clamping plate connected to the mounting seat. A one-way tube is inserted in the mounting seat. The clamping plate is provided with a through hole. The clamping plate is further provided with a retainer plate outside the through hole. Preferably, the mounting seat is provided with a positioning post projecting from the surface of the mounting seat. The tail end of the one-way tube is fixed on the positioning post. The automotive headlamp cleaner nozzle is applicable to different types of automotive headlamps through the clamping plate, and can prevent cleaning fluid from splashing over through the retainer plate.

Owner:SUZHOU BODENA TECH

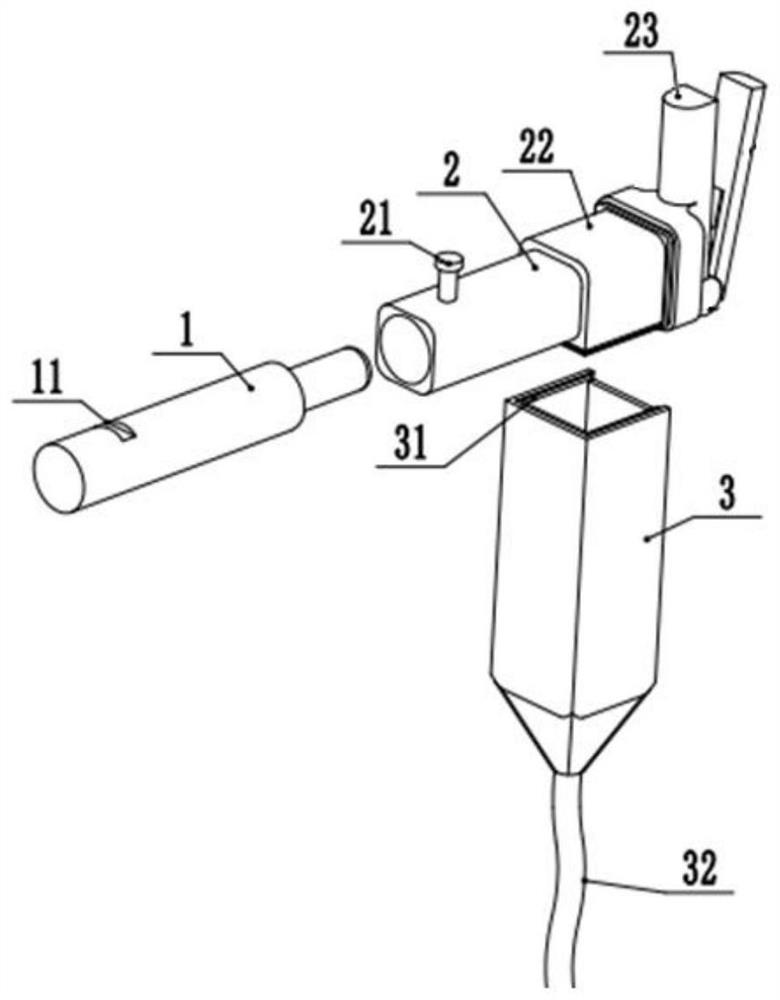

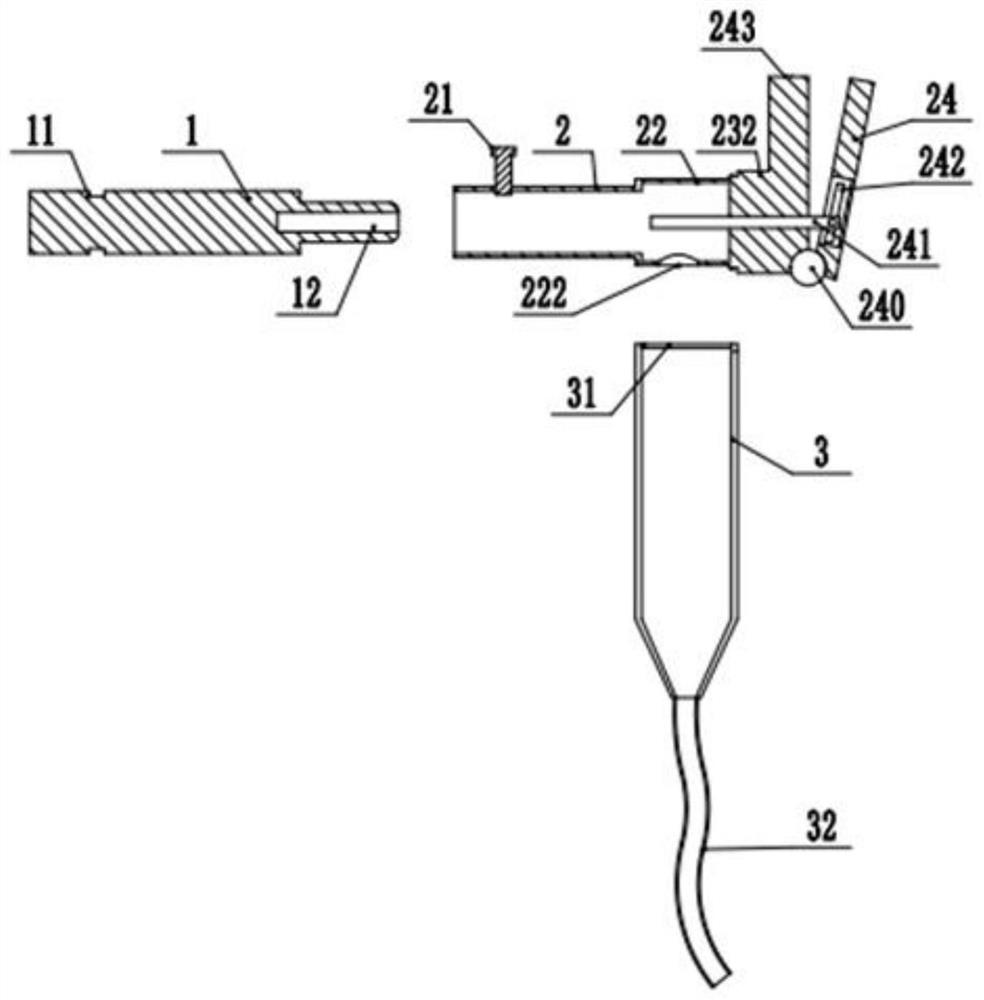

Cleaning device for glue spraying nozzle of cigarette packer

The invention discloses a cleaning device for glue spraying nozzle of a cigarette packer. The device comprises a fixed sleeve (2) and a conical leakage cylinder (3), a glue spray sleeve (22) is arranged at one end of the fixed sleeve (2), a liquid leakage hole (222) is formed in the bottom of the glue spray sleeve (22), the conical leakage cylinder (3) is detachably installed at the bottom of the glue spray sleeve (22), the glue spraying sleeve (22) is communicated with the interior of the conical leakage cylinder (3) through the liquid leakage hole (222), and an extrusion device (23) is fixedly installed on the glue spraying sleeve (22). According to the glue spraying nozzle, residual glue in the glue spraying nozzle can be completely sprayed out, glue liquid is prevented from splashing all around, and the cleaning efficiency is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

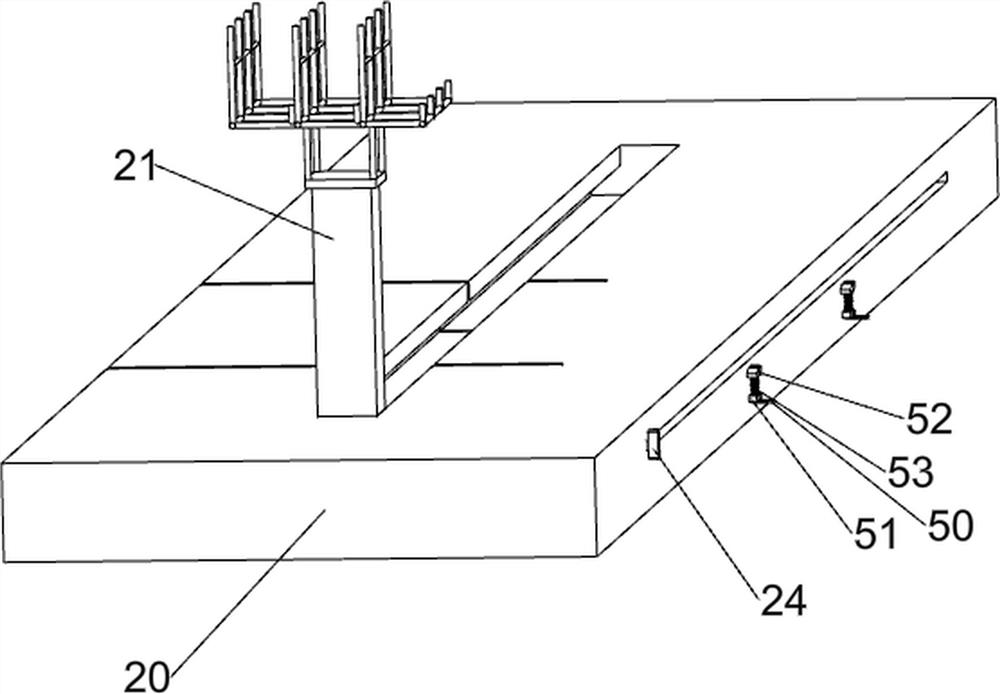

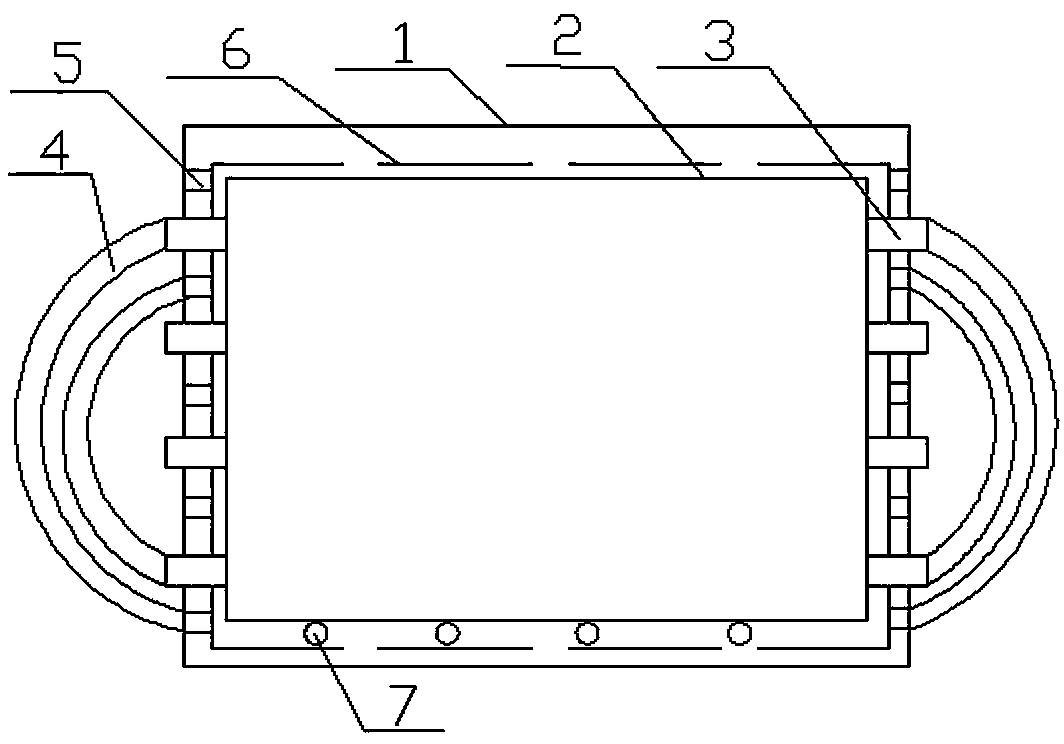

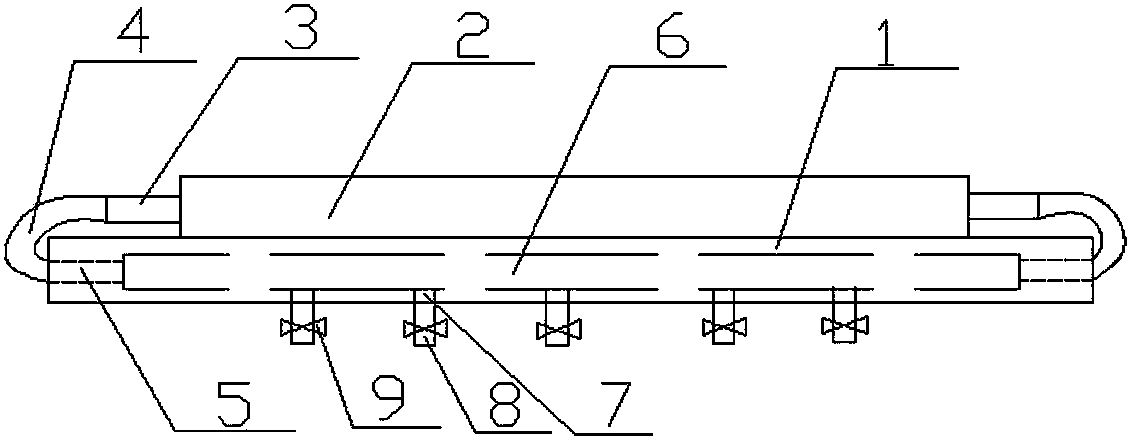

Outlet water collecting device for extrusion die for specially-shaped plastic materials

An outlet water collecting device for an extrusion die for specially-shaped plastic materials comprises a bottom plate and a die plate installed on the bottom plate, wherein a plurality of water outlet nozzles are arranged on the die plate, each water outlet nozzle is connected with a water outlet pipe, a plurality of water inlets are formed in side walls of the bottom plate, the tail end of each water outlet pipe is connected with one water inlet, water in the water outlet pipes flows through the water inlets and then is collected in a water collecting cavity formed in the bottom plate, the water collecting cavity is also communicated with a plurality of shunting holes perpendicular to the water inlets, and the water in the water collecting cavity flows out of the plurality of shunting holes. With the adoption of the outlet water collecting device, the phenomenon that high-pressure water splashes around can be effectively avoided, the production safety can be guaranteed, the device is arranged by the aid of the structure of the die, and the cost is effectively reduced.

Owner:LUOYANG JIANYUAN MOLD MFG

Peritoneal fluid extraction pipeline

PendingCN111759357AExtraction implementationDrainage realizationSurgeryVaccination/ovulation diagnosticsLaparoscopy procedureAscitic fluid

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

Safe electric cutting tool

InactiveCN108161120APrevent splashing aroundPrevent falling off and hurting peopleMetal sawing devicesMaintainance and safety accessoriesEngineering

The invention discloses a safe electric cutting tool, which comprises a working table. A groove is formed in the middle of the working table; slide rails are arranged on the left end and the right endof the working table; a first sliding chute is formed in the middle of each slide rail; a protection cover is clamped to the outer end of the working table; a second fixing block and a first fixing block are arranged on the upper sides of the front end and the rear end of the working table; a first moving rod and a second moving rod are movably connected to the left end and the right end betweenthe first fixing block and the second fixing block, and each comprise a block body and a second sliding chute; and distance-adjustable screw rods are fixedly connected to the right end of the first moving rod and the left end of the second moving rod. According to the safe electric cutting tool, through arranging a structure comprising the pressing blocks, connecting shafts, fixed bolts, the firstmoving rod, the second moving rod and fixed nuts, an effect on tightly pressing a cutting material is achieved, so that the production safety is improved.

Owner:郑州恒联威电气有限公司

A kind of automatic cleaning mechanism for drilling bit and using method

ActiveCN113338812BEasy to fixEasy clampingEarth drilling toolsDrying gas arrangementsReciprocating motionWell drilling

The invention relates to the technical field of drilling tools, and is used to solve the problem that the existing cleaning mechanism cannot fix the drilling bit, the drilling bit needs to be manually turned over during the cleaning process, and the cleaned drilling bit cannot be quickly dried. The problem that the effect needs to be improved is specifically an automatic cleaning mechanism for drilling bits and its use method, including a base, a vertical plate is installed on the top of the base, a horizontal plate is connected with the vertical plate, and a rotating clamping assembly is installed on the vertical plate; the present invention The stability of the cleaning process is ensured by the set of rotating clamping components and reciprocating cleaning components, and the drilling bit can be automatically rotated and the annular brush can be reciprocated laterally, which helps to clean the entire surface of the drilling bit. The surface of the drilling bit is cleaned by combining brushing and spraying, and the overall use effect of the cleaning mechanism is significantly improved by combining the cleaning and drying functions.

Owner:东营辰鑫应用技术开发有限公司

Collection method for waste cutting fluid of steel pipes

InactiveCN104128839APrevent splashing aroundThe operating environment is clean and tidyMaintainance and safety accessoriesSteel tubeScrap

The invention discloses a collection method for waste cutting fluid of steel pipes. A special-shaped collection tank can collect a scrap mixture completely. The inner horizontal plane of the collection tank and the bottom of a pipe groove are kept on the same height so that when the pipe groove rotates, the scrap mixture in the pipes can be smoothly discharged. Through treatment of the transition arc surface and the inclined surface, the scrap mixture will not splash in the collection tank and can flow out of the collection tank fast and stably, cooling fluid and scraps left in the pipes after the steel pipes are cut can be conveniently cleared away, and the cleanliness and tidiness of the operating environment in a cutting workshop can be guaranteed.

Owner:CHENGDU XINGBODA PRECISION MACHINERY

Gear hobbing wheel machining device capable of removing gear burrs

InactiveCN112170953APrevent splashing aroundReduce labor intensityMetal sawing devicesMaintainance and safety accessoriesMachining processWorkbench

The invention discloses a gear hobbing wheel machining device capable of removing gear burrs. The gear hobbing wheel machining device comprises a workbench, wherein a support is fixedly connected to the upper wall of the workbench; a rotatable circular saw is arranged on the support; a fixing clamp is fixedly connected to the upper wall of the workbench; two baffles are fixedly connected to the upper wall of the workbench; the circular saw and the fixing clamp are both located between the two baffles; and a collecting mechanism used for collecting wastes is arranged on the workbench. Accordingto the gear hobbing wheel machining device, workers can conveniently clean the wastes in a unified manner, the situation that the waste splashes around is avoided, the workers do not need to clean the workbench in the later period, the labor intensity of the workers is relieved, the situation that the wastes splash around in the machining process, and consequently the workers are scalded can be avoided, the safety of the workers is guaranteed, and the safety performance of the device is improved.

Owner:盐城恒发精密齿轮有限公司

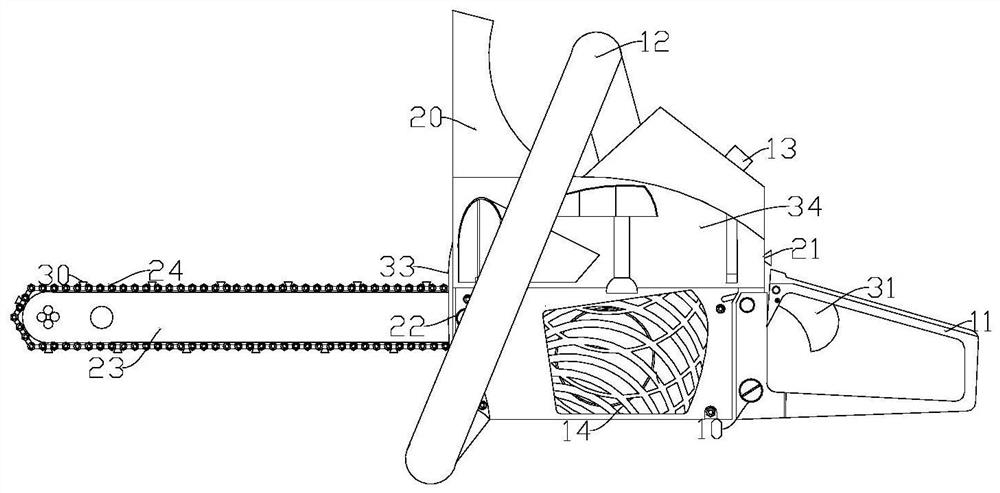

Electric saw chain blade riveting tooling

PendingCN112453569APrevent splashing aroundEasy to cleanMetal sawing devicesMetal sawing accessoriesKnife bladesManufacturing engineering

The invention discloses an electric saw chain blade riveting tooling, and belongs to the technical field of cutting. The electric saw chain blade riveting tool comprises a guide plate, a chain, a blade, a connecting plate and a baffle device; the baffle device is fixedly installed at the bottom of a machine body; the guide plate is movably connected with one side of the machine body through the connecting plate; the chain is movably connected to the upper portion of the guide plate; the blade is fixedly connected to the top of the chain; and the effect of blocking slag in the cutting process of the chain saw is achieved through cutting of the chain and blade and cooperative use of the baffle device.

Owner:WUHU JINGFENG GARDEN MACHINERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com