Electrostatic chip collecting type tapping device

A tapping device and chip collection technology, which is applied in the direction of thread cutting device, maintenance and safety accessories, thread cutting machine, etc., can solve the problems of iron filings splashing and low tapping efficiency, so as to improve tapping quality, improve tapping efficiency, Avoid shaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

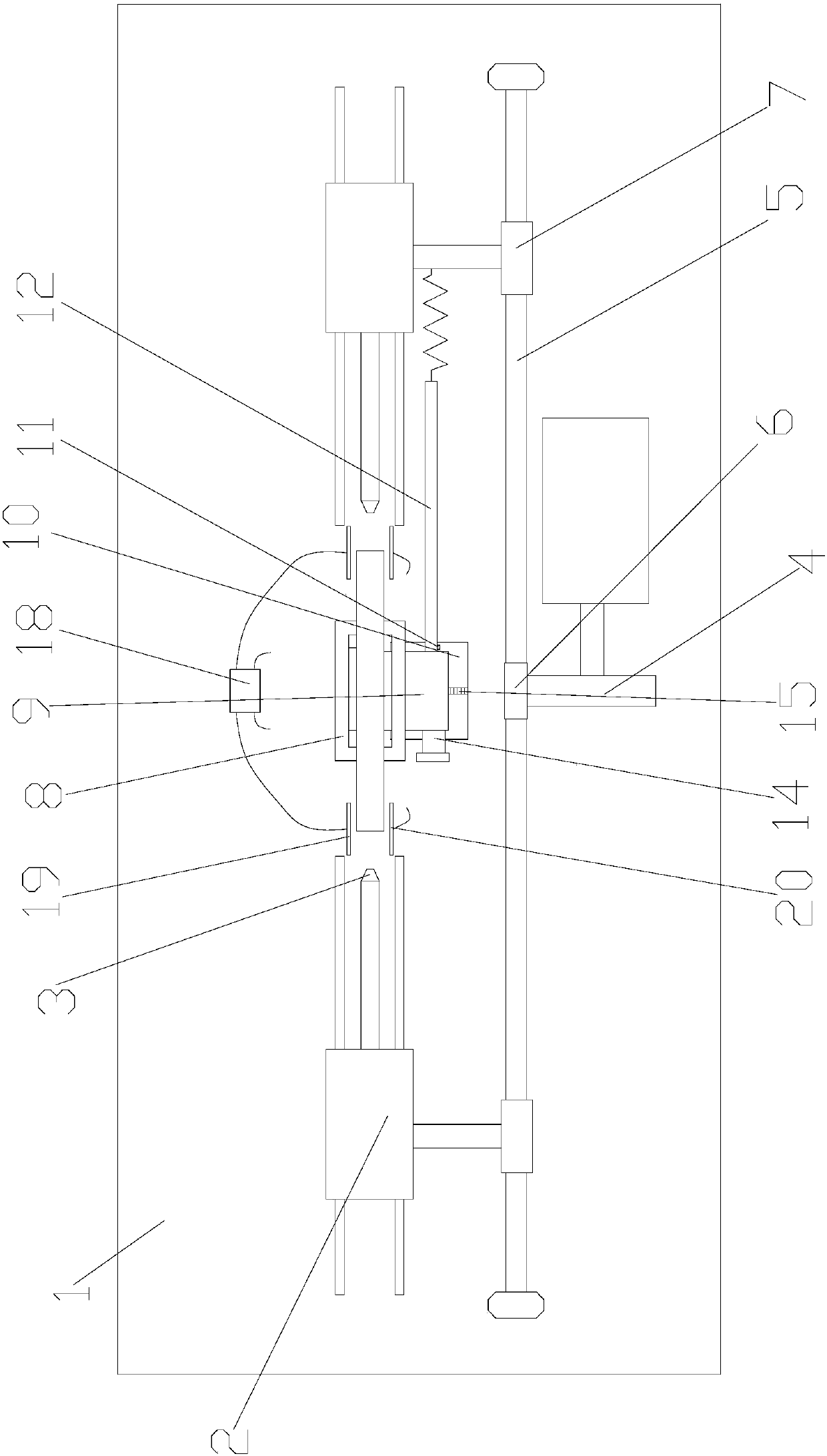

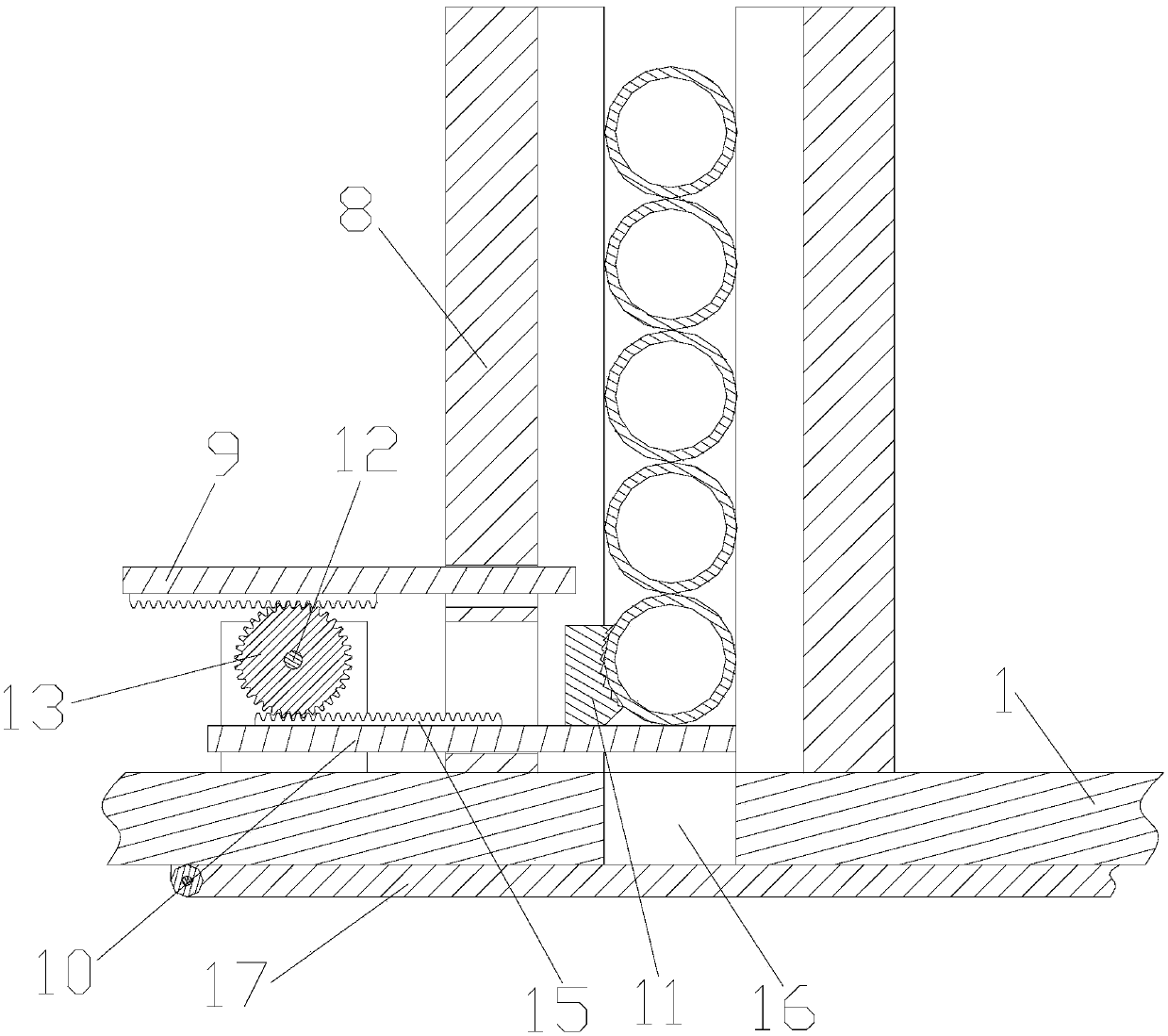

[0019] refer to figure 1 and figure 2 Shown: an electrostatic chip-collecting tapping device, including a workbench 1, on which a bidirectional tapping mechanism, a feeding mechanism, and an electrostatic collection mechanism are installed; Two symmetrically set tapping machines 2 are away from the movement, and the tapping machines 2 are all slidably arranged on the guide rail installed on the workbench 1. The tapping machine 2 includes a tapping rod, and the ends of the two tapping rods are close to each other. Both are provided with an elastic trigger switch 3; the driving member includes a worm gear 4 driven by a power mechanism and a screw 5 that is rotated and arranged on the workbench 1. The power mechanism can be a two-way rotating motor, and the elastic trigger switch 3 is electrically connected with the power mechanism. The center of 4 is connected with the output end of the power mechanism, and the worm comprises a worm segment 6 located in the middle and a left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com