Collection method for waste cutting fluid of steel pipes

A waste liquid collection and steel pipe technology, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. The effect of splashing around and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

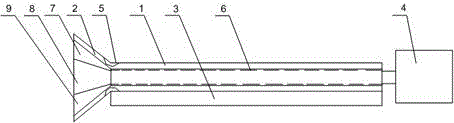

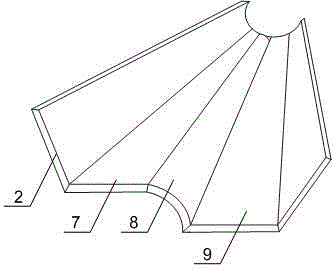

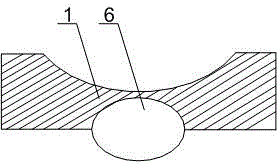

[0022] Such as Figure 1 to Figure 3 As shown, the steel pipe cutting waste liquid collection method of the present invention includes the following steps. After the steel pipe is cut, it is pushed out from the cutting space to the pipe groove 1. The rotation of the motor 4 drives the pipe groove 1 to rotate on the support shaft 6. The steel pipe follows the pipe groove 1. Rotate together, and finally stacked on the transport equipment near the cutting machine; during the process of pushing back and rotating the pipe groove 1, the residual coolant and debris in the steel pipe will flow out automatically, and the outflowing debris mixture passes through the collection groove 2 The upper horizontal surface 7 slowly flows into the inclined surface 9 under the buffer of the transitional arc surface 8, and finally the debris mixture flows from the inclined surface 9 into the waste pool below the cutting machine, which is intensively processed by the operator; when the steel pipe fal...

Embodiment 2

[0025] Such as figure 1 and figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a baffle plate 3 is obliquely arranged on one side of the pipe groove 1, and the angle between the baffle plate 3 and the pipe groove 1 is 115°~135° °; also includes a protective pad 5, the protective pad 5 is installed at the junction of the pipe groove 1 and the collection tank 2. When the pipe groove 1 rotates, the steel pipe in the groove falls directly, which is easy to collide with the ground and cause the surface of the steel pipe to be sunken; The angle between them is 115°~135°, which can buffer the falling steel pipe due to rotation, reduce the kinetic energy of the steel pipe before falling, and avoid damage to the steel pipe; after the steel pipe is cut, it is pushed into the pipe groove 1, and the pipe groove 1 The connection between the collection tank 2 and the outer surface of the steel pipe is likely to rub against the outer surface of the steel pipe, thereby ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com