A kind of automatic cleaning mechanism for drilling bit and using method

A drilling bit, automatic cleaning technology, applied in the direction of drilling equipment, drilling tools, dryers, etc., can solve the problems of bit corrosion, drilling bit fixation, inability to quickly dry the drilling bit, etc., to achieve convenient clamping and removal, lifting Good stability and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

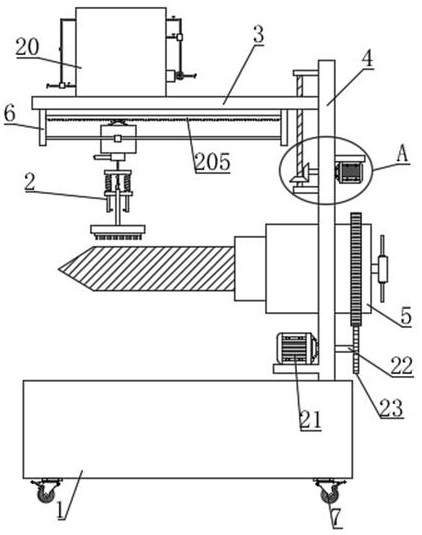

[0053] Such as Figure 1-8 As shown, the automatic cleaning mechanism for a drilling bit proposed by the present invention includes a base 1, a horizontal plate 3, a vertical plate 4 and a walking wheel 7, the top of the base 1 is fixed with a vertical plate 4 by bolts, and the bottom of the base 1 is installed There are multiple sets of walking wheels 7, through which the handling and movement of the equipment is convenient. The horizontal plate 3 is horizontally arranged above the base 1 and connected with the vertical plate 4. The vertical plate 4 is equipped with a rotating clamping assembly 5, and the rotating clamp The tightening assembly 5 is used to clamp the drilling bit, which helps to improve the stability of the drilling bit cleaning process, and the reciprocating cleaning assembly 2 is installed under the horizontal plate 3;

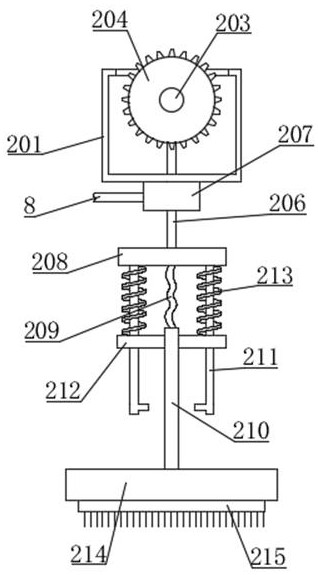

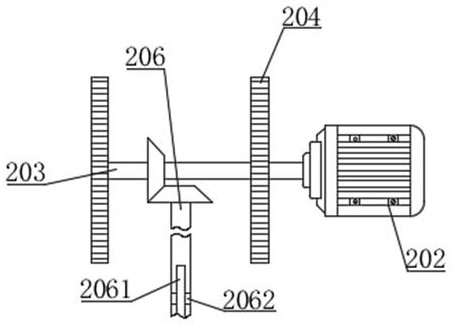

[0054] The reciprocating cleaning assembly 2 includes a movable box 201, a first motor 202, a first output shaft 203, a first gear 204, a r...

Embodiment 2

[0059] Such as figure 1 and Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the top of the horizontal plate 3 is fixed with a fixed box 20 by bolts, and the fixed box 20 is provided with a water storage chamber 11 and a heating chamber 12, and the heating chamber 12 is located in the water storage chamber. Above the chamber 11, cleaning water is stored in the water storage chamber 11, and a water inlet pipe is installed on the water storage chamber 11. The water inlet pipe is used to add cleaning water to the water storage chamber 11, and the heating chamber 12 is used to heat the input air. The top of the heating chamber 12 is fixed with multiple sets of first partitions 18 by bolts, and there is a gap between the first partitions 18 and the bottom of the heating chamber 12, and the bottom of the heating chamber 12 is fixed with multiple sets of second partitions by bolts. plate 19, and the second partition 19 is provided with a gap with t...

Embodiment 3

[0063] Such as figure 1 and Figure 10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the horizontal plate 3 is slidably connected with the vertical plate 4 through slide rails, the horizontal plate 3 can slide vertically along the vertical plate 4, and the vertical plate 4 Upper and lower two groups of second mounts 29 are installed, the horizontal plate 3 is located between the two groups of second mounts 29, and the second screw rod 30 is installed in rotation between the two groups of second mounts 29, and the second screw rod 30 is vertical. Vertically arranged and screwed with the horizontal plate 3, the vertical plate 4 is fixedly installed with the third motor 27 through the motor base, the output end of the third motor 27 is equipped with the third output shaft 28, the third motor 27 is used to drive the third output shaft 28, and the other end of the third output shaft 28 is connected to the second screw rod 30 through a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com