Device for preventing cooling water of CNC (computer numerical control) grinding head from splashing outside

A technology of cooling water and cooling water pipes, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., which can solve the problems of polluting the floor of the production workshop and waste of resources, so as to prevent splashing around and avoid Pollution, easy installation and replacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

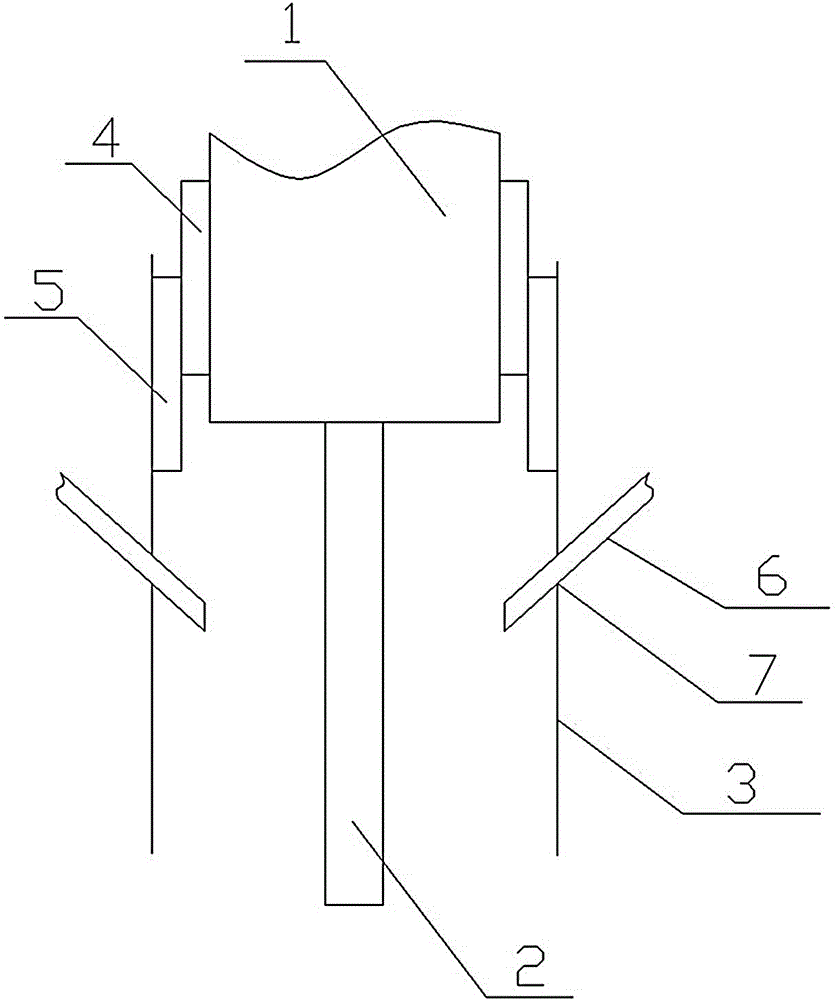

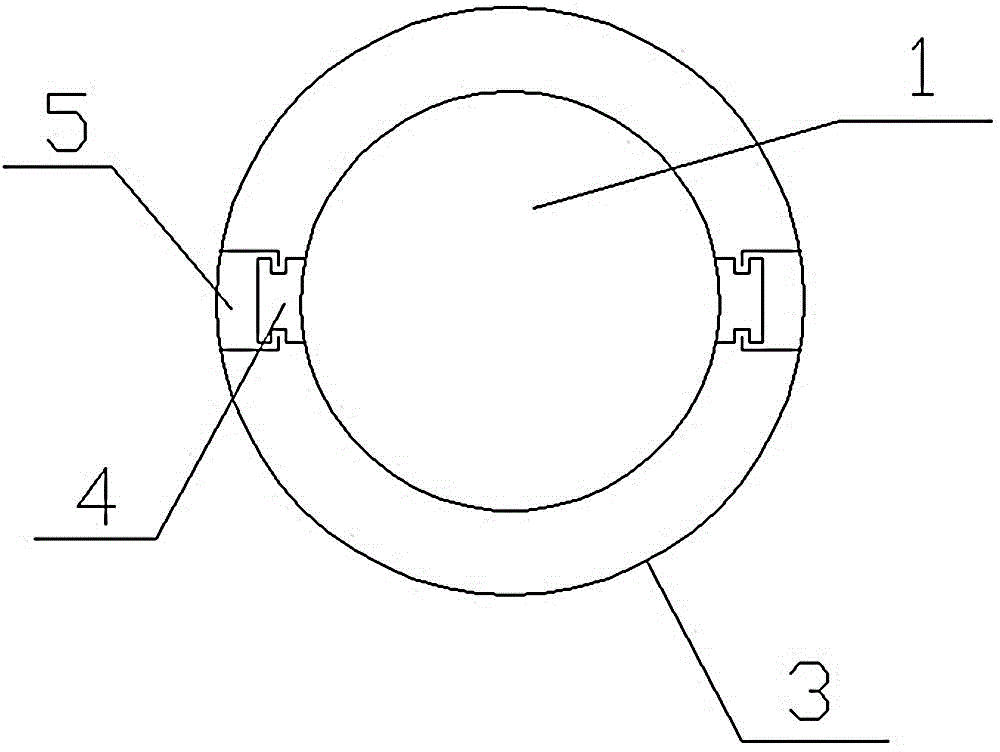

[0010] combine figure 1 and figure 2 As shown, the present invention provides a device for preventing the cooling water of the CNC grinding head from splashing. The CNC grinding head 2 is vertically arranged at the bottom of the CNC spindle 1. The device for preventing the cooling water of the CNC grinding head from splashing includes a cylindrical The protective cover 3, the inner diameter of the protective cover 3 is larger than the outer diameter of the CNC spindle 1, the inner wall of the protective cover 3 is provided with a vertical chute 5, and the outer wall of the CNC spindle 1 is provided with a slider 4 that forms a sliding fit with the chute 5 , so that the protective cover 3 can move vertically up and down along the outer wall of the CNC spindle 1; by reversing the positions of the chute and the slider, the protective cover 3 can also move vertically up and down along the outer wall of the CNC spindle 1, that is, on the CNC spindle 1. The outer wall is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com