Automatic water jet cutting machine for automobile sheet metal

A water jet and cutting machine technology, which is applied in abrasive jet machine tools, metal processing equipment, chemical instruments and methods, etc., can solve the problems of limited protection effect, normal cutting operation when the nozzle is blocked, affecting the cutting effect of water jet cutting machine, etc. To achieve the effect of avoiding splashing around and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

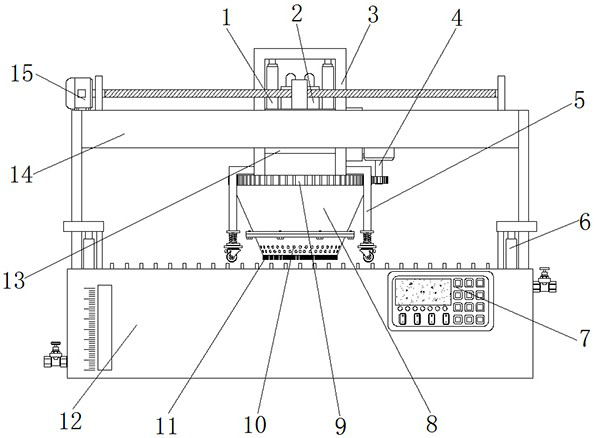

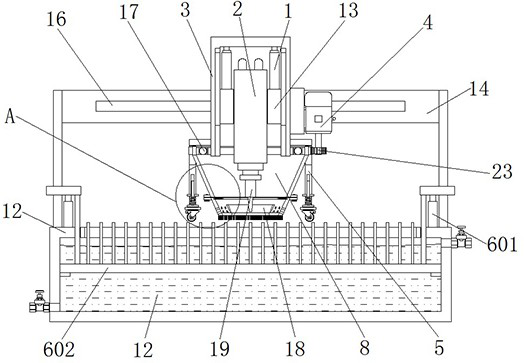

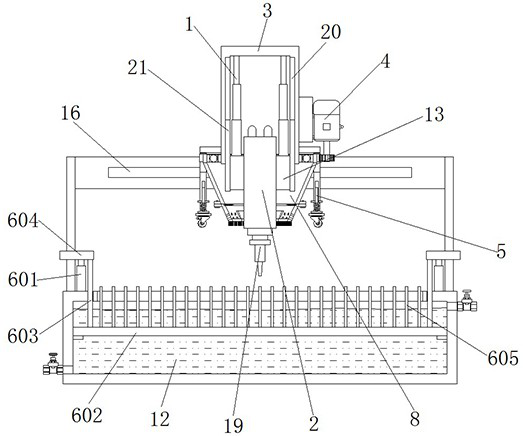

[0042] Example 1, as Figure 1-3 , Figure 5-6 and Figure 8 As shown in the figure, after the water jet cutting machine has been used for a period of time, it is regularly cleaned and maintained to control the extension of the electric telescopic rod 1 to drive the U-shaped plate 3 to rise. During the process, the U-shaped plate 3 and the funnel bin 8 also rise together, and The positions of the cutting device 2 and the nozzle 19 remain unchanged, so that the nozzle 19 is completely exposed. At this time, the maintenance personnel can inspect and maintain the nozzle 19, and can unscrew the screw at the bottom of the outer side of the funnel chamber 8. The lower bin is disassembled. At this time, the annular filter screen 22 located at the top of the lower bin is also directly exposed. The cleaning and maintenance personnel can clean the annular filter screen 22, and can also clean the annular groove 18 and the inner side of the lower bin to ensure that Subsequent to the nor...

Embodiment 2

[0043] Example 2, as Figure 1-3 and Figure 7-8 As shown in the figure, after the automobile sheet metal is placed on the multiple sets of support plates 605, the electric telescopic rod 1 is controlled to shorten, which drives the U-shaped plate 3 to descend, and the two sets of L-shaped plates 501 also descend together until all the multiple sets of universal wheels 505 are Abutting on the surface of the sheet metal of the automobile, in the process, the movable rod 503 penetrates into the interior of the movable groove 502, the spring 504 is shortened by force and stores elastic potential energy, and then the electric cylinder 601 is controlled to extend, driving the mounting plate 602, the connecting plate 604 and the support The plate 605 rises together, so that the automobile sheet metal can be more tightly contacted with the universal wheel 505, and at the same time, the contact degree of the brush 11 and the automobile sheet metal surface can be adjusted, which not on...

Embodiment 3

[0044] Example 3, as Figure 1-3 As shown in the present invention, in the process of cutting the automobile sheet metal, the cutting water sprayed from the nozzle 19 falls into the interior of the collection bin 12 after cutting the automobile sheet metal, so that the water level inside the collecting bin 12 is increased, and the first opening is kept open. valve, so that the excess cutting water inside the collection bin 12 is discharged into the dedicated collection tank, and when there are many sand particles deposited at the bottom of the collection bin 12, the second valve is controlled to open, and the corresponding sand pump is used to remove the inside of the collection bin 12. All the sand at the bottom is swept away.

[0045] Working principle: power on the device before use, before cutting the car sheet metal, place the car sheet metal on multiple sets of support plates 605, control the electric telescopic rod 1 to shorten, drive the U-shaped plate 3 down, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com