Automatic filling chopping machine

A stuffing machine and automatic technology, which is applied in slaughtering, grain processing, food science, etc., can solve the problems of single stuffing operation object, loss of nutrients, loss of umami taste, etc., to achieve excellent quality, save time, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

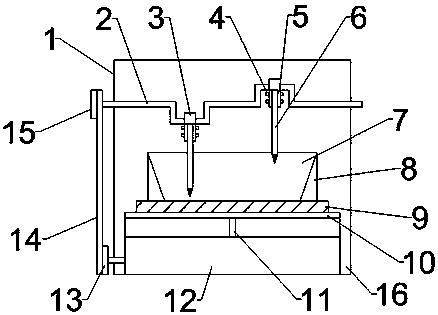

[0020] First load the stuffing on the chopping board 9, and install the surrounding board 7 and the splash-proof slope 8, and then place it on the rotating disk 10, then turn on the power and turn on the motor, adjust the bevel gear reducer, and control the power unit 12 Adjust the chopping speed of the cutter 6 and the rotating speed of the rotating disk 10 to chop the filling evenly. Under the action of the rotation of the rotating disk 10 and the short-term blocking of the alternately moving cutter 6, passive stirring and turning are realized, and During the chopping operation, it naturally moves to the periphery of the chopping board 9, and is stirred and turned under the blocking action of the shroud 7 and the splash-proof slope 8 arranged outside the chopping board 9, which can also effectively block the splashing fillings and prevent the stuffing The material is splashed around, and the left and right chopping knives are alternately used for continuous reciprocating chop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com