Welding seam detection device based on low-pressure leak hunting

A welding seam detection, low pressure technology, applied in the measurement device, by detecting the appearance of fluid at the leak point, fluid tightness testing and other directions, it can solve the problems of complex positioning mechanism, equipment accident, safety accident, etc., to improve the detection efficiency , Quick and easy detection, high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

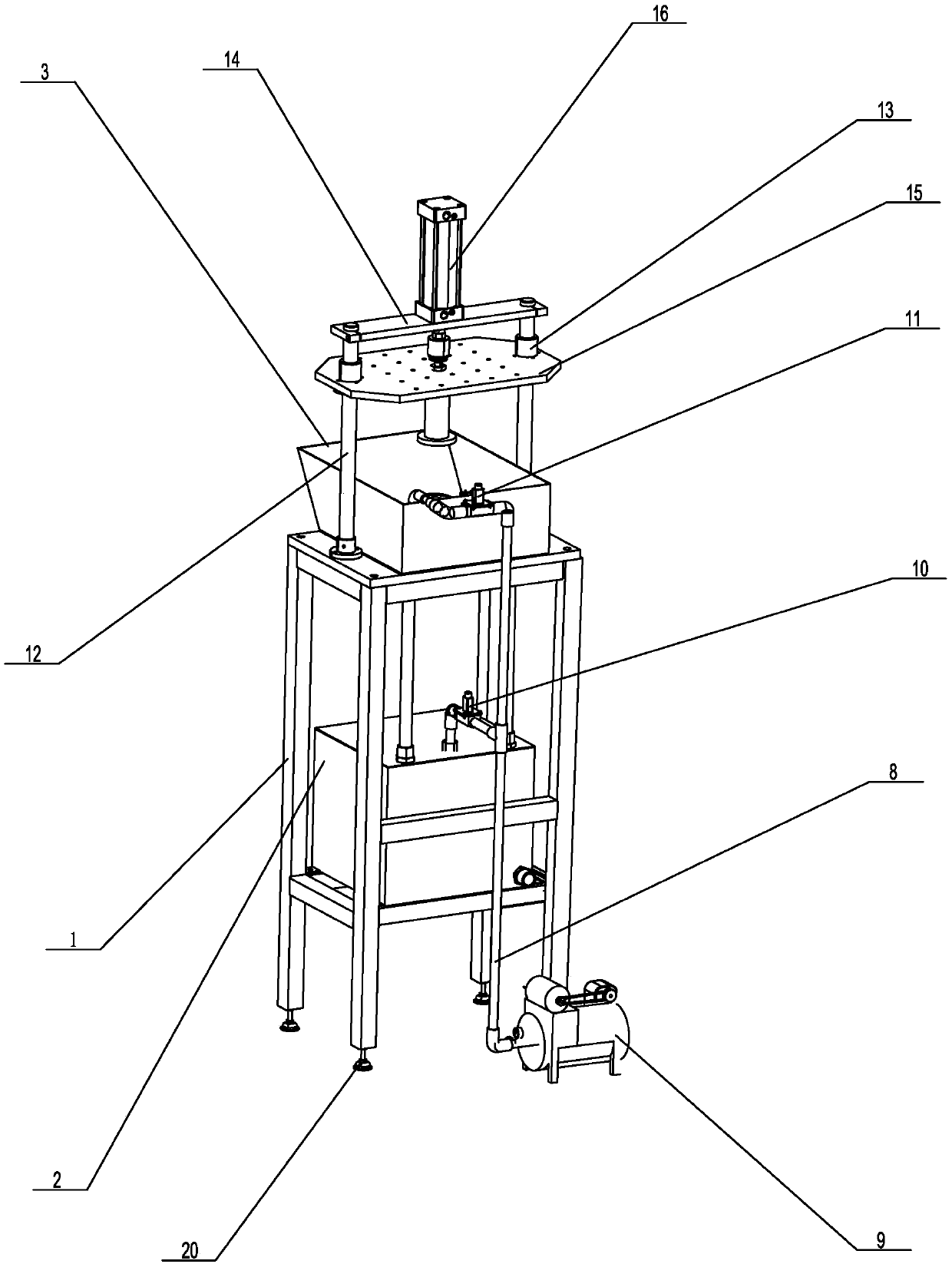

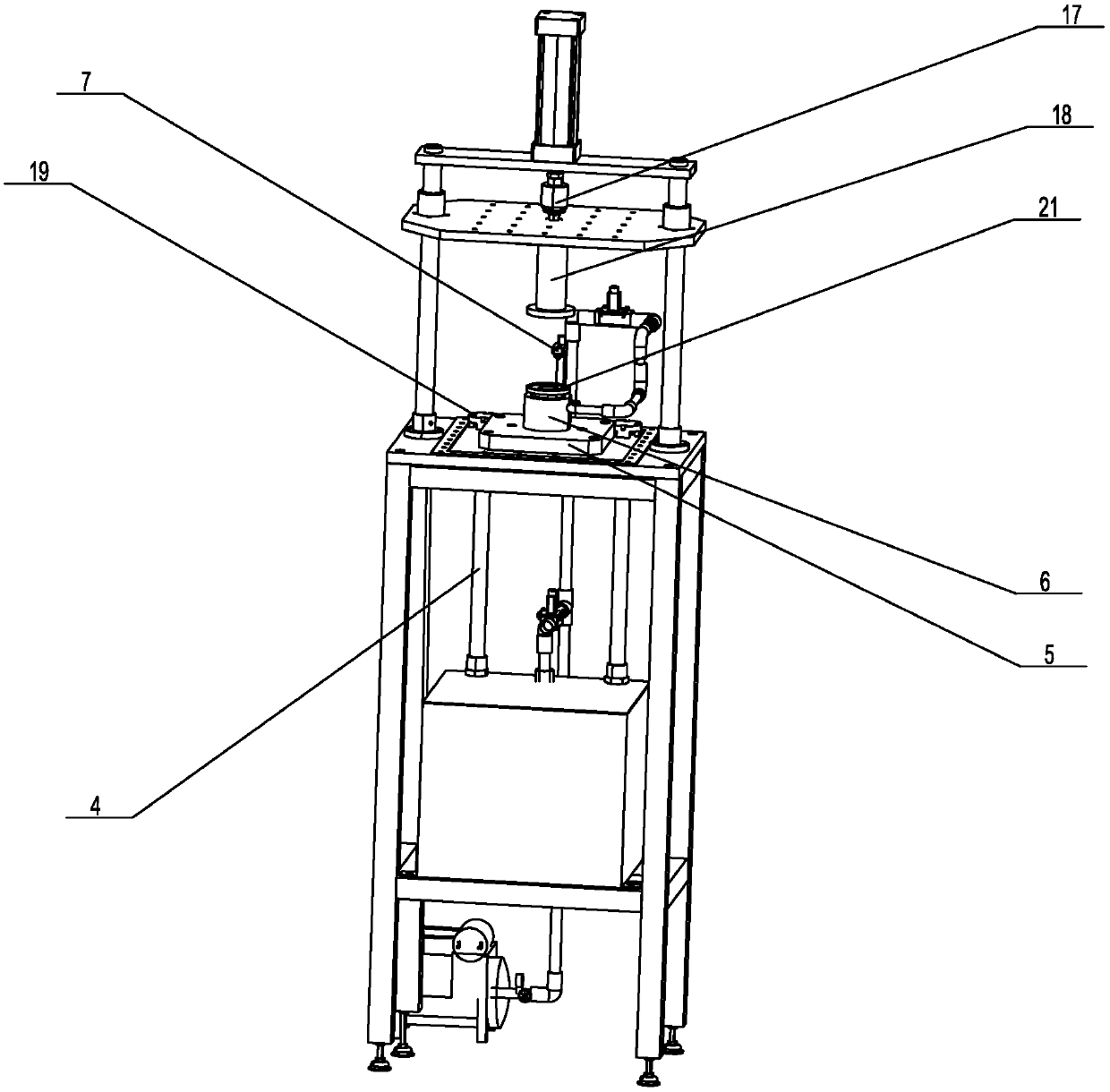

[0017] Such as figure 1 As shown, a specific embodiment of the present invention is proposed. The weld detection device based on low-pressure leak detection includes a detection bracket 1. The detection bracket 1 is set in this embodiment to include two horizontal water tank support plates and four pillars. The detection bracket 1 is from A closed water storage tank 2 and an open detection water tank 3 are arranged successively from bottom to top, and a connecting water pipe 4 is arranged between the described water storage tank 2 and the detection water tank 3. In this implementation, two connecting water pipes 4 are arranged, and two connecting water pipes 4 are realized. The water exchange between the water tanks, the detection water tank 3 is provided with a support 5, the support 5 is provided with a workpiece support 6, and the workpiece 21 that needs to detect the quality of the weld is installed on the workpiece support 6, A liquid level sensor 7 is also provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com