Centrifugal cleaning device for perilla leaves

A technology of centrifugal cleaning and blades, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of general cleaning effect, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of preventing splashing everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

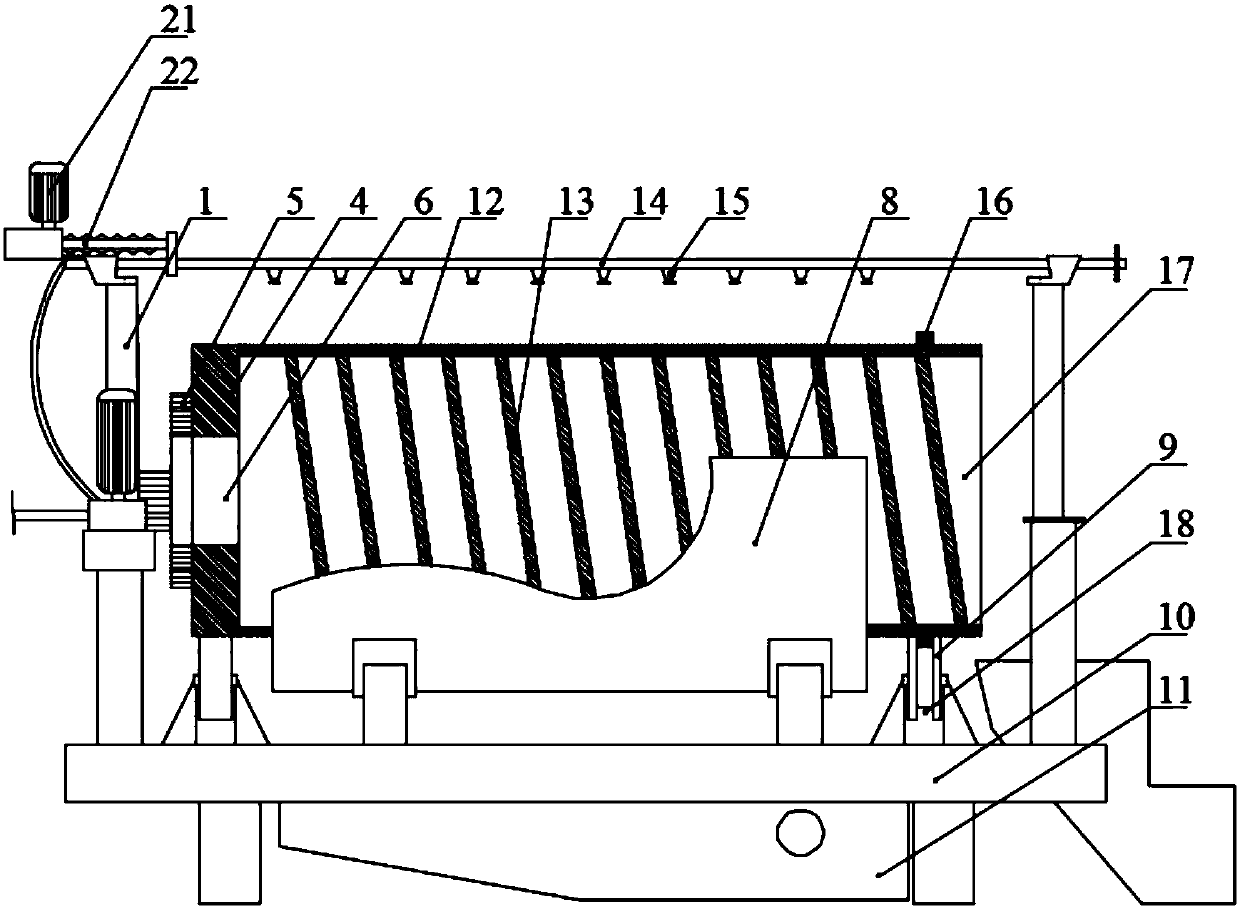

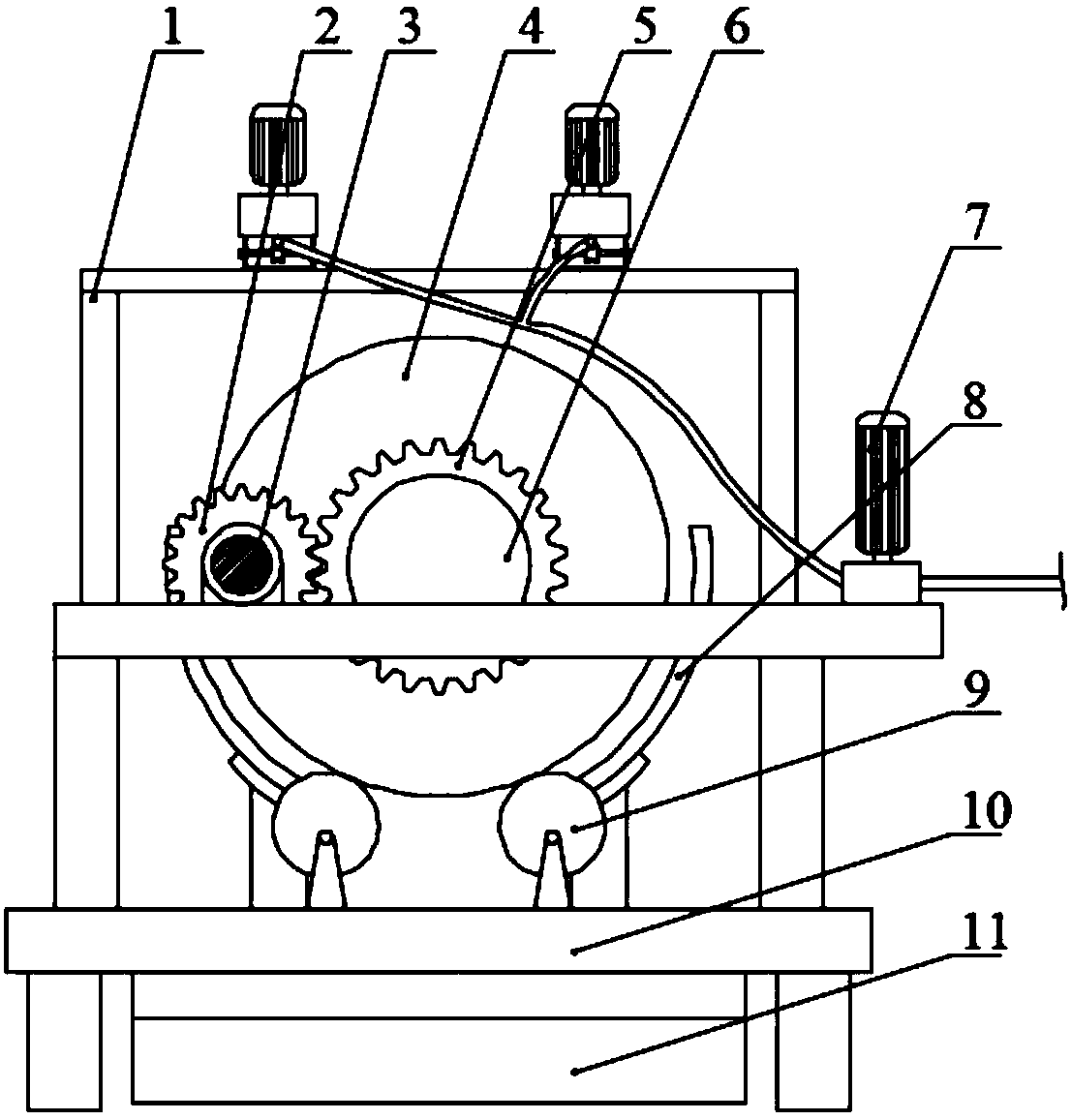

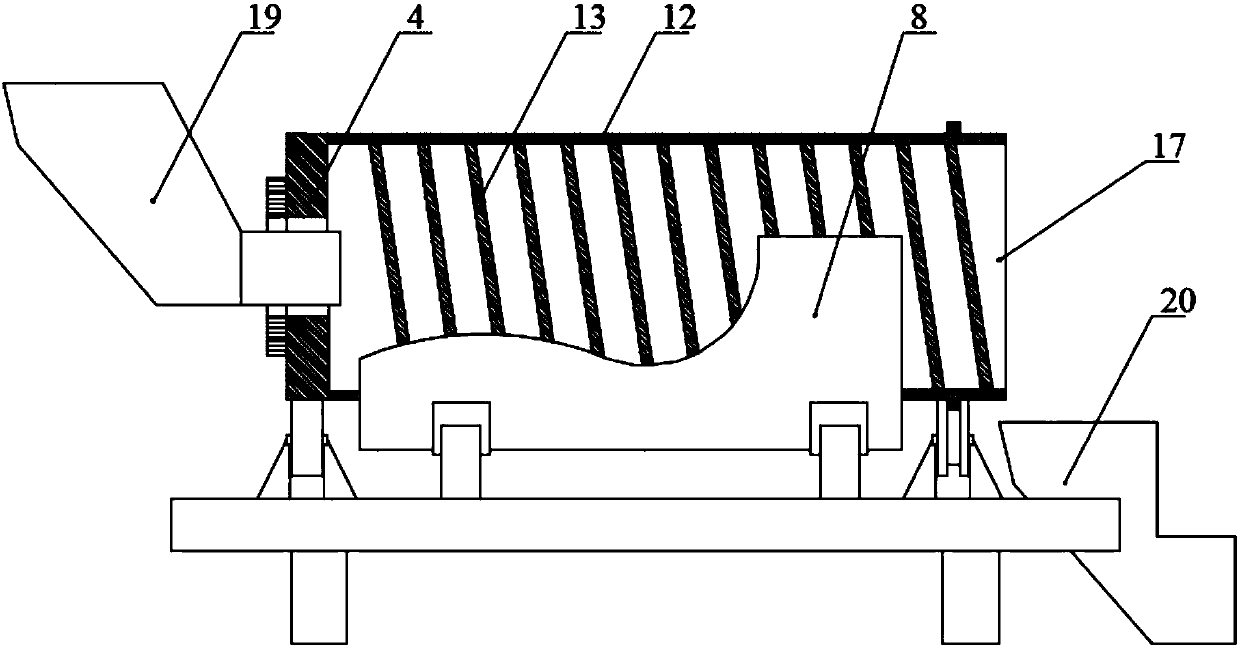

[0033] During the cleaning operation, the perilla leaves are fed into the filter drum from the feed hopper through the feed port of the turntable. At this time, the filter drum is rotated by the power unit, and the perilla leaves in the filter drum are rotated by the filter drum The generated centrifugal force tightly adheres to the inner surface of the filter drum. When the filter drum with perilla leaves rotates to the highest position, the high-pressure nozzle on the spray pipe sprays high-pressure water. The supporting pulley is slidingly supported, and the output end of the cam motor is driven by the cam motor, and then the output end of the cam motor and the fixed block of the spray wheel lever are linked to make the spray rod slide back and forth on the support pulley, and then the high-pressure nozzle is placed on the filter screen. The upper part of the drum slides and sprays, and the perilla leaves are sprayed away from the top inner wall of the filter drum, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com