A hydrogen-absorbing low-strain metal hydride hydrogen storage tank

A hydride, low-strain technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, container filling methods, etc., can solve problems such as safety accidents, container deformation, rupture, etc., to ensure safety and simple structure , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a hydrogen-absorbing low-strain metal hydride hydrogen storage tank, the following is combined with the accompanying drawings and a hydrogen storage capacity of 10m 3 , Nominal working pressure 4MPa, the outer diameter of the tank is 133mm and the wall thickness is 4mm metal hydride hydrogen storage tank with low hydrogen absorption strain as an example to further describe the present invention in detail. The following descriptions are only preferred specific embodiments of the present invention, but the protection scope of the present invention is not limited thereto.

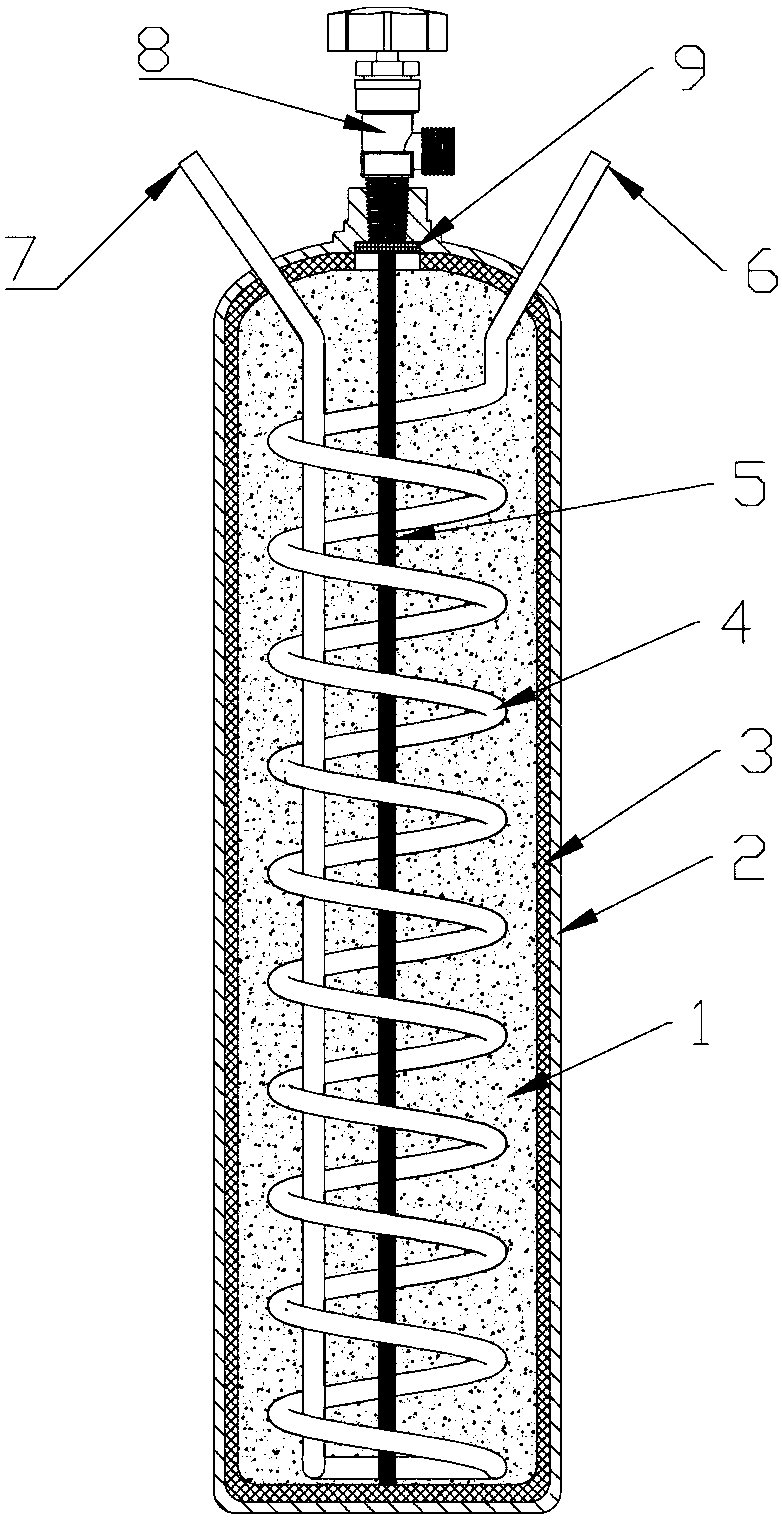

[0021] figure 1 It is a cross-sectional view of a hydrogen-absorbing low-strain metal hydride hydrogen storage tank. The hydrogen-absorbing low-strain metal hydride hydrogen storage tank mainly includes three parts: a tank body 2, a metal hydride hydrogen storage alloy bed body 1, and an elastic buffer layer 3, and the elastic buffer layer 3 is placed on the tank body 2 and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com