Self-heating type rapid hydrogen supply device

A self-heating, rapid technology, applied in the installation device of the container structure, the geometry/arrangement/size of the container structure, gas/liquid distribution and storage, etc., can solve the problem of high water purity and the inability of hydrogen production reactants to circulate Use and other issues to achieve the effect of low material purity requirements, easy reuse, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

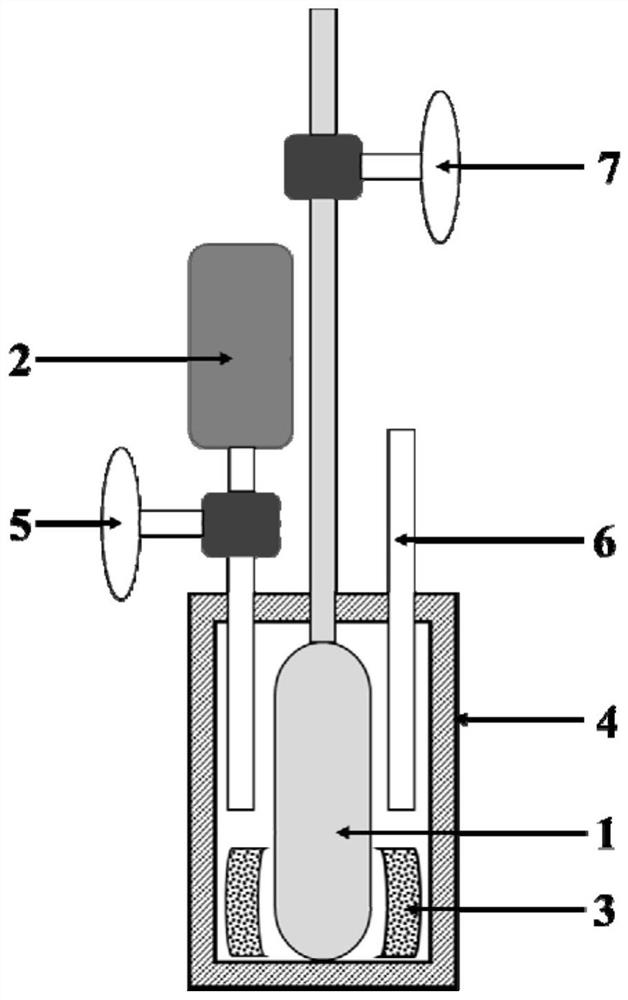

[0052]Such as figure 1 As shown, the self-heating rapid hydrogen supply device provided by the present invention includes a hydrogen storage tank 1 , a water supply tank 2 , a heating pack 3 , an insulation shell 4 , a water tank valve 5 , a thermometer 6 and a hydrogen valve 7 . The hydrogen storage tank 2 is located in the middle of the thermal insulation shell 4, and the heating pack 3 is attached to the hydrogen storage tank 1. The heating pack 3 is filled with quicklime, a heating agent, and the water storage tank 2 is located above the thermal insulation shell 4. The water tank valve 5 controls the opening and closing of water, thereby controlling the inflow of water and preventing the thermal insulation shell from expanding; the thermometer 6 is inserted into the thermal insulation shell 4, next to the heating pack, and the hydrogen storage tank 1 is externally connected to the hydrogen valve 7 to control the opening and closing of hydrogen.

[0053] The specific struct...

Embodiment 2

[0071] The self-heating rapid hydrogen supply device with the same structure as that of Example 1 is adopted, and the specific structure and use process of its components are as follows:

[0072] Specific structure:

[0073] Structure and assembly of hydrogen storage tank

[0074] The hydrogen storage tank has a length of 30cm, an outer diameter of 8cm, and an effective internal volume of about 120mL. It is designed to be filled with 3500g of titanium-based AB2 hydrogen storage alloy powder, which can realize a hydrogen supply of about 700SL. The hydrogen storage tank is equipped with valves and placed in an insulated shell.

[0075] The structure and assembly of the heating pack

[0076] Take 160g of quicklime heating agent and divide it into 4 parts on average, 40g each, put it into 4 non-woven fabric outsourcing bags, and seal them tightly; fill the 4 heating bags at a density of 1 every 90 degrees, and arrange them around the Around the hydrogen storage tank.

[0077] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com