Tin-lead alloy and preparation process thereof

A technology of tin-lead alloy and preparation process, which is applied in the field of tin-lead alloy and its preparation process, to achieve the effect of simple process, easy operation, and protection of equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

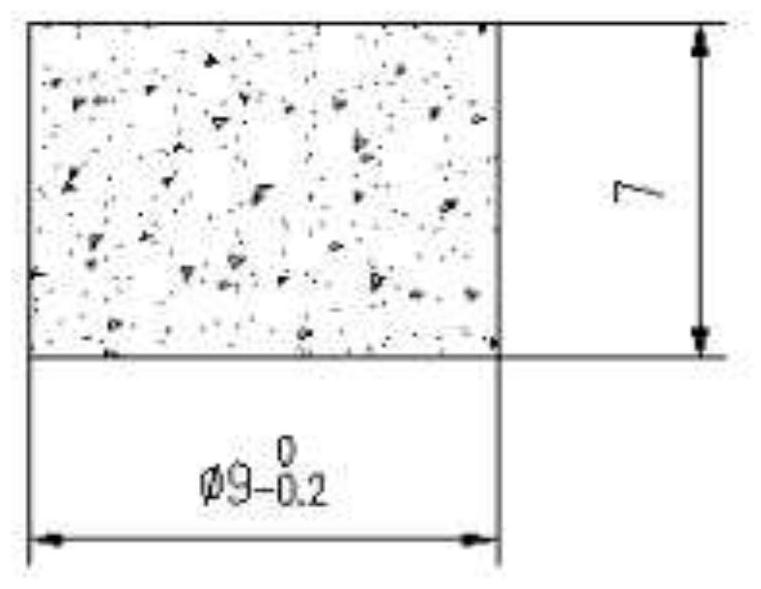

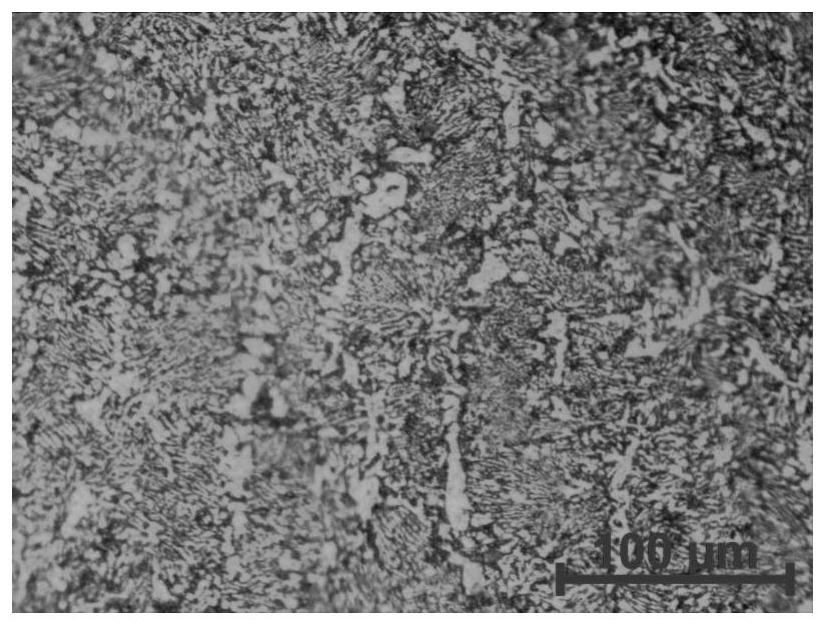

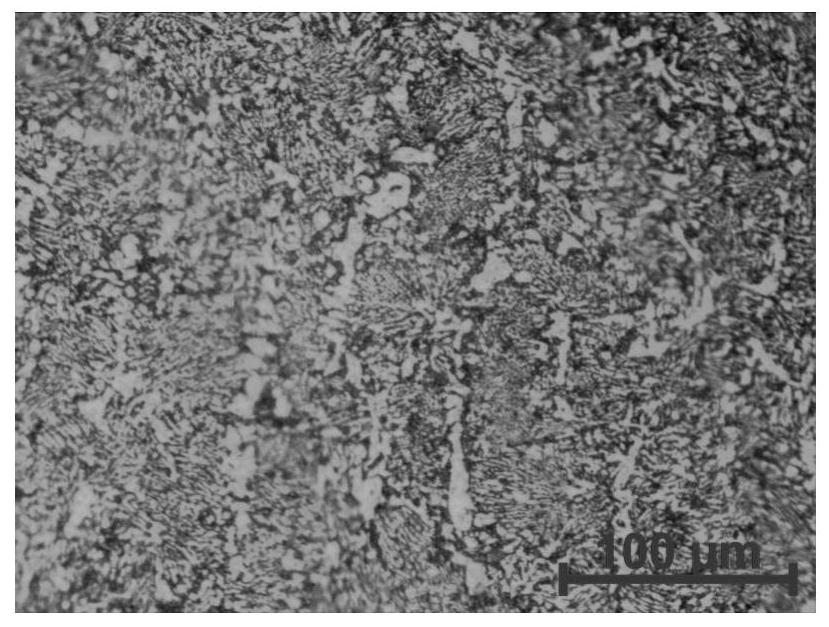

Image

Examples

Embodiment 1

[0036] A tin-lead alloy in this embodiment includes the following raw materials in parts by weight: 2 parts of tin, 30 parts of lead, and 40 parts of bismuth.

[0037] A kind of tin-lead alloy of the present embodiment and preparation technology thereof, comprise the steps:

[0038] (1) Taking 106°C as the application temperature and based on the tin-lead binary phase diagram, select 2 parts by weight of tin; the purity of the tin is ≥99.8%, the purity of the lead is ≥99.8%, and the purity of the bismuth is ≥99.8% %, the purity of antimony and indium is ≥99.8%. Lead and tin metals are granular and 20mm in size.

[0039] (2) According to the required pressure greater than 77MPa, select 30 parts by weight of lead and 40 parts of bismuth from the low melting point alloy;

[0040] (3) Put the metal raw materials in the above weight parts into the smelting furnace, adjust the smelting temperature to 700°C for smelting, and stir and melt;

[0041] (4) Adjust the melting temperatu...

Embodiment 2

[0046] A tin-lead alloy in this embodiment includes the following raw materials in parts by weight: 3 parts of tin, 40 parts of lead, and 50 parts of bismuth.

[0047] A kind of tin-lead alloy of the present embodiment and preparation technology thereof, comprise the steps:

[0048] (1) Taking 110°C as the application temperature and based on the tin-lead binary phase diagram, select 3 parts by weight of tin; the purity of the tin is ≥99.8%, the purity of the lead is ≥99.8%, and the purity of the bismuth is ≥99.8% %, the purity of antimony and indium is ≥99.8%. Lead and tin metals are granular and 28mm in size.

[0049] (2) According to the required pressure greater than 77MPa, select 40 parts by weight of lead and 50 parts of bismuth from the low melting point alloy;

[0050] (3) Put the metal raw materials in the above weight parts into the smelting furnace, adjust the smelting temperature to 750°C for smelting, and stir and melt;

[0051](4) Adjust the melting temperatur...

Embodiment 3

[0056] A tin-lead alloy in this embodiment includes the following raw materials in parts by weight: 5 parts of tin, 45 parts of lead, and 60 parts of bismuth.

[0057] A kind of tin-lead alloy of the present embodiment and preparation technology thereof, comprise the steps:

[0058] (1) Taking 115°C as the application temperature and based on the tin-lead binary phase diagram, select 5 parts by weight of tin; the purity of the tin is ≥99.8%, the purity of the lead is ≥99.8%, and the purity of the bismuth is ≥99.8% %, the purity of antimony and indium is ≥99.8%. Lead and tin metals are in granular form with a size of 40mm.

[0059] (2) According to the required pressure greater than 77MPa, select 45 parts by weight of lead and 60 parts of bismuth from the low melting point alloy;

[0060] (3) Put the metal raw materials in the above weight parts into the smelting furnace, adjust the smelting temperature to 800°C for smelting, and stir and melt;

[0061] (4) Adjust the meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com