Universal spliced tube for plastics doors and windows and profiles using spliced tube

A technology of plastic doors, windows and plastic frames, which is applied in the direction of wing leaf frames, etc., can solve the problems of increasing the investment in profile molds, increasing the pressure of profile manufacturers' production and inventory, etc., and achieve the effect of consistent material, not easy to deform, and large pressure bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

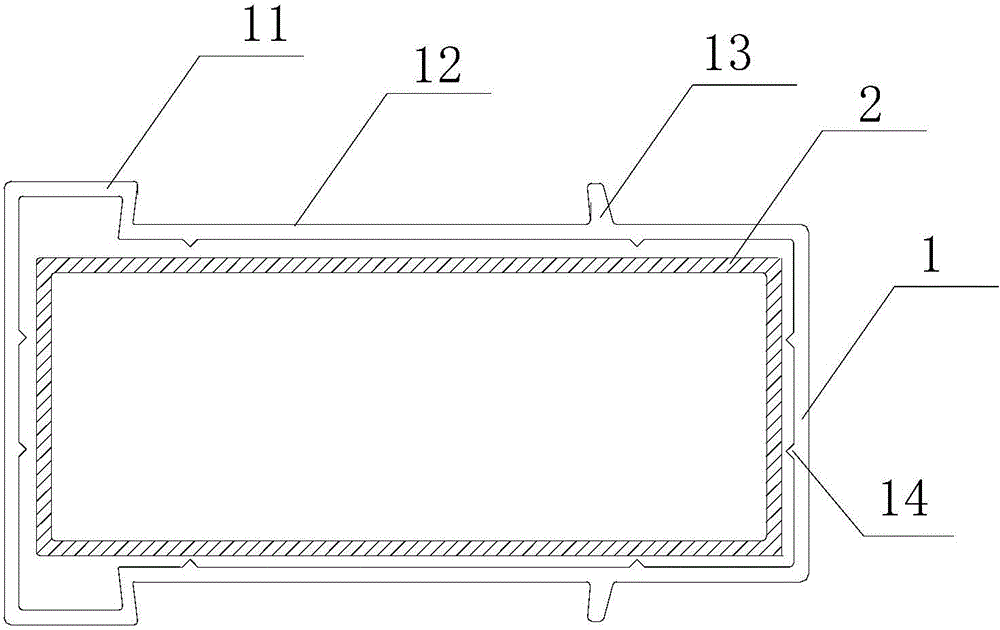

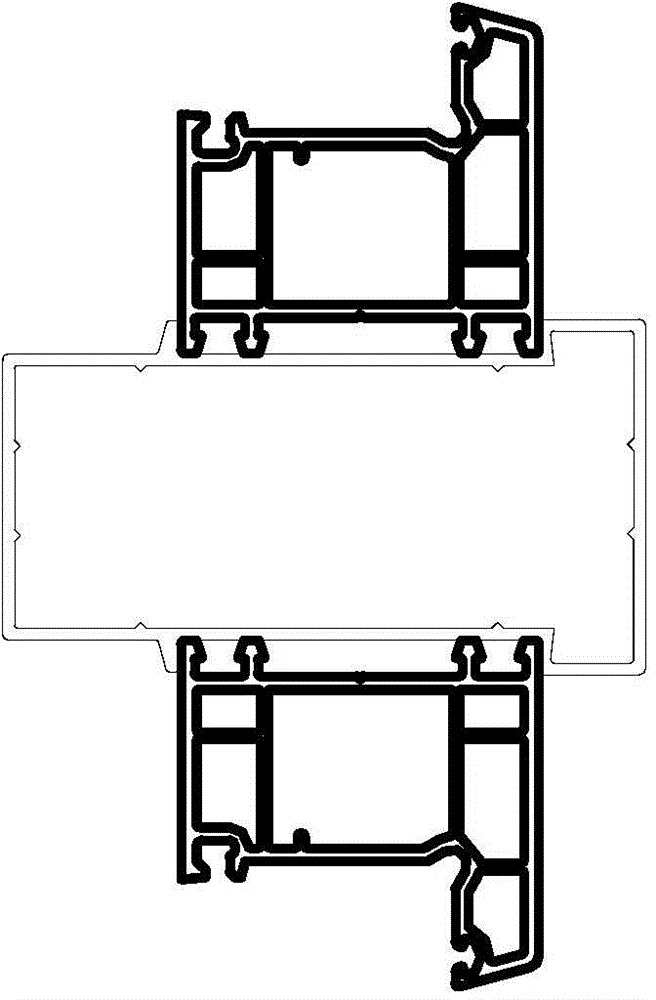

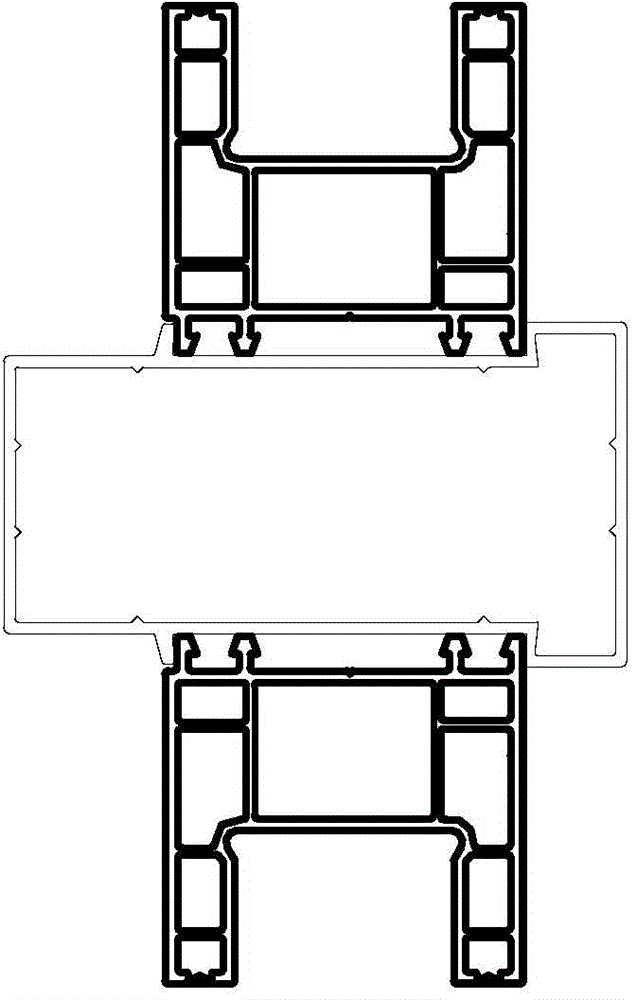

[0019] Such as figure 1 As shown, this embodiment includes a plastic frame body 1 and a steel lining 2 located in the plastic frame body 1. The cross section of the plastic frame body 1 includes an integrated claw 11 and a frame body 12, and the claw 11 is higher than the frame body. Body body 12, the cross-section of the plastic frame body 1 is T-shaped as a whole, and two sides of the frame body body 12 are respectively provided with raised blocks 13 . The clamping block 13 is an inclined structure, and the included angle between the clamping block 13 and the frame body 12 along the direction of the claw 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com