Working electrode with multiple electrodes, combined parallel test system and use method of combined parallel test system

A working electrode and parallel testing technology, applied in the field of electrolysis of water, can solve the problems of difficult testing conditions, large differences in the characteristics of the electrode body, and long time-consuming repeated testing, and achieve the effect of high comparative value and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

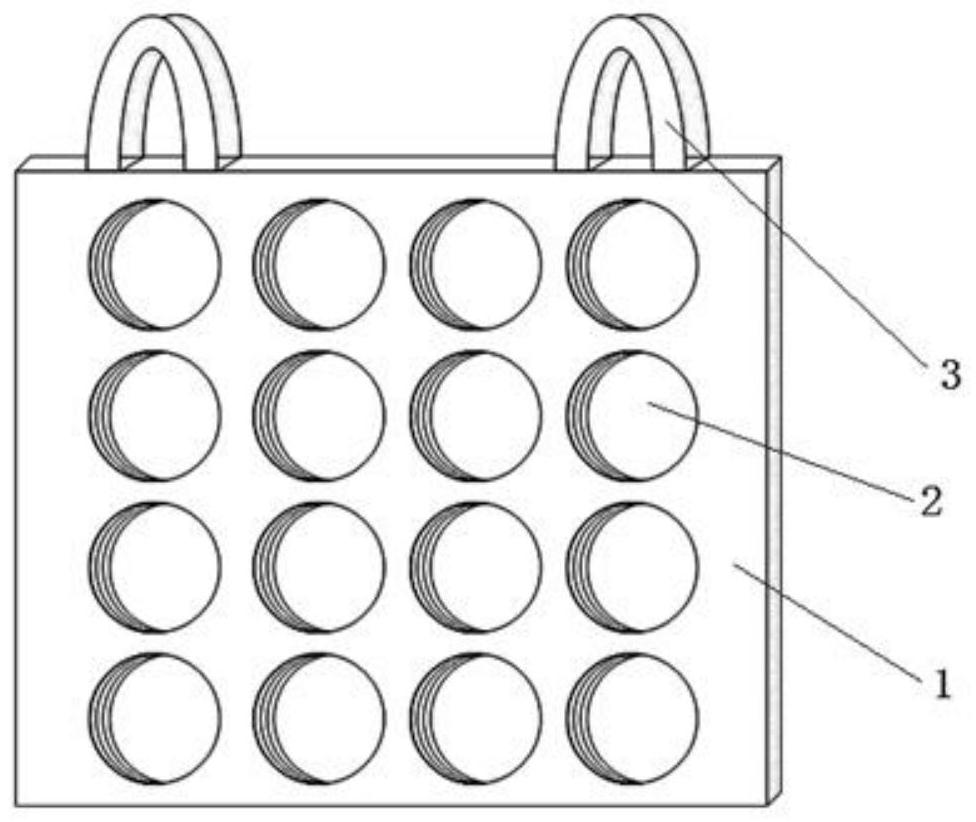

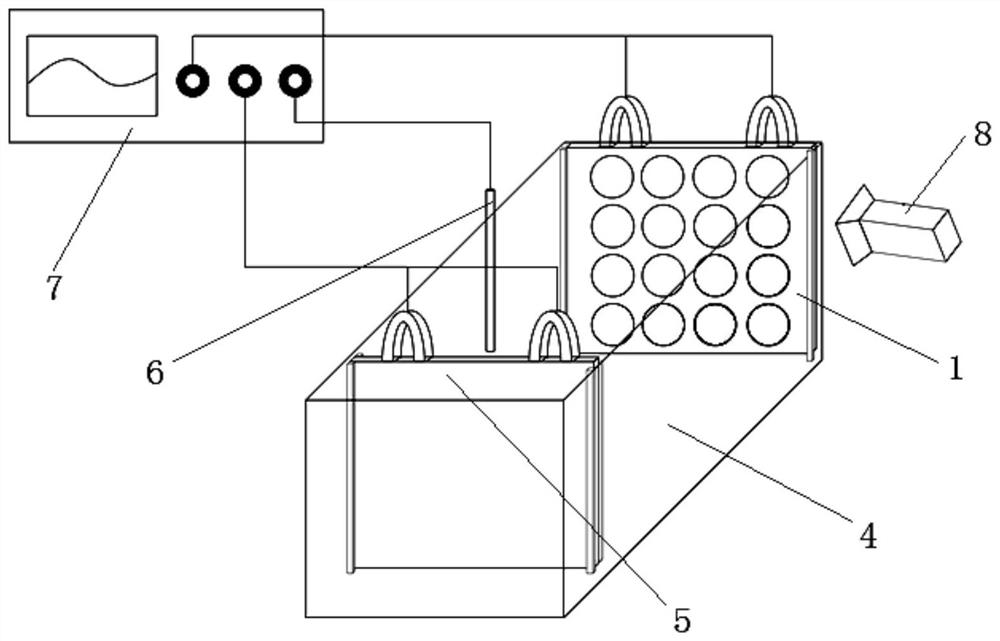

[0048] There are 5 rows and 5 rows of penetrating holes on the perforated plate with a length and width of 20 cm. The thickness of the perforated plate is 1 cm. The material of the perforated plate is nickel metal. The inner diameter of the perforated holes on the plate is 3 cm, and the inner wall is threaded , with terminal 3 on one side of the orifice plate. The penetration holes on the column orifice plate are marked as the first row 1-1~1-5, the second row 2-1~2-5, the third row 3-1~3-5, the fourth row 4-1~ 4-5, the fifth row 5-1 to 5-5.

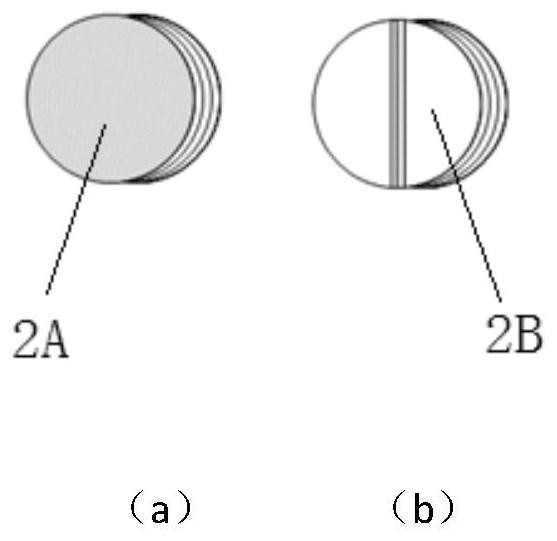

[0049] Sheet electrode 2 is 25 nickel disc electrodes, and the discs are all taken from the same nickel plate. The material and thickness of the nickel plate are consistent with those of the perforated plate. There are threads that match the threads on the orifice plate, one side of the disc is covered with an electrocatalyst layer, and the other side has a groove that can be inserted with a screwdriver, and the disc is screwed into the...

Embodiment 2

[0059] There are 5 rows and 5 rows of penetrating hole arrays on the column orifice plate with a length and width of 15 cm. The column orifice plate is 0.8 cm thick. The material of the column orifice plate is stainless steel. The inner diameter of the penetrating holes on the plate is 2 cm. There is a connection terminal 3 on one side of the column hole plate. The penetration holes on the column orifice plate are marked as the first row 1-1~1-5, the second row 2-1~2-5, the third row 3-1~3-5, the fourth row 4-1~ 4-5, the fifth row 5-1 to 5-5.

[0060] The sheet electrode 2 is 25 stainless steel disc electrodes, the discs are all taken from the same stainless steel plate, the material and thickness of the stainless steel plate are consistent with the column orifice plate, the outer diameter of the discs is 2cm, and the surface characteristics are consistent. There are threads to match the orifice plate. One side of the disc is covered with an electrocatalyst layer, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com