Preparation method of sludge-based artificial building aggregate

A technology for building aggregates and silt, applied in the field of preparation of artificial building aggregates, can solve the problems of high mining pressure of natural aggregates, troublesome recovery and disposal of silt, etc., and achieves the realization of secondary utilization value, the preparation method is simple and convenient, and the strong mechanics Effects of properties and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

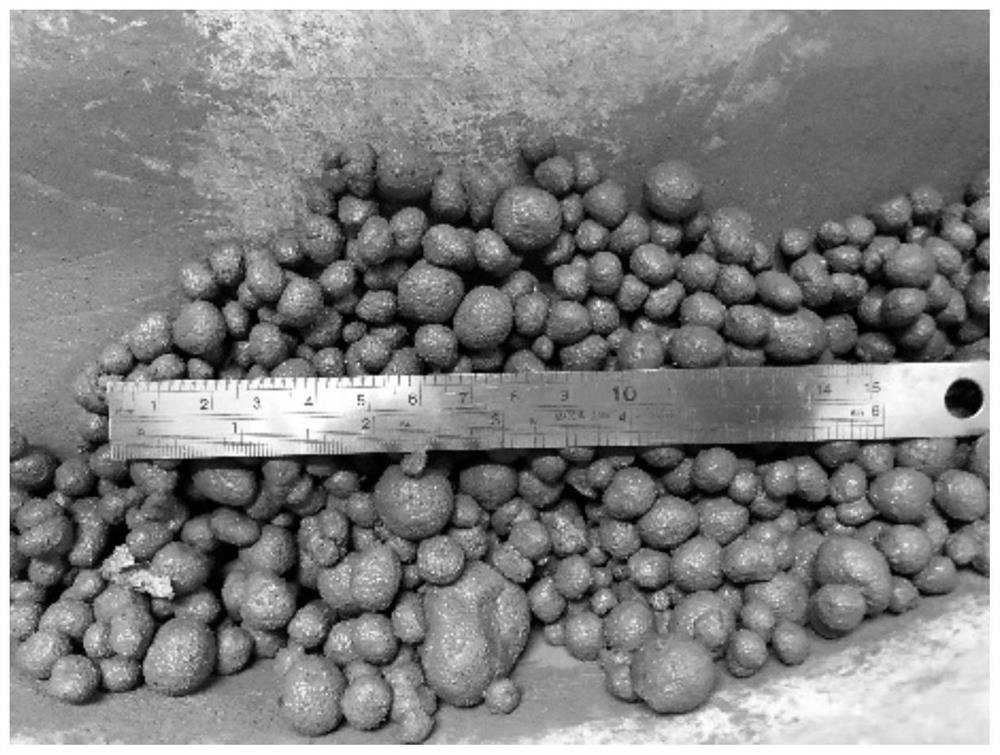

[0024] The first aspect of the embodiment of the present application provides a method for preparing an artificial building aggregate based on silt, comprising the following steps:

[0025] S01. Provide sludge, and pretreat the sludge to obtain dry sludge powder;

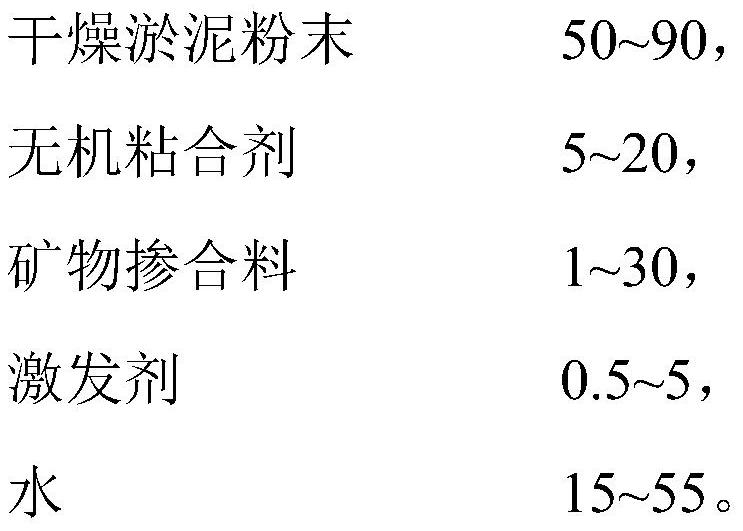

[0026] S02. The dry sludge powder is mixed with the inorganic binder, the mineral admixture and the activator to obtain the first mixture, wherein the parts of the dry silt powder, the inorganic binder, the mineral admixture and the activator are The ratio is (50~90):(5~20):(1~30):(0.5~5);

[0027] S03. Mix and granulate the first mixture and water to obtain artificial building aggregate.

[0028] The preparation method of the silt-based artificial building aggregate provided in the first aspect of the present application, in this preparation method, the dry silt powder obtained through pretreatment is used as the main raw material, and is compounded with an inorganic binder and an activator for use. Under the act...

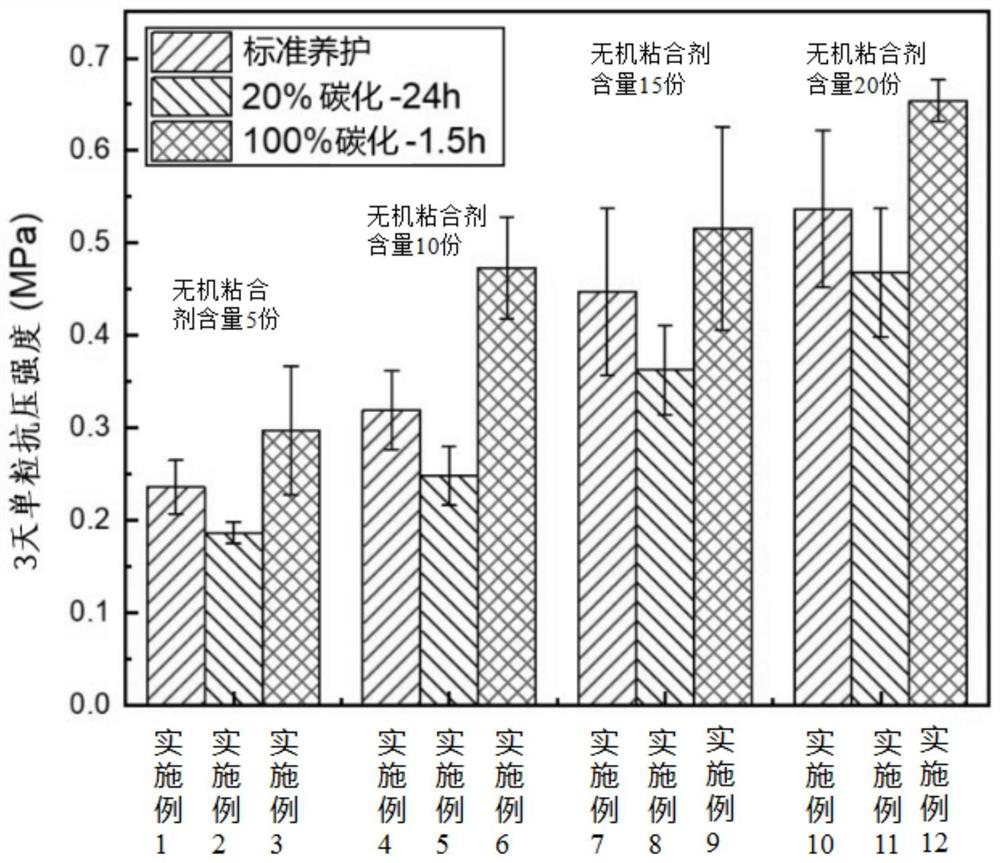

Embodiment 1

[0061] A kind of preparation method of artificial building aggregate based on silt

[0062] The preparation method comprises the following steps:

[0063] (1) providing sludge, drying the sludge at a temperature of 60° C. to 80° C., and then performing ball milling for 2 minutes to obtain dry sludge powder;

[0064] (2) carry out mixing process 3 minutes under the condition of 80 rev / mins with dry mud powder and inorganic binder, mineral admixture and exciter, obtain the first mixture, wherein, the addition part number of dry mud powder is 90 parts, the number of added parts of inorganic binder is 5 parts, the number of added parts of mineral admixture is 4 parts and the number of added parts of activator is 1 part; The agent is selected from geopolymer cement, the mineral admixture is selected from fly ash, and the activator is selected from the combination of sodium hydroxide and sodium silicate;

[0065] (3) The first mixture and water were granulated for 5 minutes under ...

Embodiment 2

[0069] Compared with Example 1, the difference is: in (5), "the rough artificial building aggregate after the curing treatment is carbonized for 3 days in the carbonization box of the carbon dioxide gas with a volume concentration of 20%" is revised to "the cured The processed crude artificial building aggregate was carbonized for 24 hours in a carbonization box with a volume concentration of 20% carbon dioxide gas, and the other steps were the same, and the artificial building aggregate was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com