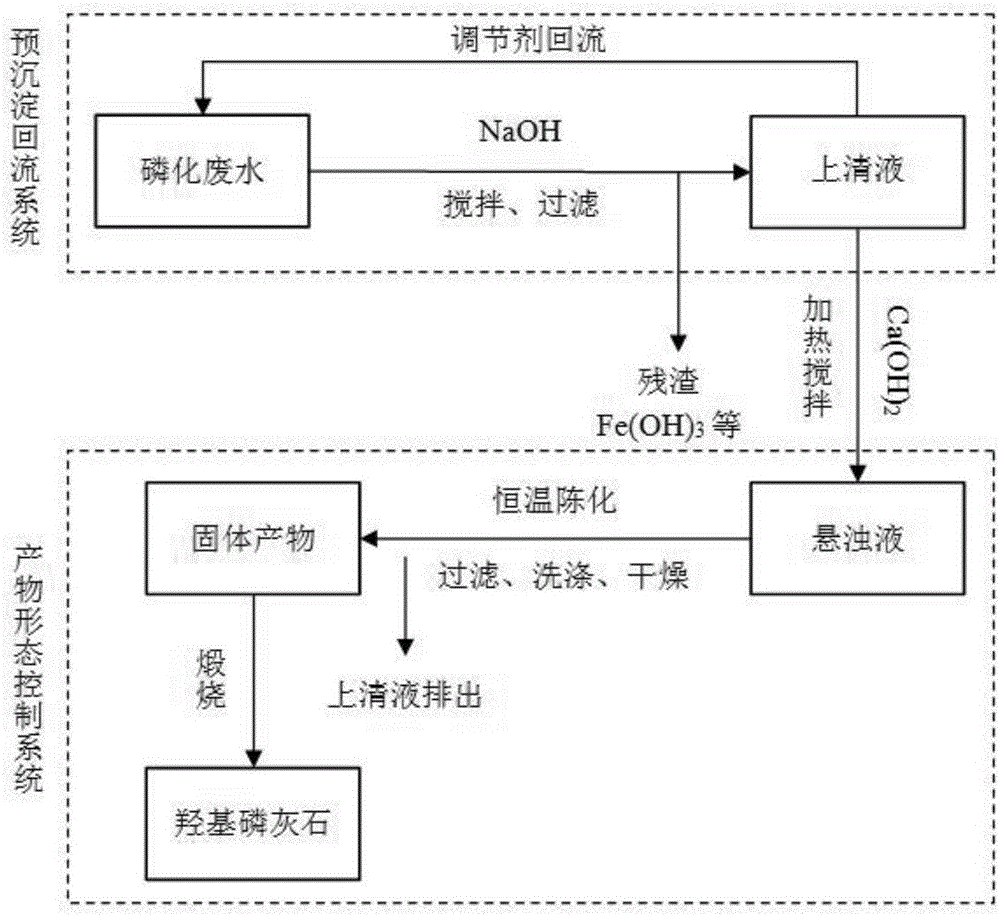

Technological method for preparing hydroxyapatite by using phosphating waste water as raw material

A technology of hydroxyapatite and process methods, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of large output of phosphating wastewater process sludge and high treatment costs, and achieve good economic and social benefits, Effects of reducing pollution and saving phosphorus resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The phosphating wastewater of a stationery factory in Hangzhou is treated by the process method of the present invention (the workpiece is not pickled before phosphating, and the wastewater contains 254 mg / L of phosphorus). First, add NaOH solution to the wastewater, adjust the pH to 7.4, and remove Fe in the wastewater 2+ 、Ni 2+ 、Cu 2+ Heavy metal ion impurities such as heavy metal ions, standing and filtering to obtain the supernatant; then adding Ca(OH) to the obtained supernatant 2 , keep n(Ca) / n(P) at 1.5, stir at 40°C for 2h, then stand and age at 40°C for 6h, then filter, wash, and dry to obtain a solid product, and finally send the obtained solid product to In a muffle furnace, it was calcined at 700°C for 4h in an air atmosphere. The phosphorus removal efficiency of phosphating wastewater can reach 93.7%, and the purity of hydroxyapatite produced is 79%.

Embodiment 2

[0024] The phosphating wastewater of a large-scale metal surface treatment enterprise in Jiangsu is treated by the process method described in the present invention. First, add NaOH solution to the wastewater, adjust the pH to 7.8, and remove Fe in the wastewater 2+ 、Ni 2+ 、Cu 2+ Heavy metal ion impurities such as heavy metal ions, standing and filtering to obtain the supernatant; then adding Ca(OH) to the obtained supernatant 2 , keep n(Ca) / n(P) at 2.0, stir at 50°C for 4h, then stand and age at 50°C for 6h, then filter, wash and dry to obtain a solid product, and finally send the obtained solid product to In a muffle furnace, calcination at 800 °C for 6 hours in an air atmosphere to obtain hydroxyapatite. The phosphorus removal efficiency of phosphating wastewater can reach 95.1%, and the purity of hydroxyapatite is 73%.

Embodiment 3

[0026] The phosphating wastewater of a certain refrigerator factory in Hefei is treated by the process method of the present invention. First, add NaOH solution to the wastewater, adjust the pH to 8.5, and remove Fe in the wastewater 2+ 、Ni 2+ 、Cu 2+ Heavy metal ion impurities such as heavy metal ions, standing and filtering to obtain the supernatant; then adding Ca(OH) to the obtained supernatant 2 , keep n(Ca) / n(P) at 3.0, stir at 60°C for 6h, then stand and age at 60°C for 6h, then filter, wash, and dry to obtain a solid product, and finally send the obtained solid product to In a muffle furnace, calcination at 1000 ° C for 8 hours in an air atmosphere to obtain hydroxyapatite. The phosphorus removal efficiency of phosphating wastewater can reach 90.8%, and the purity of hydroxyapatite is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com