Patents

Literature

113results about How to "Process parameter control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

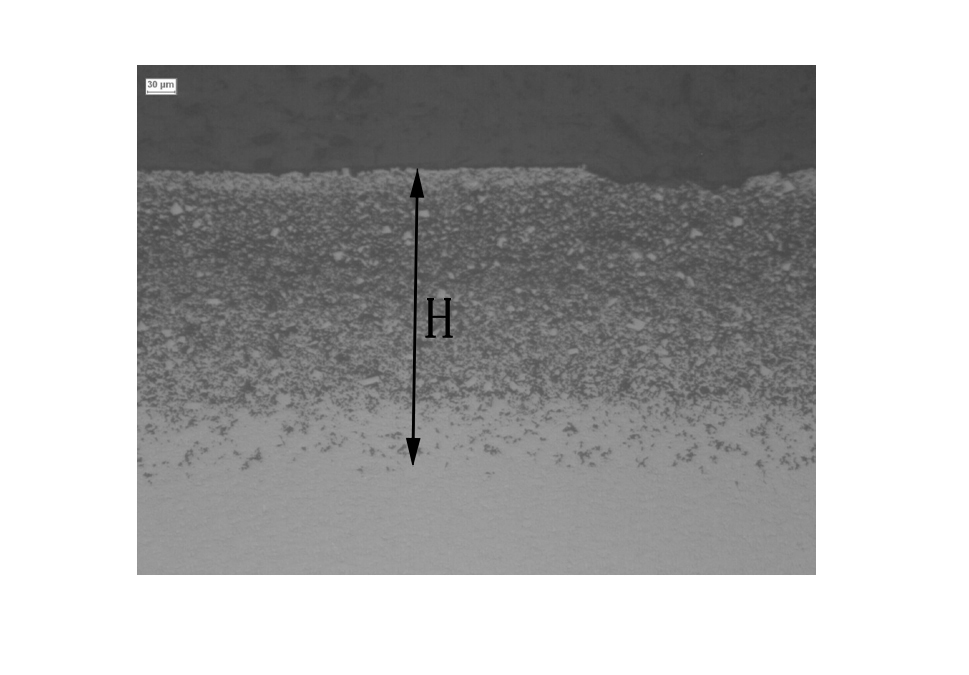

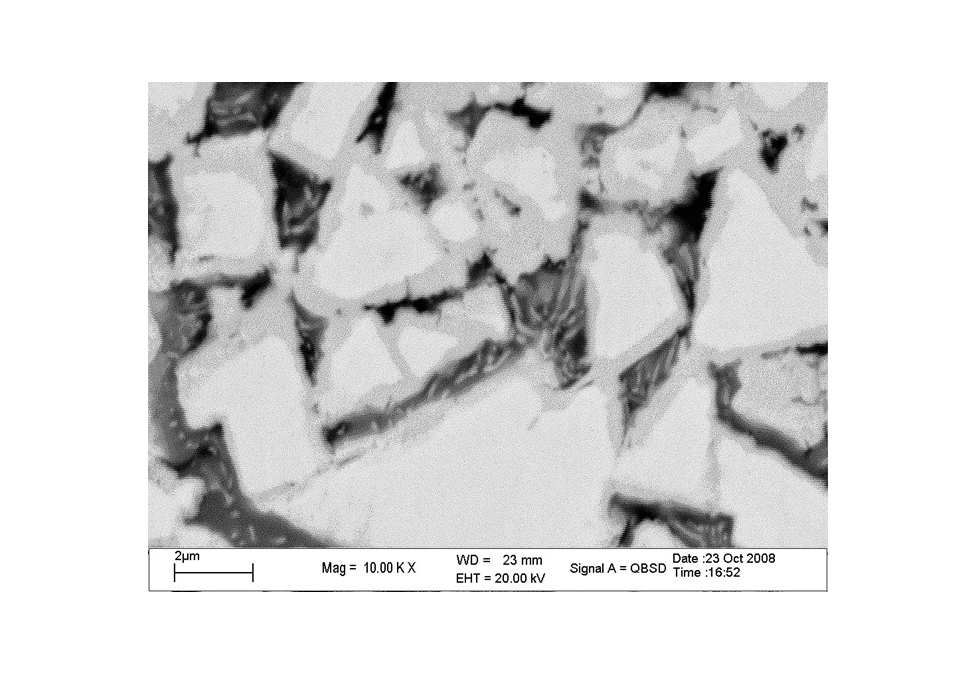

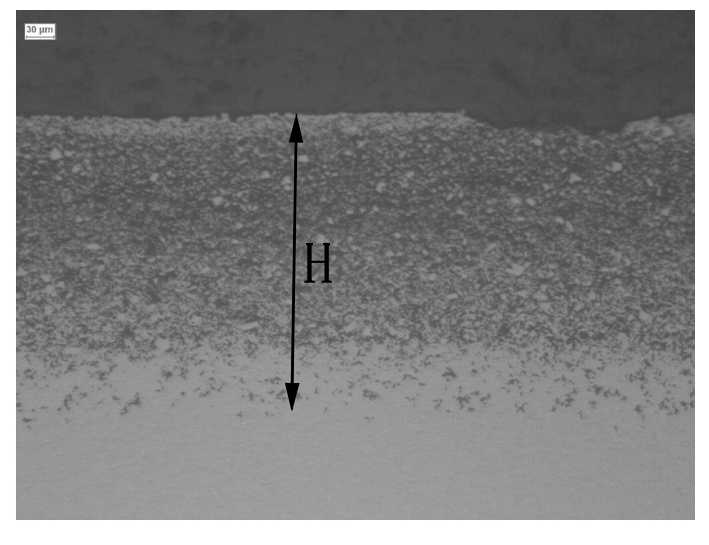

Method for surface boriding of hard alloy

The invention discloses a new method for surface boriding of hard alloy, which sequentially comprises the following steps of: removing an oxidation layer on the surface of the hard alloy; embedding the hard alloy into a solid boriding agent, putting the mixture into a nearly-closed boriding container, and putting the container into an induction heating furnace; vacuumizing the furnace, stopping vacuumizing until the vacuity is over 100 Pa, and filling inert gas or hydrogen; after the gas in the furnace reach the pressure, starting to perform induction heating to reach the boriding temperature of between 800 and 1,300 DEG C, and performing heat preservation for 0.5 to 8 hours to realize gas-solid phase boriding. The solid boriding agent comprises the following components in percentage by weight: 5 to 50 percent of boron supply agent, 2 to 40 percent of activating agent and the balance of fillers, wherein the boron supply agent is one or more of powdered B4C, BN and amorphous boron; the activating agent is two or more of powdered KBF4, NaBF4, NH4BF4, (NH4)2CO3, rare earth oxide and Mg powder, and one of the mixture is an activating agent containing a B element; and the filler consists of graphite powder granules and SiC powder or Al2O3 powder. Through the method, the boriding thickness of sintered hard alloy blank is more than 0.1 millimeter and is close to 1 millimeter, so the surface abrasion resistance of the hard alloy is improved greatly.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

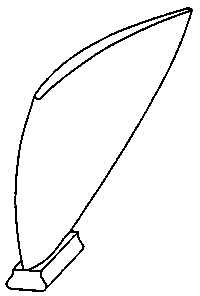

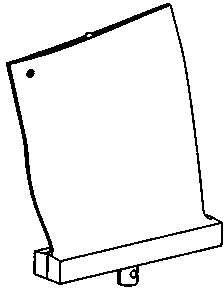

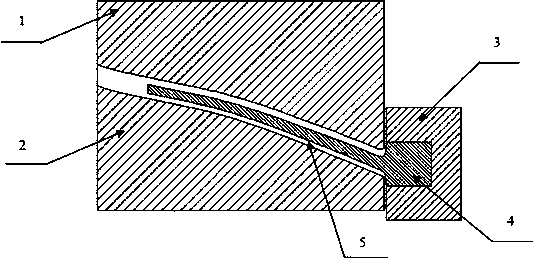

Push-bending forming process for hollow blade

InactiveCN103551472AOvercome stabilityImprove product qualityShaping toolsEngine componentsTorsional deformationLubricant

The invention discloses a push-bending forming process for a hollow blade. The process comprises producing a mould cavity curved surface according to a finished product hollow blade appearance curved surface; machining a mould according to the mould cavity curved surface and forming a mould cavity passage with two open sides in the mould; designing a chuck according to the blade tenon shape; fixing the chuck and the mould on a hot press; coating high-temperature lubricants on the inner surface of the mould cavity and the surface of a blade blank; mounting the blade blank on the chuck. The hot press acts, the mould is closed, the chuck drives the blade to move towards the mould to push the blade into the mould cavity from one end of the mould cavity passage, and the blade is forced to be bent under the action of the mould cavity inner surface and is subjected to torsional deformation; the mould is opened after the torsional deformation is kept for certain time, and the formed blade is dismounted. According to the process, slab hollow blade blanks can be formed into complex torsional forms and are provided with required torsion angles, the forming process is stable and convenient and fast, the speed is controllable, deformation distribution of all parts are uniform, and the production efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

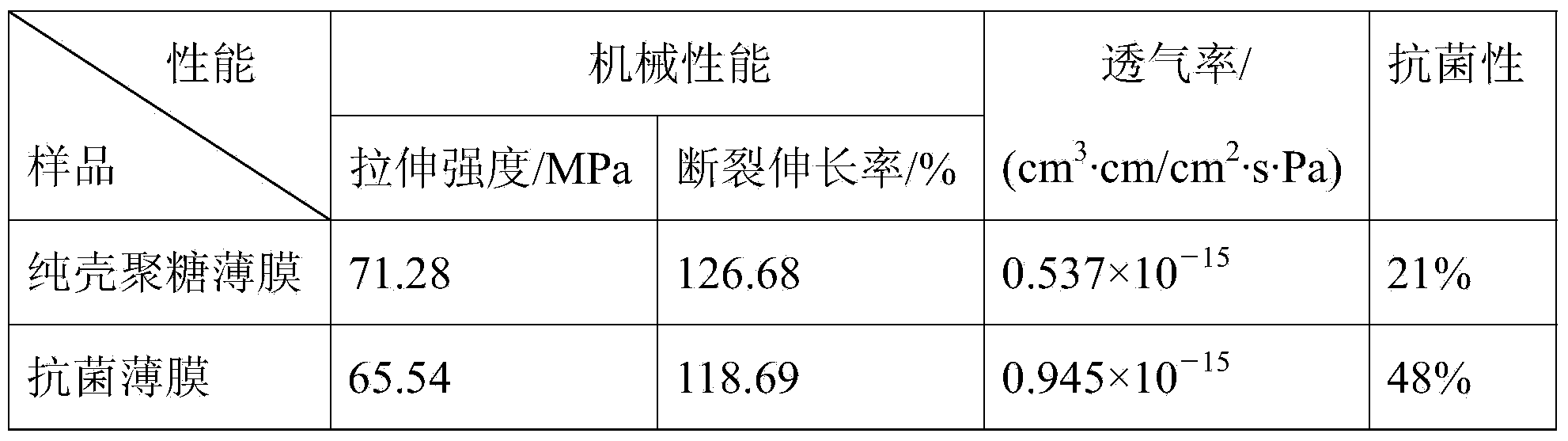

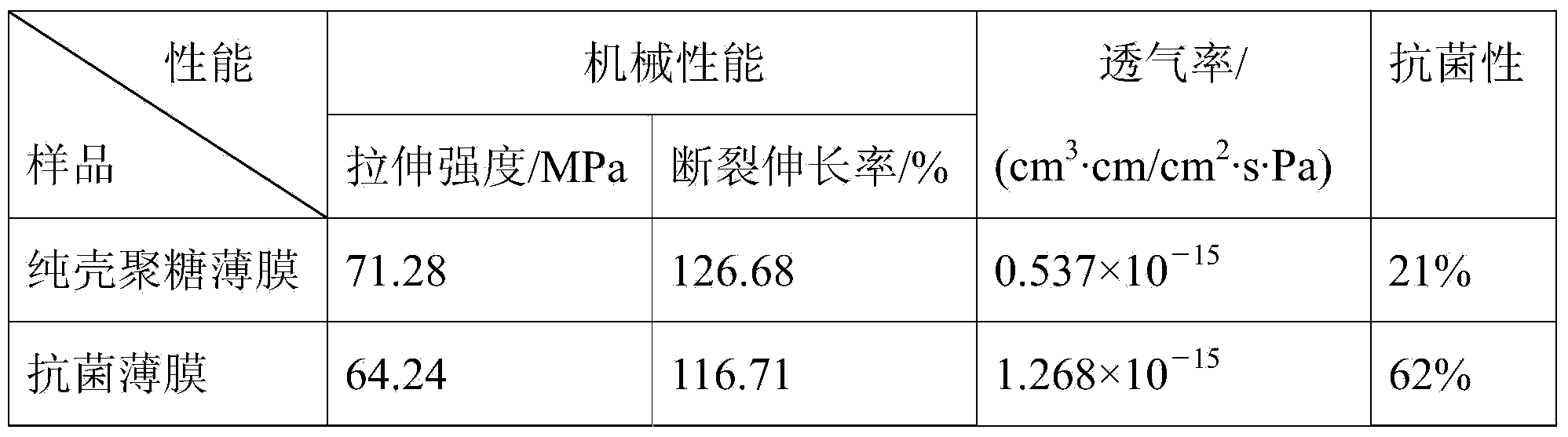

Antibacterial packaging film and preparation method thereof

The invention discloses an antibacterial packaging film and a preparation method thereof. The antibacterial packaging film comprises chitosan as a main raw material and further comprises plant essential oil which is used as an antibacterial agent. By using a plant essential oil microcapsule formed by beta-cyclodextrin and plant essential oil as the antibacterial agent, the antibacterial packaging film not only can be used for improving the stability of essential oil, but also can be used for controlled release of the essential oil. In addition, the raw material chitosan is an environment-friendly macromolecular compound, so that the antibacterial packaging film has a good film-forming property and is excellent in antibacterial property.

Owner:厦门金汇峰新型包装材料股份有限公司 +1

Method of producing a polypeptide or virus of interest in a continuous cell culture

ActiveUS8580554B2Increase productionHigh densityCulture processCell culture mediaSerum free mediaSerum free

Described herein is a chemostat-like continuous cell culture system that combines certain advantages of perfusion open systems and chemostat open systems to improve the culturing of mammalian cells, e.g., genetically modified cells, particularly in serum-free or chemically-defined media. The continuous culture system described herein involves culturing mammalian cells in a continuous cell culture system, which comprises a cell retention device, wherein the cell culture system has a dilution rate (D) of less than about 2 d−1, and a cell density of less than about 2×107 cell / mL. Also described herein is a method for producing a polypeptide and / or virus of interest in a continuous cell culture, the method comprising culturing mammalian cells expressing the polypeptide and / or virus of interest in a continuous cell culture system, which comprises a cell retention device, wherein the cell culture system has a dilution rate (D) of less than about 2 d−1, and a cell density of less than about 2×107 cell / mL; and recovering the polypeptide and / or virus of interest from medium of the cell culture system.

Owner:TAKEDA PHARMA CO LTD

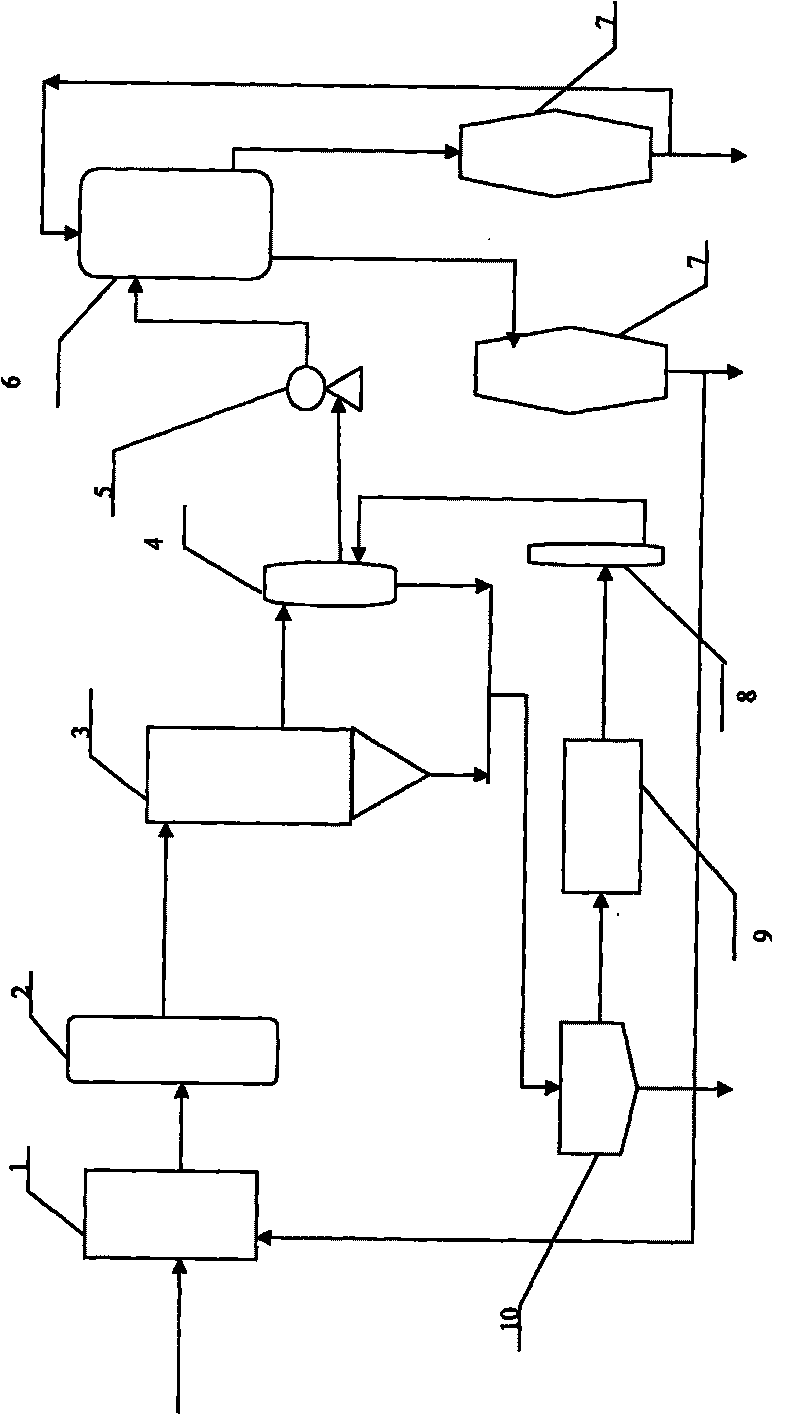

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

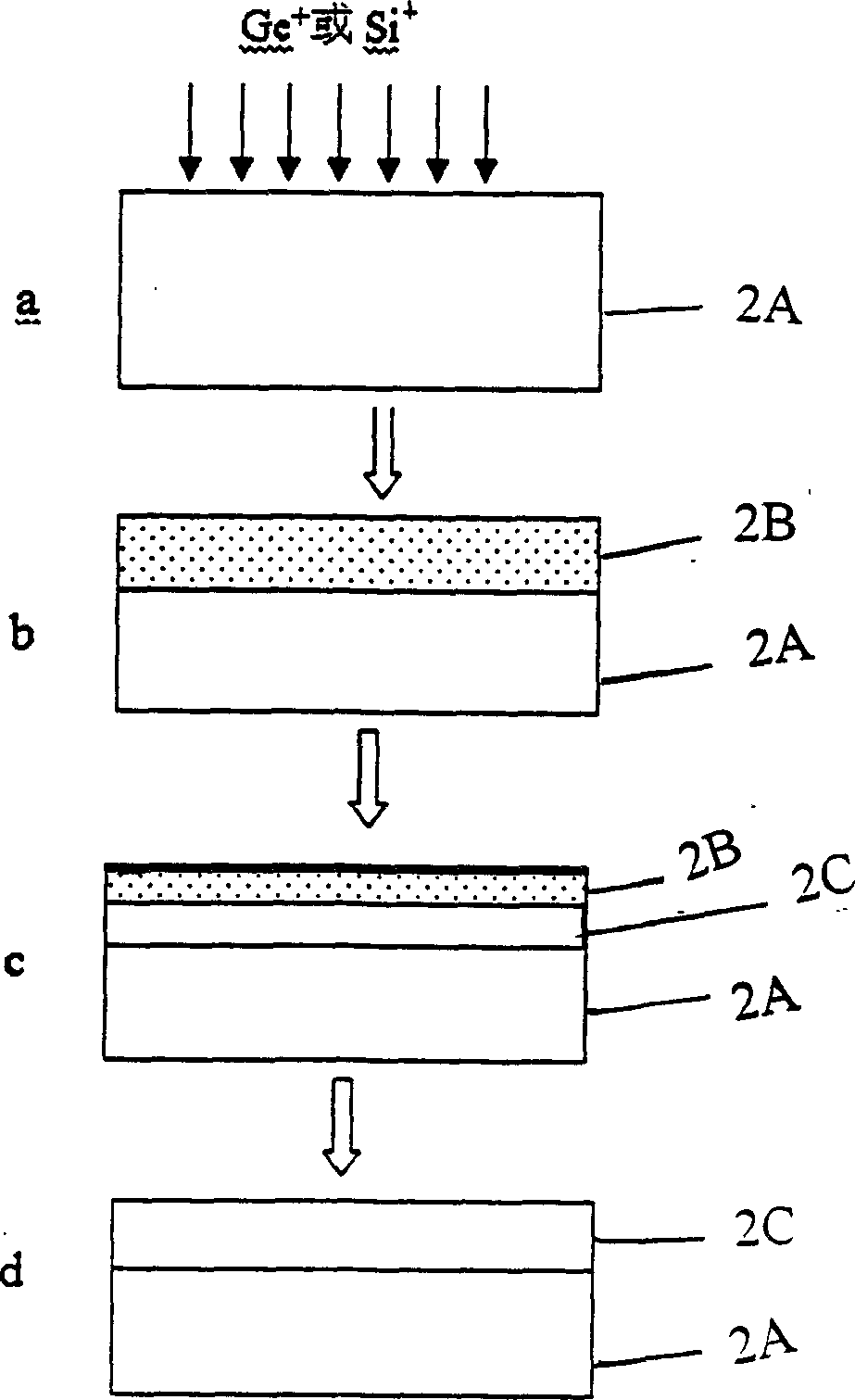

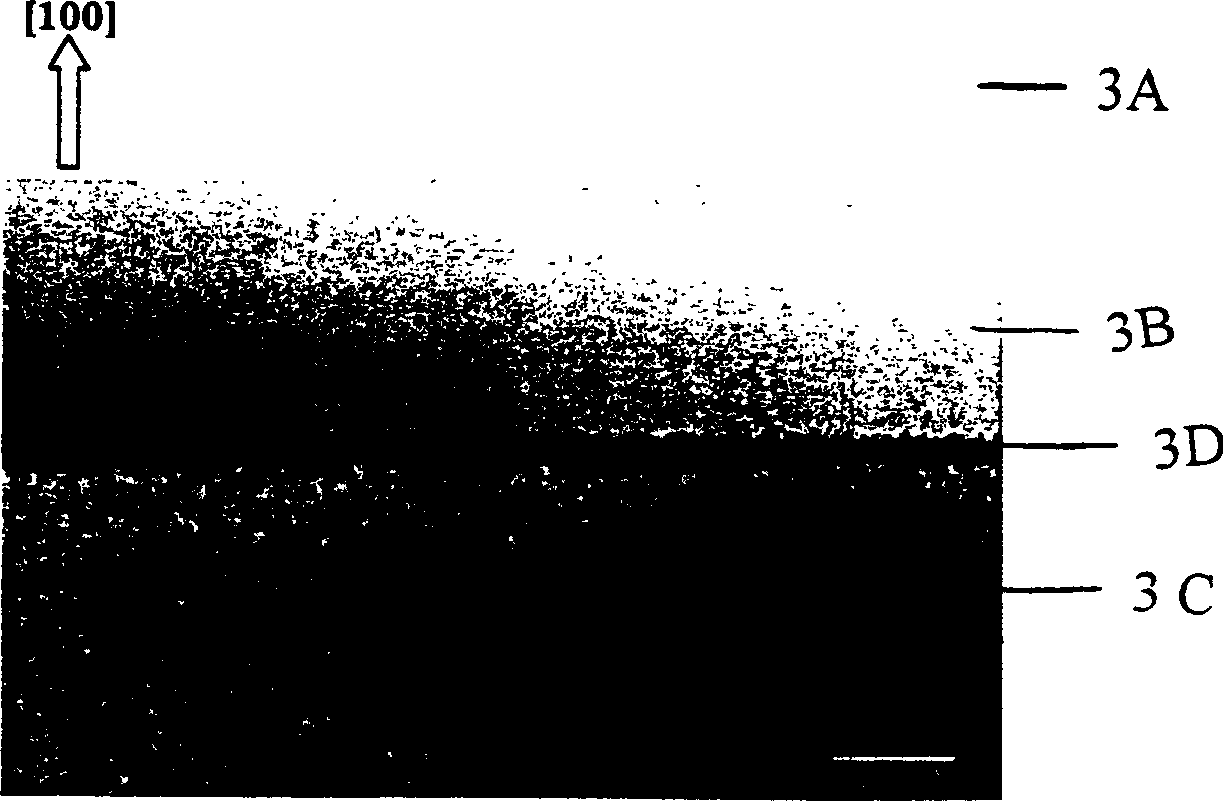

Method for eliminating primary pit defects of silicon monocrystal device making area

ActiveCN1632919AGood crystallization and high qualityIncrease growth rateSemiconductor/solid-state device manufacturingSurface layerRapid thermal annealing

This invention relates to a method to eliminate the silicon pad device process area original defection, which is used to eliminate the original defection of the silicon crystal surface. This method uses direct pull method to use silicon crystal pas as original silicon pad and injects the low dose ion of Ge#+[+] or Si#+[+] into the surface layer of the original silicon to make it non-crystal and then uses rapid heat annealing or oven annealing to make the silicon surface non-crystal layer.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

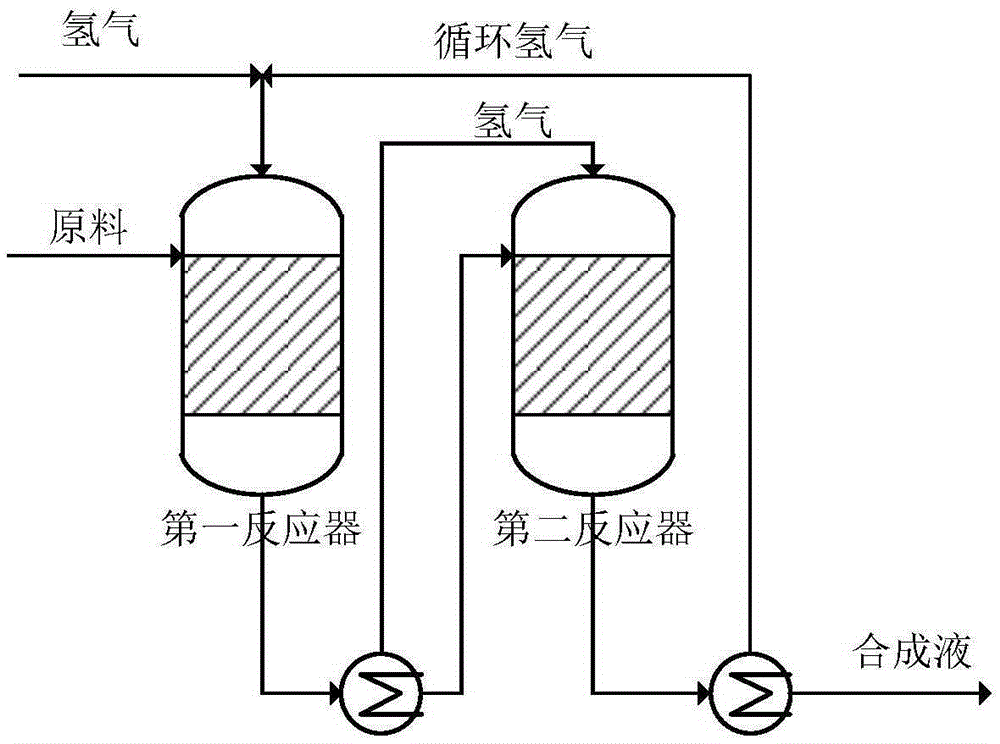

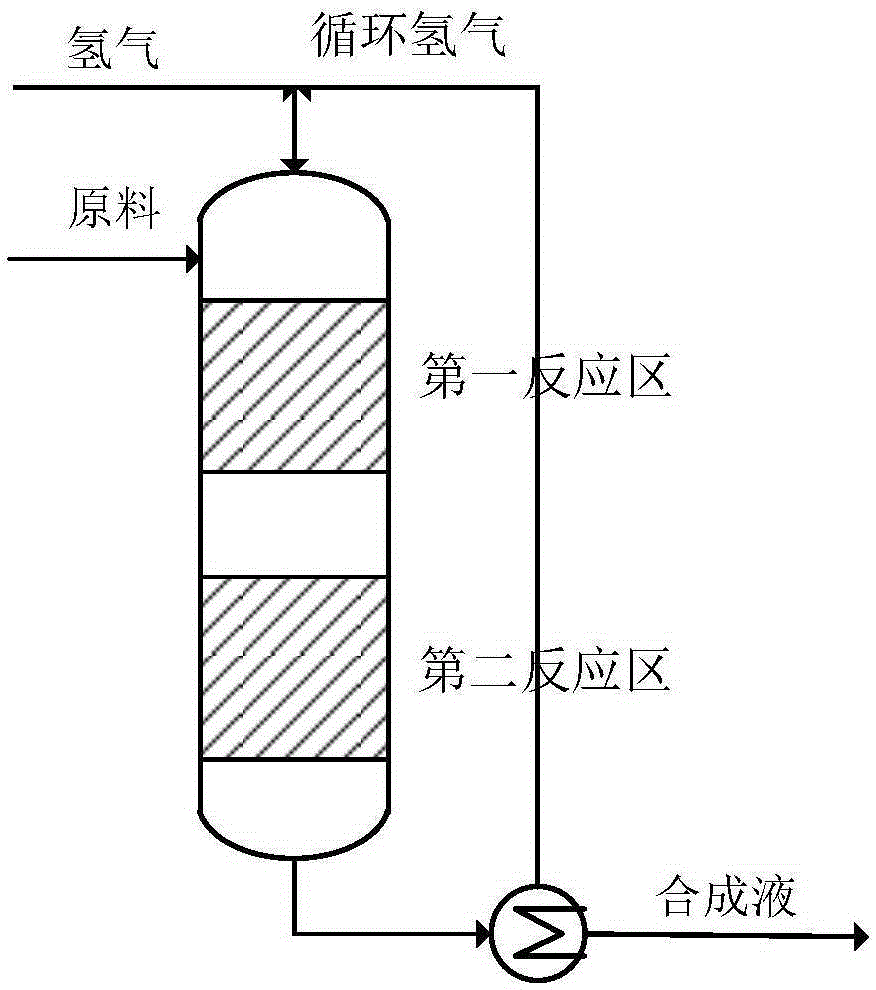

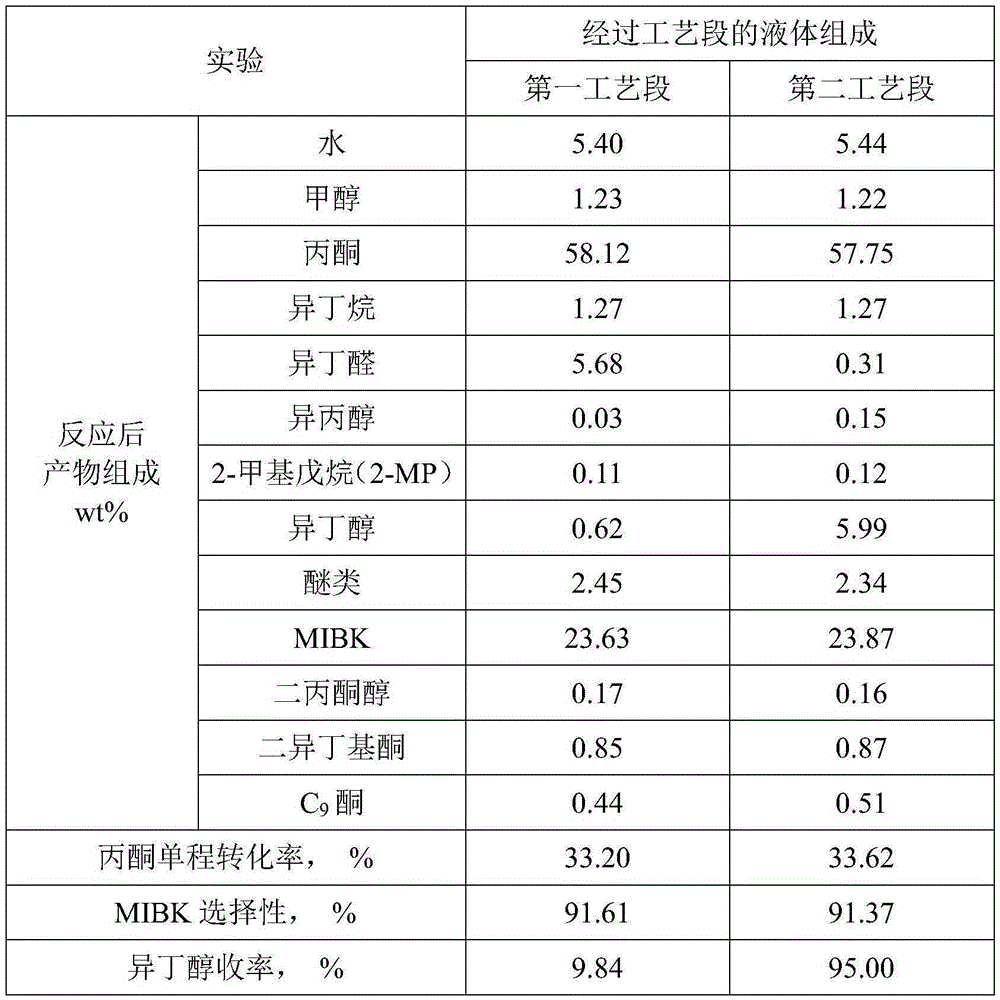

Method for preparing MIBK through industrial by-product low-purity acetone

ActiveCN105237373AExtended service lifeProcess parameter controlOrganic compound preparationCarbonyl compound preparationReaction temperatureSide reaction

The invention discloses a method for preparing MIBK through industrial by-product low-purity acetone. The method is performed through two segments of technologies. In the first segment of technology, acetone is converted into MIBK and part of impurities under the action of MIBK synthetic catalysts; in the second segment of technology, under the action of protective catalysts, main impurities are converted into products easy to separate and it is guaranteed that acetone is not lost basically. The method can achieve conversion of most part of substances difficult to separate in raw material, products are easy to eliminate through rectification, reaction temperature of a main reaction catalyst bed layer is remarkably lowered, the service life of main catalysts is remarkably prolonged, unexpected side reaction is inhibited, and therefore the product yield and the economical efficiency of a device are further improved. MIBK superior products with the purity being 99.5wt% can be obtained by separating reaction products.

Owner:WANHUA CHEM GRP CO LTD

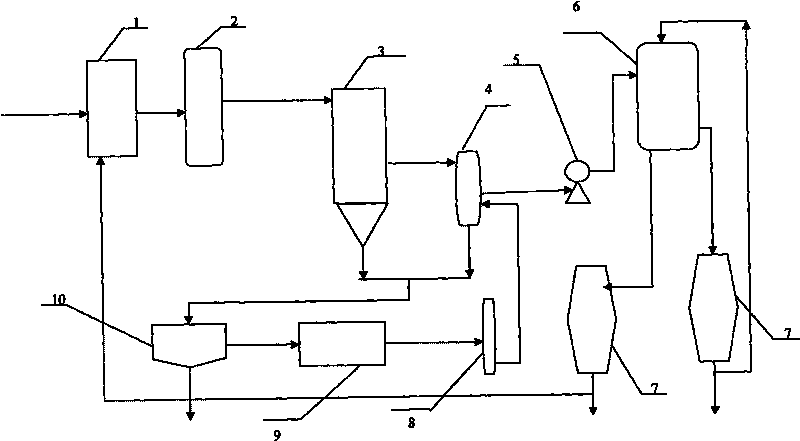

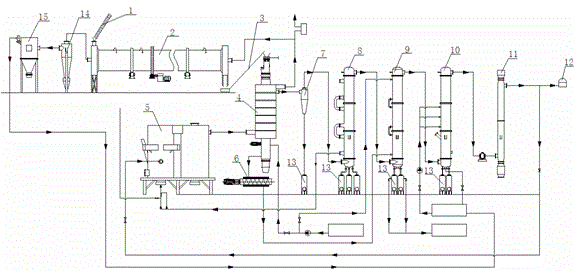

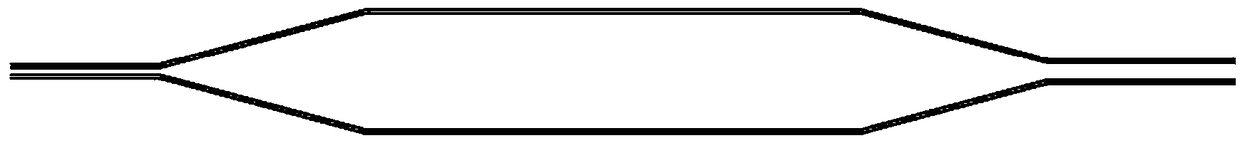

Biomass pyrolysis gas-oil poly-generation system

ActiveCN104861996AImprove qualityImprove pyrolysis effectBiofuelsIndirect heating destructive distillationCooling towerThermodynamics

The invention discloses a biomass pyrolysis gas-oil poly-generation system. The biomass pyrolysis gas-oil poly-generation system comprises a belt conveyor (1), a rotary baking furnace (2), a straight-through type pyrolyzing furnace (4), a spiral discharging machine (6), a cyclone separator I (7), an air cooling tower (8), a water cooling tower (9), a scrubbing tower (10), a purification tower (11) and a gas storage tank (12), wherein the pyrolysis gas outlet at the upper part of the straight-throguh type pyrolyzing furnace (4) is connected to the gas inlet of the cyclone separator I (7); the gas outlet of the cyclone separator I (7) is connected to the gas inlet of the gas storage tank (12) through the air cooling tower (8), the water cooling tower (9), the scrubbing tower (10) and the purification tower (11); the liquid outlets of the cyclone separator I (7), the air cooling tower (8), the water cooling tower (9) and the scrubbing tower (10) are connected with an inlet of a water-sealing tank (13) respectively. The biomass pyrolysis gas-oil poly-generation system is easy to control technological parameters, relatively good in pyrolysis effect and relatively high in production efficiency.

Owner:武汉光谷蓝焰新能源股份有限公司

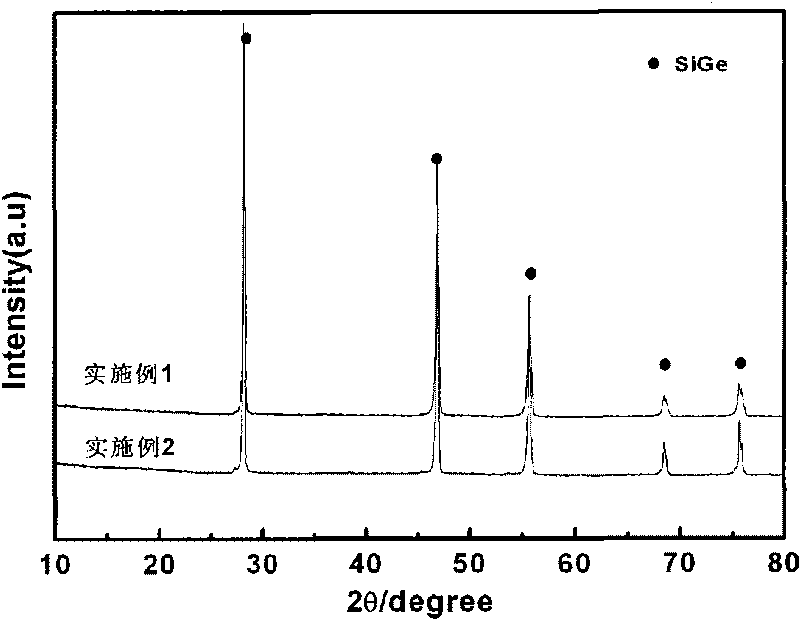

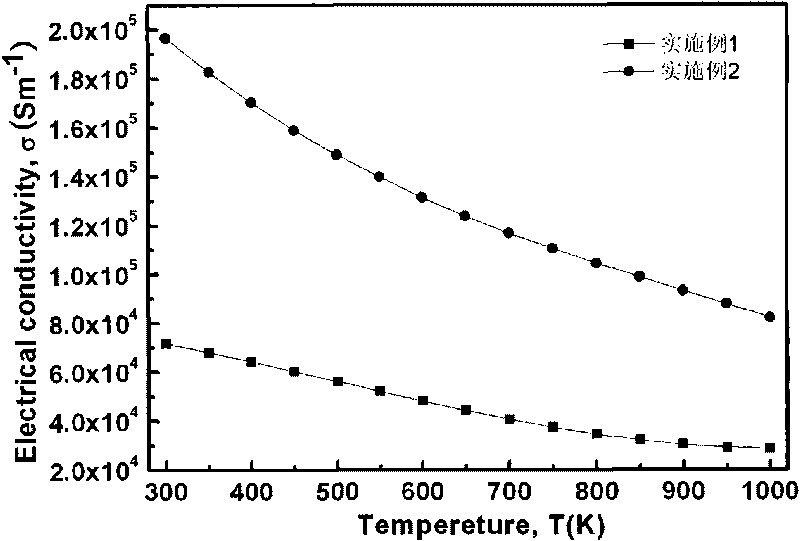

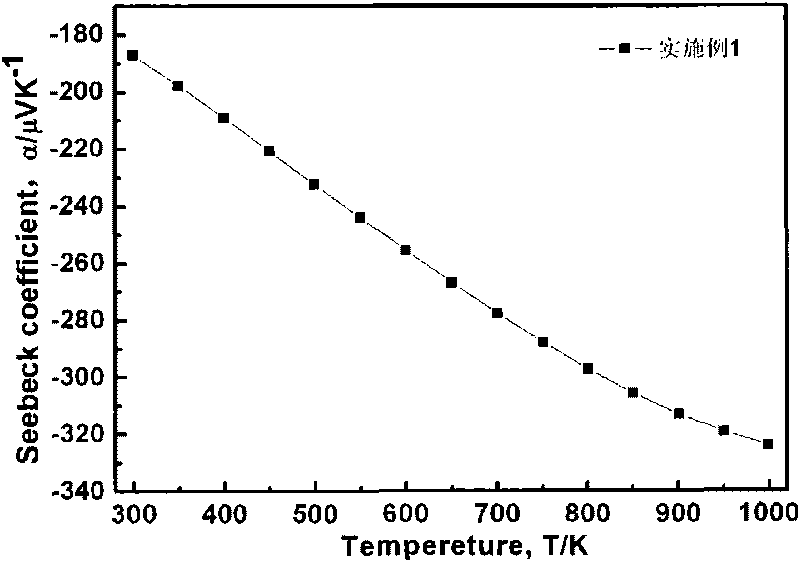

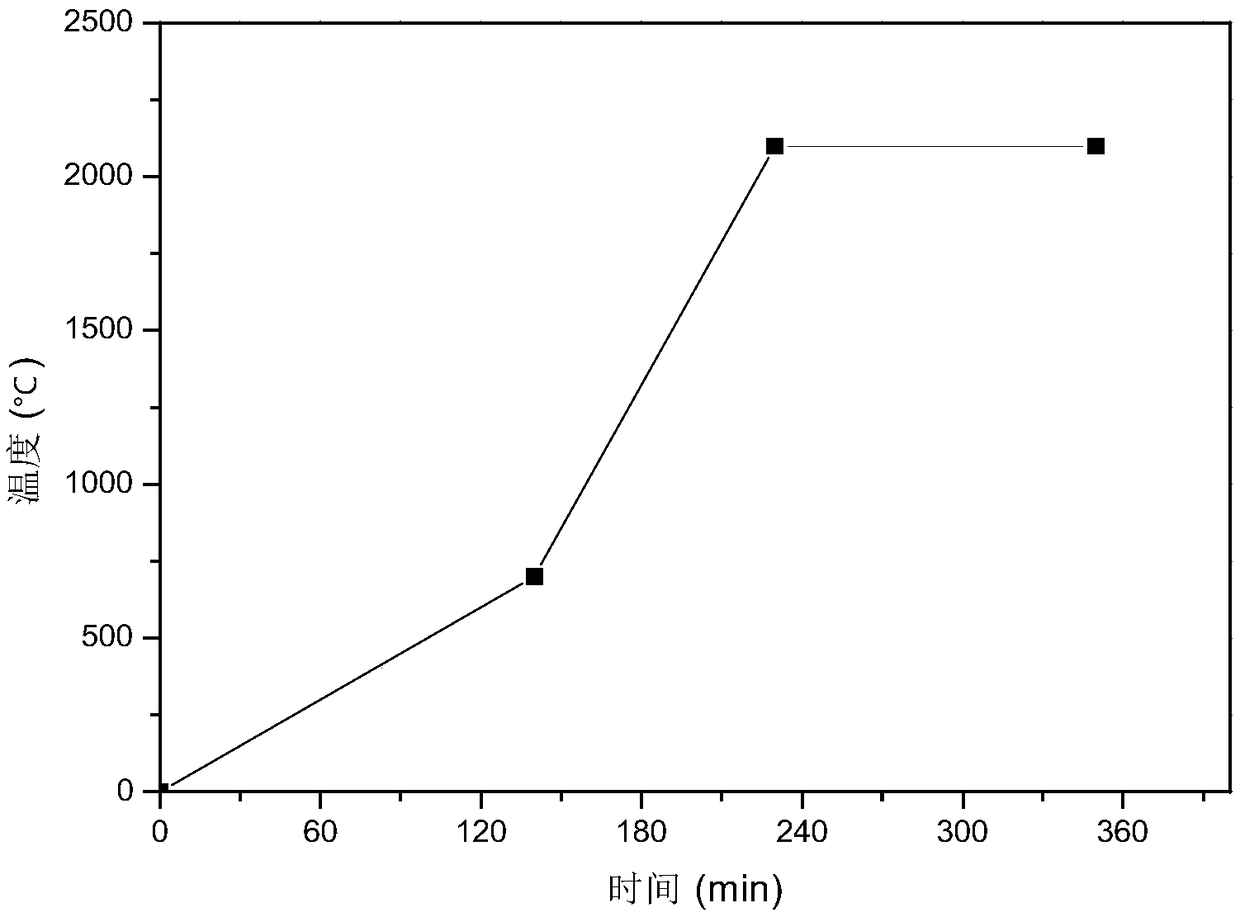

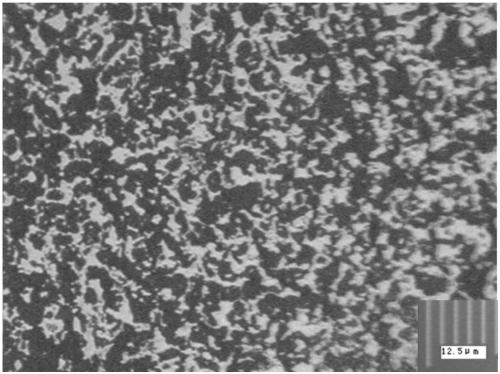

Preparation method of SiGe alloy thermoelectric material

The invention relates to a preparation method of a SiGe alloy thermoelectric material. The preparation method of the SiGe alloy thermoelectric material is characterized by comprising the following steps of: (1) weighing high-purity Si blocks, high-purity Ge blocks and dopants as raw materials according to a chemical formula Si80Ge20X0-3, wherein X in the chemical formula stands for elements of the dopants; mixing the high-purity Si blocks, the high-purity Ge blocks and the dopants, then melting for 2 to 3 times with 30s each time in an argon arc melting furnace to obtain an alloy block body; (2) grinding and crushing the alloy block body obtained in the step (1), then ball-milling for 1 to 2h in a ball mill by taking alcohol as a ball-milling process controlling agent, and drying to obtain alloy powder; and (3) carrying out electro-discharging plasma sintering on the alloy powder obtained in the step (2) to obtain compact and blocky SiGe alloy thermoelectric material. The invention has the advantages of simple process, short preparation time, easily-controlled process parameters and high performance of the prepared material.

Owner:WUHAN UNIV OF TECH

Method for producing nano-iron powder

A process for preparing Fe nanoparticles from carbonyl iron includes such steps as heating the carbonyl iron to become vapor, mixing it with CO gas, feeding the mixture into a decomposing apparatus, and hot decomposing while controlling the internal temp and pressure to be 150-400 deg.C and 1-10 KPa.

Owner:JINCHUAN GROUP LIMITED

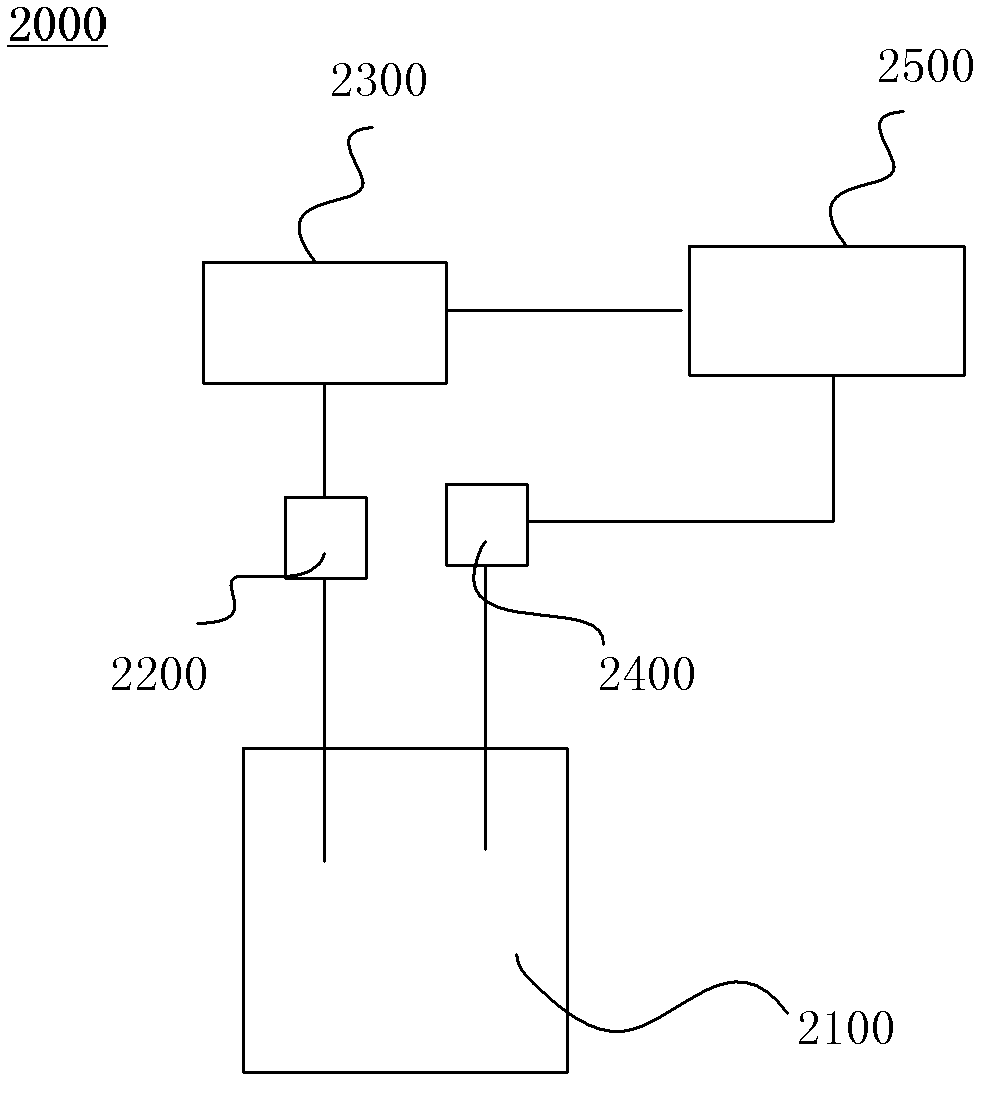

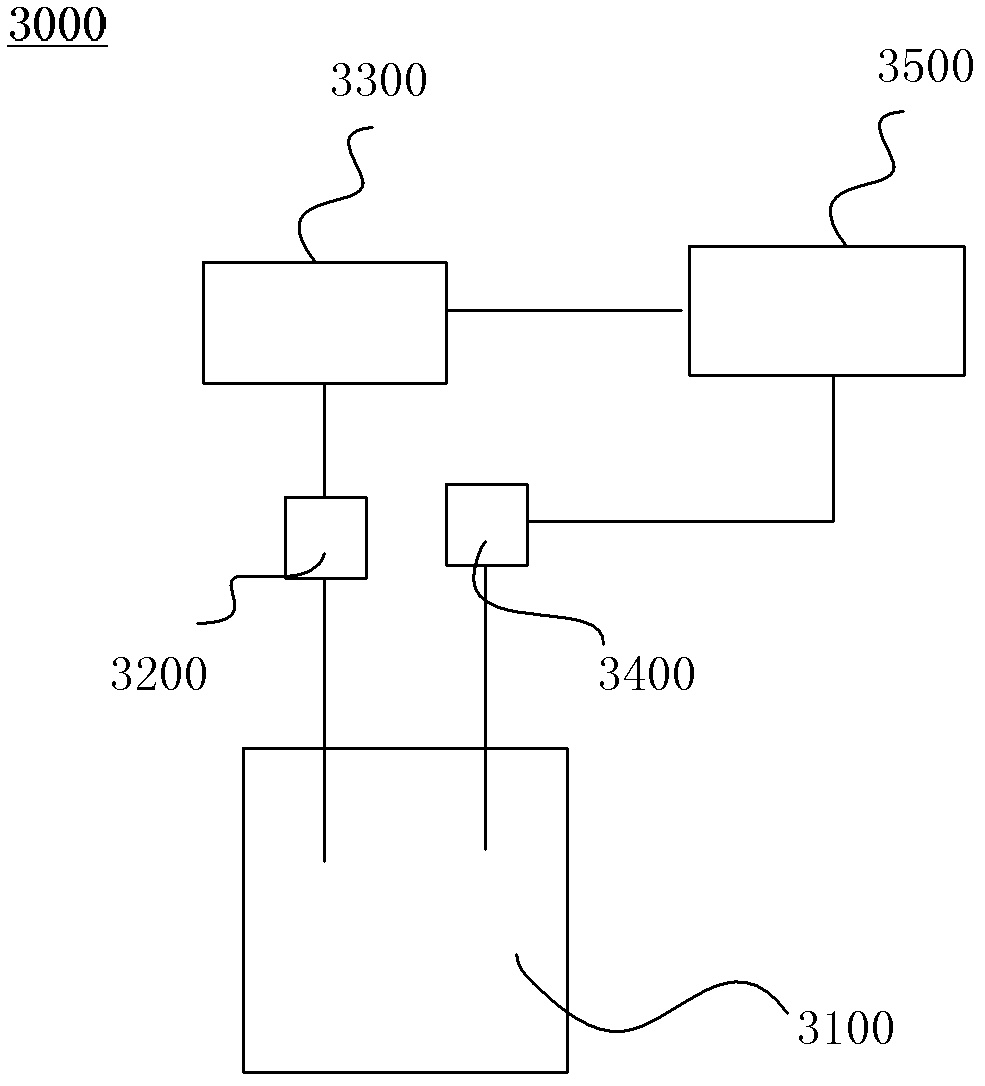

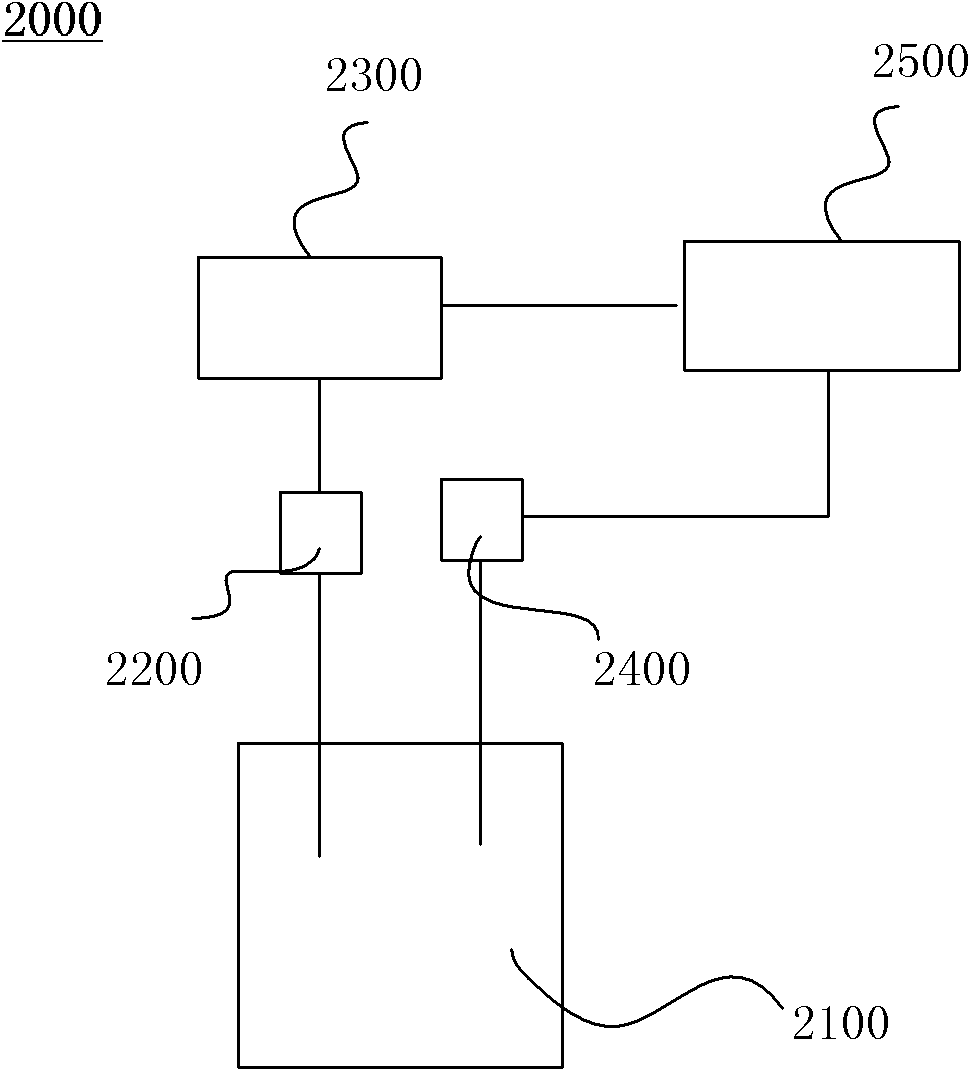

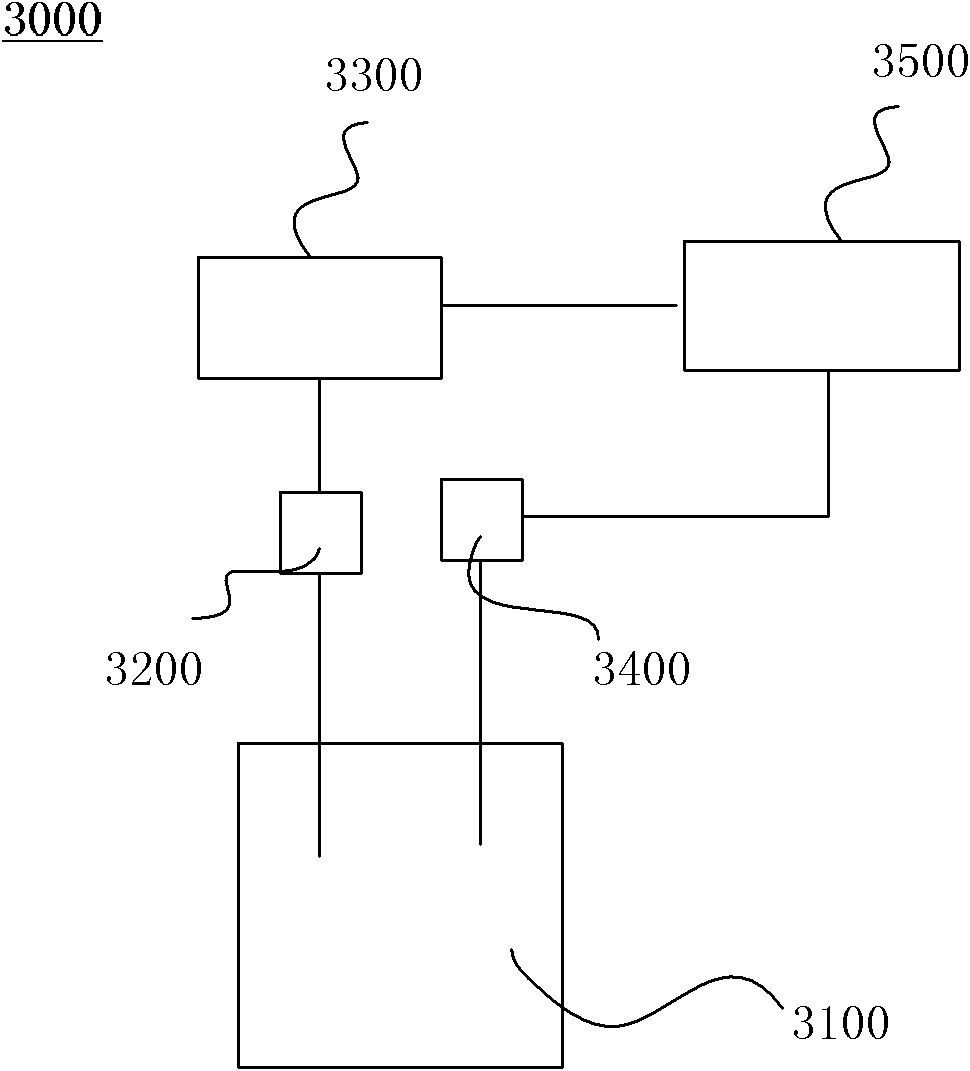

Method of Producing a Polypeptide or Virus of Interest in a Continuous Cell Culture

Described herein is a chemostat-like continuous cell culture system that combines certain advantages of perfusion open systems and chemostat open systems to improve the culturing of mammalian cells, e.g., genetically modified cells, particularly in serum-free or chemically-defined media. The continuous culture system described herein involves culturing mammalian cells in a continuous cell culture system, which comprises a cell retention device, wherein the cell culture system has a dilution rate (D) of less than about 2 d−1, and a cell density of less than about 2×107 cell / mL. Also described herein is a method for producing a polypeptide and / or virus of interest in a continuous cell culture, the method comprising culturing mammalian cells expressing the polypeptide and / or virus of interest in a continuous cell culture system, which comprises a cell retention device, wherein the cell culture system has a dilution rate (D) of less than about 2 d−1, and a cell density of less than about 2×107 cell / mL; and recovering the polypeptide and / or virus of interest from medium of the cell culture system.

Owner:TAKEDA PHARMA CO LTD

Preparation method of nanocellulose antibacterial sustained-release film

InactiveCN109232931AInhibit microbial growthExtend food storage and preservation timeBiological growthChemistry

The invention discloses a preparation method of a nanocellulose antibacterial sustained-release film. The method comprises the following steps: firstly, weighing 100 parts of nanocellulose colloid, 0.08 part of TEMPO powder and 0.52 part of NaBr powder, and diluting the substances with distilled water until the solid content is 1 percent; adding 0.4 to 4 parts of NaClO solution, adjusting and keeping a pH value of the system to 10, adding absolute ethyl alcohol and enabling the reaction to be ended; then centrifugally washing to obtain nanocellulose oxide; secondly, taking the nanocellulose colloid and a nanocellulose oxide sustained-release control agent, mixing and diluting until the solid content is 1 percent to obtain mixed nanocellulose suspension; thirdly, preparing a nisin solutionwith the concentration of 1 percent, adding the solution into the mixed nanocellulose suspension, and carrying out magnetic stirring to obtain a film forming liquid; fourthly, pouring the film formingliquid into a die and drying to obtain the nanocellulose antibacterial sustained-release film. The antibacterial sustained-release film prepared by the preparation method disclosed by the invention has good mechanical properties and slow release function of an antibacterial agent and can effectively inhibit the growth of microorganisms.

Owner:GUANGXI UNIV

Meat duck compound feed and preparation method thereof

InactiveCN105146219ASolving Feather Pecking ProblemsGuaranteed healthy growthAnimal feeding stuffDigestionSoybean Phospholipids

The first aim of the invention is to provide a meat duck compound feed which is prepared from the following components by weight percent: corns, wheat, sorghum, corn DDGS, soybean meal, guar meal, cottonseed meal, complex enzyme preparation, calcium hydrogen phosphate, salt, soybean phospholipid oil, lysine, rock flour, methionine, threonine, microecologics and compound premix. According to the invention, due to the reasonable matching of all materials, especially the reasonable matching of guar meal and sorghum, all the materials sufficiently exert the efficacies; compound premix, compound enzyme preparation and microecologics are added to the formula, so that vitamin, trace elements and the like are further supplemented and the digestion utilization rate of the feed is improved. The second aim of the invention is to provide a preparation method of the meat duck feed, which adopts a simple process and is suitable for large-scale production; harmful organisms in the feed material can be killed, and the health of animals is benefited; pollution of excrement to the environment can be alleviated, feed cost and breeding cost can be lowered, and breeding benefits can be increased.

Owner:GUANGDONG XIANGDA CAMEL FEED CO LTD

Method for preparing high-strength boron carbide porous ceramics

The invention discloses a method for preparing high-strength boron carbide porous ceramics. The method comprises the following steps: (1) proportioning raw materials: 80-95wt% of boron carbide powder,0-3.0wt% of suspending agent, 3-15wt% of binder, 5-12wt% of sintering assistant and 0-12wt% of lubricant; (2) adding distilled water into the raw materials, and carrying out mixing in a ball mill orstirring mill, so as to obtain boron carbide slurry, wherein boron carbide granules 1# and boron carbide granules 2# in the boron carbide slurry are uniformly distributed and suspended; (3) subjectingthe boron carbide slurry to spraying granulation, and carrying out drying, so as to obtain boron carbide powder with fluidity; (4) molding the boron carbide powder, so as to obtain boron carbide biscuits; and (5) placing the boron carbide biscuits into a vacuum or atmosphere no-pressure sintering furnace. According to the method, the weak points that the quantity of sealed pores is large, a ceramic matrix is complicated in ingredient, the strength is low, and the like can be overcome, and boron carbide can have more extensive application.

Owner:NINGBO VULCAN TECH CO LTD

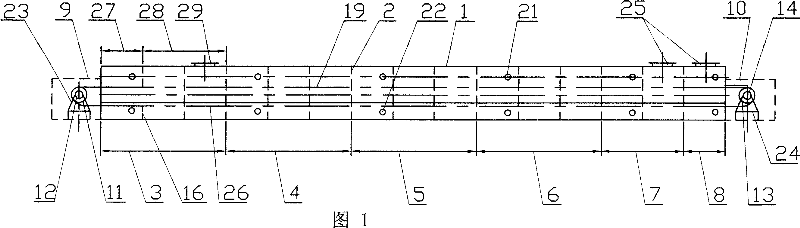

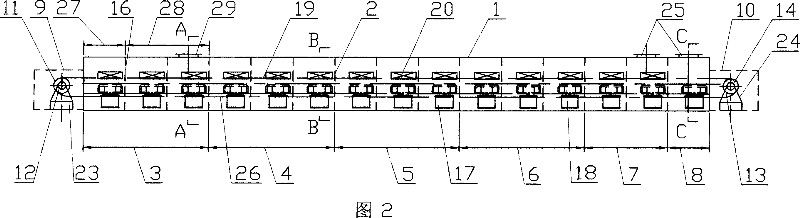

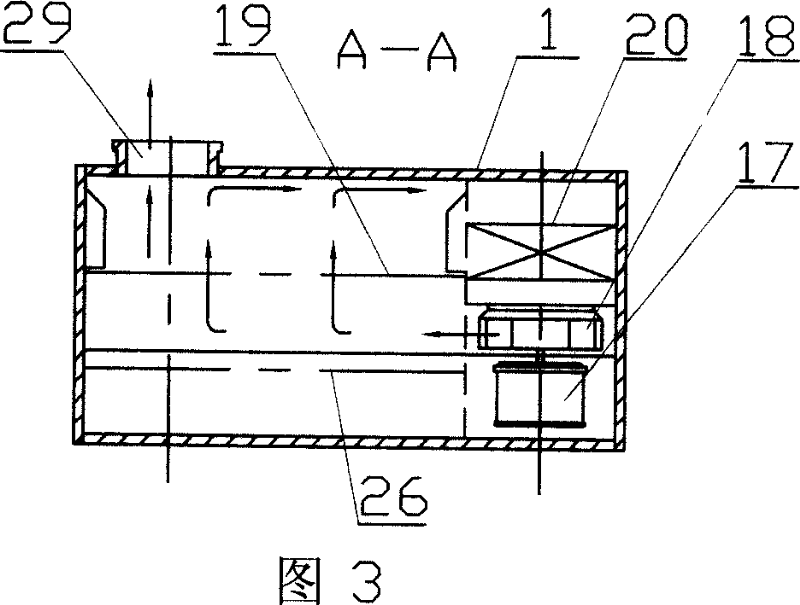

Internal recycling drying machine of rubber raw materials

InactiveCN101038127ALow costTo achieve the purpose of energy savingDrying solid materials with heatDrying machines with progressive movementsFeed driveButadiene-styrene rubber

A rubber material internal circulation drying machine relates to a rubber material drying machine. Aiming at the problem that the existing direct discharging rubber material drying machine has big heat consume and high maintain cost. The front and rear of a box (1) of the present invention are disposed with a feeding drive device (9) and a discharging drive device (10) connected by a material conveyer belt. The box (1) is divided into five drying chambers and one cooling chamber (8) by a frame (2). The fifth drying chamber (7) and the cooling chamber (8) are disposed with air inlets (25). The first drying chamber (3) is composed of a first front drying chamber (27) and a first rear drying chamber (28) which is disposed with air outlet (29). One side of the box (1) is mounted with a motor (17) and a blower (18). A heat exchanger (20) is disposed in the box (1). An upper temperature measuring device (21) and a lower temperature measuring device (22) are disposed on the upper side and lower side of the material conveyer belt. Compared with the existing technology, the present invention can save energy by 30%, and can reduce manufacturing cost by 35% compared with the same kinds of products, and is especially adapted to drying process for nitrile-butadiene rubber and styrene-butadiene rubber.

Owner:HARBIN INST OF TECH

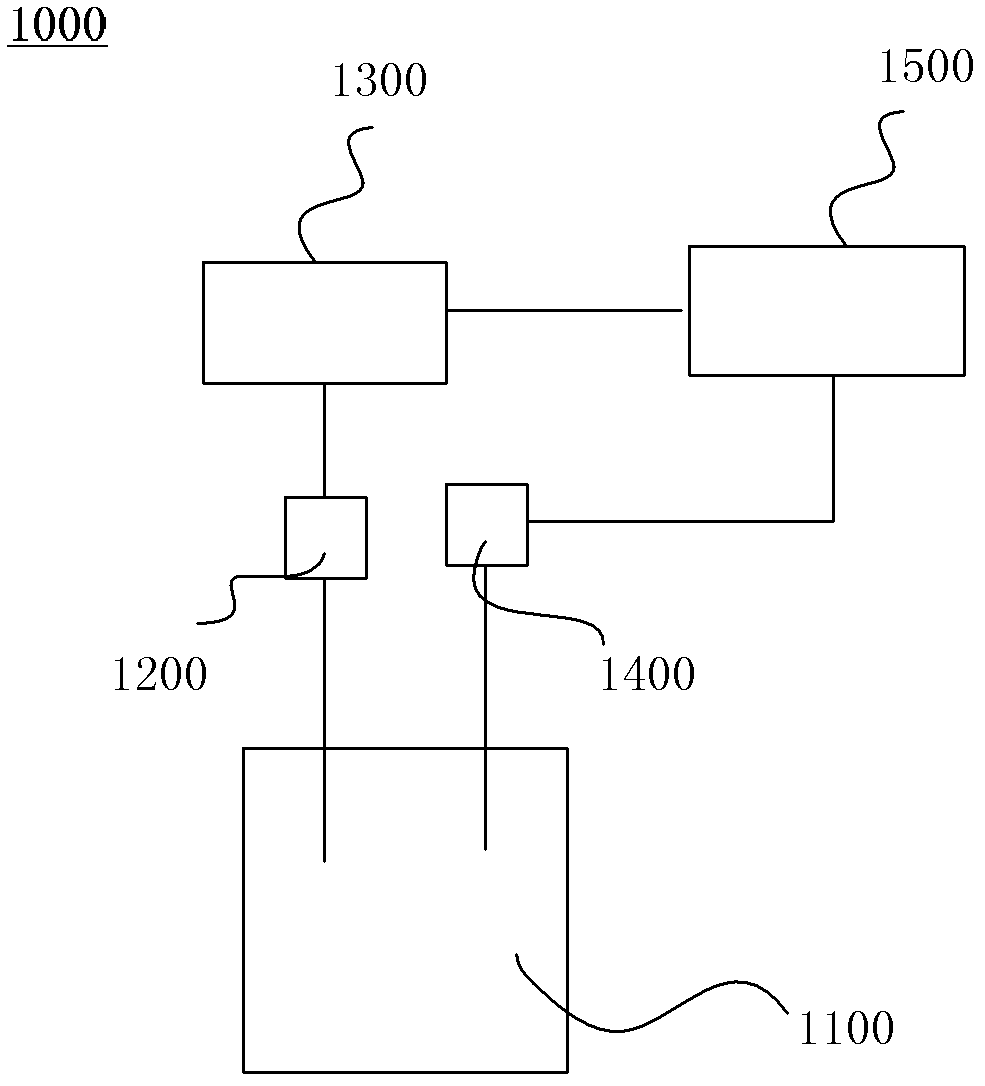

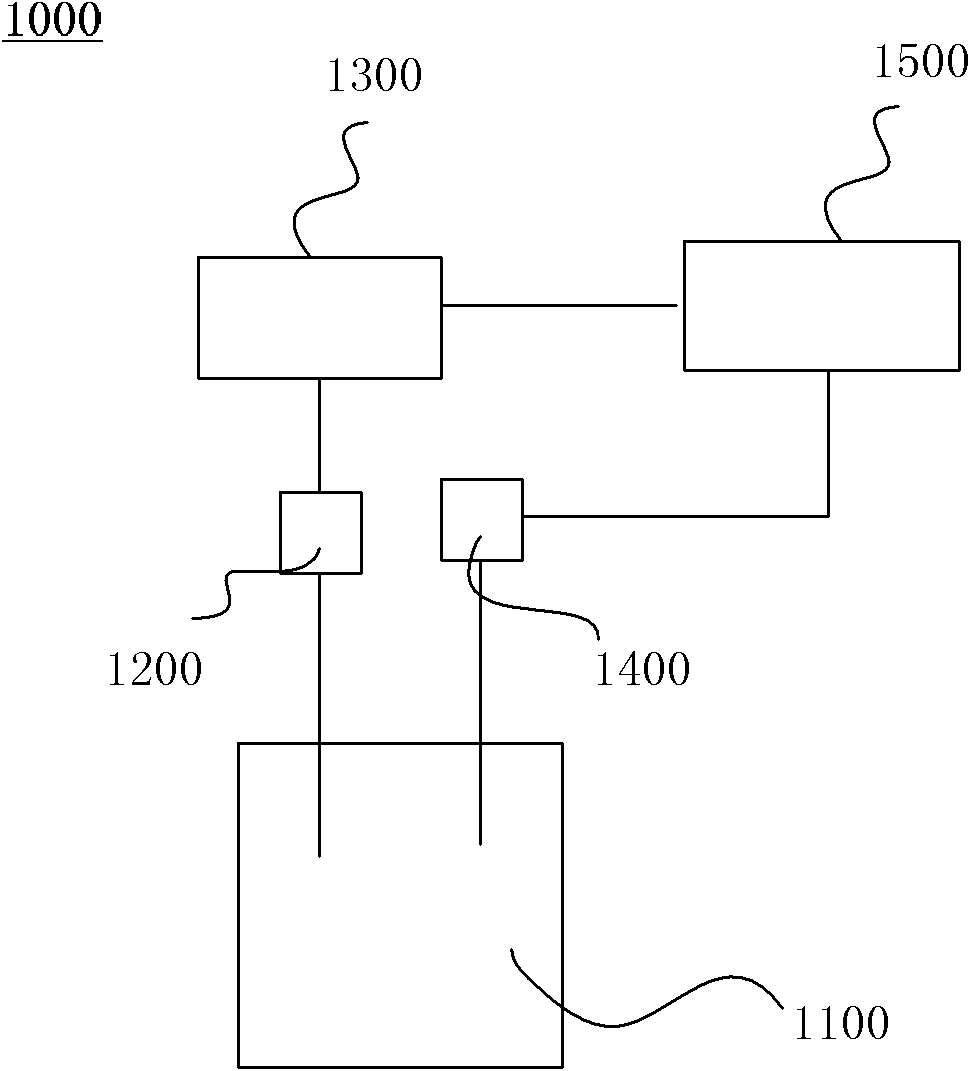

Free alkalinity control system and application thereof

InactiveCN102492944AControl monitoringIncrease concentrationPretreated surfacesMetallic material coating processesAlkalinityPretreatment method

The invention provides a free alkalinity control system and application thereof, particularly a free alkalinity control system and a pretreatment method for coating a metal workpiece. The free alkalinity control system comprises a sampling device, a titration apparatus, a feeding device and a free alkalinity control device. The system can effectively control the alkalinity in the reactor.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

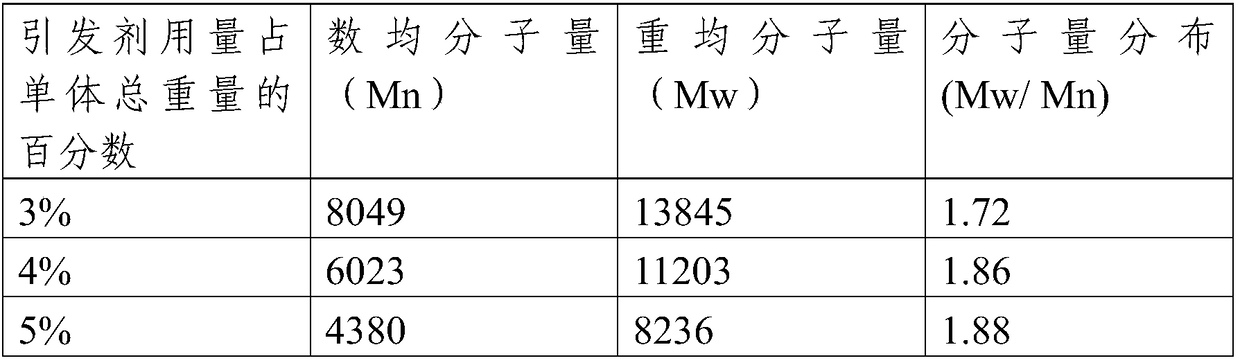

Method for synthesizing GMA acrylic resin by microchannel reaction

The invention relates to a method for synthesizing GMA acrylic resin by microchannel reaction. The method adopts an improved process of solution polymerization. Through the microchannel reaction process, the problems of difficult guaranteeing of safety of a reaction device, easy explosive polymerization of products and poor stability of the product quality caused by unstable release of reaction heat in solution polymerization are solved through the microchannel reaction process. At the same time, the molecular weight distribution of the polymer is narrow, and the polymer material performance is better.

Owner:山东柳湾新材料有限公司

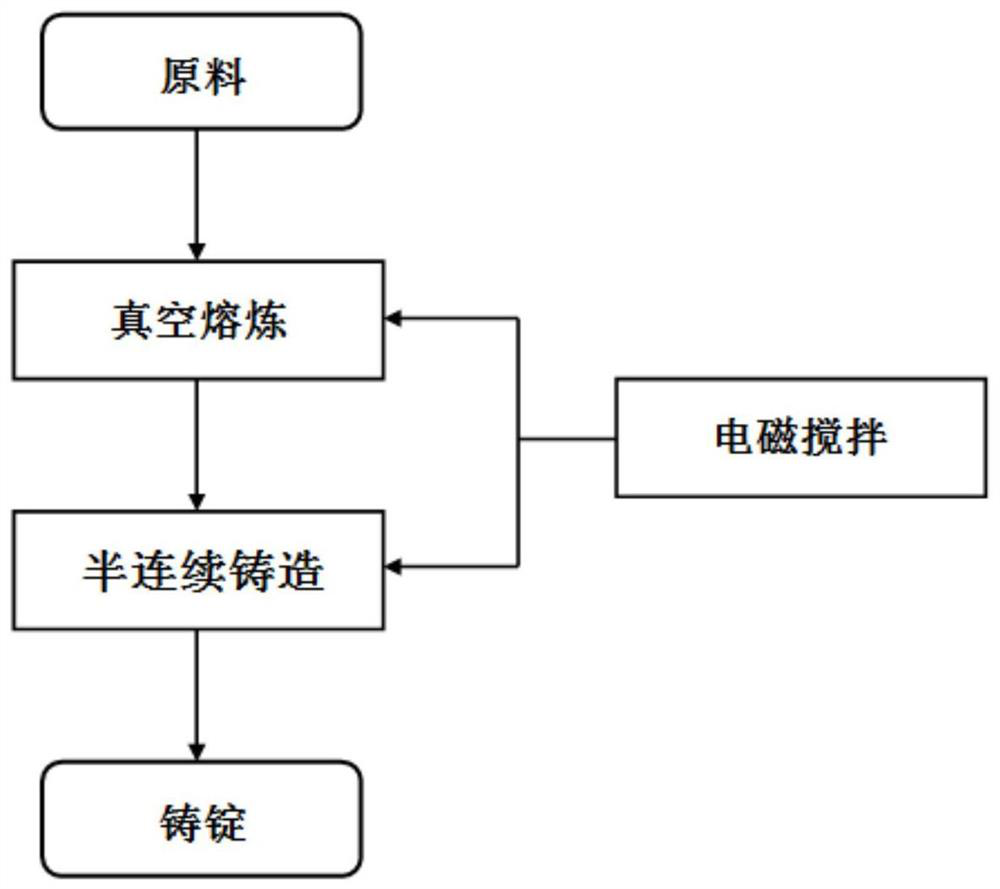

Manufacturing method of titanium bronze alloy cast ingot

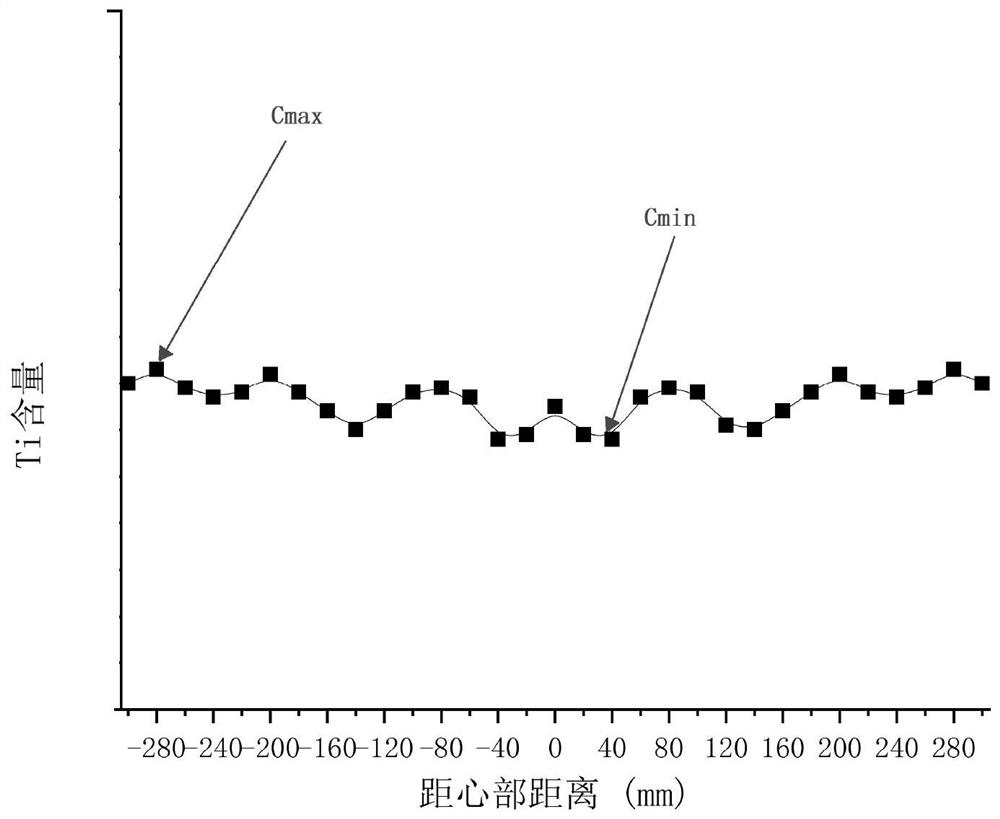

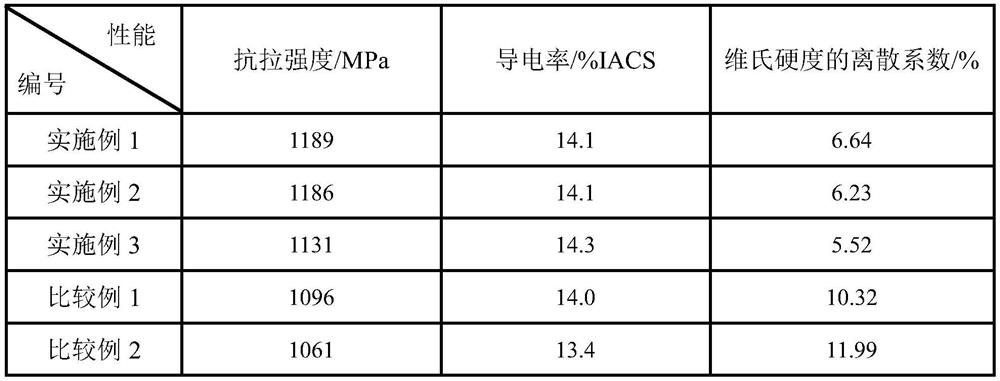

InactiveCN111992684AReduce center segregationReduce other casting defectsStirring devicesManufacturing technologyIngot

The invention discloses a manufacturing method of a titanium bronze alloy cast ingot. The titanium bronze alloy cast ingot is manufactured through vacuum melting and semi-continuous casting, and electromagnetic stirring operation is adopted for auxiliary production in the vacuum melting process and the semi-continuous casting process. In the vacuum melting process, the vacuum degree is controlledto range from 10<-3>Pa to 10Pa, and the vacuum melting temperature is controlled to range from 1100 DEG C to 1400 DEG C. In the semi-continuous casting process, the pull casting temperature is controlled to range from 1000 DEG C to 1200 DEG C, and the pull casting speed is controlled to range from 20mm / min to 120mm / min. According to the manufacturing method of the titanium bronze alloy cast ingot,by means of the optimized manufacturing technology, the macrosegregation tendency of titanium bronze alloy is controlled, the macrosegregation rate of the titanium bronze alloy cast ingot is controlled to be 8% or below, the dispersion coefficient of the vickers hardness of the cross section of a finished strip is smaller than or equal to 7%, the comprehensive performance of the titanium bronze alloy cast ingot is obviously improved, the production cost of the titanium bronze alloy cast ingot is reduced, and the good application prospect is provided for titanium bronze alloy products.

Owner:宁波博威新材料有限公司

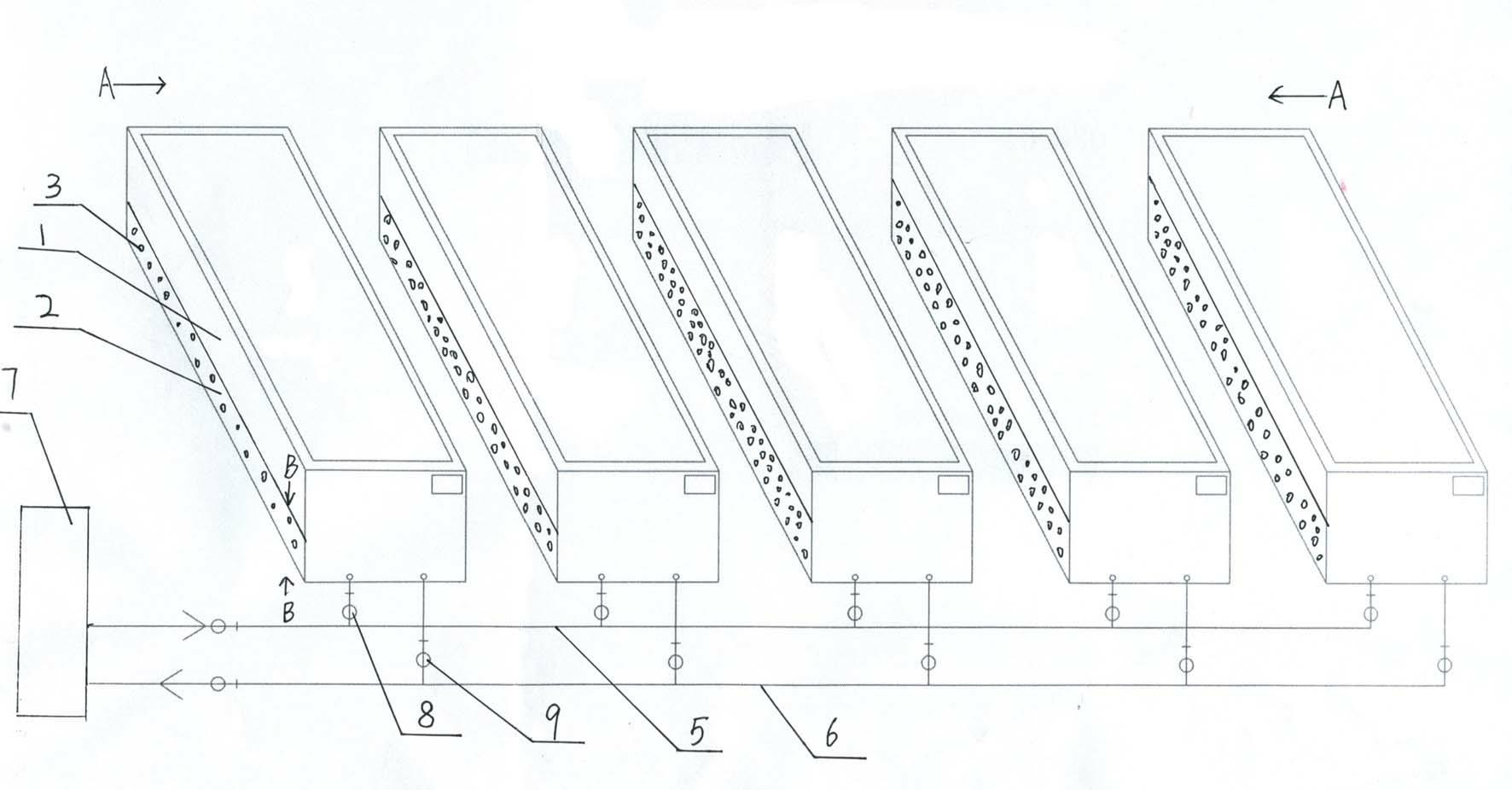

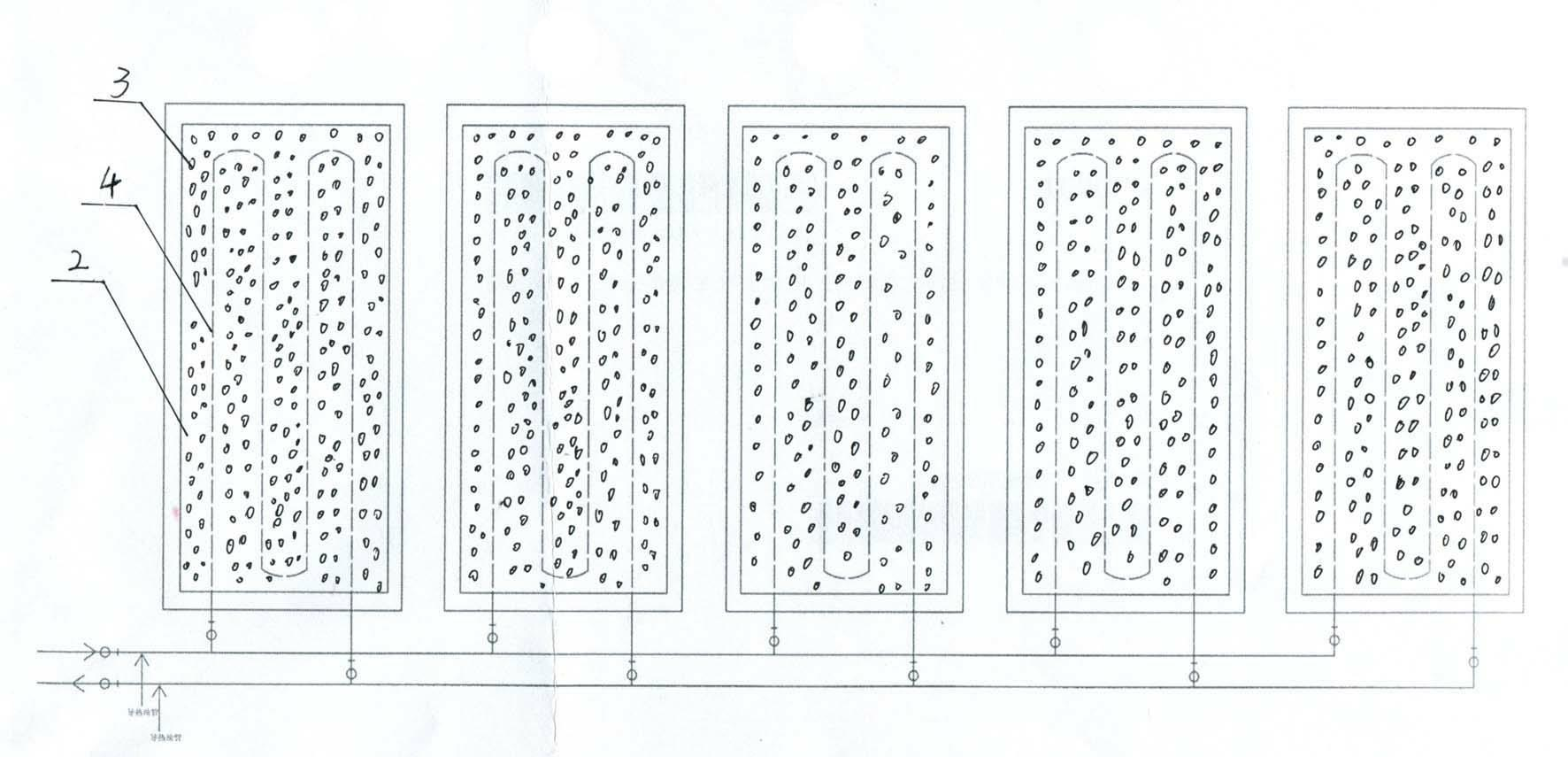

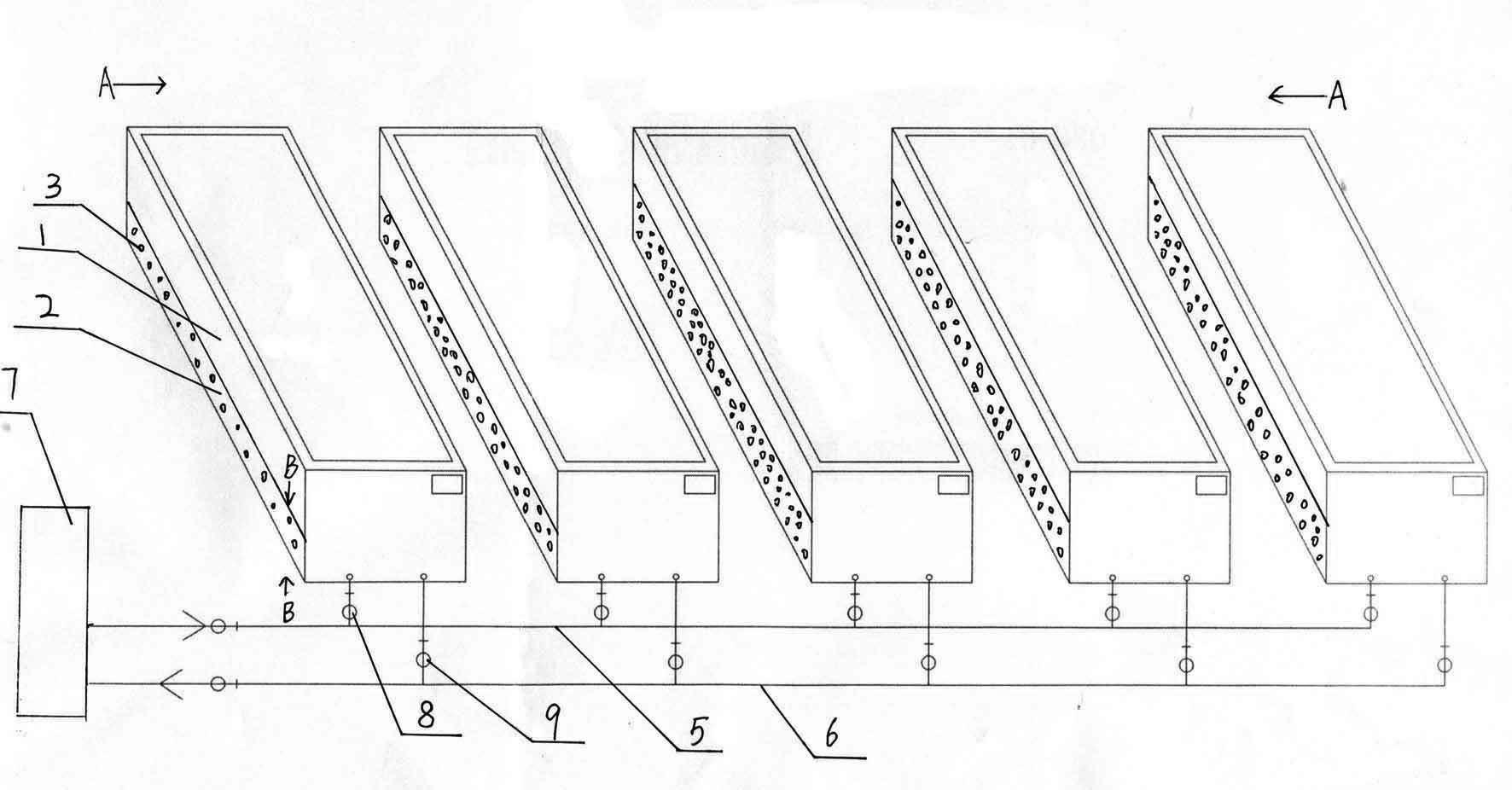

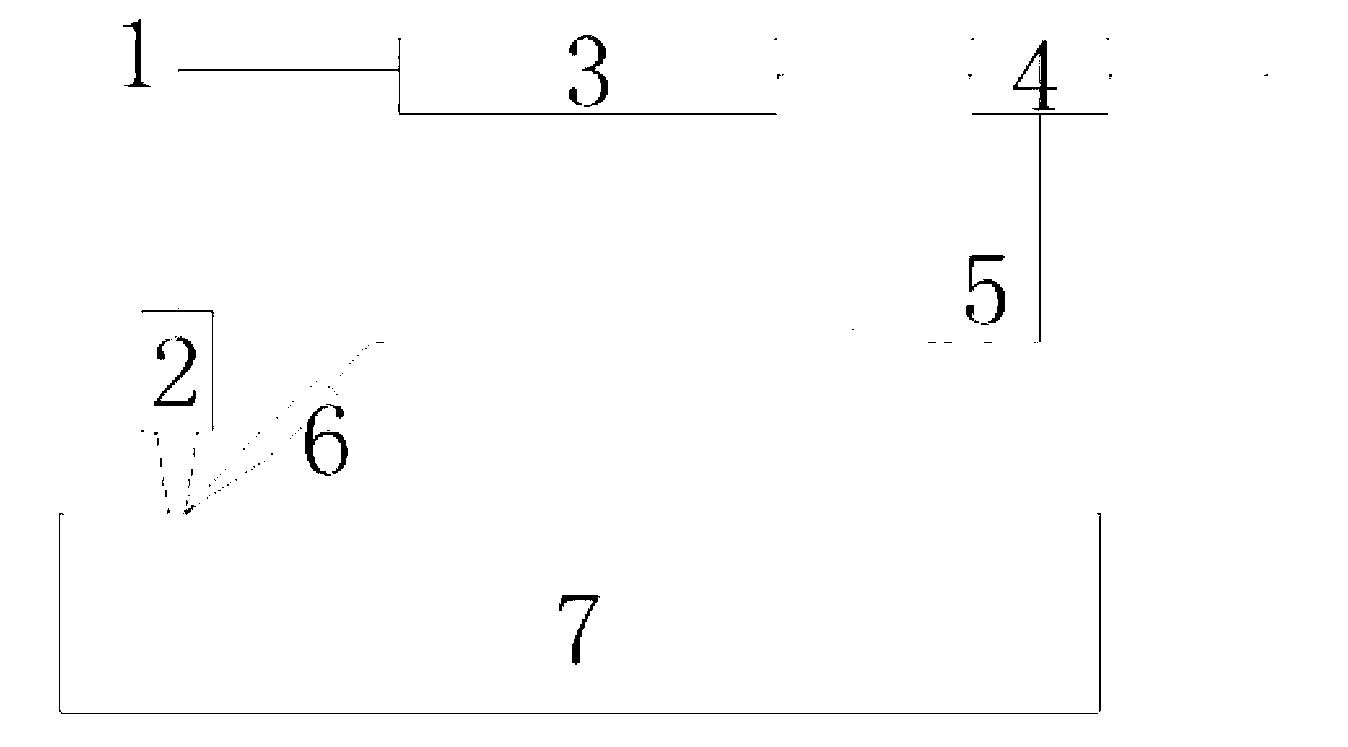

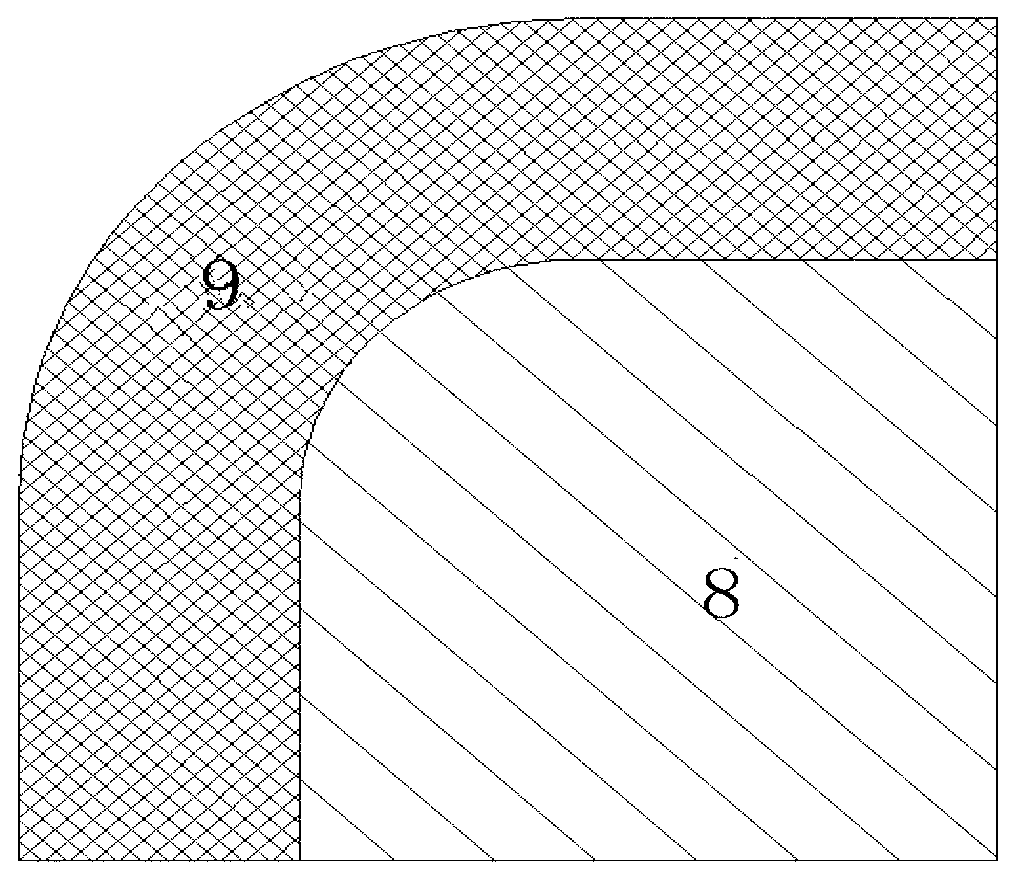

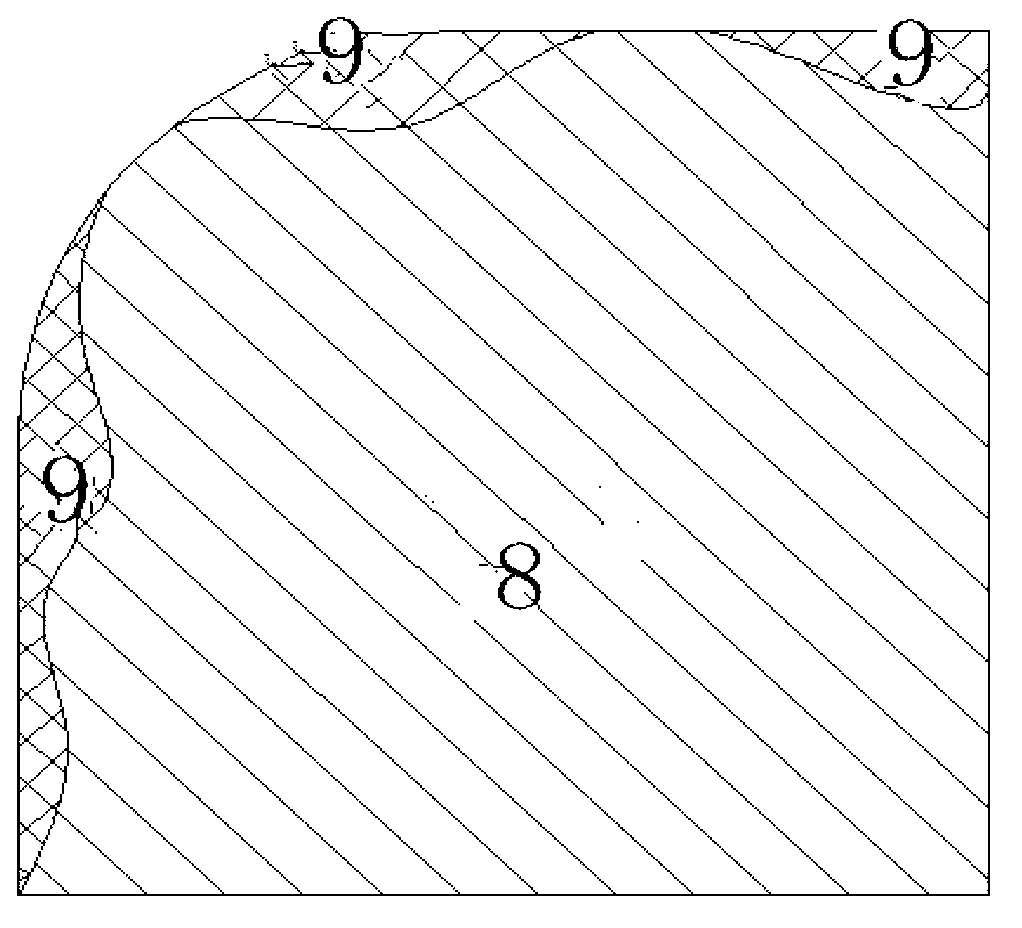

Fumigating ferment pool for brewing vinegar

InactiveCN102559475ATemperature controlProcess parameter controlVinegar preparationHeating oilBrewing

The invention belongs to the technical field of mature vinegar brewing devices and particularly relates to a fumigating ferment pool for brewing vinegar. The invention mainly solves the problems of high labor intensity, low working efficiency and high production cost found in a traditional vat used for fumigation. The invention adopts the following technical scheme: the fumigating ferment pool for brewing the vinegar comprises multiple fumigating ferment pools, wherein an interlayer is arranged on the lower part of each fumigating ferment pool, heat transfer oil is filled in each interlayer, a heating oil pipe which is not communicated with the heat transfer oil is arranged in each interlayer, the inlet of the heating oil pipe is connected with an oil inlet pipe through an oil inlet pump, the outlet of the heating oil pipe is connected with an oil outlet pipe through an oil outlet pump, the oil inlet pipe is connected with the outlet of a boiler, and the oil outlet pipe is connected with the inlet of the boiler. With the adoption of the technical scheme, the heat transfer oil in the interlayer of each fumigating ferment pool is utilized to brew vinegar through fumigating ferment, so that the temperature of the heat transfer oil can be effectively controlled, and further, the technological parameters of vinegar brewing are controlled, the labor force can be saved and the production cost can be reduced.

Owner:SHANXI LAOCHENYIHAO BIOLOGICAL SCI & TECH CO LTD

Full-automatic high-energy laser surface hardening system

InactiveCN103290177ANo post-processing requiredEliminate process development processLoop controlClosed loop

The invention discloses a full-automatic high-energy laser surface hardening system. The common high-energy laser surface hardening is an open loop process, and under the conventional equipment conditions, because of the problems of uniformity, curved surface, corner, transitional surfaces and the like of the workpiece surface material, the heating temperature is non-uniform, the hardening surface is warped, the thermal deformation is large, even the local surface is molten, and the original precision of a workpiece is damaged. The laser light wave frequency signal is measured, and the central temperature of light spots is detected, so that the workpiece surface temperature is tracked in real time, the laser output power is controlled through the automatic laser power regulation system, and the peak value of the workpiece surface temperature is controlled in a small range; moreover, an automatic laser processing system established on the surface temperature closed-loop control system comprises high-energy laser, a real-time surface temperature monitoring system, a feedback system and an automatic laser power regulation system. According to the workpiece surface hardened by the system, because the surface laser power is effectively controlled, the hardening layer is uniform, the thermal deformation is small, and the machining precision requirement is met.

Owner:张家港和昊管理咨询有限公司

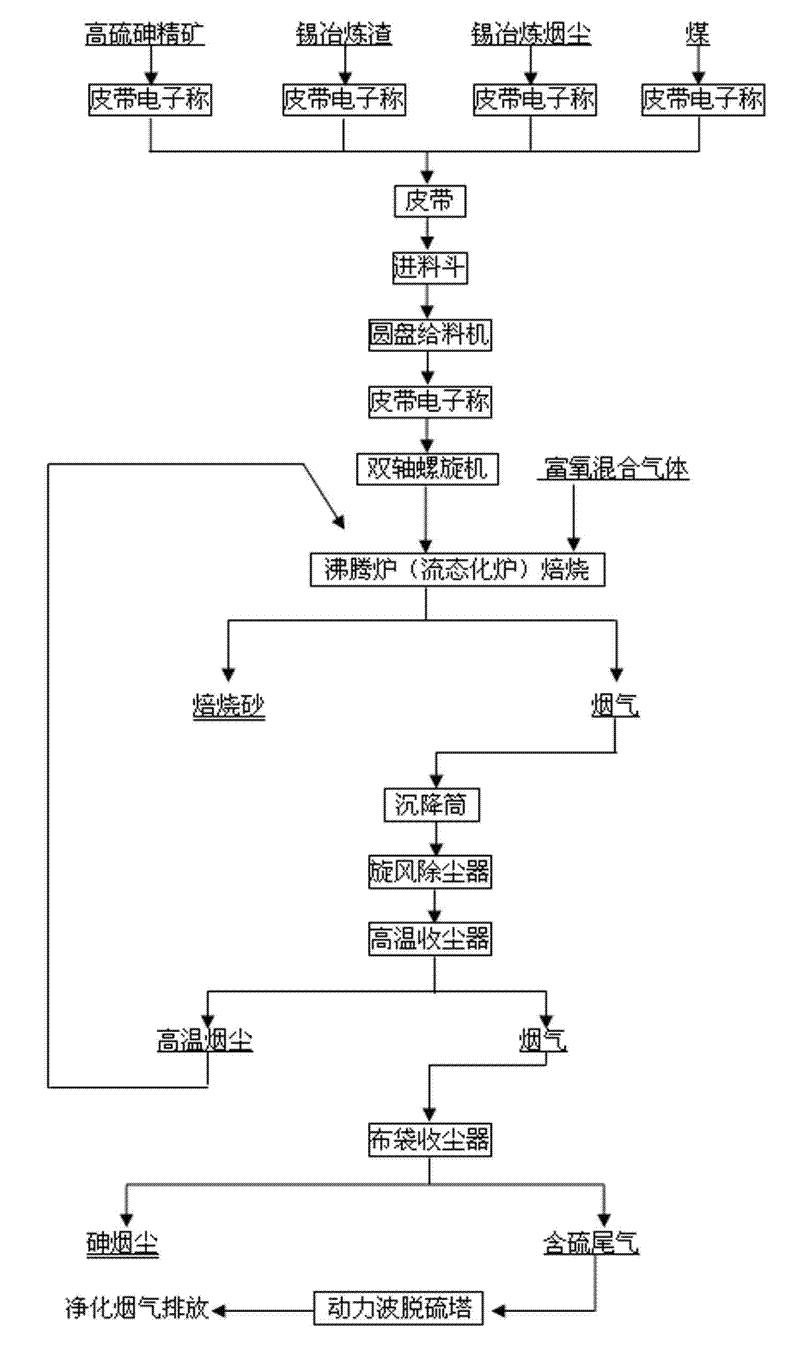

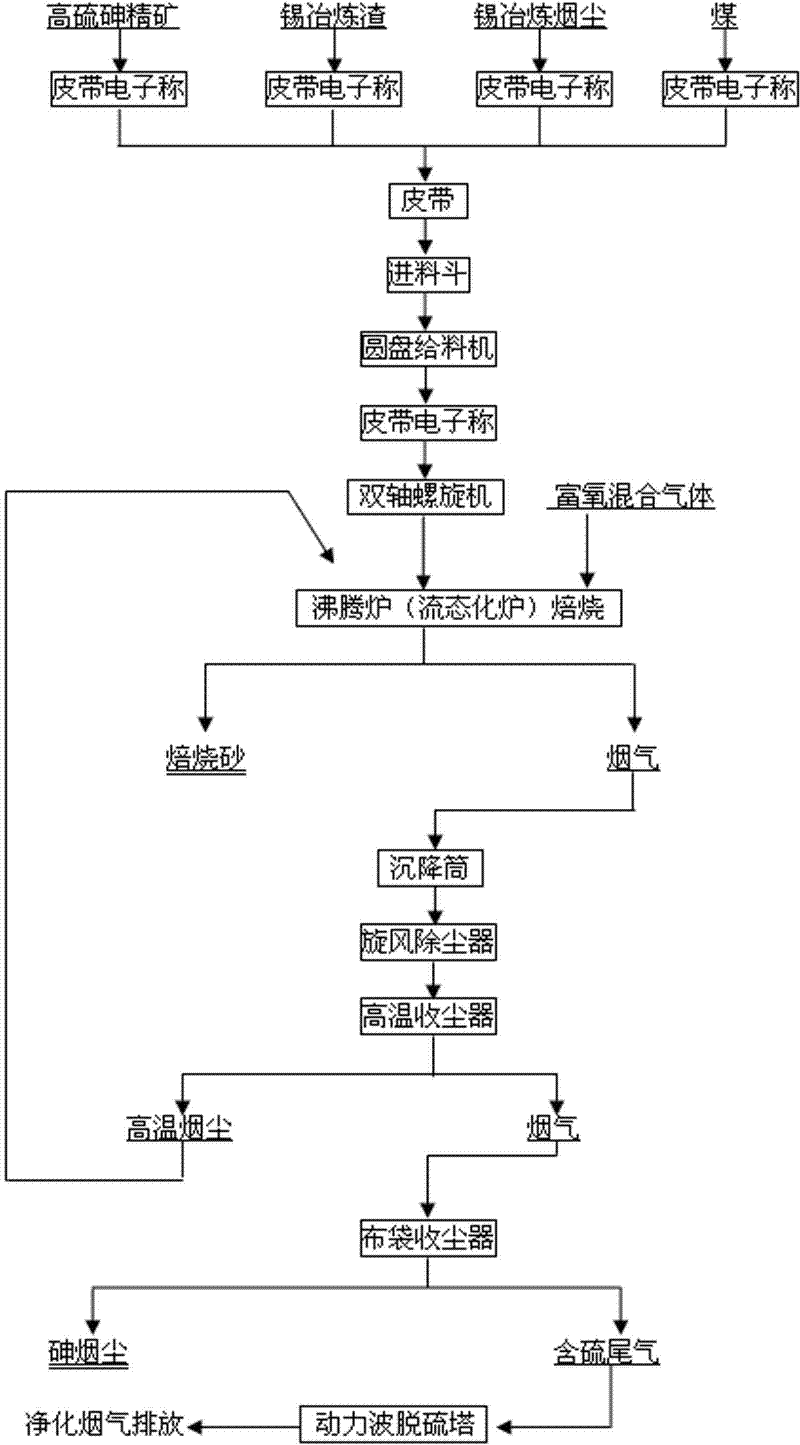

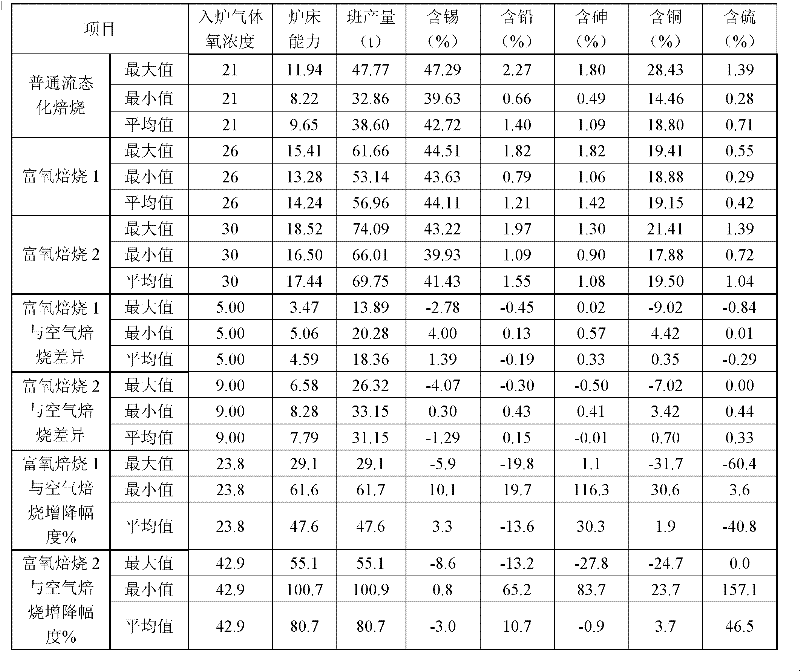

Method for roasting tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen

InactiveCN102230074AIncrease the furnace concentrationReduce the amount of furnaceProcess efficiency improvementExhaust gasArsenic

The invention belongs to the technical field of tin metallurgy, in particular relates to a novel method for roasting a tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen. The method comprises the following steps of: mixing oxygen into a charged gas of a fluidized furnace; controlling the oxygen quantity to reach 22-45 wt% of the total charged gas; carrying out oxygen-enriched fluidized roasting on the material at 600-1000 DEG C; and adding the oxygen in such a way that the quantity of the charged air is gradually reduced and the oxygen quantity is gradually increased so that the total charged gas is invariable and the oxygen concentration satisfies the process parameters while a charging system is started for charging. According to the invention, the arsenic and sulfur removing rate can be effectively increased, the roasting quality can be improved, the smoke gas quantity generated by treatment of the unit material can be reduced, the heat loss can be reduced, the heat utilization rate can be increased, the furnace hearth capacity can be improved without increasing the area of the furnace hearth, the treatment quantity can be increased and the production efficiency can be enhanced; meanwhile, the concentration of SO2 in the smoke gas can be increased so that the problems of low SO2 concentration in the tail gas, unfavorable acid making and environment pollution can be solved to change the harm into the treasure in the tail gas acid making.

Owner:YUNNAN TIN GROUP HLDG

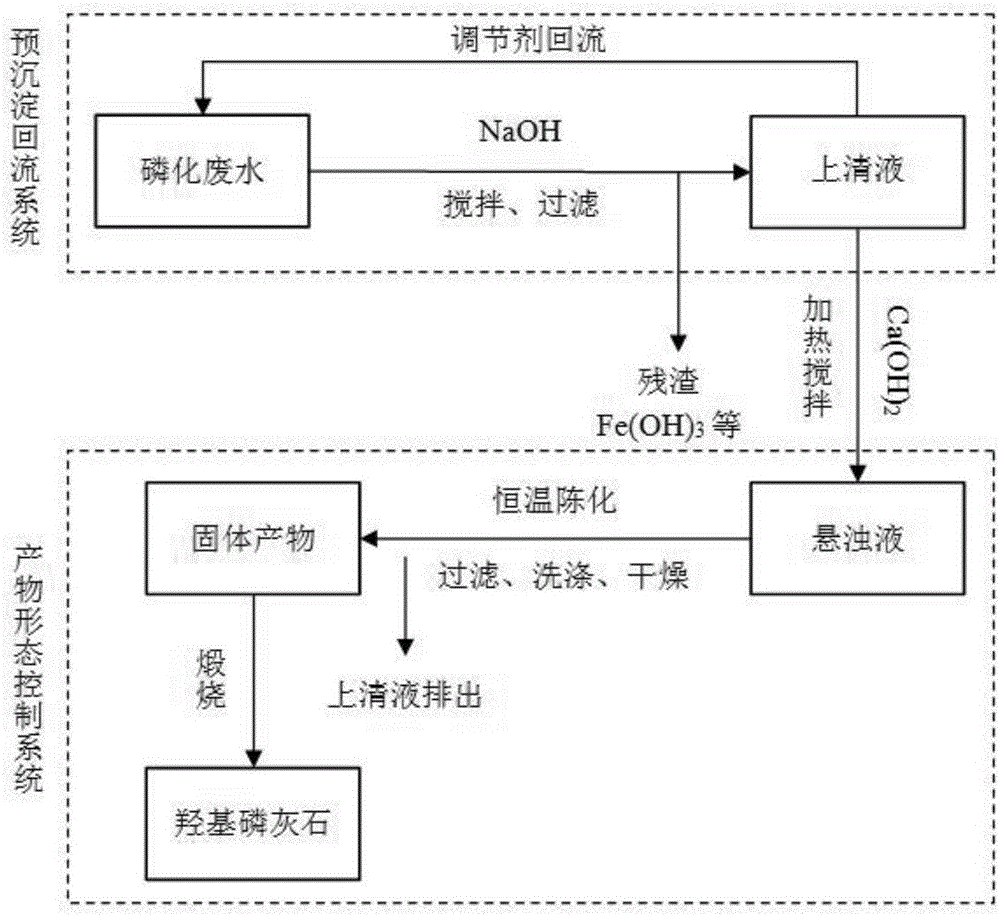

Technological method for preparing hydroxyapatite by using phosphating waste water as raw material

InactiveCN106586994AAvoid interferenceGuaranteed purityWater/sewage treatment by flocculation/precipitationPhosphorus compoundsHigh concentrationEmission standard

The invention relates to a technological method for preparing hydroxyapatite by using phosphating waste water as a raw material. Aiming at high concentration phosphating waste water, the method is used for disposing the high concentration phosphating waste water with NaOH as a regulator and Ca(OH)2 as a precipitant, and preparing hydroxyapatite at the same time. Fractional precipitation and a product morphology control method are adopted to ensure the purity of the hydroxyapatite and improve the quality of the hydroxyapatite. Simple in process and operation, the method can not only remove most PO4<3-> and heavy metal ions in phosphating waste water to make effluent quality up to an emission standard but also recycle the by-products, so that the method has good economic benefits and application prospects.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

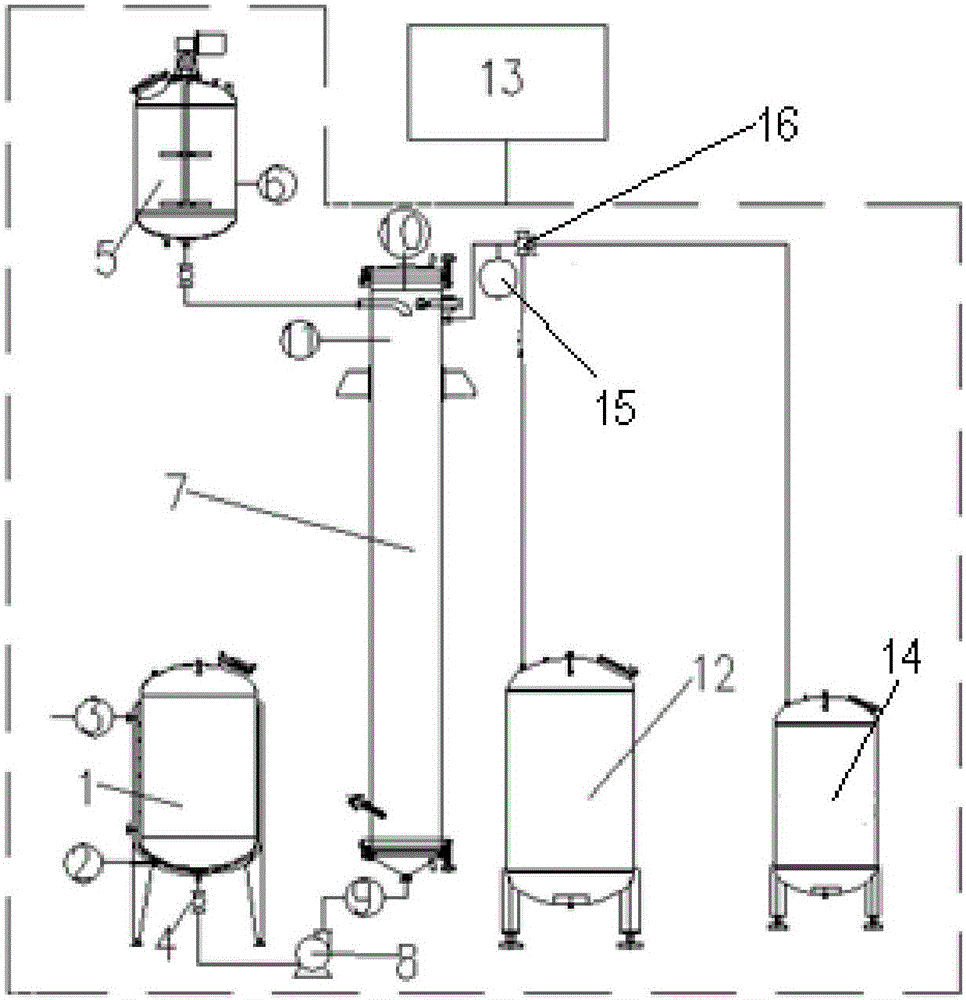

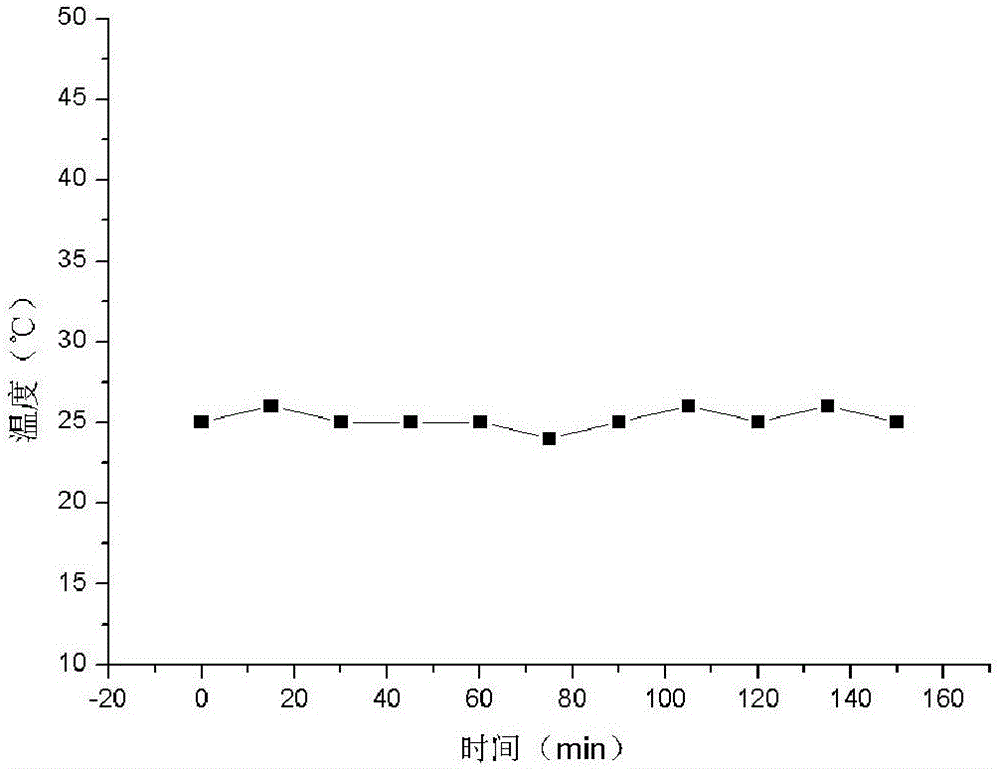

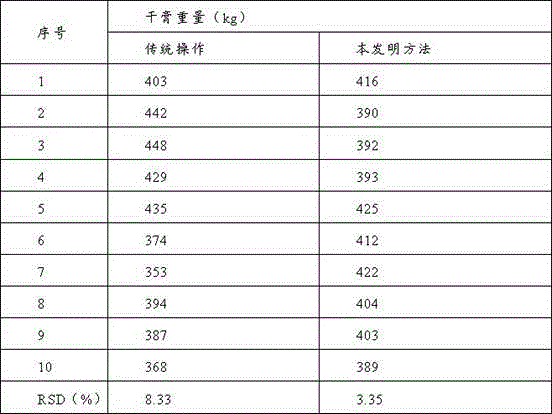

Control method and device of serinus mozambicus mozambicus extract extraction technology

ActiveCN106362433AEvenly distributedSmall standard deviationSolid solvent extractionPlant ingredientsTemperature controlEthyl ester

The invention provides a method and device of a serinus mozambicus mozambicus extract extraction technology. The method and device can achieve continuous and stable extraction of a serinus mozambicus mozambicus extract. The control method of the serinus mozambicus mozambicus extract extraction technology comprises the following steps of 1, extracting agent preparation control, wherein water saturation ethyl acetate is prepared inside a preparation tank to be adopted as an extracting agent; 2, extraction tower constant volume control, wherein a weighing sensor is arranged inside an extract storage tank, the total weight of the extract is worked out, and the extract is uniformly distributed into extraction columns of the extraction tower through a weight reduction method; 3, extraction control, wherein the extracting agent in the step 1 is added into the extraction tower, and when the addition amount of water saturation ethyl acetate added into the extraction tower reaches the total volume of the extraction tower, the extraction process is ended; 4, extracting agent temperature control, wherein the real-time temperature of the extracting agent inside the extraction tower is detected, and when the real-time temperature of the extracting agent inside the extraction tower is lower than a set value, the temperature of the extracting agent inside the preparation tank is regulated; 5, extraction tower liquid level control, wherein when the liquid level reaches the high level, an alarm is given or extraction is stopped.

Owner:JIANGSU KANION PHARMA CO LTD

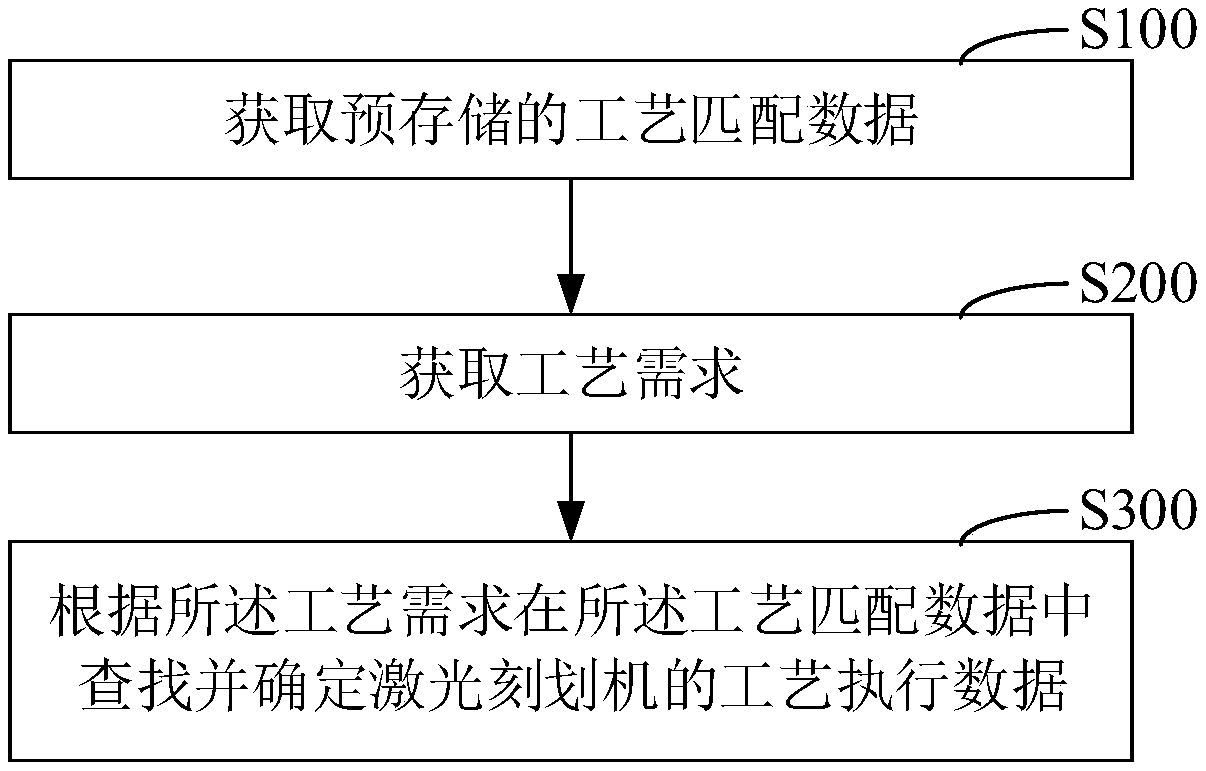

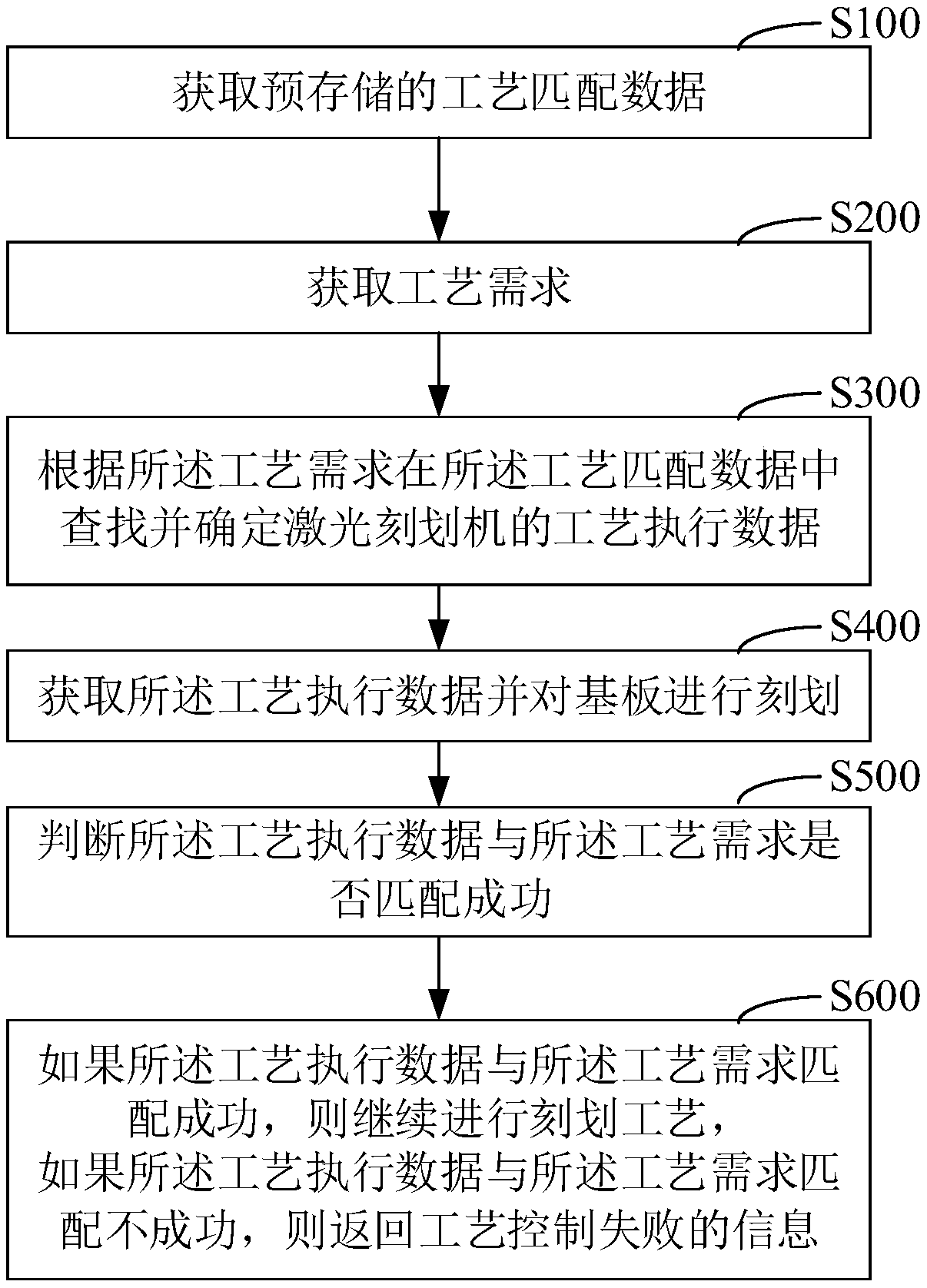

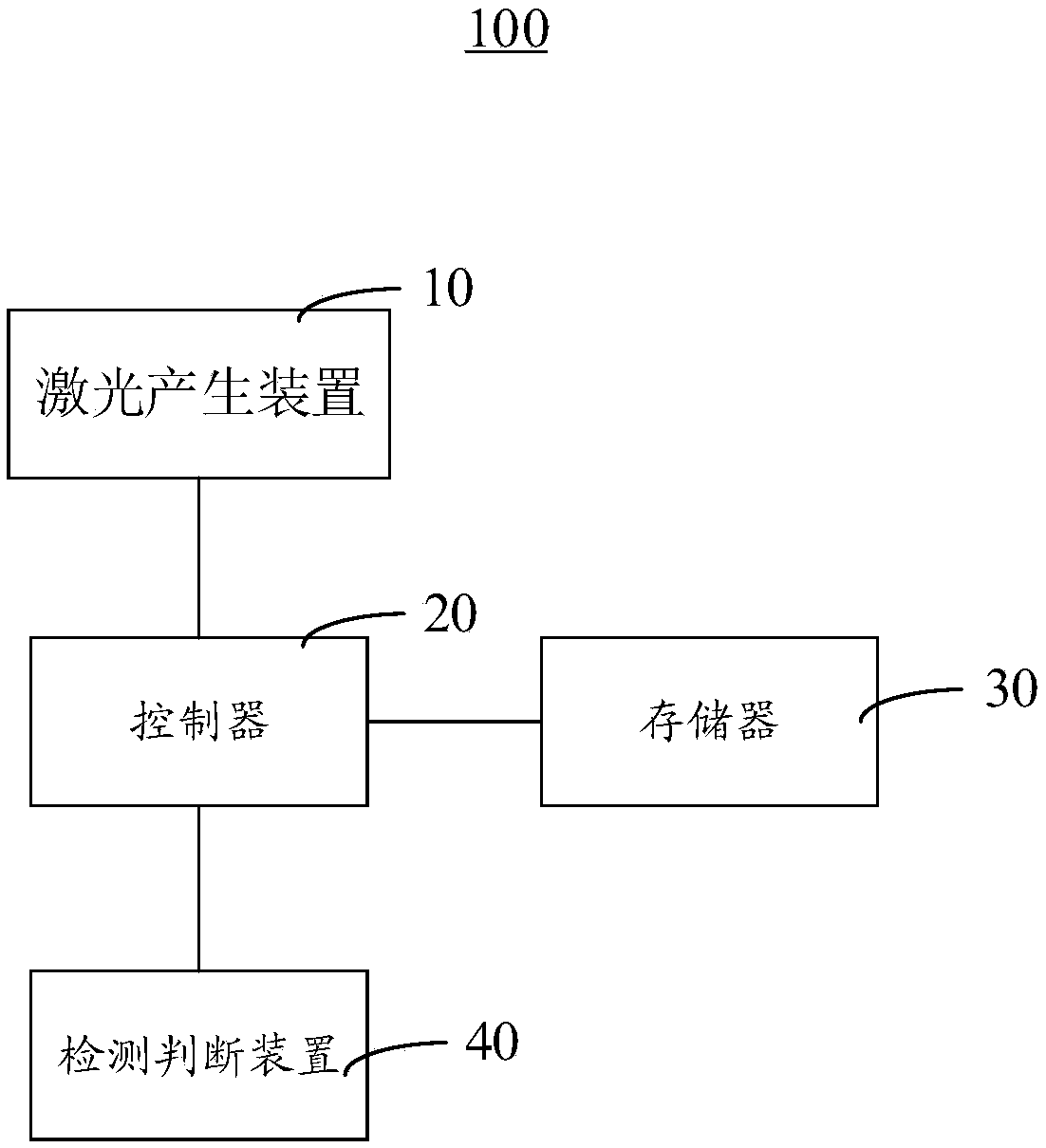

Laser scribing machine and evaluation method of process capability of laser scribing machine

InactiveCN109128518AProcess parameter controlPrecise Laser Scribing ProcessResourcesLaser beam welding apparatusLaser scribingEngineering

The invention relates to a laser scribing machine and an evaluation method of the process capability of the laser scribing machine. According to the evaluation method for the process capability of thelaser scribing machine, process execution data of the laser scribing machine can be found and determined in process matching data according to process requirements, and process parameters of the laser scribing machine can be quickly and accurately controlled. A controller of the laser scribing machine obtains the process requirements. The pre-stored process matching data is obtained from the laser scribing machine. Parameters corresponding to the process requirements are selected from the process matching data, and the laser scribing machine is made to carry out laser irradiation, so that anaccurate laser scribing process is achieved. The evaluation method of the process capability of the laser scribing machine is simple and easy to operate, various factors can be comprehensively considered to pre-store the process matching data, and the process parameters of the laser scribing machine can be quickly and accurately controlled.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

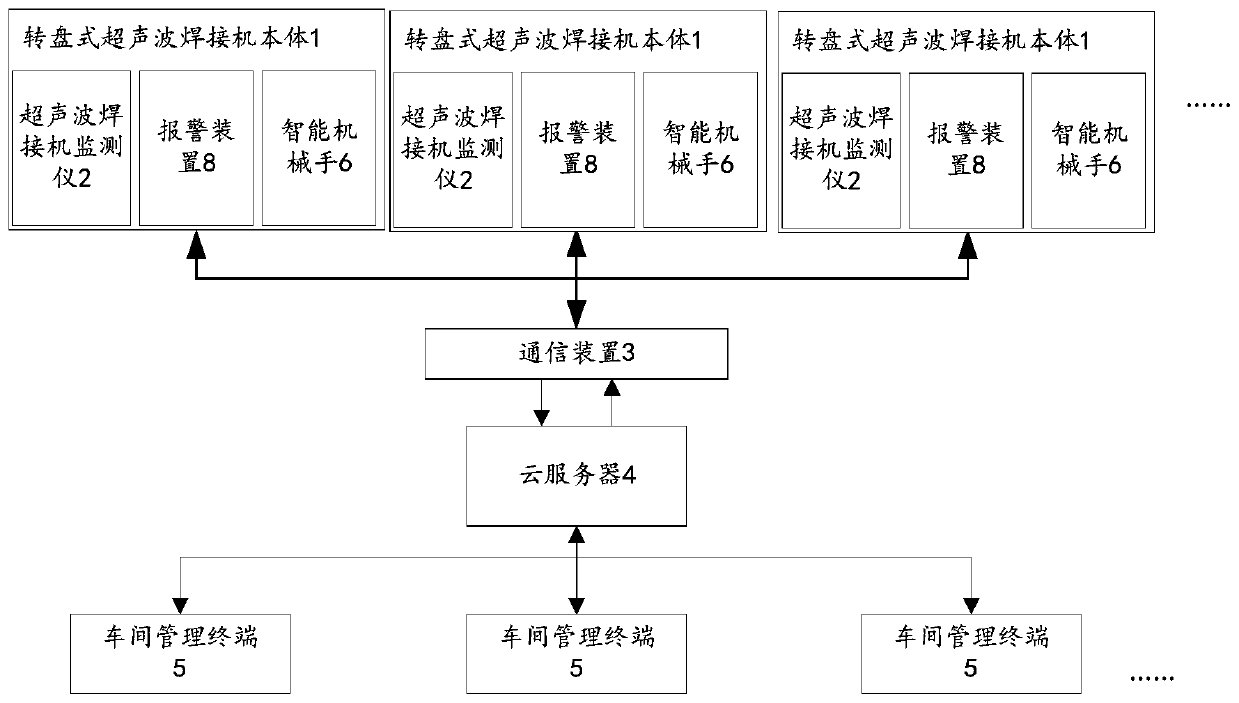

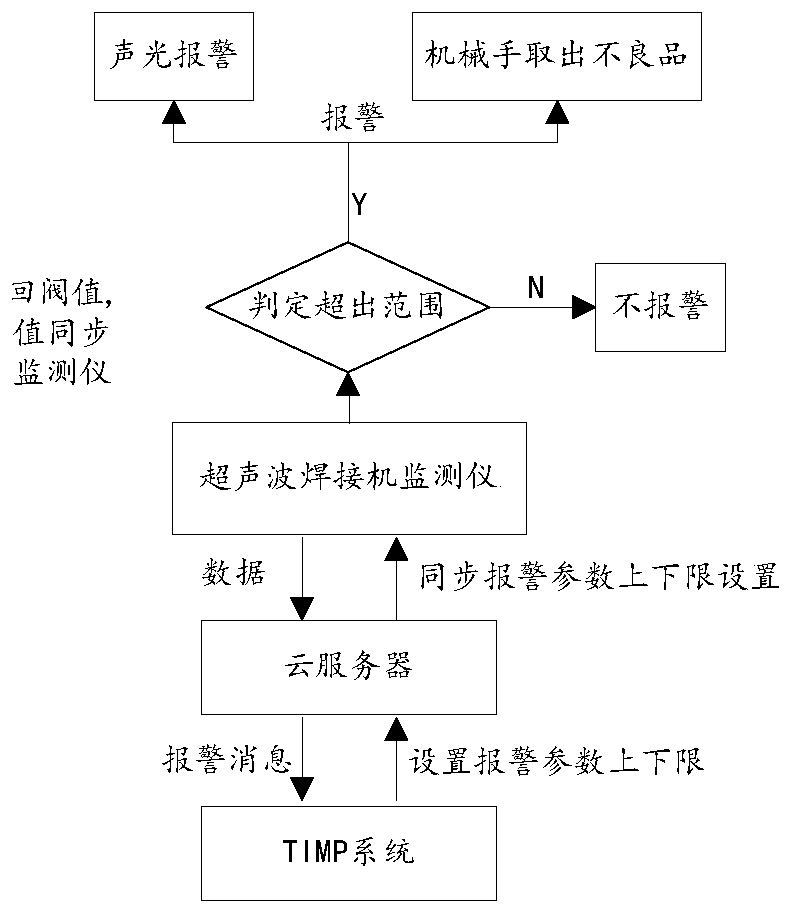

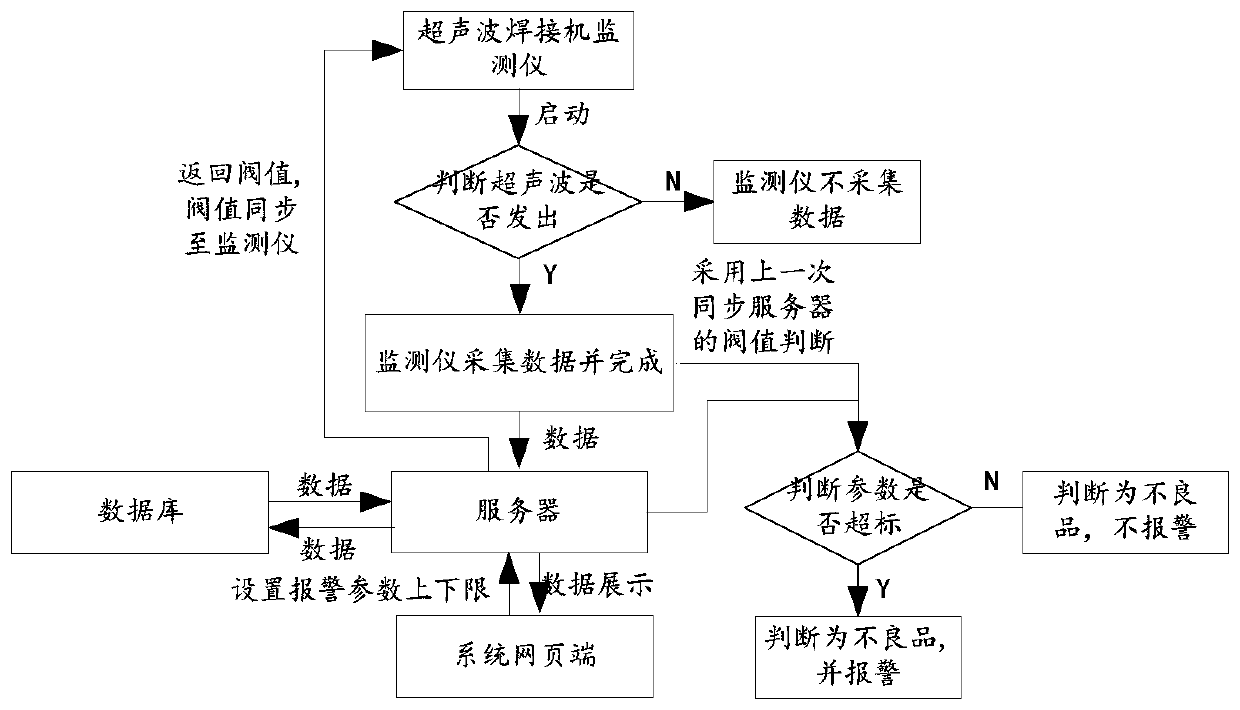

Alarm system of intelligent rotary disc type ultrasonic welding machine

InactiveCN109760322AMonitoring Process ParametersProcess parameter controlUltrasonic weldingComputer terminal

The invention discloses an alarm system of an intelligent rotary disc type ultrasonic welding machine. The alarm system comprises a rotary disc type ultrasonic welding machine body, an ultrasonic welding machine monitor, a communication device, a cloud server, a workshop management terminal and an alarm device, wherein an intelligent mechanical arm is controlled by a control device of the ultrasonic welding machine body; the ultrasonic welding machine monitor is used for collecting voltage, current, air pressure, frequency, yield, welding time and the like; and the communication device is usedfor transmitting the data to the cloud server, the alarm device comprises a sound alarm device and an alarm display module, when the ultrasonic welding machine monitor judges that the running data exceeds a set normal operation threshold value, the ultrasonic welding machine monitor sends an alarm command to the alarm device, the sound alarm device sends an alarm sound, the alarm display module displays the alarm content, meanwhile, the control device controls the intelligent mechanical arm to clamp defective products to a defective product area of a discharging channel. According to the alarm system, the technological parameters in the running process can be monitored and the alarming function can be realized.

Owner:广州桃琳软件科技有限公司

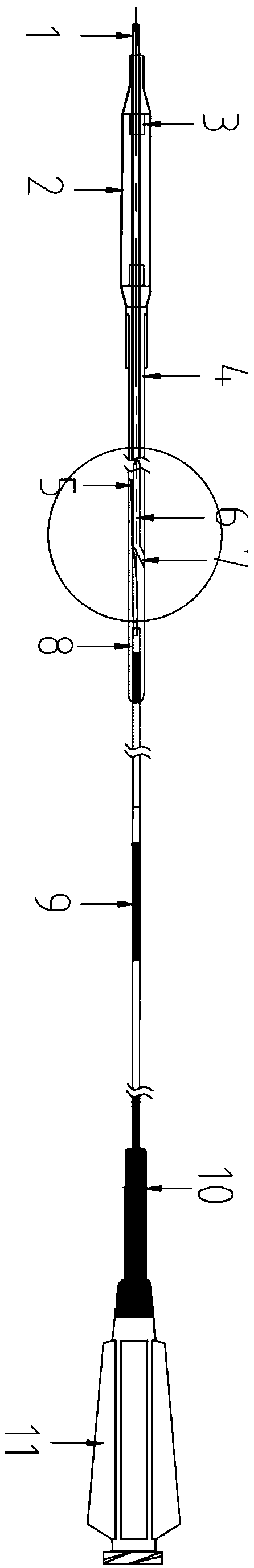

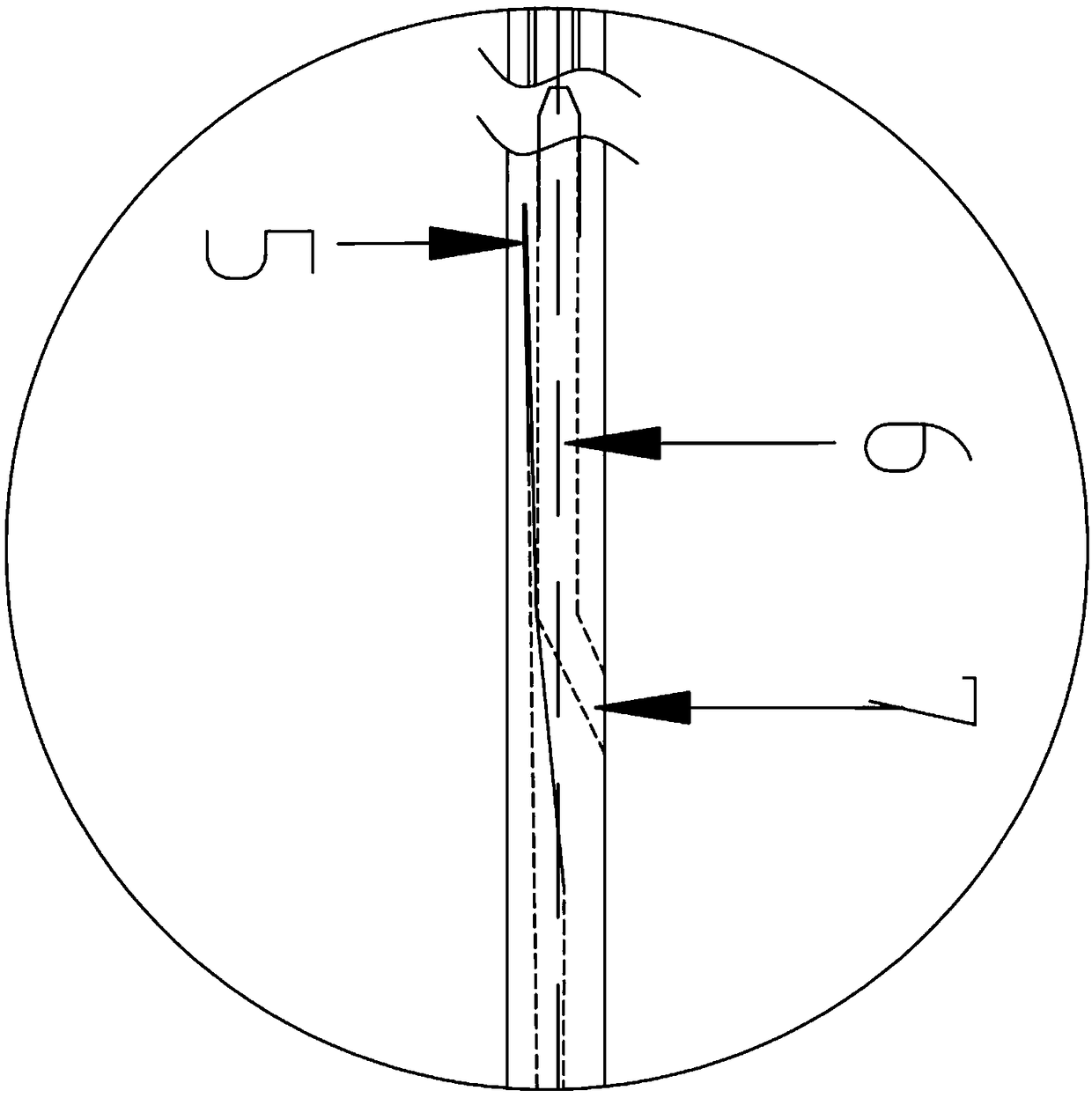

Drug coated balloon dilating catheter and process thereof

InactiveCN108744233AProcess parameter controlShort absorption timeBalloon catheterCoatingsBalloon dilatation catheterPolyethylene oxide

The invention discloses a drug coated balloon dilating catheter and a process thereof. The drug coated balloon dilating catheter comprises a drug coated balloon, an outer cavity tube, an inner cavitytube and a connector. The surface of the drug coated balloon is coated with a drug coating, a release drug in the drug coating is a sirolimus derivative BA9, and a carrier of the release drug is polyethylene oxide. A manufacturing process of the drug coated balloon dilating catheter includes steps of catheter assembly and drug coating. The drug coated balloon has advantages of short tissue absorption time, high drug absorption efficiency and high drug coated balloon release rate, and high tissue safety is realized. Compared with an existing taxol drug coated balloon, the drug coated balloon has advantages of promising application prospect.

Owner:JW MEDICAL SYSTEMS LTD

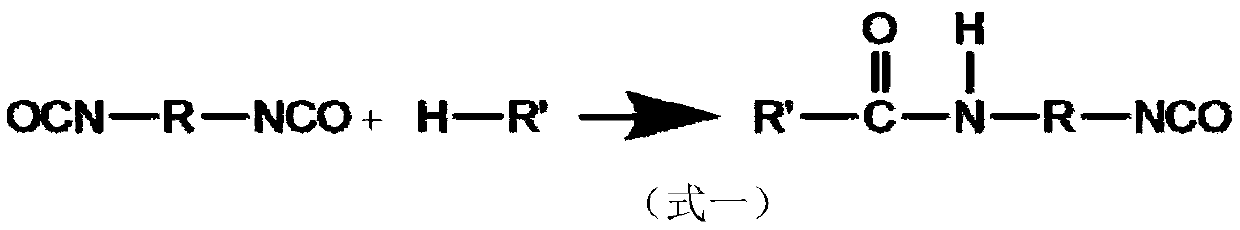

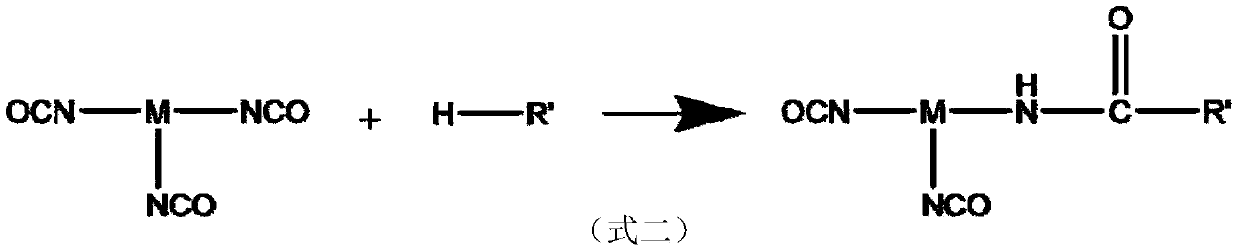

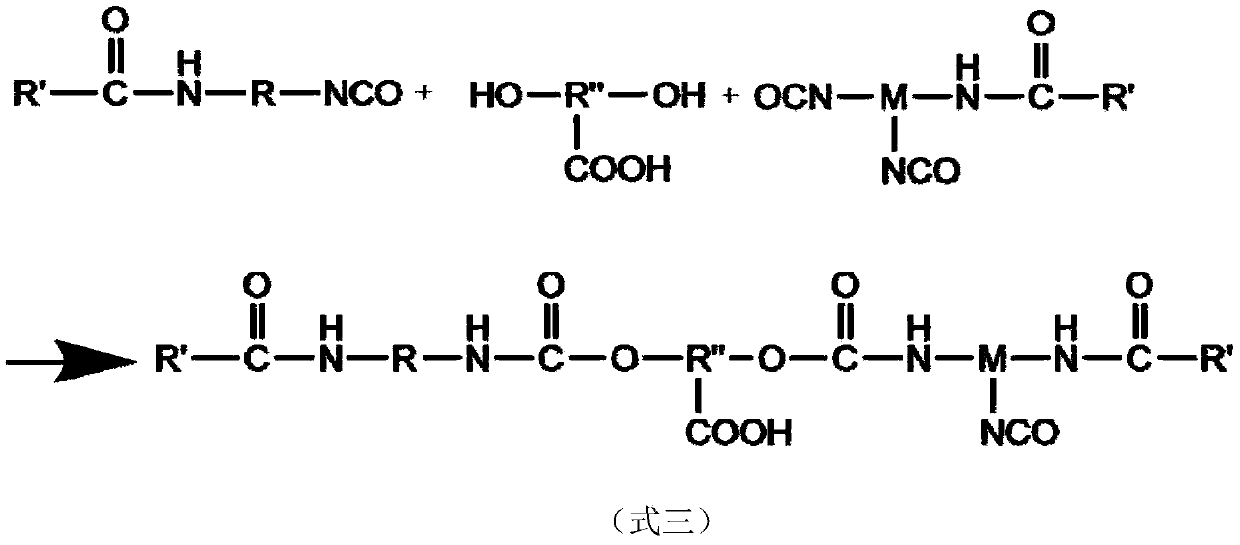

Water-soluble blocked polyurethane curing agent and preparation method and application thereof

ActiveCN110423323AGood water solubilityImprove surface qualityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSolubilityWater based

The invention discloses a water-soluble blocked polyurethane curing agent and a preparation method and application thereof. The preparation method comprises the following steps: partially blocking isocyanate, then reacting the partially blocked isocyanate with dihydroxymethylcarboxylic acid to form a product A, and then enclosing all the remaining -NCO in the product A to obtain the water-solubleblocked polyurethane curing agent. The blocked polyurethane curing agent of the invention is mainly composed of a trifunctional isocyanate prepolymer, and has the advantages of small molecular weight,high solid content, high NCO%, good water solubility and dissolvability in water at any ratio; and the curing agent is very convenient to use, is mainly used in combination with water-based resin forpreparation of water-based stoving varnish and water-based high-temperature adhesives, and has good application prospects in the coating of heat-sensitive materials.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

Production of spherical nickel powder

A process for preparing superfine nematospherical Ni particles includes such steps as proportionally mixing carbonyl nickel vapor with CO gas, controlling the pressure of a decomposing reactor to 5-15 Kpa and its internal temp to be divided into 6 temp segments, filling said gas mixture in said decomposing reactor from its top, the carbonyl nickel dropping down while thermal decomposing to become superfine dendritic Ni particles (0.2-6 microns) and colliding between the Ni particles.

Owner:JINCHUAN GROUP LIMITED

PH (Potential of Hydrogen) control system and application thereof

InactiveCN102495647AImprove efficiency and effectivenessEffective control of process parametersControlling ratio of multiple fluid flowsChemical variable controlMetal workingControl system

The invention provides a pH (Potential of Hydrogen) control system and an application thereof and particularly provides a pH control system. The pH control system comprises a sampling device, a pH detection device, a charging device and a pH control device, wherein the sampling device is used for extracting a sample in a reactor; the pH detection device is connected with the sampling device and is used for carrying out pH detection on the sample extracted by the sampling device, so as to determine a pH value of the sample; the charging device is connected with the reactor and is used for adding a feed liquid into the reactor; and the pH control device is respectively connected with the pH detection device and the charging device and used for turning on or off the charging device to add the feed liquid into the reactor on the basis of the pH value, obtained in the pH detection device, of the sample. The invention further provides a method for processing a metal work piece before coating by using the pH control system. By utilizing the pH control system, the pH value of a solution in the reactor can be effectively controlled.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

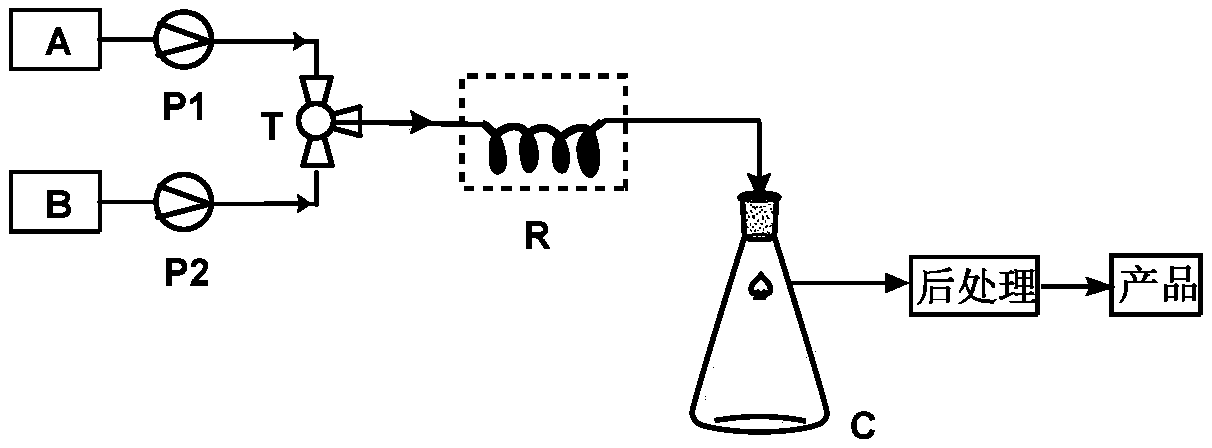

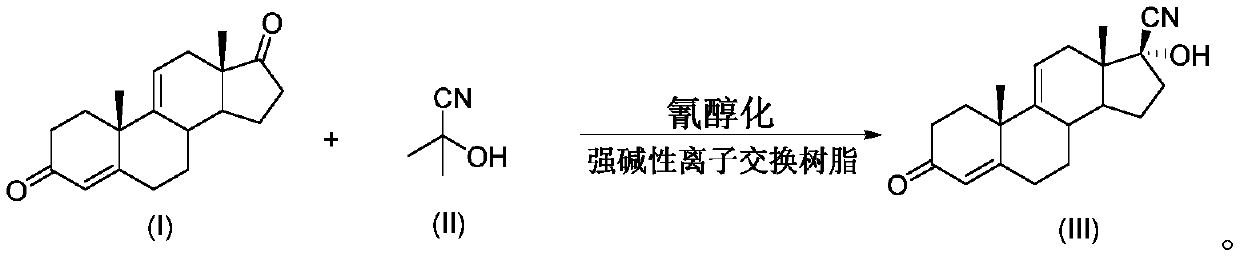

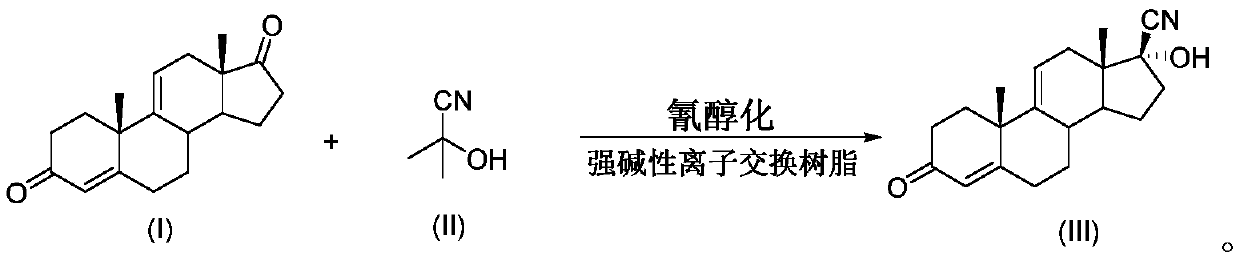

Method for preparing 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione

InactiveCN111320665ASmall amount of online responseReduce backmixingSteroidsChemical/physical processesOrganic solventIon exchange

The invention discloses a method for preparing 17 beta-cyano-17 alpha-hydroxy-9-dehydroandrostenedione. The method comprises the following steps: (1) dispersing 9-dehydroandrostenedione (I) and acetone cyanohydrin (II) into an organic solvent; (2) carrying out a cyanohydrination reaction on the obtained mixed raw material liquid in a tubular reactor filled with strongly basic ion exchange resin, and (3) carrying out post-treatment on the material liquid after the cyanohydrination reaction to obtain 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione (III), the reaction formula of which is shown in the specification.

Owner:台州仙琚药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com