Push-bending forming process for hollow blade

A hollow blade and forming process technology, which is applied in the field of hollow blade push-bending forming process, can solve the problems of unstable torsion forming process effect, complicated equipment, and many defects, and achieve stable and convenient forming process, improved forming effect, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

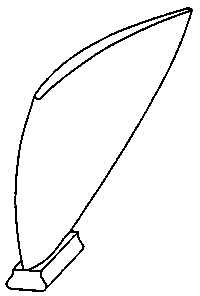

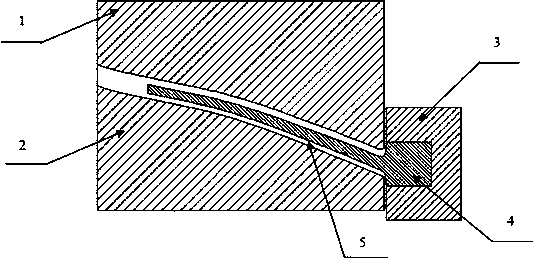

[0041] 1. Generate the mold cavity surface according to the contour surface of the finished hollow blade.

[0042] 2. Process the mold according to the obtained mold cavity surface.

[0043] 3. The first mold half 1 is installed horizontally on the pressure head of the heat press, the second half mold 2 is installed horizontally on the working table of the heat press, and the blade 4 is installed on the chuck 3 arranged horizontally.

[0044] 4. The push bending forming process is as follows:

[0045] (1) The formed hollow blade blank is installed on the chuck 3 and sent into the furnace for heating;

[0046] (2) The pressure head of the hot press goes down, and the first half-mold 1 and the second half-mold 2 are closed;

[0047] (3) The chuck 3 moves towards the mold, and the blade 4 is pushed into the mold from one end of the mold cavity channel 5, and the blade is twisted and bent under the action of the mold;

[0048] (4) The pressure head of the hot press returns, and...

no. 2 example

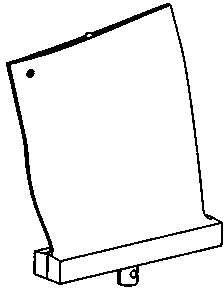

[0051] 1. Generate the mold cavity surface according to the contour surface of the finished hollow blade.

[0052] 2. Process the mold according to the obtained mold cavity surface.

[0053] 3. Install the first half-mold 1 upright on the worktable of the heat press and fix it, the second half-mold 2 is installed upright on the movable slider of the worktable of the heat press, and the chuck 3 is installed on the pressure head of the heat press And fixed, the blade 4 is installed upright on the blade chuck 3 .

[0054] 4. The push bending forming process is as follows:

[0055] (1) Install the hollow blade blank to be formed on the chuck 3, and send it into the furnace for heating;

[0056] (2) The slider of the worktable of the hot press moves, and the first half-mold 1 and the second half-mold 2 are closed;

[0057] (3) The pressure head of the hot press moves downward, driving the blades to move towards the mold, pushing the blades from one end of the mold cavity channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com